Variable-stiffness protective sheath for natural cavity operation and application method thereof

A natural cavity, variable stiffness technology, applied in the field of minimally invasive surgery, it can solve the problems of large bending curvature, small bending curvature, and inability to change the diameter, and achieves a reduction in difficulty, a large range of stiffness changes, and protection from scratches and stab wounds. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

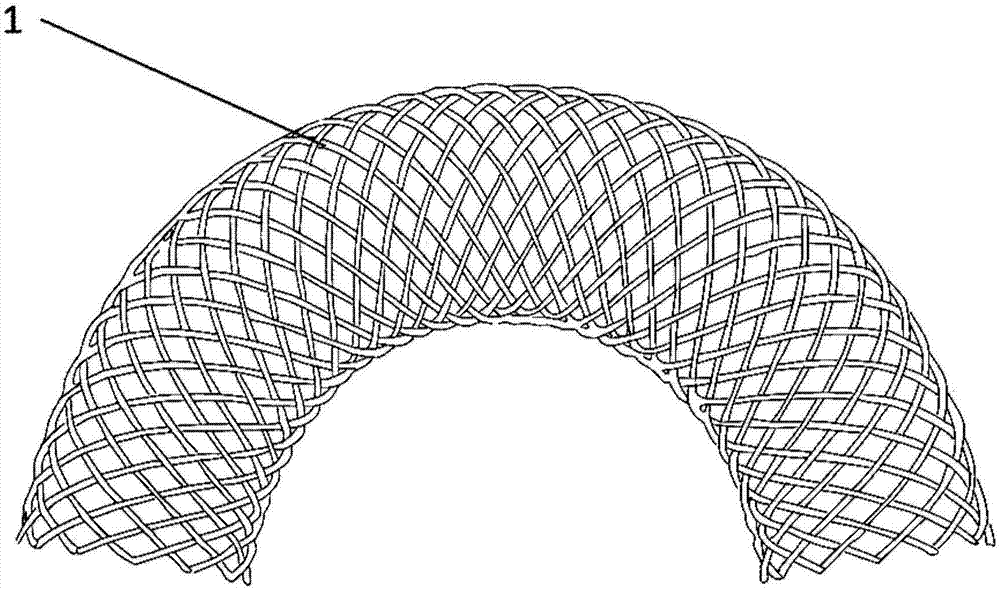

[0037] An embodiment of the present invention provides a variable stiffness protective sheath for natural orifice surgery, which is mainly composed of a variable stiffness braided tube structure and a state conversion device for changing the rigid and flexible state of the braided tube. In the rigid braided tube structure, the phase change of the low melting point alloy filled in the plastic hose is used to control the overall structural stiffness of the protective sheath braided tube.

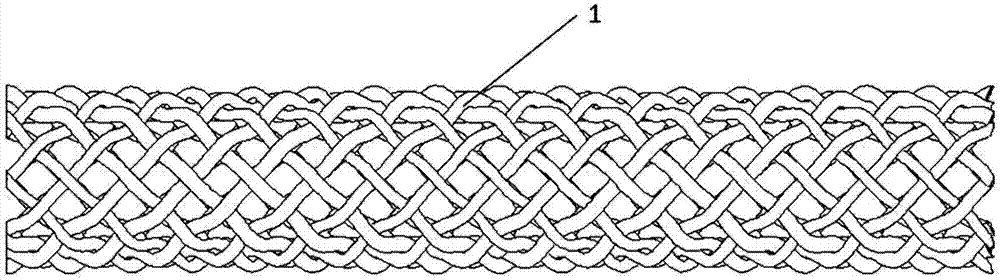

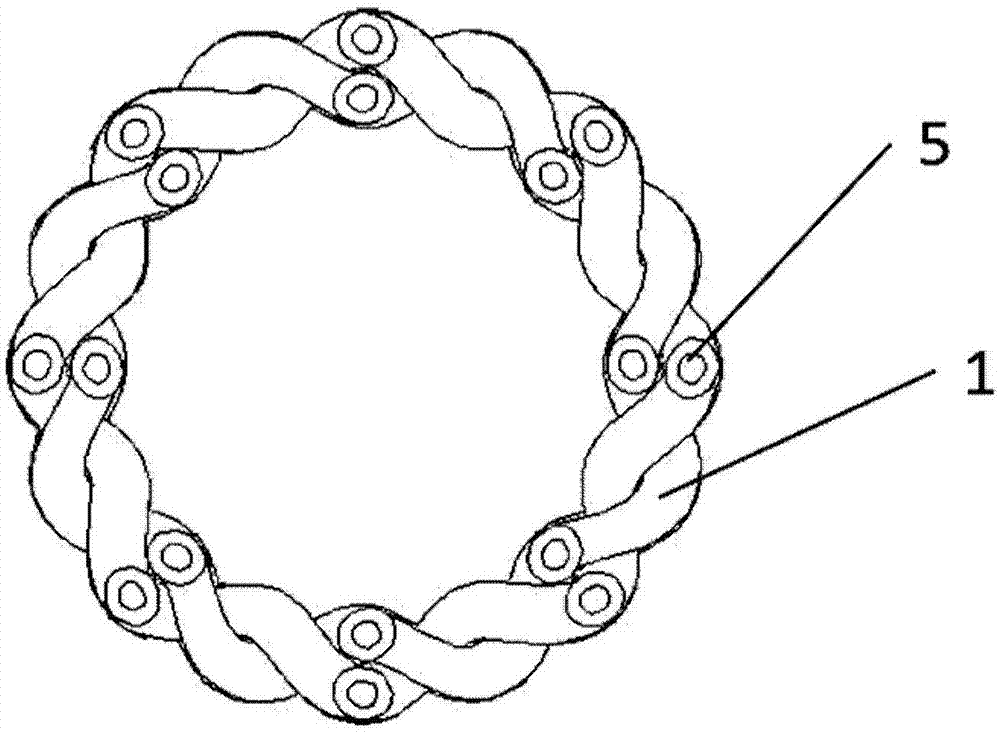

[0038] figure 1 It is the front view of the variable stiffness protective sheath braided tube used in natural orifice surgery according to the embodiment of the present invention, figure 2 It is a side view of the variable stiffness pro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com