Patents

Literature

118results about How to "Reduce surface stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Arrangement and method for producing a three-dimensional product

ActiveUS7635825B2Reduce surface stressAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgySupply energy

Owner:ARCAM AB

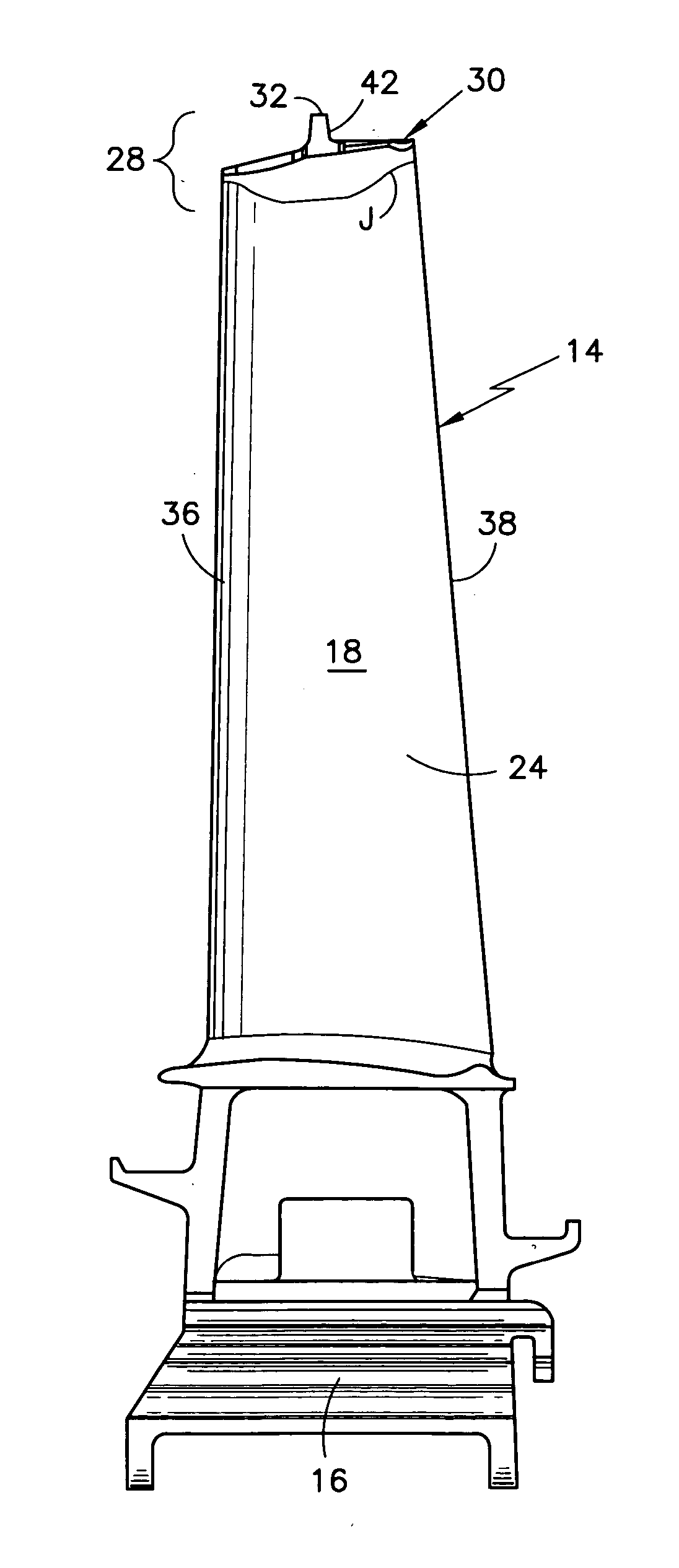

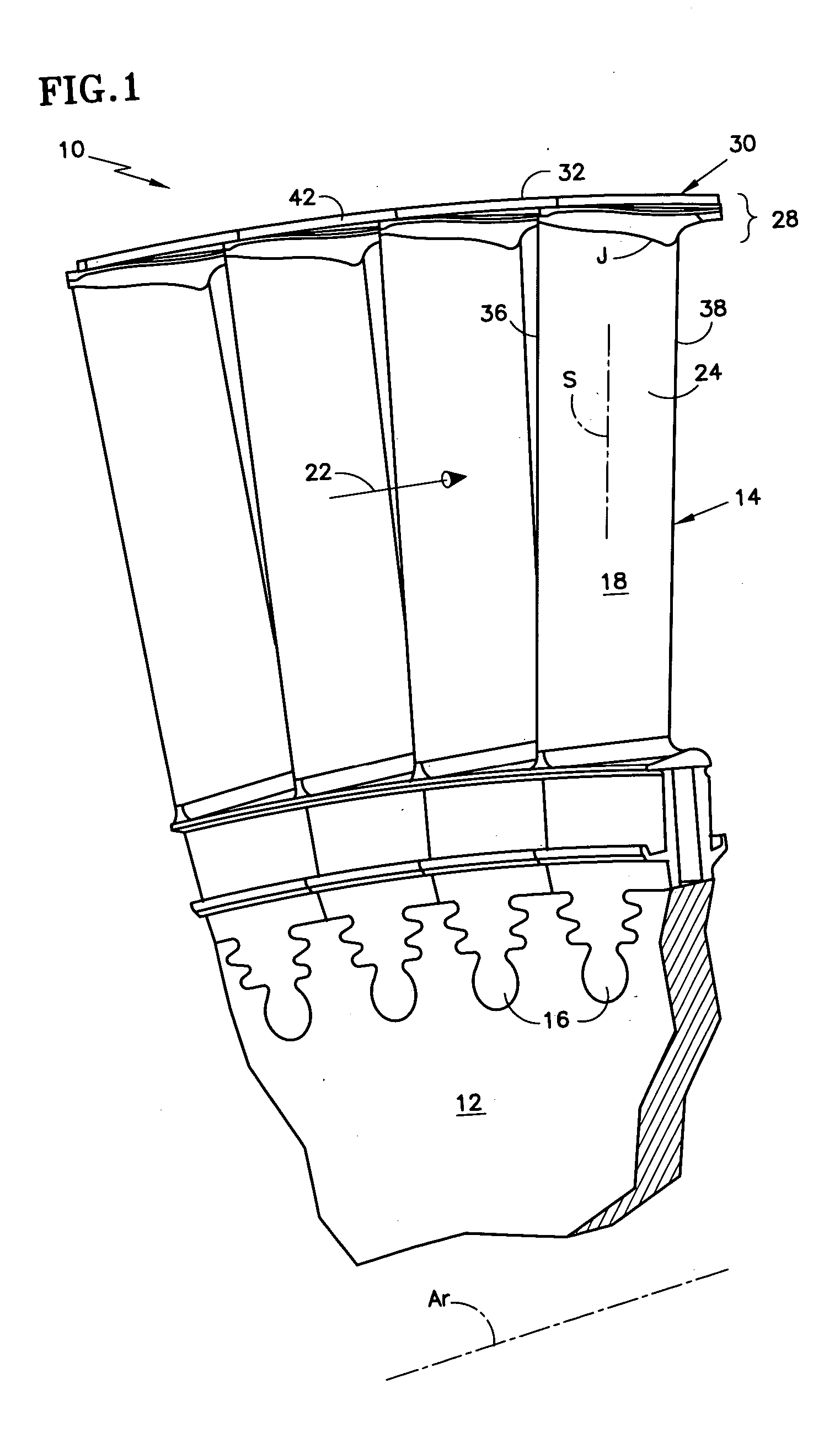

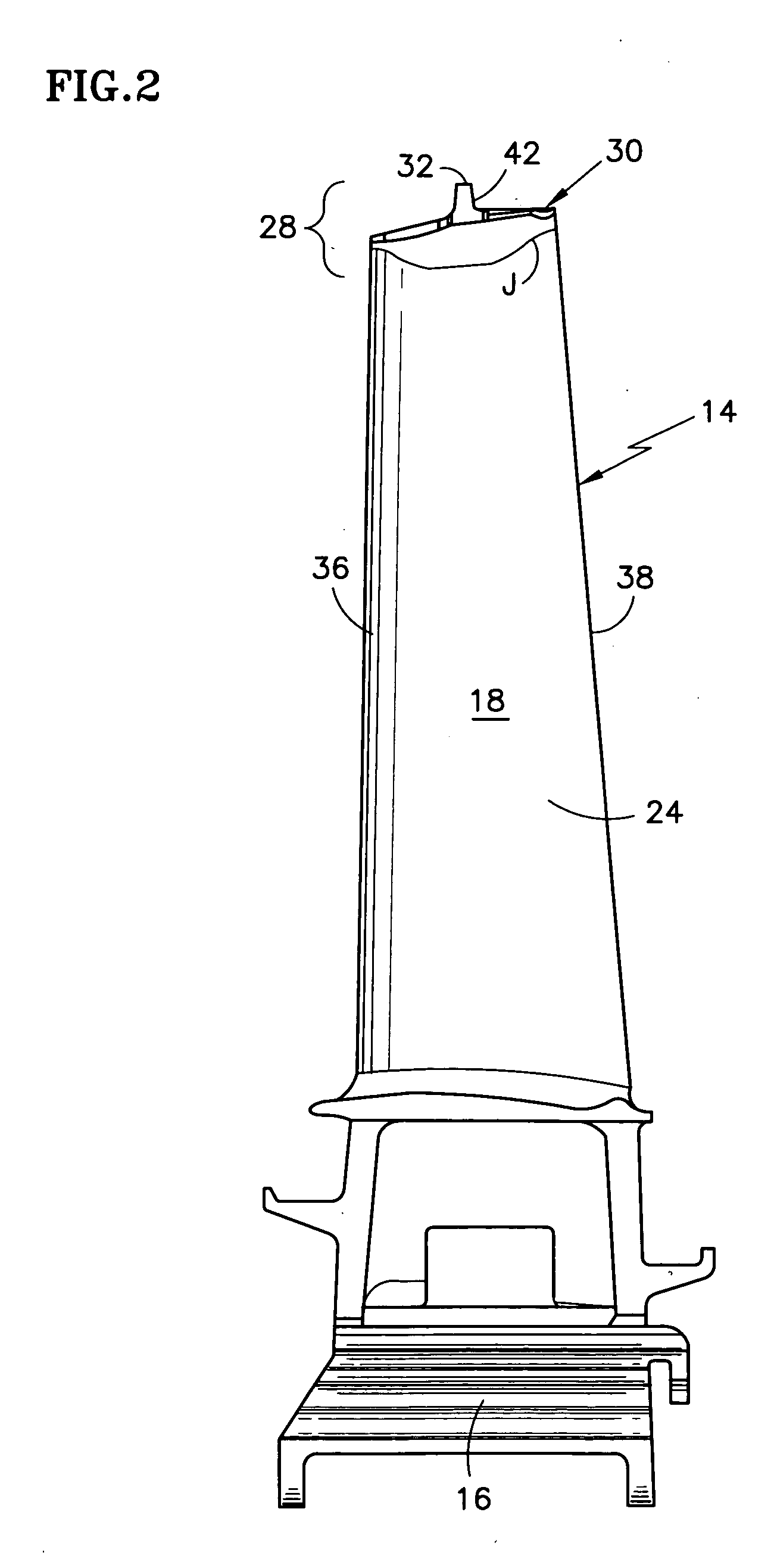

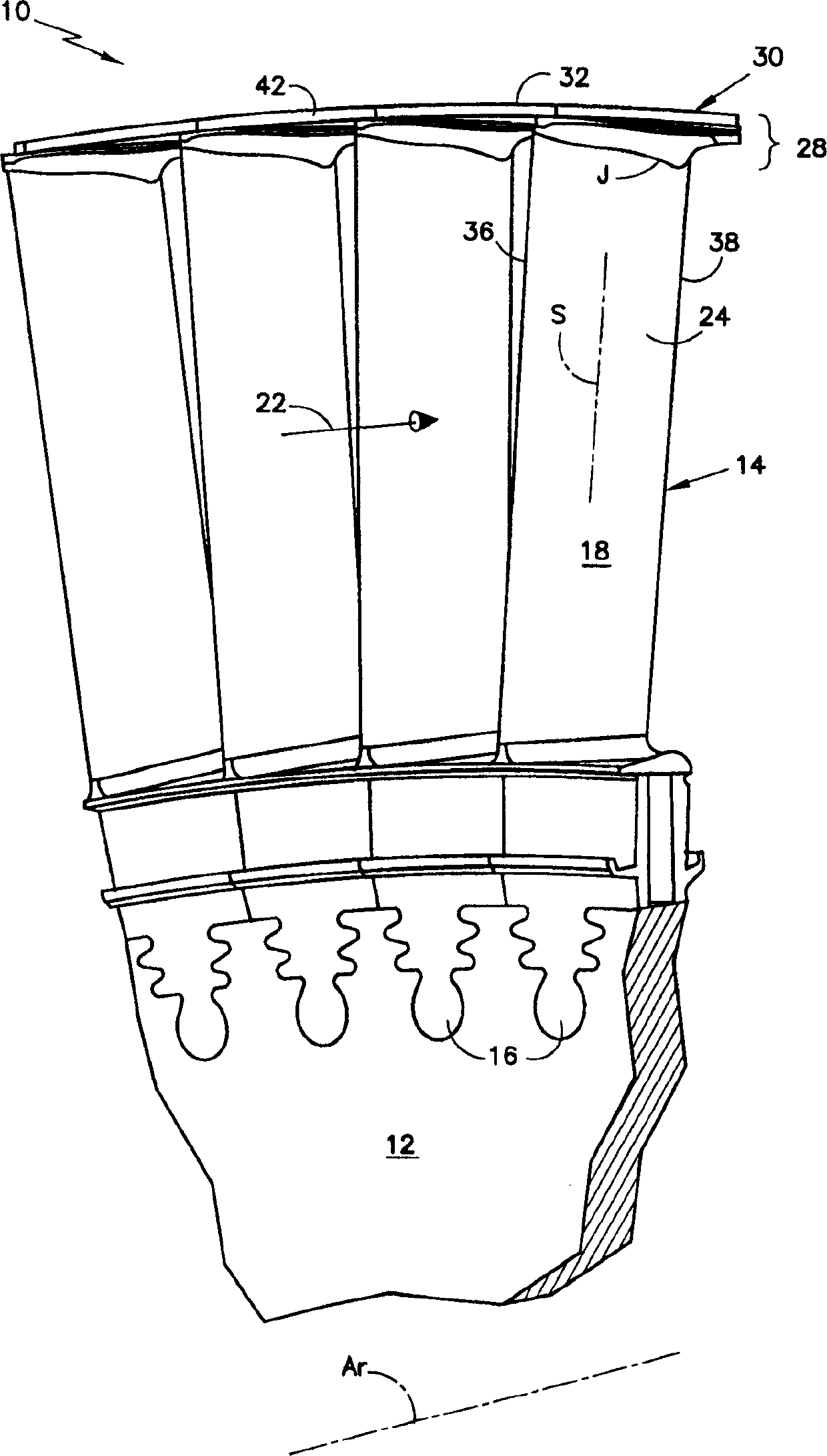

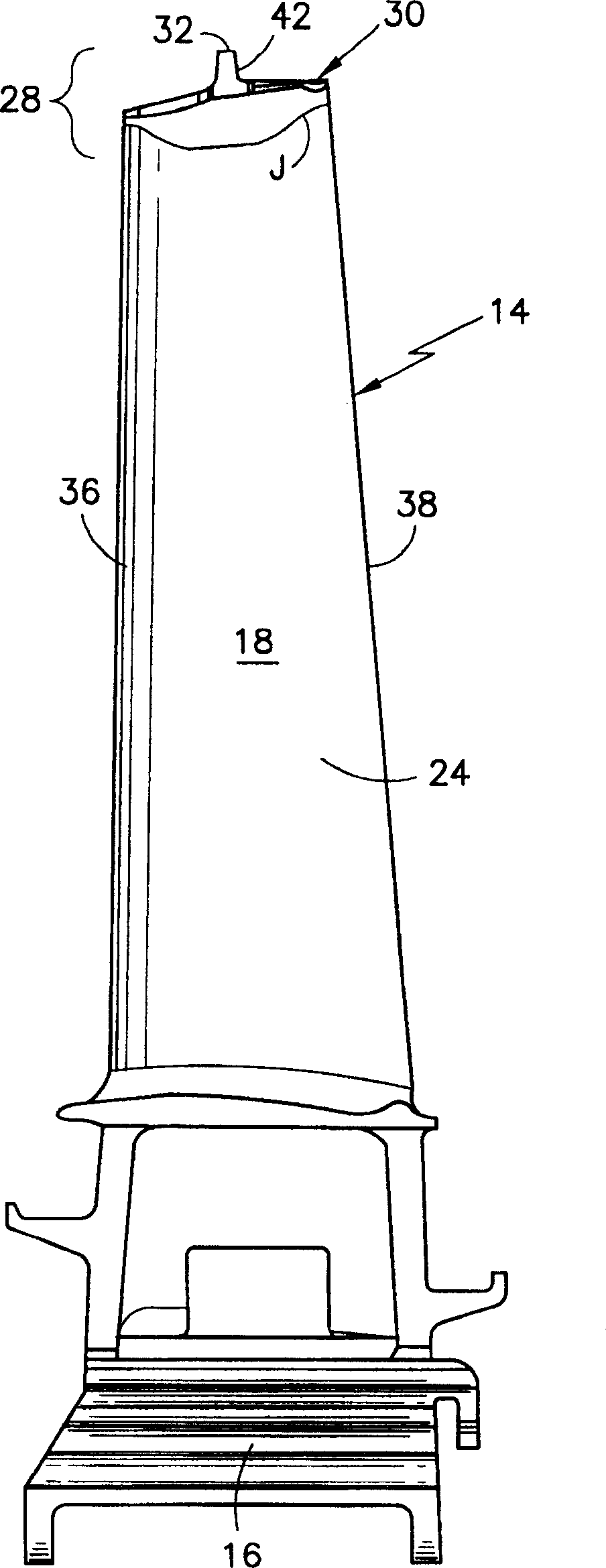

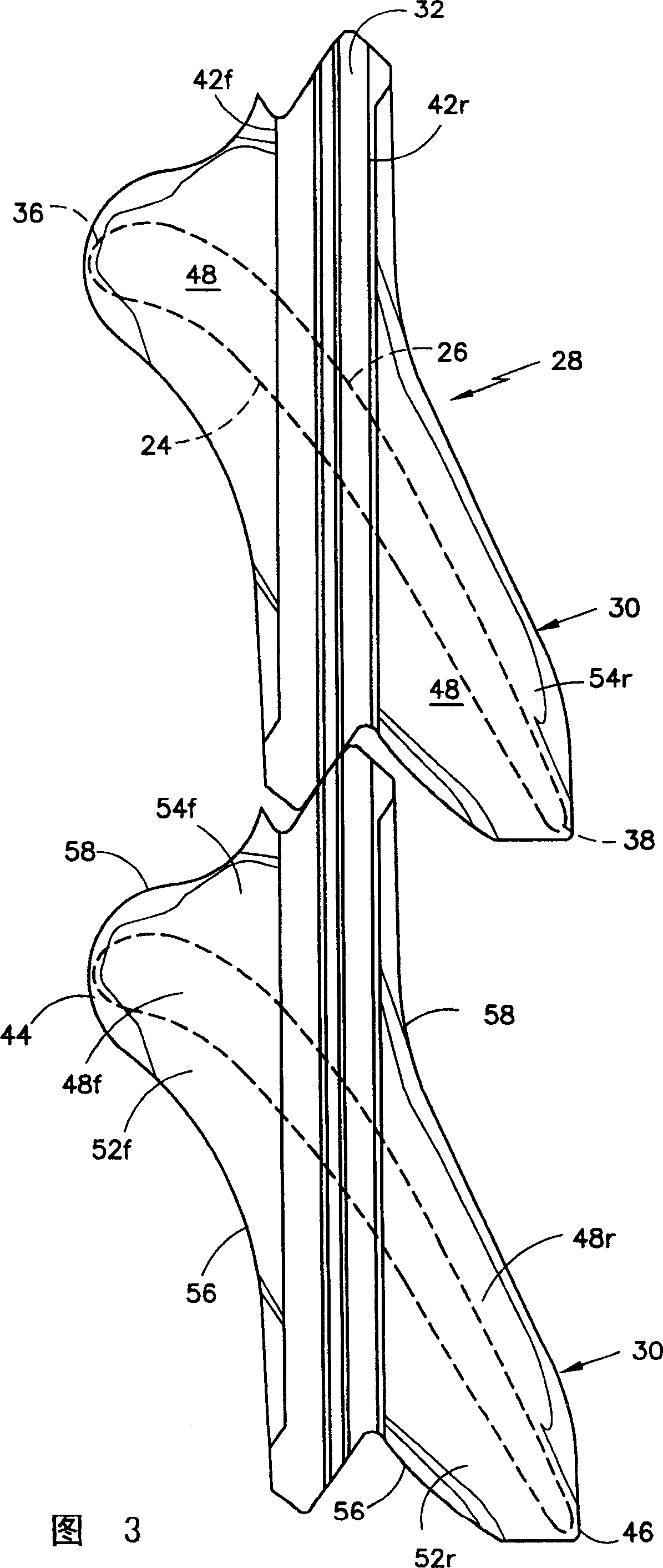

Rotor blade for a rotary machine

ActiveUS20050169761A1Reduce stress concentration factorReduce surface stressPropellersEngine manufactureLeading edgeTrailing edge

A rotor blade having a wing and beam construction for a tip shroud is disclosed. Various construction details are developed for providing a transition zone that extends from the suction side and pressure side of the airfoil to provide a flow path surface of the shroud. In one detailed embodiment, the transition zone over substantially all of its extent between the leading edge region and the trailing edge region is contoured to extend to the sides of the wings to provide a spanwise taper that extends to the side of the wing.

