Log dyeing method

A dyeing method and technology for logs, applied in the field of wood dyeing, can solve the problems of high pressure and difficult to evenly dye wood, and achieve the effects of increasing service life, increasing utilization value, and being widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

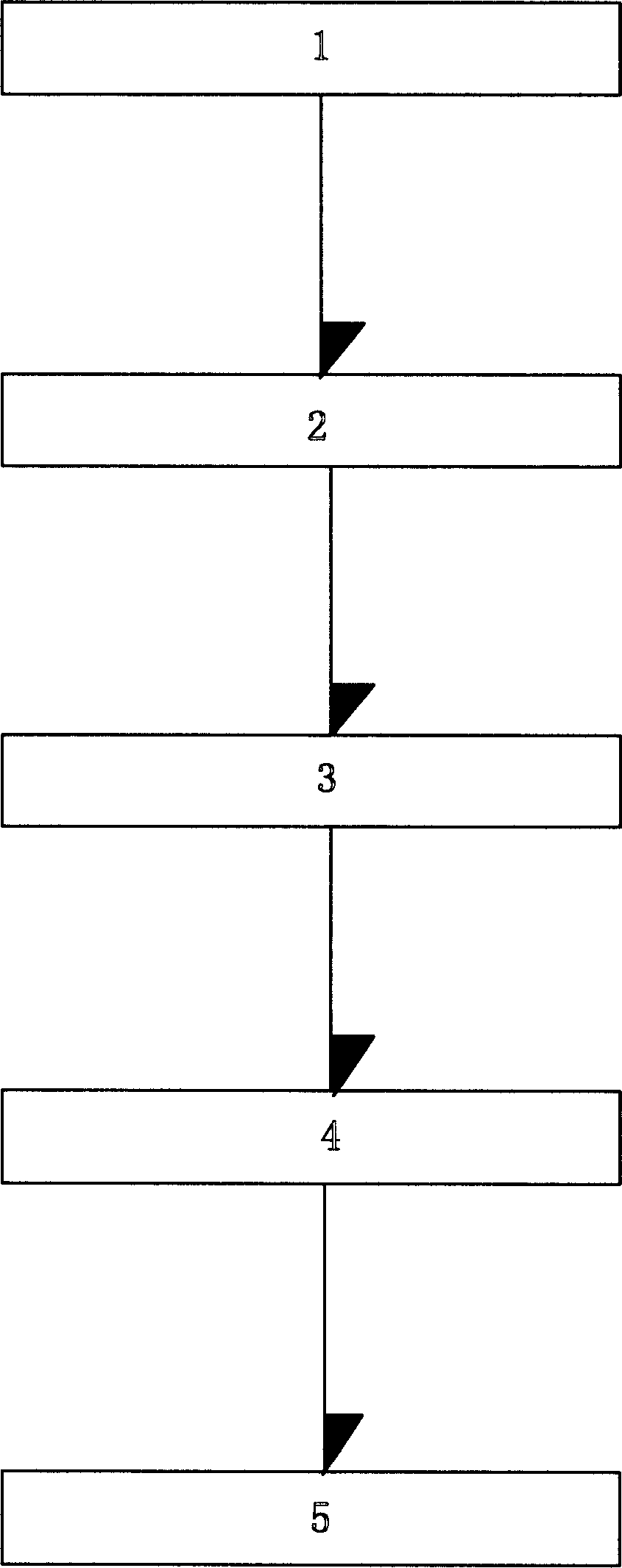

[0027] In the figure, 1 is material selection and drying; 2 is dyeing, including room temperature dipping and hot-press dyeing; 3 is cleaning; 4 is drying;

[0028] Wood dyeing is a chemical or physical chemical combination of dyes and wood to make the wood have a certain firm color. It is an important means to improve the surface quality of wood, improve the visual characteristics of wood and increase the added value of wood.

[0029] Due to the large thickness, long wood, and thick dyeing depth, it is difficult to dye the wood evenly and thoroughly by the self-permeability of the dyeing solution under conventional conditions. →Atmospheric pressure→Cycle dyeing process", through compressed air pressurization, so that the dye solution can penetrate into the interior of the wood more smoothly.

[0030] The dye penetration process is divided into three stages, that is, the diffusion stage of the dye to the fiber surface, the adsorption stage of the dye on the fiber surface, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com