Adhering structure of non-metal sheet and adhering method thereof

A non-metallic sheet and non-metallic technology, applied in the field of non-metallic sheet pavement structure, to achieve the effect of convenient disassembly, wide application range and fast construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0063] Preparation Example 1 Adhesive Layer

[0064] Heat and melt the first hot-melt resin (specifically, hot-melt adhesive) at 90° C., add moisture-absorbed moisture-proof silica gel powder to it, and stir evenly to obtain a molten mixture. Wherein, the mass ratio of the moisture-proof silica gel powder to water is 1:0.45; the mass ratio of the first hot-melt resin to the moisture-proof silica gel powder absorbing water is 3:1.

preparation example 2

[0065] Preparation example two putty layer

[0066] Mix the second hot-melt resin (specifically, hot-melt adhesive), calcium carbonate powder, quartz sand, and iron oxide pigment in a mass ratio of 1:1:2:0.05, heat until the second hot-melt resin melts, and stir to make the mixture uniform (judged by the color uniformity of the iron oxide pigment), after cooling, it is placed in a mold for solidification and molding to obtain a sheet-like thermoplastic putty layer.

Embodiment 1

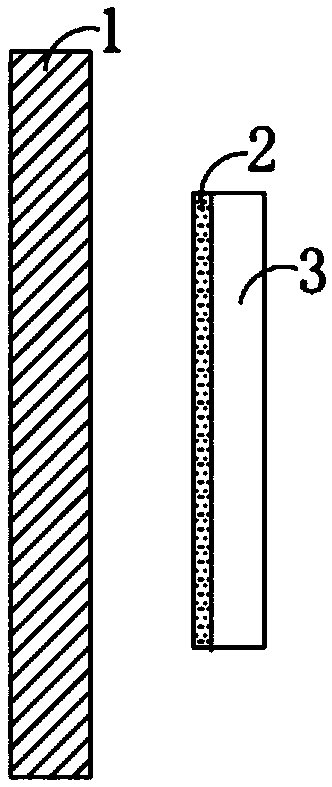

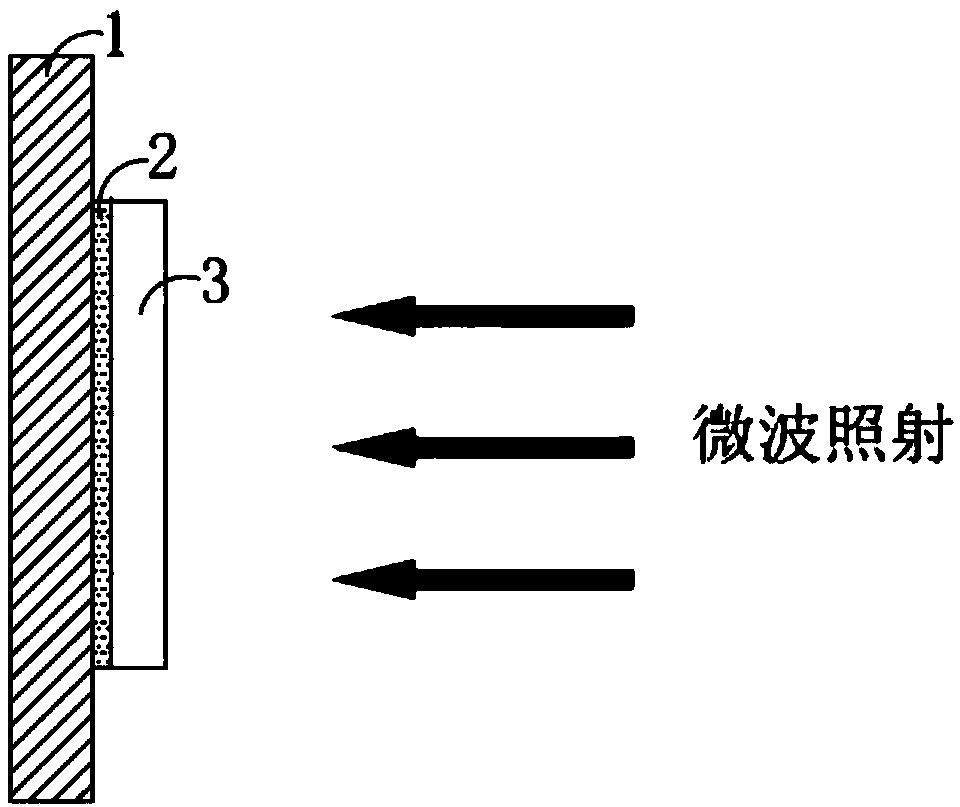

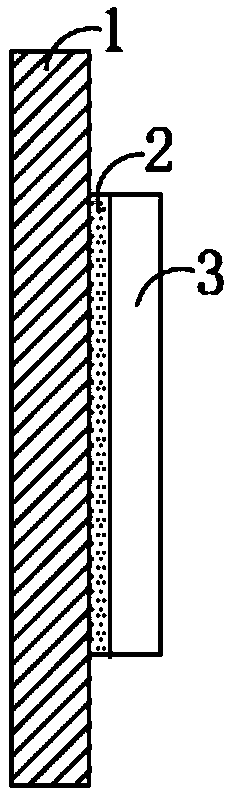

[0068] This embodiment provides a paving structure of non-metallic sheets, such as image 3 shown, including:

[0069] A layer to be bonded 1, the layer to be bonded 1 can be a building surface such as a wall, a ground or a roof;

[0070] An adhesive layer 2 with a thickness of 0.5 mm on the top of the layer to be bonded 1, the adhesive layer 2 is the adhesive layer in Preparation Example 1;

[0071] The non-metallic sheet 3 arranged above the adhesive layer 2 is ceramic tiles.

[0072] The present embodiment also provides a method for laying the above-mentioned non-metallic sheet, comprising the following steps:

[0073] Such as figure 1 As shown, the surface of the non-metallic sheet 3 is coated with an adhesive layer with a thickness of 0.5 mm, and the side coated with the adhesive layer 2 is attached to the layer 1 to be bonded; wherein, the adhesive layer 2 is a preparation example The adhesive layer in one, specifically, is coated and scraped on the non-metallic shee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com