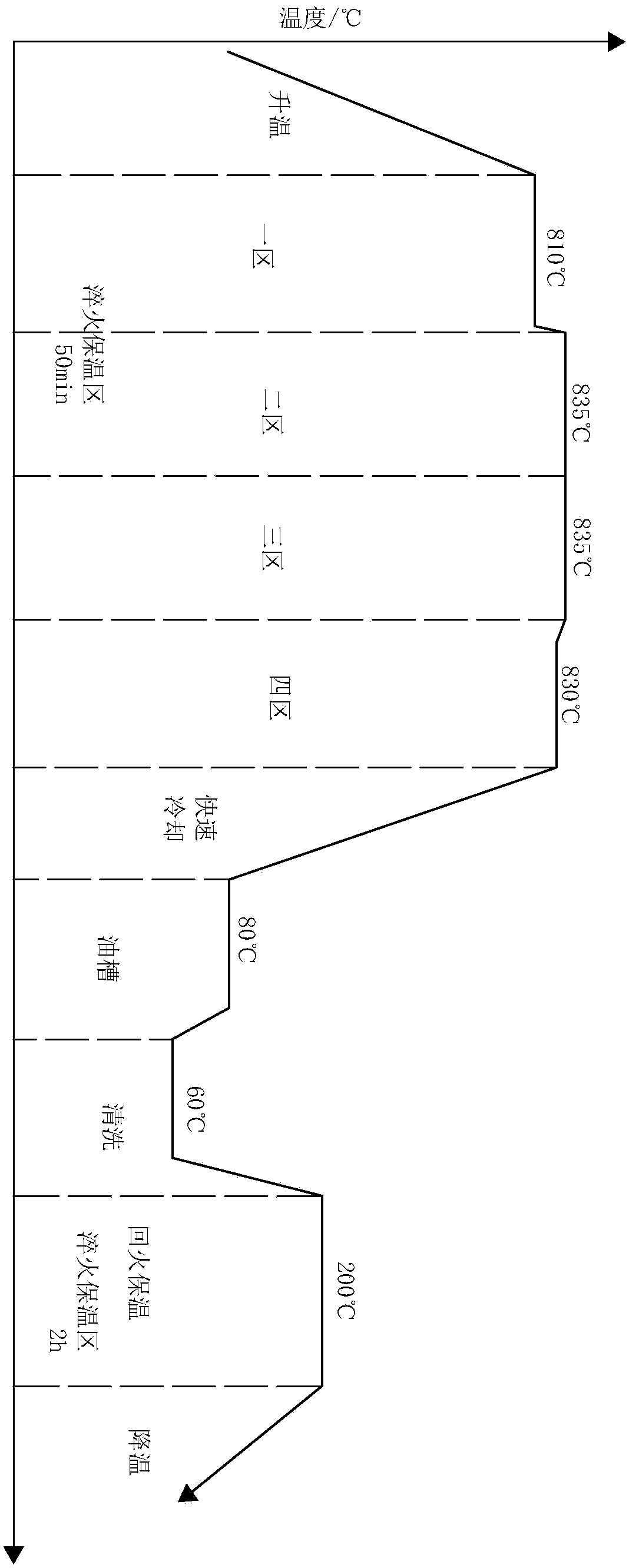

GCr15 bearing ring heat treatment process

A technology of bearing ring and process, which is applied in the field of heat treatment of GCr15 bearing ring, can solve the problems of large deformation, large deformation, large quenching force, etc., and achieve accelerated grinding, high crack resistance, and improved production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