Owner:RTX CORP

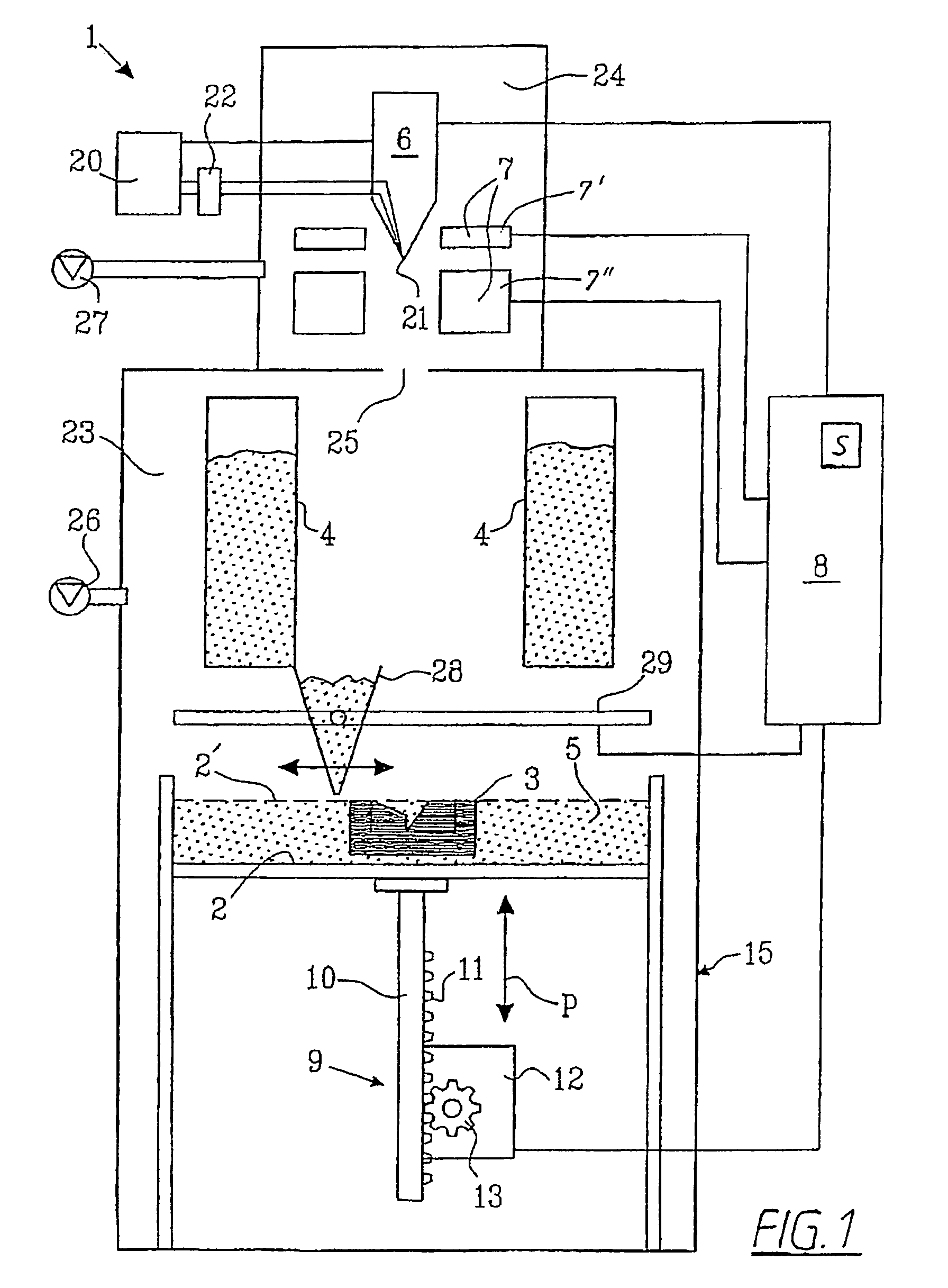

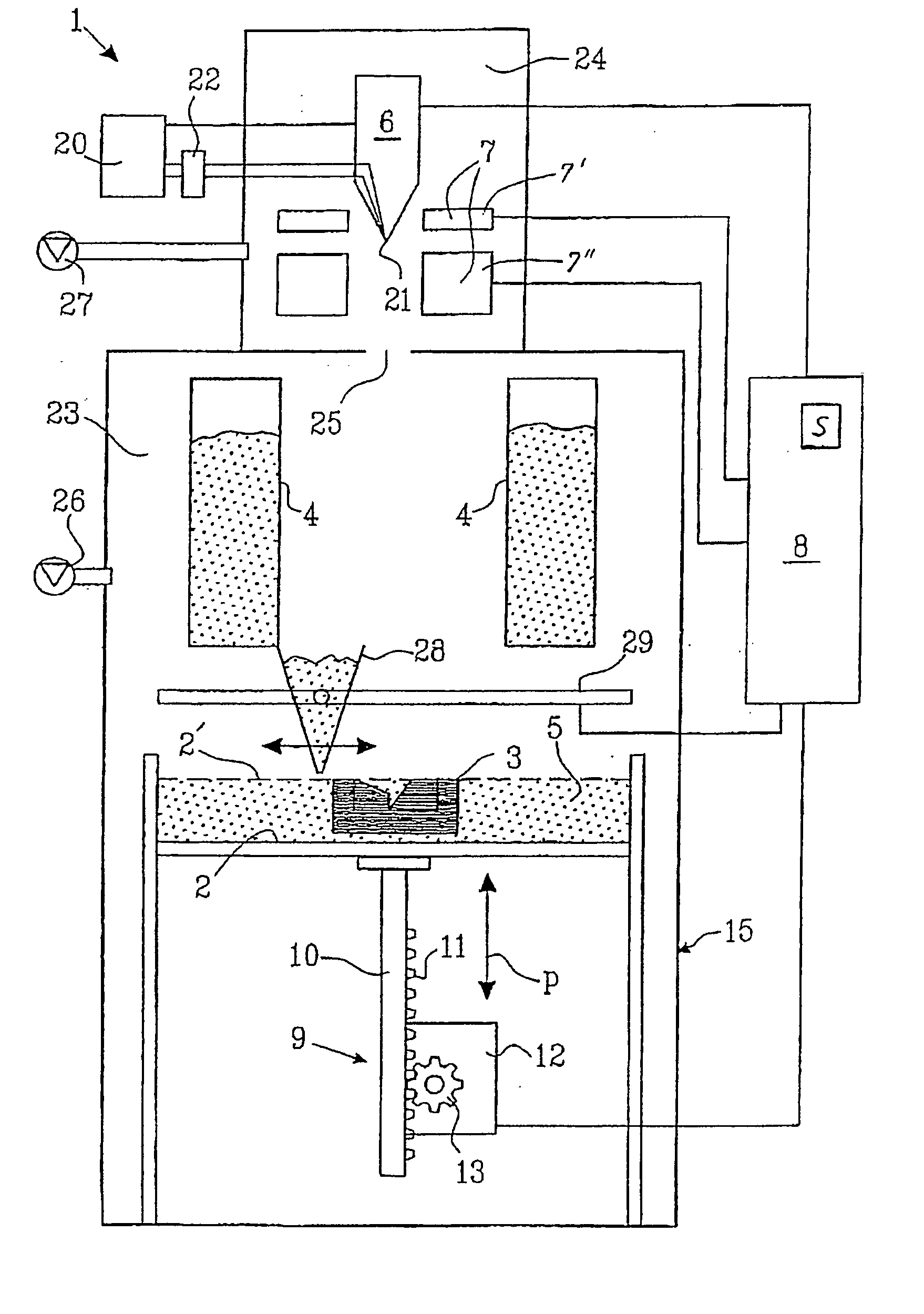

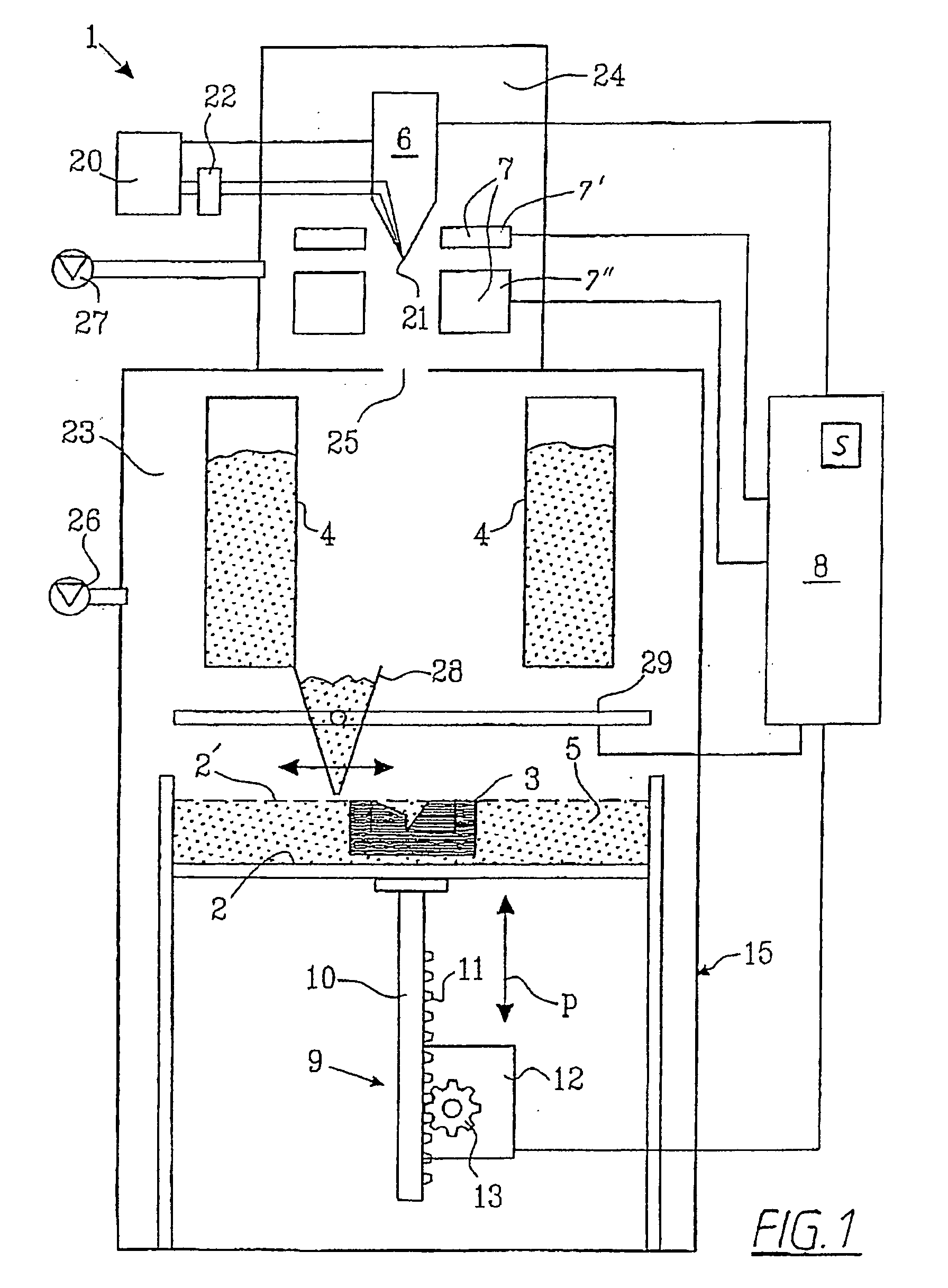

Arrangement and method for producing a three-dimensional product

ActiveUS20060157454A1Reduce surface stressReduce generationAdditive manufacturing apparatusIncreasing energy efficiencyMetallurgySupply energy

An arrangement and method for production of three-dimensional bodies by successive fusing together of selected areas of a powder bed, which parts correspond to successive cross sections of the three-dimensional body, which method comprises the following method steps: application of powder layers to a work table, supplying energy from a radiation gun according to an operating scheme determined for the powder layer to said selected area within the powder layer, fusing together that area of the powder layer selected according to said operating scheme for forming a cross section of said three-dimensional body, a three-dimensional body being formed by successive fusing together of successively formed cross sections from successively applied powder layers.

Owner:ARCAM AB

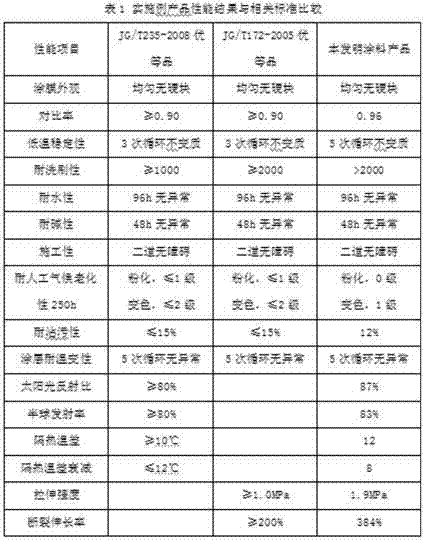

Waterborne exterior elastic reflective heat insulation coating and production method thereof

The invention relates to a waterborne exterior elastic reflective heat insulation coating and a production method thereof. The waterborne exterior elastic reflective heat insulation coating is prepared by the following raw materials by mass: 30-60 parts of a pure acrylic elastic emulsion, 3-10 parts of a hollow ceramic bead, 10-25 parts of a pigment, 5-20 parts of filler, 15-30 parts of water, 0.2-1.0 part of a wetting dispersant, 0.3-0.8 part of an antifoaming agent, 0.1-1.0 part of a mildew-resistant bactericide, 0.2-0.5 part of hydroxyethyl cellulose, 0.3-1.0 part of a thickening agent, 1-3 parts of an antifreezing agent, 0.4-0.8 part of a film forming auxiliary agent, 0.2-0.6 part of a levelling agent, and an amount of a neutralizer for adjusting the pH value to 8-9. The invention also includes the production method of the waterborne exterior elastic reflective heat insulation coating. The waterborne exterior elastic reflective heat insulation coating provided in the invention hasgood stability, good workability and heat insulation effect, sound elasticity and waterproof effect as well as satisfying environmental protection property, thus especially being suitable for application in the building industry.

Owner:双塔涂料科技有限公司

Quantum dot sealing method, quantum dot compound particle and applications

ActiveCN105778887AReduce interactionReduce the likelihood of reunionsLuminescent compositionsNon-linear opticsLiquid-crystal displayQuantum dot

The invention discloses a quantum dot sealing method, a quantum dot compound particle and applications. According to the method, quantum dots are made into quantum dot compound particles, then a blocking layer is arranged on the surface of each quantum dot compound particle so as to seal the quantum dots; after sealing, the interaction among quantum dots is reduced, thus the possibility of agglomeration is reduced; moreover, the air and water are obstructed; at the same time, the possibility that quantum dots are disturbed and destroyed by contacting the external environment, when the quantum dots are further dispersed into other materials or cured or during the device preparation process is reduced; the luminous efficiency of quantum dot is improved effectively, the service life of quantum dot is prolonged; and the provided quantum dot compound particle can be applied to optical devices such as light conversion material of liquid crystal display and has the advantages of high luminous efficiency of quantum dots and long service life.

Owner:TCL CORPORATION

Thermal insulation coating and preparation method thereof

The invention relates to a thermal insulation coating and a preparation method thereof, and the preparation method comprises the following steps: adding hollow granular micro-bubbles made of special materials, hollow glass beads and an opaque polymer on the basis of a water base, a bonding agent base material and a filler, combining active hydroxyl genes thereof with a molecular chain of an emulsion polymer and forming a dense net layer structure in a coating, wherein the coating has the comprehensive thermal insulation function of reflecting, blocking and radiating solar heat and has the significant effects of thermal insulation and energy conservation. The coating has strong adhesion to the surface of a building, the thickness of a coating dry film is only 60 mu m-150 mu m, and the coating is not only thermal-insulating, but also water-proof. The coating has excellent air permeability and long-lasting antibacterial property, as well as the advantages of pollution prevention, self-cleaning, sound isolation, aging resistance, long service life, easy construction and manpower conservation; compared with the traditional thermal insulation material, the coating has excellent performance-price ratio.

Owner:刘志光

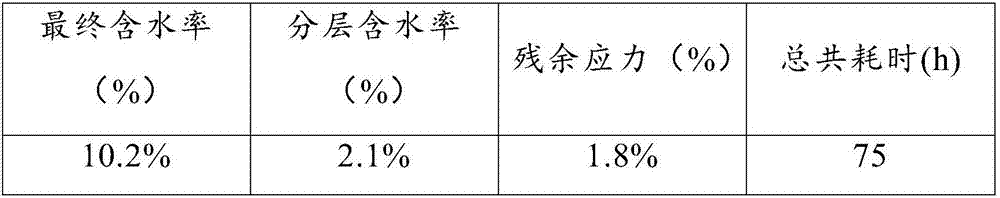

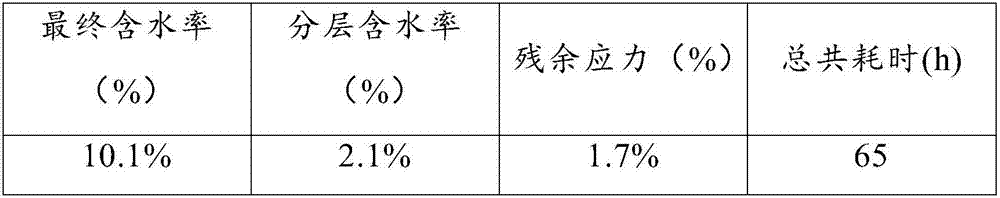

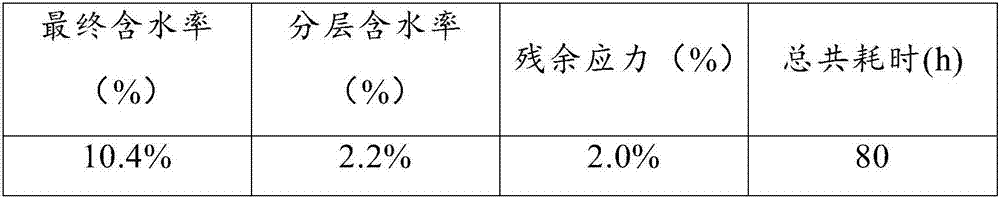

Wood drying process

InactiveCN105202870AIncrease temperatureIncrease moisture contentDrying solid materials with heatHearth type furnacesSurface stressHigh humidity

The invention discloses a wood drying process. The wood drying process comprises the steps of 1, preheating; 2, high-temperature and high-humidity treatment; 3, drying; 4, maintenance. When the wood drying process is adopted for drying wood, the surface stress and internal stress of wood can be eliminated, surface cracking or internal cracking of wood can be prevented, the original quality of wood is maintained, defects such as air shrinkage, bending, crinkling and deformation do not occur easily, the rate of wood damage caused by improper drying is reduced greatly, and meanwhile, energy is saved and drying time is shortened.

Owner:王璐

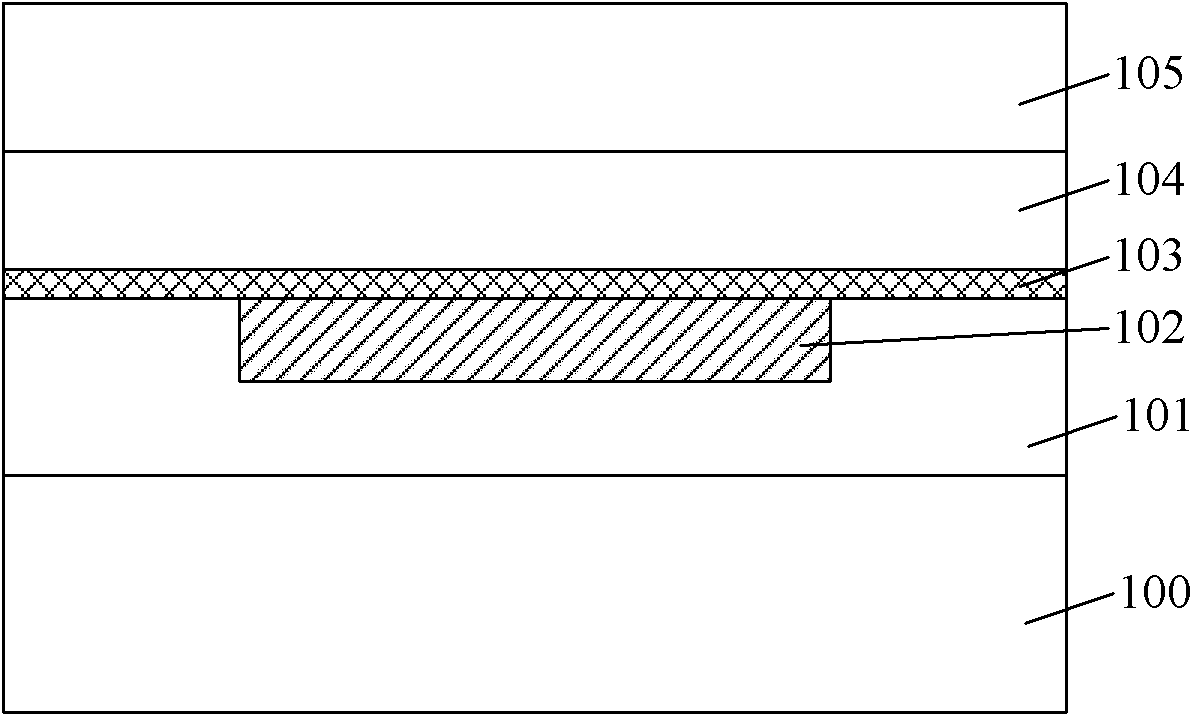

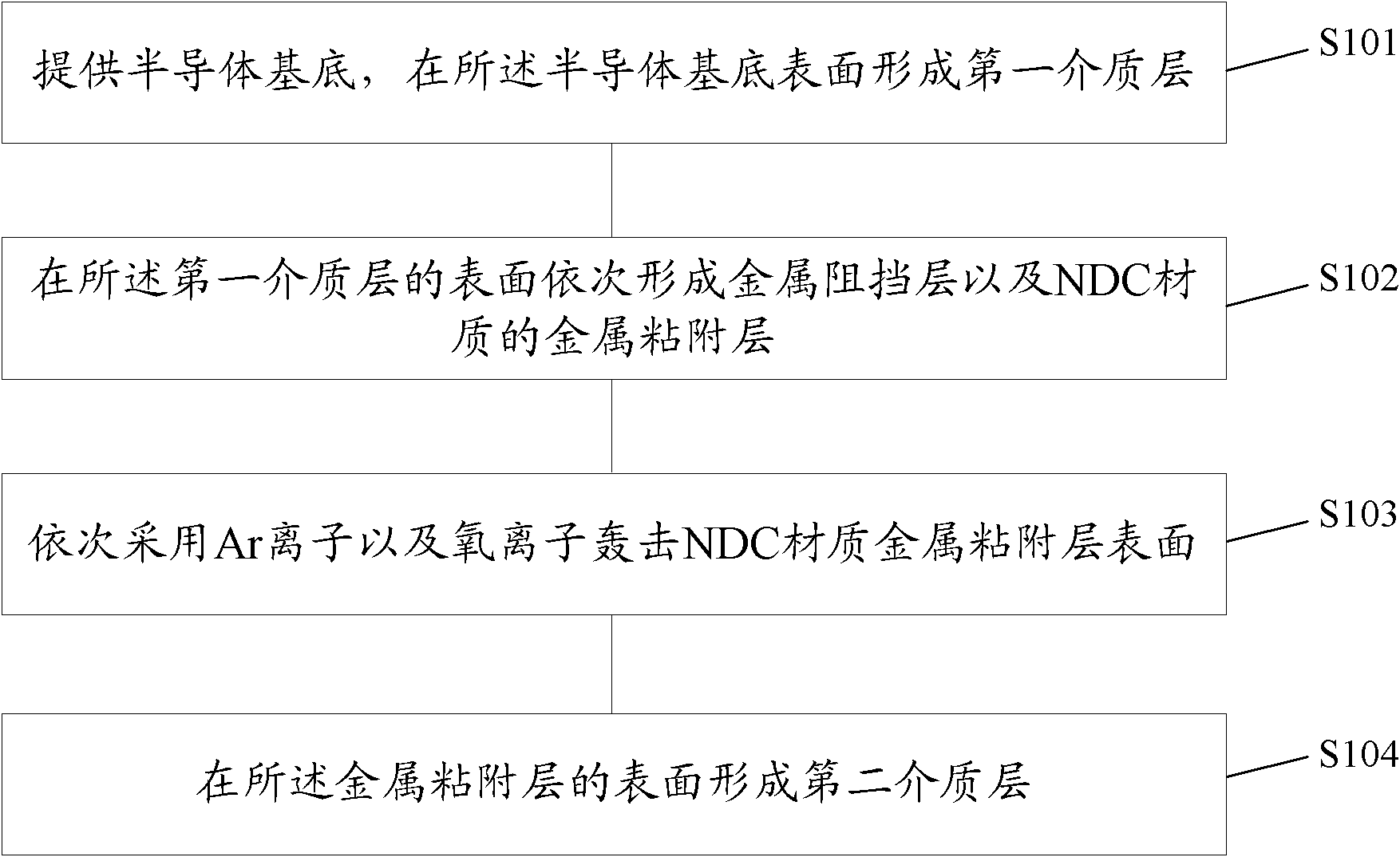

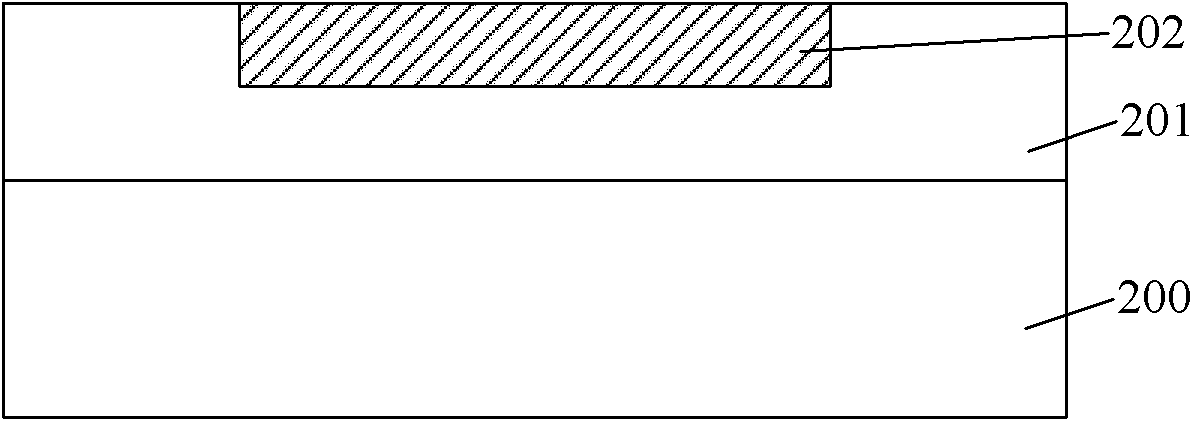

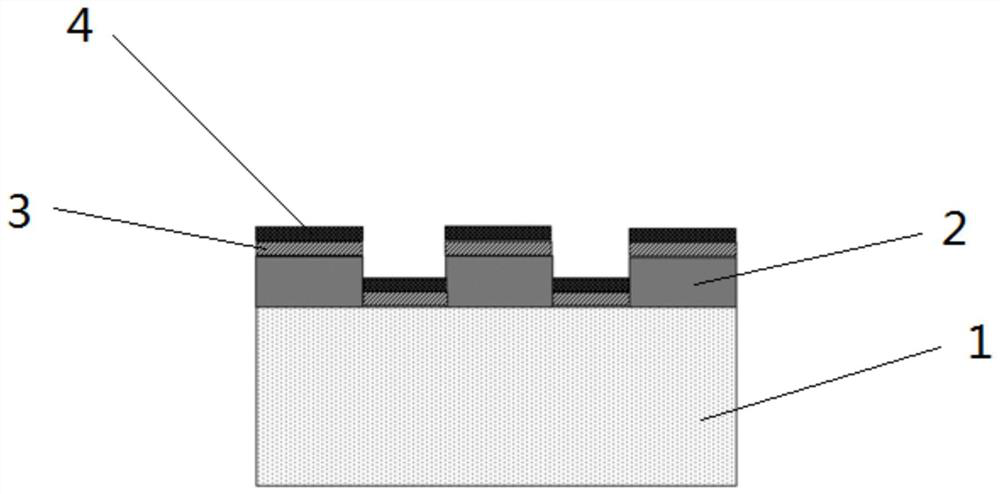

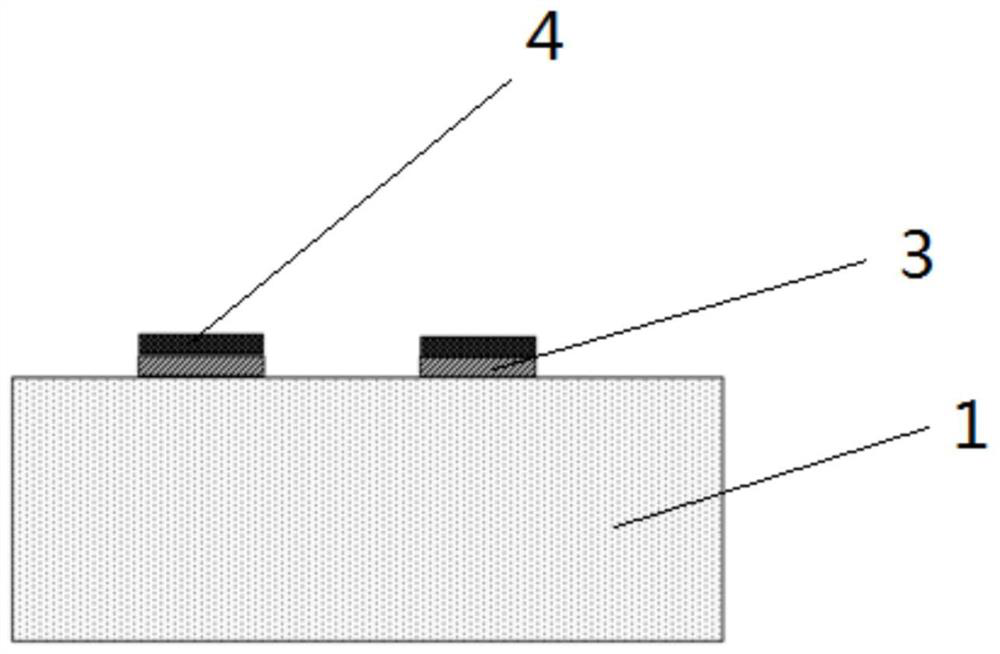

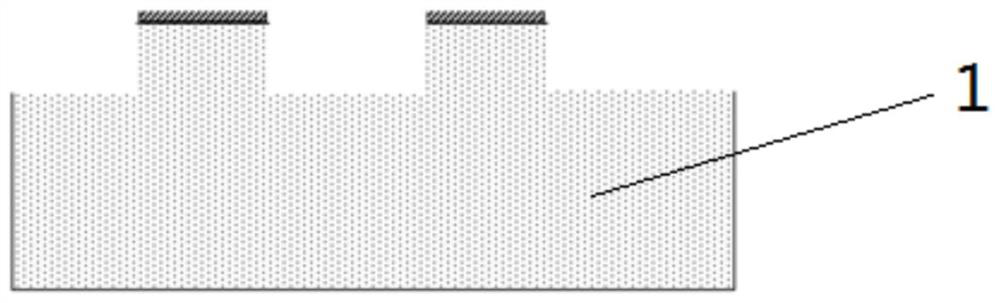

Semiconductor structure and forming method thereof

ActiveCN102468228AImprove adhesionDoes not affect electrical performanceSemiconductor/solid-state device detailsSolid-state devicesSurface stressSemiconductor structure

