Patents

Literature

179 results about "Core strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

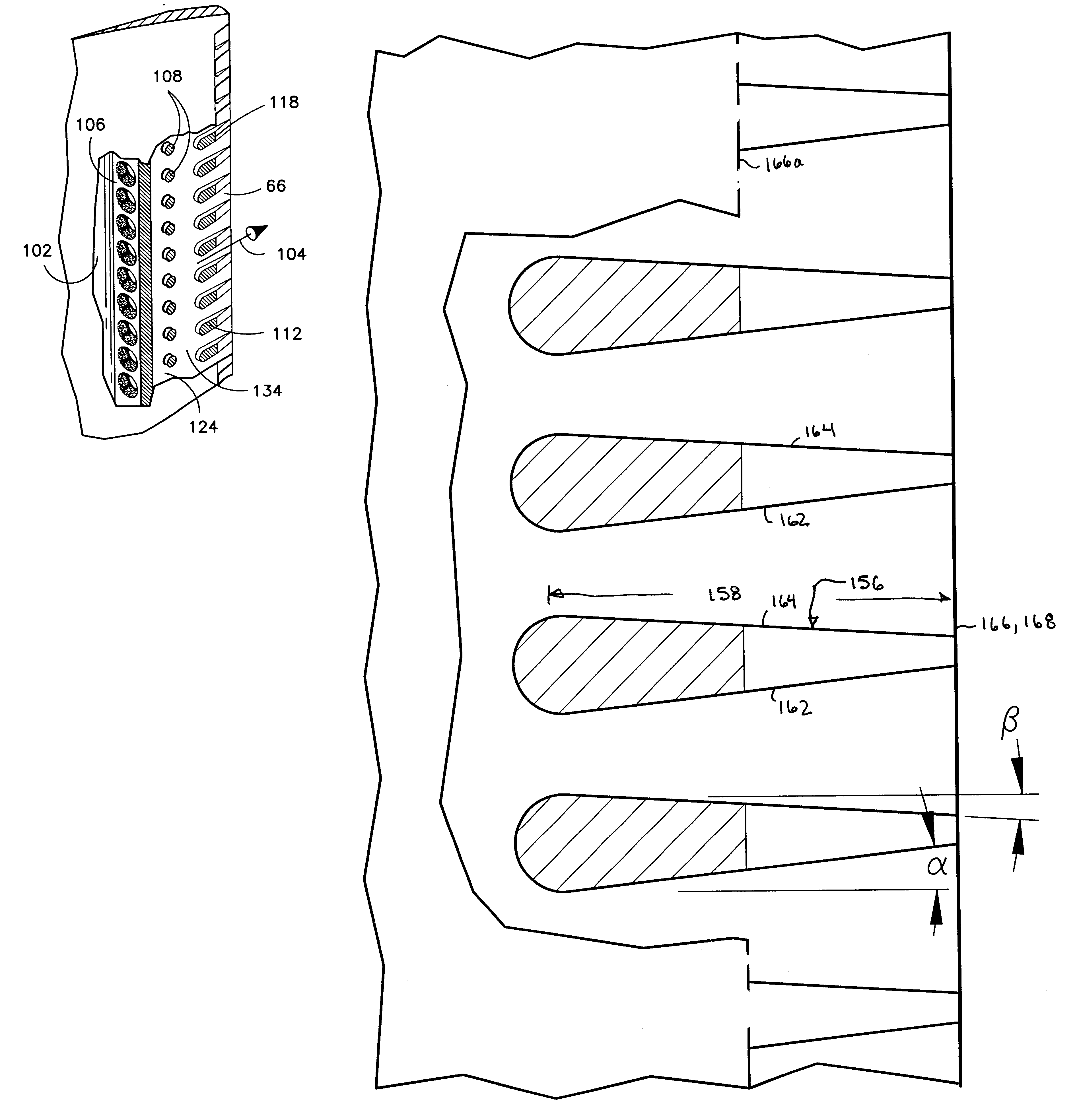

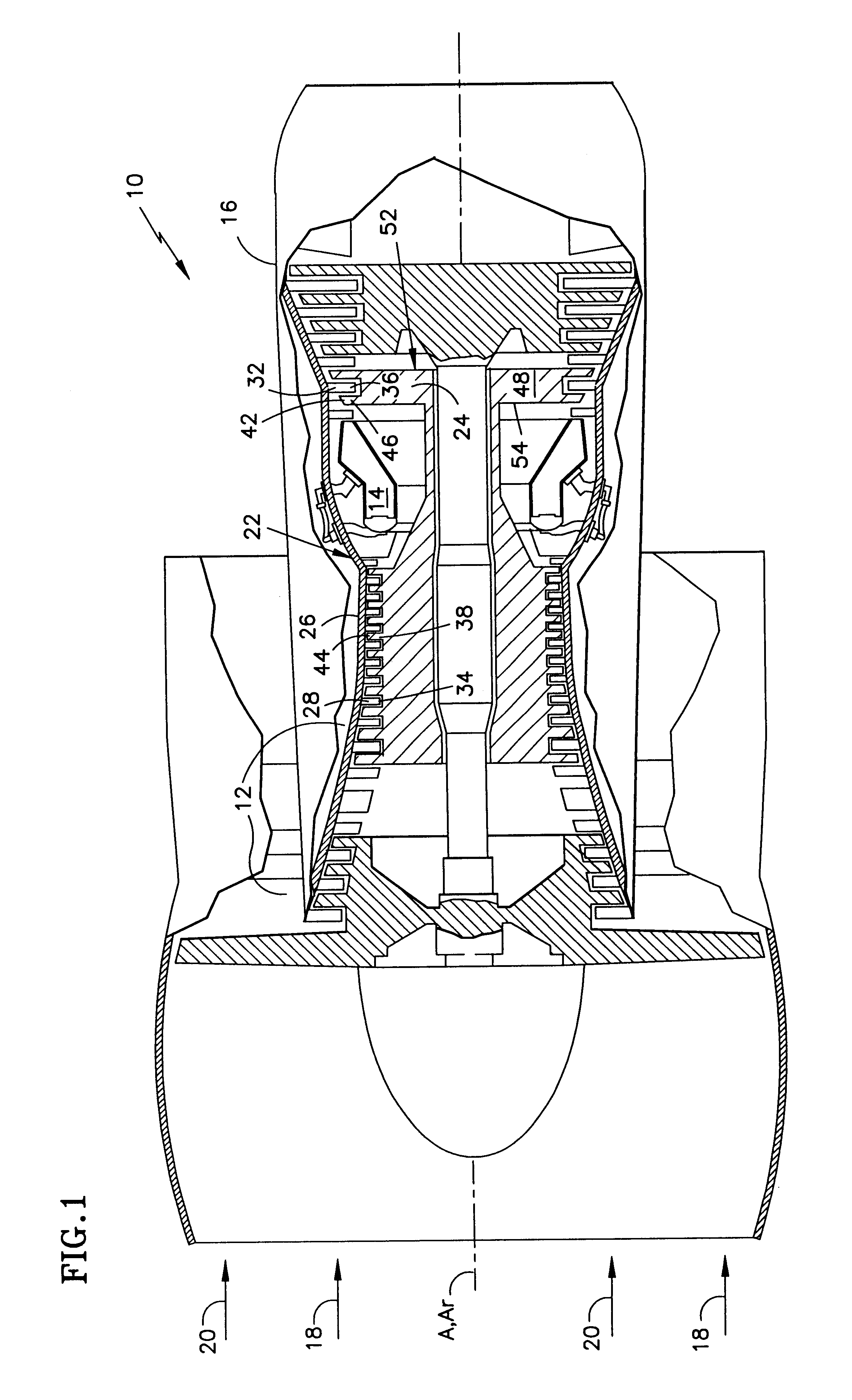

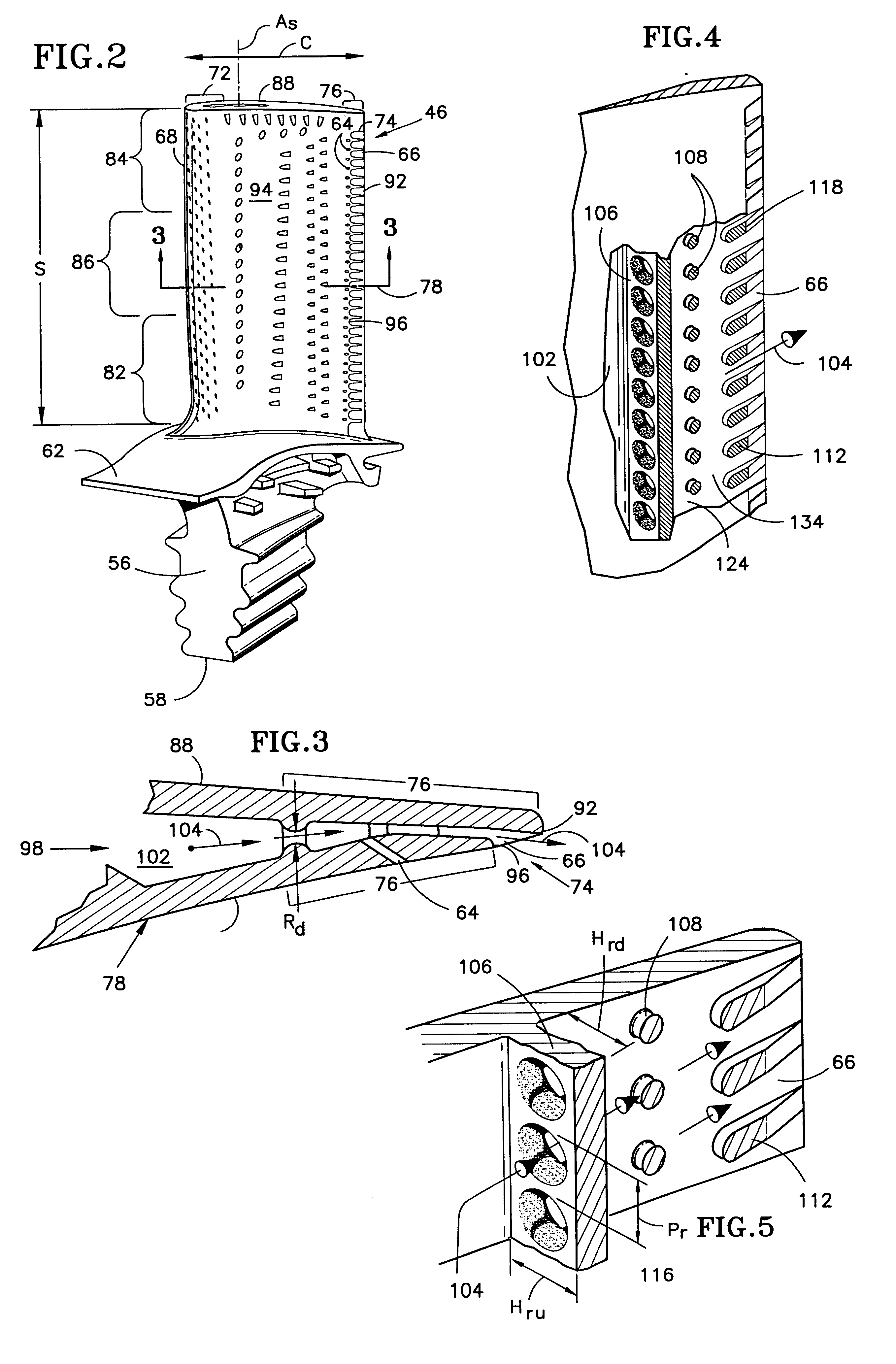

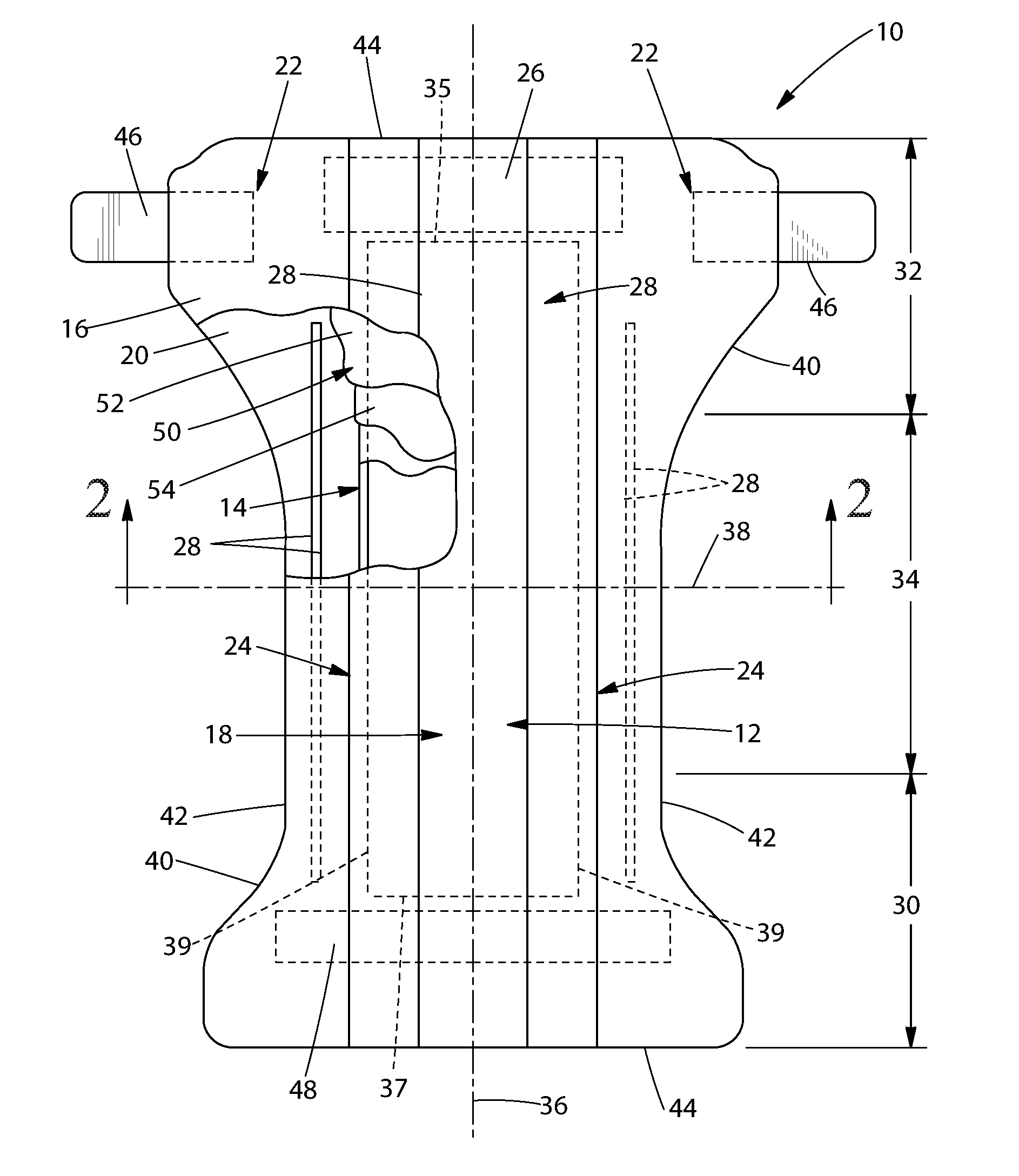

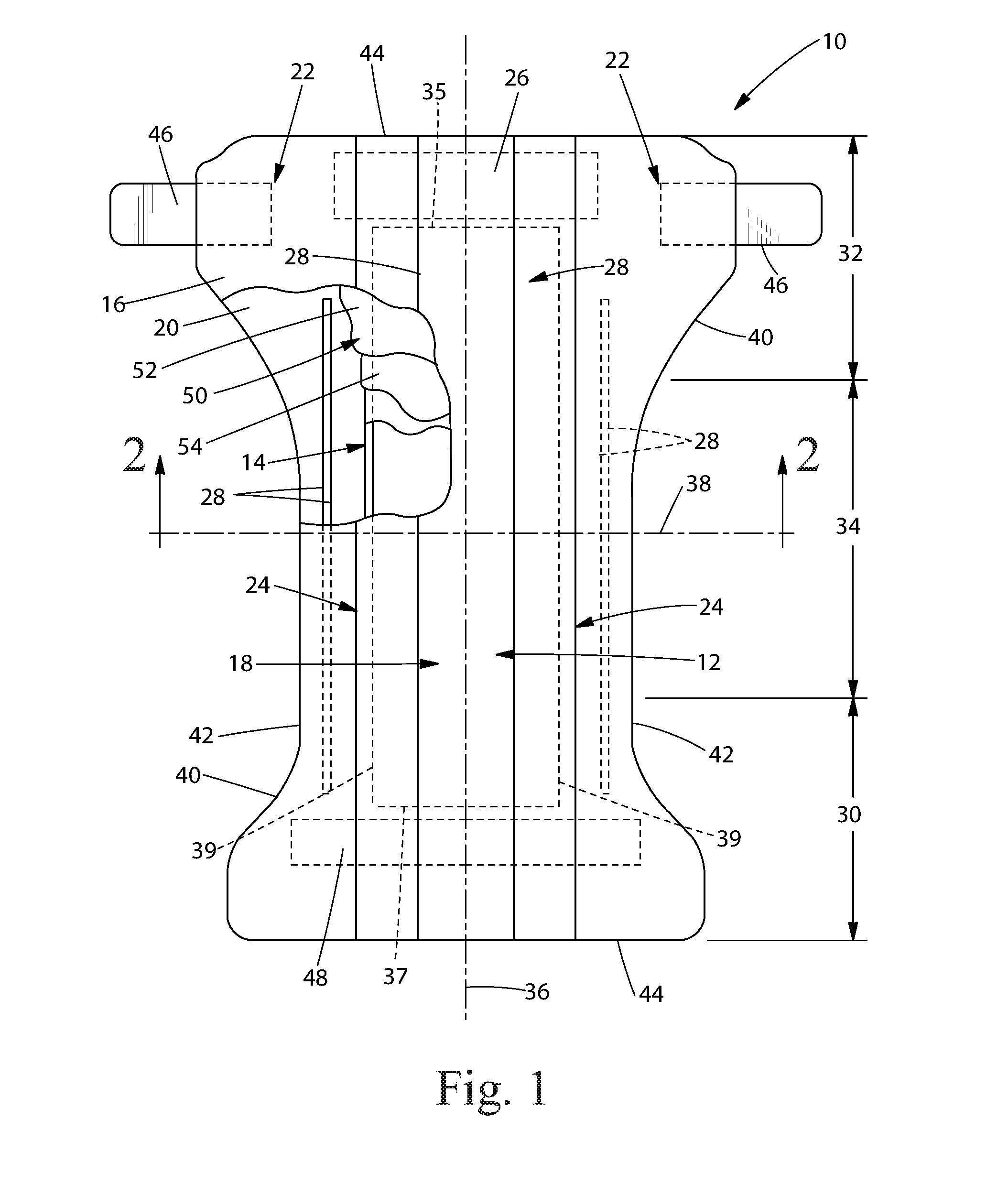

Coolable airfoil structure

InactiveUS6234754B1Durability and thermomechanical performanceIncreased durabilityPump componentsEngine fuctionsCastabilityInternal heat transfer

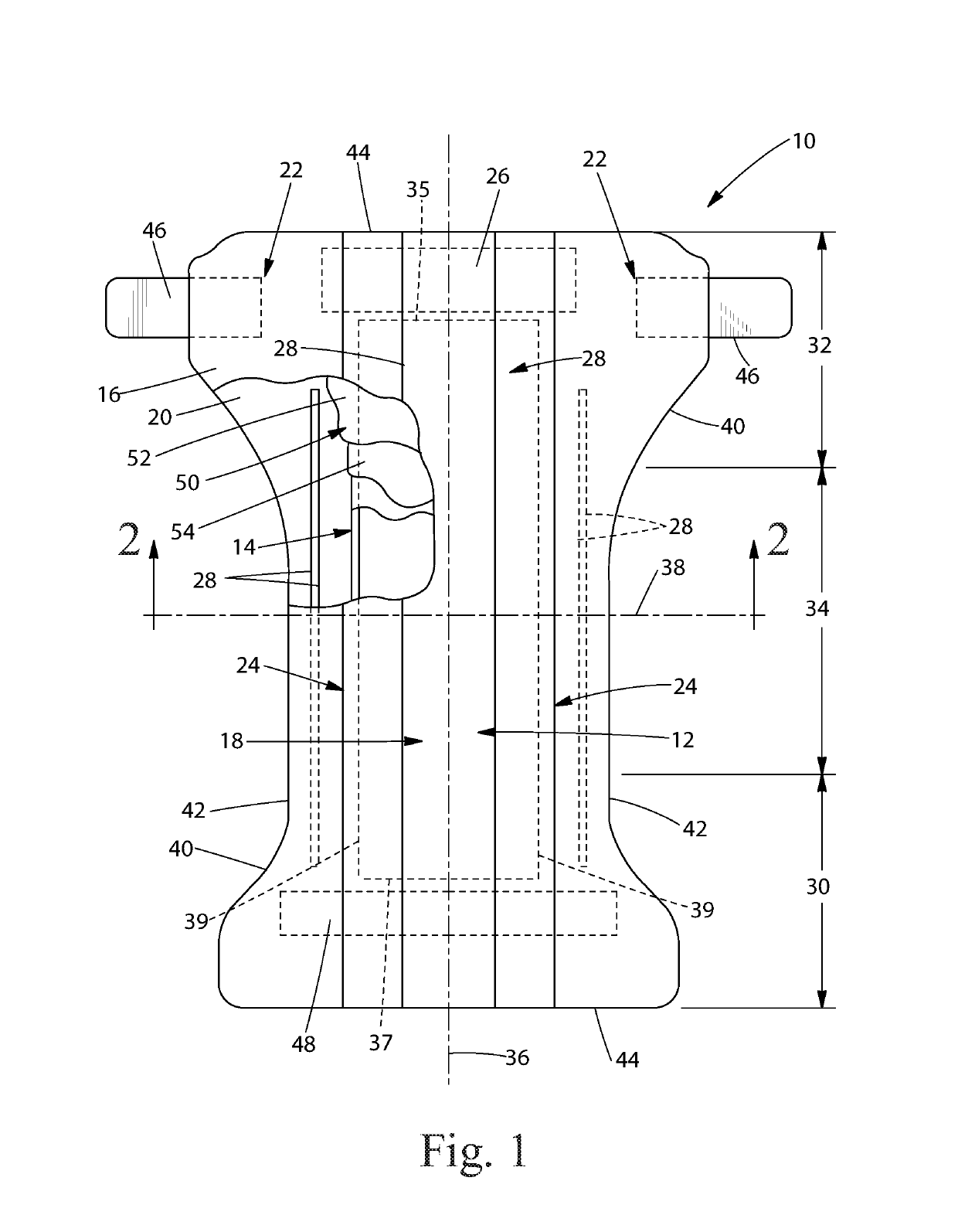

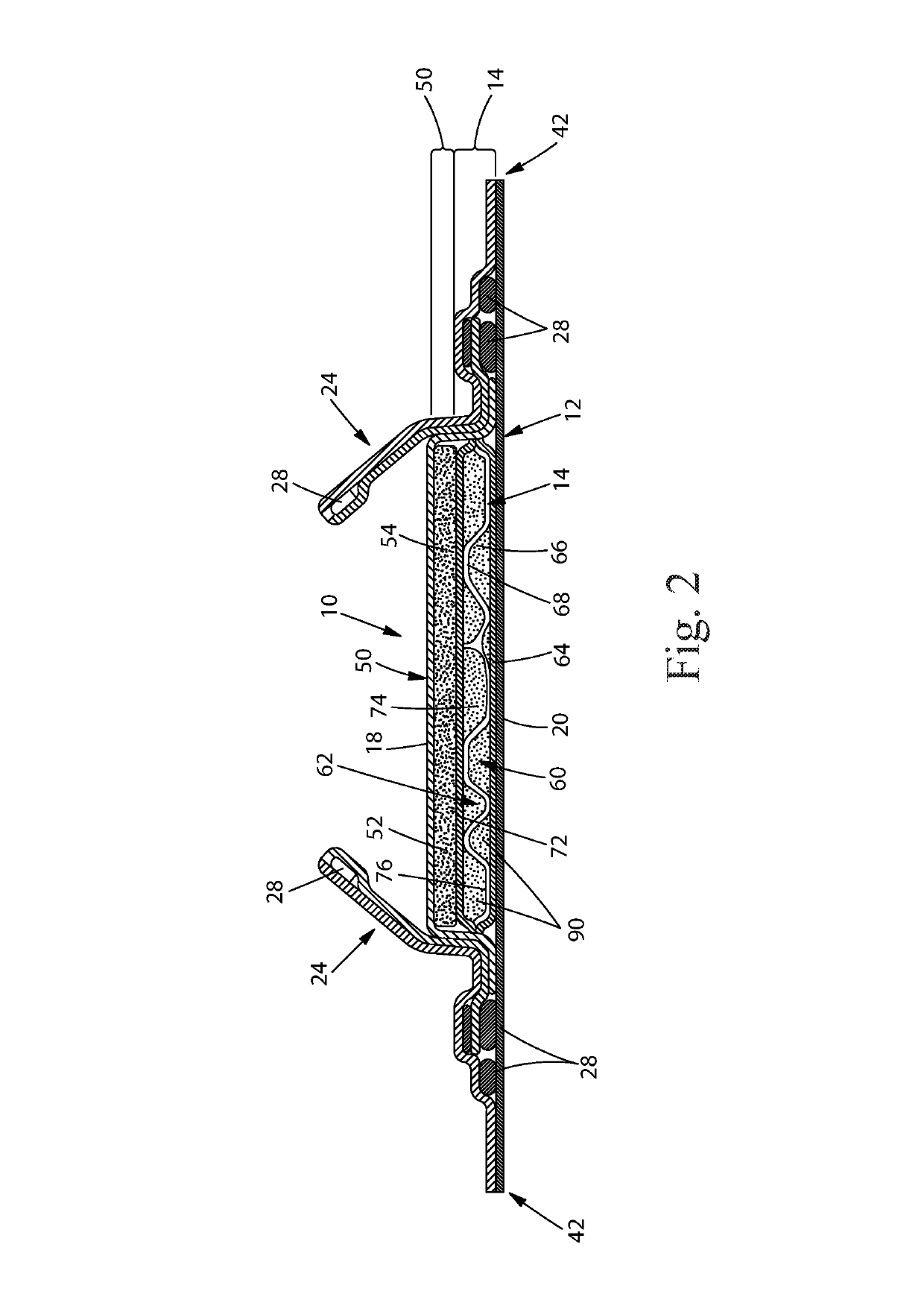

A coolable airfoil structure having internal heat transfer features through which cooling air is flowed under operative conditions is disclosed. Various construction details and features are developed which affect the castability and core strength during manufacture and strength and cooling effectiveness of the airfoil after manufacture. In one particular embodiment, the airfoil has a plurality of heat transfer members disposed in the rearmost section of the trailing edge region which comprises a single impingement rib, a single row of pedestals and a single row of chordwisely extending flow dividers.

