Upper-grade structure of vacuum extruder

A high-level, vacuum technology, applied in ceramic molding machines, ceramic extrusion dies, supply devices, etc., can solve the problems of hindering the mixing and extrusion of mud materials, small extrusion force, and easy formation of dead mud areas. The effect of increased pressure and good compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

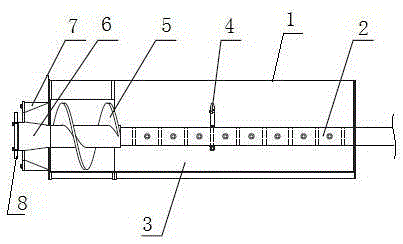

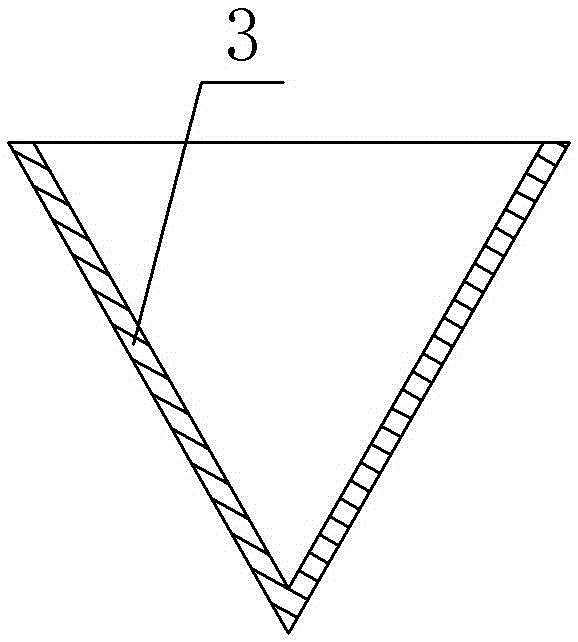

[0020] Embodiment 1 is basically as attached figure 1 and image 3 As shown, a superstructure of a vacuum extruder includes an extrusion cylinder 1, an extrusion shaft 2, a stirring knife 4 and a spiral reamer 5 installed on the extrusion shaft 2, and the extrusion cylinder 1 is equipped with a feed mouth, this embodiment also includes a V-shaped extrusion groove 3 located in the extrusion cylinder 1, the extrusion shaft 2 is connected to the slot of the extrusion groove 3 through bearing rotation, and the extrusion shaft 2 is close to the inlet A number of mixing knives 4 are installed on one side of the feed port, and a spiral reamer 5 is welded on the side of the extrusion shaft 2 away from the feed port.

[0021] In this embodiment, the mixing knives 4 are distributed in a spiral on the extrusion shaft 2 , the angle formed between two adjacent mixing knives 4 is 90°, and the mixing knives 4 are connected to the extrusion shaft 2 by bolts. . The mixing knife 4 forming a ...

Embodiment 2

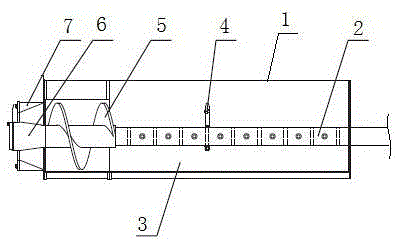

[0024] Such as figure 2 As shown, the difference from Embodiment 1 is that: the end of the extrusion shaft 2 away from the feed inlet is connected with a disc-shaped slime cutting disc 8 . The disc-shaped mud cutting cutter head 8 rotates together with the extruding shaft 2, and when the mud material is extruded, it can be broken into pieces by the disc-shaped mud cutting cutter head 8, so that the air in the mud material can be discharged.

[0025] Specific workflow:

[0026] Take embodiment 1 as an example to describe in detail below: figure 1 As shown, in specific use, start the vacuum extruder, the extrusion shaft 2 rotates, and then add the mud to be processed from the feed port, and the extrusion shaft 2 drives the stirring knife 4 and the spiral reamer 5 to rotate during the rotation process. The mixing knife 4 stirs the mud in the extrusion groove 3. Since the extrusion groove 3 is V-shaped, the mud is squeezed with the side wall of the extrusion groove 3 when being...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com