Quick workpiece cooling device for hardware processing

A rapid cooling and workpiece technology, applied in household refrigeration devices, applications, refrigerators, etc., can solve the problems of uneven cooling, workpiece deformation, expensive equipment installation, etc., to improve the molding quality and dimensional accuracy, prevent deformation and cracking, The effect of not easy to cool dead corners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

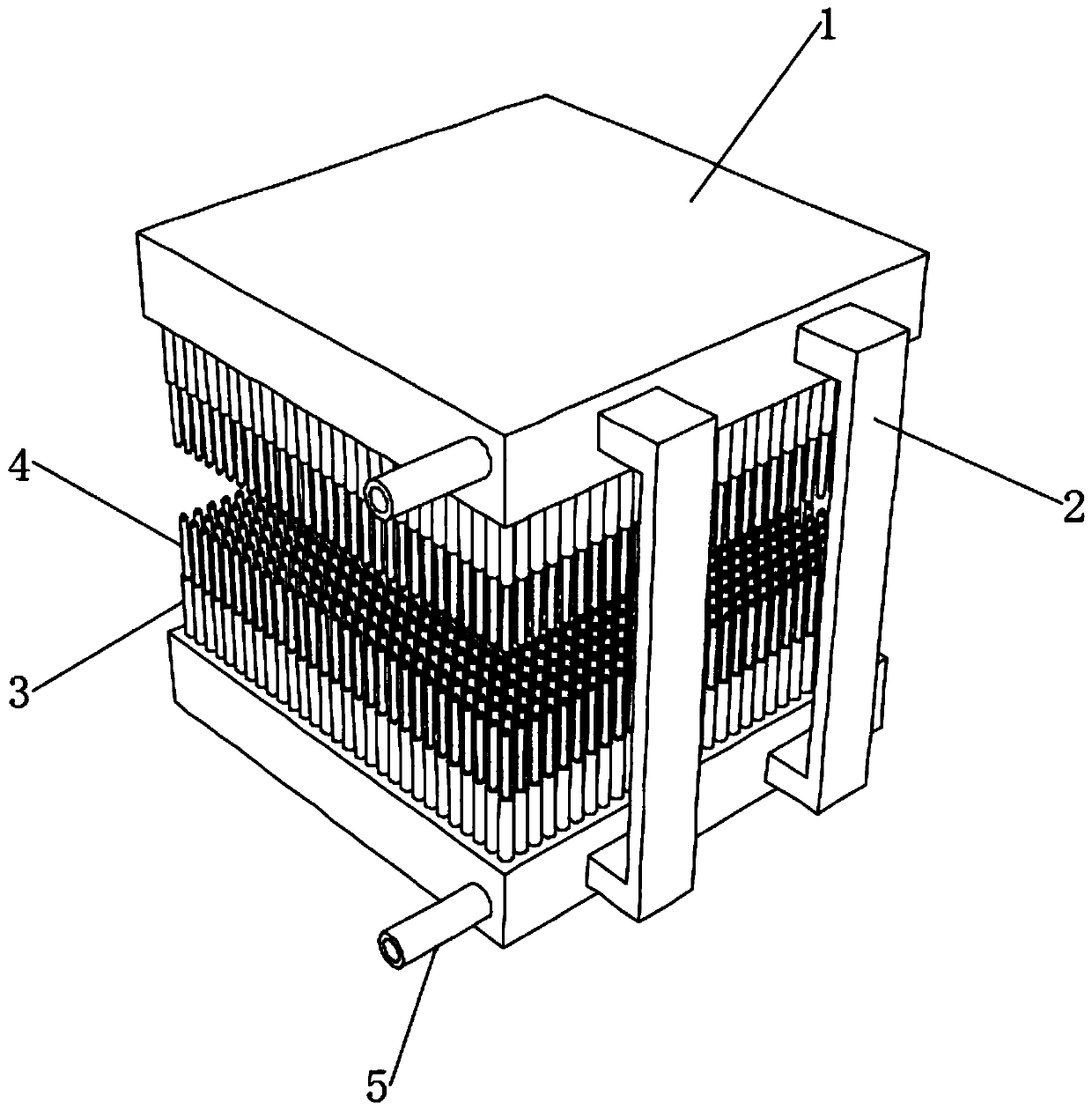

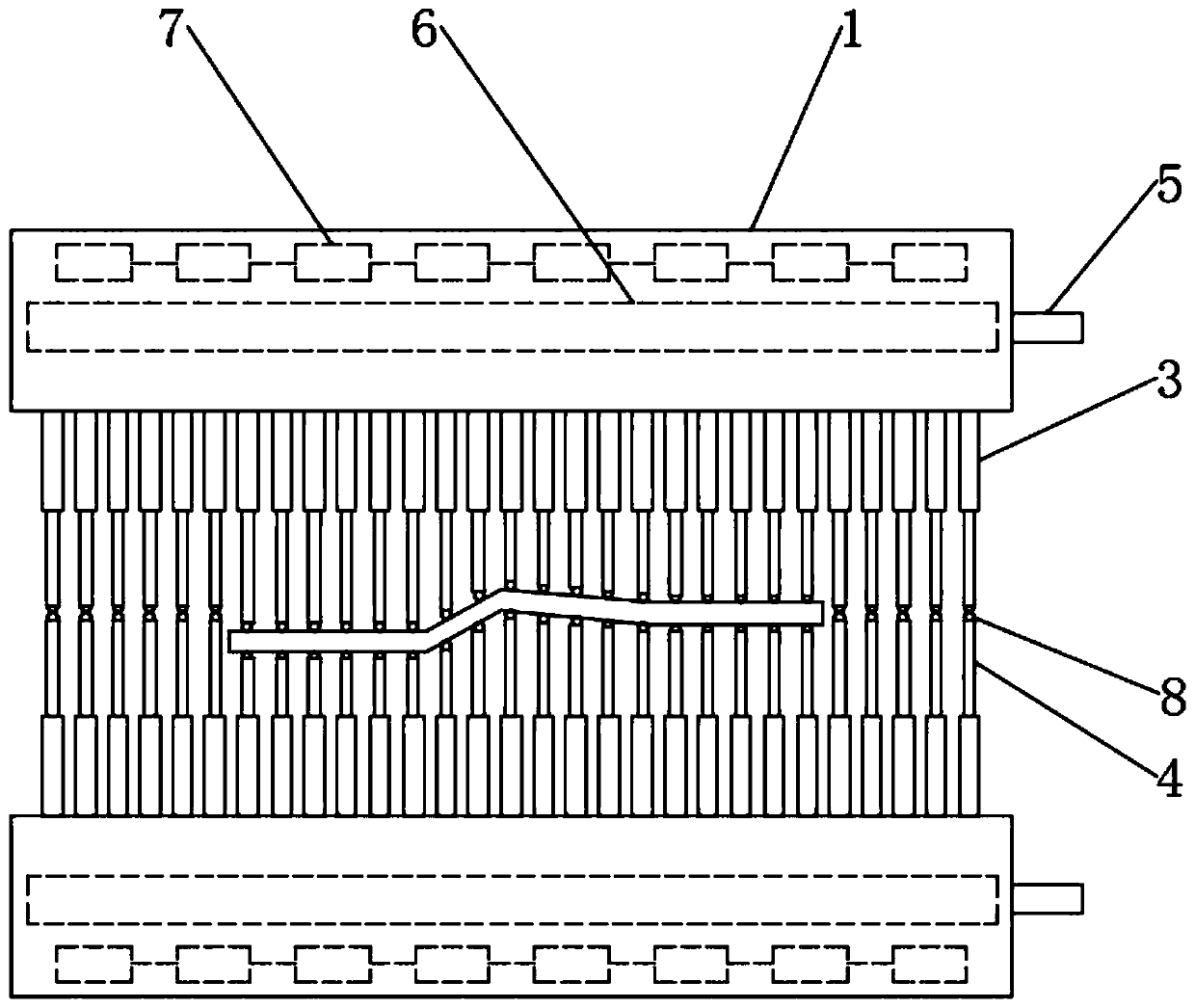

