Method for finishing processing of controllable deforming electronic beam

A finishing and electron beam technology, applied in the field of controllable deformation electron beam finishing, can solve the problems of uneven energy distribution in the overlapping area of the beam spot, increase of the plane area of the vacuum chamber of the processing device, and stress concentration on the surface of the material, etc. The effect of uniform irradiation energy distribution, low surface stress and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below with reference to the drawings and specific embodiments.

[0020] The controllable deformation electron beam finishing processing method of the present invention is based on the electron beam processing method and is realized by controlling the deformation and deflection of the electron beam by a computer.

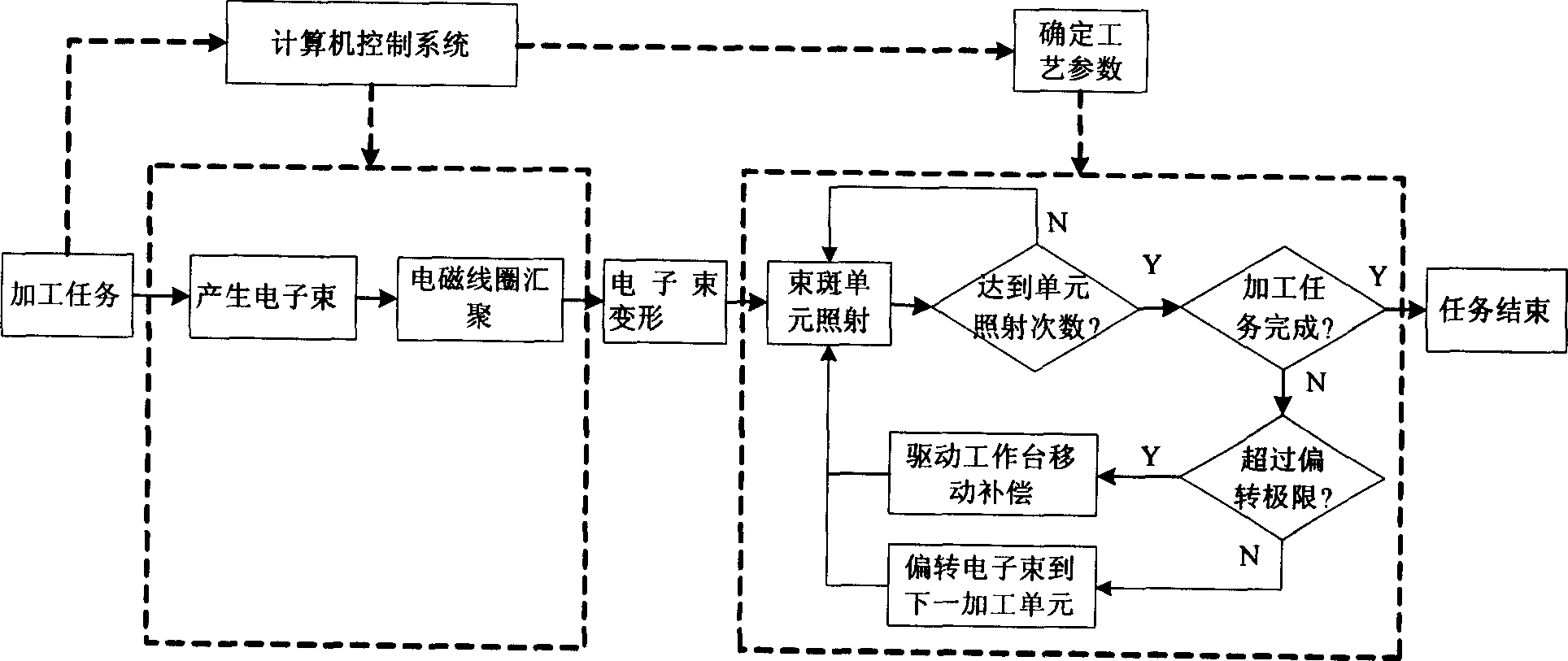

[0021] Such as figure 1 As shown, the method of the present invention inputs the processing task into the computer, and the computer control system controls the electron beam generator connected to it to generate electron beams, which are converged by the electromagnetic coil and deformed. The deformed beam spot unit is based on the number of irradiation and energy density of the processing task. Process parameters such as, irradiation position, etc.; at the same time, command the controllable workbench to move for compensation; finally end the task. In the figure, the solid line represents the process, and the dotte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com