Petroleum pipeline plugging device

A plugging device, oil pipeline technology, applied in the direction of pipe components, pipes/pipe joints/pipe fittings, mechanical equipment, etc., can solve the problems of pipe instrument blockage, large resource consumption, pipeline pollution, etc., to prevent accidents and reduce preparation work , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

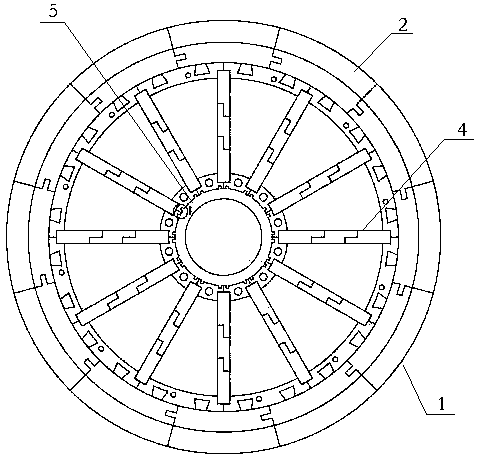

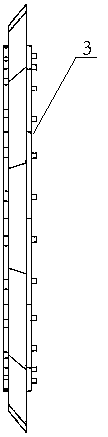

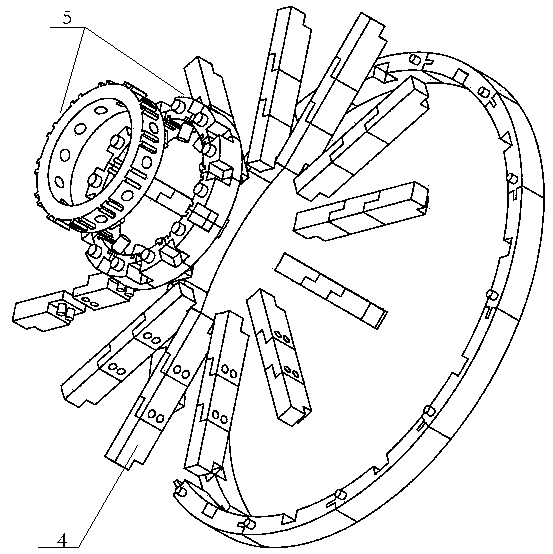

[0033] Such as Figure 1-3 As shown, an oil pipeline plugging device related to the present invention includes a plugging part, and the plugging part is assembled from a plurality of pluggable plugging parts, and the plugging parts are provided with A plug-in structure that cooperates with each other, and the plurality of plugging parts are connected through a set of plug-in structures that cooperate with each other. The side of the part is also provided with a rib-shaped sealant, and the side of the sealant close to the opening of the pipeline to be repaired is provided with a groove, and the sealing part between the baffle and the end opening is also provided with a In the interfitting plug-in structure, at least one side of the blocking part body parts extends outward along a direction forming a certain angle with the generatrix of the blocking part to form a flexible or elastic edge with elasticity or flexibility, The sealing part and the set flexible or elastic edge form...

Embodiment 2

[0046] Such as Figure 4-7 As shown, the present invention relates to a petroleum-soluble umbrella-shaped occluder, which includes a bolt-shaped sealing part made of petroleum-soluble materials, and the pressure-receiving part is cylindrical and contains an inner hollow part, a circular Cylindrical sealant composition. The plugging part, the pressure receiving part and the sealant are all made of petroleum-soluble materials. The plugging part moves toward the pressure-bearing part under the pressure generated in the pipeline, and the sealant is squeezed when moving. After the sealant is squeezed, it fills the small gap between the plugging part and the pressure-bearing part and the inner wall of the pipe, and connects the plugging part and the bearing The small gap between the edge of the pressure part and the inner wall of the pipe is tightly sealed. The plugging part is forced to move backward, and the screw-shaped protrusion designed by the bolt-shaped plugging part is st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com