Extrusion screw for regenerating waste rubber

A technology for extruding screw and waste rubber, applied in the field of extruding screw, can solve the problems of unsatisfactory material melting effect and little change of screw edge, etc., and achieve the effect of large extrusion force, speeding up flow rate, and maintaining smooth feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

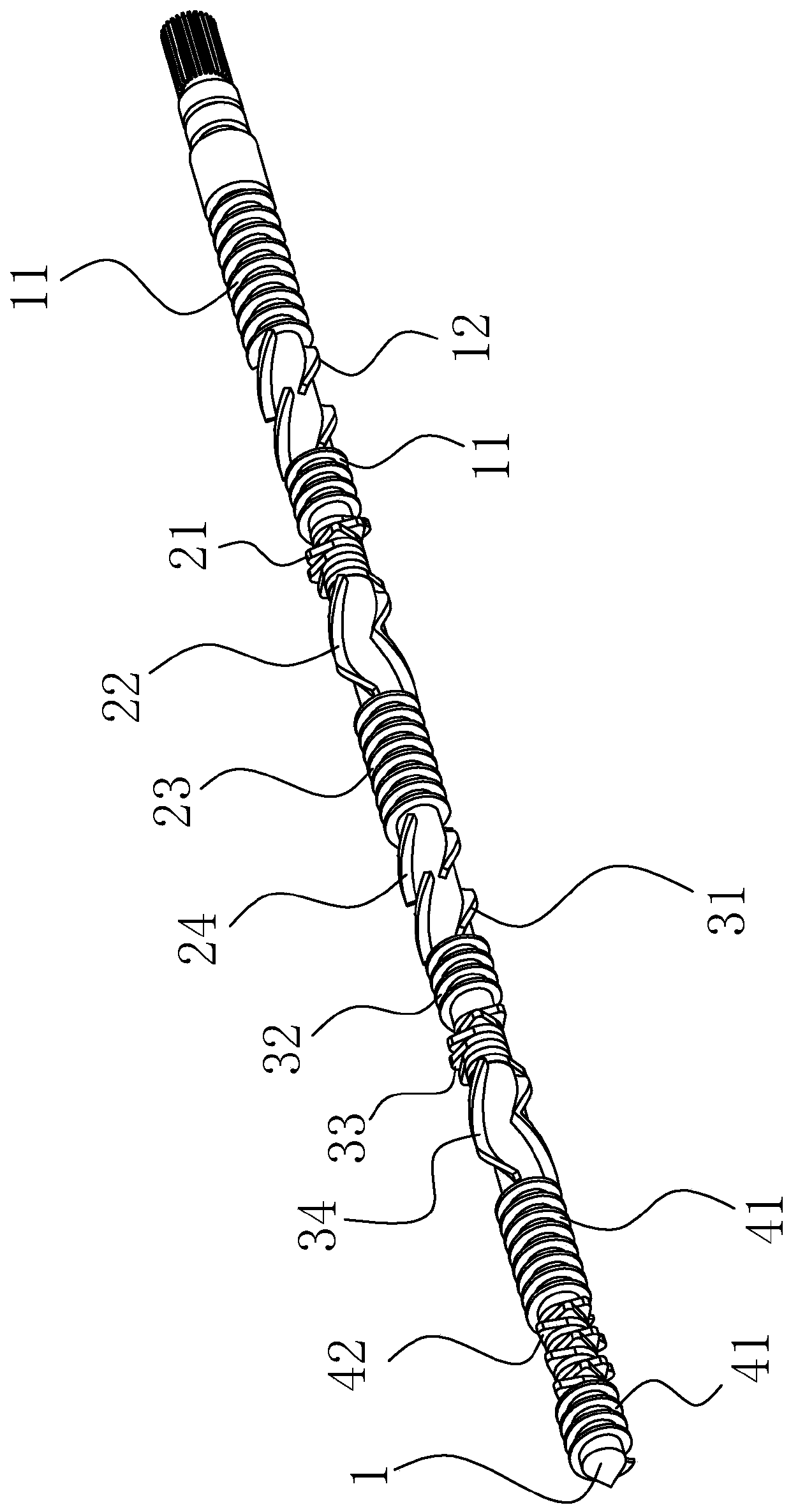

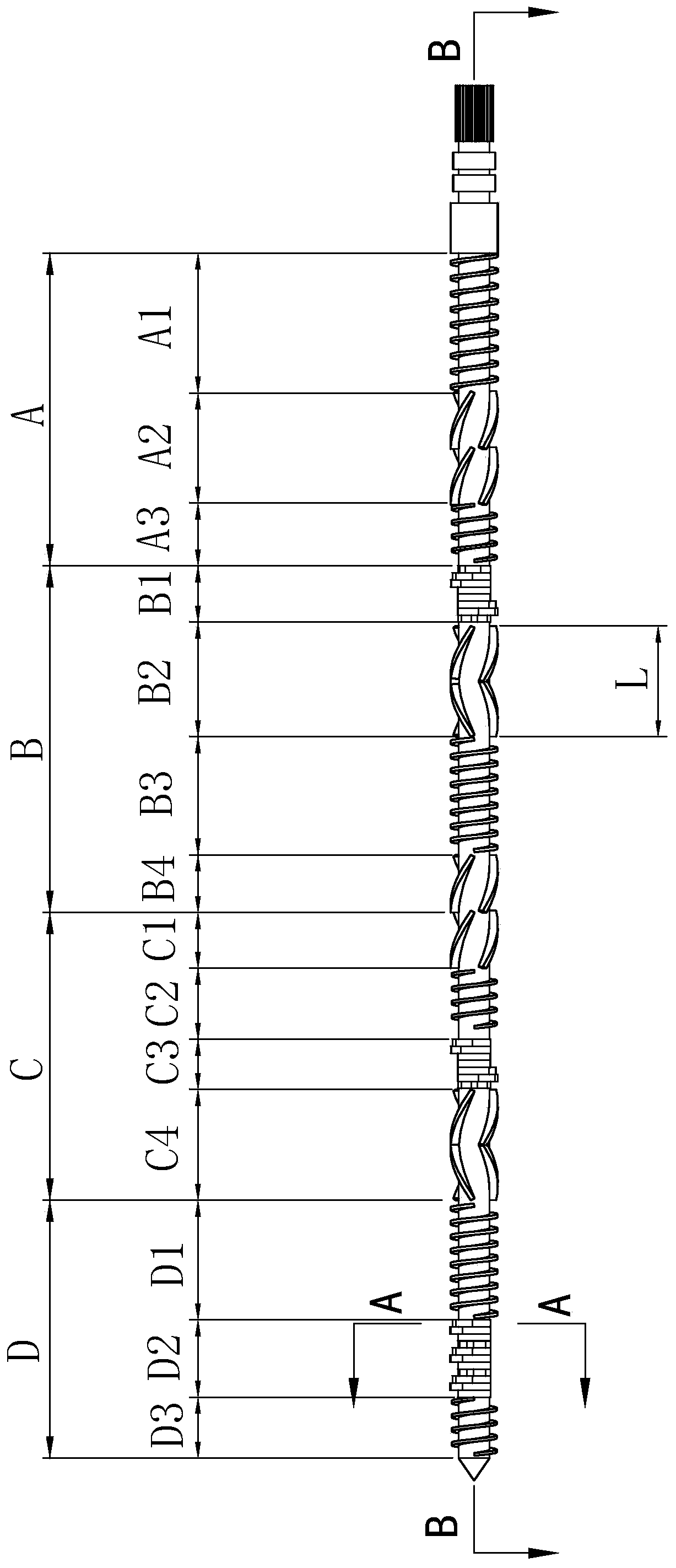

