Patents

Literature

119 results about "Reticular fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Reticular fibers, reticular fibres or reticulin is a type of fiber in connective tissue composed of type III collagen secreted by reticular cells. Reticular fibers crosslink to form a fine meshwork (reticulin). This network acts as a supporting mesh in soft tissues such as liver, bone marrow, and the tissues and organs of the lymphatic system.

Method for preparing reticular fiber reinforced hollow fiber membrane of polyvinylidene fluoride

InactiveCN1864828AAperture size controllableStrong blast resistanceSemi-permeable membranesBursting strengthHollow fibre membrane

The invention discloses a method for preparing intensified netted hollow fiber membrane, belonging to technology for preparing hollow fiber membrane. The process comprises: taking polyvinylidene fluoride as membrane material, N,N-dimethyl formamide as disslovant, polyvinyl pyrrolidon as additive, preparing membrane liquid according to a certain proportion among them; textiling hollow fiber membrane under certain temperature, pressure and dragging speed; braiding net with synthetic fiber out of hollow fiber membrane, putting intensified hollow fiber membrane sequentially through membrane producing liquid and coagulating bath; coating and congealing under certain temperature, pressure and dragging speed, and getting final product. The invention is characterized in that there is no clogging, the flow resistance is small, stretching intensity amounts to 10-50 MPa, bursting strength is 0.5-1 MPa, and the process is continous and easy for industrialization.

Owner:TIANJIN UNIV

Human umbilical cord mesenchymal stem cell exosome type external cream and preparation method thereof

InactiveCN107854418AEasy to get materialsA large amountCosmetic preparationsToilet preparationsFiberBase cream

The invention provides human umbilical cord mesenchymal stem cell exosome type external cream and a preparation method thereof, and aims at the solving the problem in effectively inducing human umbilical cord mesenchymal stem cells to massively synthesize and secrete mesenchymal stem cell exosome capable of specifically promoting epidermis cell and hypodermal cell to proliferate, divide and differentiate, promoting the formation of collagenous fibers, reticular fibers and elastic fibers, and adjusting the secreting functions of collagen and mucopolysaccharide. The cream comprises human umbilical cord mesenchymal stem cell exosome extracting liquid and a base cream formula based on the mass ratio ranging from (1:20) to (3:10), wherein the human umbilical cord mesenchymal stem cell exosome extracting liquid is prepared by performing hungry culture on P2-P5 generations of human umbilical cord mesenchymal stem cells and stimulating through epidermal growth factors. The prepared cream has the effects of improving the skin quality, resisting the aging of skin cells, recovering the normal structure and physiological function of the skin, reducing the skin atrophy exsiccosis, and moisturizing the skin tissue.