Owner:UNITED TECH CORP

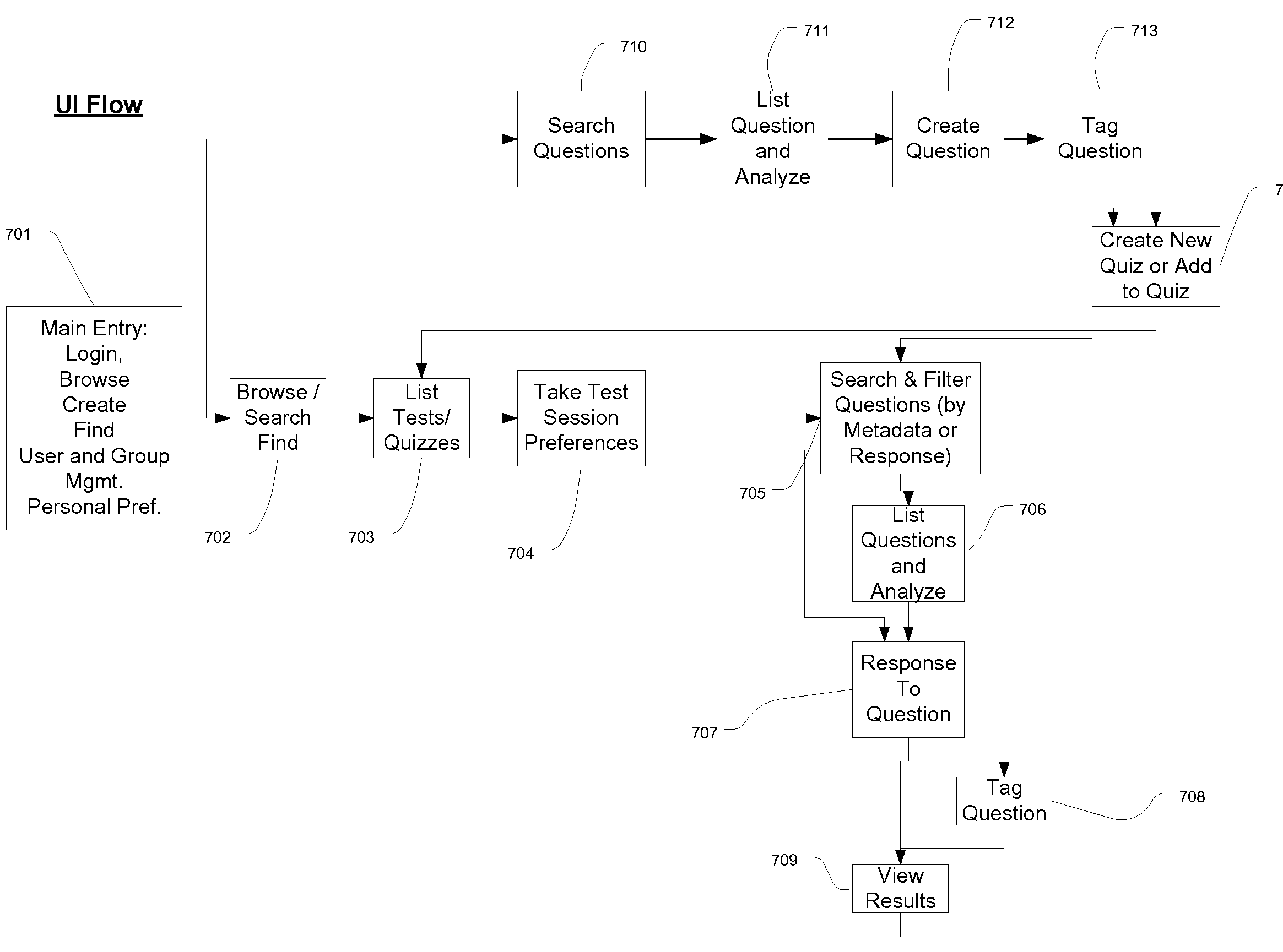

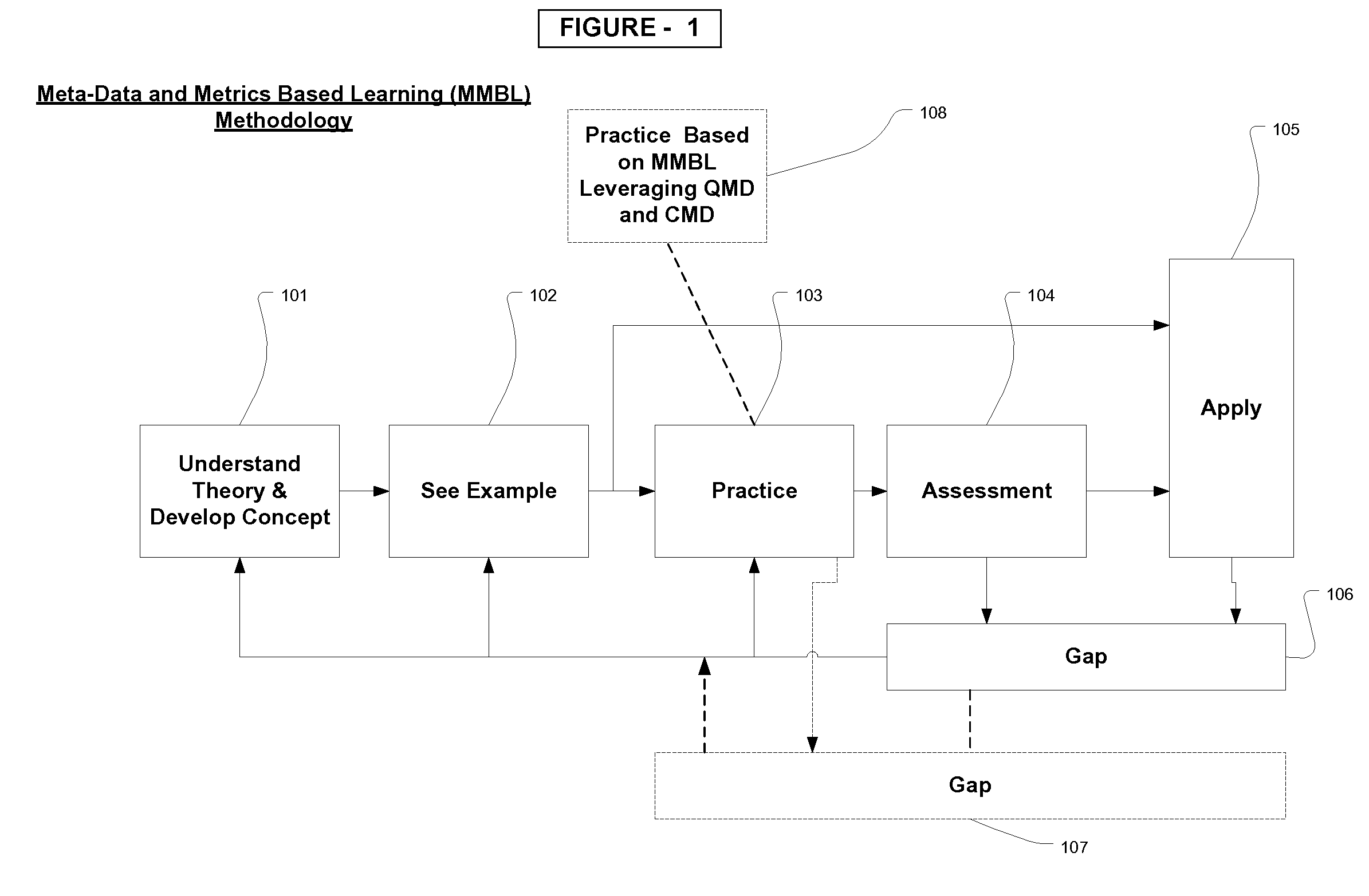

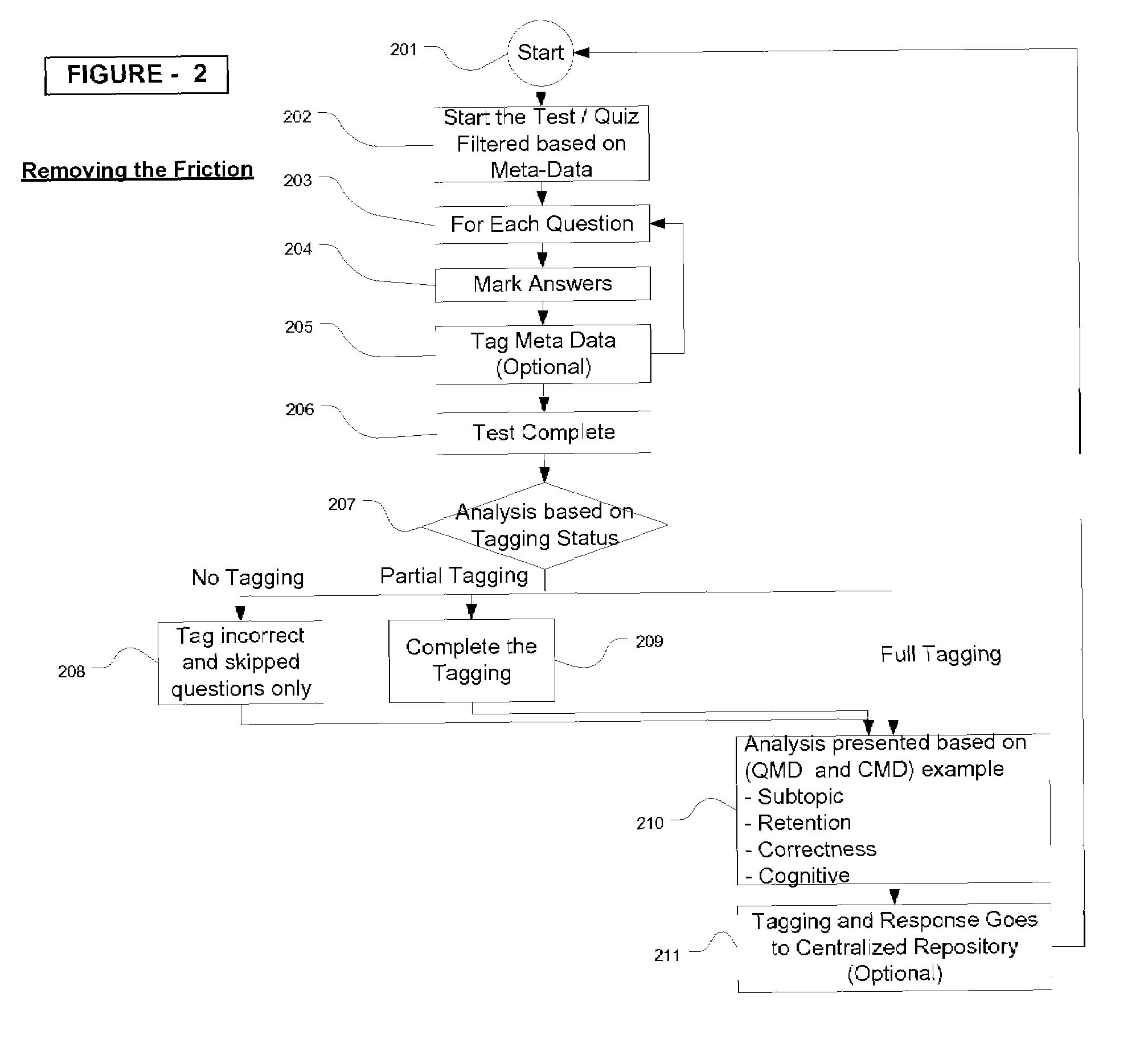

Meta-data and metrics based learning

InactiveUS20070172809A1Less timeFocusElectrical appliancesMechanical appliancesSystems analysisComputerized system

The invention relates generally to a system and methodology for learning, and in particular for practicing for tests. The system and method employs algorithms for performing various analytics. A computerized system analyzes Meta-Data associated with the Tests, Questions and the learner / student response to those and provides information which helps the learner / student learn faster, get a deeper understanding of the subject area and helps them focus and practice for the subject area of needs. As the data for a student is collected the system can analyze the core strength and weakness of student for the subject, topic or subtopic etc. and in various other dimensions. Additionally as data from multiple students is aggregated the methodology defines the mechanism to analyze and quantify the outcome from three areas of learning namely, the learner effort, an instructor effort and the quality of learning contents. Such a meta-data based learning methodology greatly reduces the potential for guess and subjective analysis and improves the learning of an individual based on the quantifiable data, either at the user choice or being driven by the system recommendation.

Owner:GUPTA ANSHU

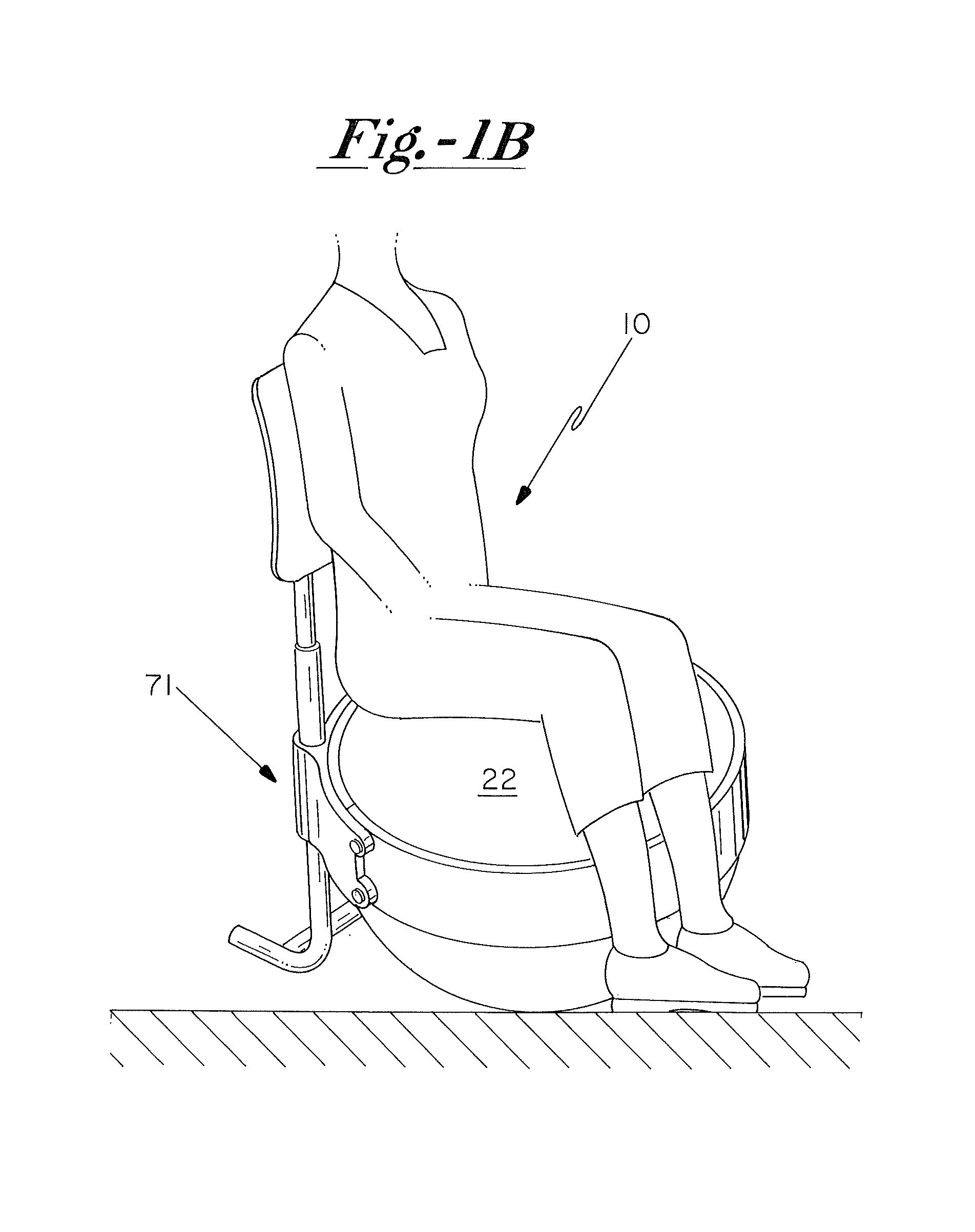

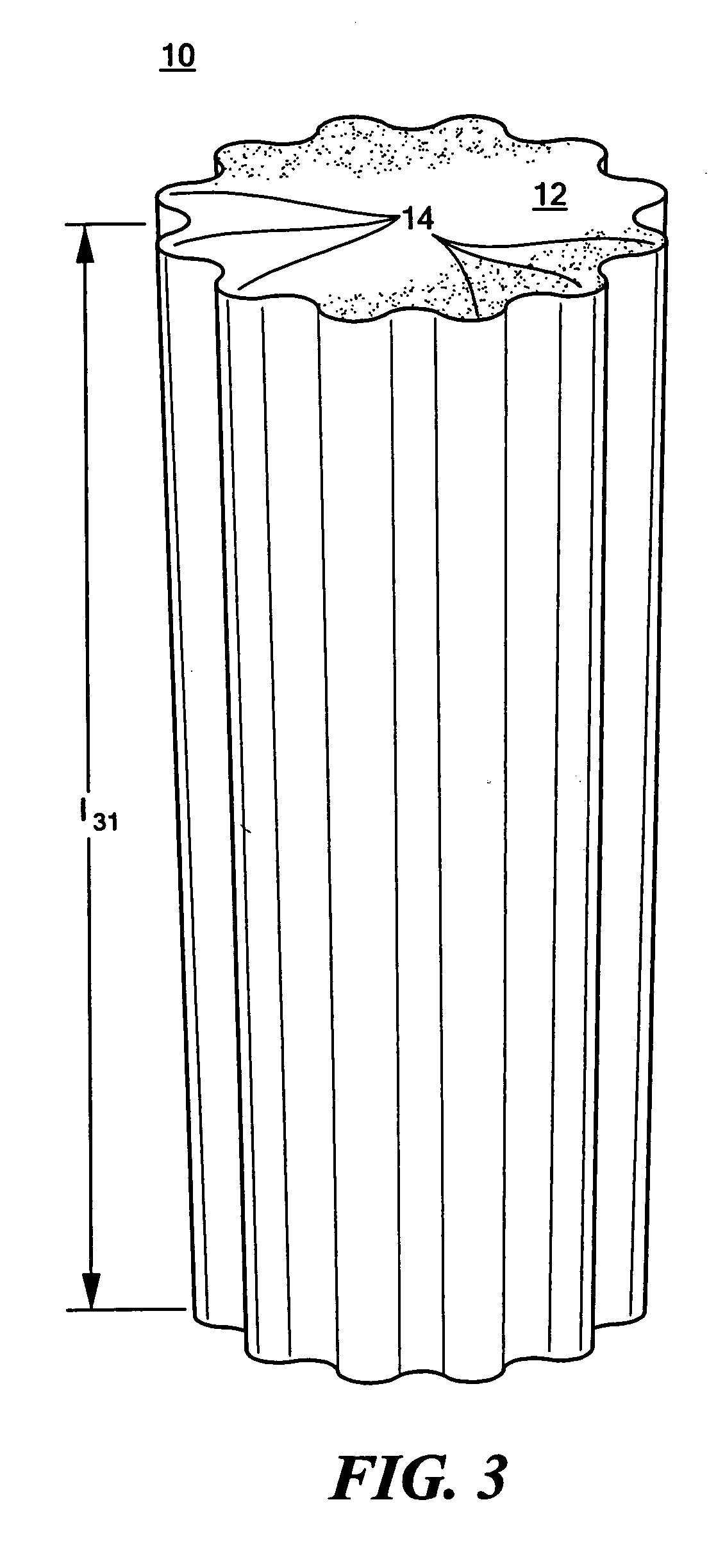

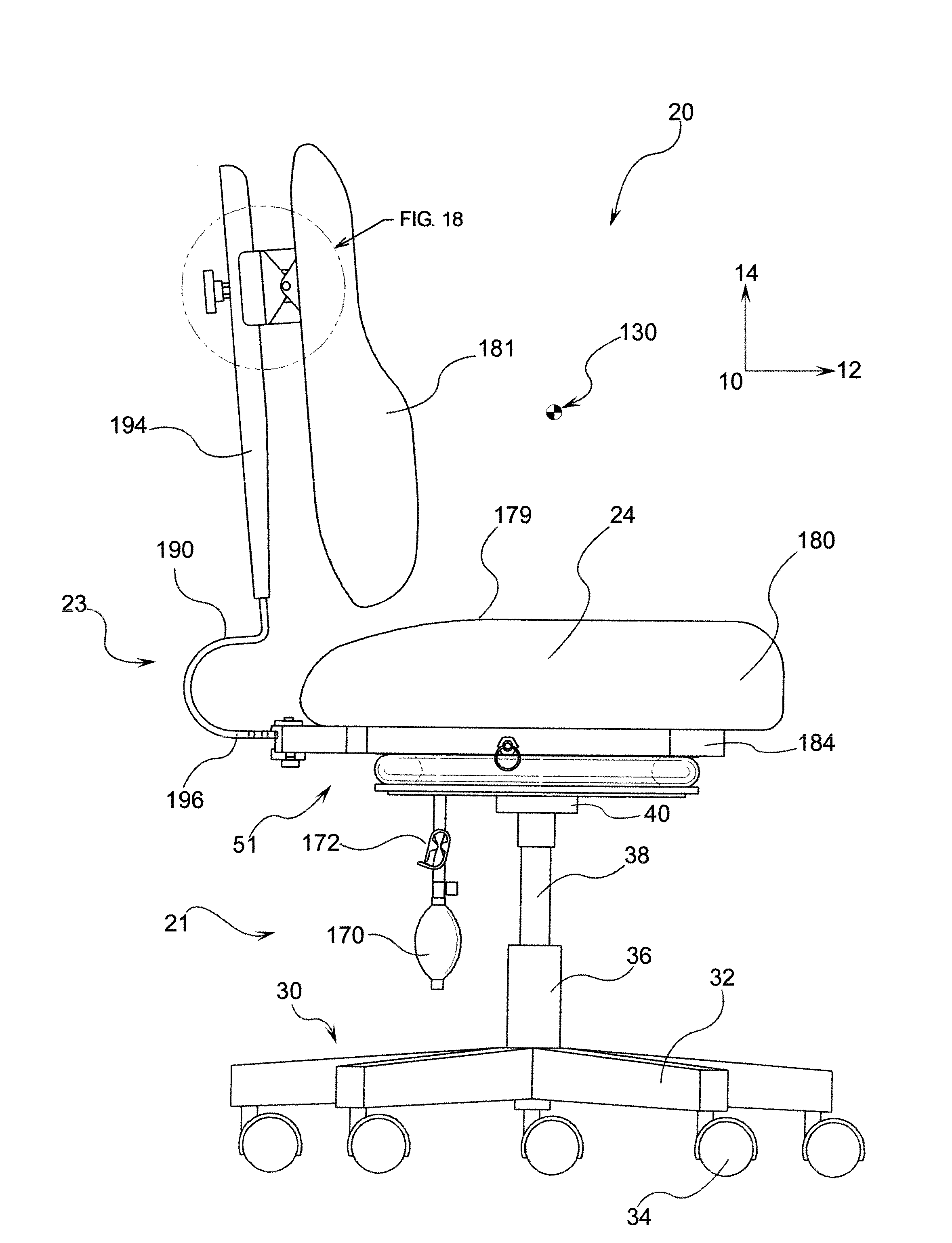

Chair with multiple pivot axes

A chair apparatus is provided with multiple pivot axis for improving core strength, posture, and circulation of the user. The chair apparatus includes a seat portion that is capable of pivotal movement about multiple pivot axes and along a surface. The chair apparatus further includes a frame coupled to the seat portion, wherein the frame limits the pivotal movement of the seat portion only when the chair apparatus is placed in a supported orientation.