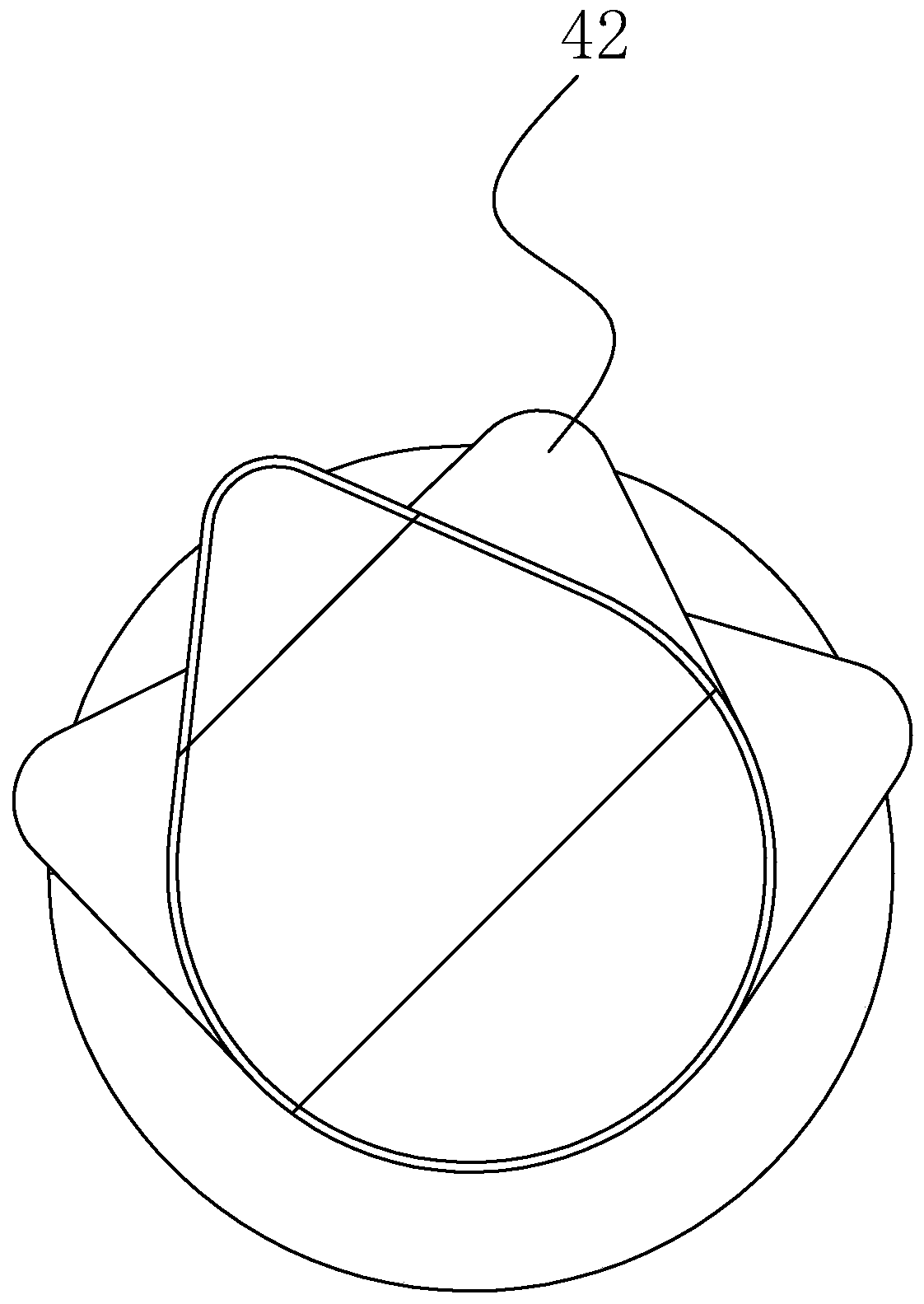

[0021] Such as Figure 1 to Figure 5 As shown, the extrusion screw used for waste rubber regeneration in this embodiment includes a rod body 1 and a screw flight arranged on the rod body 1. The screw flight is divided into a feeding section A, a melting section B, a mixing section C and The discharge section D, the melting section B includes a melting section B1, a second melting section B2, a third melting section B3 and a fourth melting section B4, and the melting section B1 is composed of N cams 21 arranged axially along the rod body. The top connecting line of the N cams 21 is a helix and the direction of rotation of the helix is the same as that of the feeding section A. The second melting section B2 is an inverted V-shaped helicoid protrusion 22 in a top view projection, and the helix is The protrusions 22 are evenly distributed on th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com