Tooth implant

A technology for implants and body parts, applied in dentistry, prostheses, dental implants, etc., can solve the problems of slow fusion between dental implants and surrounding bone tissue, unfavorable bone tissue regeneration, unfavorable cell growth, etc., to achieve shortened fusion time, The effect of overcoming the instability of the interface and sufficient transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

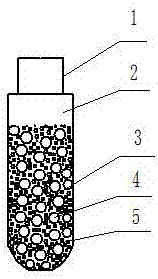

[0028] The artificial tooth implant of this embodiment is made of pure titanium, and the body is made of porous titanium material with a secondary pore structure. The cavities are all connected to each other, and the cavities at all levels are also connected to each other. Its preparation method is:

[0029] (1) Preparation of porous titanium body

[0030] a. Material preparation

[0031]Titanium powder with a particle size of 100nm-150nm is used as raw material, methylcellulose with a particle size of 370nm-500nm is used as the smallest pore-forming agent, and polystyrene with a particle size of 370nm-500nm is used as a binder. Niobium powder: methyl cellulose: polystyrene: distilled water in a volume ratio of 1:2:1:8 to make a slurry.

[0032] Use polyester foam with a rib diameter of 160µm-300µm, fill the slurry uniformly with foam impregnation method, form a green body and dry, and then crush to obtain raw materials, pore-forming agents and polyester foam with particle...

Embodiment 2

[0040] The artificial tooth implant in this example is similar to Example 1, except that the body is made of porous niobium, and the abutment and neck are made of dense niobium. The pore diameter of the stage cavity is 280nm-420nm, each stage of the cavity is connected to each other and the holes of each stage are also connected to each other. Its preparation method is similar to Example 1.

[0041] The first-stage porosity of this kind of porous niobium is 46%, the elastic modulus is 43GPa, the second-stage porosity is 42%, and the elastic modulus is 49.5GPa. The overall porosity of the body is 77%.

Embodiment 3

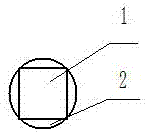

[0043] The artificial tooth implant of this embodiment is similar to Embodiment 2, the difference is that the abutment is porous niobium, and the neck is porous niobium, the holes of the porous niobium of the abutment and the porous niobium of the neck are interconnected, and the porous niobium of the abutment is The pores of niobium and the porous niobium in the neck are interpenetrating, and the pores of the porous niobium in the neck and the hierarchically porous niobium in the body are interpenetrating. The abutment and the neck are respectively prepared by pore-forming agent method. 40%, the pore size is 340nm-460nm, and the pore size of the neck is 10µm-16µm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com