Owner:POLK LOUIS F

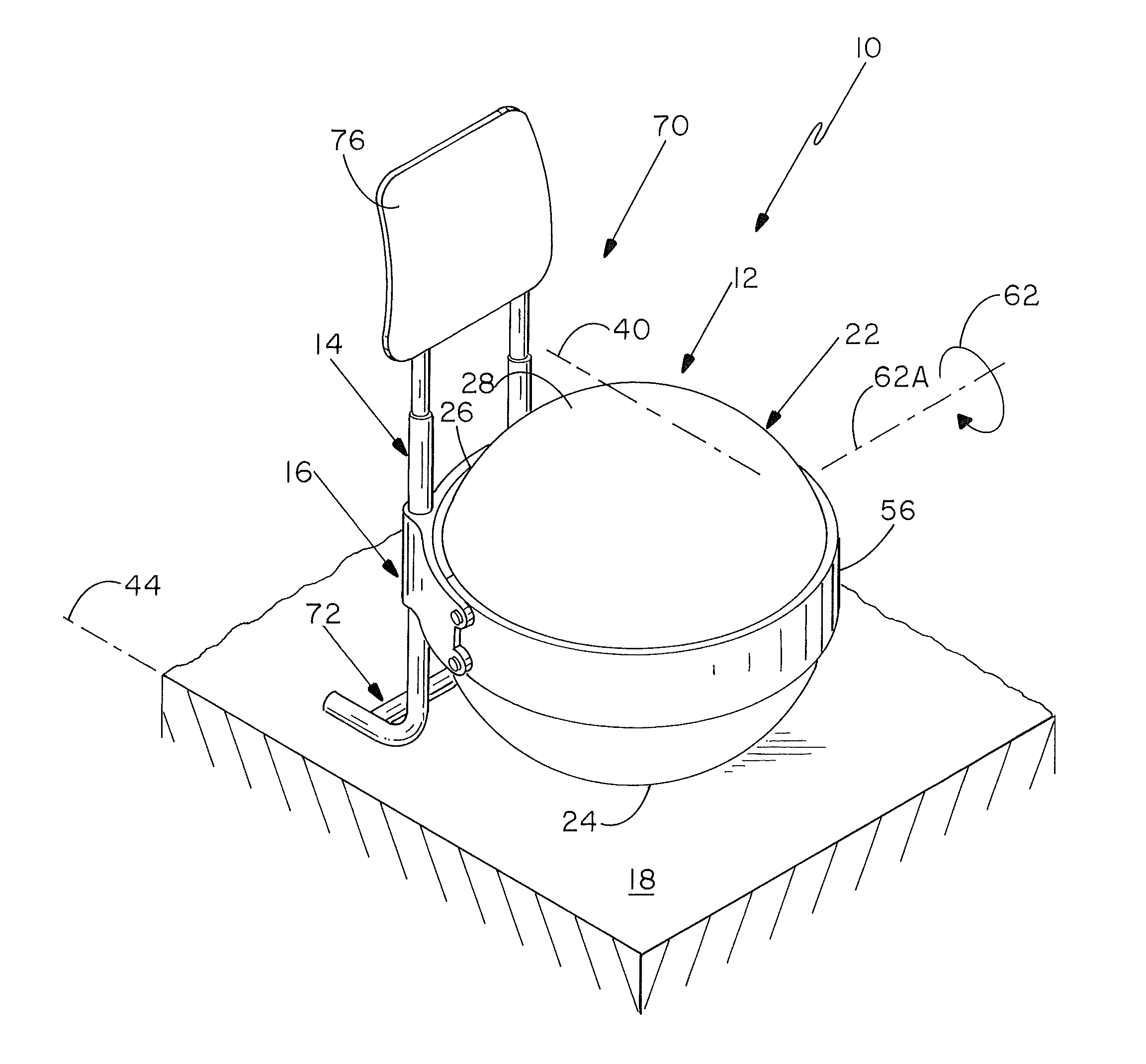

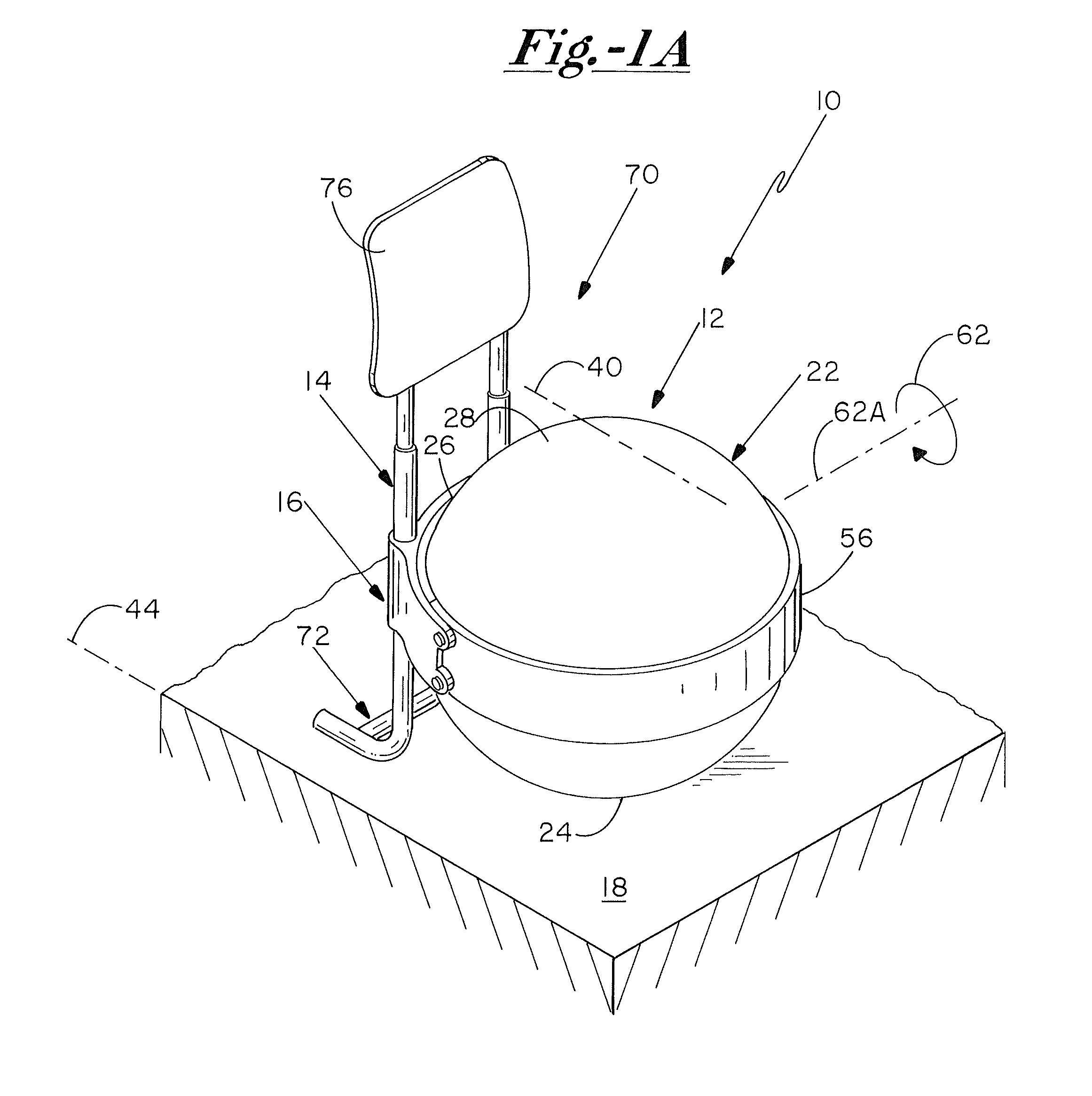

Method and apparatus to enhance proprioception and core health of the human body

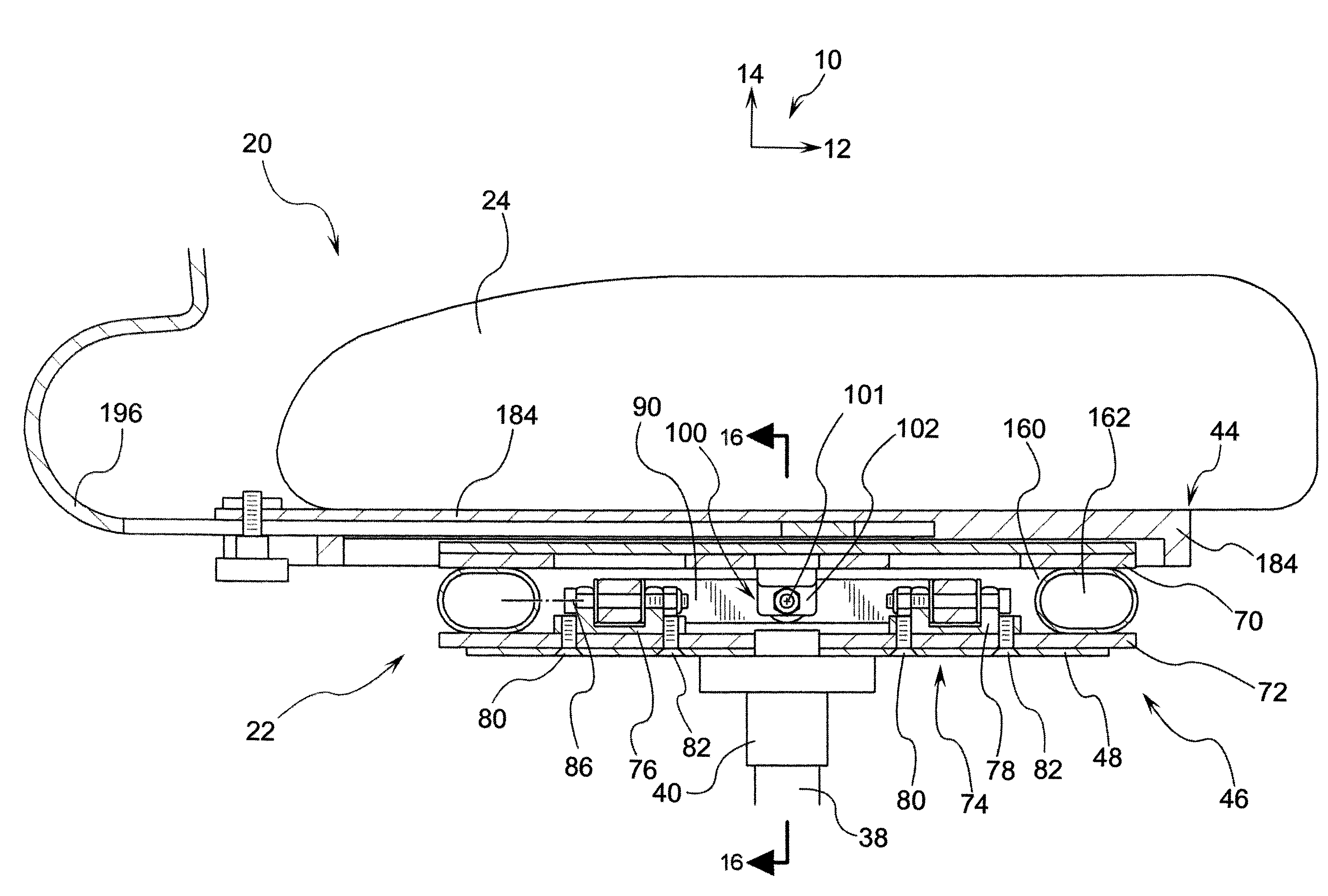

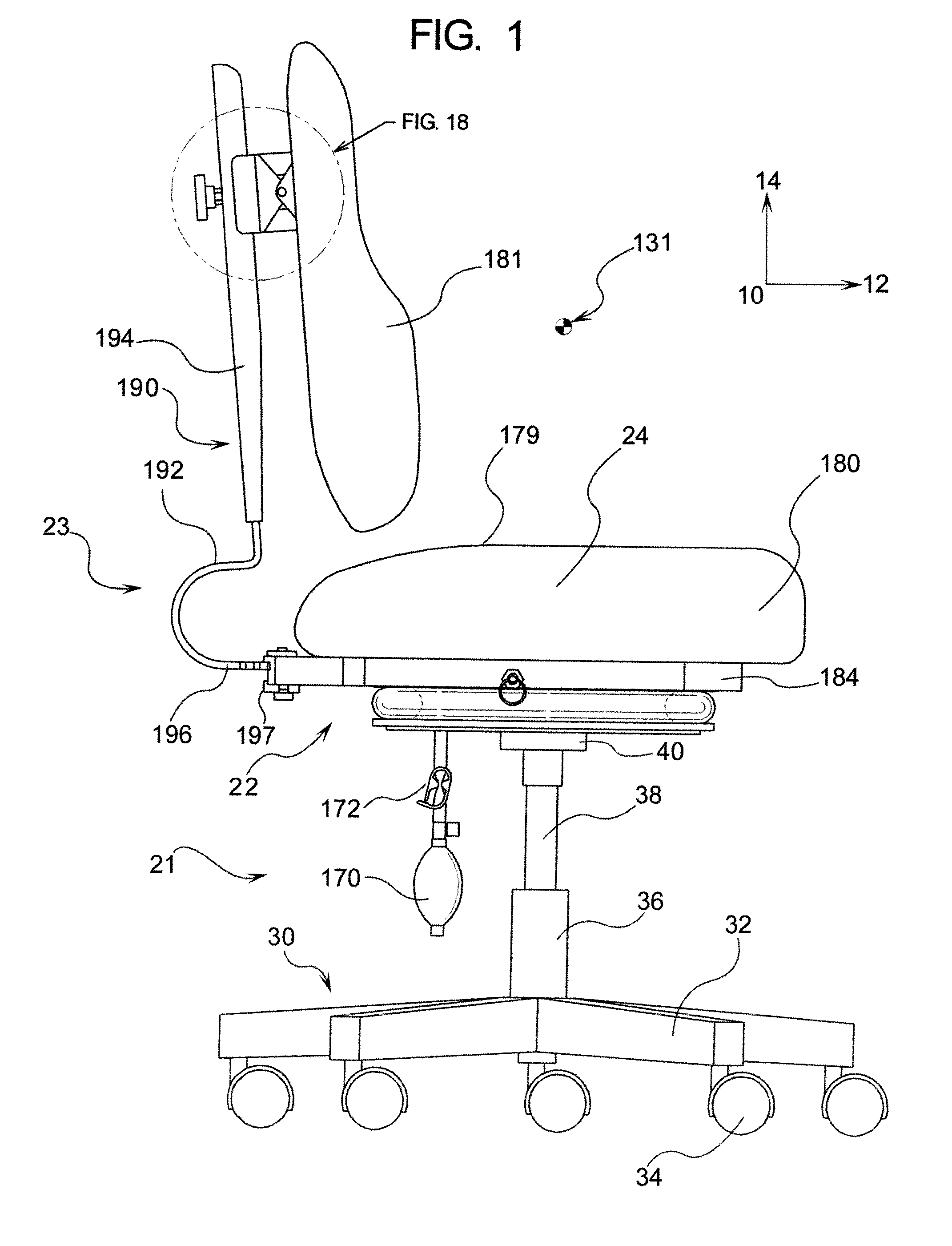

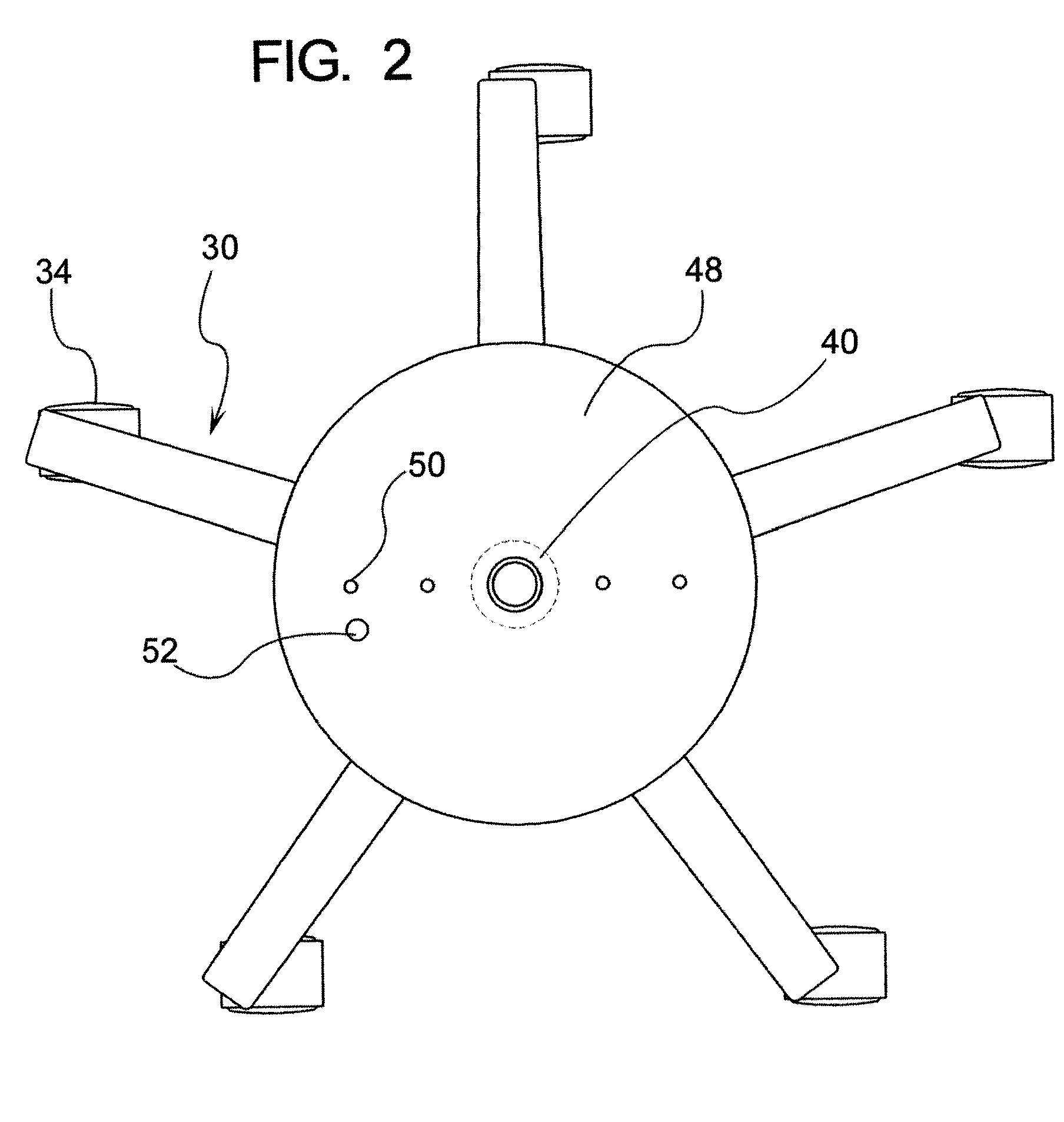

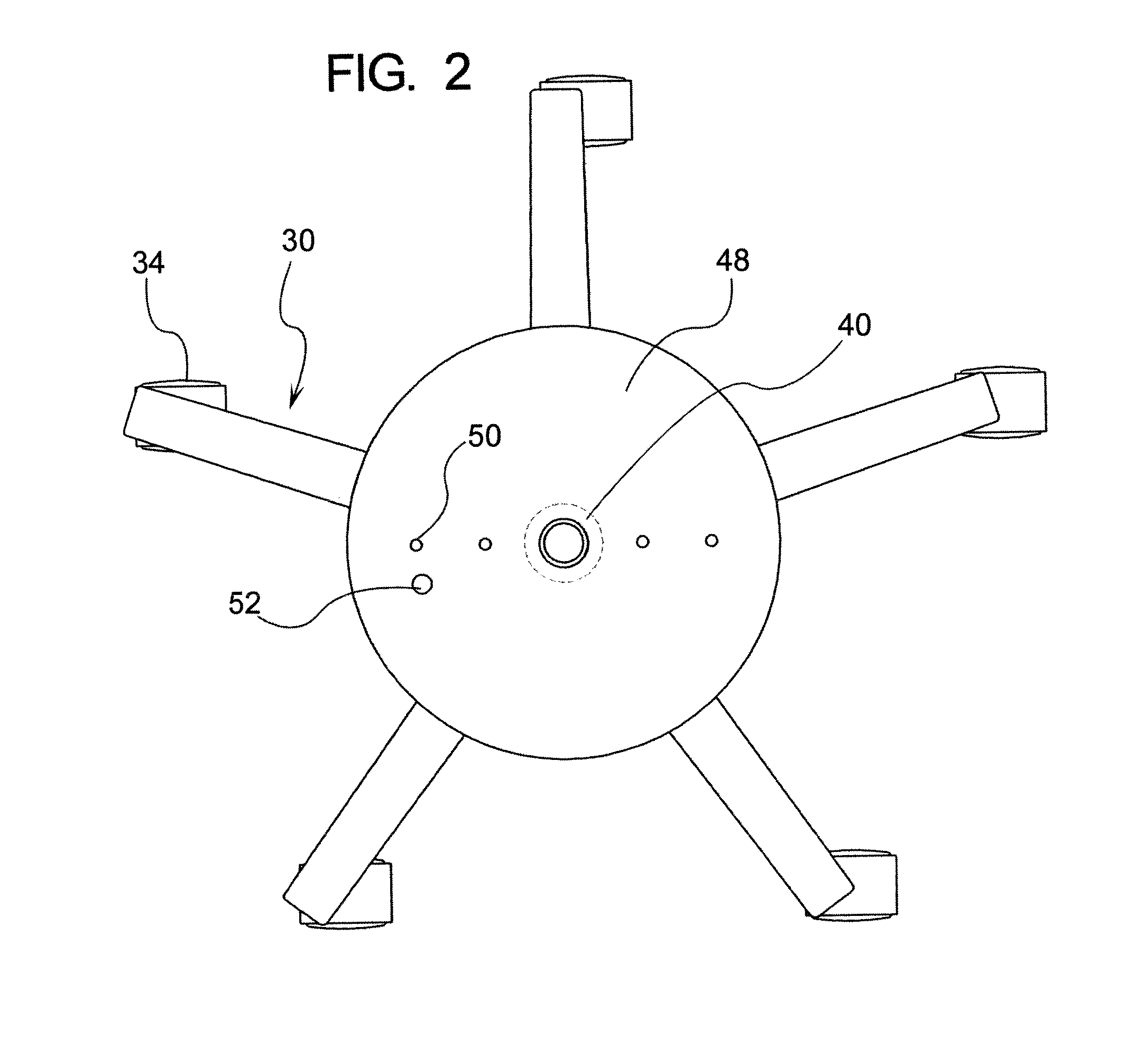

ActiveUS7686396B2Enhance proprioceptionImprove balanceOperating chairsDental chairsImpaired proprioceptionHuman body

A device to actively enhance proprioception and core strength of its user consisting of a motion control system providing a tilt plate that is dampened with a suspension system to provide a system to deliver an exercise regimen that automatically detects and strengthens core muscles in an unobtrusive manner by allowing the individual to move freely while seated. The device can be configured into a chair, stool, wheelchair seat insert, vehicle or airplane seat or exercise device generically known as balance board. The device is intended to enhance the user's proprioception core strength, sense of balance, and overall physical well being.

