Micro-hemispherical resonant gyroscope based on borosilicate glass annealing forming and manufacturing method thereof

A technology of borosilicate glass and hemispherical resonant gyro, which is applied in the field of micro-inertial sensors, can solve the problems of low electrode consistency, difficulty in ensuring symmetry, and large surface stress, so as to reduce lithography and etching errors, structure Simple, low surface stress effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

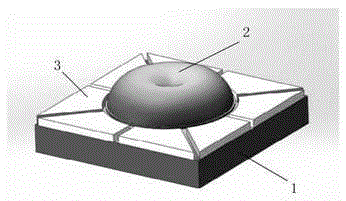

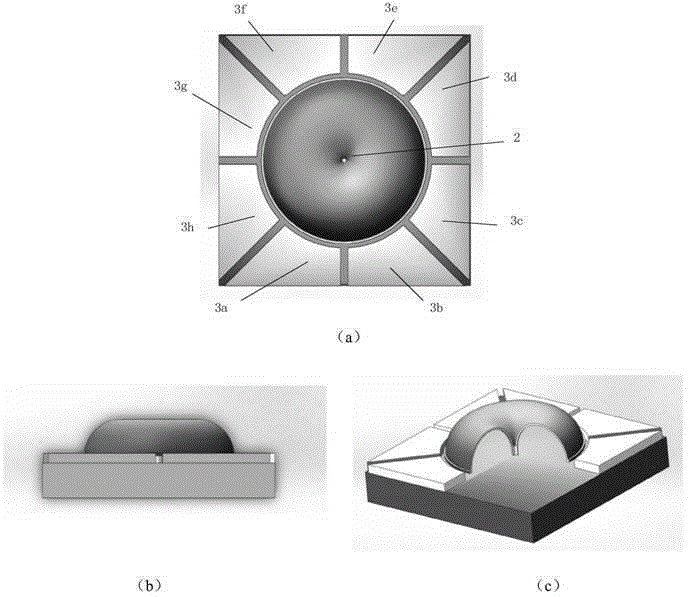

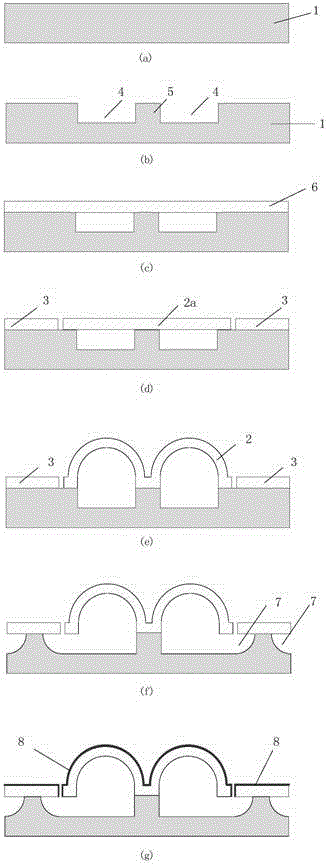

[0014] combine figure 1 with figure 2 , the present invention is based on borosilicate glass annealed miniature hemispherical resonator gyroscope, including:

[0015] a silicon substrate 1;

[0016] A hemispherical harmonic oscillator 2;

[0017] A central pillar 5 connects the hemispherical resonator and the silicon substrate;

[0018] Eight planar electrodes 3 arranged on the silicon substrate 1 and uniformly arranged around the hemispherical resonator, the eight planar electrodes 3 are four drive electrodes 3a, 3c, 3e, 3g and four detection electrodes 3b, 3d, 3f , composed of 3h, all driving electrodes, detecting electrodes and the hemispherical resonator are not in contact, and the driving electrodes and detecting electrodes are distributed sequentially at intervals, that is, there is a detecting electrode between every two driving electrodes, and similarly, between every two detecting electrodes is a driving electrode.

[0019] The present invention is based on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com