The invention provides a semiconductor structure and a forming method thereof. The forming method comprises the following steps of: providing a semiconductor substrate; forming a first dielectric layer on the surface of the semiconductor substrate; forming a metal blocking layer on the surface of the first dielectric layer; forming a metal adhesion layer made of NDC (Naphthalene Dicarboxylate) materials on the surface of a metal diffusion layer; sequentially carrying out Ar ion and oxygen ion bombardment on the surface of the metal adhesion layer; and forming a second dielectric layer on the surface of the metal adhesion layer. A compact oxide film can be formed on the surface made of NDC materials, so that the surface stress is reduced, the adhesivity between the NDC materials and the adjacent dielectric layers is improved, and meanwhile, the electrical performance of the device cannot be influenced.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

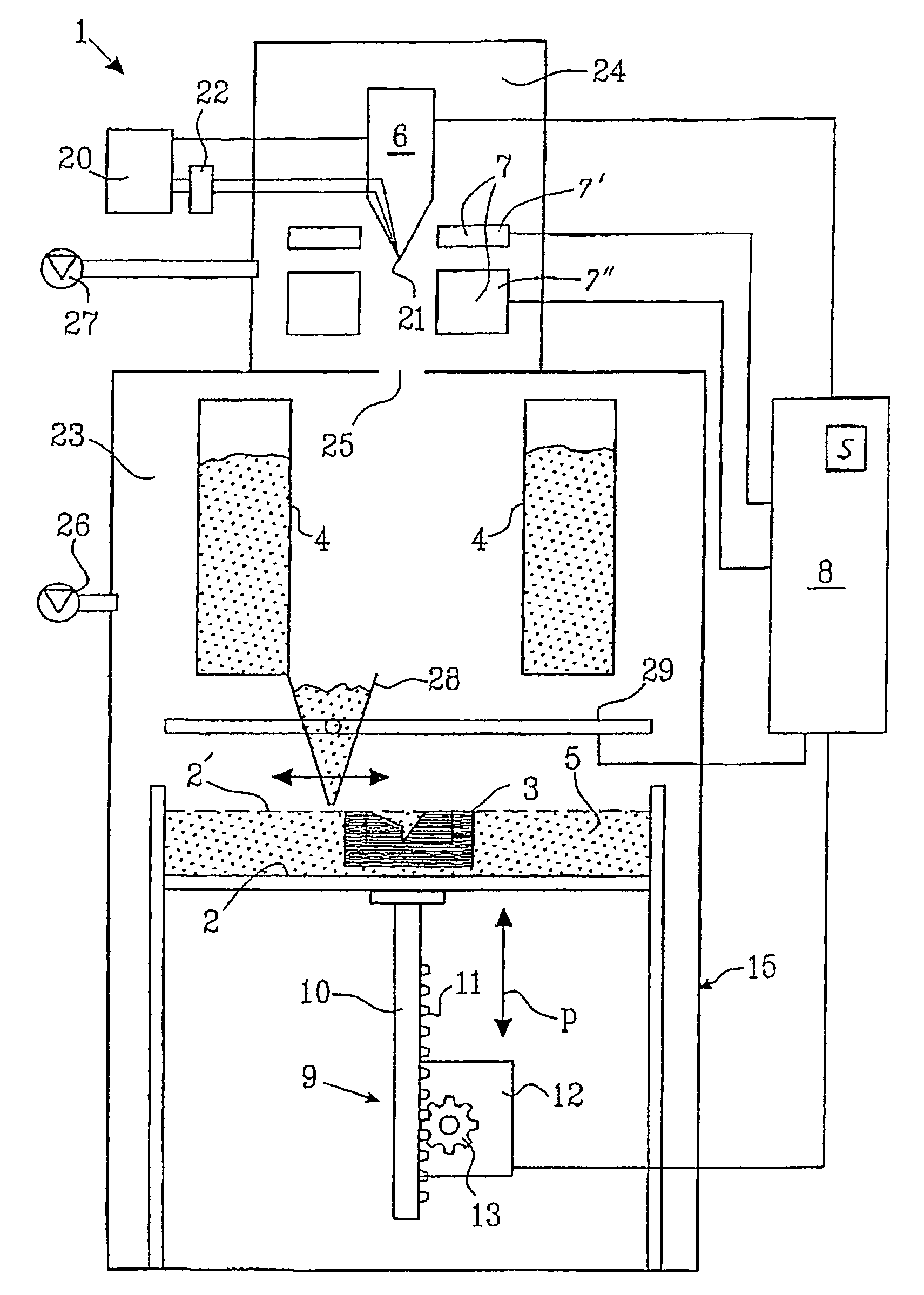

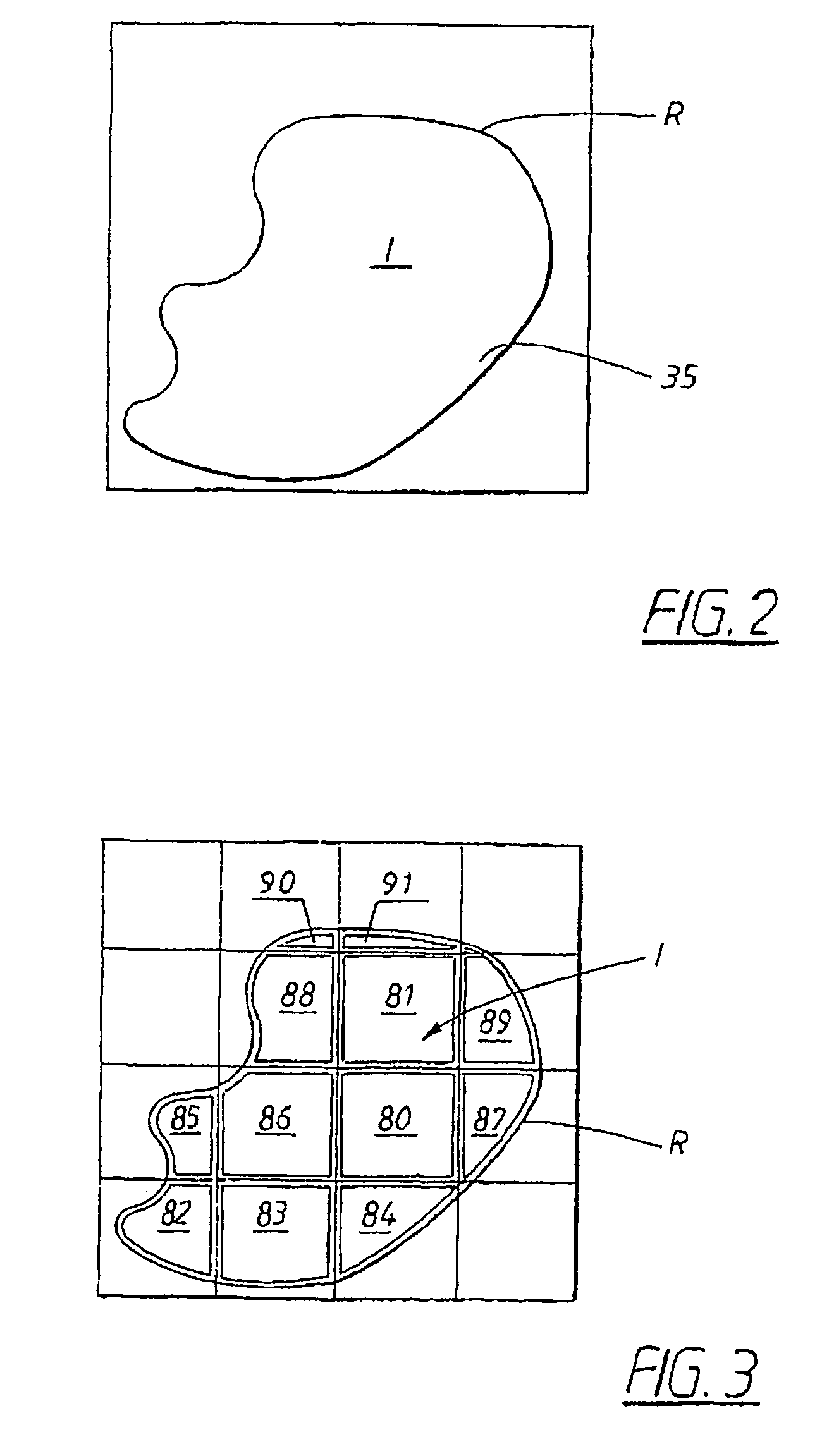

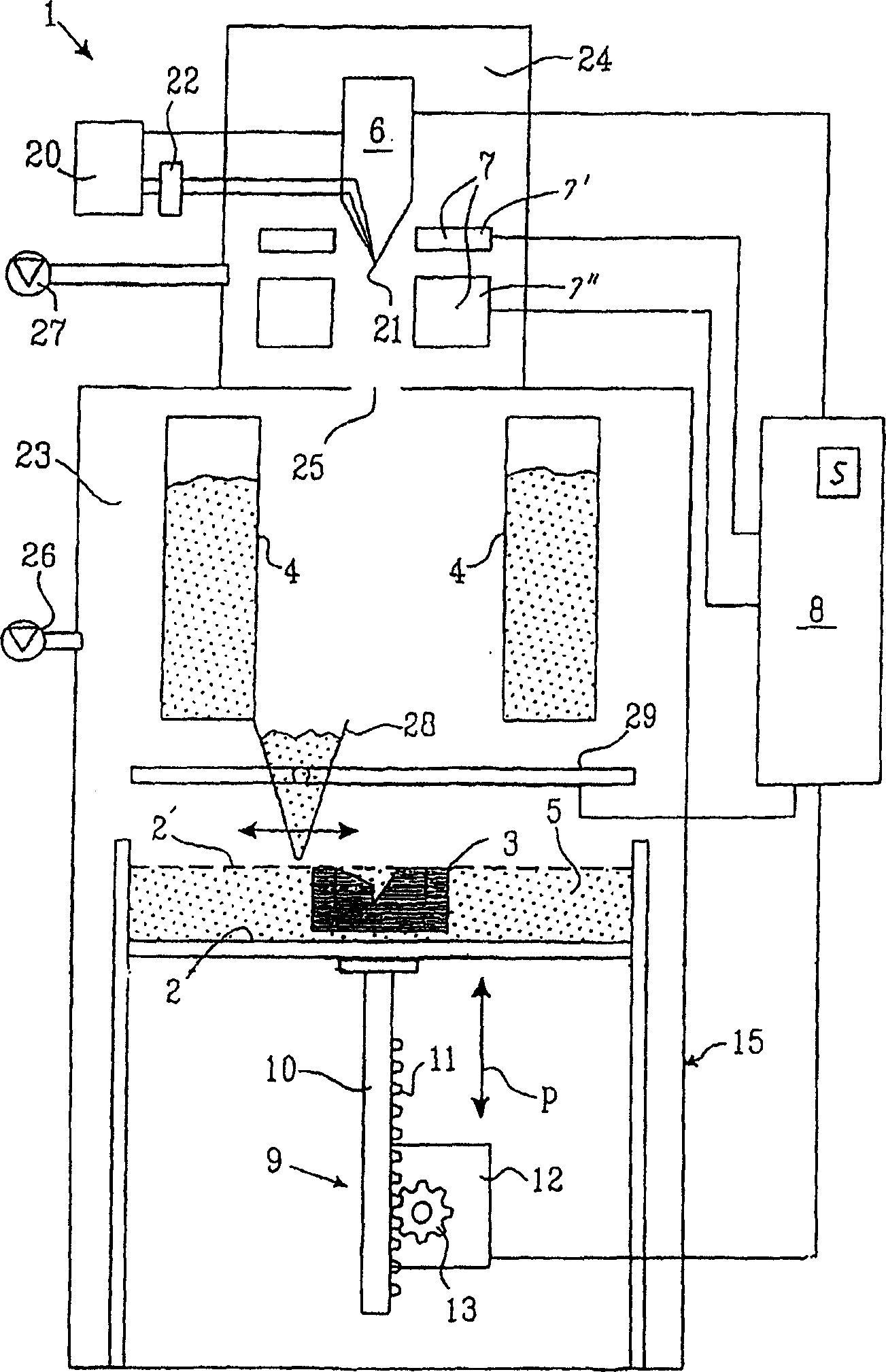

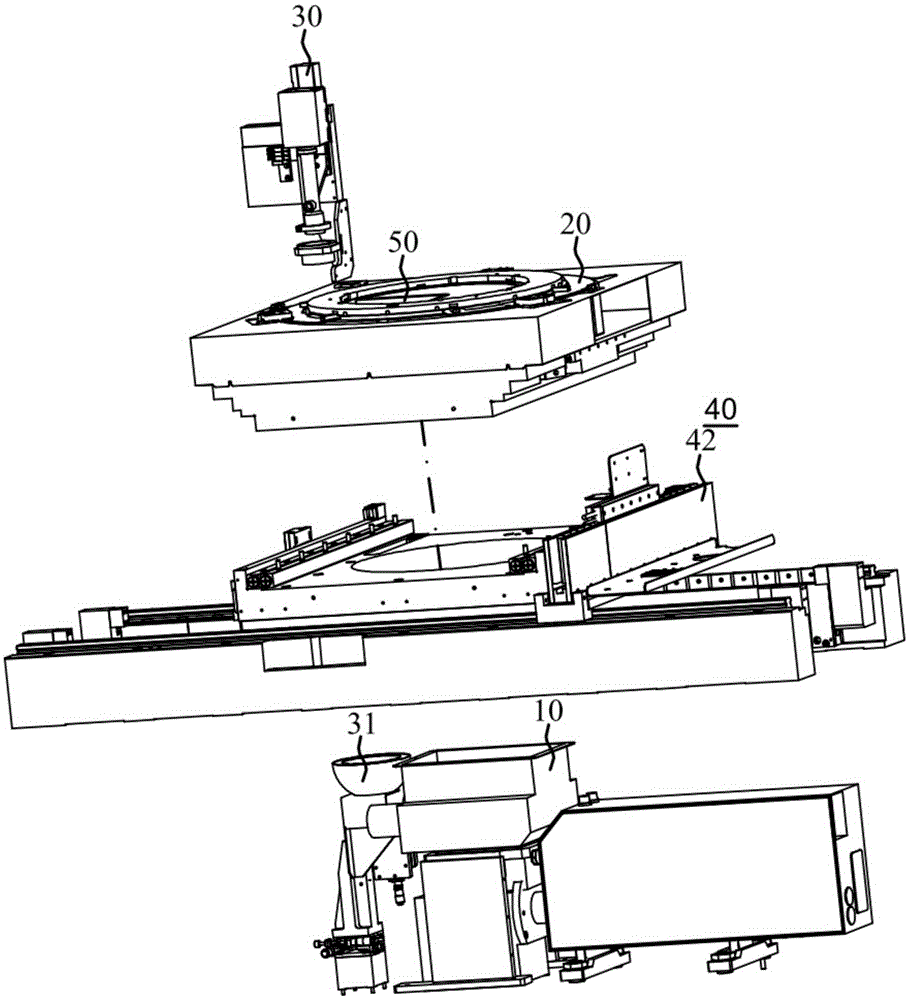

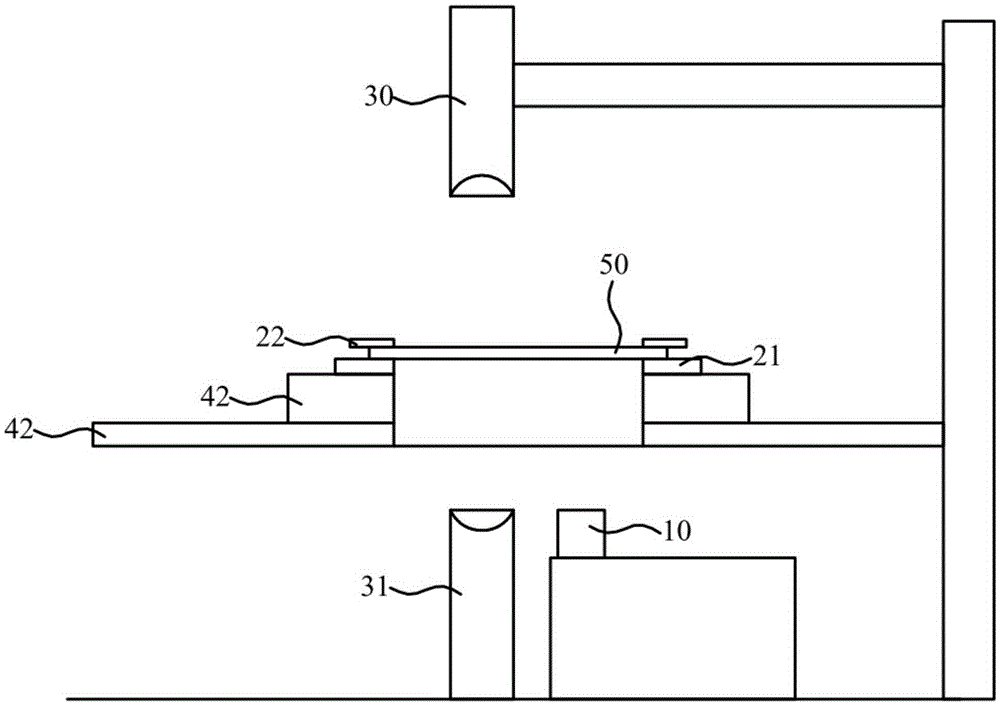

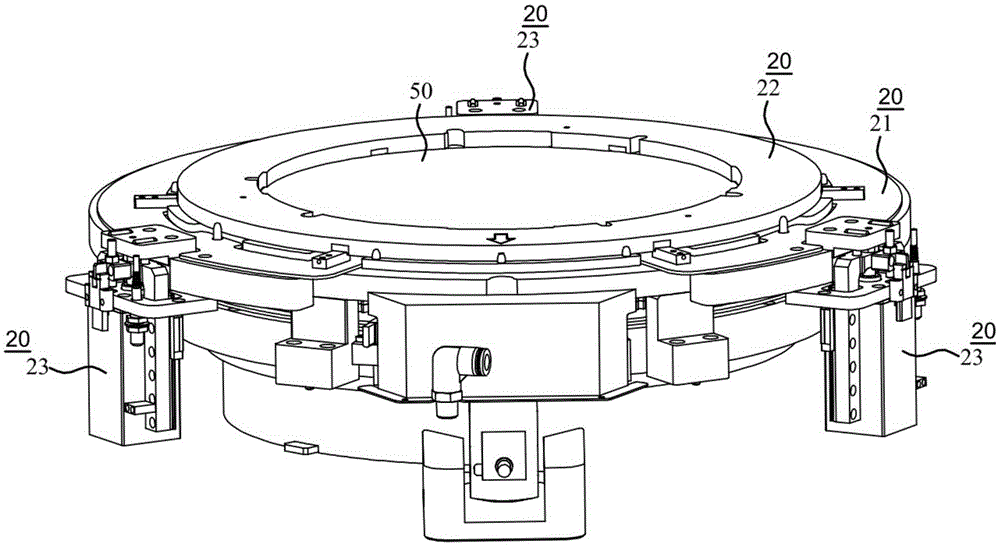

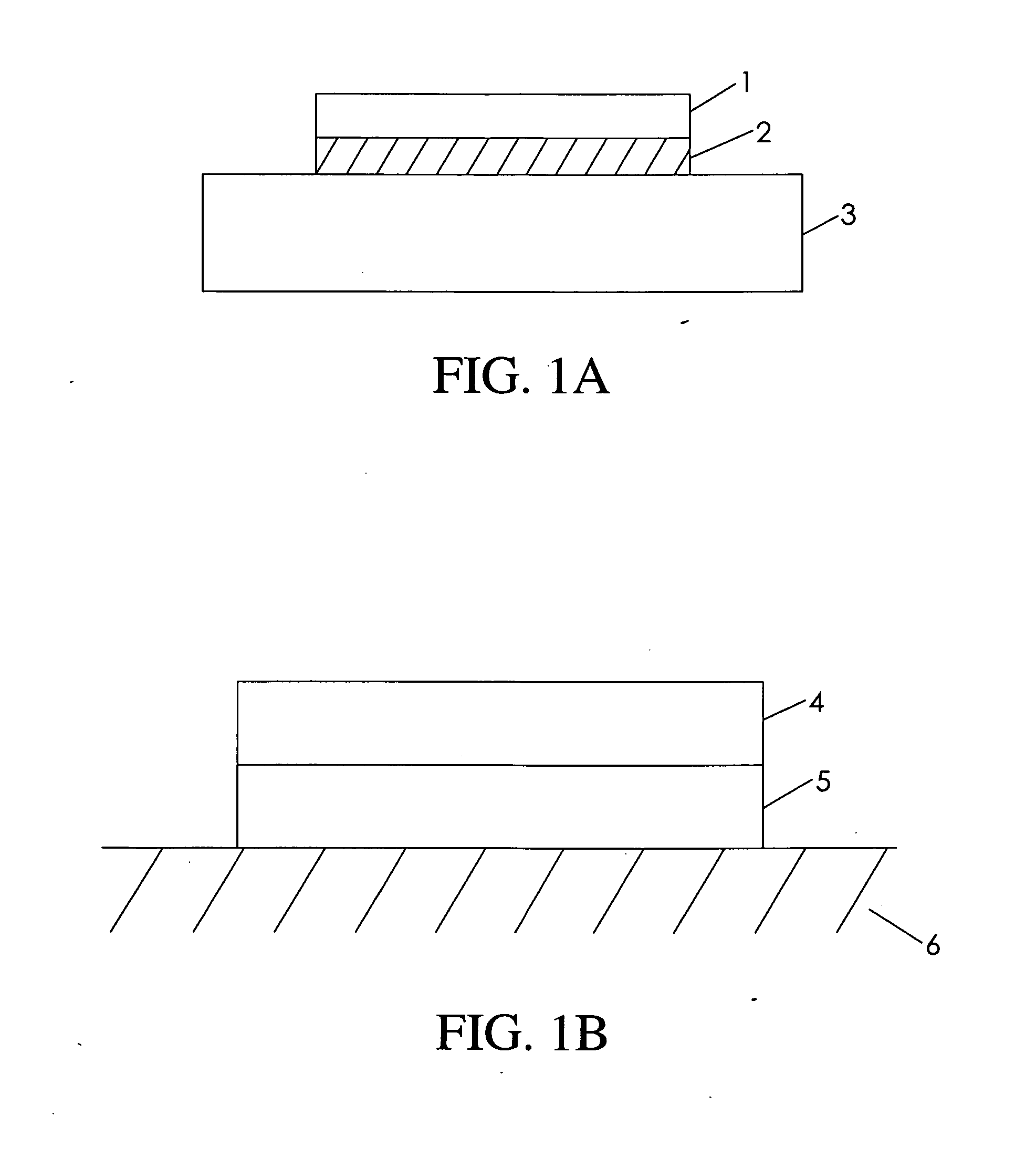

Arrangement for production of a three dimensional object

InactiveCN1729068AReduce surface stressReduce shape deviationAdditive manufacturing apparatusIncreasing energy efficiencyWorkbenchPhysics

An apparatus for manufacturing a three-dimensional product, the apparatus comprising: a workbench on which the three-dimensional product is constructed, a powder dispenser configured to distribute a thin layer of powder onto the workbench to form a powder layer, a radiation gun for delivering energy to the powder to fuse the powders together, and for directing a beam emitted by the radiation gun onto the powder layer to fuse a portion of the powder layer into a means for forming cross-sections of said three-dimensional product, and a control computer storing therein information relating to successive cross-sections of said three-dimensional product, said cross-sections constituting said three-dimensional product, wherein said control computer is adapted to The means for guiding the radiation gun over the powder layer are controlled according to an operating scheme for forming cross-sections of the three-dimensional object by successively converting the cross-sections formed successively by the powder distributor fused together to create the three-dimensional object. and methods of manufacturing three-dimensional products using such devices.

