Novel Beta/Gamma-TiAl alloy with ultra-fine grain

A technology of ultra-fine grains and alloys, applied in the field of TiAl alloys, which can solve the problems of the influence of the grain size of the alloy structure and the difference in influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] (1) Selection of raw materials

[0044] The purity of each metal component selected for the preparation of the master alloy ingot of the present invention is shown in Table 1, and the alloy composition is Ti-43Al-6Nb-1Cr-1Mo-0.2B (atomic percentage).

[0045] (2) Preparation of master alloy ingot

[0046] Under the protection of high-purity argon gas, a water-cooled copper crucible electromagnetic induction suspension melting equipment is used to melt master alloy ingots. The specific procedures are as follows:

[0047] 1) After the surface of the metal raw material is mechanically polished to remove the oxide skin on the surface, the material is prepared according to the designed composition ratio, and the weight of each ingot is about 40g. Vacuum down to 5×10 -3 Pa; Fill the furnace with a certain amount of high-purity argon gas (99.999%), and the pressure range of argon gas is 0.8~1.0MPa. Half the weight of Al is smelted together with other alloys int...

Embodiment 2

[0053] Using the same composition as in Example 1, the master alloy ingot preparation method adopts non-consumable arc melting in a water-cooled copper crucible, and its specific procedures are as follows:

[0054] 1) After mechanically grinding the surface of the metal raw material to remove the oxide skin on the surface, prepare the material according to the designed composition ratio; put the prepared material into the water-cooled copper crucible in the melting furnace according to the weight of about 40g per ingot, cover Vacuum the upper furnace cover to 2×10 -3 Pa; fill a certain amount of high-purity argon (99.999%) into the furnace, and the pressure range of argon is 0.4~0.6MPa.

[0055] 2) Before melting the master alloy ingot, melt the Ti ingot used for gas absorption 2~3 times.

[0056] 3) Multi-pass smelting master alloy ingots: use non-consumable tungsten electrodes to first melt Ti, Nb, Cr, Mo and other high melting point components together unde...

Embodiment 3

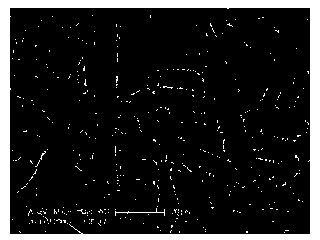

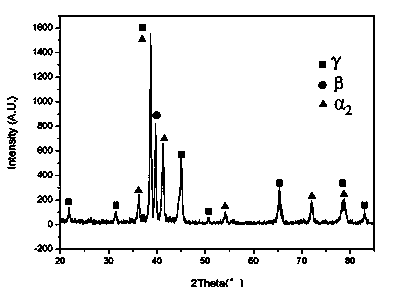

[0059] Using the same preparation method as in Example 1, the alloy composition is Ti-43Al-4Nb-4Mo-0.2B (atomic percentage). Such as Figure 4 , the obtained alloy has an average grain size of 10 μm, while stabilizing a large amount of β-phase to room temperature and enriching at the lamellar grain boundaries ( Figure 5 , 6 ), but black long strips of B compound Ti appeared in the tissue 2 B, will affect the processing properties of the alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com