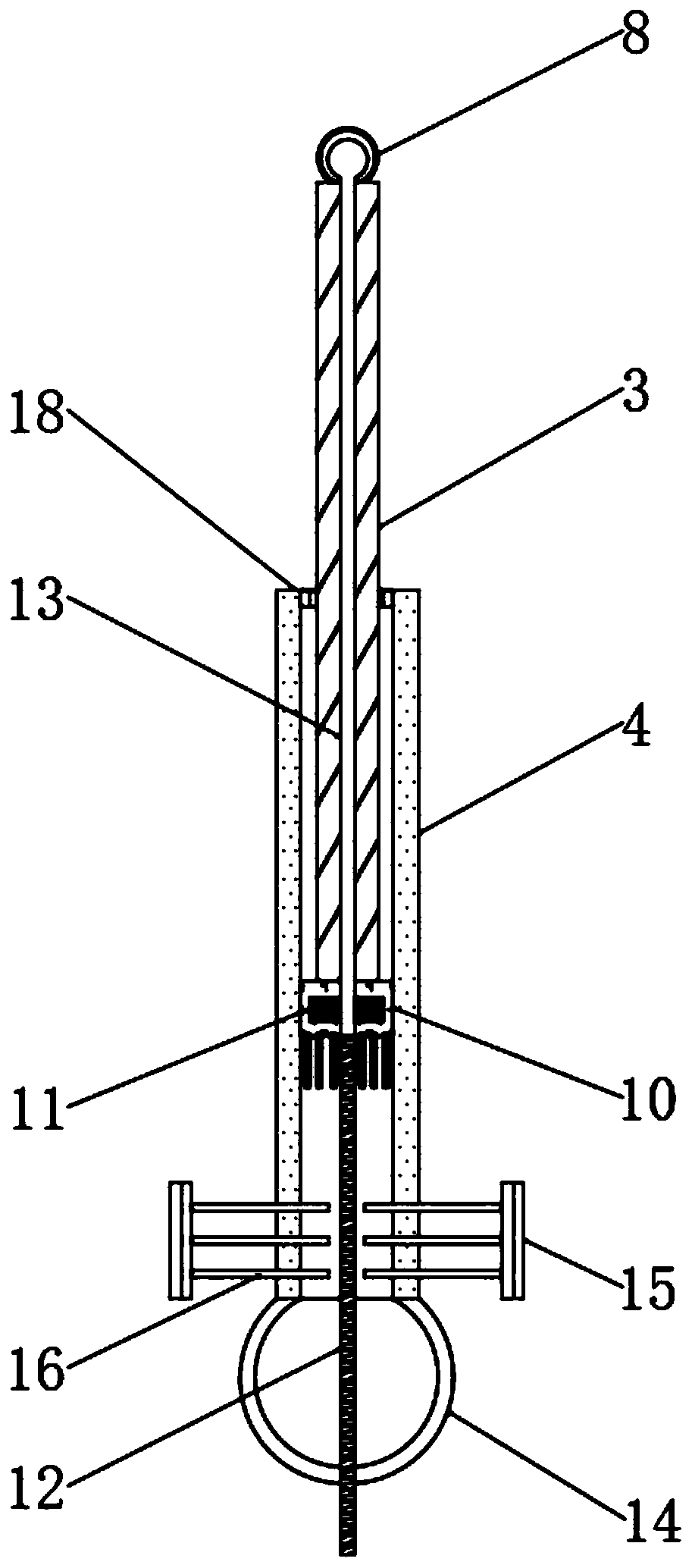

[0042] see Figure 1-3 , a workpiece rapid cooling device for metal processing, comprising a pair of cooling tables 1, a pair of support frames 2 are fixedly connected between the pair of cooling tables 1, and a pair of cooling tables 1 are fixedly embedded with a plurality of evenly distributed outer surfaces near one end of each other. The fixed cylinder 3 and the outer fixed cylinder 3 are inserted with an internal dynamic shaping rod 4, and one end of the internal dynamic shaping rod 4 located in the outer fixed cylinder 3 is fixedly connected with a magnetic piston, and a pair of internal dynamic shaping rods 4 are fixedly connected at one end close to each other There is an elastic liquid bag 14, which is made of elastic material and can be deformed according to the hydraulic pressure. The magnetic piston and the outer fixed cylinder 3 are provided with a common gas flow channel 13, and the strong magnet 11 and the elastic liquid bag 14 is fixedly connected with a coolin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com