Owner:EXPECTATIONS

Therapeutic, fitness, and sports enhancement device

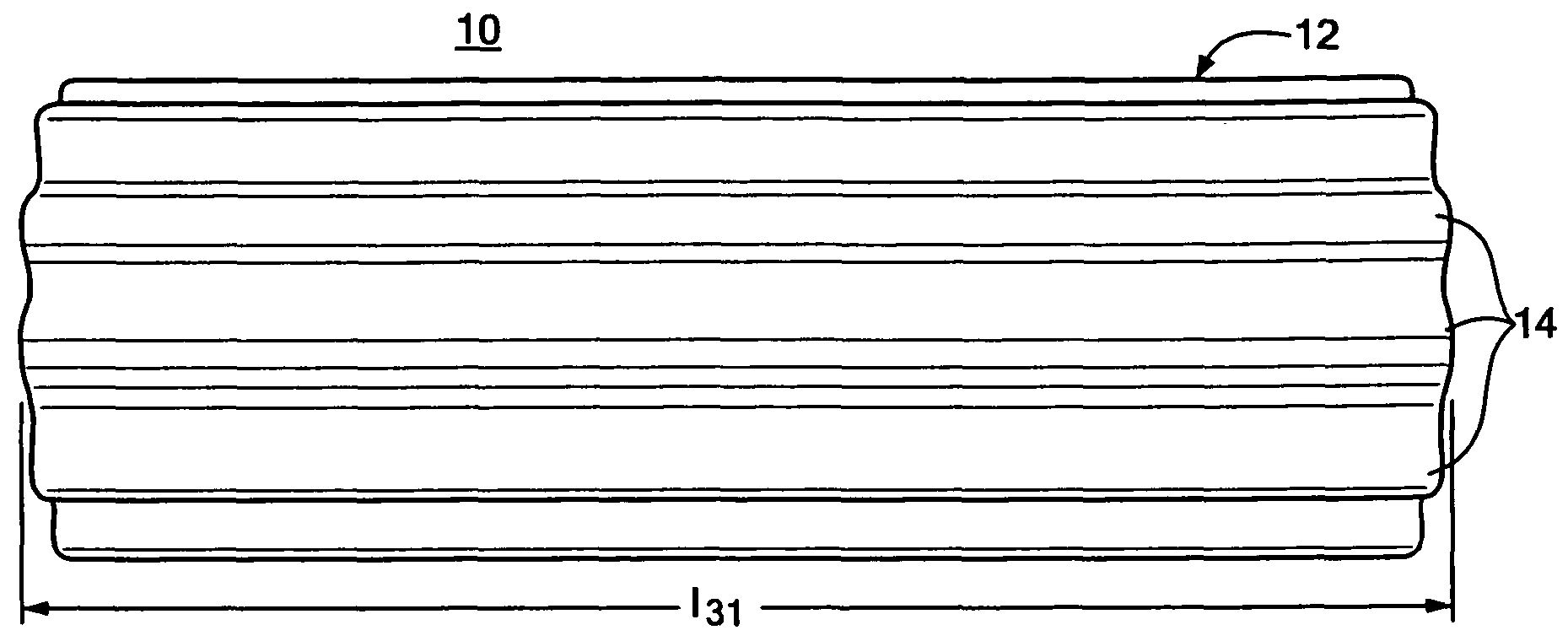

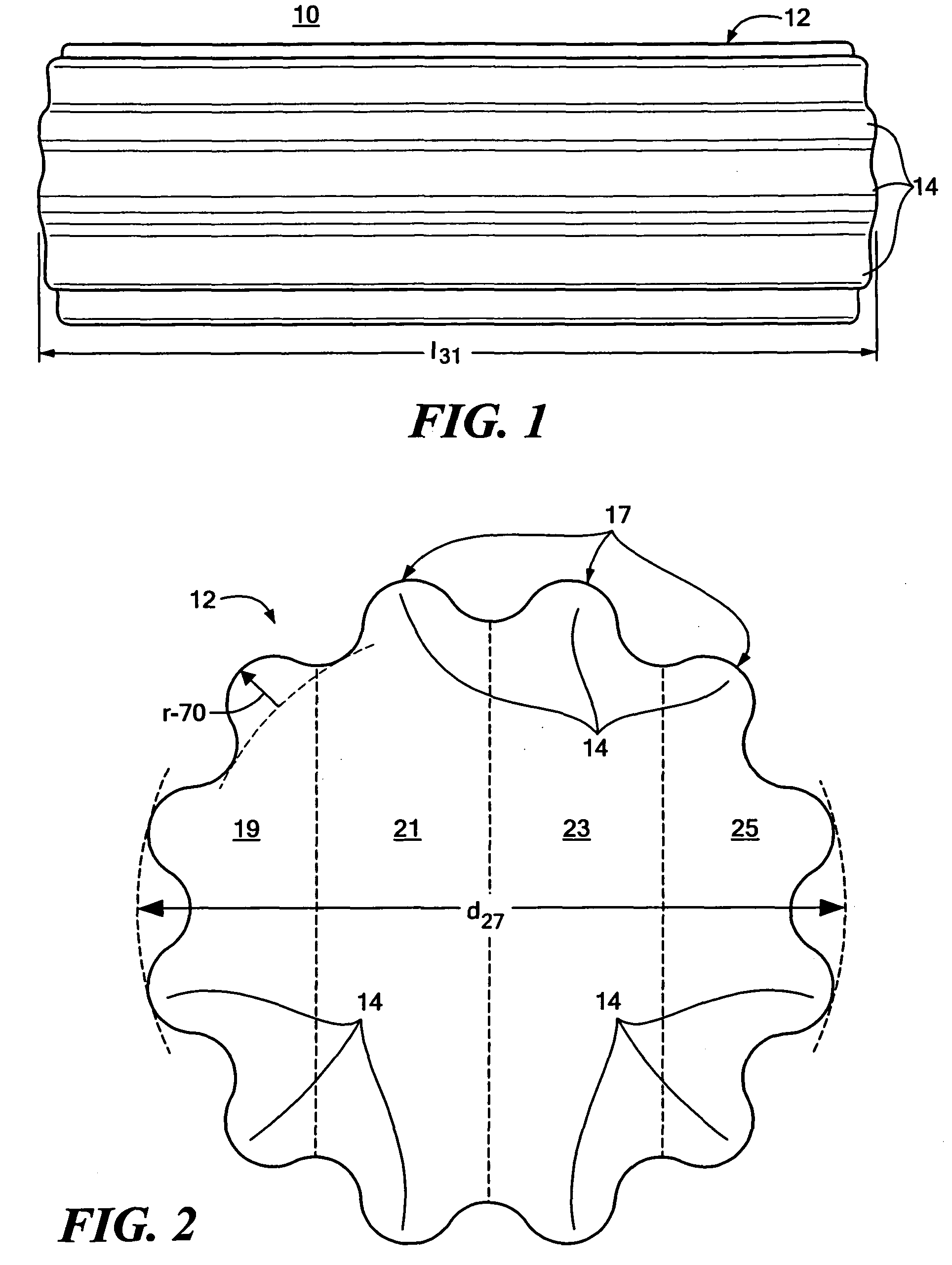

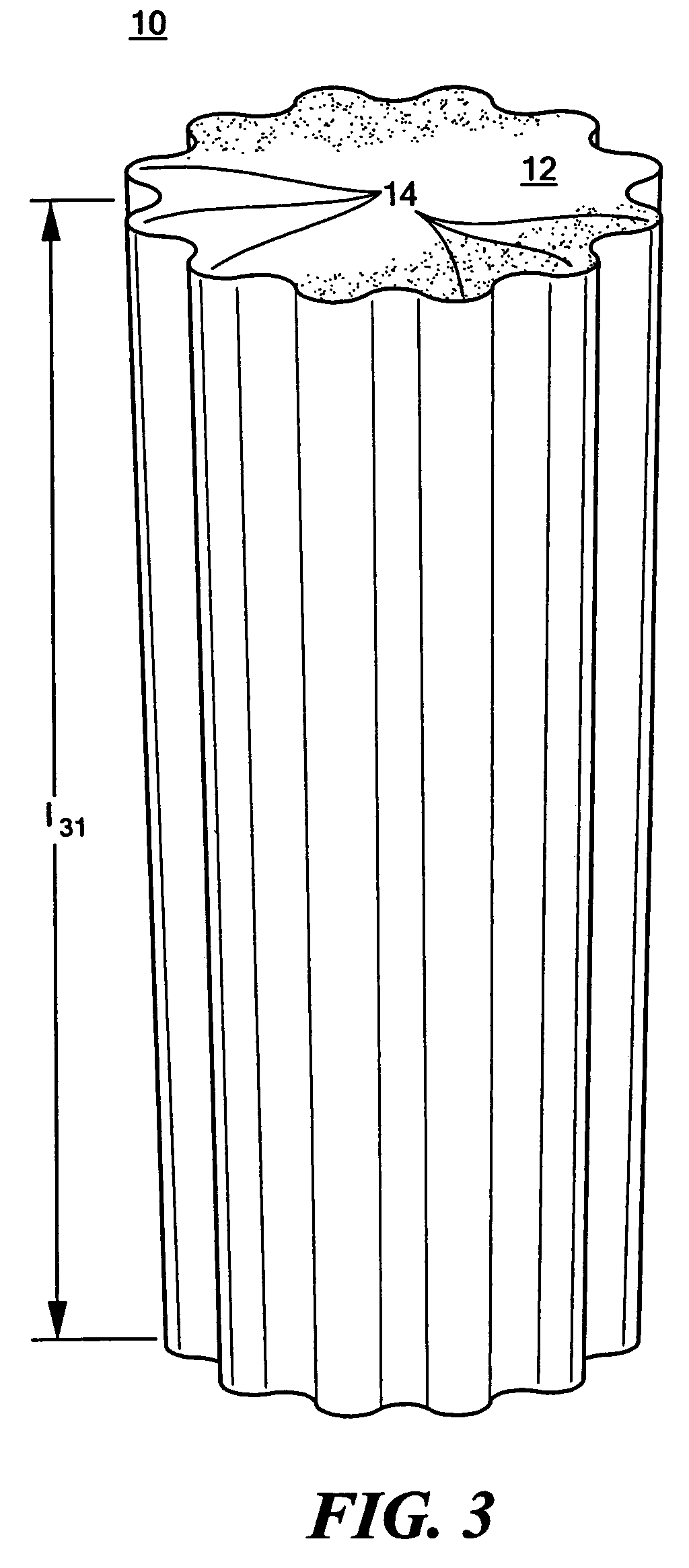

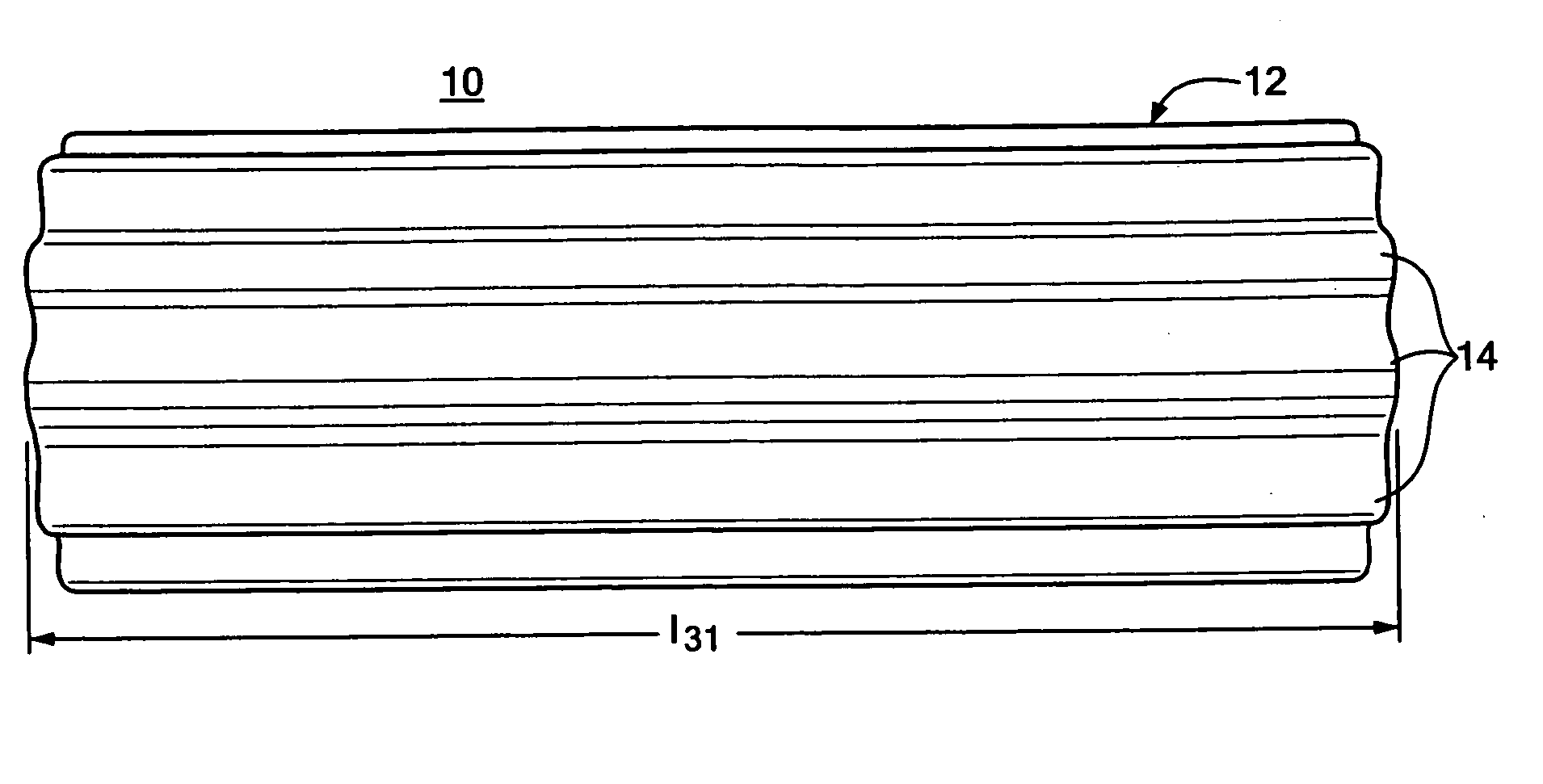

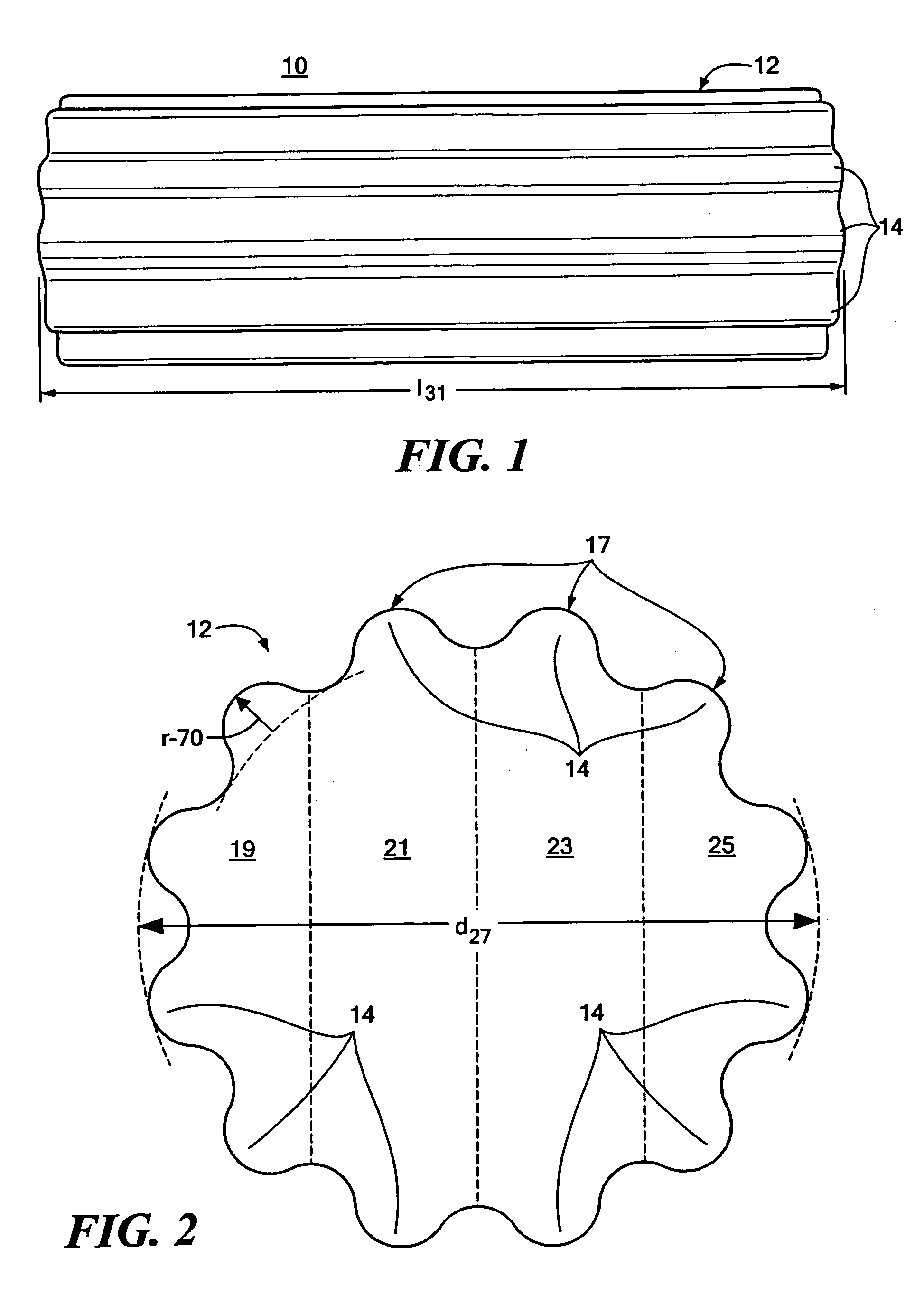

ActiveUS7918774B2Maximize mobilizationEnhance distensibilityCeramic shaping apparatusRoller massageUltimate tensile strengthBiomedical engineering

A therapeutic, fitness, and sports enhancement device including a cylindrically shaped body having a plurality of shaped projections configured to enhance mobilization of soft tissue and optimize body core strength and balance training.

Owner:PERFORMANCE SOLUTIONS

Therapeutic, fitness, and sports enhancement device

ActiveUS20080090707A1Improves balance trainingPromote recoveryCeramic shaping apparatusRoller massageBiomedical engineeringSoft tissue

A therapeutic, fitness, and sports enhancement device including a cylindrically shaped body having a plurality of shaped projections configured to enhance mobilization of soft tissue and optimize body core strength and balance training.

Owner:PERFORMANCE SOLUTIONS

Method and apparatus to enhance proprioception and core health of the human body

ActiveUS20080079301A1Enhance proprioceptionEliminates cause for poor sitting posture related back painOperating chairsDental chairsImpaired proprioceptionHuman body

A device to actively enhance proprioeption and core strength of its user consisting of a motion control system providing a tilt plate that is dampened with a suspension system to provide a system to deliver an exercise regimen that automatically detects and strengthens core muscles in an unobstrusive manner by allowing the individual to move freely while seated And can be configured into a chair, stool, wheelchair seat insert, vehicle or airplane seat as well as into an exercise device generically known as balance board and enhance the user's proprioception core strenght, sense of balance and overall physical well being.

Owner:EXPECTATIONS

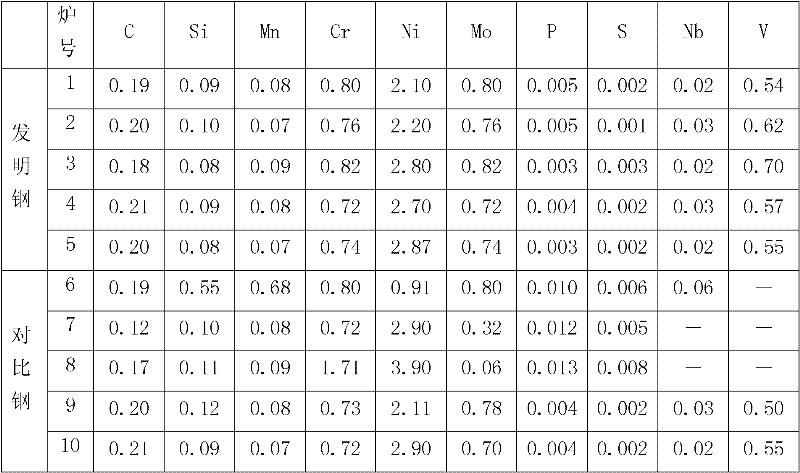

Carburized bearing steel for high-speed railways and preparation method thereof

The invention relates to a carburized bearing steel for high-speed railways and a preparation method thereof, belonging to the technical field of steel for railways. The bearing steel comprises the following chemical elements in percentage by weight: 0.18-0.24% of C, at most 0.10% of Si, at most 0.10% of Mn, at most 0.01% of P, at most 0.005% of S, 0.5-2.0% of Cr, 1.5-4.5% of Ni, 0.3-1.5% of Mo, 0.02-0.10% of Nb, 0.3-0.9% of V, and the balance of Fe and inevitable impurities. The preparation method comprises the following steps: proportioning and controlling the components; carrying out vacuum smelting; carrying out hot working on a steel ingot to obtain a steel product; carrying out surface carburized hardening treatment on the steel product; and carrying out heat treatment on the steel product. The invention satisfies the requirements in the service process of the bearing steel for high-speed trains, and implements good cooperation of high surface hardness and high core strength / toughness.

Owner:CENT IRON & STEEL RES INST

Method for producing wear-resistant composite roller

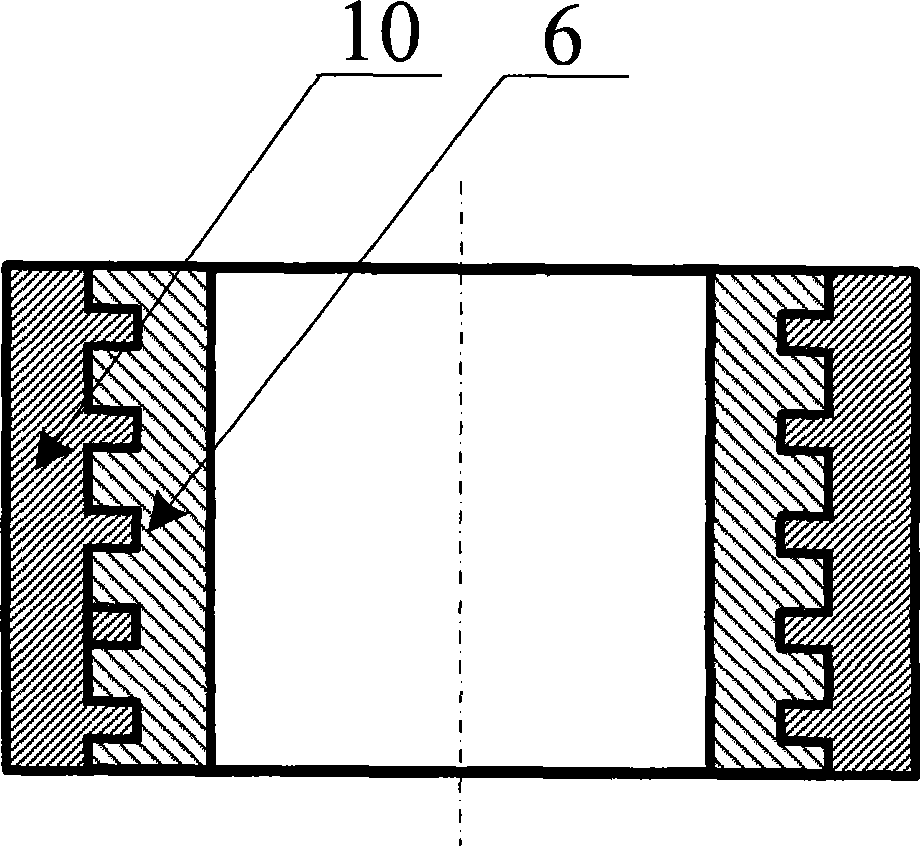

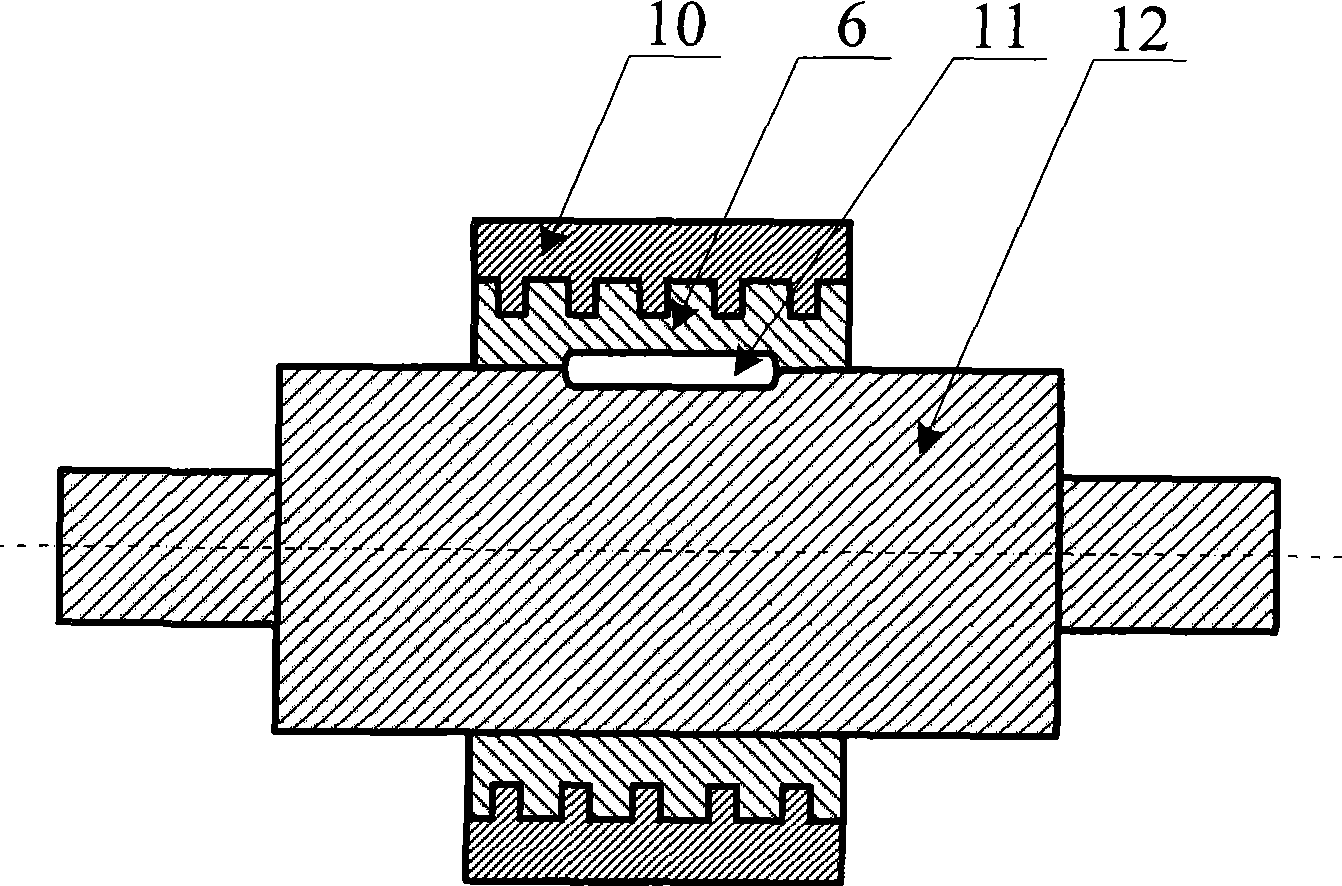

InactiveCN101412105ANo crackingImprove bindingRollsMetal rolling arrangementsInterference fitSurface layer

The invention relates to a method for manufacturing a wear resistant composite roll, which belongs to the technical field of steel rolling. The most difficult problems in the technology transfer of the prior combined composite roll are the improvement on the processability of an outer-layer roll sleeve and the improvement on the processing efficiency. The method comprises the following steps: opening a groove on the outer surface of a roll collar inner sleeve, washing the roll collar inner sleeve by using diluted hydrochloric acid and alcohol, then painting borax on the surface of the roll collar inner sleeve and in the groove, and air-drying the roll collar inner sleeve and placing the roll collar inner sleeve in a casting mould; pouring outer layer wear resistant molten metal through a bottom pouring method to obtain an imbedded composite roll sleeve; and combining the imbedded composite roll sleeve with a cast steel or forged steel rolling shaft through splines and integrating the imbedded composite roll sleeve and the cast steel or forged steel rolling shaft through interference fit so as to obtain the wear resistant composite roll. The composite roll has the advantages of high hardness for the outer surface layer, good wear resistance, high roll core strength, good tenacity, firm combinations between the roll sleeve and the roll core and between the roll sleeve outer surface layer and the roll collar inner sleeve and the like.

Owner:BEIJING UNIV OF TECH

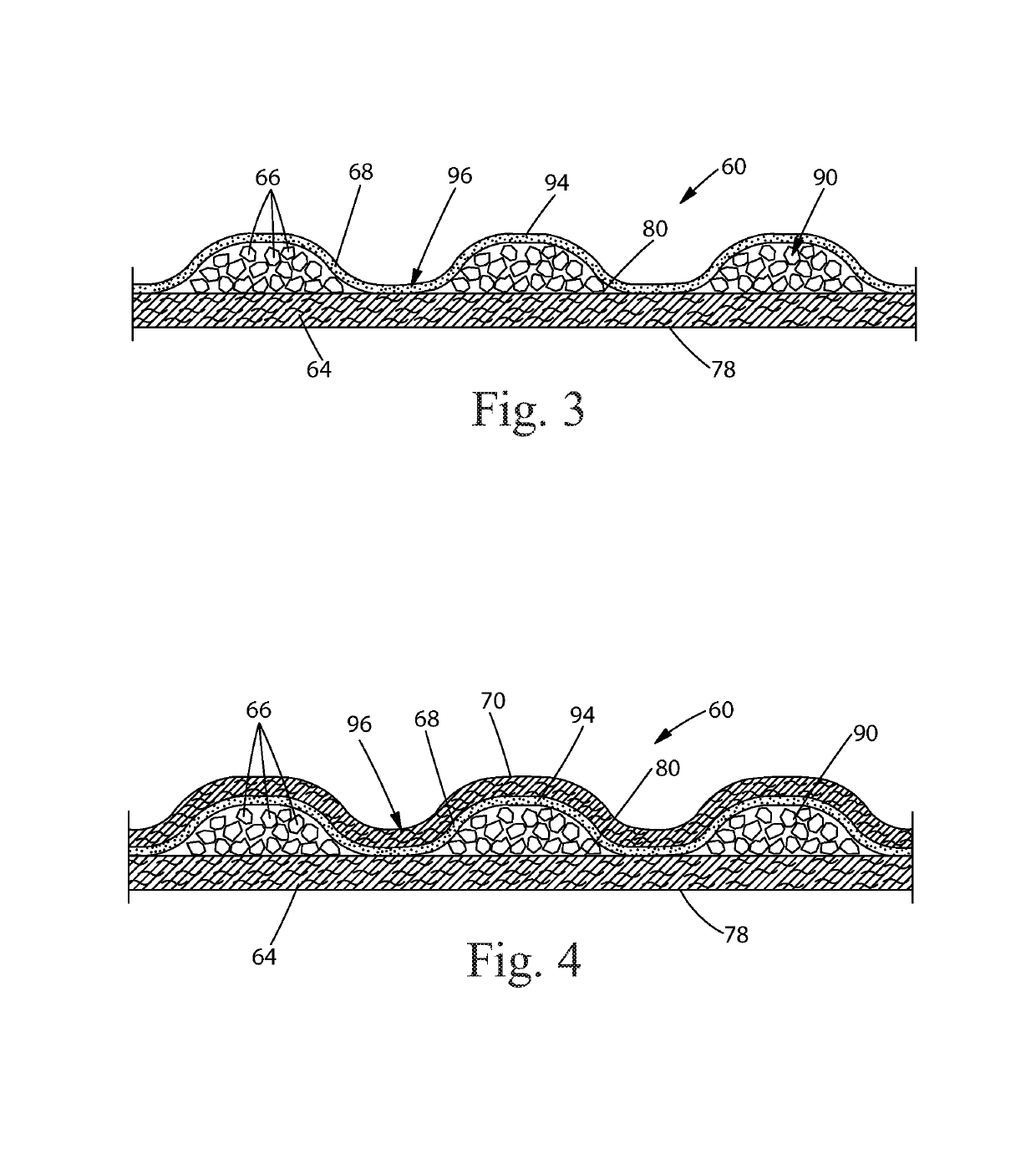

Absorbent articles with improved cores

Absorbent articles and absorbent core structures with improved core strength and stability with long core end seal and channel hang times.

