Preparing method of ultrathin amorphous alloy strip

A technology of amorphous alloys and strips, which is applied in the field of preparation of amorphous alloy strips, and can solve the problems of affecting the flatness of the outer surface of the strip, prone to scratches on the outer surface of the strip, and large internal stress of the amorphous strip. , to achieve the effect of improving quality and finished product performance, enhancing scraping and correction, and uniform thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the ultrathin amorphous alloy strip of the present embodiment comprises the following steps:

[0030] (1) Using Co 69 Fe 4 Ni 2 Si 10 B 15 The alloy is a master alloy, which is put into an intermediate frequency induction furnace for induction heating and melting, and heated to 100°C above the melting point of the target master alloy for slag removal treatment;

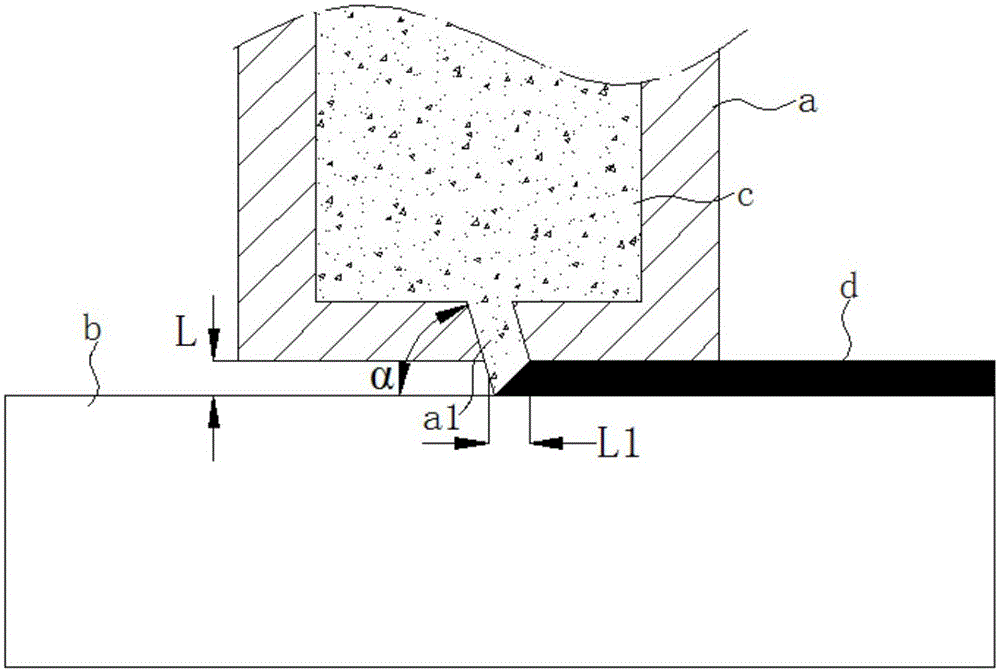

[0031] (2) Preheat the nozzle package to 800°C in advance, then pour the molten steel obtained in step (1) into the nozzle package through the heat preservation launder, and adjust the molten steel c to be between the upper end surface of the molten steel and the bottom of the nozzle a The height difference is 10cm. The molten steel c enters the nozzle a through the filter hole. Under the pressure of 0.1MPa, the molten steel is sprayed obliquely to the surface of the cooling body b through the flow channel a1 at the lower end of the nozzle a, and the spraying direction of the molte...

Embodiment 2

[0035] The preparation method of the ultrathin amorphous alloy strip of the present embodiment comprises the following steps:

[0036] (1) Using Fe 77 Si 8 B 15 The alloy is a master alloy, which is put into an intermediate frequency induction furnace for induction heating and melting, and heated to 200°C above the melting point of the target master alloy for slag removal treatment;

[0037] (2) Preheat the nozzle package to 1000°C in advance, then pour the molten steel obtained in step (1) into the nozzle package through the heat preservation launder, and adjust the molten steel c to be between the upper end surface of the molten steel and the bottom of the nozzle a The height difference is 100cm, the molten steel c enters the nozzle a through the filter hole, and the molten steel sprays obliquely to the surface of the cooling body b under the pressure of 0.3MPa, and the spraying direction of the molten steel is opposite to the rotation direction of the cooling body b, and ...

Embodiment 3

[0041] The preparation method of the ultrathin amorphous alloy strip of the present embodiment comprises the following steps:

[0042] (1) Using Co 69 Fe 4 Ni 2 Si 10 B 15The alloy is a master alloy, which is put into an intermediate frequency induction furnace for induction heating and melting, and heated to 100°C above the melting point of the target master alloy for slag removal treatment;

[0043] (2) Preheat the nozzle package to 900°C in advance, then pour the molten steel obtained in step (1) into the nozzle package through the heat preservation launder, and adjust the molten steel c to be between the upper end surface of the molten steel and the bottom of the nozzle a The height difference is 50cm. The molten steel c enters the nozzle a through the filter hole. Under the pressure of 0.25MPa, the molten steel is sprayed obliquely to the surface of the cooling body b through the flow channel a1 at the lower end of the nozzle a, and the spraying direction of the molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com