A food 3D printer with a parallel robotic arm turntable

A 3D printer and robotic arm technology, applied in the field of additive manufacturing, can solve the problems of not being able to adapt to the needs of the family, limited structural design, small application range, etc., and achieve the effect of convenient adjustment of the origin, convenient adjustment, and strong viewing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

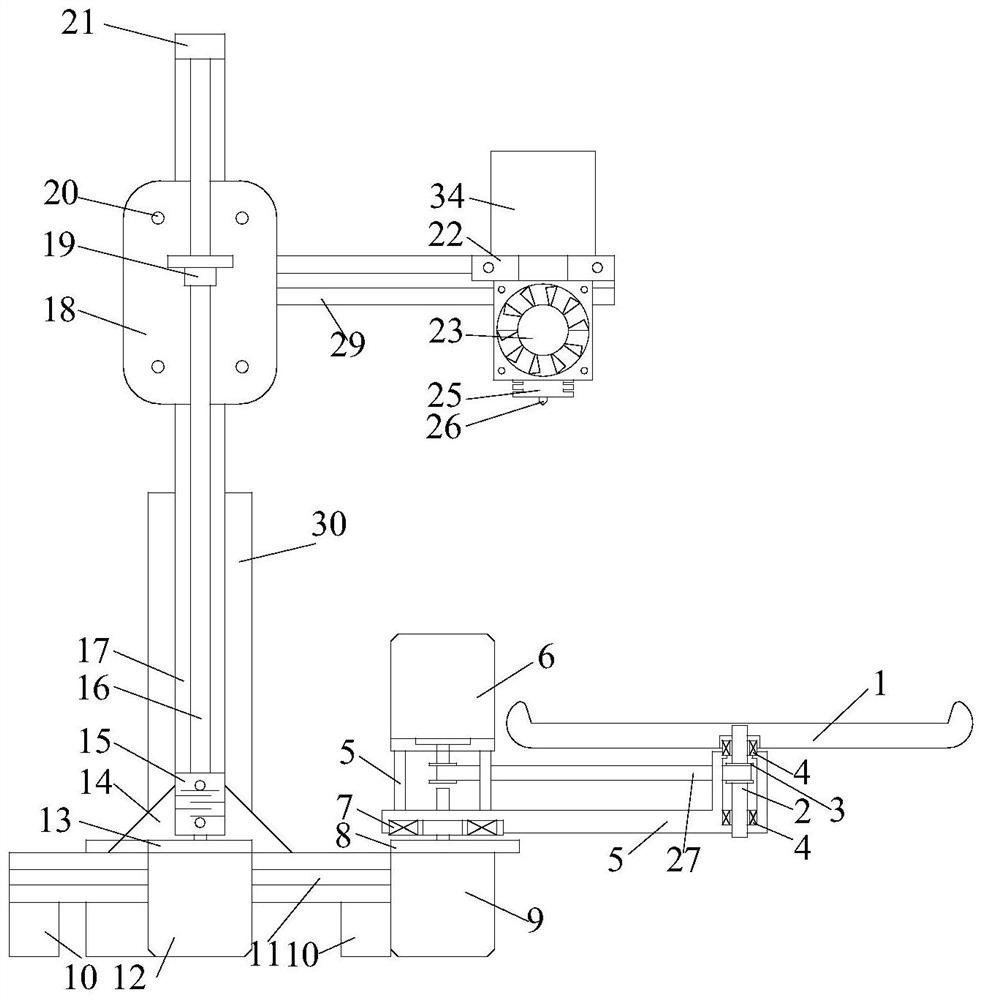

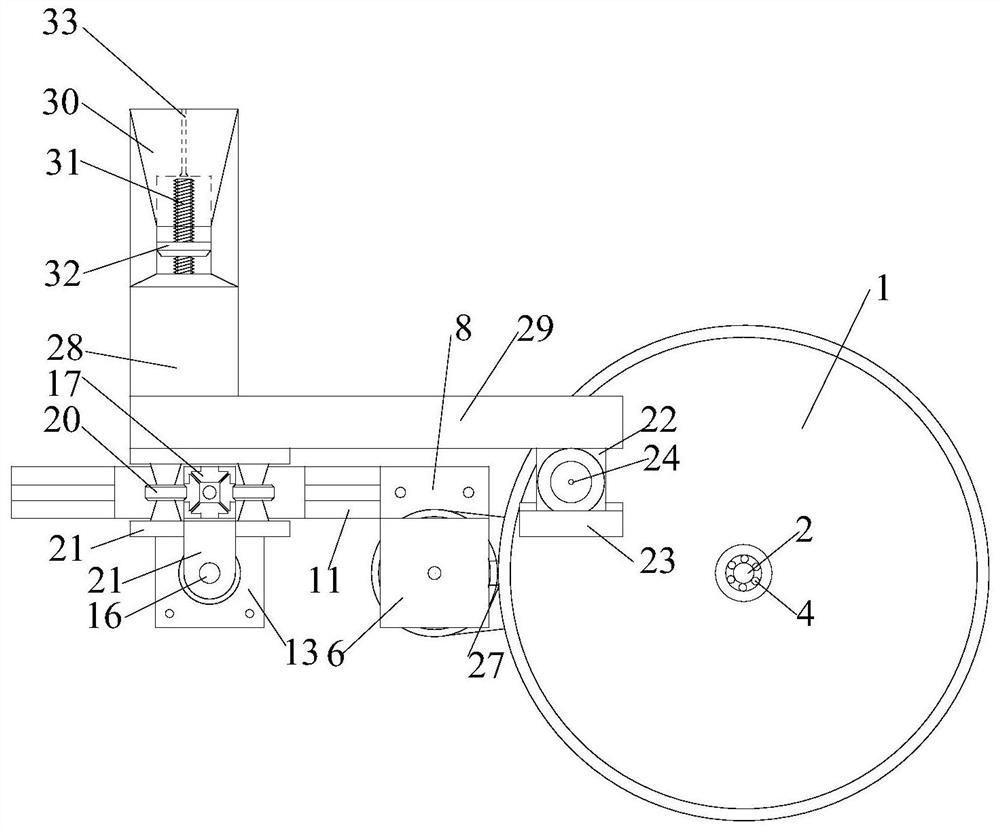

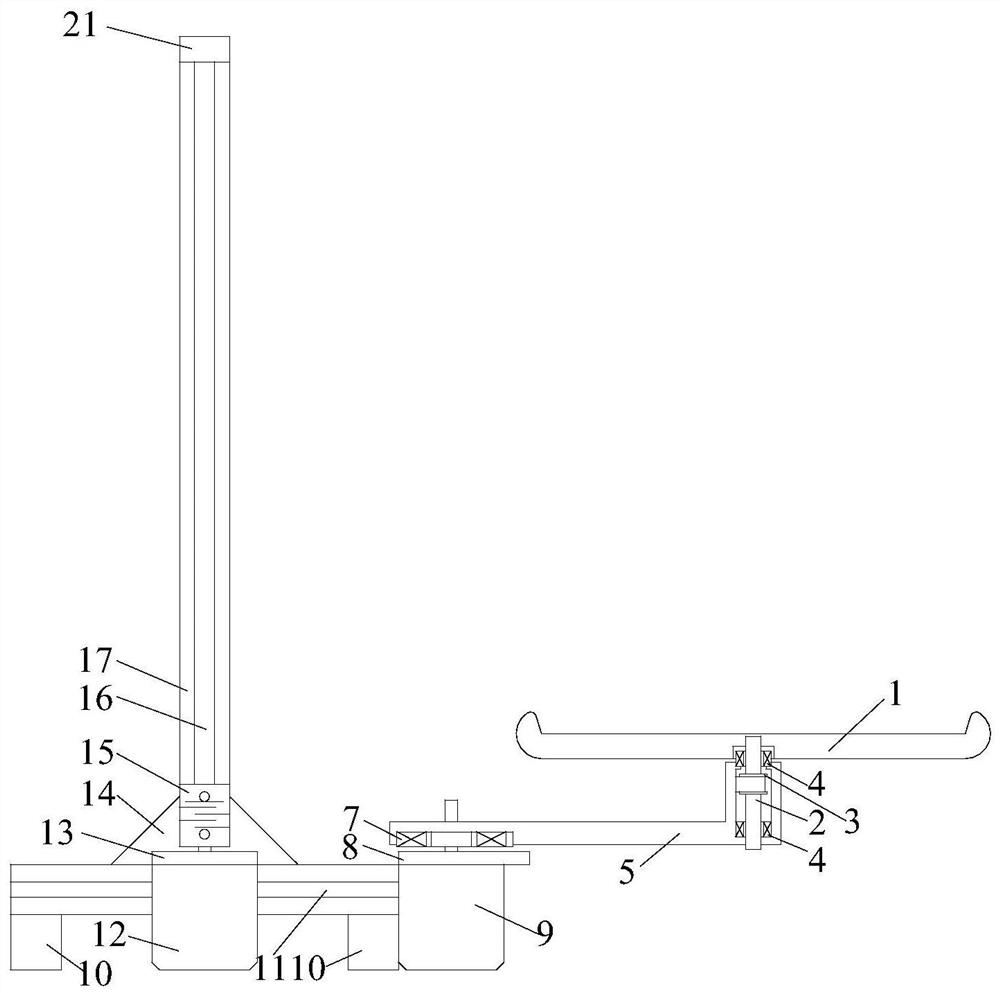

[0035] Such as figure 1 , figure 2 As shown, the parallel mechanical arm type turntable food 3D printer, the specific connection method includes, the rotating dinner plate 1 is attached with peeling paper, the center lower part of the rotating dinner plate 1 is installed with the dinner plate rotary bearing group 4, and the dinner plate rotary bearing group 4 The inner ring is covered with a dinner plate rotating shaft 2, the dinner plate rotating shaft 2 is covered with a dinner plate rotation synchronous wheel 3, the dinner plate rotation synchronous wheel 3 is covered with a dinner plate drive belt 27, and the other end of the dinner plate drive belt 27 is set on the dinner plate drive. On the output shaft of the motor 6, the output shaft of the dinner plate drive motor 6 is covered with the same synchronous gear as the dinner plate rotation synchronous w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com