Owner:THE PROCTER & GAMBLE COMPANY

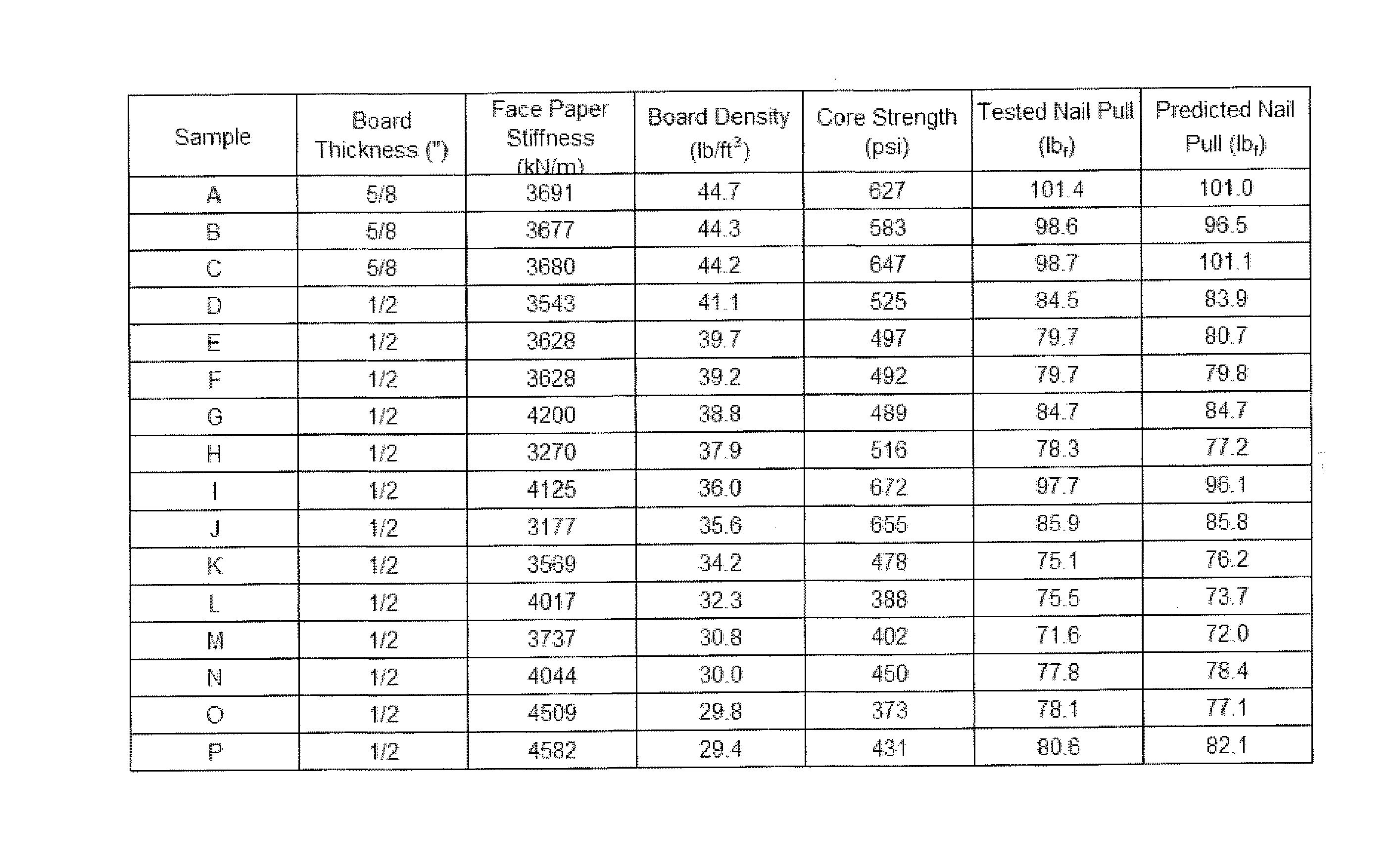

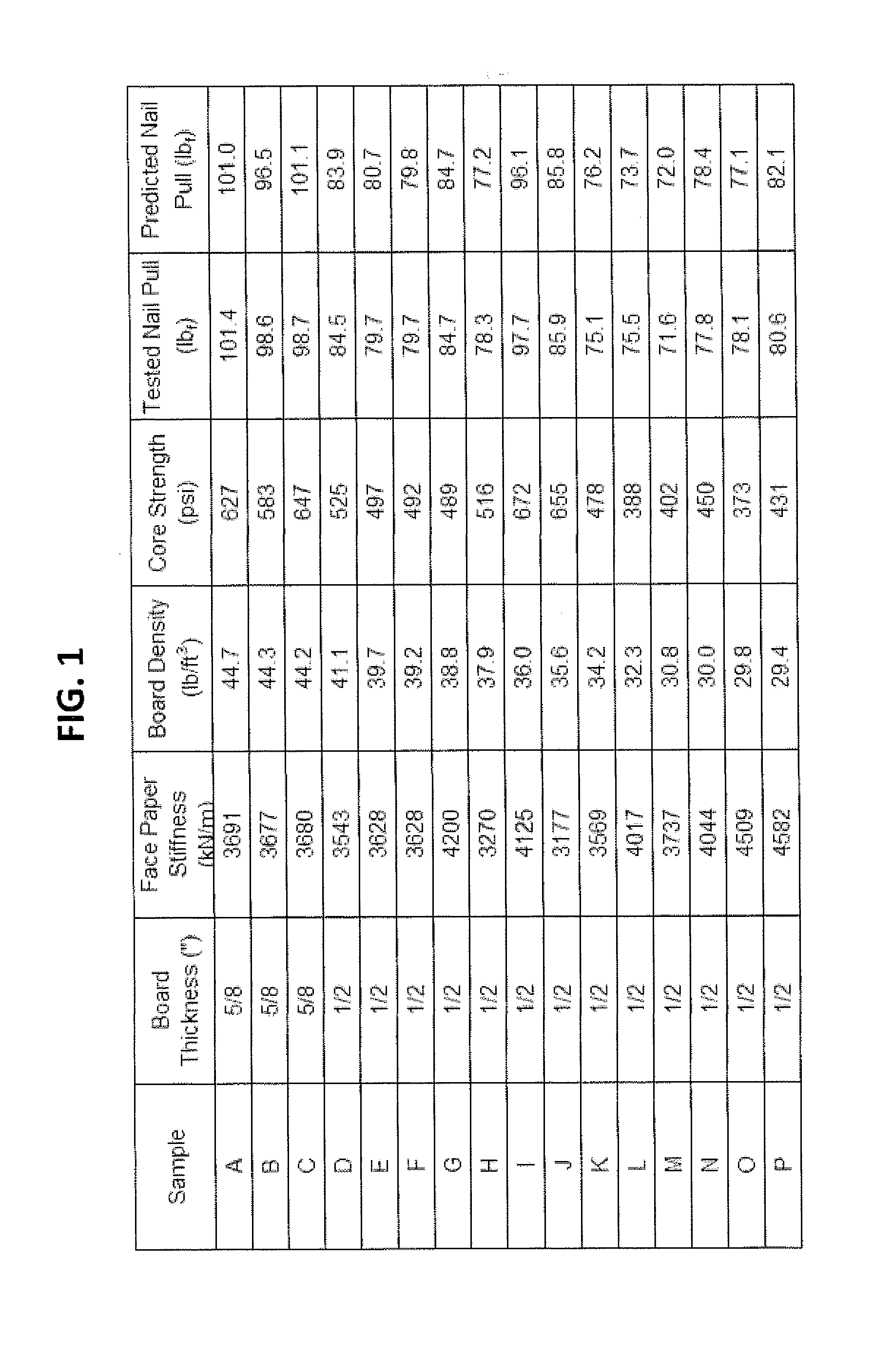

Method for determining structural parameters of composite building panels

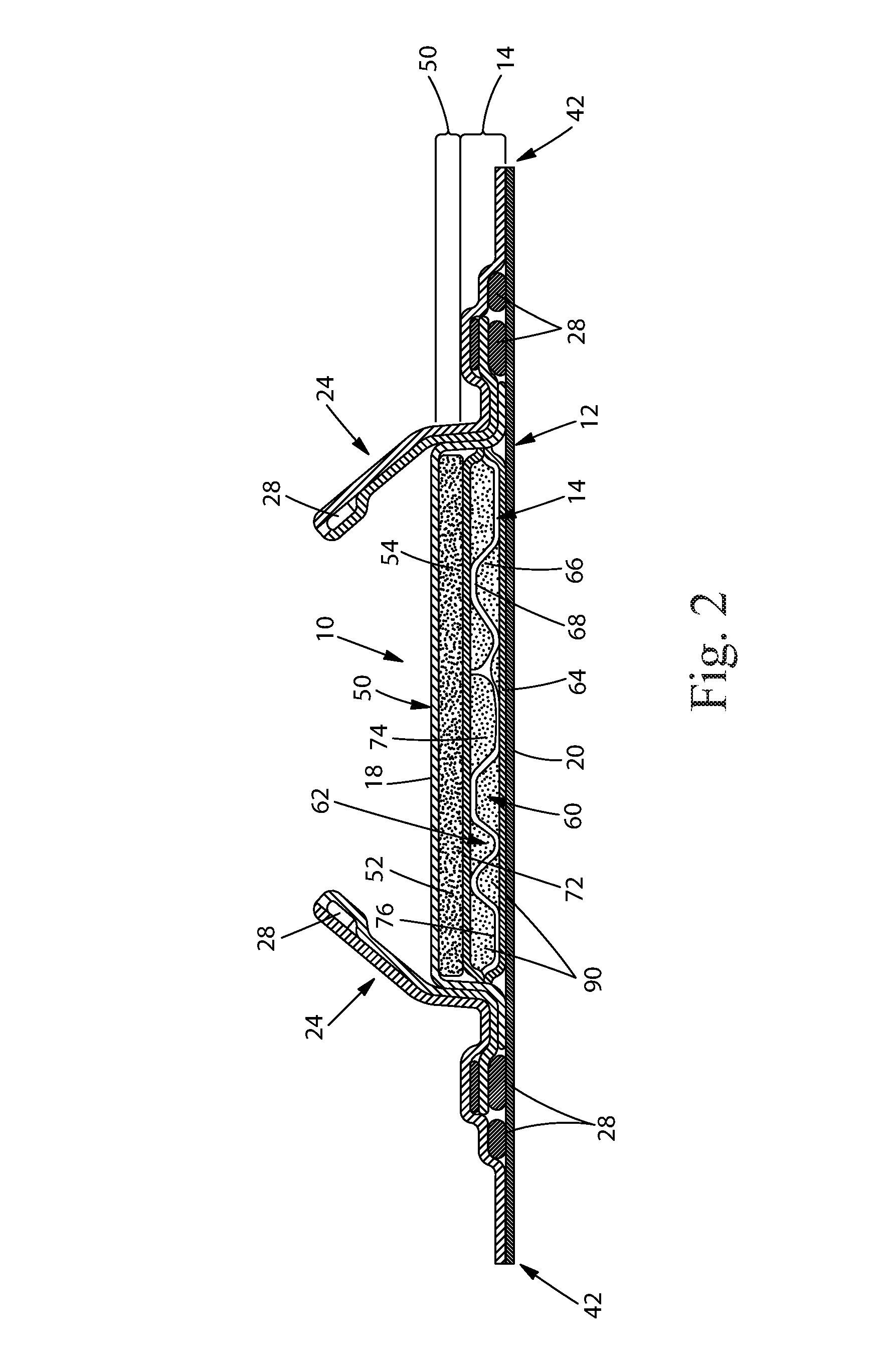

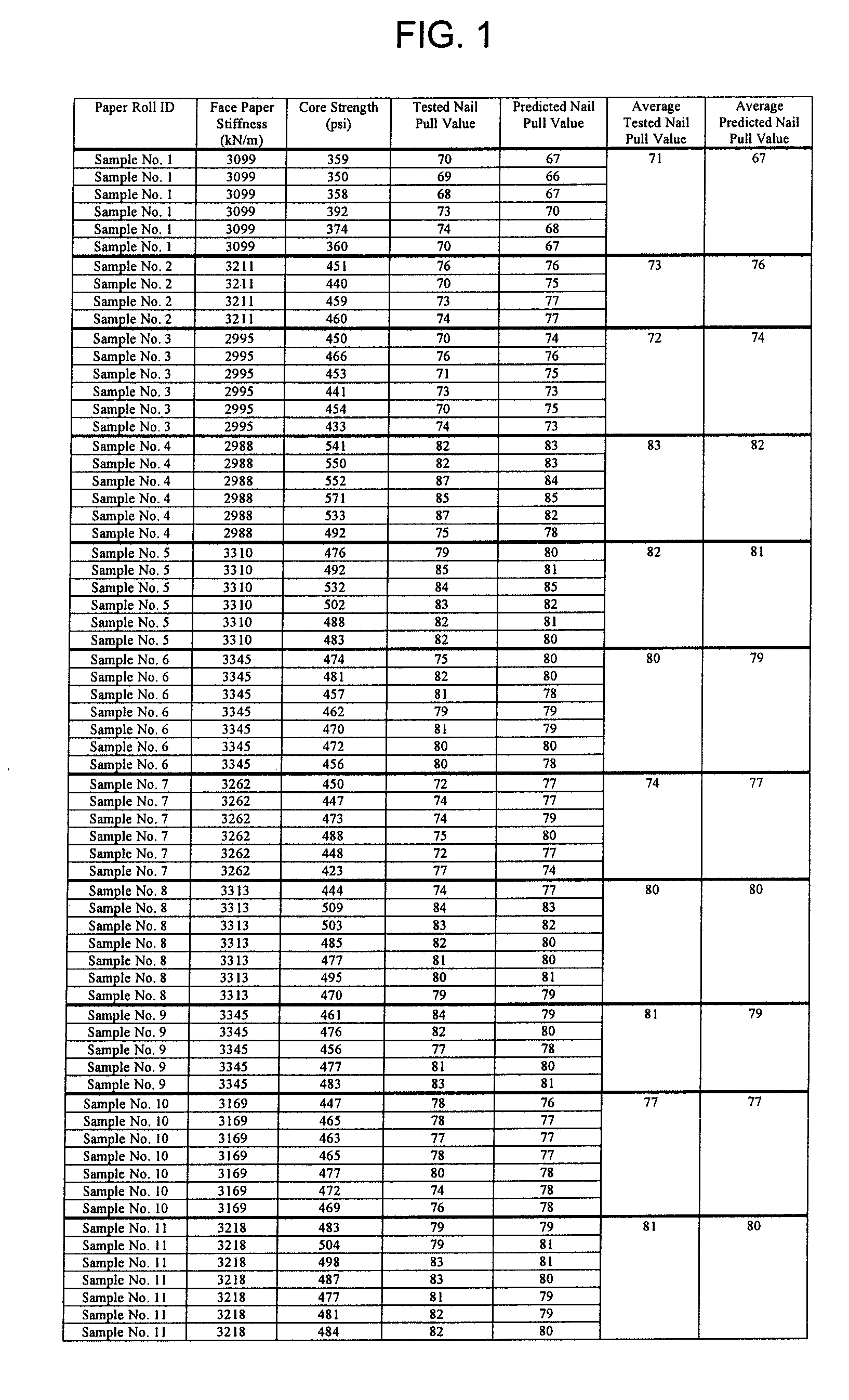

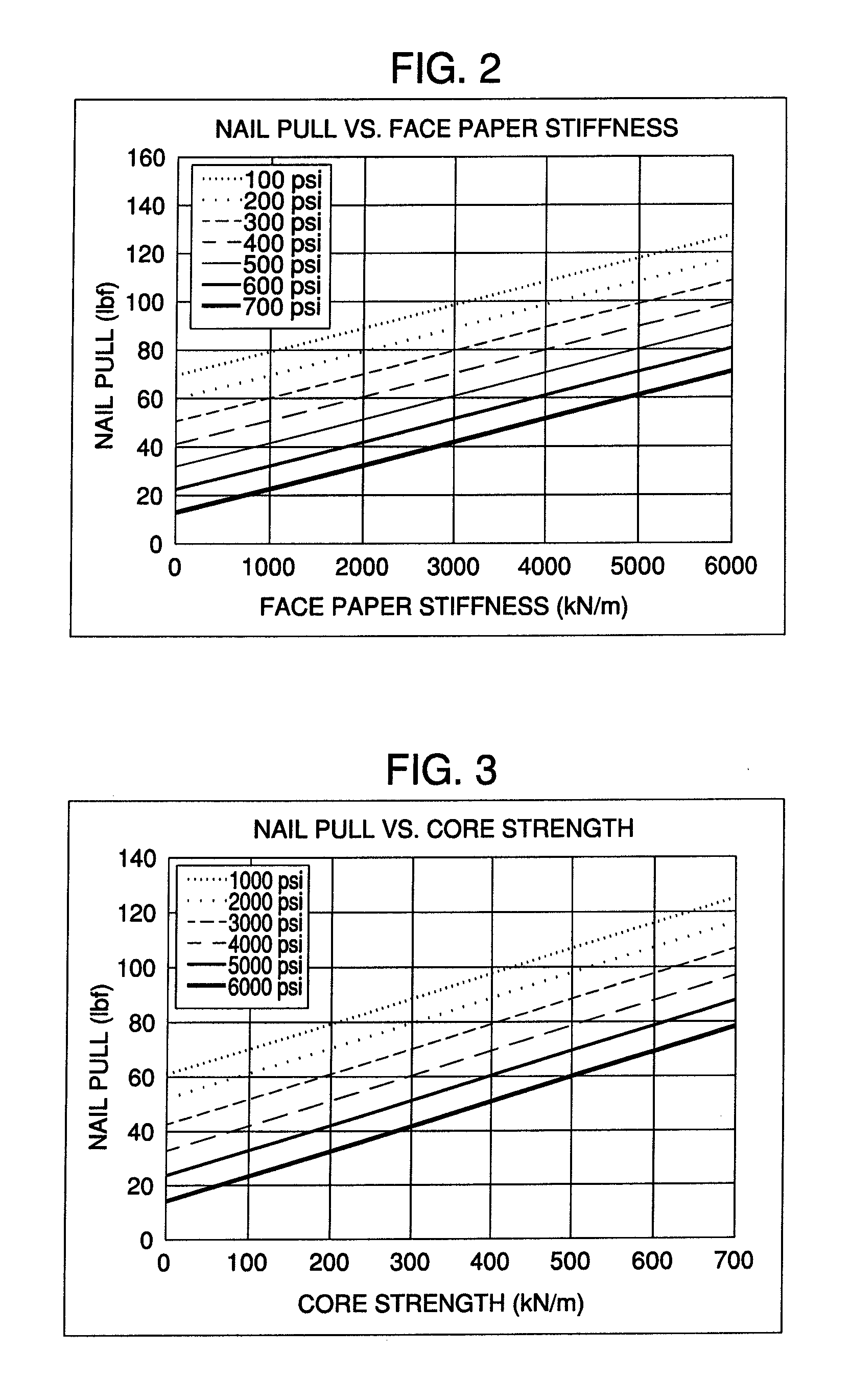

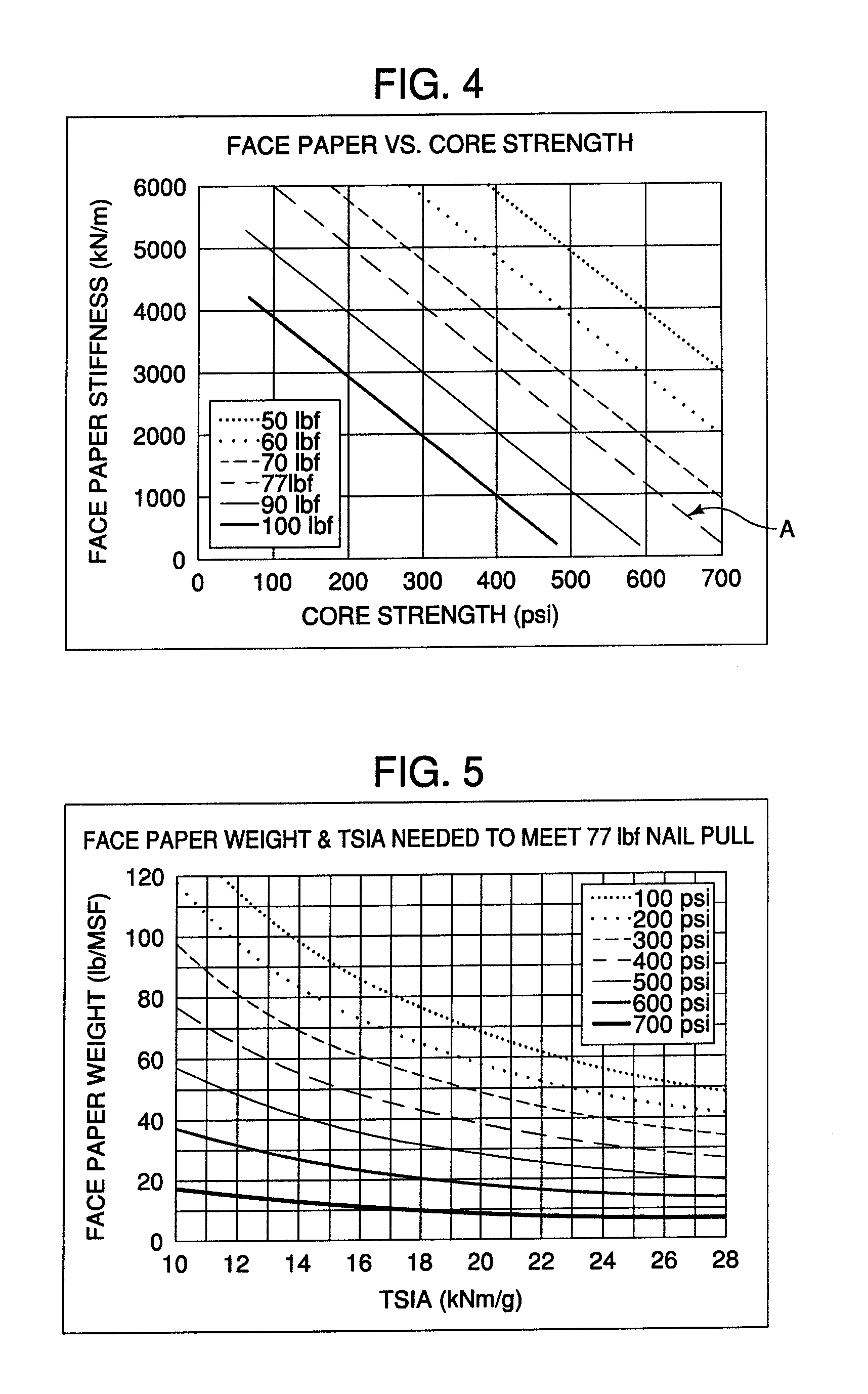

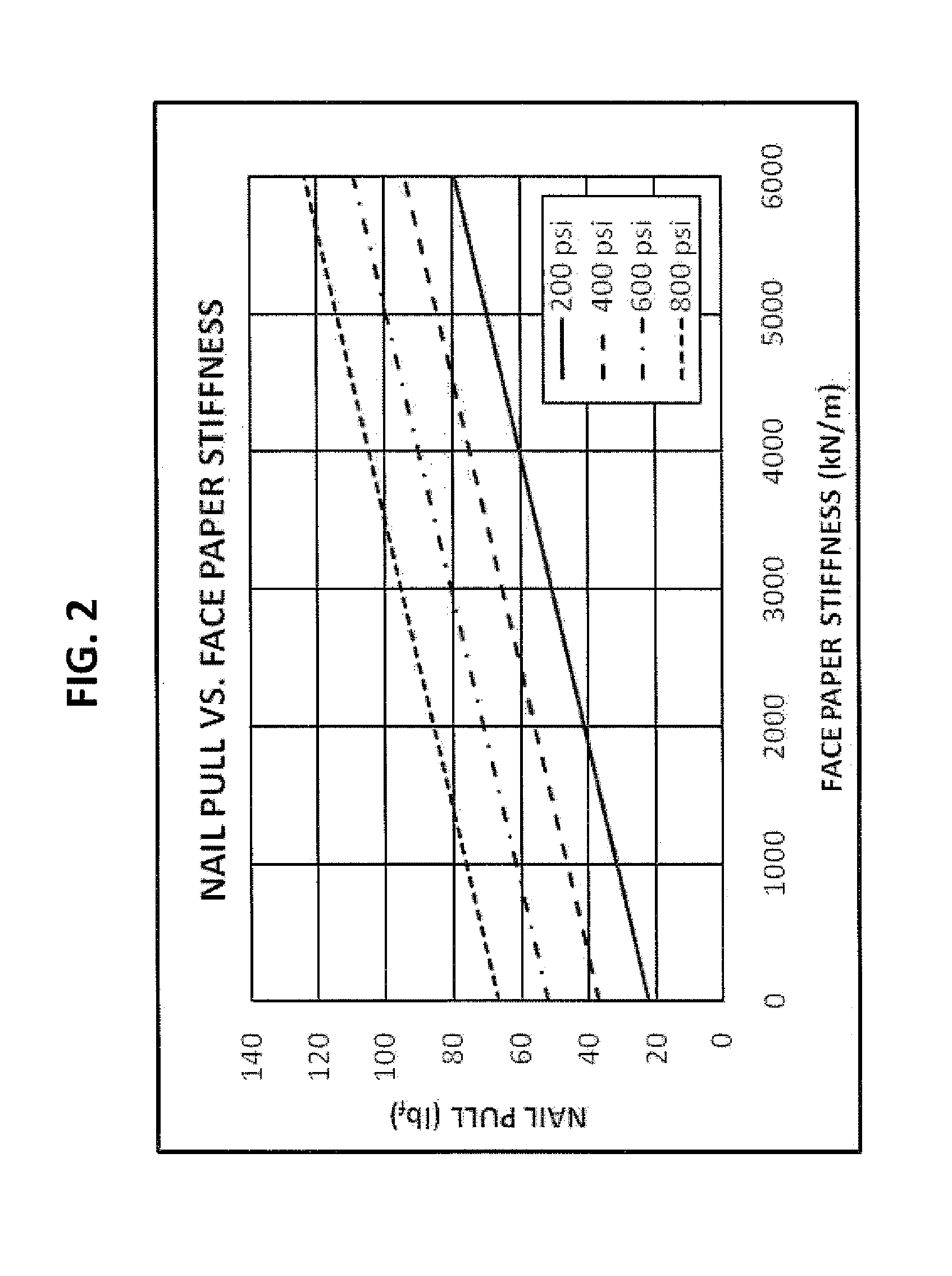

ActiveUS20110046898A1Low costShorten production timeCeilingsCovering/liningsDisplay deviceEngineering

A method of determining face paper properties of wallboard including providing a core strength value of the wallboard, determining a required nail pull value based the wallboard specifications and calculating a face paper stiffness value based on the provided core strength value and the determined nail pull value. The method includes displaying the calculated face paper stiffness value on a display device.

Owner:UNITED STATES GYPSUM CO

Gasoline deep etherification modification method

ActiveCN103509591AIncrease the etherification contentIncrease liquid collectionTreatment with hydrotreatment processesHydrocarbon oils refiningAlcoholHeat resistance

The invention relates to a gasoline deep etherification modification method which comprises the following steps: an olefin-containing raw material and methanol are mixed; and in the presence of a solid strongly-acidic catalyst under the olefin etherification reaction condition of 95 DEG C above, secondary carbon olefin and tertiary carbon olefin in the gasoline and methanol are subjected to etherification reaction to obtain etherified gasoline, wherein the solid strongly-acidic catalyst is a high-temperature-resistant strongly-acidic catalyst, of which the heat resistance temperature is 125-250 DEG C and the acid core strength is greater than H0=-8.According to the method provided by the invention, the tertiary carbon olefin participates in the etherification reaction, and the secondary carbon olefin also participates in the etherification reaction, thereby greatly enhancing the etherified substance content in the gasoline, lowering the olefin content, enhancing the octane number, indirectly adding more cheap alcohols into the gasoline in a mode of etherified substances, increasing the liquid yield of the gasoline and lowering the gasoline cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

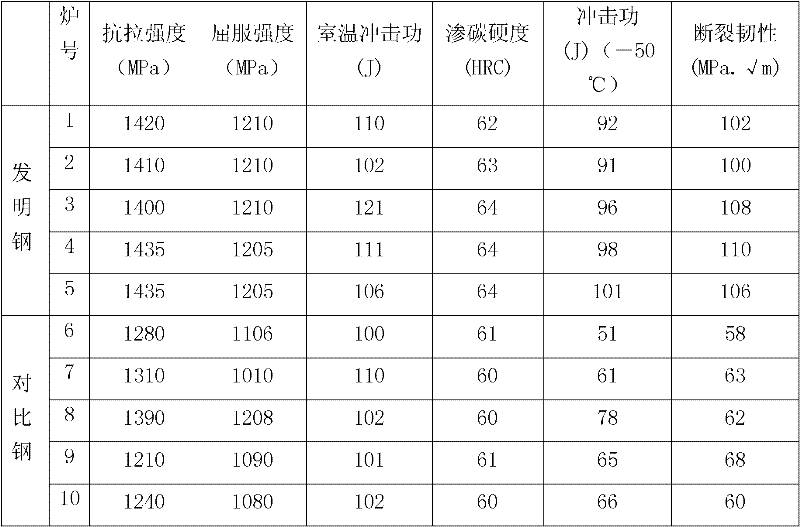

Method for compositely centrifugal pouring high chromium centrifugal composite cast iron roll with alloy semisteel intermediate layer

The invention relates to a composite cast iron roll technology field, in particular to a method for using alloy semi-steel middle transition layer composite centrifugation to cast high chromium double composite cast iron roll, which includes the following process steps: respectively melting the steel water in the transition layer of the alloy semi-steel, external high chromium casting iron melting and core ball graphite casting iron melting; conducting modification treatment to the steel water in the transition layer in the middle of the alloy semi-steel and the steel water of the external high chromium casting iron and conducting spheroidization and inoculation treatment to the core ball graphite casting iron steel water, and adopting the centrifugation casting method to cast high chromium casting steel and the steel water in the transition layer of the alloy semi-steel; preparing fixture and mould closing; casting core ball graphite casting steel water with static casting method; cooling and opening box, conducting heat treatment and processing inspection. The component weight percentage of the steel water in the middle transition layer of the alloy semi-steel is: C 1.4 to 2.6, Si 1.0 to 2.0, Mn 0.5 to 1.5, P being less than 1.0, S being less than 0.03, Cr 3 to 8, Ni 0.5 to 1.5 and Mo 0.5 to 1.5. The structure layer and the core strength of the roll are respectively over 320MPa and 400MPa, thus the performance being very safe and reliable.

Owner:ANSTEEL HEAVY MACHINERY CO LTD

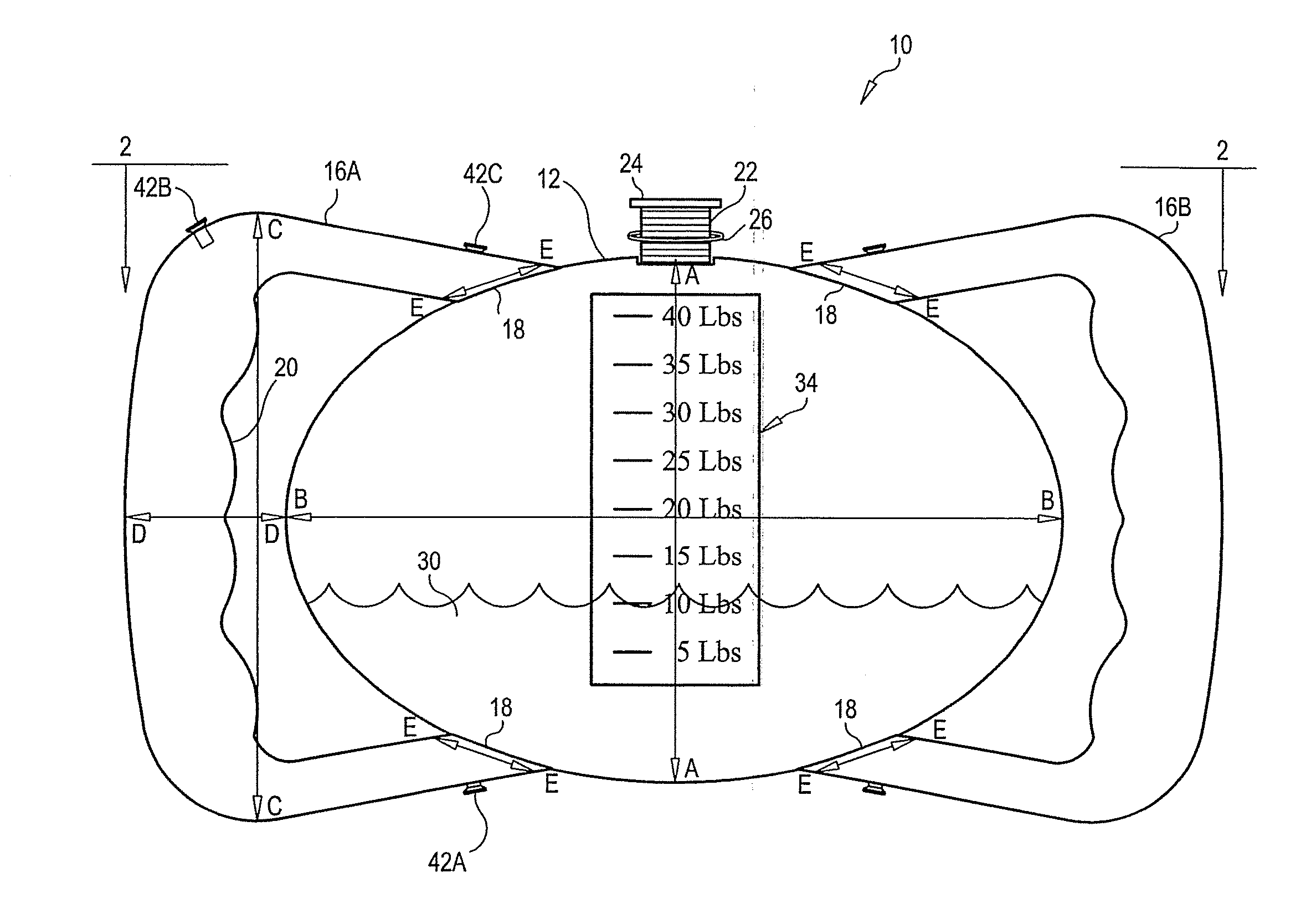

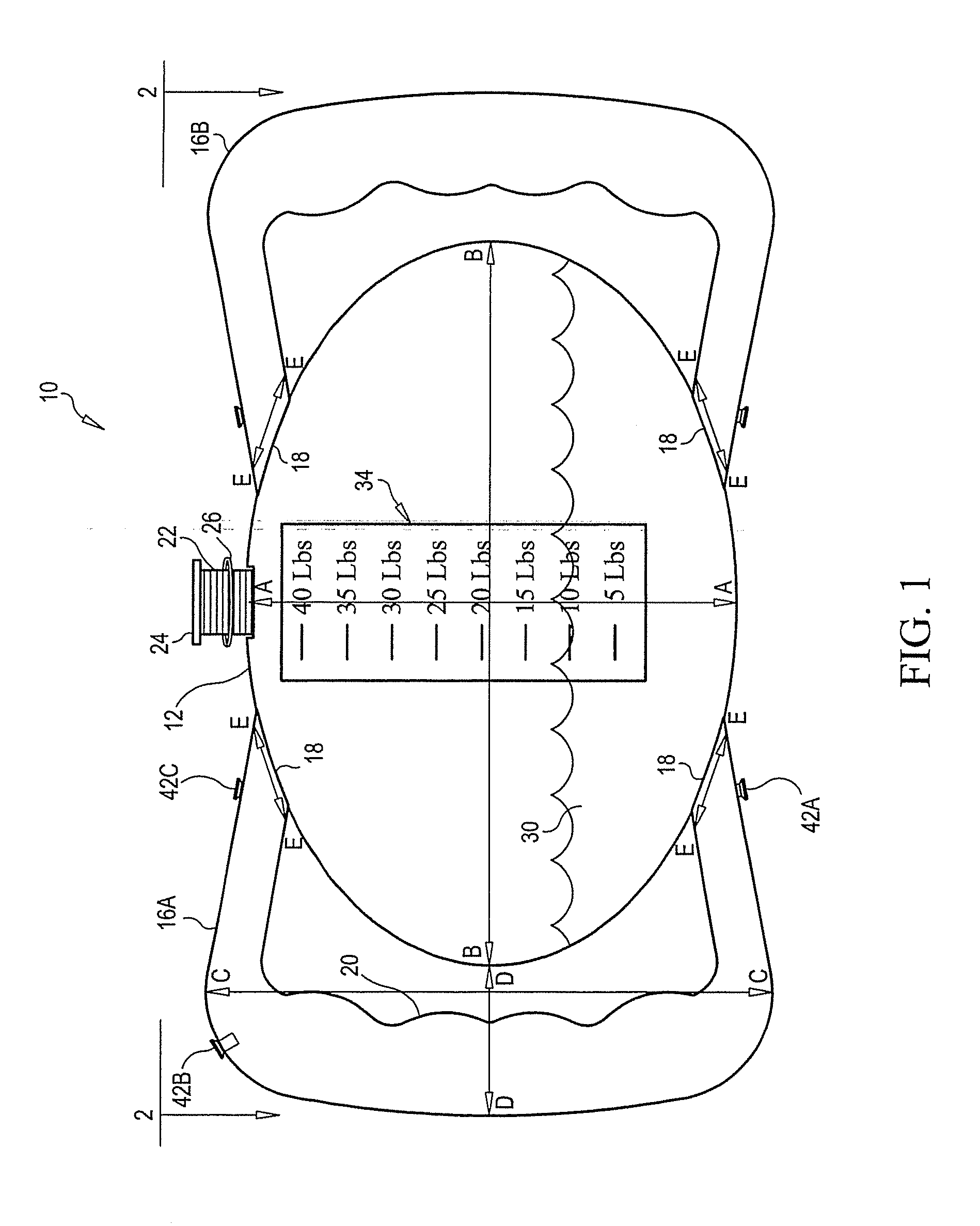

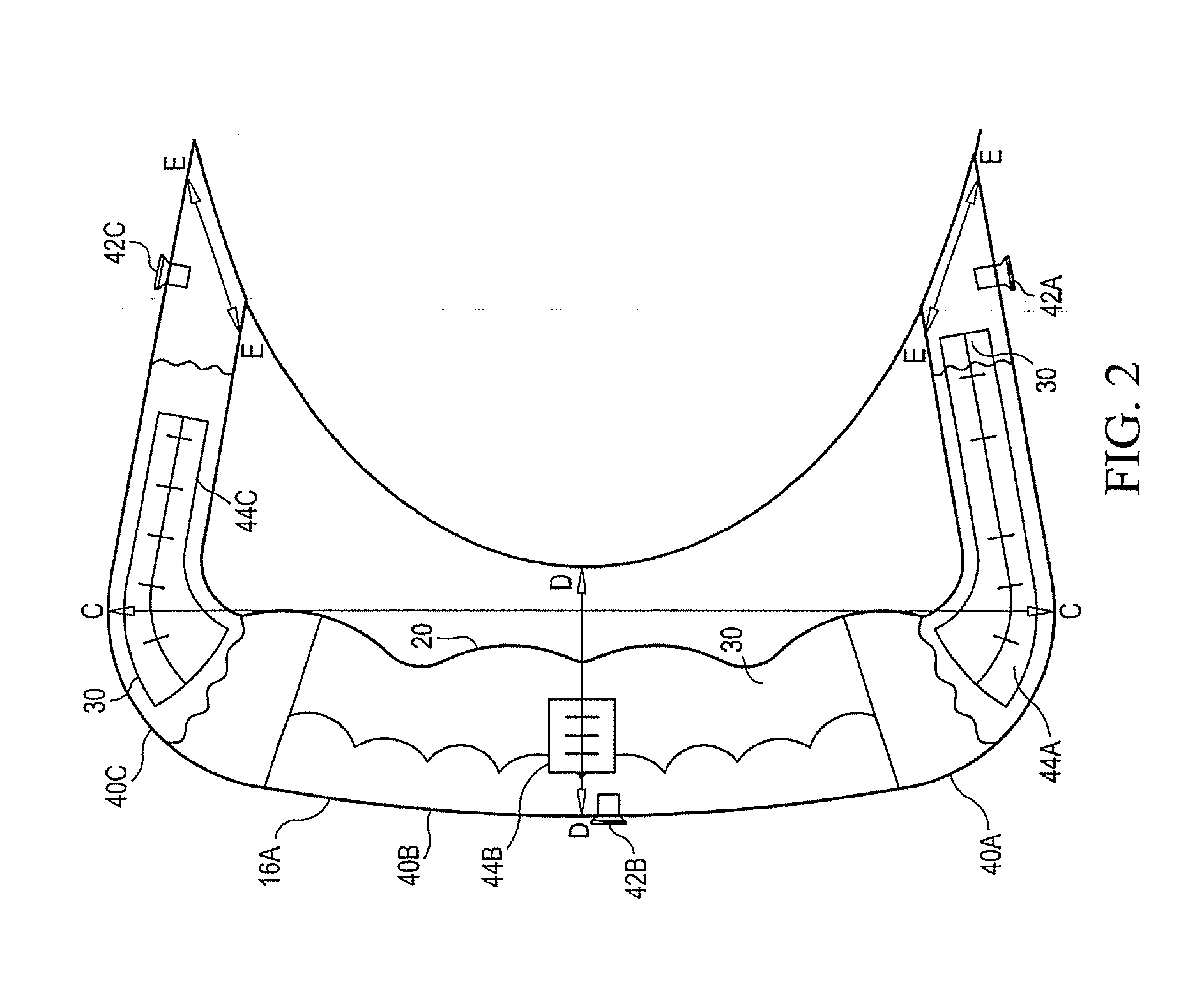

Functional training device

A versatile, functional training device of substantially elliptical shape and comprising a fluid weight that employs principles of unstable resistance as a means of increasing balance, stability, overall strength, core strength and proprioception while increasing lean muscle mass and burning calories. During operation, a user moves the device through a regimen of individualized movements, and the fluid weight moves and shifts inside the device, creating a instability at a point of resistance. The device comprises D-shaped handles with finger grooves adapted for maneuverability. The handles also may be filled with fluid to increase the weight and adaptability of the device across multiple activities and physical regimens. Measuring scales are provided on the device to measure the amount of fluid added to or removed from the device. The device may be transparent or translucent, and the fluid weight may be tinted to aid in visibility.