Owner:ARCAM AB

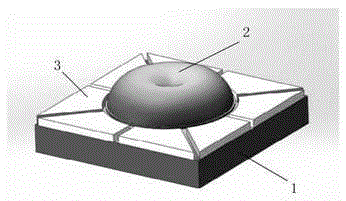

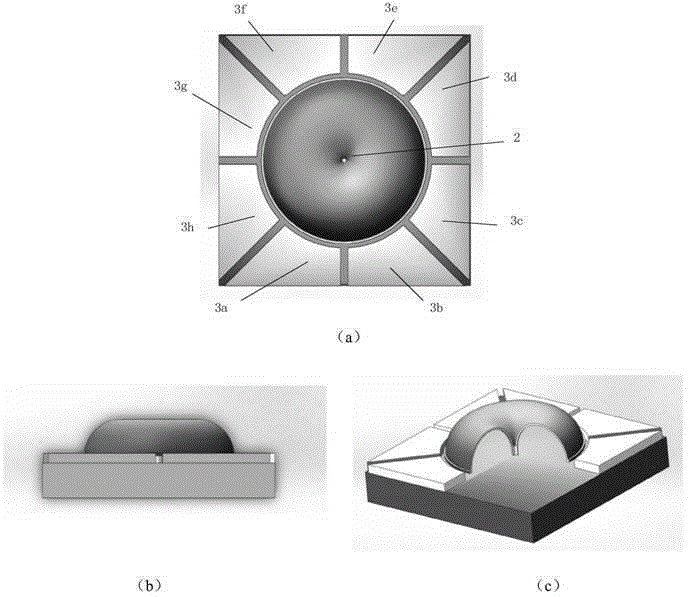

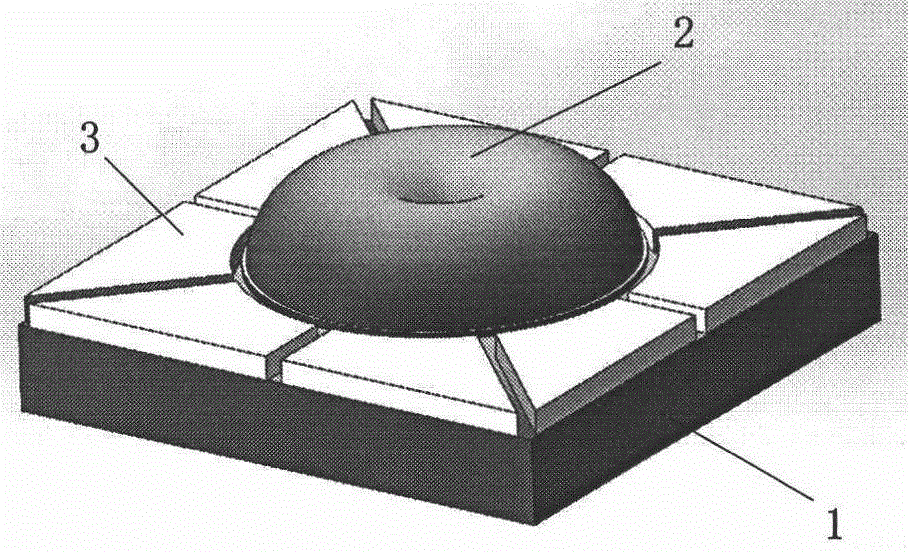

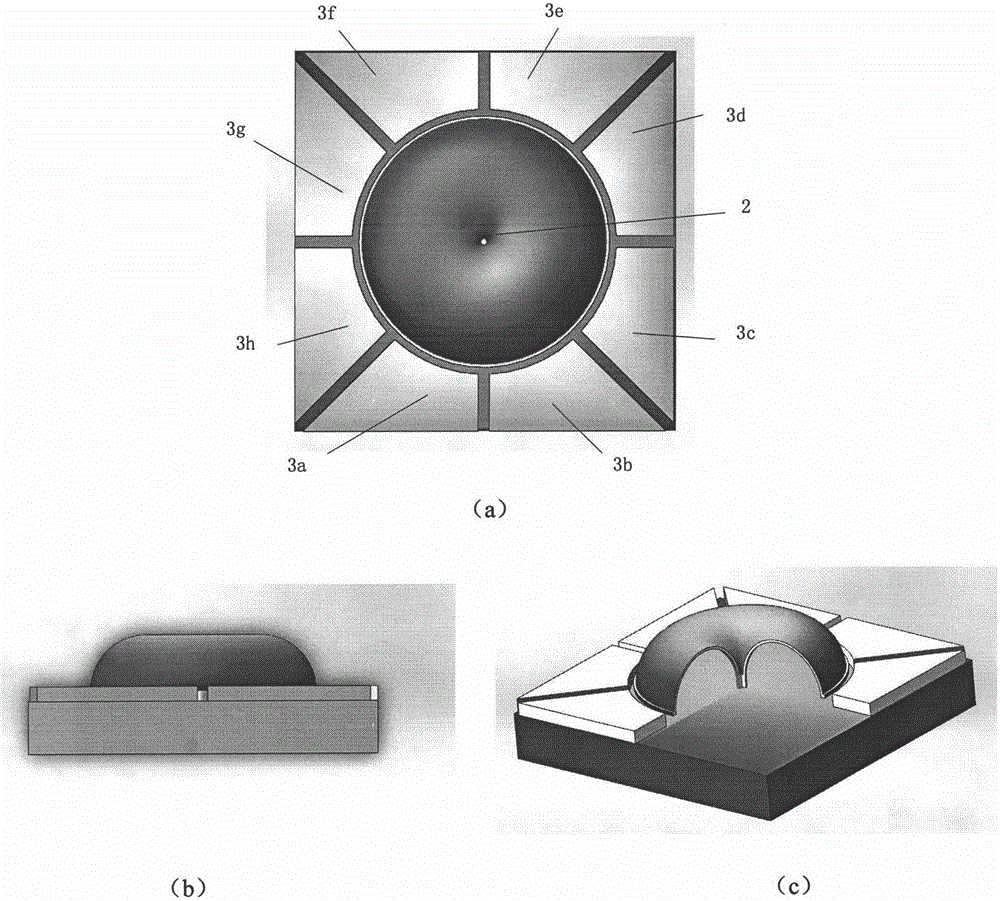

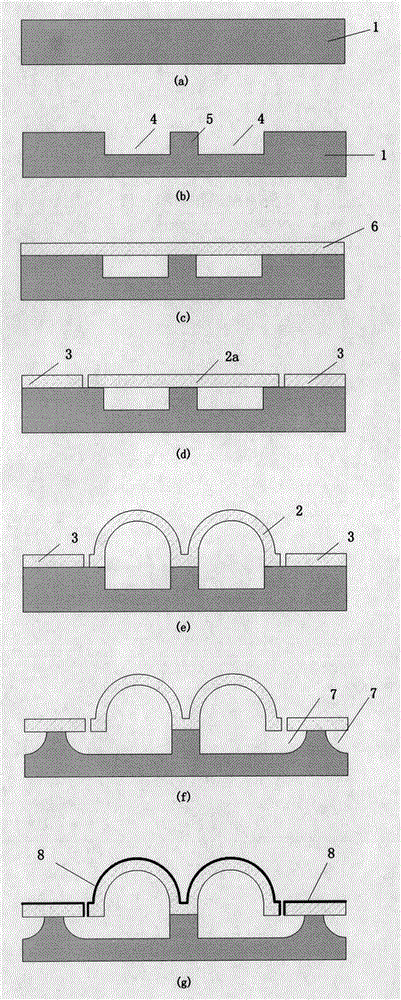

Micro-hemispherical resonant gyroscope based on borosilicate glass annealing forming and manufacturing method thereof

ActiveCN105424019AIncrease etch rateReduce surface stressSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesSurface stressGyroscope

The invention discloses a micro-hemispherical resonant gyroscope based on borosilicate glass annealing forming and a manufacturing method thereof. A silicon wafer serves as a substrate to form a silicon substrate. A cylindrical cavity and a center supporting column in the circle center of the cavity are etched on the upper surface of the silicon wafer. The center supporting column is connected with the center of a hemispherical harmonic oscillator to form a suspended structure. Meanwhile, eight flat-plate electrodes are evenly distributed around the hemispherical harmonic oscillator and on the periphery of the cylindrical cavity of the upper surface of the silicon wafer. The eight flat-plate electrodes are composed of four drive electrodes and four detection electrodes, all the drive electrodes, the detection electrodes and the hemispherical harmonic oscillator are not in contact and have same gaps, and the drive electrodes and the detection electrodes are sequentially distributed at intervals. The glass metal blowing type micro-hemispherical resonant gyroscope manufactured through the method has stable performance and a wider application range because of the advantages of being simple in structure, low in surface stress, high in symmetry and the like.

Owner:NANJING UNIV OF SCI & TECH

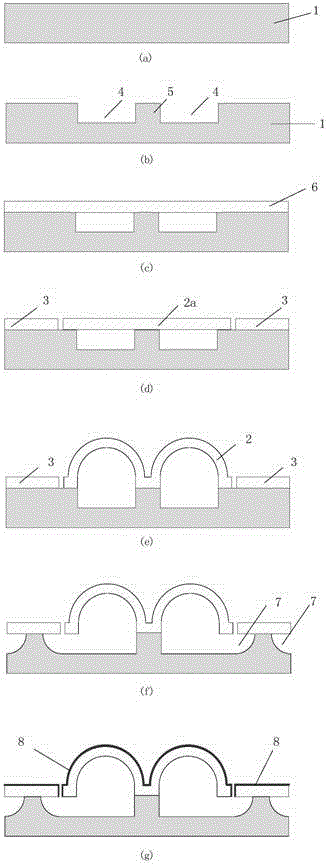

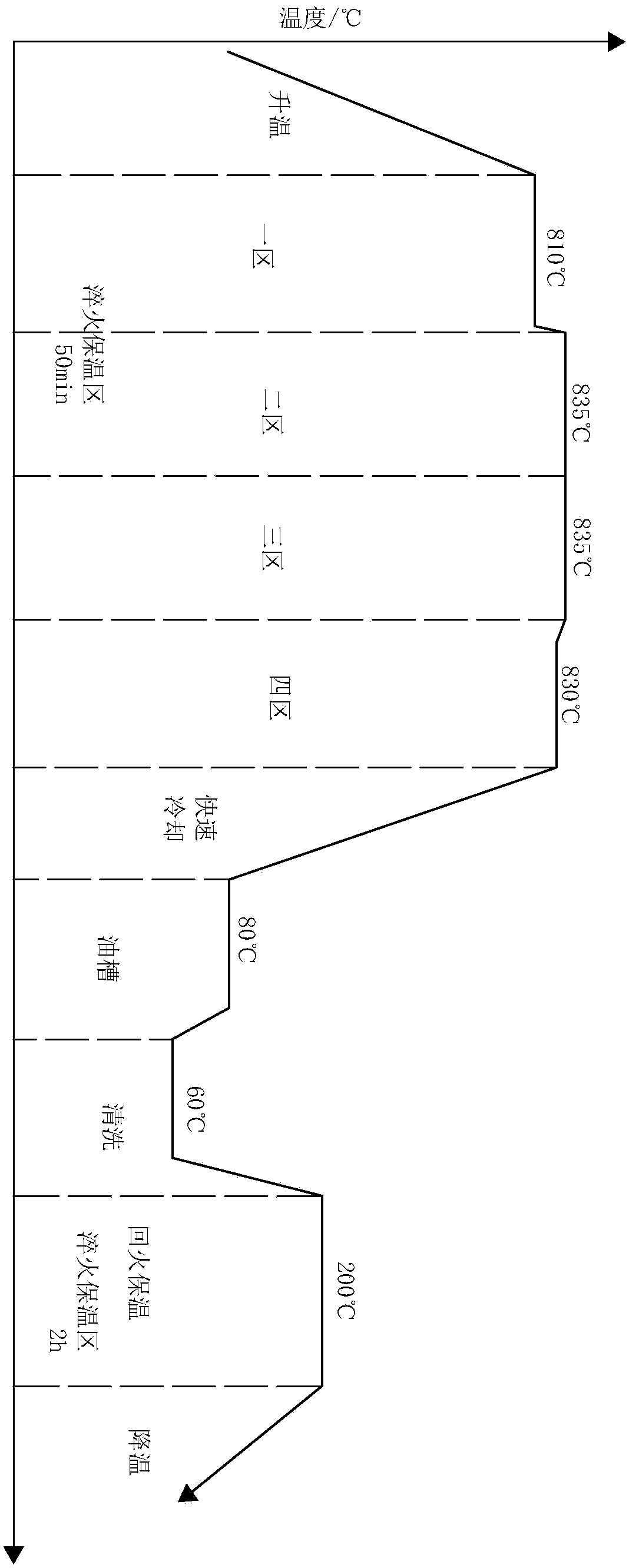

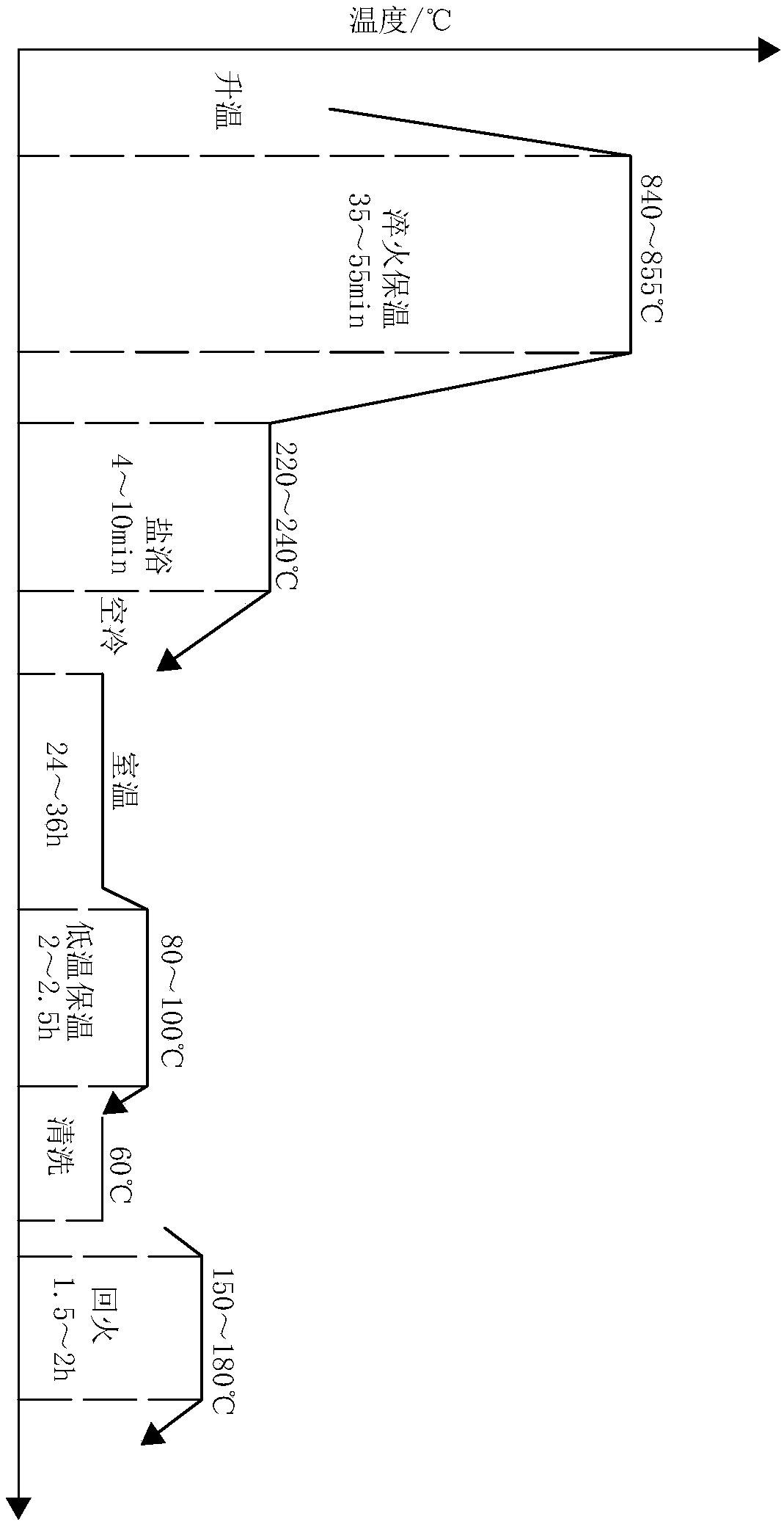

Machining process of marine gear

The invention discloses a machining process of a gear. The machining process comprises the following steps of forging, normalizing, rough turning, finish turning, hobbing, carburizing, inner hole and inner hole end face finish turning, quenching, tempering, shot blasting, inner hole and inner hole end face grinding, key groove cutting and final finished product obtaining. According to the machining process of the gear, the gear face can have high hardness, the core strength can be guaranteed, the surface hardness of a hole in the transmission shaft cooperation position is reduced, meanwhile, structure stress is reduced, and the use performance of the gear is more reasonable.

Owner:孙阳

A kind of polypropylene coating material and preparation method thereof

InactiveCN102268207AReduce surface stressReduce processing temperatureCoatingsLow-density polyethyleneDispersity

The invention discloses a polypropylene coating material and a preparation method thereof. The polypropylene coating material comprises the following components in parts by weight: 78.0-83.0 parts of polypropylene material, 0.6-1.2 parts of surfactant, 0.5-1.2 parts of acetone, 0.5-1.0 part of lubricating agent, 10.8-20.0 parts of LDPE (Low-Density Polyethylene), 0-4.9 parts of LLDPE (Linear Low Density Polyethylene) and 0-1.0 part of polypropylene chemical degradation agent. The invention further discloses a method for preparing the polypropylene coating material. According to the invention,an appropriate amount of substances such as the surfactant and the like are added into the polypropylene coating material, so that the surface stress of a coating film is lowered, the activity is increased, the width of a formed film during coating is increased, and the phenomenon of shrinkage is lightened; and the surfactant has high dispersity, so that the formed film is uniform, and the product quality is improved.

Owner:南京金浦锦湖化工有限公司

Cathode material of solid oxide fuel cell and preparation and application thereof

ActiveCN105226294AReduce surface chargeReduce surface stressCell electrodesSputteringScreen printing

The invention discloses a cathode material of a solid oxide fuel cell and a preparation method thereof. The cathode material is characterized in that the cathode material is a composite negative electrode formed by a perovskite oxide and an oxide MO2 modified on the surface of the perovskite oxide, wherein M is Ti, Zr, Nb, Ce, Ru or Sn, the mass content of the oxide MO2 in the composite negative electrode accounts for 1-20%, the particle size of the oxide MO2 is 0.5 to 100 nanometers, and the oxide MO2 in the composite negative electrode coats the surface of the perovskite oxide. The perovskite oxide can be first prepared on the surface of an electrolyte or a partition layer of the battery by methods of coating, silk-screen printing, flow casting and the like, and then the oxide MO2 is modified on the surface of the perovskite oxide in the negative electrode by methods of solution impregnation, sol impregnation, magnetron sputtering and the like. The cathode material disclosed by the invention is endowed with excellent electrochemical performance and favorable stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Micro-hemispherical resonator gyroscope based on borosilicate glass annealing forming and preparing method

InactiveCN105021179AIncrease etch rateReduce surface stressSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesSurface stressHemispherical resonator gyroscope

The invention discloses a micro-hemispherical resonator gyroscope based on borosilicate glass annealing forming and a preparing method of the micro-hemispherical resonator gyroscope. A silicon wafer is used as a substrate to form a silicon substrate, a cylindrical cavity and a center supporting pillar in the circle center of the cavity are etched on the upper surface of the silicon wafer, and the center supporting pillar is connected with the center of a hemispherical resonator to form a suspension structure. Meanwhile, eight flat plate type electrodes are evenly distributed on the periphery of the cylindrical cavity in the upper surface of the silicon wafer and around the hemispherical resonator, and the eight flat plate type electrodes are composed of the four driving electrodes and the four detection electrodes. All the driving electrodes and all the detection electrodes are not in contact with the hemispherical resonator, identical gaps exist, and the driving electrodes and the detection electrodes are arranged in sequence alternately. The prepared glass metal blowing type micro-hemispherical resonator gyroscope has the advantages of being simple in structure, low in surface stress, high in symmetry and the like, and therefore the micro-hemispherical resonator gyroscope can have stable performance and a wider application range.

Owner:NANJING UNIV OF SCI & TECH

Welding process of boss of hydrogenation reactor

ActiveCN103170815AAvoid the hassle of surfacingAvoid levelingArc welding apparatusEngineeringWelding process

The invention relates to a welding process of a boss of a hydrogenation reactor. A port in one end of a cylindrical shell section is processed flatly after coiling, circle checking and flaw detection of the cylindrical shell section are qualified; and then a surfacing position of the boss is marked, and thus the trouble that a cylinder body is firstly leveled and then overturned for surfacing the boss when the boss is surfaced is avoided, the leveling procedure during processing of the boss is avoided, therefore the production time is saved, the levelness of the boss is ensured, and the purpose of ensuring the welding quality of the boss is achieved.

