Welding process used for passive device

A passive device and welding process technology, which is applied in welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of rising cost, failure, and difficulty in batch automatic production of waterproof sealing rings, and achieves reductions in production costs and welding strength. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to facilitate the understanding of the present invention, the present invention will be described more fully below with reference to the associated drawings. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be embodied in many different forms and is not limited to the embodiments described herein. On the contrary, these embodiments are provided to make the understanding of the disclosure of the present invention more thorough and comprehensive.

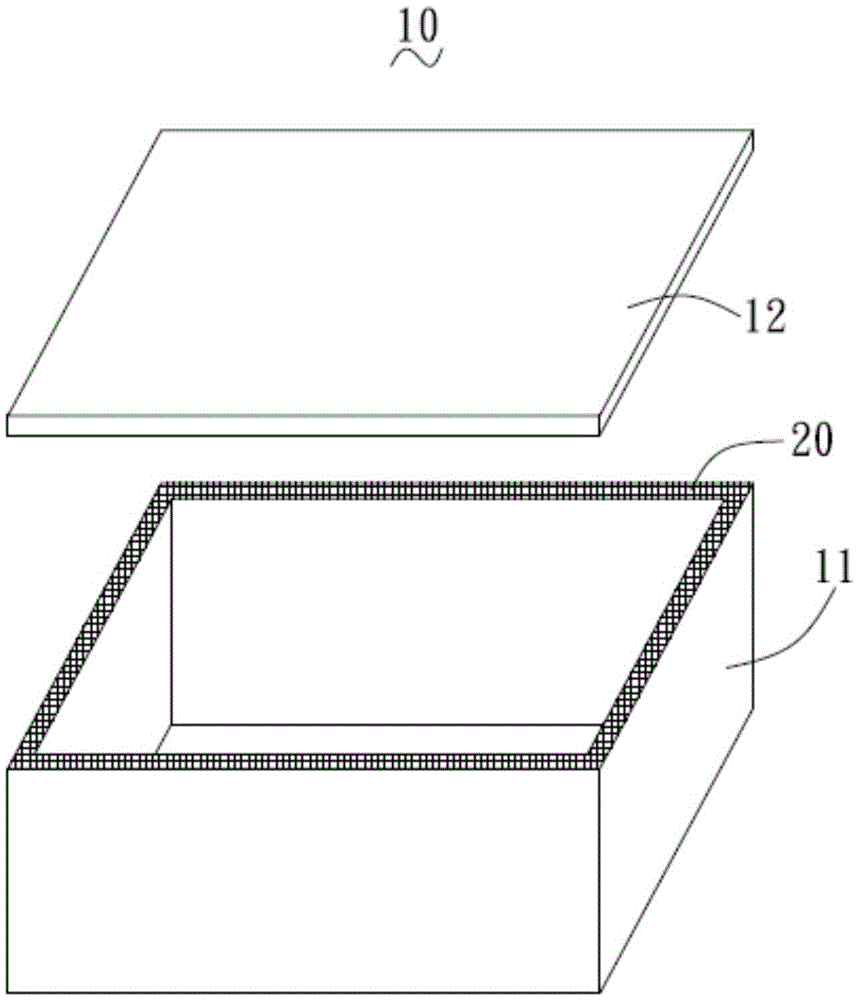

[0019] The invention provides a welding process for passive devices, and the passive devices can be combiners, couplers, multi-system access platforms and the like. Such as figure 1 As shown, the passive device 10 includes a box body 11 and a waterproof cover 12 packaged on the box body 11 . Soldering processes for passive components 10 include:

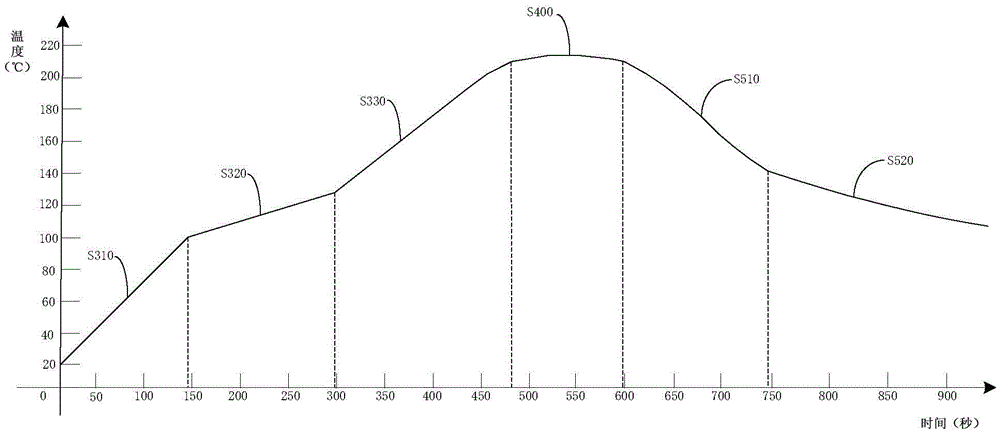

[0020] Step S1 : printing the stirred solder paste on the joint between the box body 11 and the waterproo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com