Owner:MOBIUS ENTERPRISES

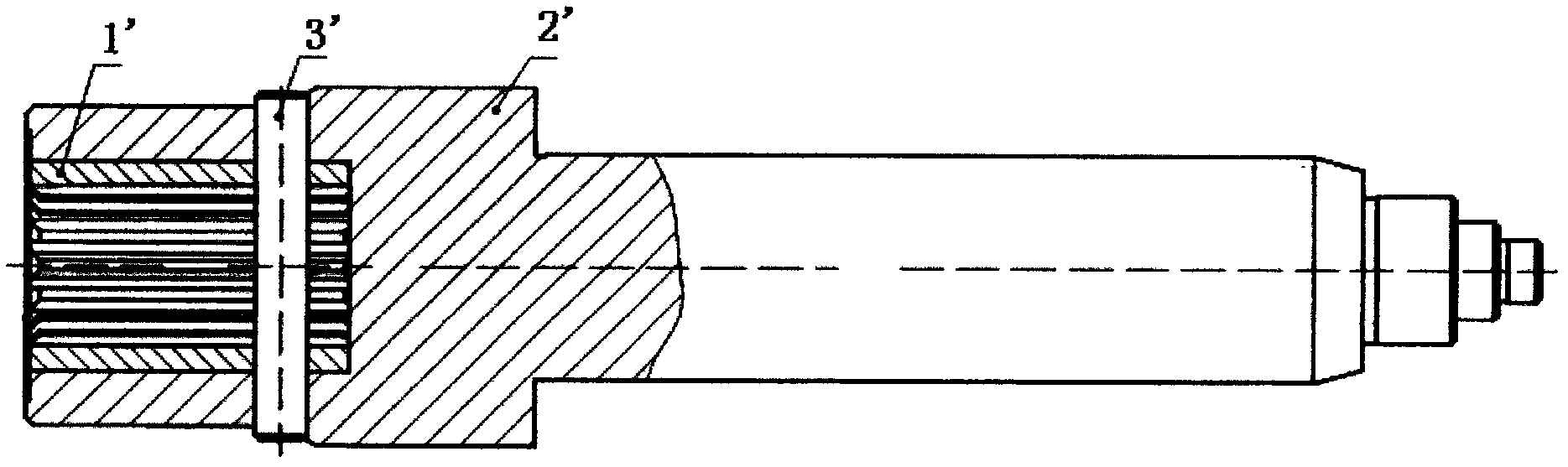

High-precision rectangular spline shaft manufacturing process

The invention relates to the technical field of spline shafts, in particular to a high-precision rectangular spline shaft manufacturing process. According to the high-precision spline shaft manufacturing process, first, materials are selected, namely, 40Cr materials (selected according to the requirement) are adopted; second, rough turning machining is conducted on the spline workblank; third, thermal refining is conducted, wherein the rigidity HB is 250-280, and spline shaft core strength is improved; fourth, digital controlled lathe semi-finish turning is conducted, wherein a reserved bearing block margin is 0.3-0.5mm; fifth, spline rolling is conducted, namely, a spline milling machine for a grinding hob is used for machining the spline width and the bottom diameter, the margin of 0.3-0.4mm is reserved; sixth, quenching (heating processing) is conducted, namely, high-frequency quenching is adopted at the spline position, the rigidity HR is 48-53, and the rigidity of the spline position is improved; seventh, external diameter grinding of a cylindrical grinding machine is conducted (drawing technical requirements are met as needed); eighth, spline grinding is conducted, namely, a molding gear grinding machine is adopted, and a grinding wheel is corrected; ninth, the spline size is detected. The high-precision rectangular spline shaft manufacturing process improves the precision of the spline shaft, and improves working efficiency.

Owner:常州市格里森前进齿轮有限公司

Precoated sand used for sand prevention for intermediate and low temperate oil deposit and preparation method thereof

InactiveCN102660246ASimple preparation processReduce dosageDrilling compositionEpoxyAging resistance

The invention relates to precoated sand used for sand prevention for intermediate and low temperate oil deposit and a preparation method thereof. The preparation method comprises the following steps of: 1)evenly mixing 40-50 parts of epoxy resin and 12-25 parts of solvent to prepare solution; 2) adding 2-4 parts of ketamine curing agent into the solution to be evenly mixed; 3) evenly mixing 1.6-2.2 parts of coupling agent and 1000 parts of quartz sand; 4) adding the solution into the quartz sand to be evenly mixed; and 5) dispersing pre-packaged sand, rolling to scatter the sand to be packaged after the sand to be packaged is thoroughly dried, and bagging to be packaged in a sealing mode. The precoated sand prepared with the preparation method disclosed by the invention has the advantages of small use amount of required sand consolidation agent and low medicament cost, and the volatile polyamine curing agent with pungent smell is modified into latent curing agent which is free from peculiar smell and is easy to store. The precoated sand has a simple preparation technology, can be used without being prepared, can be stored for a long time in the dry place, has the advantages of good temperature resistance, ageing resistance and corrosion resistance, high solidified sand core strength and good permeability.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

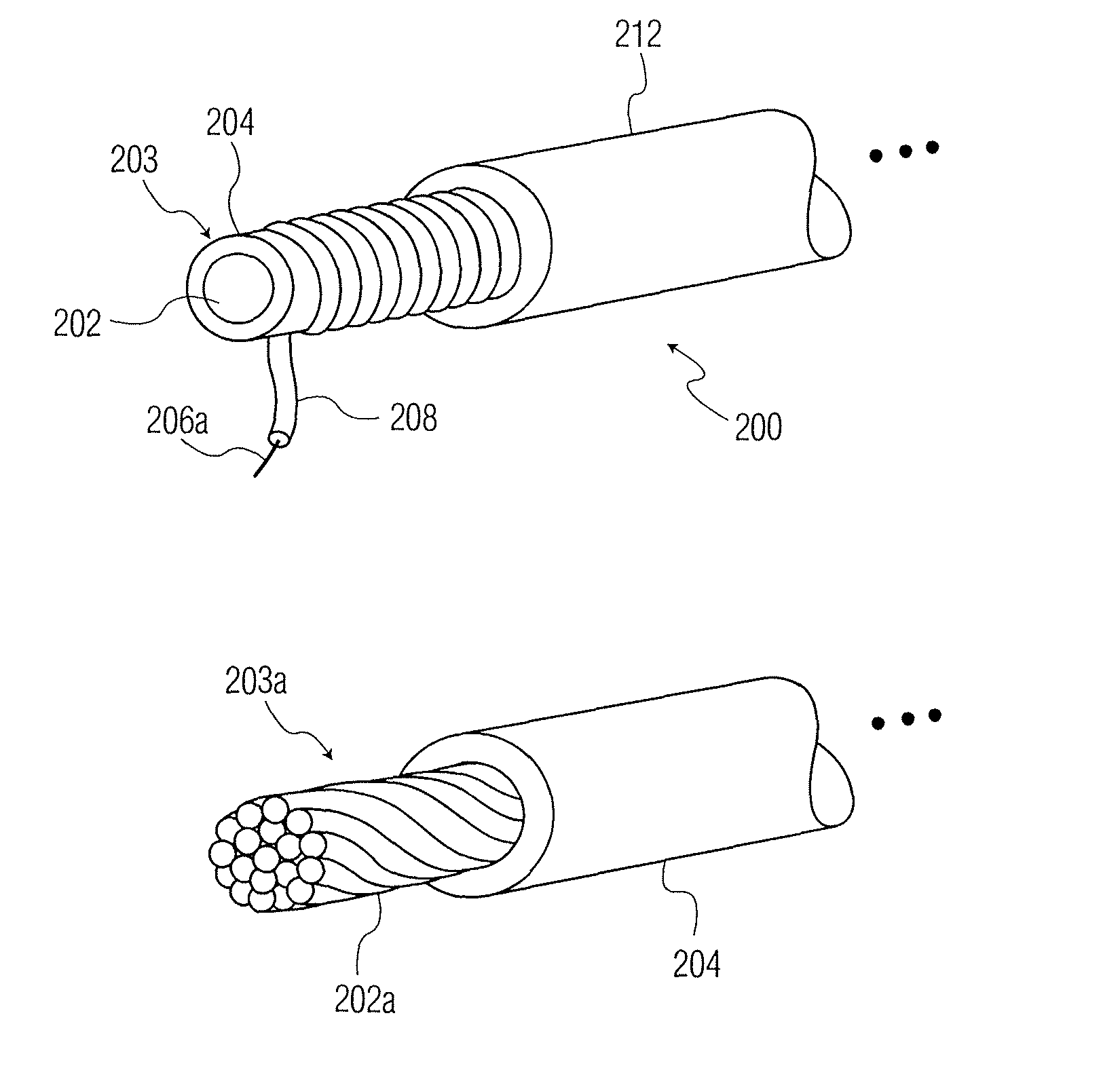

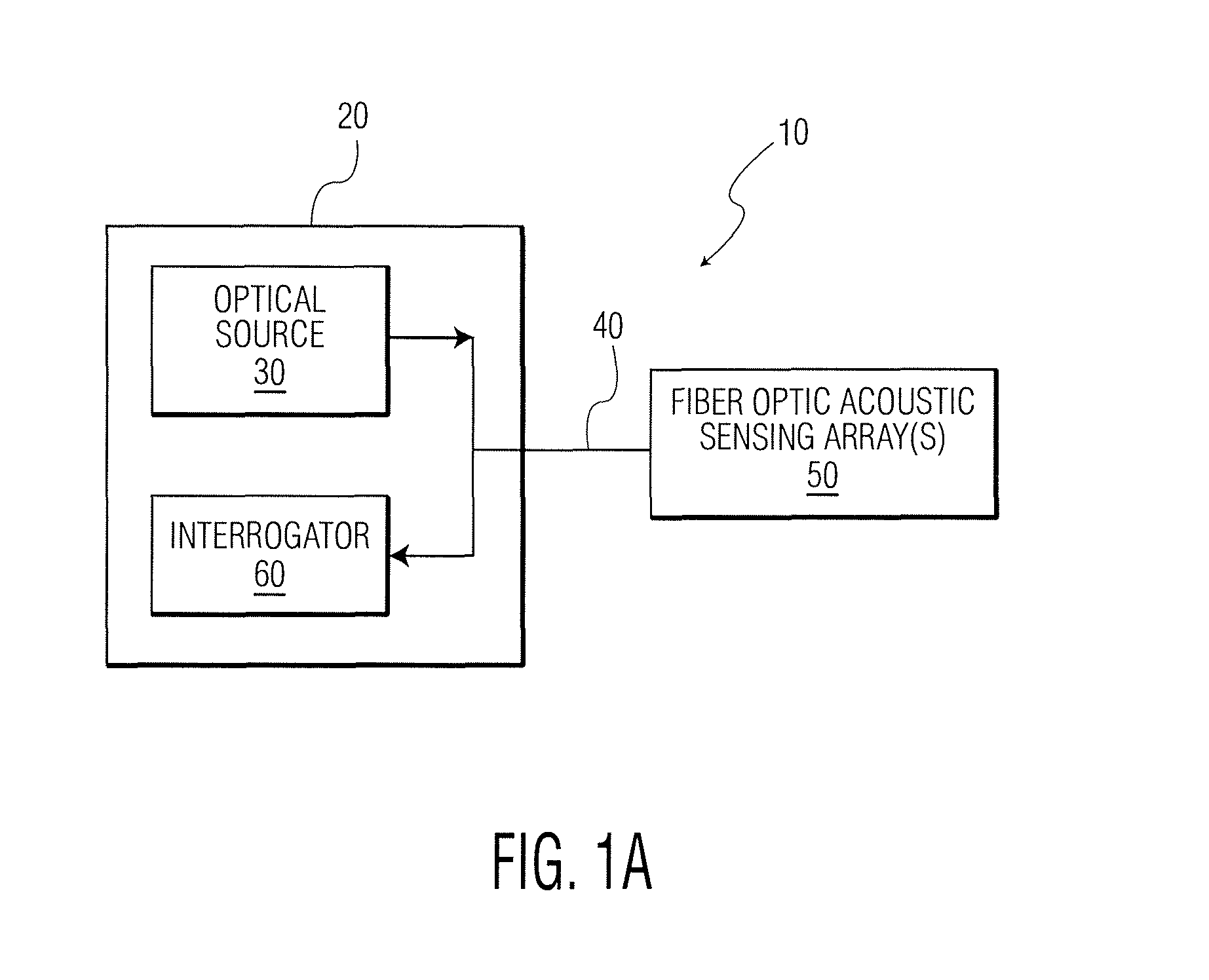

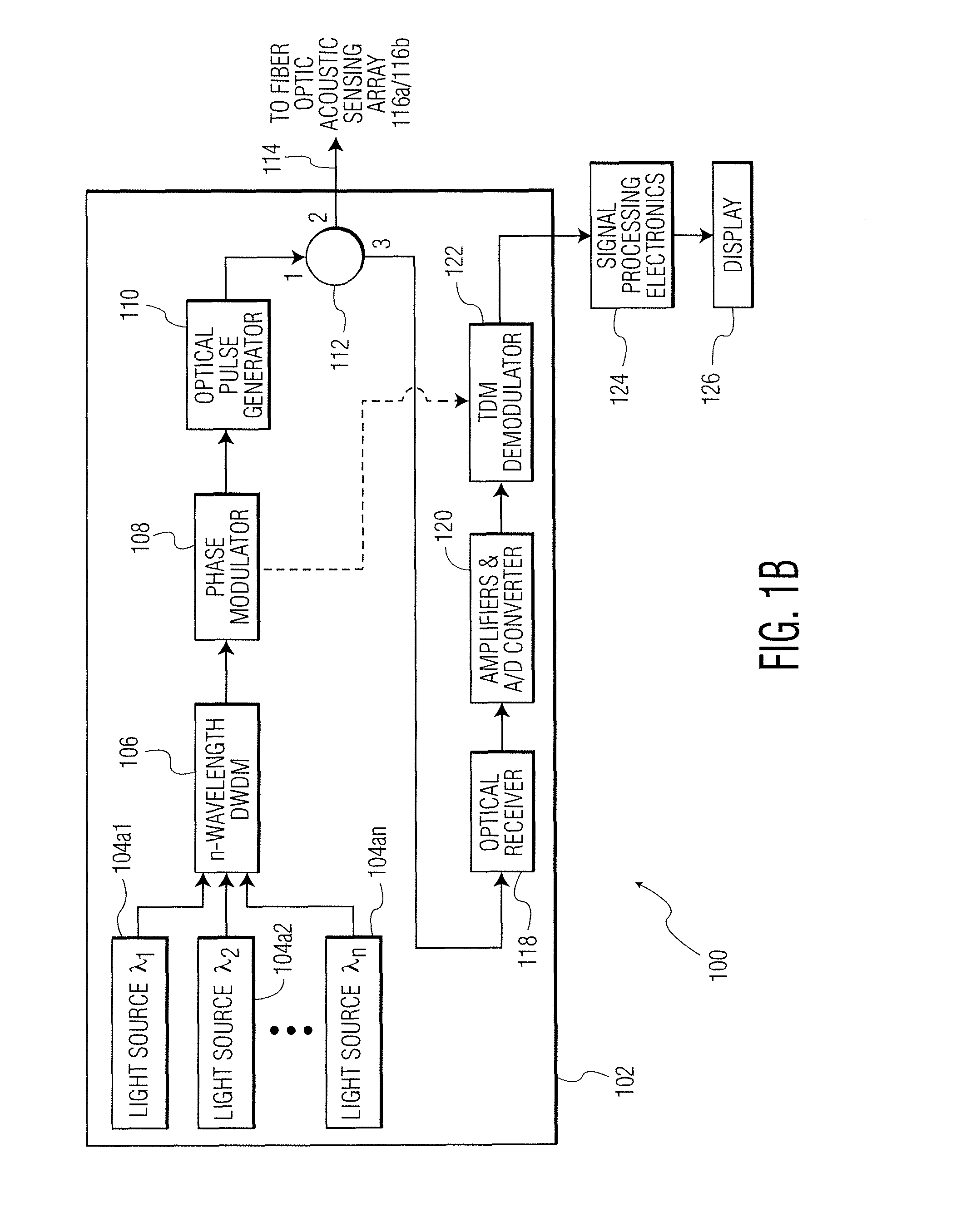

Fiber optic acoustic sensor arrays, fiber optic sensing systems and methods of forming and operating the same

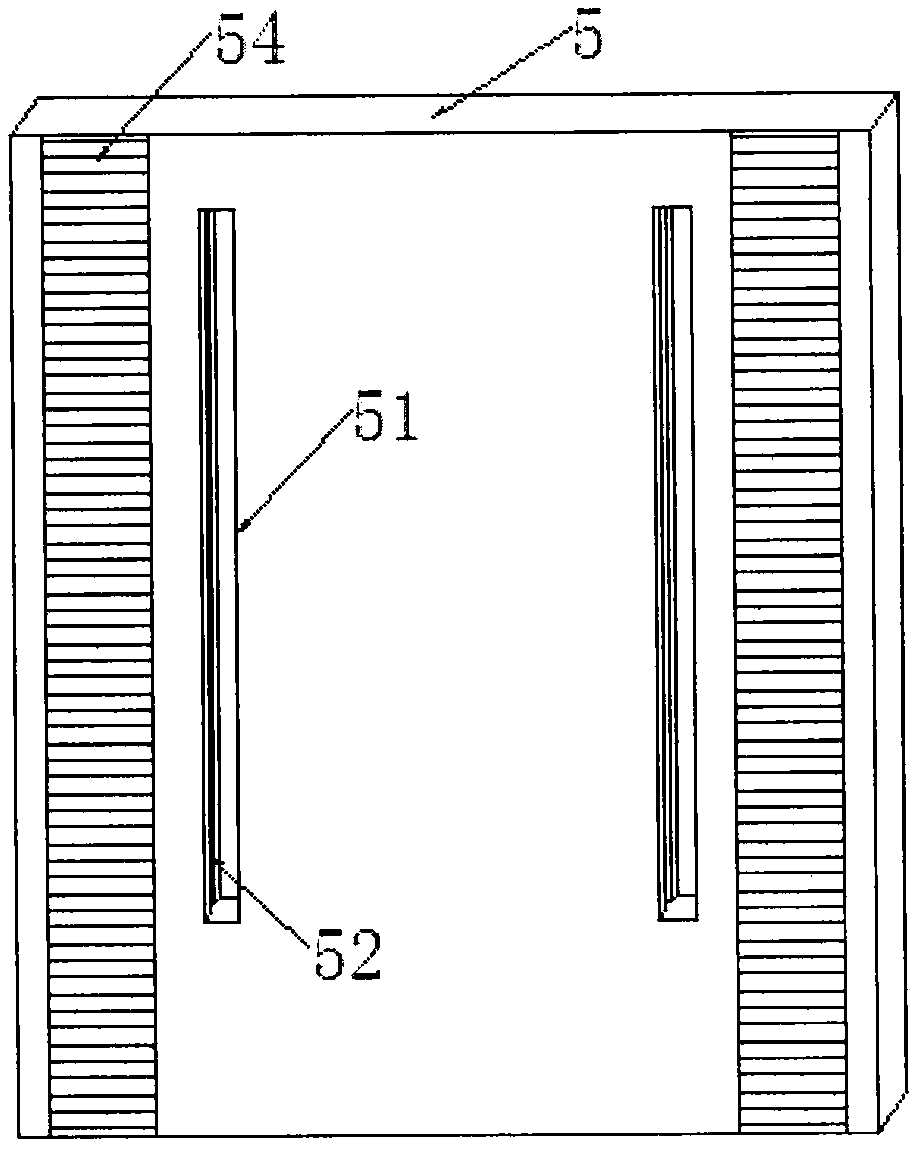

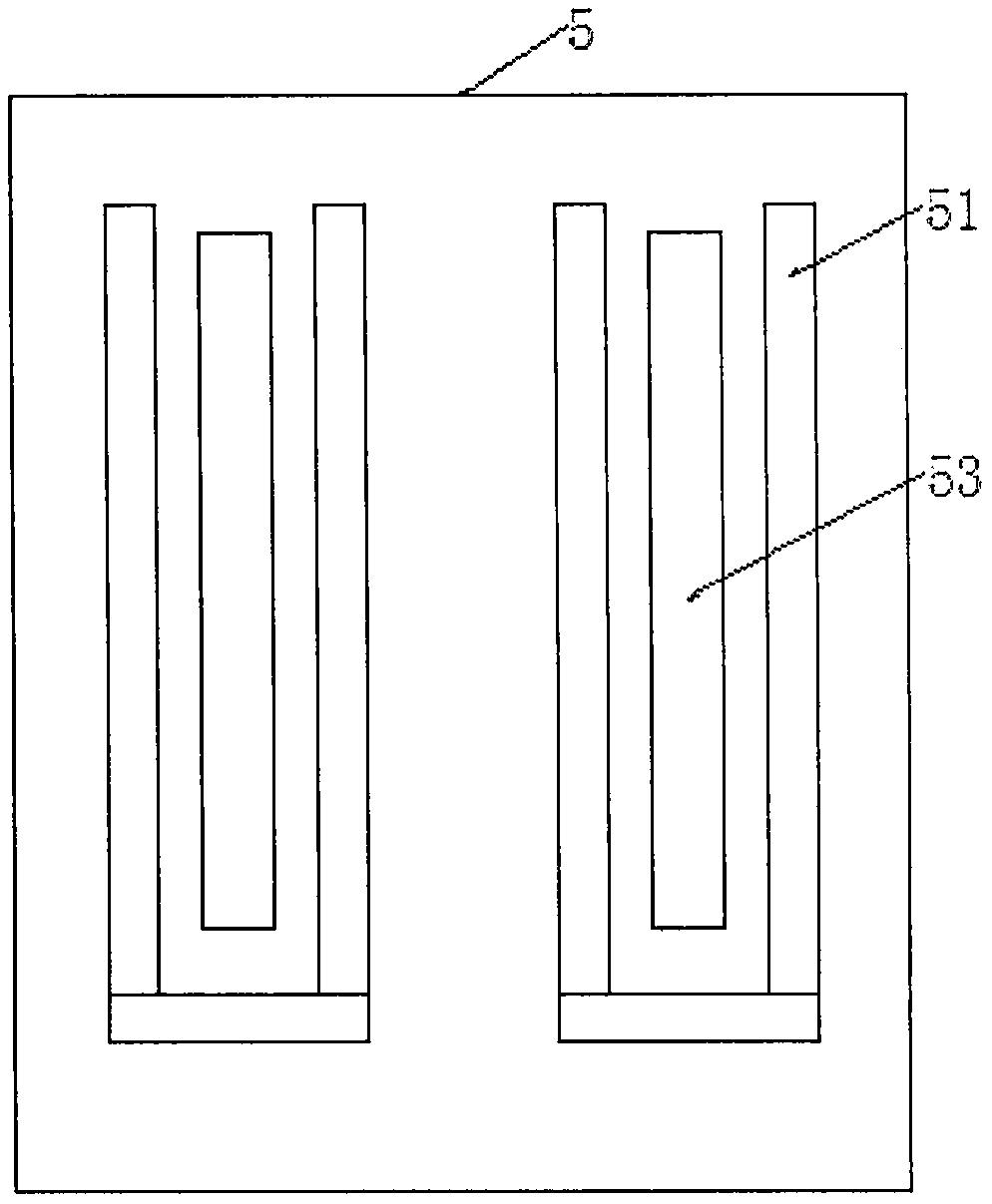

A fiber optic acoustic sensing array. The fiber optic acoustic sensing array includes a core strength member and an optical fiber wound on the core strength member. The optical fiber includes a plurality of Fiber Bragg Gratings, and is coated with a voided plastic coating. An outer jacket covers the optical fiber coated with the voided plastic coating. Also disclosed are fiber optic sensing systems, methods of forming a fiber optic acoustic sensing array, and methods of operating fiber optic sensing systems.