Owner:青岛兰石重型机械设备有限公司

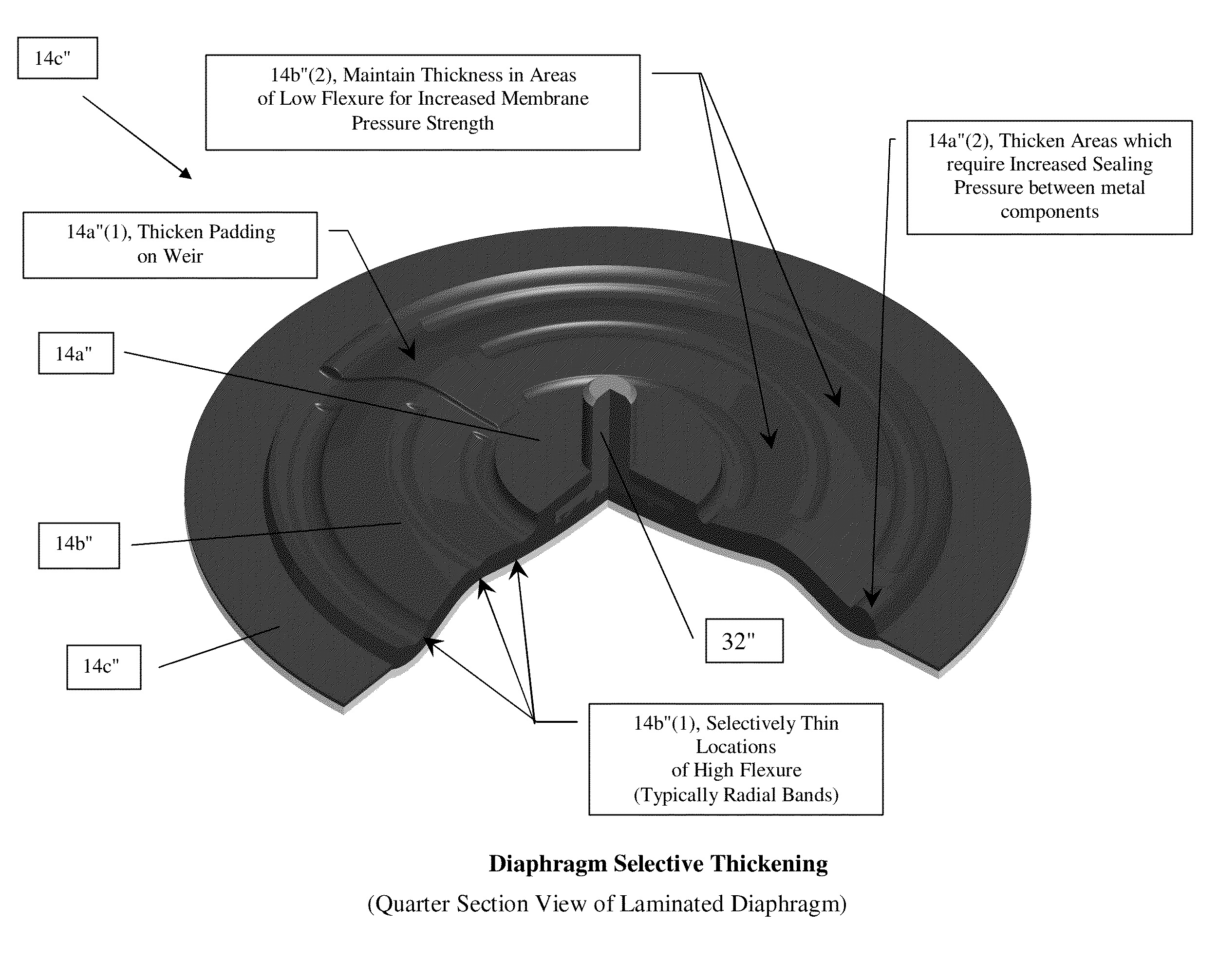

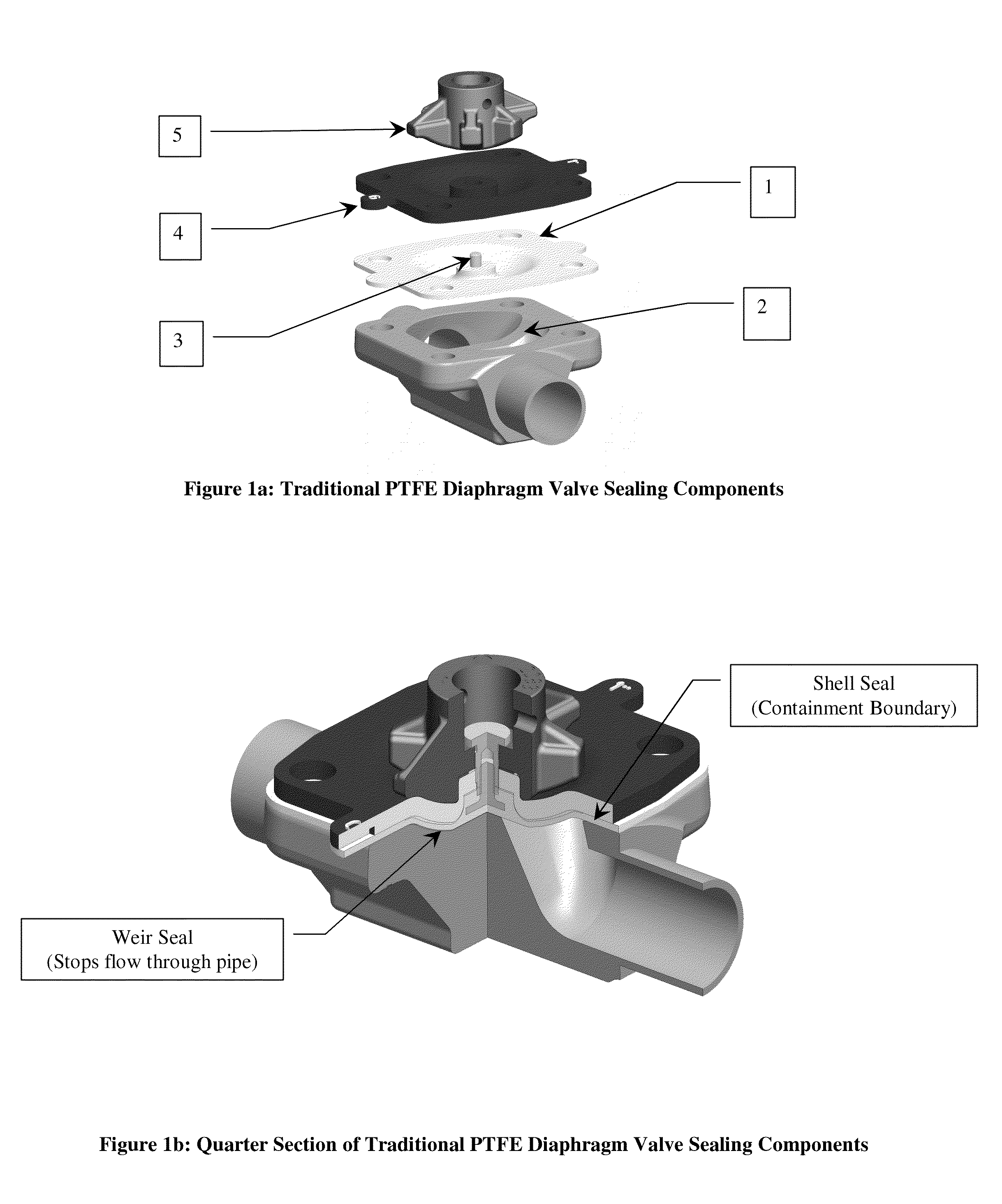

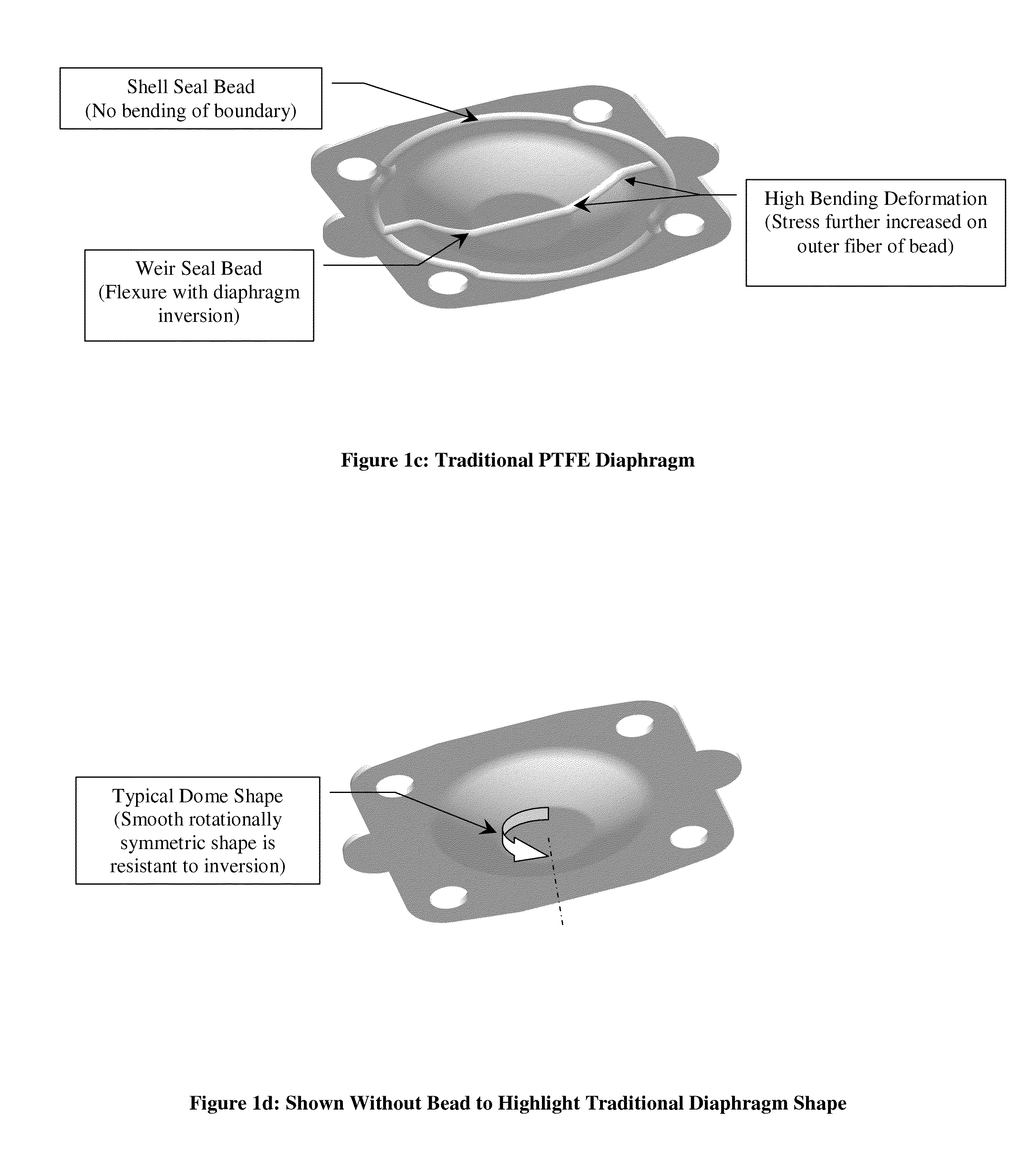

Diaphragm and backing cushion shaping for increased membrane life

InactiveUS20140061525A1Improve life expectancyReduce surface stressDiaphragm valvesEngine diaphragmsCushionMembrane configuration

A weir-type diaphragm valve a valve body with a fluid channel and a weir having a weir sealing portion; and a diaphragm with two or more diaphragm portions, including a diaphragm weir sealing portion at the weir to respond to one force and travel against the weir sealing portion to close the weir-type diaphragm valve and stop fluid flow through the fluid channel, and respond to a second force and travel away from the weir sealing portion to open the weir-type diaphragm valve and allow fluid flow through the fluid channel, a center flexing portion off the weir configured to experience convex and concave flexing extremes when the weir-type diaphragm valve is closed and opened, and an outer sealing portion configured to be fully constrained between components, one of which includes the valve body, when the weir-type diaphragm valve is closed and opened. The diaphragm portions have different characteristics based on different material stresses associated with different functionality that each portion is configured to perform when the weir-type diaphragm valve is closed and opened.

Owner:ITT MFG ENTERPRISES LLC

Laser marking device and method thereof

InactiveCN106486388AAvoid repetitive full compressionsReduce surface stressSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device detailsEngineeringMechanical engineering

The present disclosure relates to a laser marking device and a method thereof. The laser marking device comprises a laser system, a wafer leveling system, a first imaging system and a mobile system: the wafer leveling system carries and levels a warped wafer to be processed; the mobile system underneath properly adjusts a position of the wafer; the first imaging system detects the wafer to recognize a product category and positioning status; the laser system underneath labels laser marks on the wafer; all wafers are marked in the cyclic process.

Owner:E&R ENG CORP

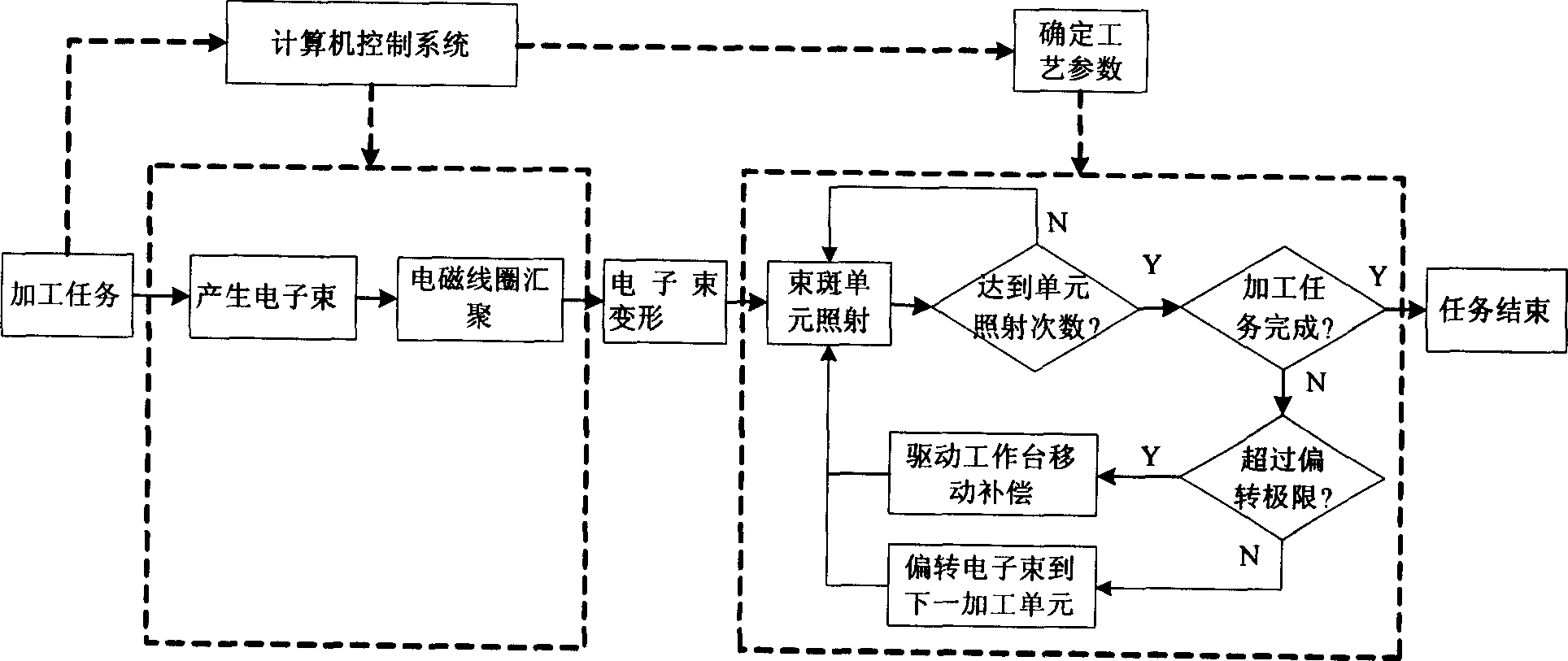

Method for finishing processing of controllable deforming electronic beam

InactiveCN1792548AOptimizing Process ParametersRealize intelligent processingComputer control systemSurface roughness

A precise machining method with cross-section shape controllable electronic beam includes such steps as calculating and controlling the energy density, radiation times, radiated positions, and deflection of electronic beam, and using the light diaphragm made of Mo to obtain needed electronic beam. Its apparatus is composed of computer control system, electronic beam generator, electromagnetic coil, deflection coil and bench control system.

Owner:CHONGQING UNIV OF TECH

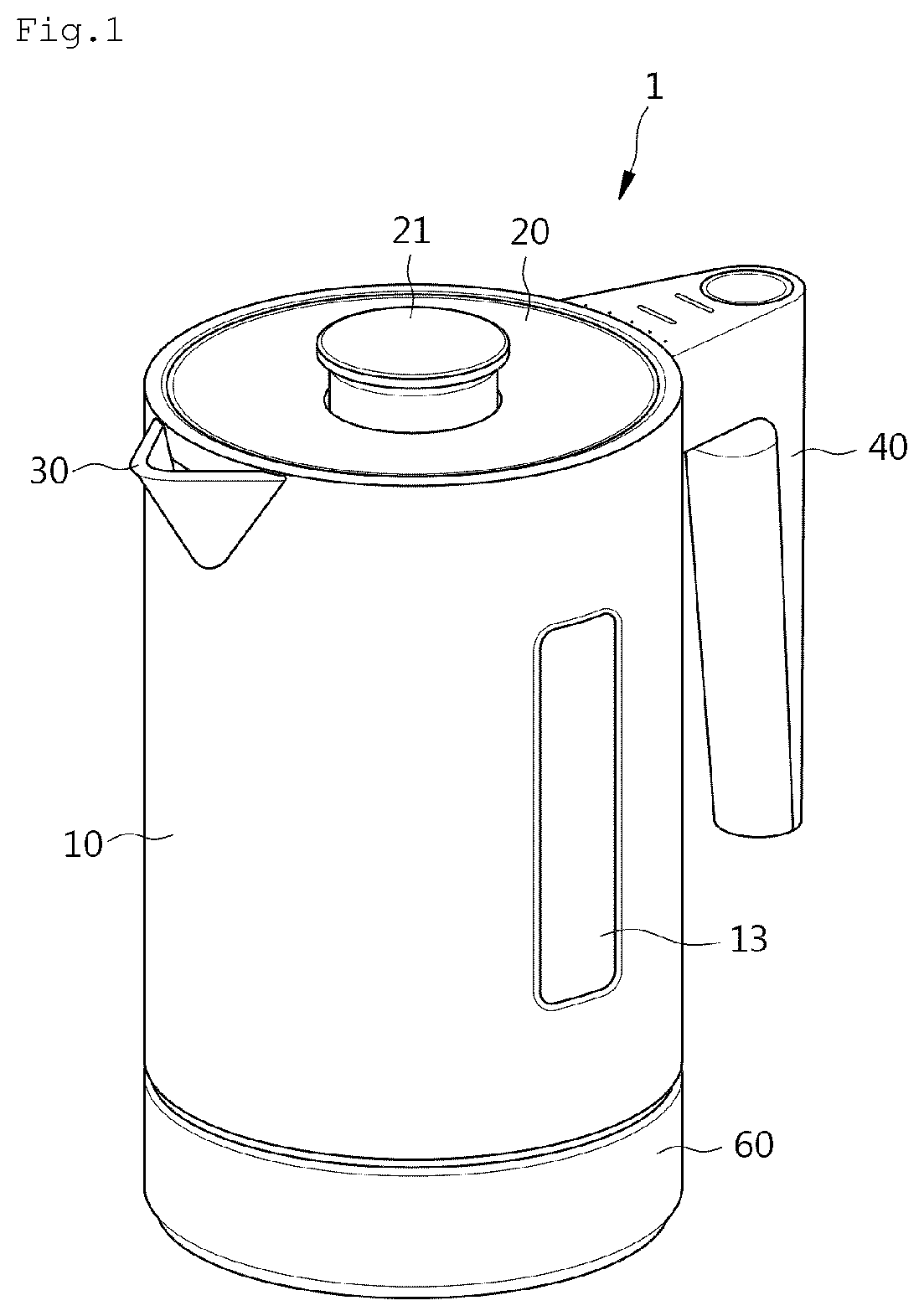

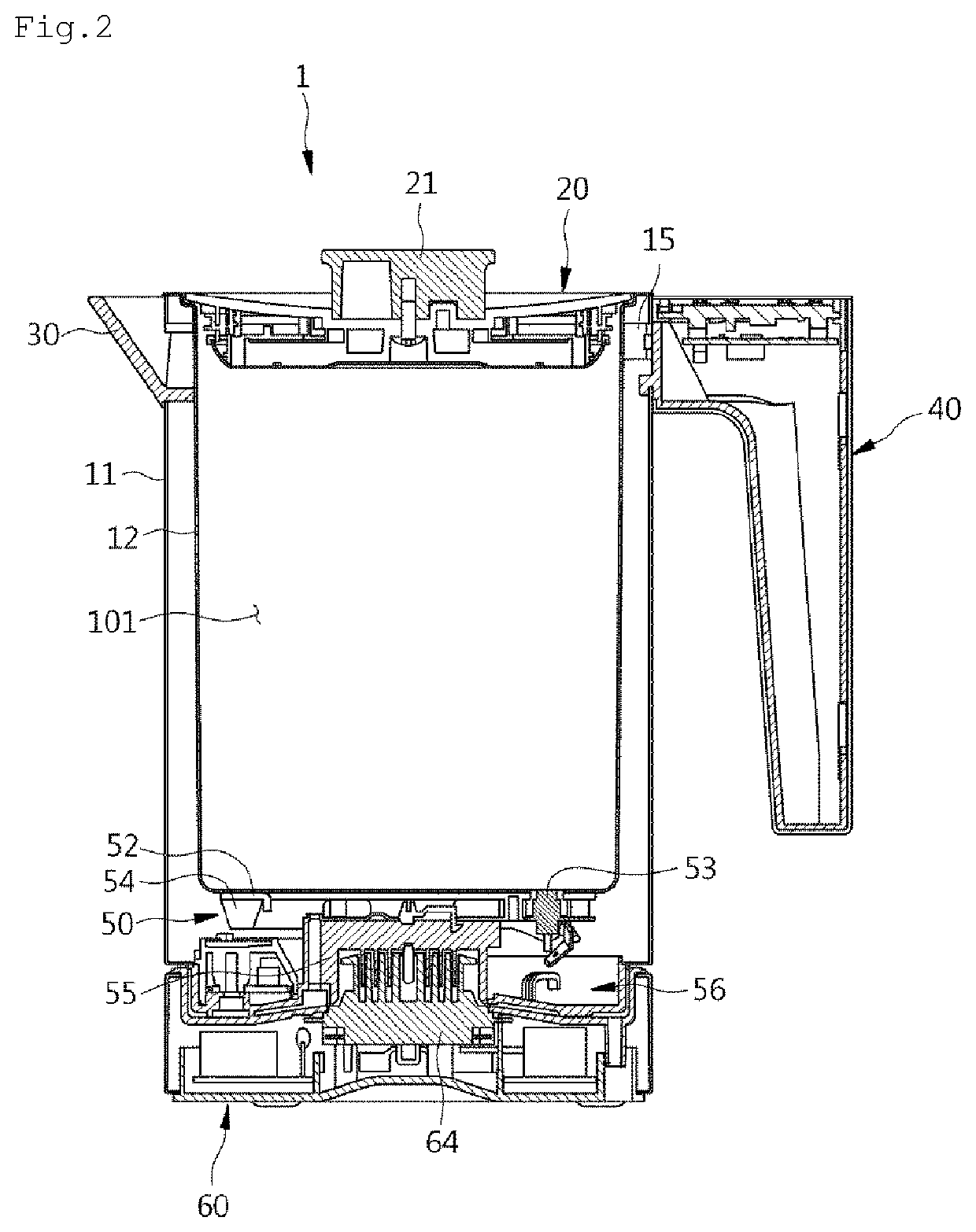

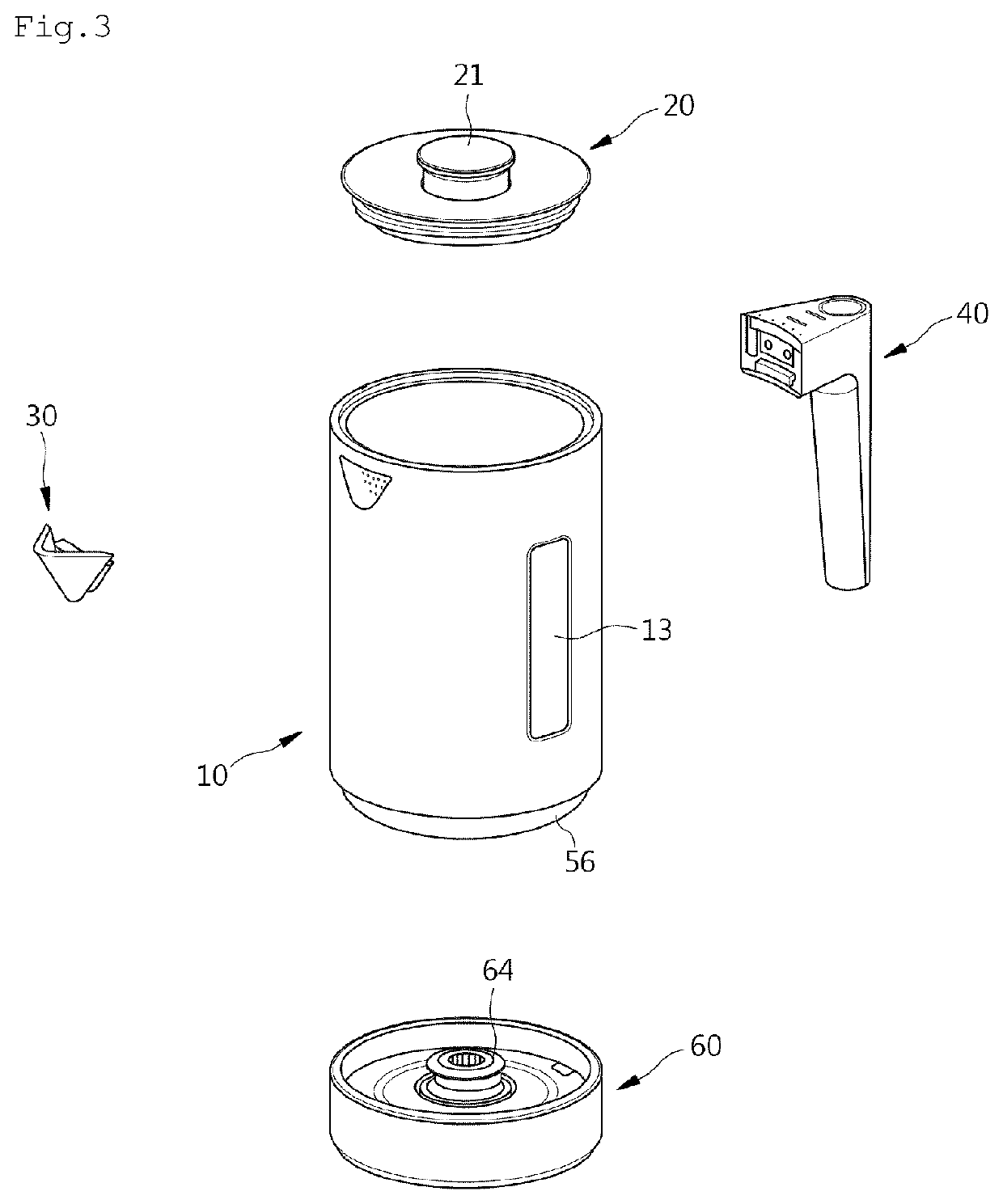

Electric kettle

PendingUS20220240709A1Reduce surface stressAvoid accumulationWater-boiling vesselsEngineeringMechanical engineering

Proposed is an electric kettle in which a main body is provided with a water level window. The electric kettle of the present disclosure includes the main body configured to receive water or food therein and provided with the water level window through which the level of water contained inside the main body is seen, a lid provided on an open upper side of the main body so as to cover the open upper side of the main body, and a base provided at a lower side of the main body so as to support the main body, wherein a flow path in which a fluid flows is formed in the water level window and has a bottom surface formed to be inclined. According to such a configuration, a fluid remaining inside the water level window decreases.

