Method for producing wear-resistant composite roller

A manufacturing method and technology of composite rolls, which are applied in the direction of rolls, metal rolling, manufacturing tools, etc., can solve the problems affecting the normal use of combined composite rolls, prone to pores on the bonding surface, and reduce the strength of the bonding layer, etc., so as to improve the bonding effect , shorten the processing time, improve the effect of bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

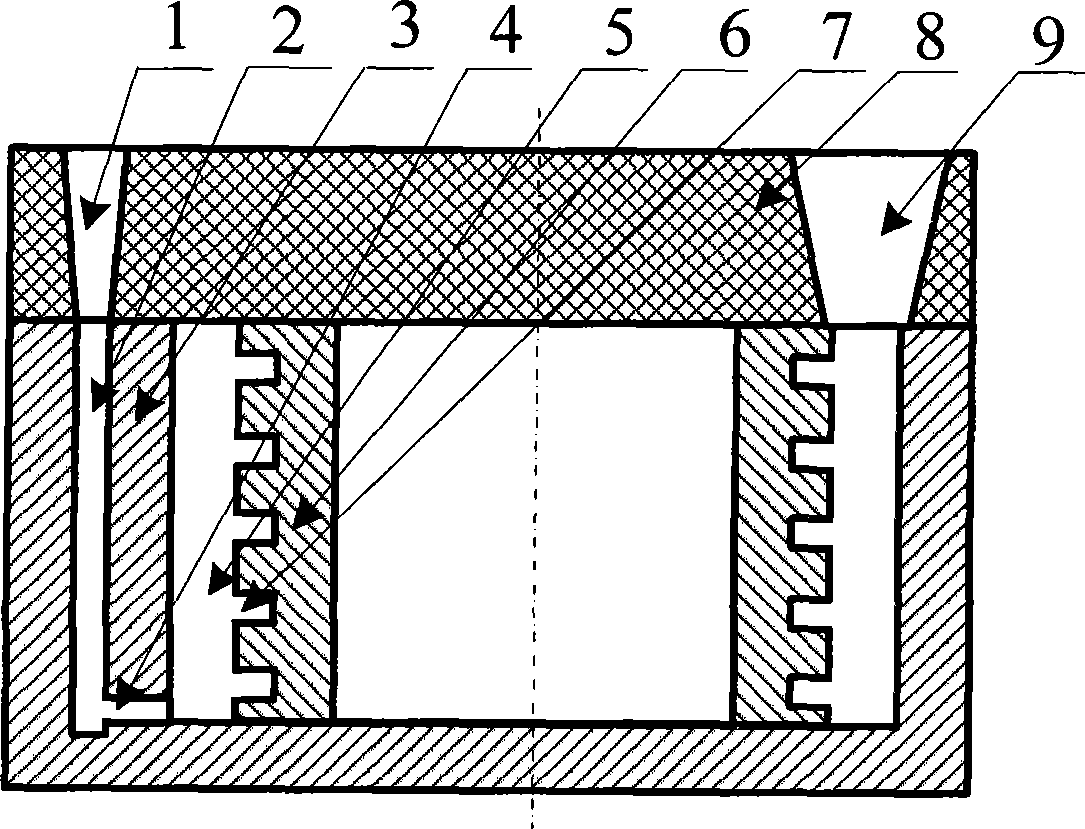

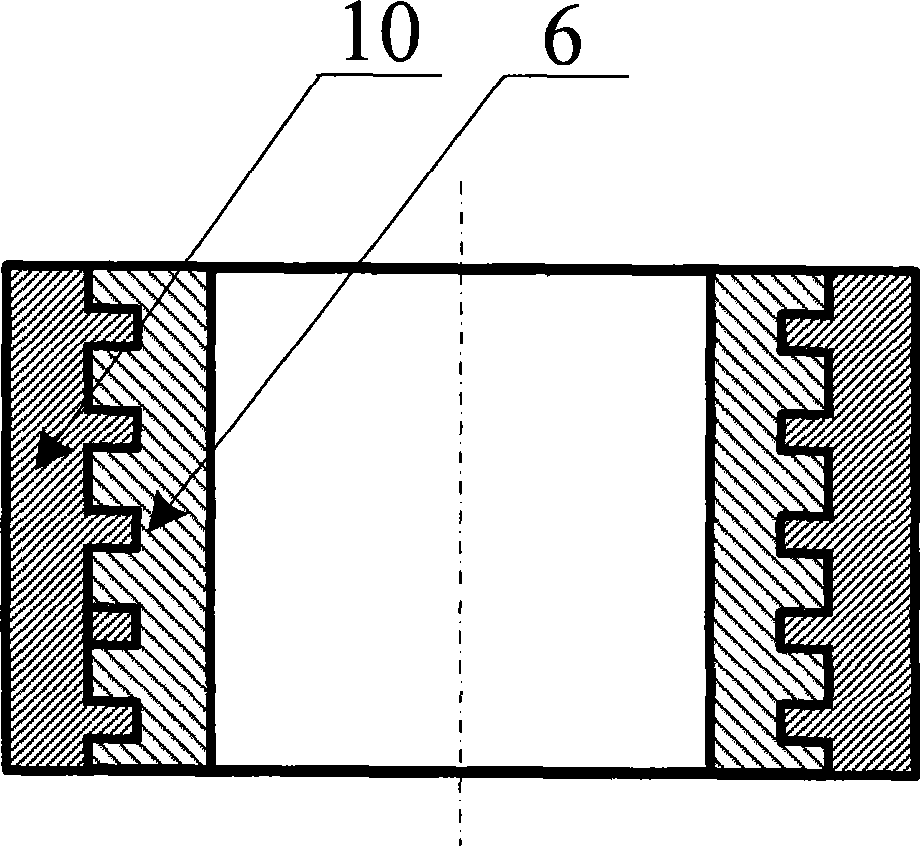

[0028] 1) Process the steel pipe into the roller ring inner sleeve 6, and open a plurality of grooves 7 on the outer surface of the roller ring inner sleeve 6, the groove width is 12mm, the groove depth is 10mm, and the groove spacing is 20mm;

[0029] 2) Soak the inner sleeve 6 of the roller ring with dilute hydrochloric acid to remove impurities and scale on the outer surface, rinse it in alcohol, take it out and dry it naturally, and coat the outer surface of the inner sleeve 6 and the groove 7 with a layer of Thickness 1.0 borax, after natural drying, place in cavity 5 of cast iron metal mold 3;

