Method and device for manufacturing metal powder

A technology of metal powder and manufacturing method, which is applied in the field of metal powder manufacturing and devices, and can solve problems such as complicated procedures, high cost, and complicated manufacturing process of metal abrasive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

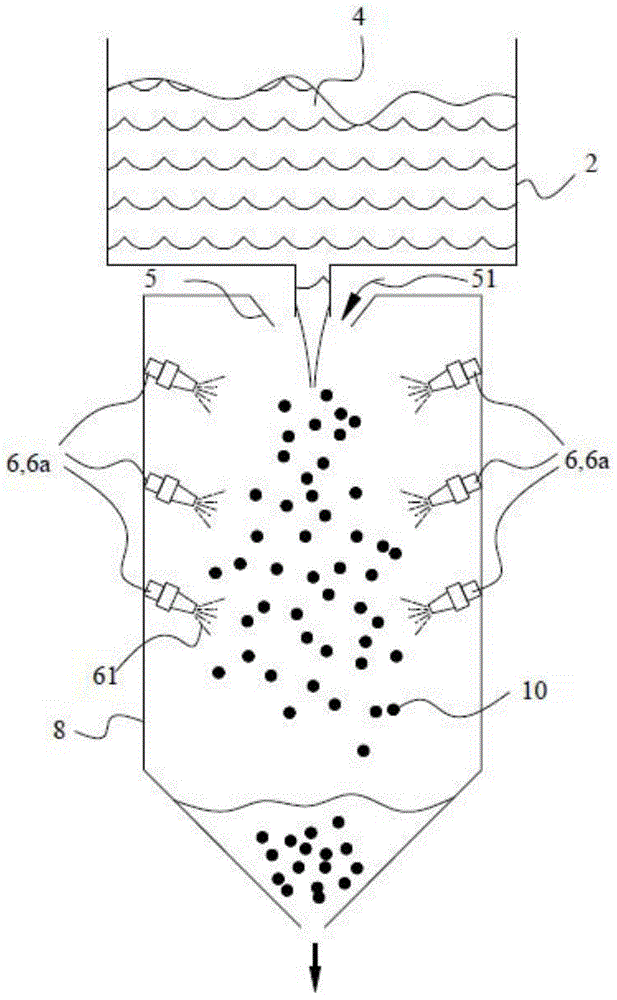

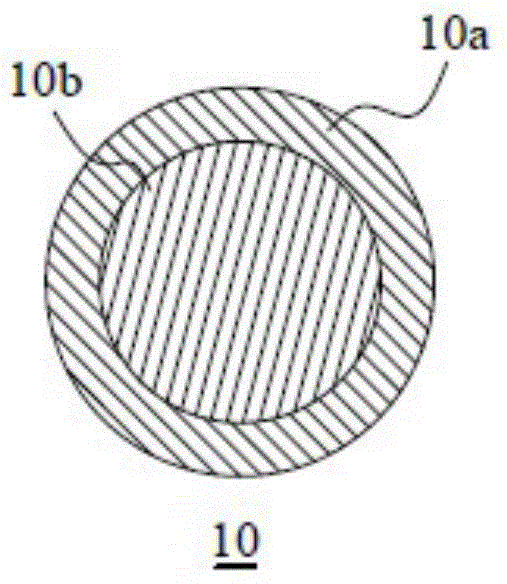

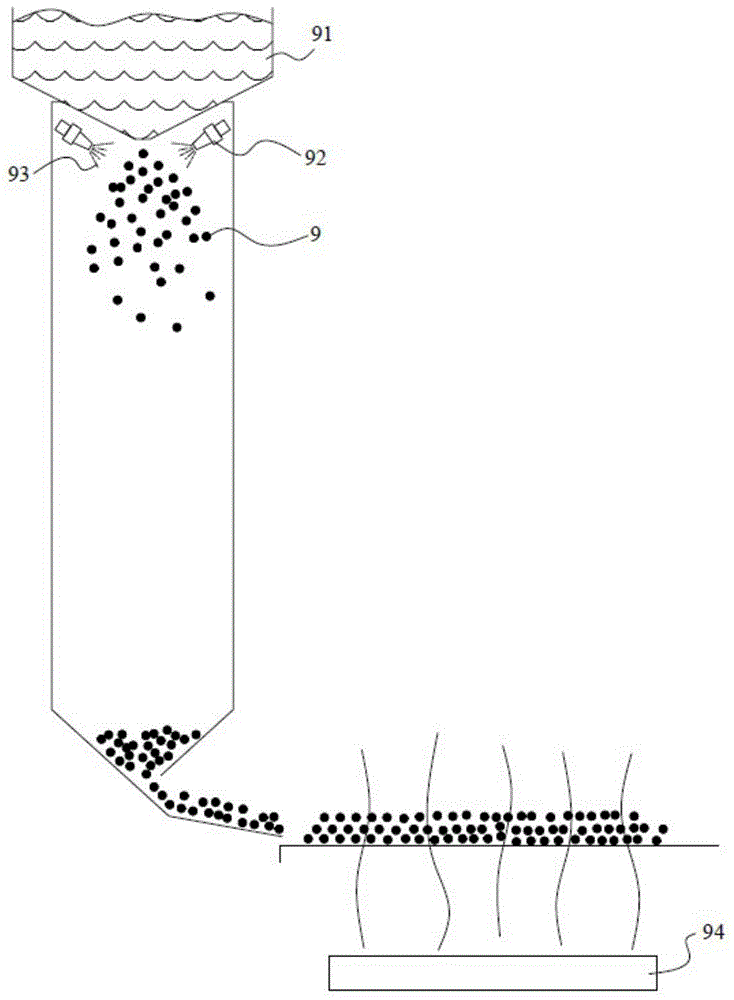

[0038] Such as figure 1 As shown, the manufacturing method of the metal powder provided by the present invention is mainly the method of manufacturing iron-based metal droplets and rapid heat treatment. The equipment for completing the method mainly includes a supply part 2, and the iron-based metal melt 4 is housed in the supply part 2, and the carbon content of the iron-based metal melt 4 is 0.02wt.%~0.5wt.%. 2 is connected with a receiving portion 8 below, and the receiving portion 8 is used to introduce the molten iron-based metal 4. The outlet end of the molten iron-based metal 4 of the supply part 2 is provided with an atomizing device 5 , and the atomizing device 5 has a nozzle to provide an inert gas 51 to blow the molten iron-based metal 4 into several...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com