Owner:LG ELECTRONICS INC

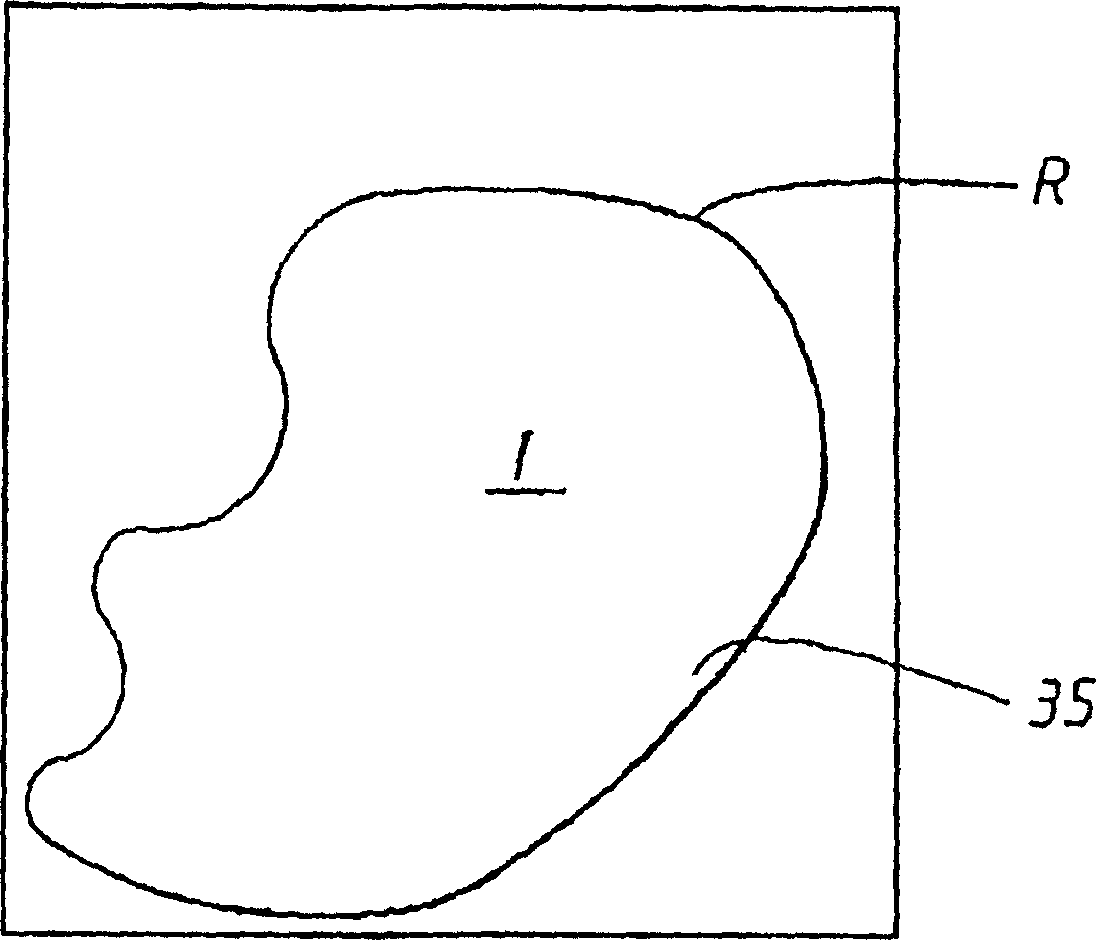

Rotor blade for a rotary machine

InactiveCN1648416AReduce surface stressReduced stress concentration factorEngine manufactureOther chemical processesLeading edgeTrailing edge

A rotor blade (14) having an airfoil (18) and beam construction for a tip shroud (30) is disclosed. Various construction details are developed for providing a transition zone (34) that extend from the sides (26,24) of the airfoil (18) to limit stesses at shroud-airfoil interface, at the disk-root interface and to extend the creep life of the blade while providing a flow path surface of the shroud (30).

Owner:UNITED TECH CORP

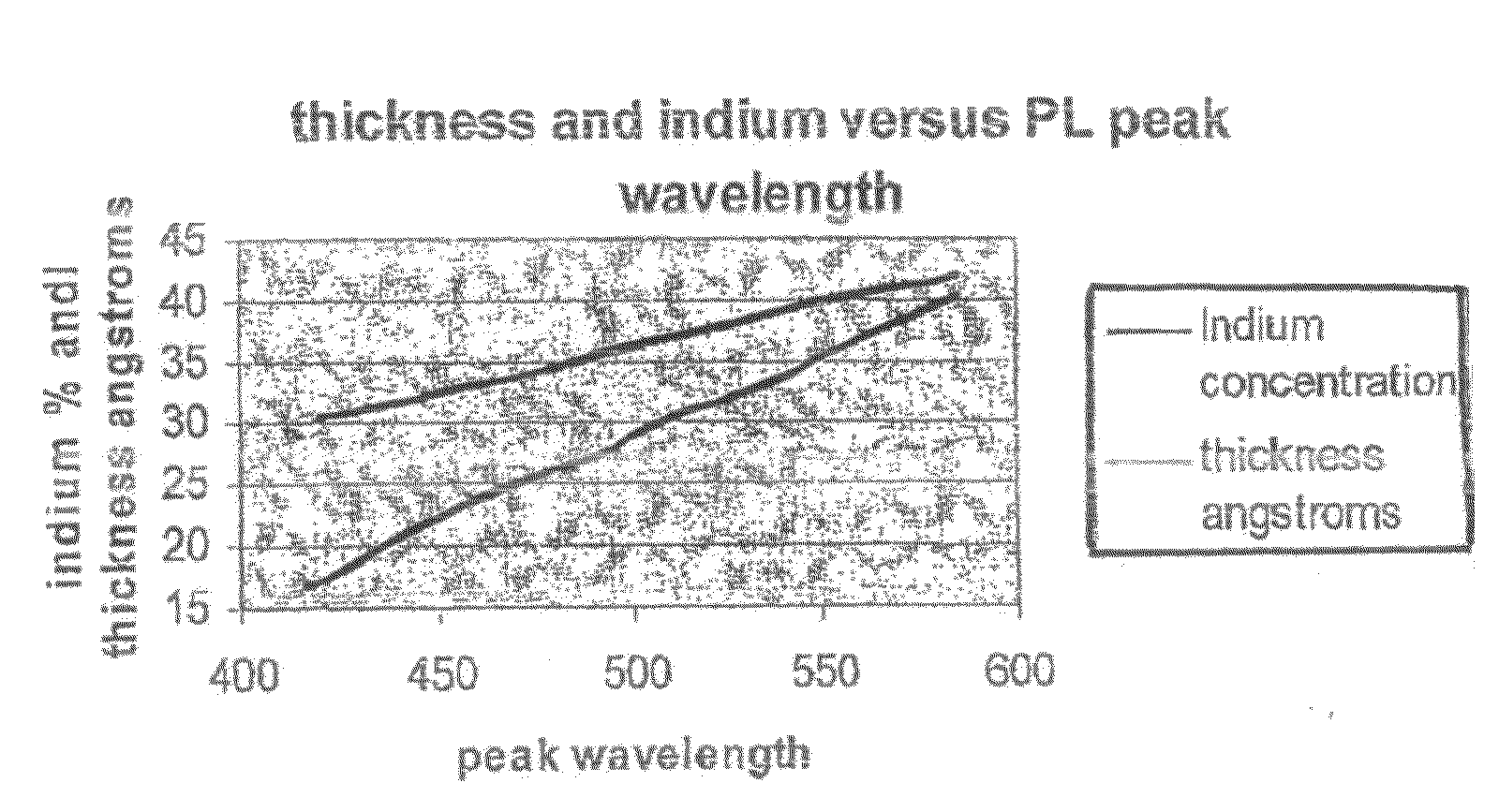

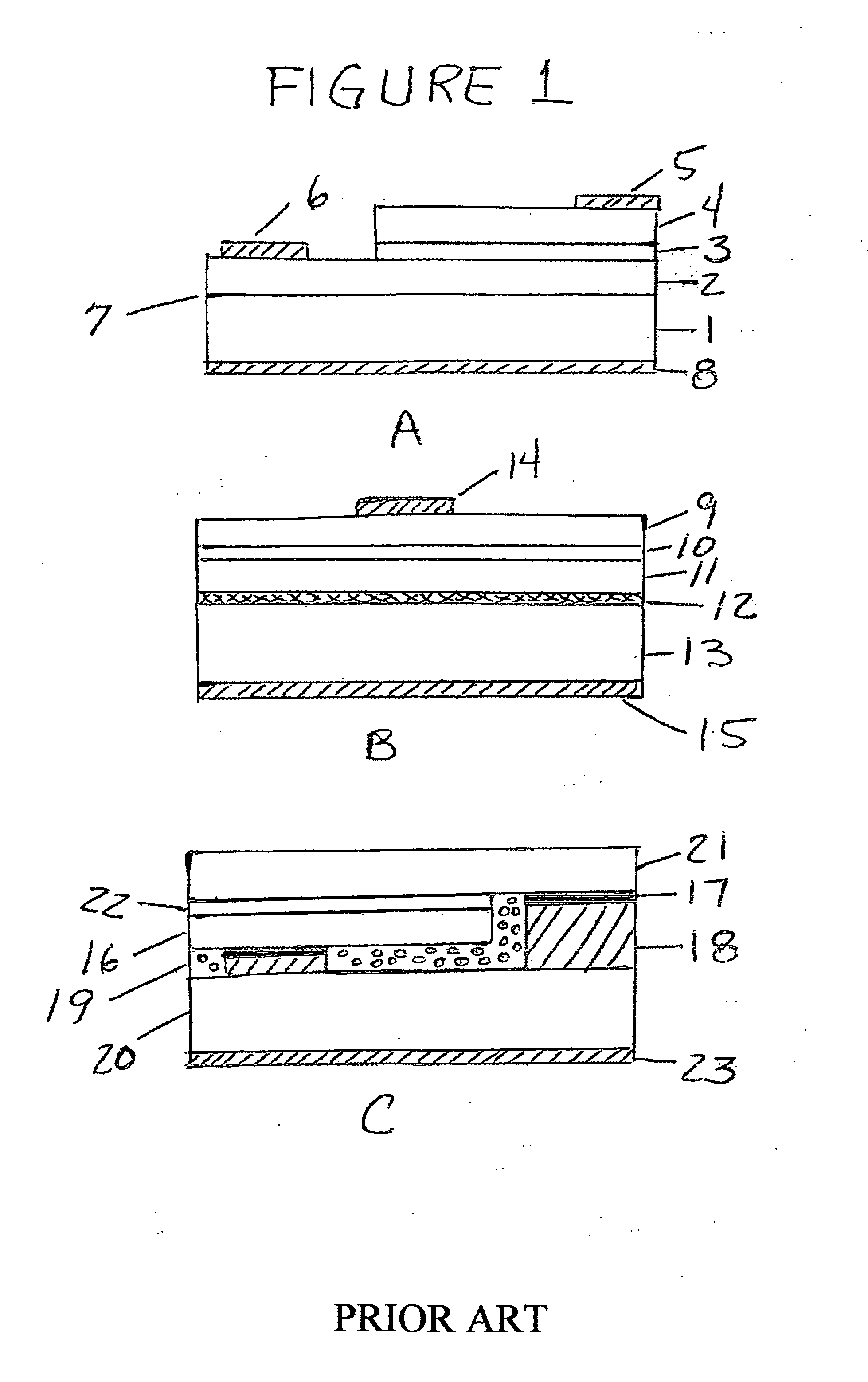

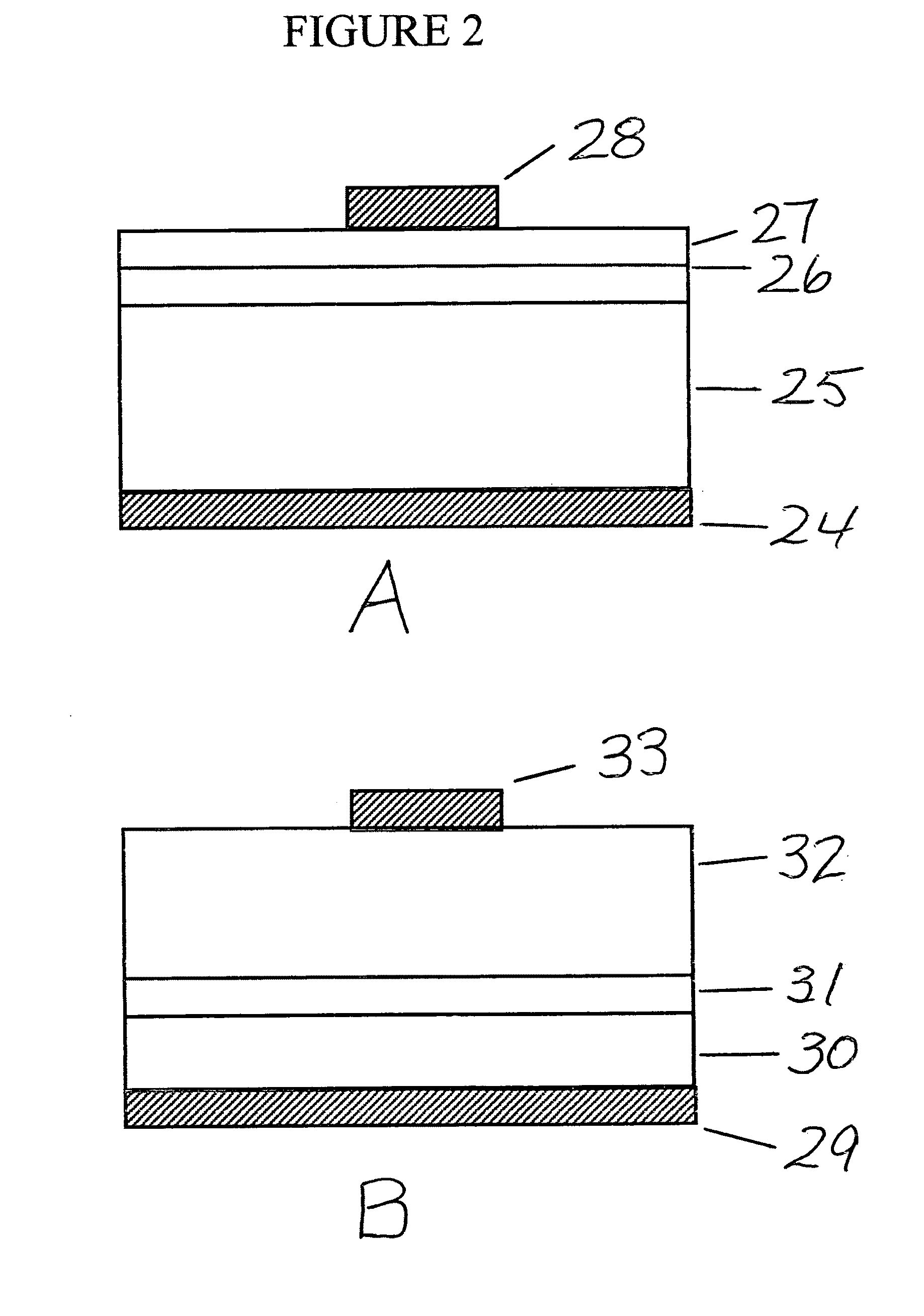

Methods for and devices made using multiple stage growths

InactiveUS20110024775A1Increasing concentration of aluminumImprove crystal qualitySemiconductor/solid-state device detailsSolid-state devicesSemiconductor structureDevice form

Surface modification of individual nitride semiconductor layers occurs between growth stages to enhance the performance of the resulting multiple layer semiconductor structure device formed from multiple growth stages. Surface modifications may include, but are not limited, to laser patterning, lithographic patterning (with the scale ranging from 10 microns to a few angstroms), actinic radiation modifications, implantation, diffusional doping and combinations of these methods. The semiconductor structure device has enhanced crystal quality, reduced phonon reflections, improved light extraction, and an increased emission area. The ability to create these modifications is enabled by the thickness of the HVPE growth of the GaN semiconductor layer.

Owner:GOLDENEYE

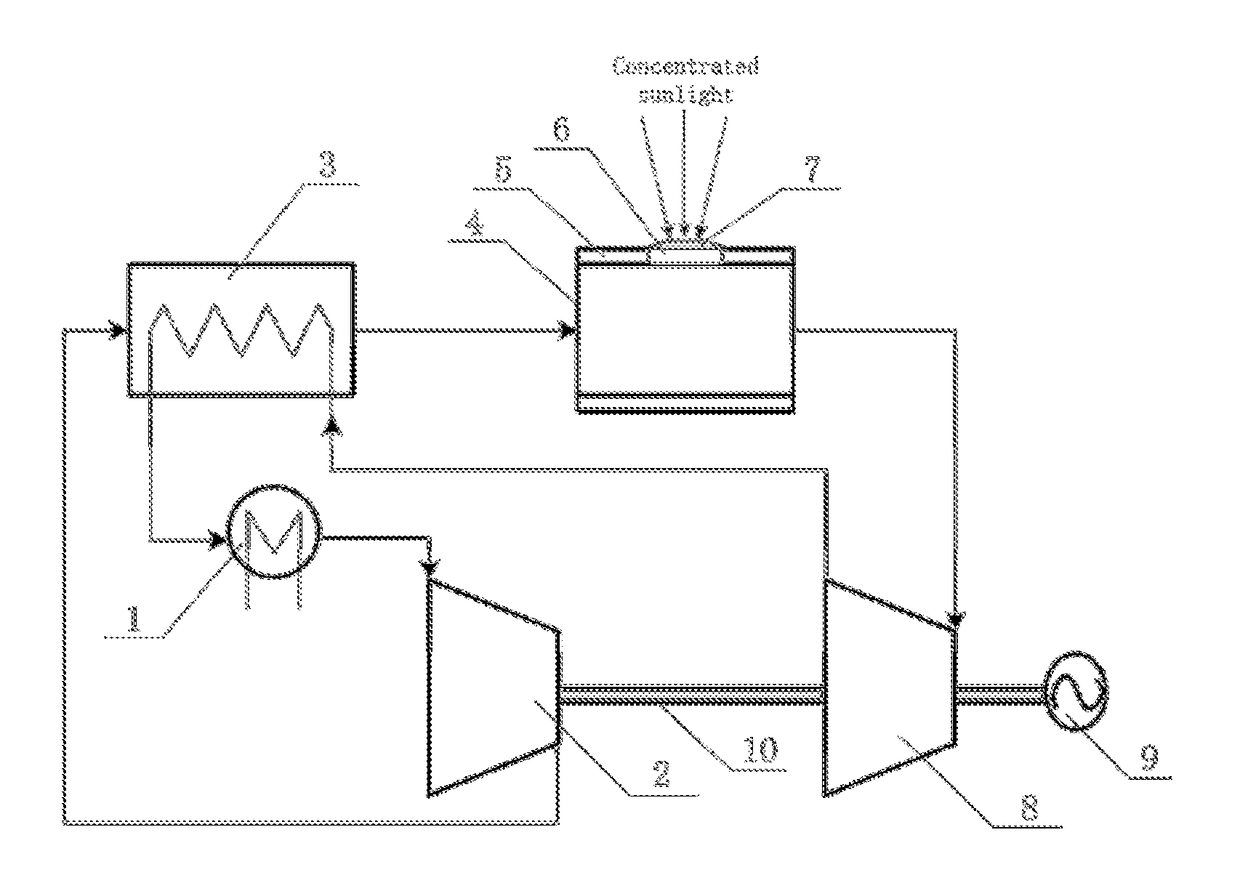

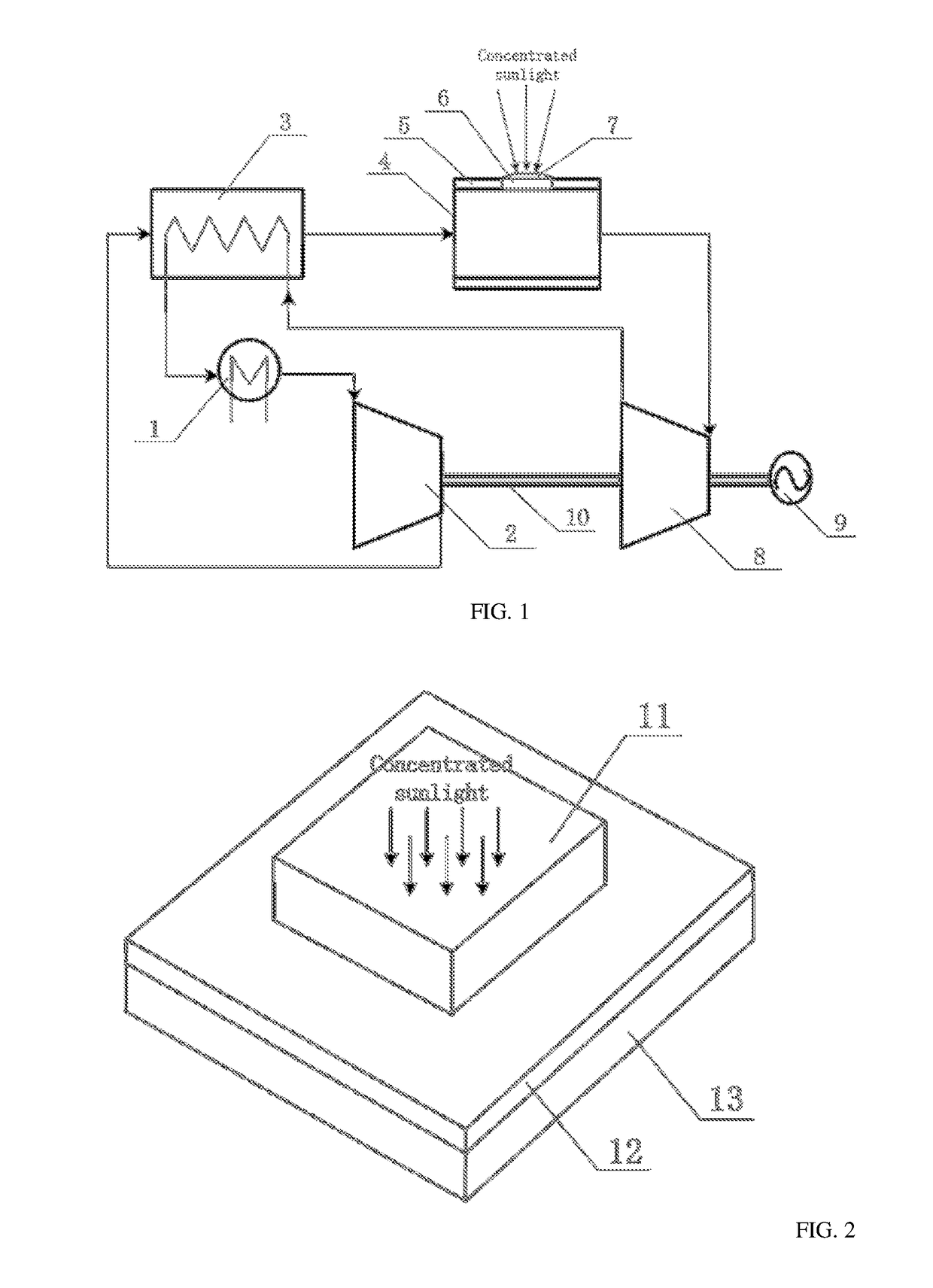

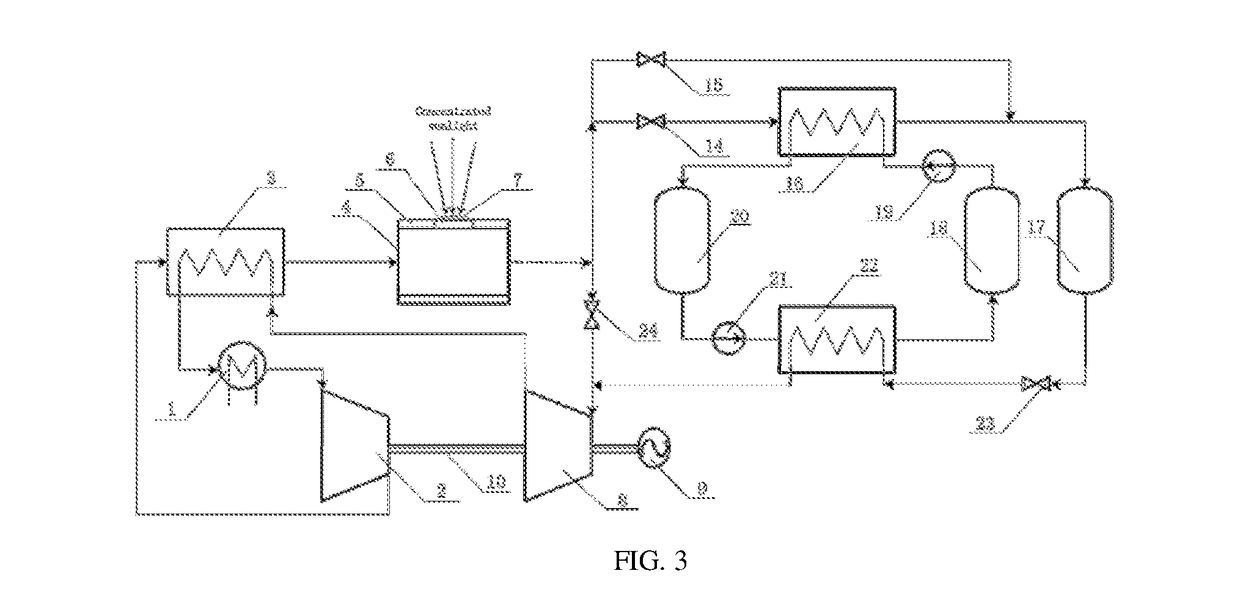

Method and apparatus for solar power generation through gas volumetric heat absorption based on characteristic absorption spectrum

ActiveUS20180038353A1Efficient use ofAmount of heat absorption can be changedSolar heating energyFrom solar energyThermal energyPower cycle

The present application discloses a method and an apparatus for solar power generation through gas volumetric heat absorption based on characteristic absorption spectrum. A radiation energy conversion device absorbs concentrated solar radiation and converts radiation energy into thermal energy; the thermal energy is transferred to the other side of the radiation energy conversion device and then is converted into radiation energy; and the energy is transferred in a receiver cavity. The working gas from the outlet of a recuperator flows into the receiver cavity and absorbs the radiation energy. The heated working gas with high temperature flows into a turbine, doing shaft work through expansion. The expanded working gas flows through the recuperator to exchange heat. The working gas flows into a cooler, a compressor and the recuperator in sequence, and then flows into a receiver cavity to be heated volumetrically, completing a thermal power cycle.