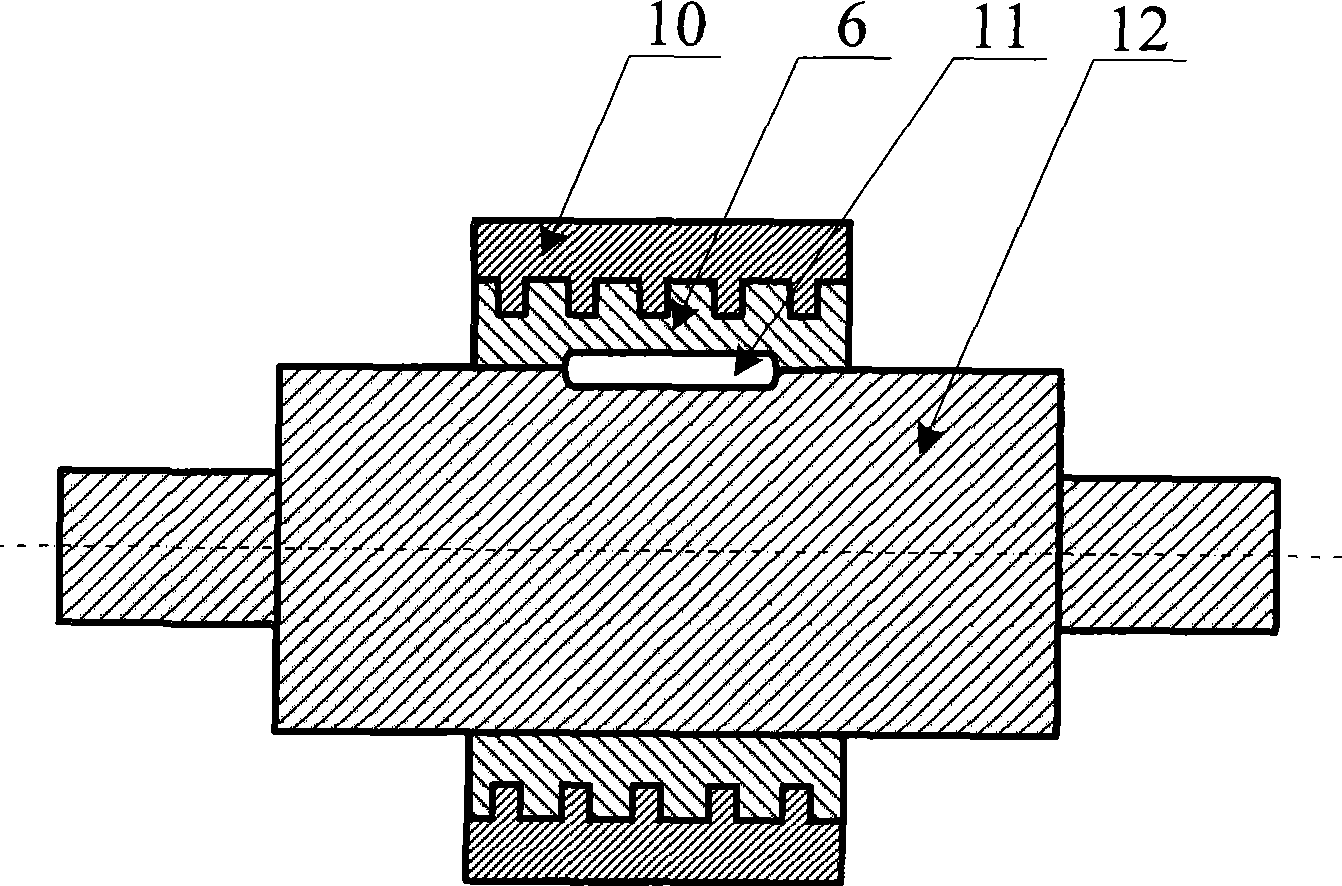

[0030]3) The outer wear-resistant metal melt enters the cavity 5 through the sprue cup 1, the sprue 2, and the inner runner 4, and the outer wear-resistant metal 10 is poured by the bottom pouring method, and the outer wear-resistant metal 10 is made of high Carbon high-speed steel, the specific composition is as follows (% by weight): 1.93% C, 4.07% Cr, 5.21% W, 4.06% V, 2.04% M...

Embodiment 2

[0033] 1) Process the steel pipe into the roller ring inner sleeve 6, and open grooves 7 on the outer surface of the roller ring inner sleeve 6, the groove width is 15mm, the groove depth is 10mm, and the groove spacing is 25mm;

[0034] 2) Soak the inner sleeve 6 of the roller ring with dilute hydrochloric acid to remove impurities and scale on the outer surface, rinse it in alcohol, take it out and dry it naturally, and coat the outer surface of the inner sleeve 6 and the groove 7 with a layer of Borax with a thickness of 0.82mm is placed in the cavity 5 of the cast iron metal mold 3 after being dried naturally;

[0035] 3) The outer wear-resistant metal melt enters the cavity 5 through the sprue cup 1, the sprue 2, and the inner runner 4, and the outer wear-resistant metal 10 is poured by the bottom pouring method, and the outer wear-resistant metal 10 is made of high Chromium wear-resistant white cast iron, the specific composition is as follows (weight%): 3.06%C, 18.71%Cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com