Laser marking device and method thereof

A printing device and laser technology, applied in laser welding equipment, electrical components, welding/welding/cutting items, etc., can solve the problems of unrecorded status, incapable of real-time inspection and post-inspection, increase of wafer yield change, etc., to achieve damage reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

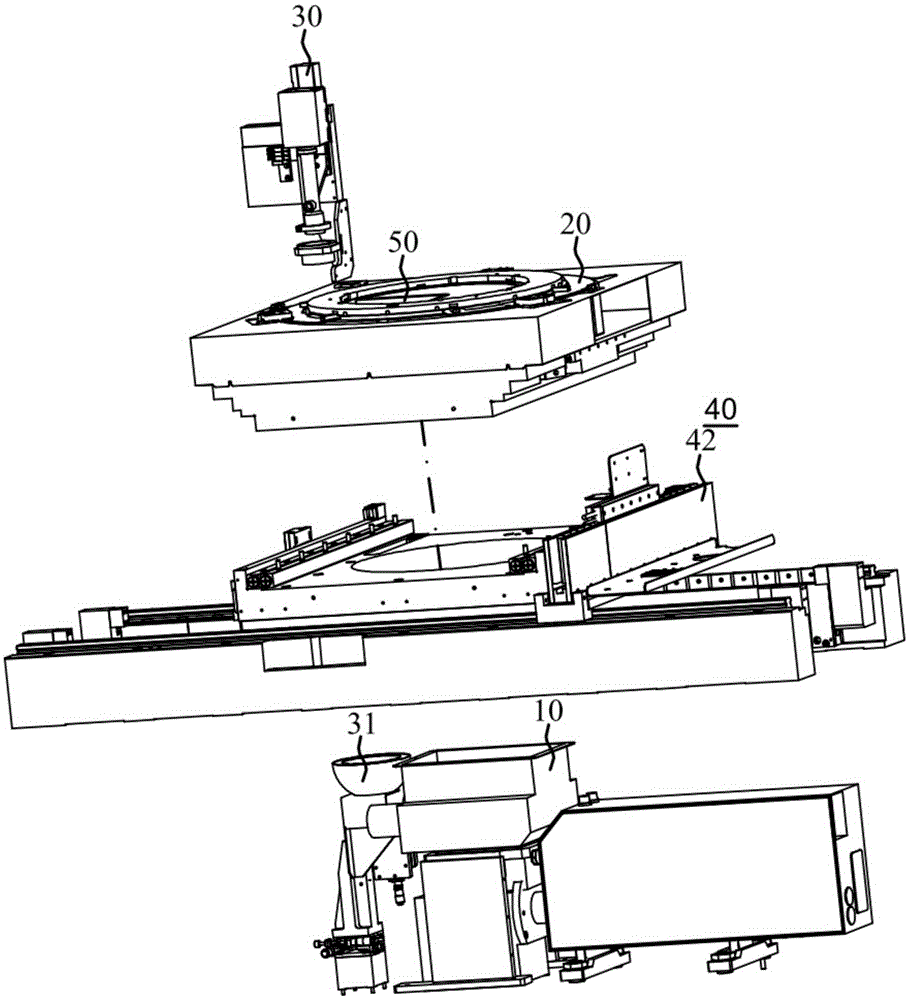

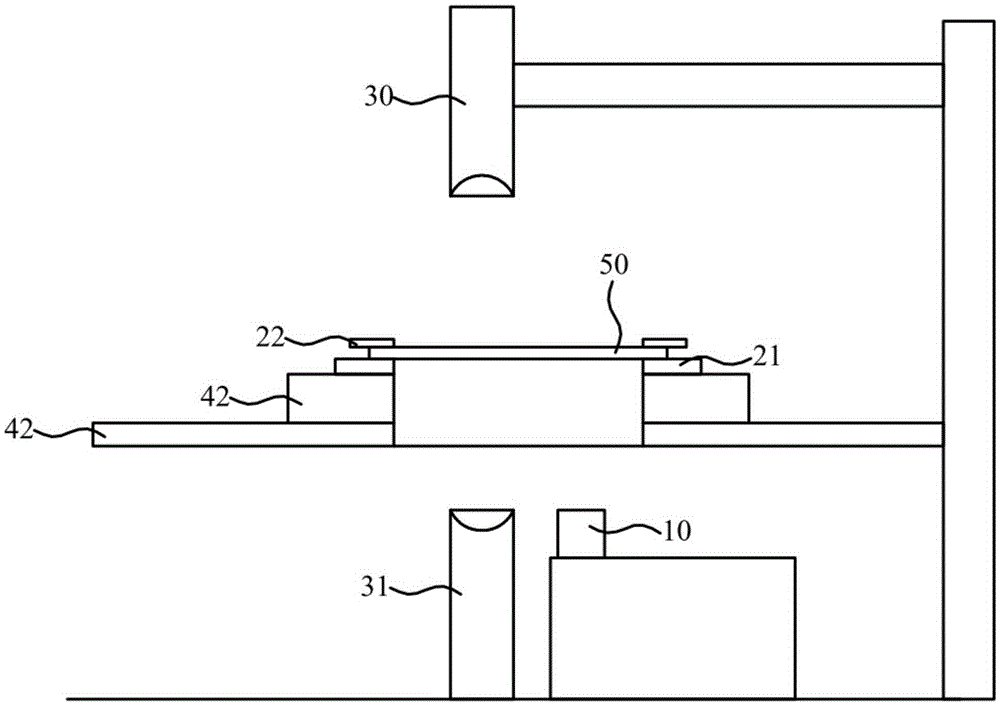

[0040] Such as Figure 1 to Figure 12 Shown is a laser printing device and its method provided by the present invention. Such as figure 1 As shown, the apparatus of the present invention includes a laser system 10 , a wafer leveling system 20 , a first imaging system 30 and a moving system 40 .