Owner:ZHEJIANG UNIV

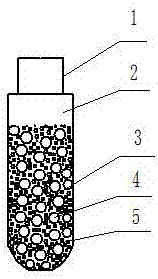

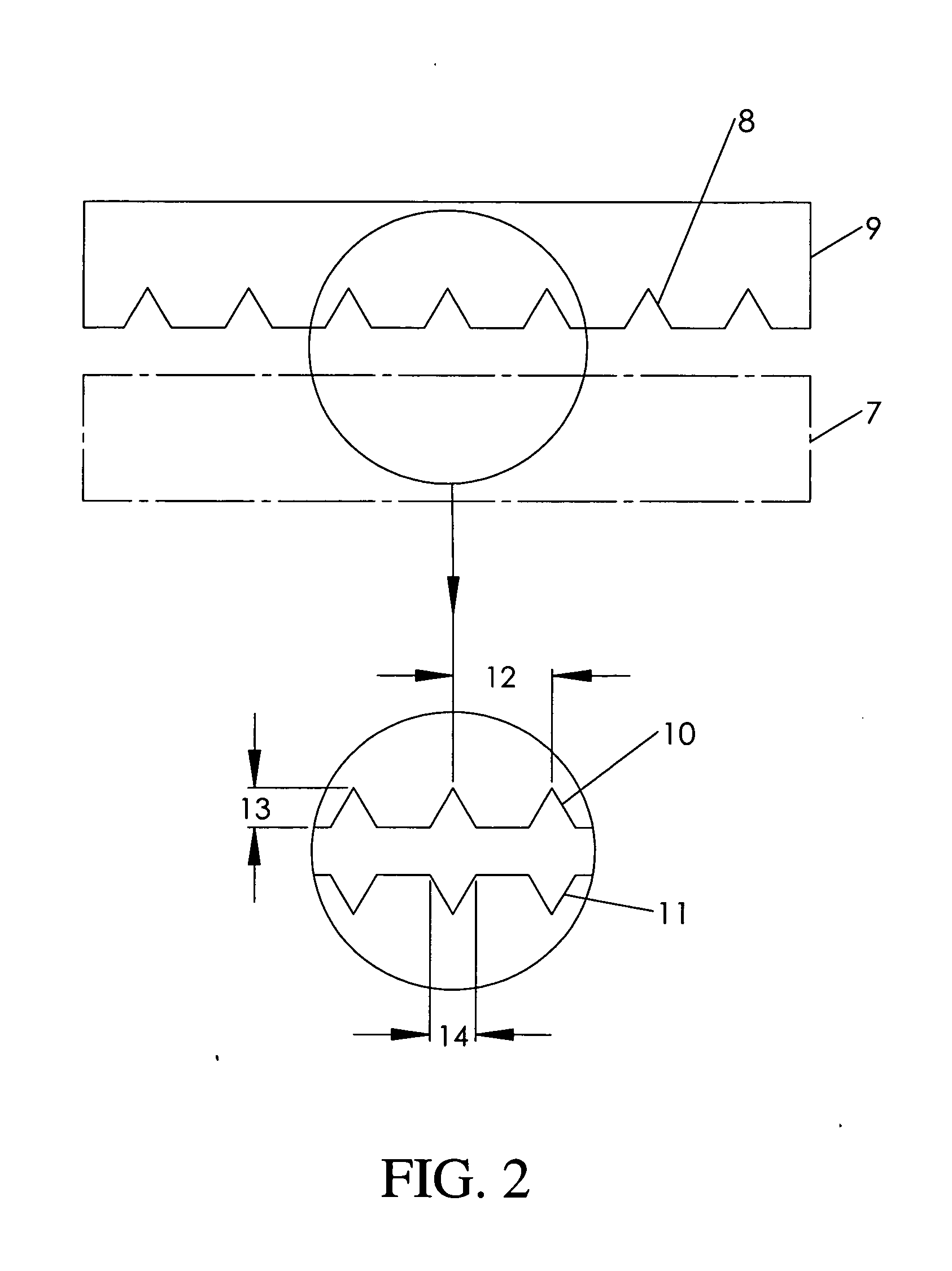

Preparing method of ultrathin amorphous alloy strip

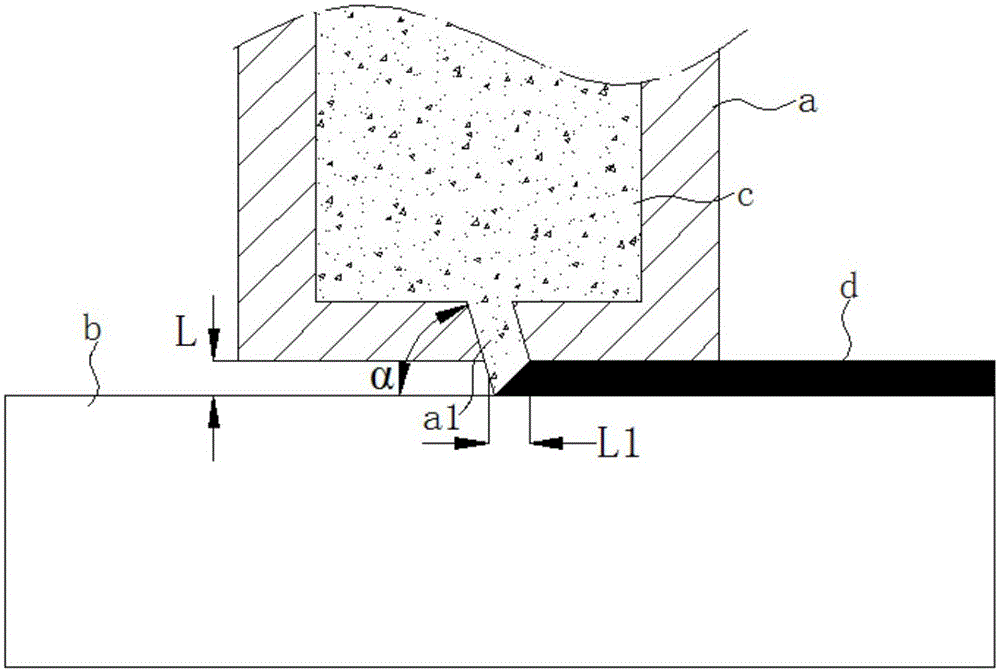

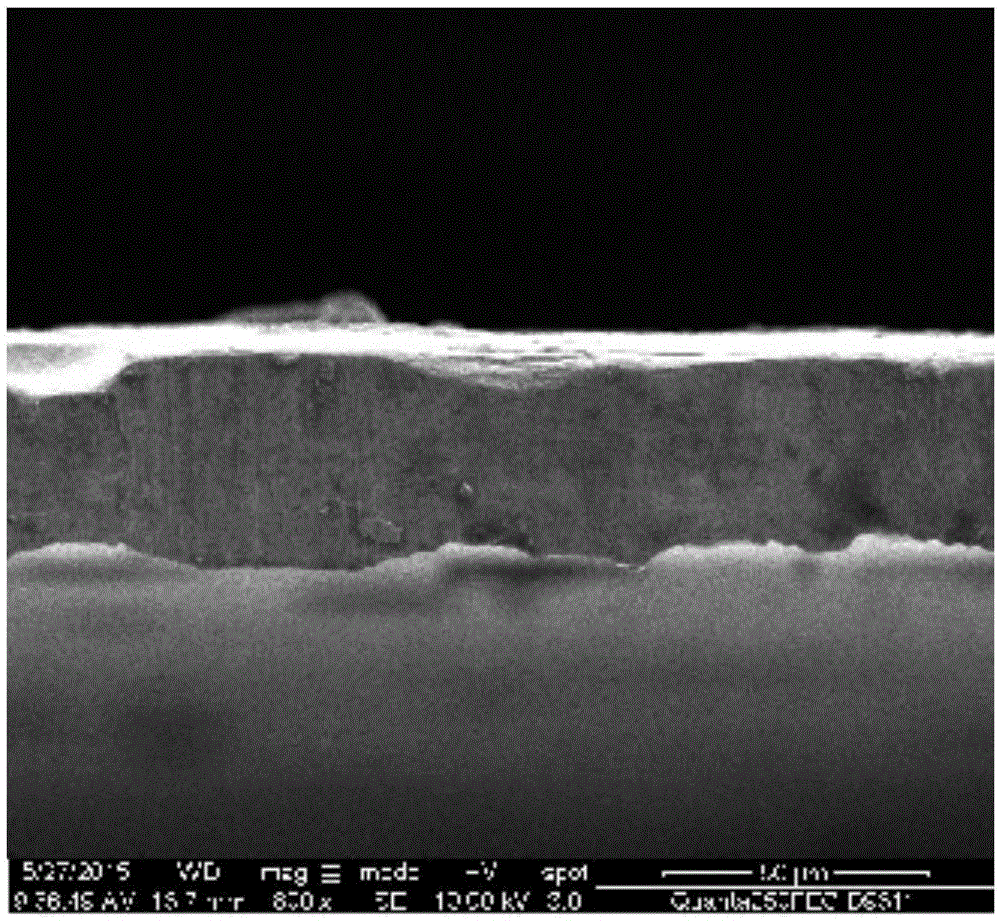

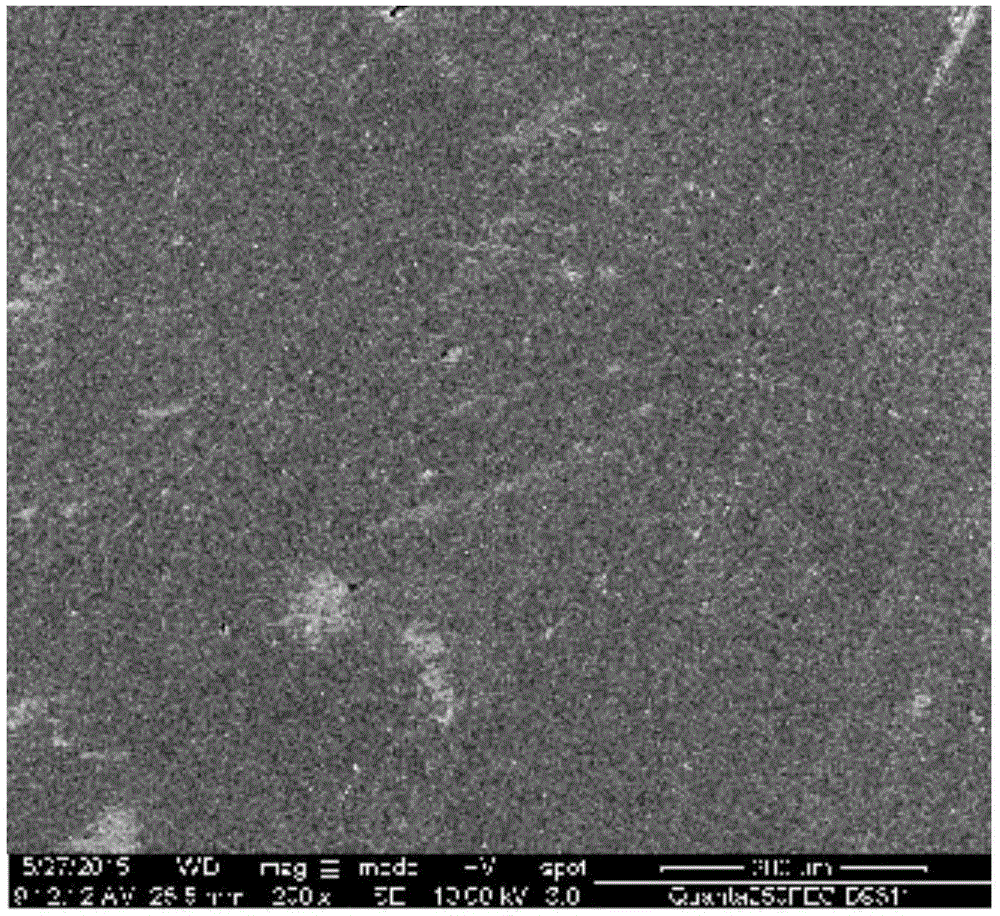

The invention relates to a preparing method of an ultrathin amorphous alloy strip. Molten steel obliquely sprays the surface of a cooling body, and the spraying direction of the molten steel is opposite to the rotating direction of the cooling body. Meanwhile, the distance between the lower end face of a nozzle and the cooling body is reduced, and therefore the scraping pressing and correcting functions on molten steel laminar flow from the lower end face of the nozzle are improved, and the prepared amorphous alloy strip is thin and even. Meanwhile, the smoothness and density of the free surface of the amorphous alloy strip are improved. The acute angle formed between a nozzle runner and the surface of the cooling body is set in the range of 15-85 degrees, the transverse disturbance of the amorphous alloy strip to the laminar flow molten liquid is small in cooperation with the scraping pressing and correcting functions of the lower end face of the nozzle, and therefore the surface stress of the strip is reduced, and the transverse radian of the strip is reduced; and the quality and the finished product performance of the amorphous alloy strip are improved.

Owner:CHINA WEAPON SCI ACADEMY NINGBO BRANCH

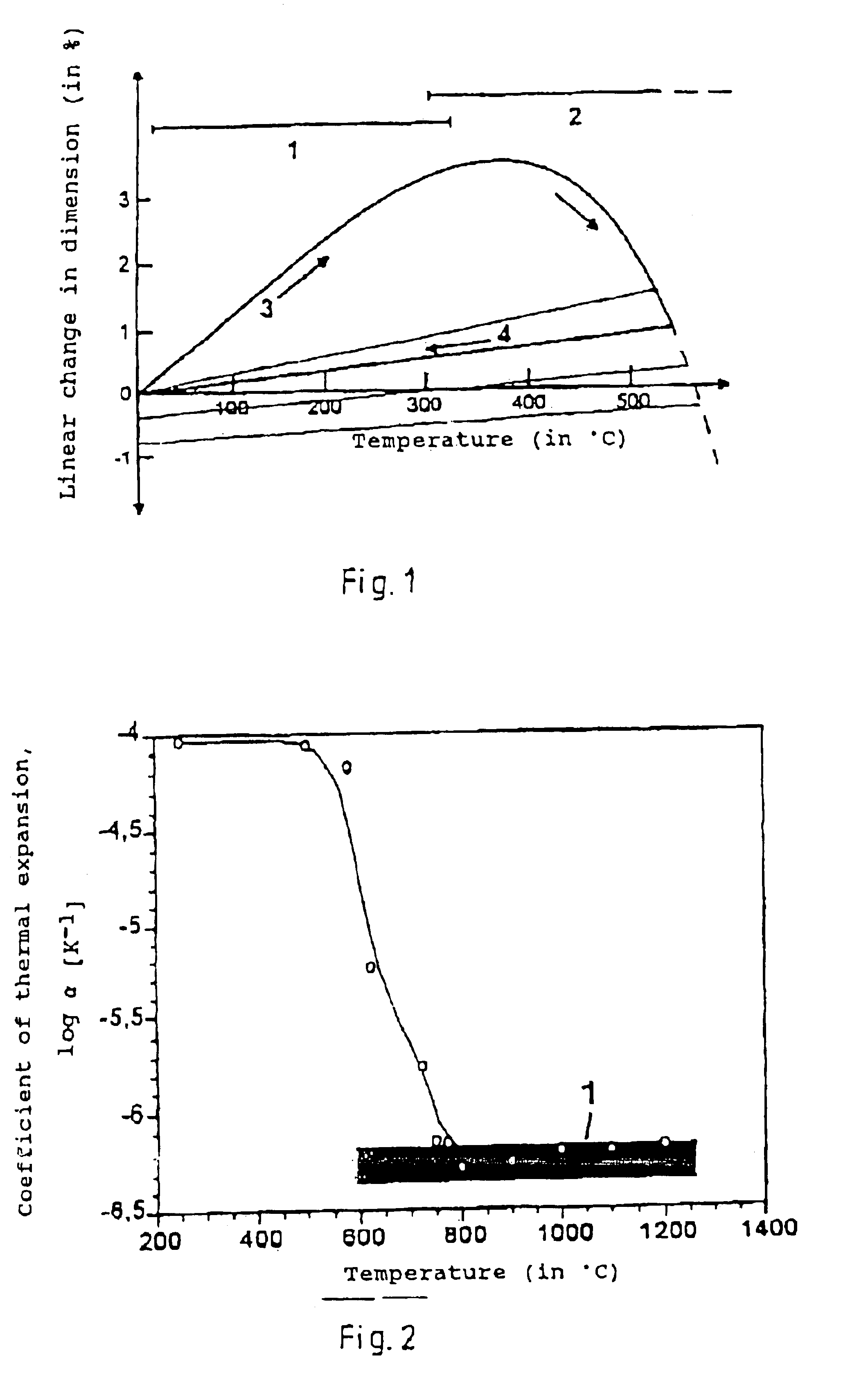

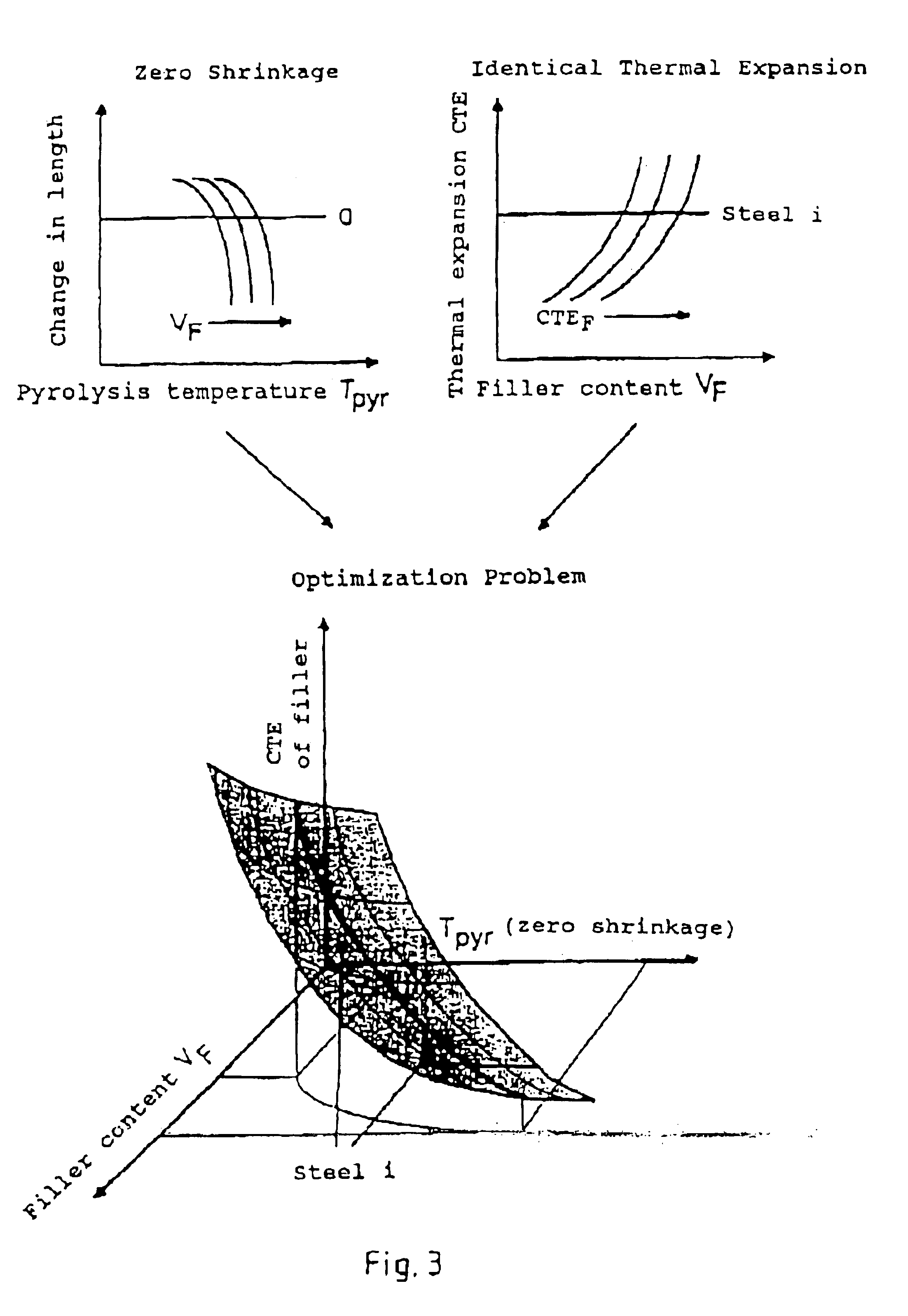

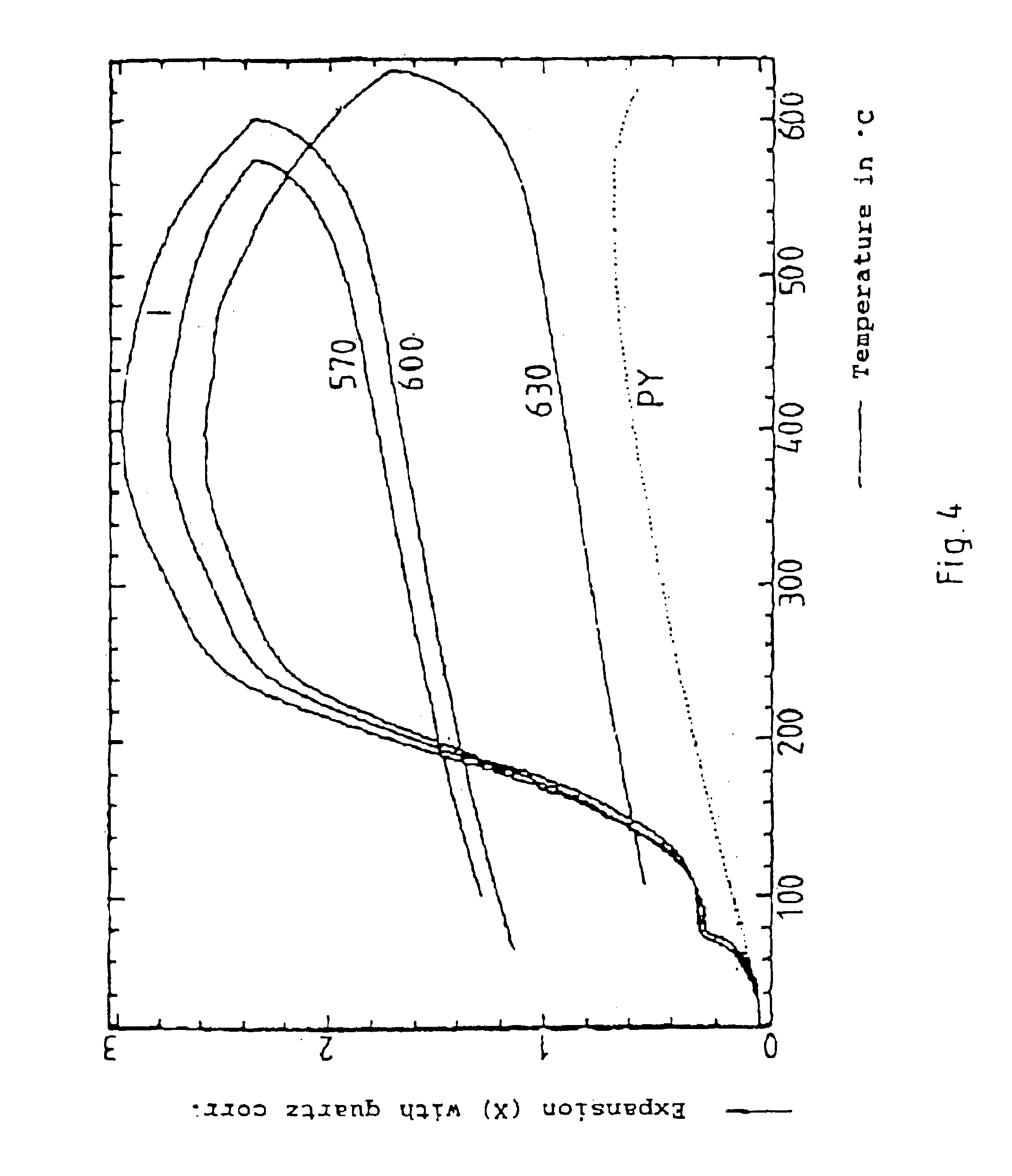

Polymerceramic materials with thermal expansion characteristics similar to those of metals

InactiveUS6783866B1Zero shrinkageLow costPretreated surfacesRecord information storageComposite constructionCeramic composite

The invention relates to polymer ceramic composite materials with a virtually zero shrinkage compared to the original model after concluding partial pyrolysis and with a comparable thermal expansion behavior (preferably in an application range of 400° C. or less) to metal construction materials, in particular gray cast iron or steel, which are obtainable by methods described below; corresponding composite constructions and molded parts; and methods for producing and using these materials, composite constructions and molded parts. The polymer ceramic composite materials can for instance be used instead of or in contact with steel or gray cast iron temperature-proof molded parts, predominantly in mechanical engineering, without postmachining after the creative forming.