Owner:AVALON SCI

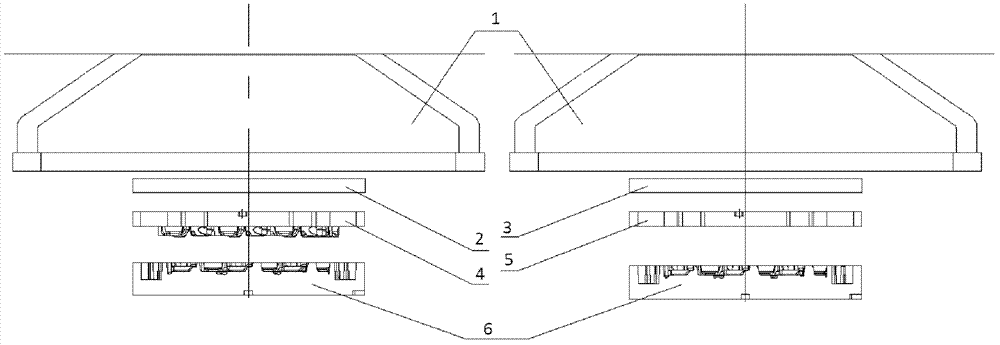

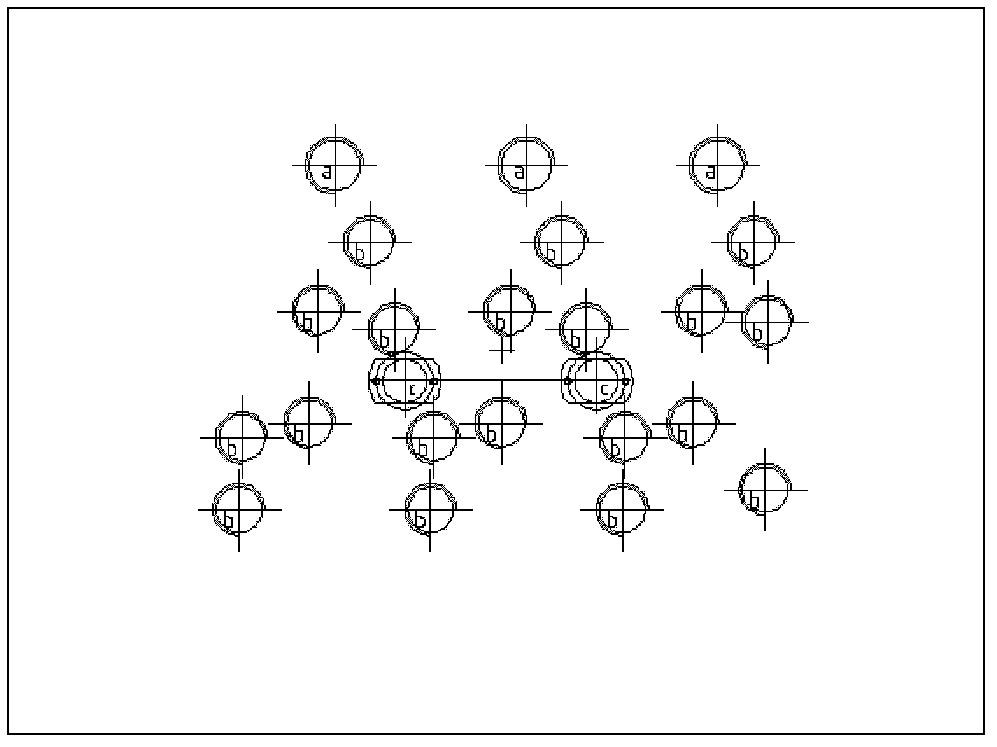

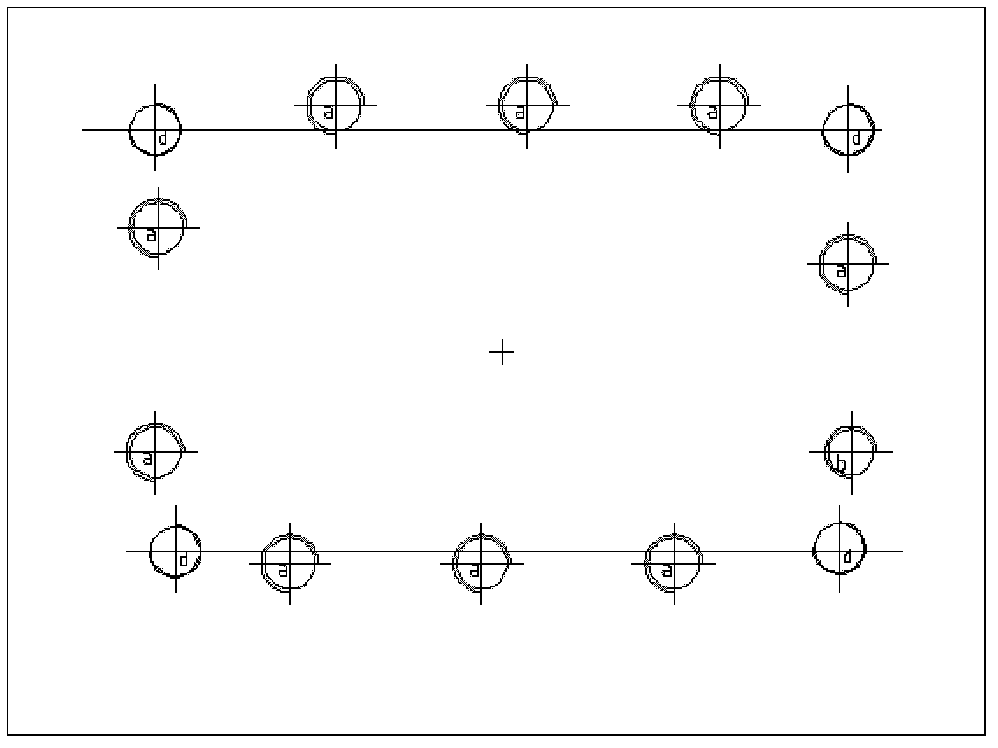

Stiffening core composite pile and construction method thereof

The invention relates to a strength-core composite pile and a construction method. The outer periphery of the pile body is a granular pile, and a high-bonding strength pile core is arranged in the center of the granular pile. The construction method comprises the construction of the granular pile by the vibrating tube sinking method, and then driving the pile core with high bonding strength by the vibrating tube sinking method in the center of the granular pile. The invention can effectively reduce foundation deformation, enhance strength and rigidity of foundation soil, accelerate drainage and consolidation of soft soil, and prevent foundation soil from liquefying.

Owner:邓亚光

Method for determining structural parameters of composite building panels

ActiveUS20110192518A1Increase manufacturing costIncrease shipping costsCeilingsCovering/liningsDisplay deviceEngineering

A method of determining face paper properties of all types of wallboard including providing a core strength value of the wallboard, determining a required nail pull value based the wallboard specifications and calculating a face paper stiffness value based on the provided core strength value and the determined nail pull value. The method includes displaying the calculated face paper stiffness value on a display device.

Owner:UNITED STATES GYPSUM CO

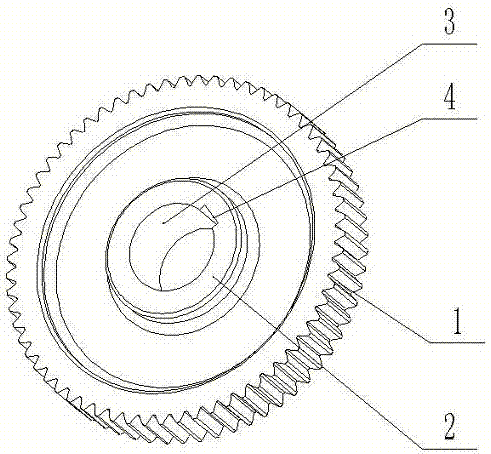

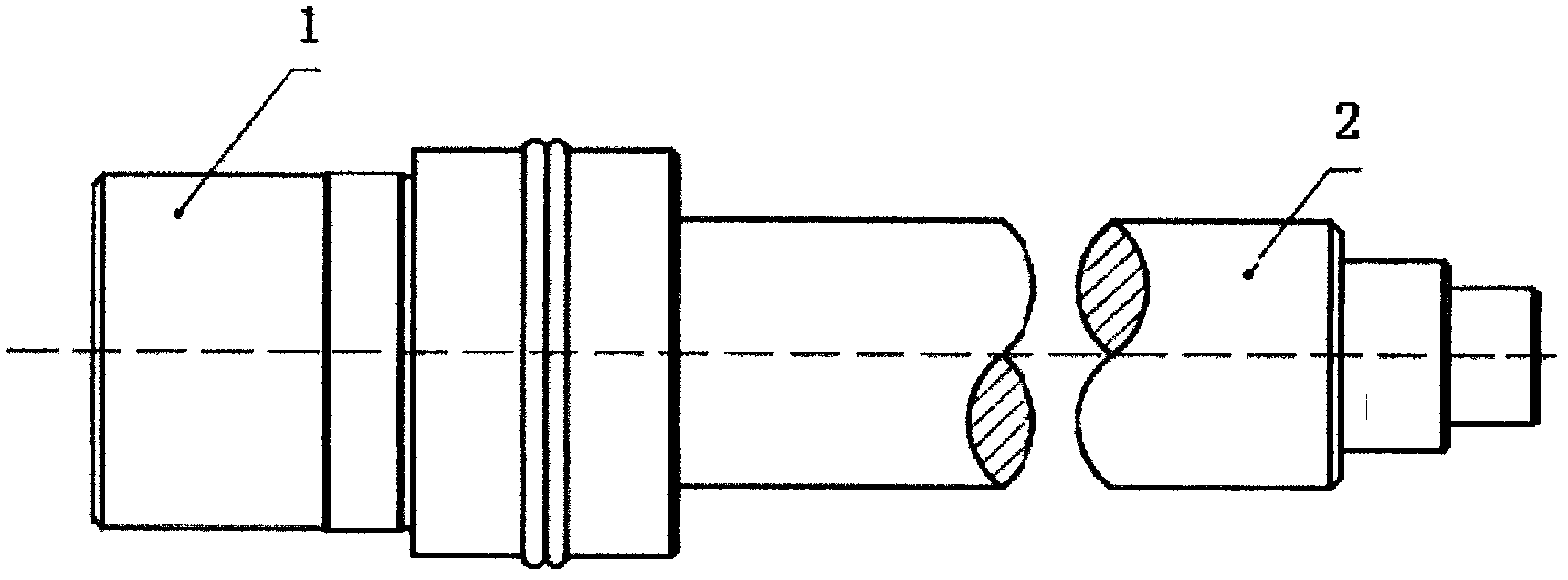

Machining process of marine gear

The invention discloses a machining process of a gear. The machining process comprises the following steps of forging, normalizing, rough turning, finish turning, hobbing, carburizing, inner hole and inner hole end face finish turning, quenching, tempering, shot blasting, inner hole and inner hole end face grinding, key groove cutting and final finished product obtaining. According to the machining process of the gear, the gear face can have high hardness, the core strength can be guaranteed, the surface hardness of a hole in the transmission shaft cooperation position is reduced, meanwhile, structure stress is reduced, and the use performance of the gear is more reasonable.

Owner:孙阳

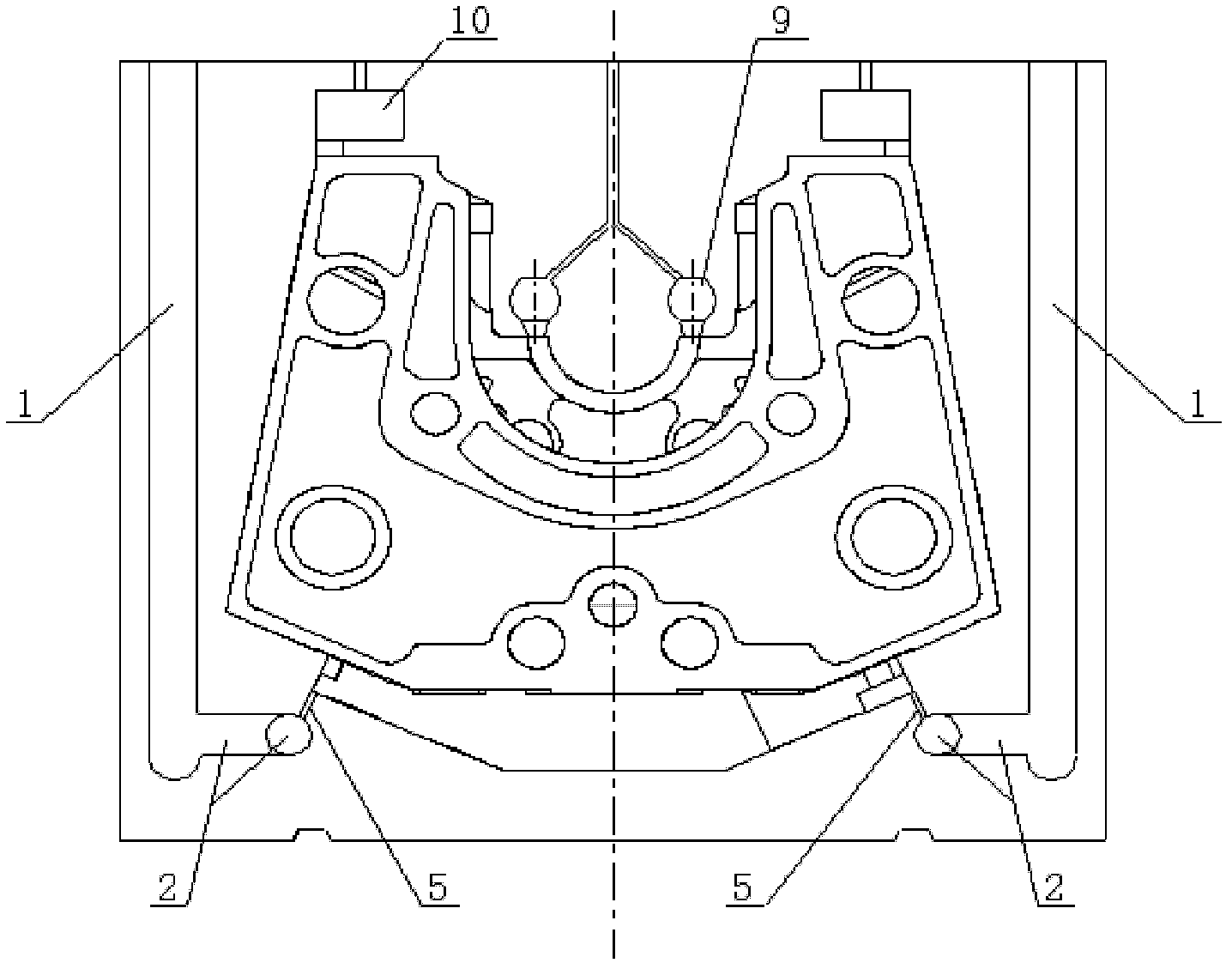

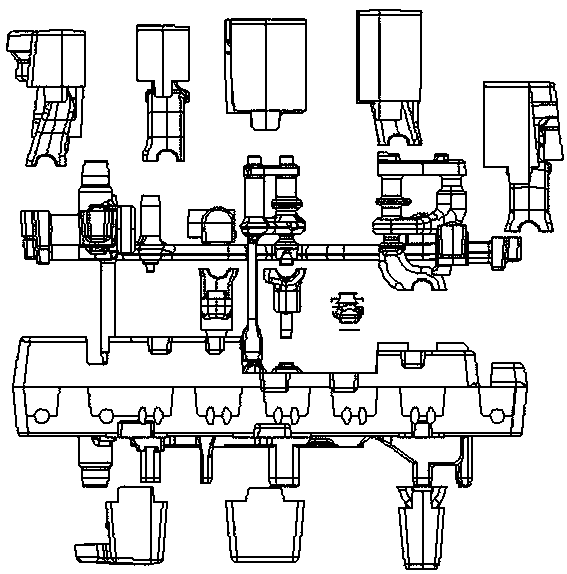

Casting core-splitting process for Vee cylinder block

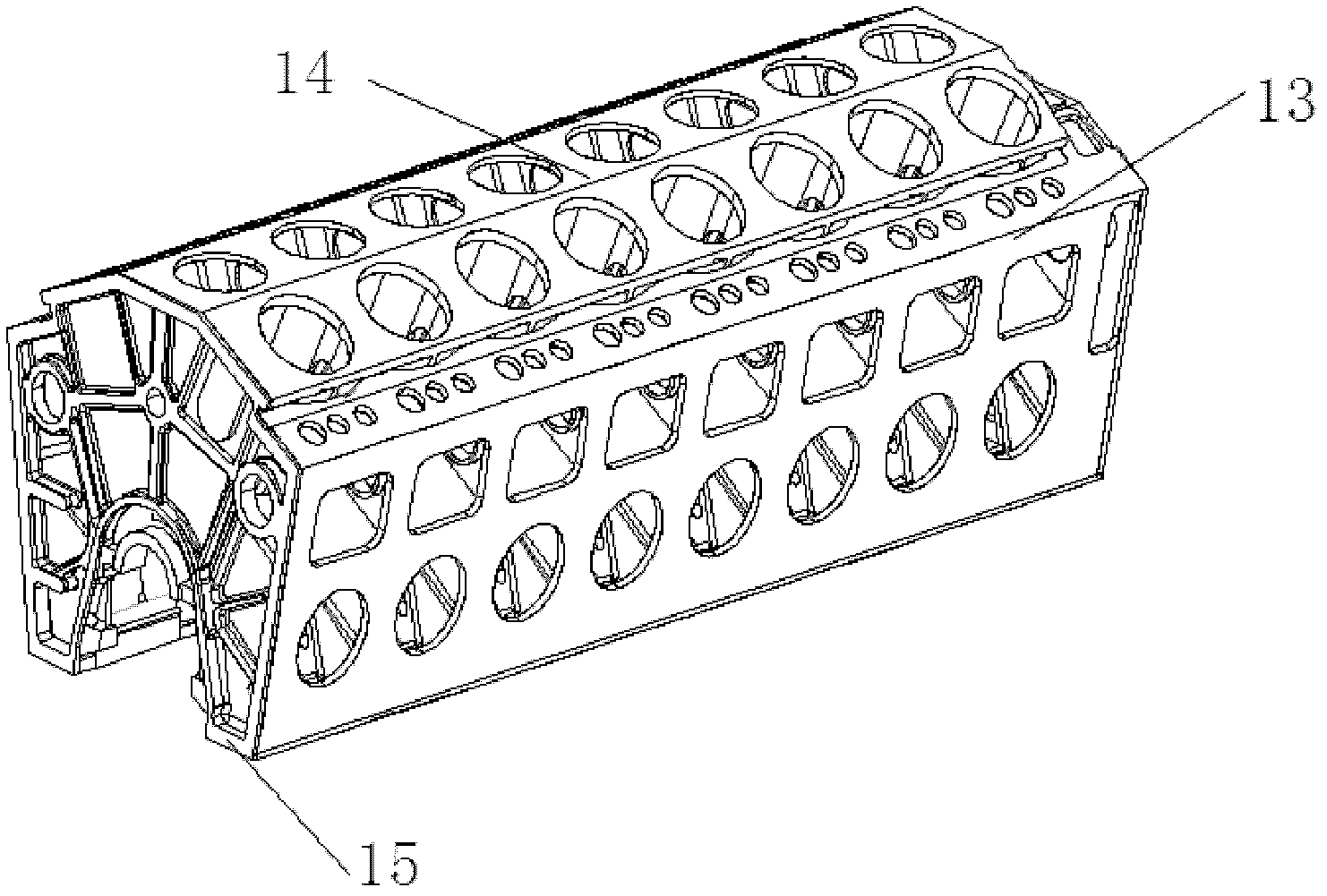

ActiveCN103121083AEasy to coreGuaranteed StrengthFoundry mouldsFoundry coresCylinder blockMechanical engineering

The invention discloses a casting core-splitting process for a Vee cylinder block. Integral enclosing core splitting is applied. The casting core-splitting process for the Vee cylinder block includes the steps of firstly, allowing the top of the Vee cylinder block to face down and legs to face up, and designing the bottom surface and outer side of a sand core; secondly, splitting the whole sand core into a front insert core, a rear insert core and a plurality of main cores between the front insert core and the rear insert core along a splitting line from the front end to the rear end of the Vee cylinder block; and thirdly, designing a universal tapper chamber core on each main core independently. By the integral enclosing splitting manner with the auxiliary core positioning measure, the number of the cores is creased, mould manufacturing process is simplified, appearance structure is simplified, core setting is convenient, positioning in core setting is accurate, core strength is ensured, deformation in turnover and casting process is avoided, productivity is improved, and production cost is saved.

Owner:GUANGXI YUCHAI MASCH CO LTD

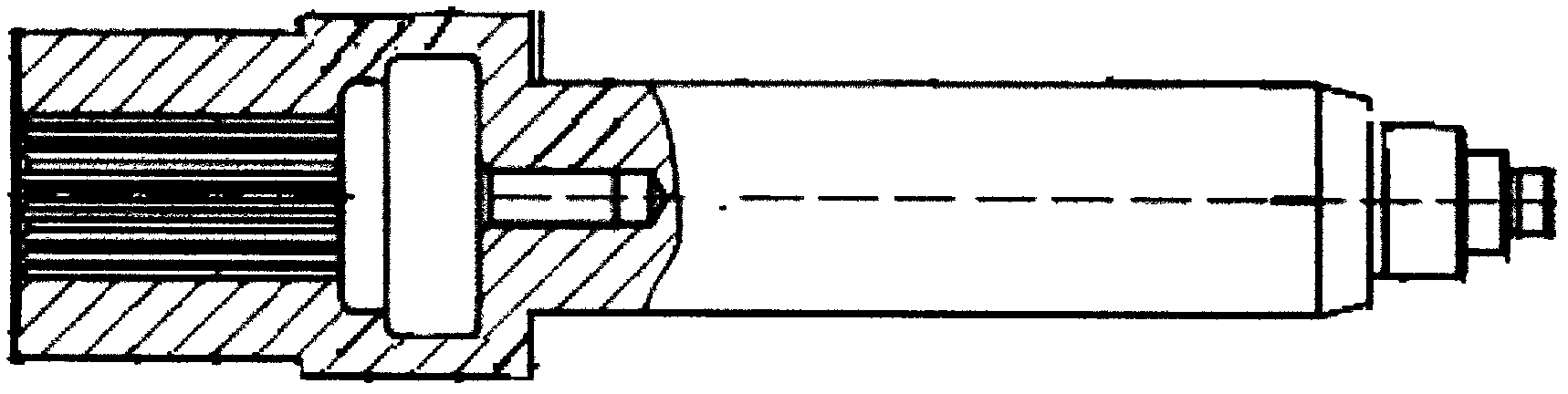

Internal spline shaft and preparation method thereof

The invention discloses an internal spline shaft and a preparation method thereof. The internal spline shaft comprises a head part and a tail part, and the head part and the tail part are connected through friction welding. The preparation method comprises the following steps of: preparing a head part blank of the internal spline shaft by using alloy steel subjected to hardening and tempering; carrying out nitriding or carburizing treatment on the head part blank; pressing a core shaft in an internal spline of the head part blank to carry out coarse grinding; preparing a tail part blank of the internal spline shaft by using alloy steel; carrying out friction welding on the head part blank and the tail part blank so as to form an integral structure; and pressing a core shaft into an internal spline of the head part of the integral structure, and then carrying out cylindrical grinding processing on the integral structure by using a double-centre method so as to obtain a finished product. The internal spline shaft disclosed by the invention is obtained directly by way of two-section friction welding; the internal spline shaft is simpler in process, high in precision and long in service life; the preparation method is high in production efficiency, and a spline tooth is processed by using a broaching machine, thereby effectively ensuring the precision of the spline; and the heat treatment mode of the internal spline shaft is a nitriding or carburizing mode, so that the contradiction between the surface hardness and the core strength of the spline tooth is solved.

Owner:NINGBO JIECHENG AXLE TRADE

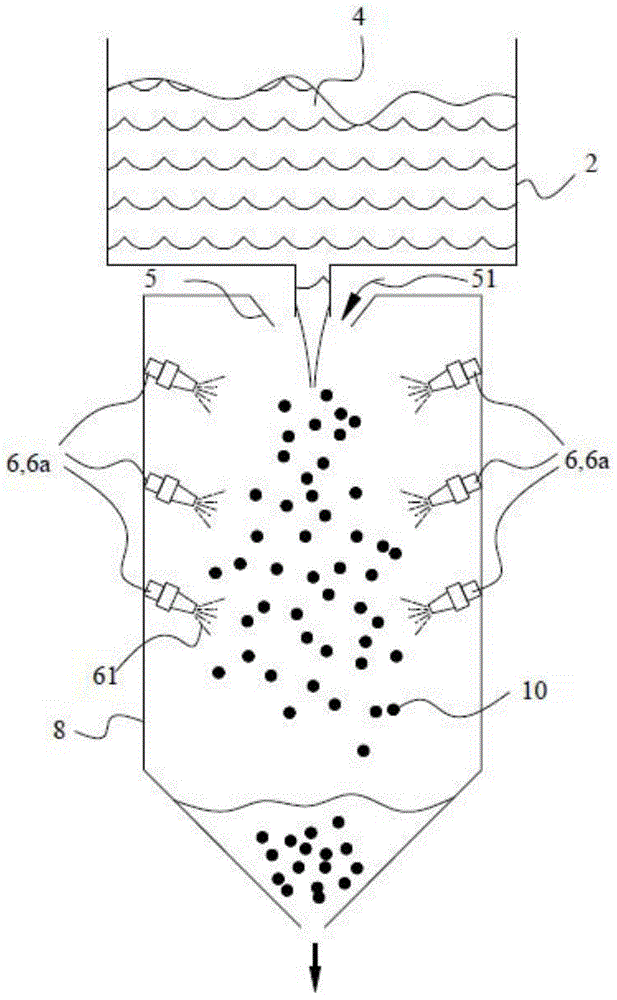

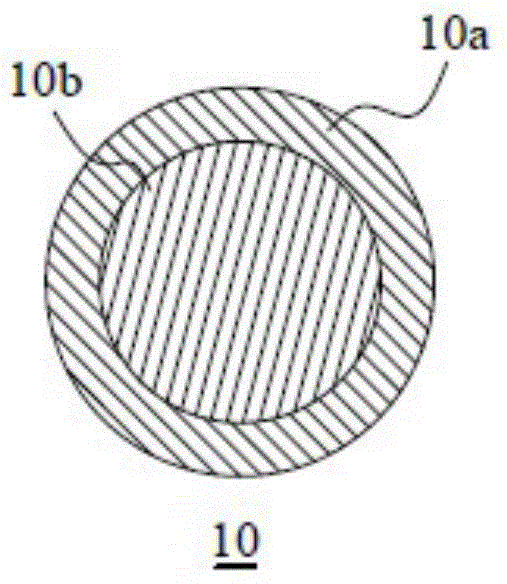

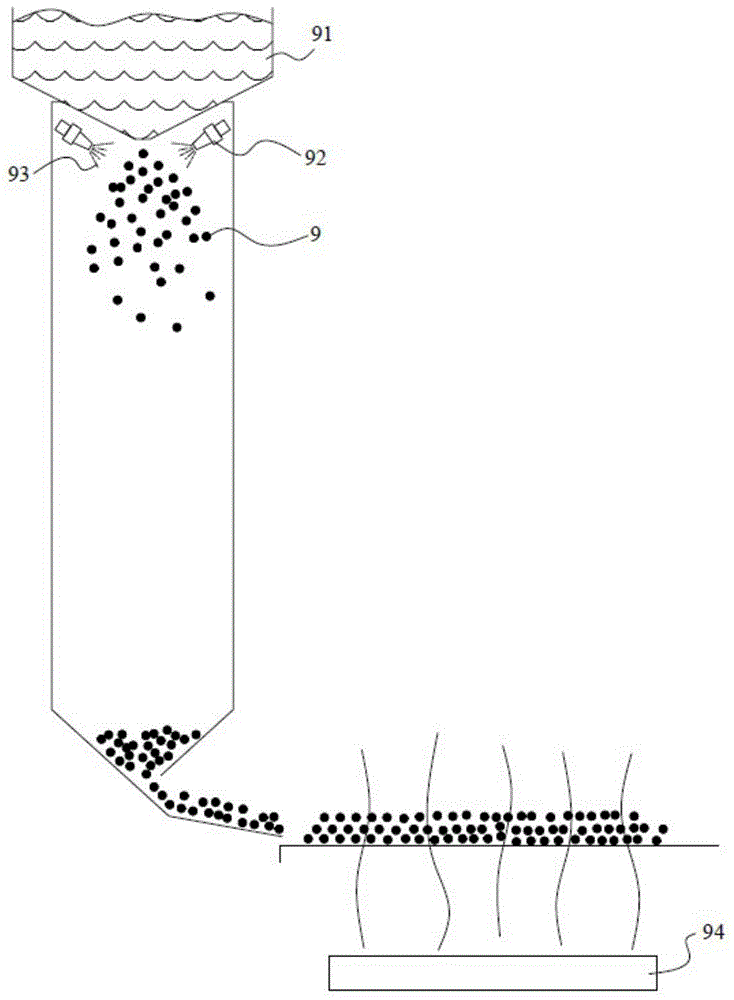

Method and device for manufacturing metal powder

The invention discloses a method and a device for manufacturing metal powders. A Fe-based metallic melted liquid is blown into small metal liquid drops by an atomization device, and then quenching treatment is performed on the metal liquid drops by a high-voltage cooling mechanism spraying a cooling fluid. Through the cooling fluid, temperature of the metal liquid drops is rapidly reduced, and the metal liquid drops are solidified into steel ball shaped metal powders. Through the properties of the cooling fluid of the high-voltage cooling mechanism, cooling speed is changed, and changing the surfaces and core strength of the metal powders can be selected.