[0041] The laser system 10 refers to a laser (Light Amplification by Stimulated Emission of Radiation, LASER) generating device, which is mainly composed of three elements: the excitation source, the gain medium, and the resonant structure. It is very widely used in the precision processing and semiconductor industries due to its non-processing stress and precise characteristics. Generally, dust collection devices are provided around to collect the dust generated by processing.

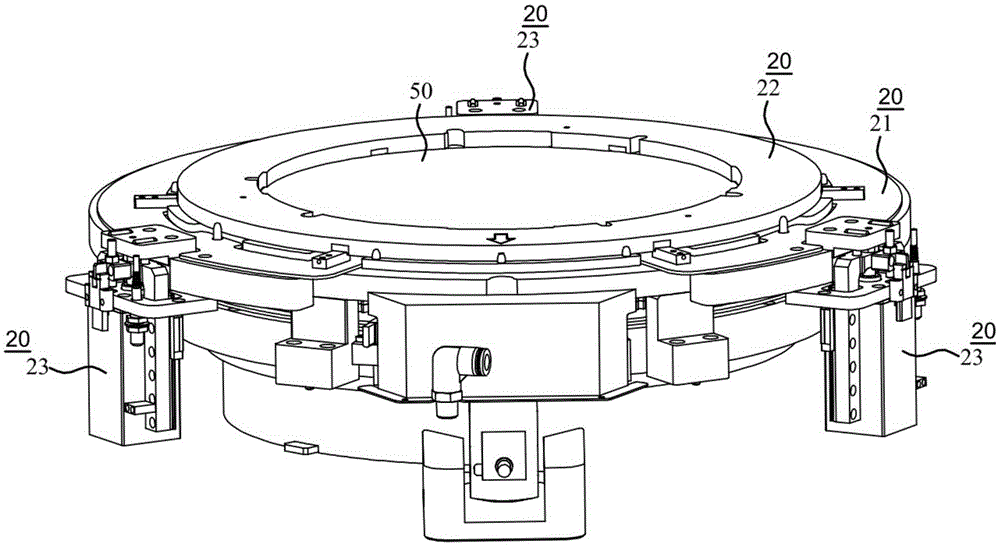

[0042] Such as Figure 5 , Figure 6As shown, the wafer leveling system 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com