Owner:RAUSCHERT

Vacuum drying method for phoebe zhennan board

InactiveCN107036394AIncrease temperatureUniform temperatureDrying solid materials without heatDrying gas arrangementsWater vaporPulp and paper industry

The invention discloses a vacuum drying method for a phoebe zhennan board. The vacuum drying method comprises the steps of preheating, steam heating, vacuumization, humidification treatment and the like. The preheating time is proportional to the board thickness. In the step of steam heating, the steam temperature is 50-70 DEG C, and a psychrograph is introduced into the process to monitor the humidity in a drying device. The vacuum degree of the drying device is kept at 0.008-0.012 MPa during vacuumization. When humidification treatment is conducted, the vapor temperature is 55-60 DEG C, the temperature difference of the psychrograph is controlled to be 5-6 DEG C, and the treatment time is 10-20 h. By adoption of the drying steps, the phoebe zhennan board cannot crack, color changes are small, the drying time is short, and the drying quality is high.

Owner:SICHUAN AGRI UNIV

Lithium tantalate micro-patterning method based on reactive ion etching

PendingCN111627811AImprove adhesionIncreasing the thicknessSemiconductor/solid-state device manufacturingReactive-ion etchingPhotoresist

The invention discloses a lithium tantalate micro-patterning method based on reactive ion etching, belongs to the technical field of semiconductors, and particularly relates to lithium tantalate crystal micro-patterning, so as to solve the problem that patterns are easy to damage due to large stress among materials of each layer, and the method comprises the following steps: sequentially plating aTi metal mask and a Cr metal mask on the surface of photoresist; preparing a metal mask pattern on the surface of the lithium tantalate substrate by using a stripping method; carrying out reactive ion etching on the lithium tantalate substrate with the prepared metal mask pattern by adopting fluorine-based plasma; carrying out physical bombardment on the lithium tantalate substrate for 30 secondsto 2 minutes by adopting argon plasma so as to remove high-boiling-point non-volatile substances such as lithium fluoride and fluotantalate formed on the surface of the sample; and repeating the etching step until the micro-patterning of the lithium tantalate substrate is completed. According to the method, the micron-scale depth pattern is manufactured on the lithium tantalate substrate, the purposes that the inclination angle of the side wall of the pattern is large and the surface of the groove is smooth are achieved, a high selection ratio of a metal mask is obtained, and the etching depth is large.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

GCr15 bearing ring heat treatment process

InactiveCN108165722AReduced risk of heat treatment crackingSmall amount of deformationFurnace typesHeat treatment furnacesTemperature controlHeating time

The invention relates to a GCr15 bearing ring heat treatment process. The GCr15 bearing ring heat treatment process comprises the following steps that a bearing ring is put into a mesh belt furnace tobe heated and quenched, the quenching and heating temperature is 840-855 DEG C, and the heating time is selected within 35-55 min according to the size and wall thickness of the ring; then the bearing ring falls into a salt bath quenching solution with the temperature controlled at 220-240 DEG C, and after the bearing ring stays in the salt bath for 5-10 min, the bearing ring is rapidly fetched out; the fetched bearing ring is put in air to be cooled, and after a sample is cooled to the room temperature, the sample is put at the dry and ventilated position for 24-36 hours; then the bearing ring is put into a tempering furnace at 80-100 DEG C and subjected to heat insulation for 2-2.5 hours; and the bearing ring is washed, and then the tempering and heat insulation are conducted for 1.5-2hours at the temperature of 150-180 DEG C. Under the process, the bearing ring can obviously reduce quenching stress and deformation, and a stable austenite structure with the higher content is formed.

Owner:C&U CO LTD +2

Tooth implant

ActiveCN107280789AEasy to fixLow elastic modulusDental implantsTissue regenerationBone tissueNeck parts

The invention provides an artificial tooth implant. The artificial tooth implant is composed of a body part, a neck part and an abutment, wherein the body part is a porous metal material; the porous metal material is a multi-grade-pore metal material; the multi-grade-pore metal material is composed of all grades of pore cavities which are graded according to the pore diameter size of the material and all grades of cavity walls for forming the pore cavities through surrounding; all grades of the pore cavities are mutually communicated respectively and all grades of the pore cavities are also mutually communicated respectively; the number of grades is two at least. Compared with the fusion time of a traditional artificial tooth implant with a body part which is a porous metal material with single pores, the fusion time between the artificial tooth implant and an adjacent bone tissue is remarkably shortened; the artificial tooth implant is firmly fixed on a gum so that the problems that an interface is not stable and loose are overcome.

Owner:CHONGQING RUNZE PHARM CO LTD

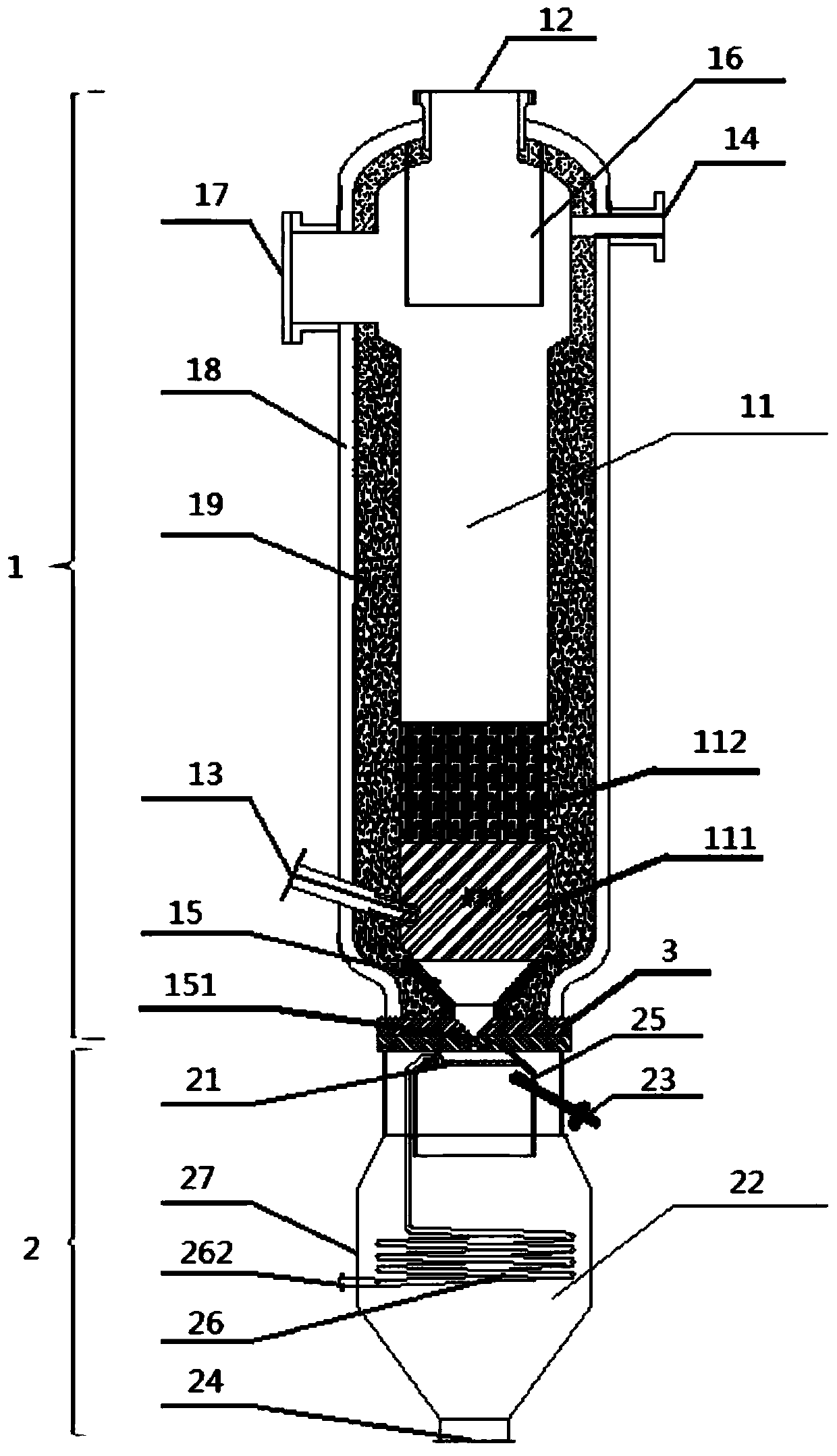

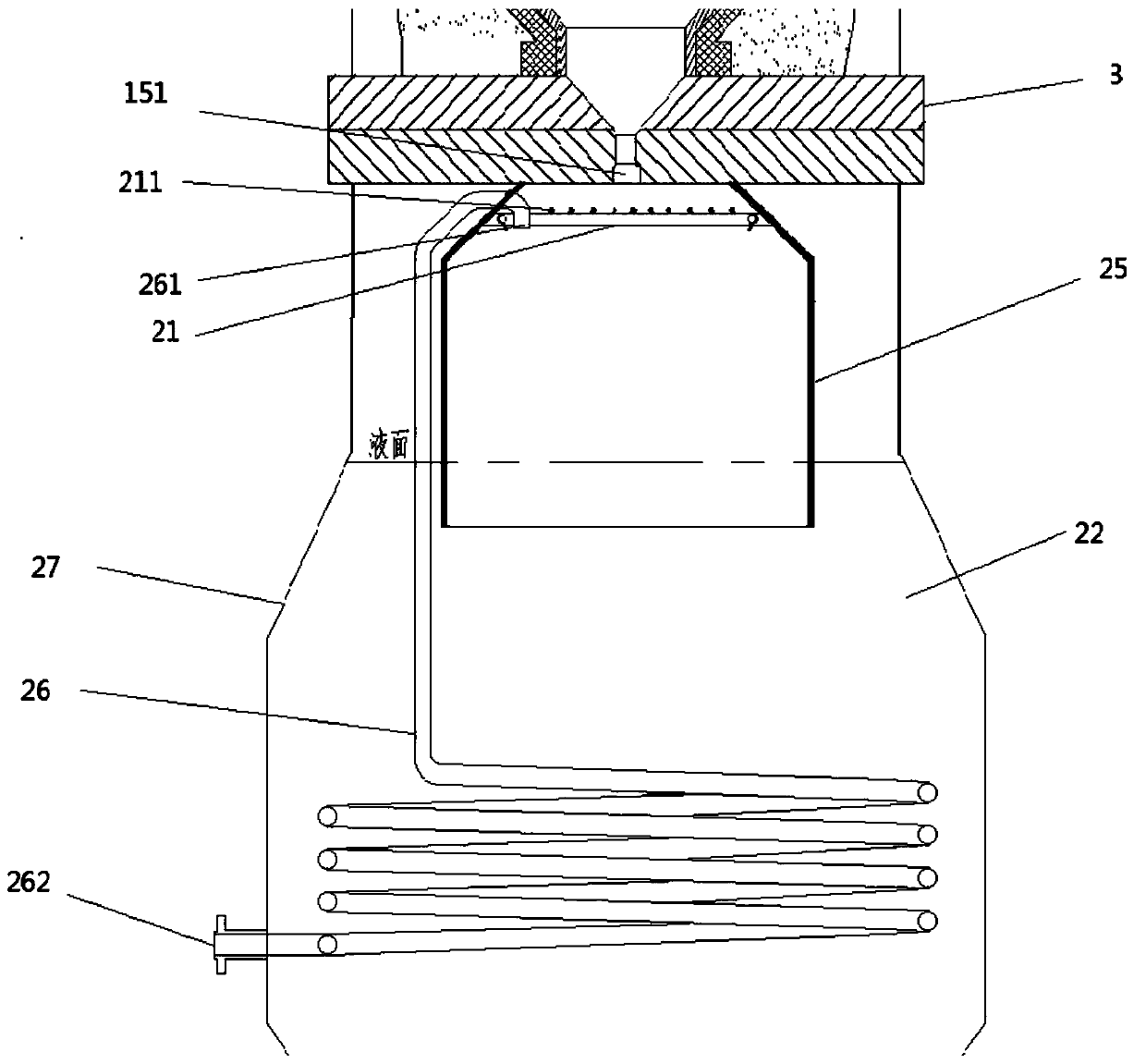

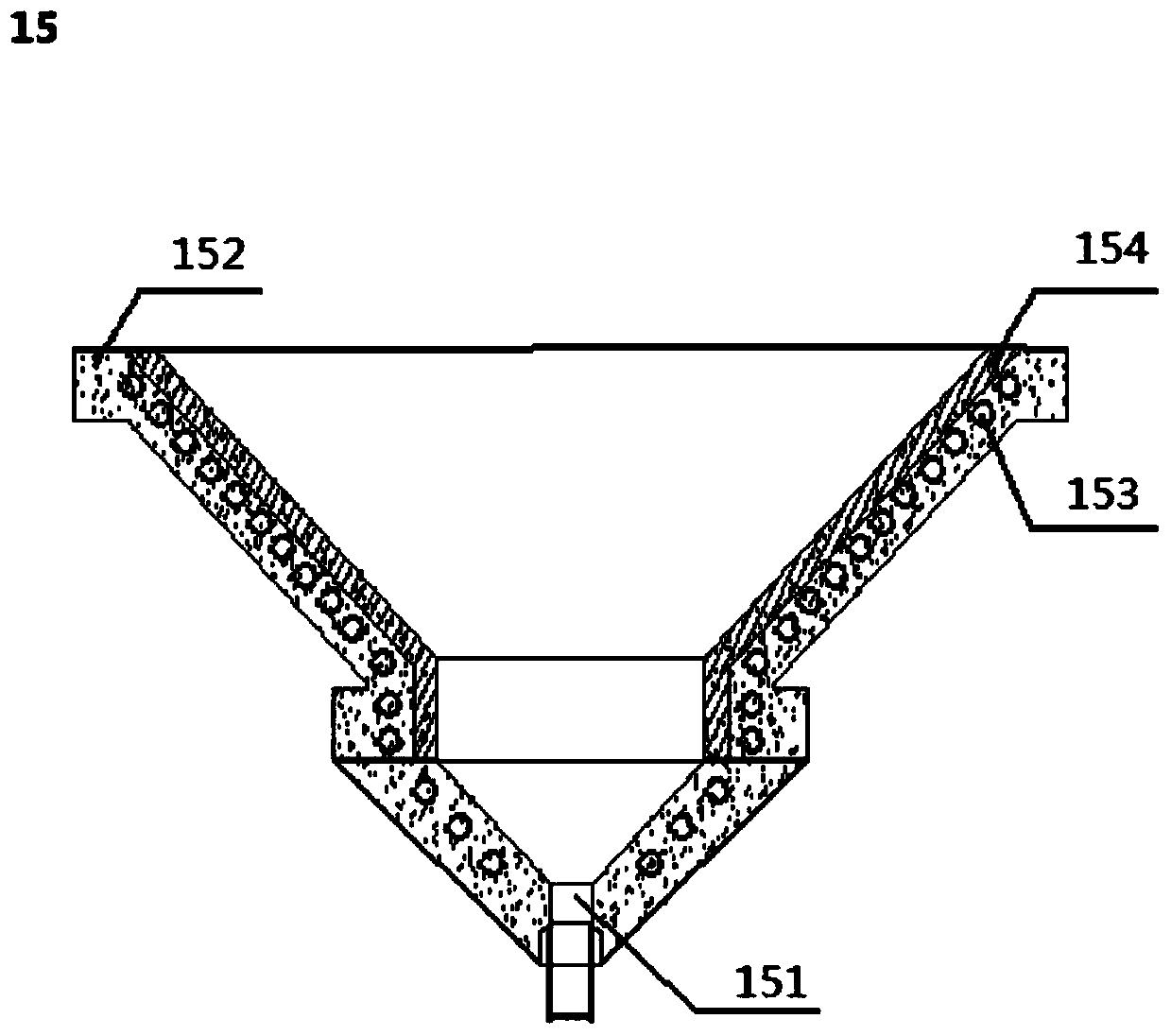

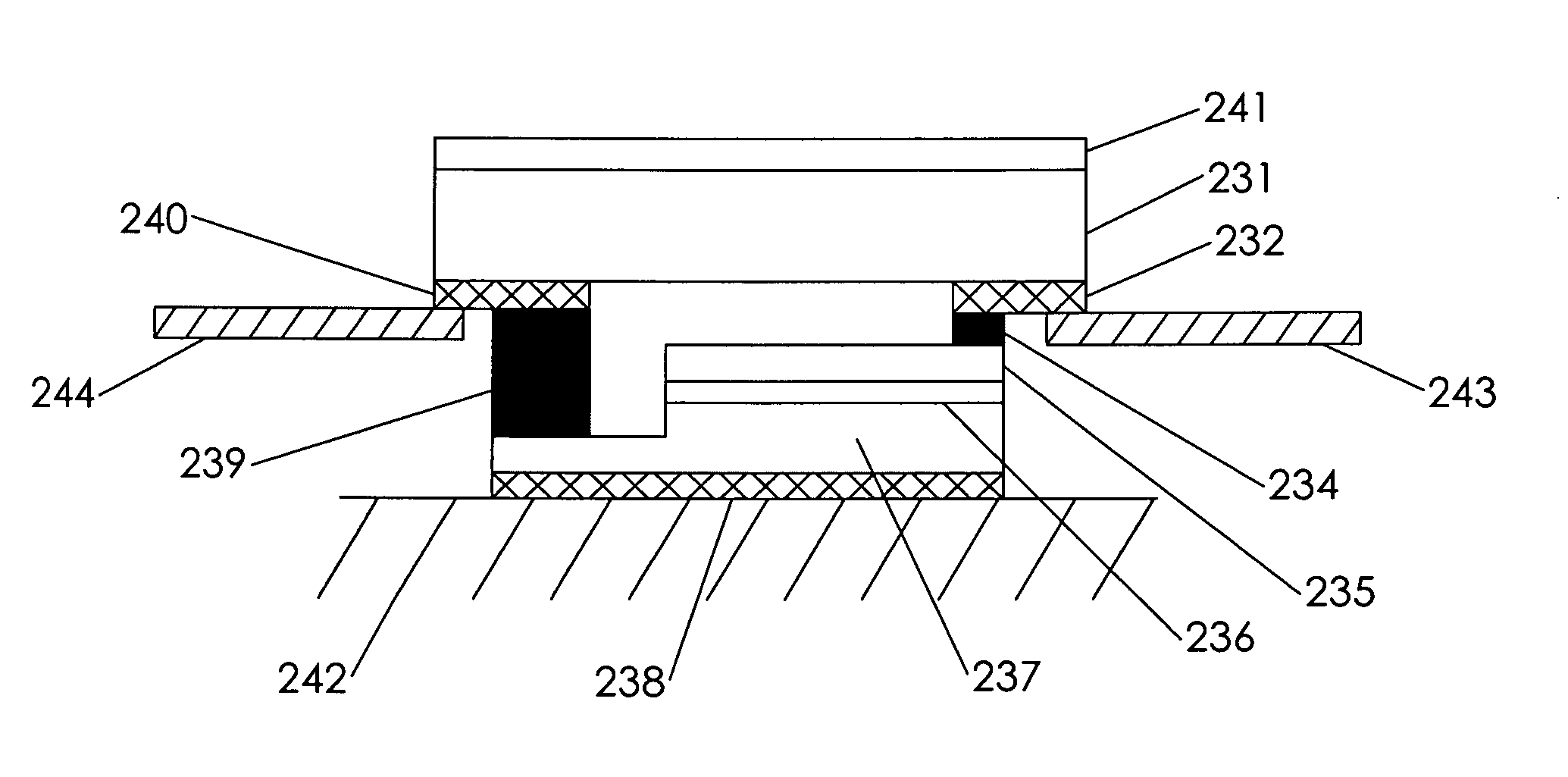

Gasification reduction device and method for co-production of yellow phosphorus and synthesis gas

PendingCN111394133AGuarantee continuous and stable operationConducive to environmental protection and green emissionsHydrogen separationChemical industrySlagProcess engineering

The invention provides a gasification reduction device for co-production of yellow phosphorus and synthesis gas. The gasification reduction device comprises a phosphocoal gasification reduction unit and a chilling unit. The phosphocoal gasification reduction unit is communicated with the chilling unit vertically, and the phosphocoal gasification reduction unit is used for realizing gasification reduction reaction of all materials in the phosphocoal gasification reduction unit to obtain phosphorus-containing furnace gas; and the chilling unit is used for cooling slag formed in the phosphocoal gasification reduction reaction process into a solid state and discharging the solid state. The invention also provides a method for implementing co-production of yellow phosphorus and synthesis gas byusing the gasification reduction device. The gasification reduction device is a technology which is high in energy utilization rate, optimized in process, energy-saving, environment-friendly and lower in cost.

Owner:贵州航天迈未科技有限公司

Flexible semiconductor devices based on flexible freestanding epitaxial elements

ActiveUS20140319533A1Increase radius of curvatureStress minimizationZinc oxides/hydroxidesNitrogen-metal/silicon/boron binary compoundsLithographic artistEngineering

Flexible semiconductor devices based on flexible freestanding epitaxial elements are disclosed. The flexible freestanding epitaxial elements provide a virgin as grown epitaxy ready surface for additional growth layers. These flexible semiconductor devices have reduced stress due to the ability to flex with a radius of curvature less than 100 meters. Low radius of curvature flexing enables higher quality epitaxial growth and enables 3D device structures. Uniformity of layer formation is maintained by direct absorption of actinic radiation by the flexible freestanding epitaxial element within a reactor. In addition, standard post processing steps like lithography are enabled by the ability of the devices and elements to be flattened using a secondary support element or vacuum. Finished flexible semiconductor devices can be flexed to a radius of curvature of less than 100 meters. Nitrides, Zinc Oxides, and their alloys are preferred materials for the flexible freestanding epitaxial elements.

Owner:GOLDENEYE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com