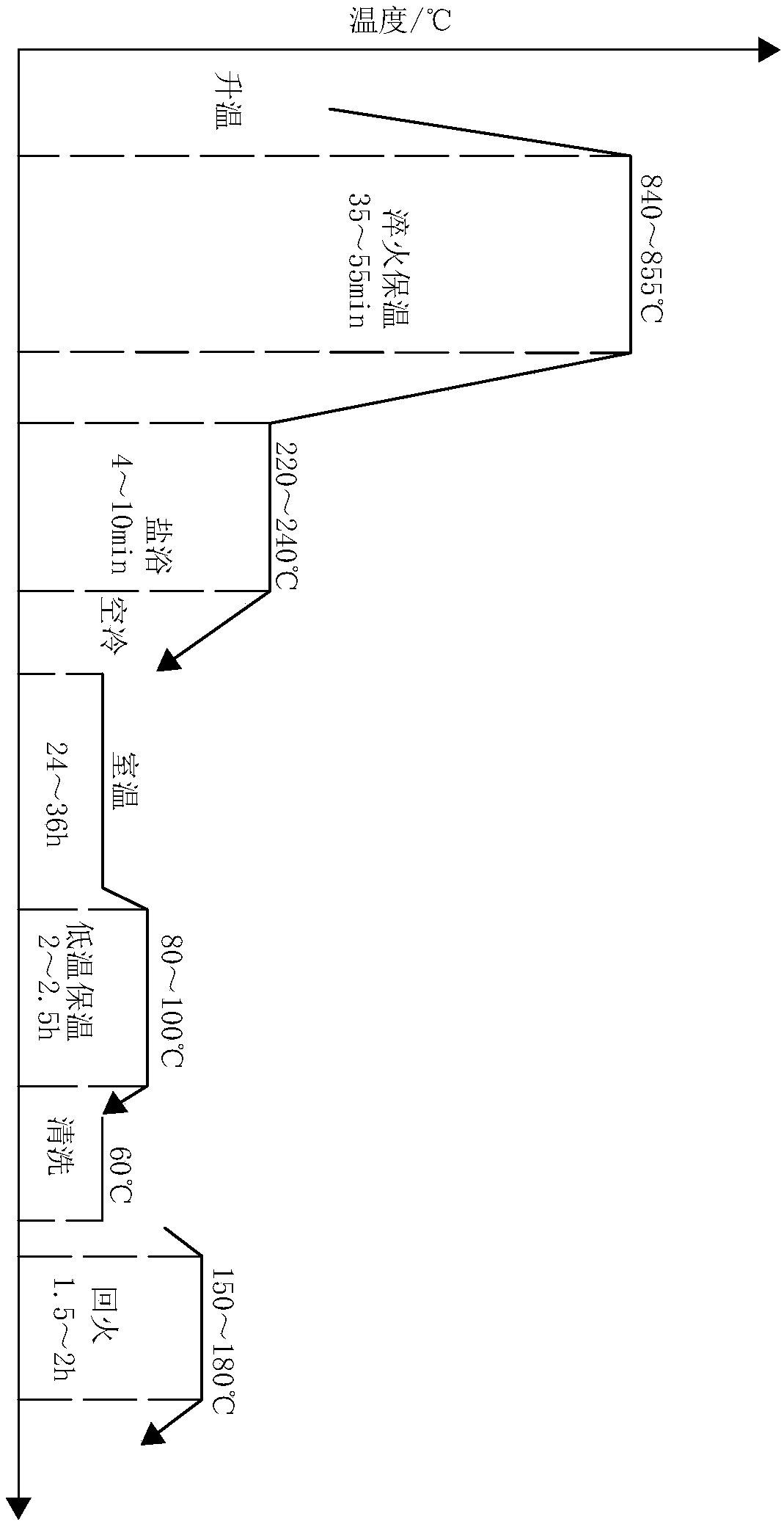

Embodiment 1

[0021] ① Place the bearing ring in a mesh belt furnace and heat it for quenching. The quenching heating temperature is 840°C, and the heating time is selected at 35 minutes by the size and wall thickness of the ring;

[0022] ② Step ① The bearing ring after treatment falls into the salt bath quenching liquid whose temperature is controlled at 240 ℃, and after staying in the salt bath for 10 minutes, quickly take out the bearing ring;

[0023] ③Place the taken out bearing ring in the air to cool, and after the sample cools to room temperature, place the sample in a dry and ventilated place for 24 hours;

[0024] ④ Place the bearing ring treated in step ③ in a tempering furnace at 80°C for 2 hours;

[0025] ⑤ Clean the bearing ring after step ④, and then temper at 150°C for 1.5h (conventional tempering). Get the 1# bearing ring.

Embodiment 2

[0027] ① Place the bearing ring in a mesh belt furnace and heat it for quenching. The quenching heating temperature is 855°C, and the heating time is selected at 35 minutes according to the size and wall thickness of the ring;

[0028] ② Step ① The bearing ring after treatment falls into the salt bath quenching liquid whose temperature is controlled at 240 ℃, and after staying in the salt bath for 10 minutes, quickly take out the bearing ring;

[0029] ③Place the taken out bearing ring in the air to cool, and after the sample cools to room temperature, place the sample in a dry and ventilated place for 24 hours;

[0030] ④ Place the bearing ring treated in step ③ in a tempering furnace at 80°C for 2 hours;

[0031] ⑤ Clean the bearing ring after step ④, and then temper at 150°C for 1.5h (conventional tempering). Get the 2# bearing ring.

Embodiment 3

[0033] ① Place the bearing ring in a mesh belt furnace and heat it for quenching. The quenching heating temperature is 855°C, and the heating time is selected at 45 minutes by the size and wall thickness of the ring;

[0034] ② Step ① The bearing ring after treatment falls into the salt bath quenching liquid whose temperature is controlled at 240 ℃, and after staying in the salt bath for 10 minutes, quickly take out the bearing ring;

[0035] ③Place the taken out bearing ring in the air to cool, and after the sample cools to room temperature, place the sample in a dry and ventilated place for 24 hours;

[0036] ④ Place the bearing ring treated in step ③ in a tempering furnace at 80°C for 2 hours;

[0037] ⑤ Clean the bearing ring after step ④, and then temper at 180°C for 1.5h (conventional tempering). Obtain the 3# bearing ring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com