Owner:METAL INDS RES & DEV CENT

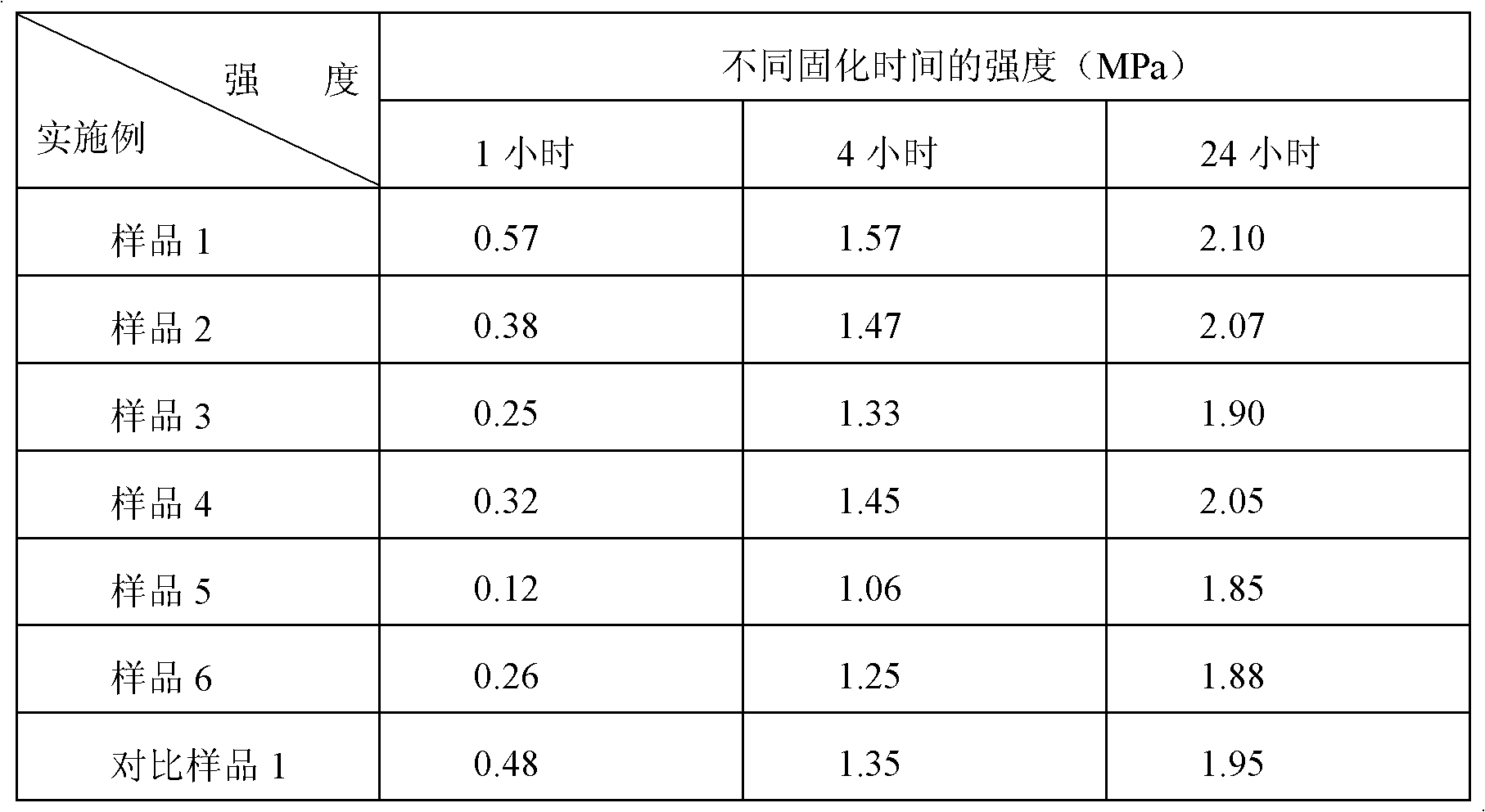

Curing agent for Furane self-hardening resin, preparation method thereof and Furane self-hardening resin sand

ActiveCN102513500AReduce manufacturing costSmall smellFoundry mouldsFoundry coresFirming agentP-Toluenesulfonic acid

The invention discloses a curing agent for Furane self-hardening resin, a preparation method thereof, and Furane self-hardening resin sand. The raw material of the curing agent comprises mother liquor and water, and the mother liquor is industrial waste acid produced during the production process of benzene sulfonic acid, p-toluenesulfonic acid and xylenesulfonic acid. The mother liquor in the raw material used for preparing the curing agent is wide in source and low in cost and can remarkably reduce the manufacturing cost of the curing agent for Furane self-hardening resin; compared with the curing agent prepared by using the traditional method, the curing agent prepared by using the method in the invention has the advantages as follows: the differences are not great, and even the curing agent is superior to the traditional curing agent; the curing agent provided in the invention can be used for solidifying the Furane self-hardening resin sand, has a weak smell during a sand mulling process, is moderate in solidifying speed, is high in sand mold and core strength after being poured, has excellent mold and core collapsibility and ensures that old sand can be reproduced easily. The preparation method provided by the invention is simple in process and is shorter in period.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

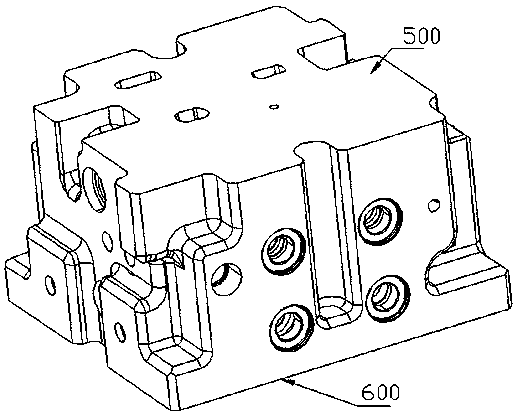

Casting method of hydraulic valve casting

InactiveCN109128010AHigh strengthGuaranteed StrengthFoundry mouldsFoundry coresIntegrated design3d printer

The invention relates to a casting method of a hydraulic valve casting. The casting method is characterized by comprising the following steps: designing a mold core including a hydraulic valve; selecting the bottom surface of the hydraulic valve and the top surface of the hydraulic valve as split surfaces of the mold core and dividing the mold core into a bottom core, an intermediate core and an upper cover core; printing the intermediate core by adopting a 3D printer; printing the bottom core and the upper cover core by adopting the 3D printer and / or preparing the bottom core and the upper cover core by adopting a wooden pattern; assembling the bottom core and the intermediate core; assembling the upper cover core on the intermediate core. The casting method of the hydraulic valve casting, provided by the invention, has the benefits that the intermediate core of the hydraulic valve and the external contour are combined together, so that the quantity of sand cores is reduced, and the process step is simplified; through the integrated design of the intermediate core, the sand core strength of the intermediate valve core is enhanced, so that the problems of sand core deformation andthe like are solved.

Owner:KOCEL INTELLIGENT FOUNDRY IND INNOVATION CENT CO LTD

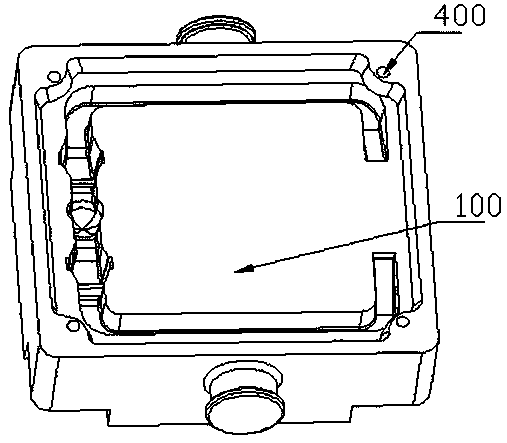

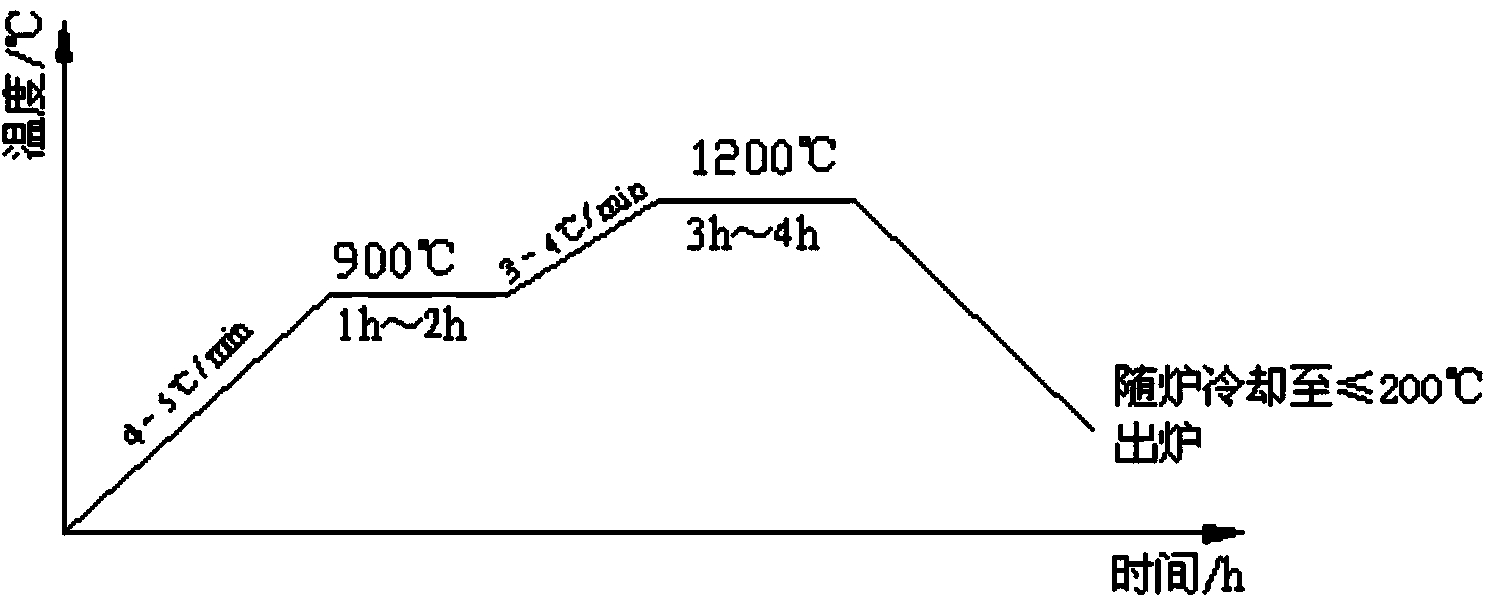

Ceramic secondary reinforcement method

InactiveCN104107879AImprove high temperature strengthImprove pass rateFoundry mouldsFoundry coresCeramicPrecision casting

The invention relates to the field of precise casting of fusible patterns, and especially relates to a solution scheme of core breakage and leakage defects caused by insufficient ceramic core strength. A ceramic core secondary reinforcement method comprises the following steps: 1, secondary roasting of a de-waxed die shell with a ceramic core: heating from normal temperature to 900DEG C under a heating rate of 4-5DEG C / min, carrying out heat insulation for 1-2h, heating from 900DEG C to 1200DEG C under a heating rate of 3-4DEG C / min, carrying out heat insulation for 3-4h, cooling with a furnace to below 200DEG C, and discharging the obtained die shell from the furnace; and 2, secondary reinforcement on the secondary-roasted die shell with the ceramic: slowly dumping an ethyl silicate hydrolysate into the roasted die shell from the sprue cup of the die shell until the level of the ethyl silicate hydrolysate reaches the sprue cup, immersing for 20-40min, dumping out the ethyl silicate hydrolysate, naturally drying, and chemically hardening to obtain a die shell to be cast.

Owner:AECC AVIATION POWER CO LTD

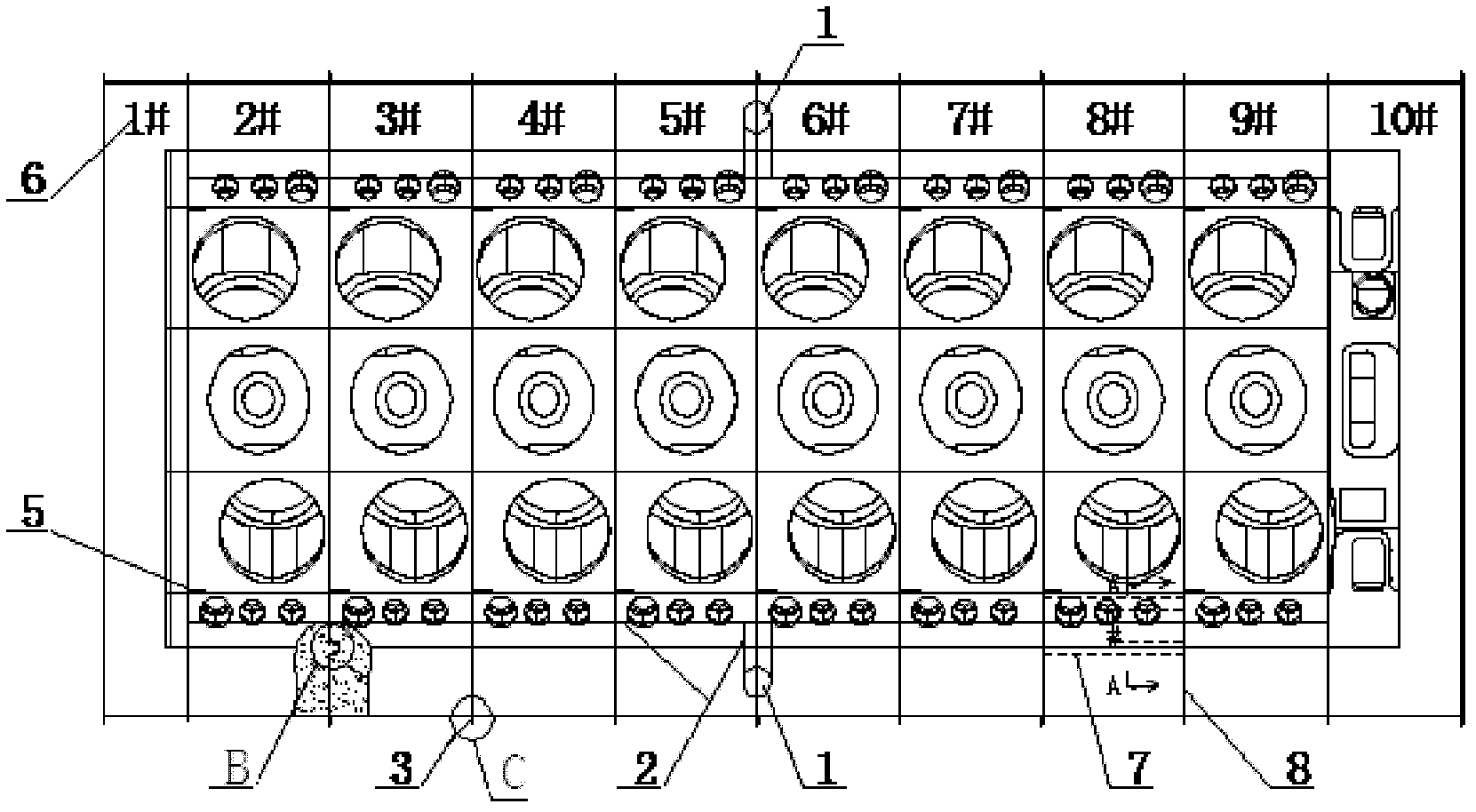

Composite sand core sand shooting device and method

ActiveCN103192035AReduce dosageGuaranteed StrengthFoundry mouldsMoulding machinesShooting methodEngineering

The invention discloses a composite sand core sand shooting device comprising a lower core box and upper core boxes provided with sand shooting holes. The upper core boxes are at least two independent upper core boxes, wherein the mold cavity of each upper core box respectively corresponds to different positions of the lower core box. Preferably, the number of the upper core boxes is 2, wherein one upper core box has a mold cavity corresponding to the middle part of the mold cavity of the lower core box, and the other upper core box has a mold cavity corresponding to the peripheral part of the mold cavity of the lower core box. The position where the upper core box corresponds to the middle part of the mold cavity of the lower core box is a hollow cavity. One of the purposes of the invention is to provide a composite sand core sand shooting device used in cold core manufacturing, and another purpose of the invention is to provide a composite sand core sand shooting method used in composite sand core sand shooting. Therefore, a sand core, with which sand core strength can be ensured and cost can be effectively saved, can be manufactured.

Owner:GUANGXI YUCHAI MASCH CO LTD

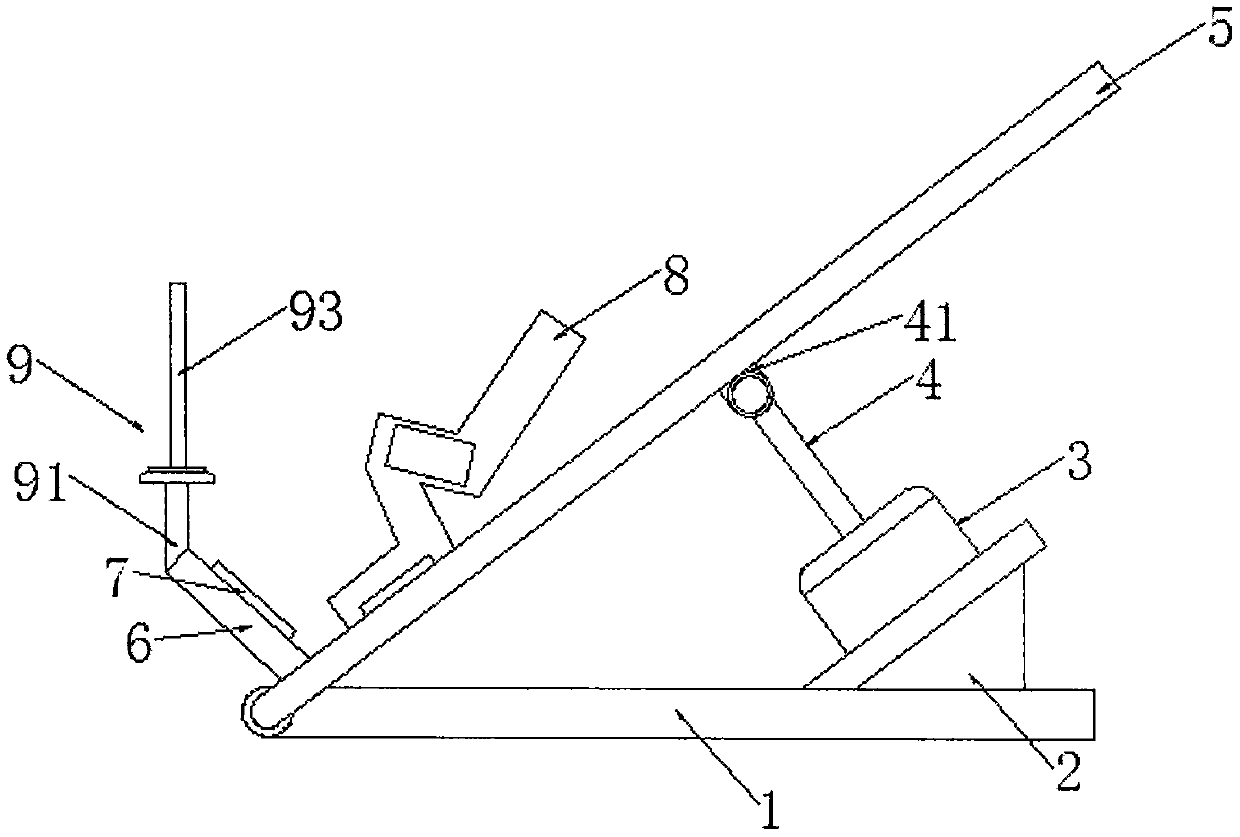

Professional lower limb leaping ability core strength training device

InactiveCN110038268AReasonable designHighly professionalMuscle exercising devicesEngineeringOblique plane

The invention discloses a professional lower limb leaping ability core strength training device. The device comprises a base, an inclination angle adjustable training frame, resistance capable of adjusting a seat to rise, a touch screen control interface and a built-in sensor; a fixed base is fixedly installed on the upper end face of the base, a track inclination angle adjustment control hydraulic machine is fixedly installed on the oblique plane of the upper end of the fixed base, a push rod is fixedly connected to an output end of the track inclination angle adjustment control hydraulic machine, a fixed block is rotationally installed at the end of the push rod, a backing plate is arranged on the upper end face of the base, two opposite corners of the base and the backing plate are rotationally installed, the equipment track inclination angle can be configured and recorded, the force of two feet pedaling on the ground, the seat rising distance, the speed and other related training business parameters which can be calculated through sensor data can be measured, and other program training guide and effect evaluation can be extended on a touch screen. The device refers to the humanmechanics, structure design is reasonable, the professional degree is high, the quality is guaranteed, and convenience is brought to use.

Owner:胜狮(北京)科技有限公司

Absorbent articles with improved cores

Absorbent articles and absorbent core structures with improved core strength and stability with long core end seal and channel hang times.

Owner:PROCTER & GAMBLE CO

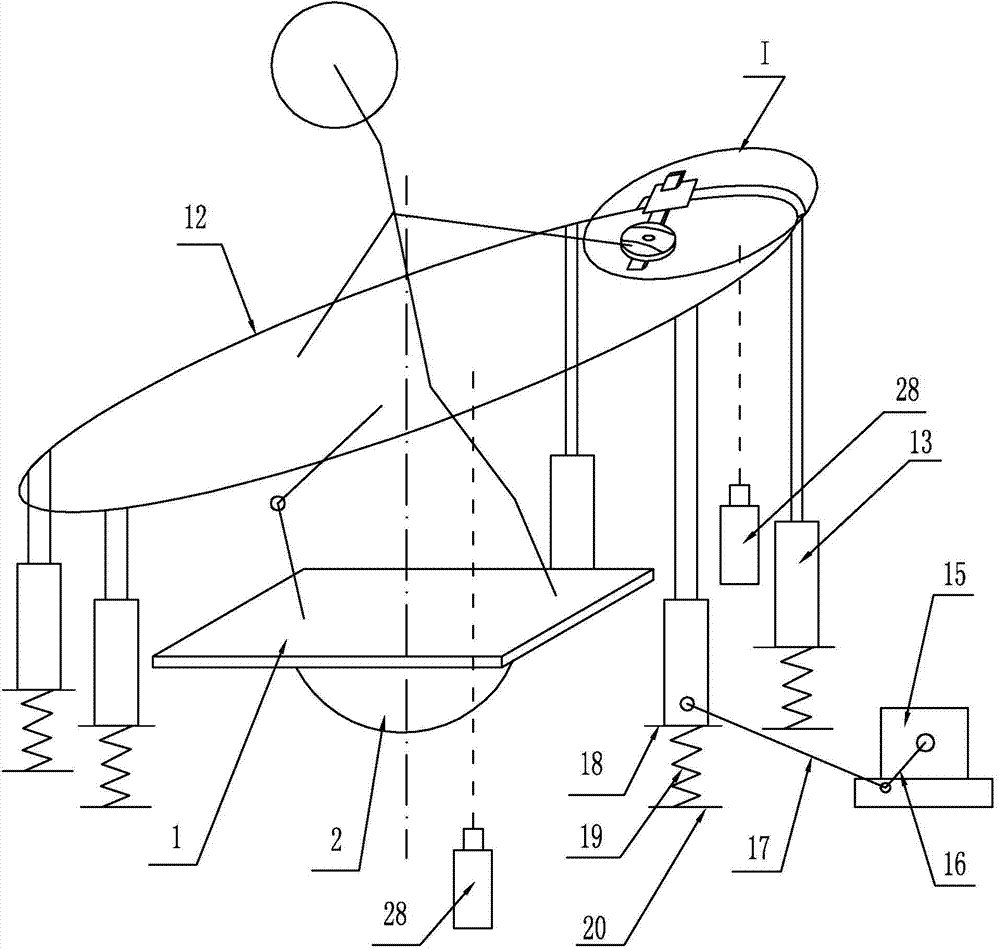

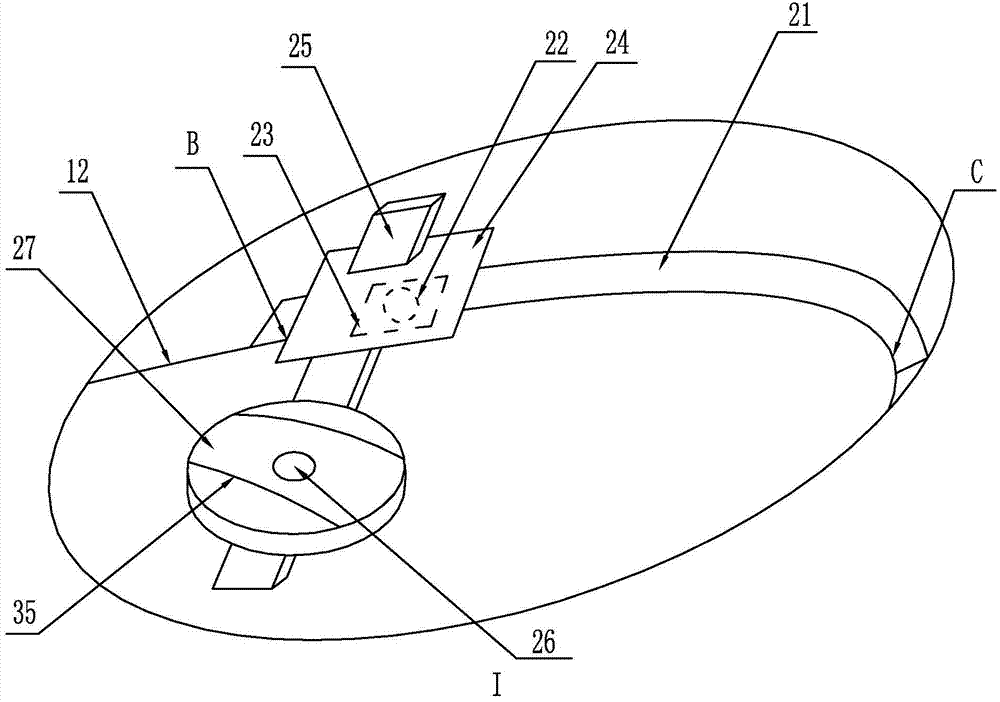

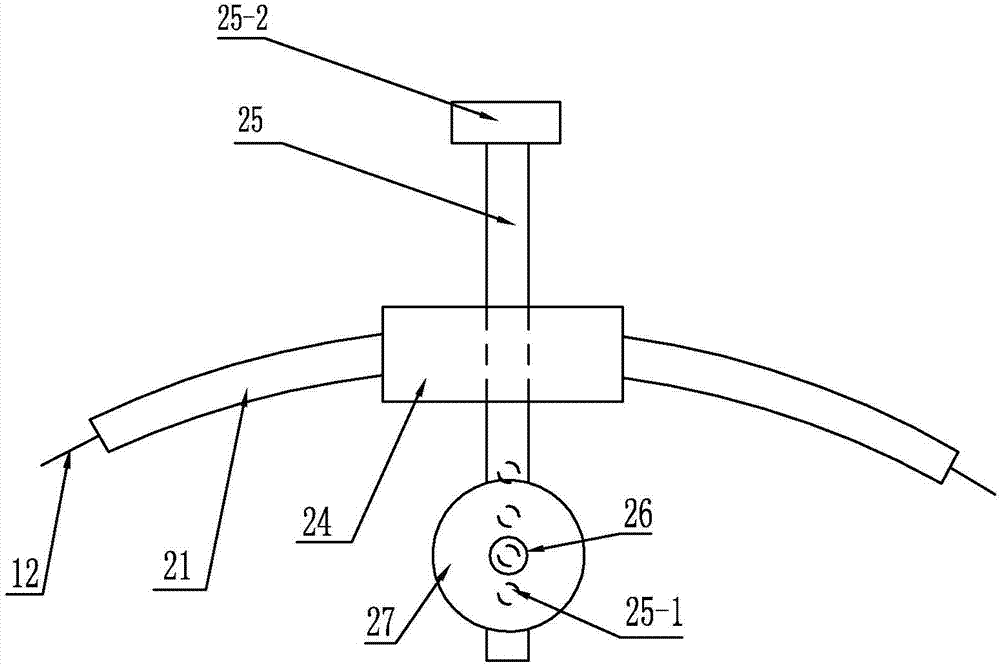

Laser type super-equal-length discus core strength training and motion information feedback monitoring device

InactiveCN103751999AReal-time display of body balance statusAdjust posture in real timeMovement coordination devicesCardiovascular exercising devicesEngineeringControl circuit

The invention provides a laser type super-equal-length discus core strength training and motion information feedback monitoring device, relates to a discus core strength training and motion information feedback monitoring device and aims at solving the problem that an existing discus special sport is lack of a laser type super-equal-length core strength training means and a motion information feedback monitoring means performed in an unstable state. The laser type super-equal-length discus core strength training and motion information feedback monitoring device comprises an annular track, a crank connecting-rod mechanism, a rear driving mechanism, a balance training device having an information feedback function, a pressure sensor, two laser velocimeters, multiple lifters and multiple elastic fixing racks identical to the lifters in number. The crank connecting-rod mechanism comprises a crank, a connecting rod and a first motor. The balance training device having the information feedback function is arranged under the annular track and comprises a pedal, a balance base, a control circuit and three distance measuring sensors. The laser type super-equal-length discus core strength training and motion information feedback monitoring device is used for core strength training and motion information feedback monitoring of a super-equal-length discus subjected to laser velocity measurement.

Owner:HARBIN NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com