Owner:南京九圣生物医学科技股份有限公司

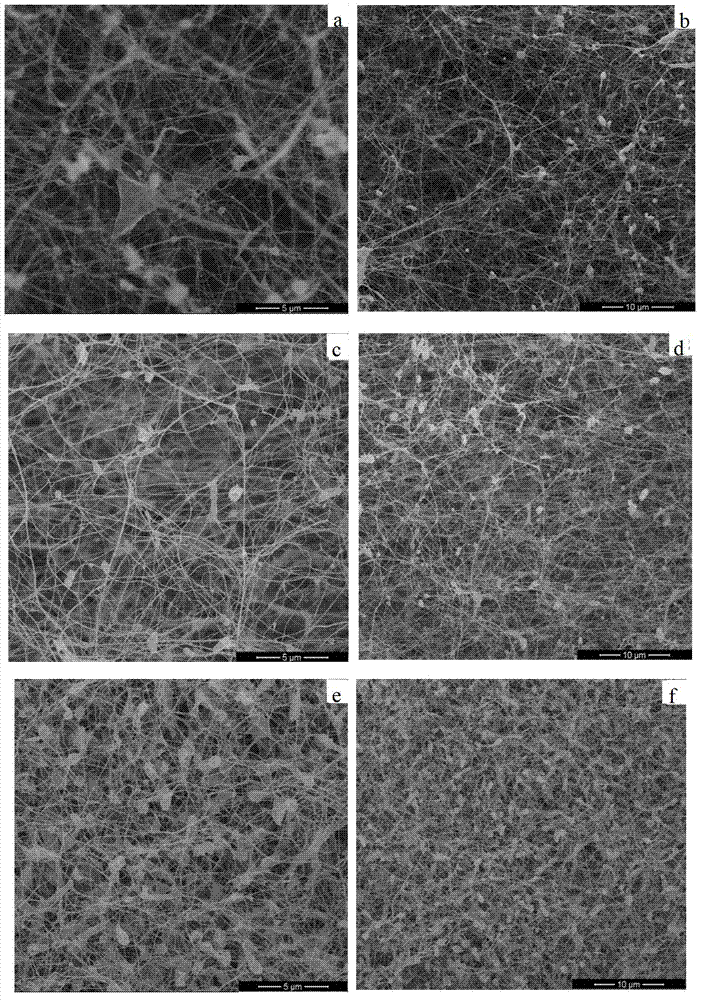

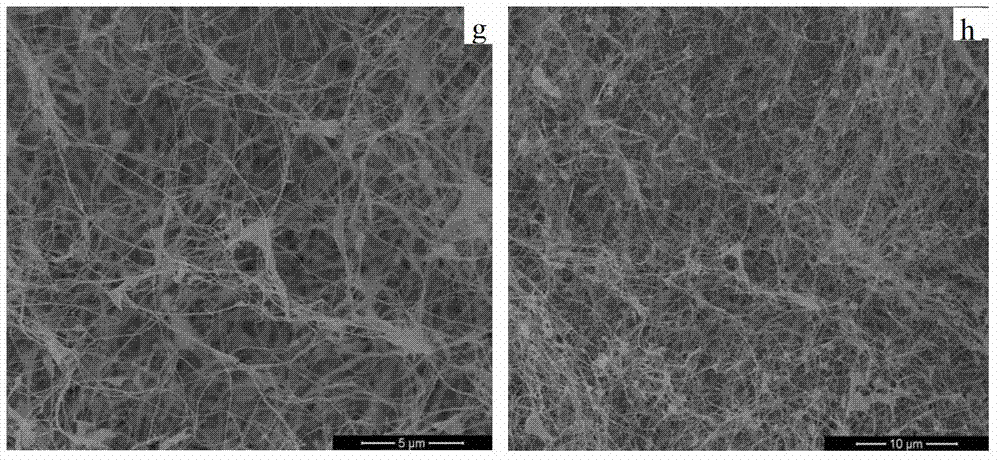

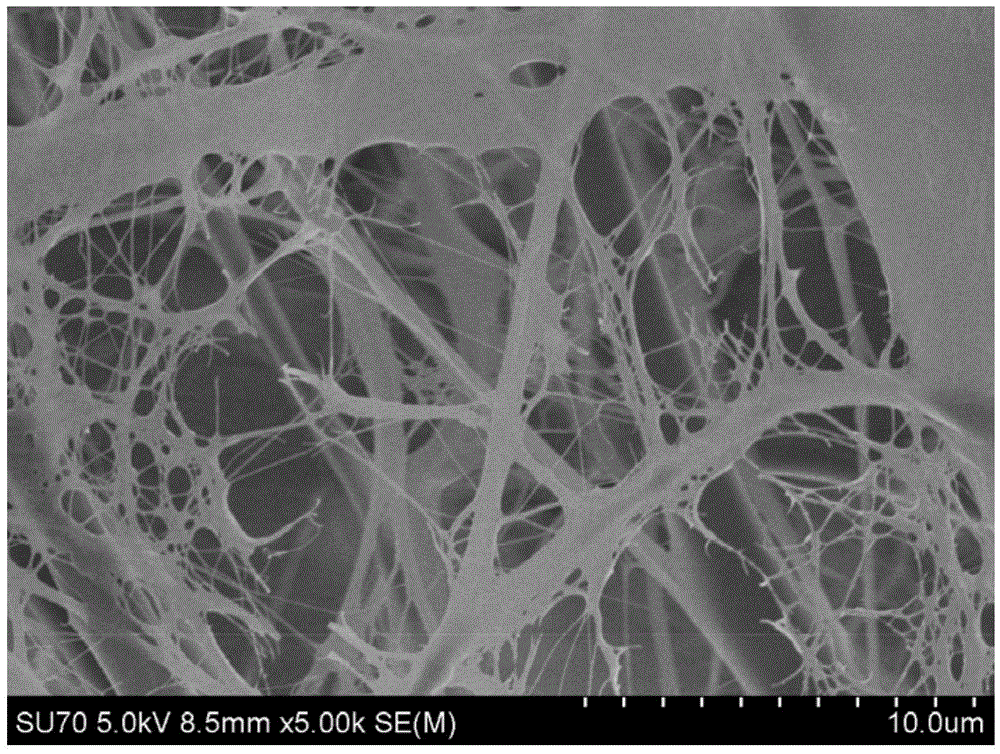

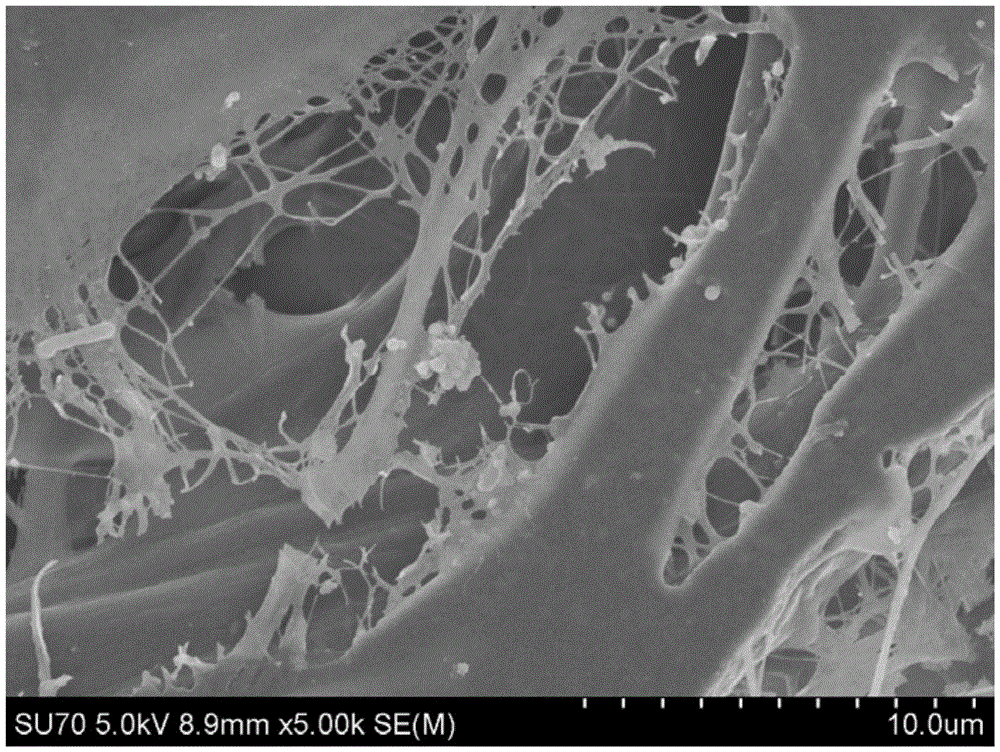

Preparation method of graphene/bacterial cellulose composite material

InactiveCN102924755AInhibition of agglomerationSimple preparation processBiocideOther chemical processesFiberCulture fluid

The invention discloses a preparation method of a graphene / bacterial cellulose composite material. Bacterial cellulose and graphene are co-cultured in situ to obtain the graphene / bacterial cellulose composite material, wherein the graphene evenly grows in the bacterial cellulose reticular fiber structure. The preparation method comprises the following steps: 1) preparing a bacterial cellulose culture fluid, and sterilizing at high temperature under high pressure for 30-60 minutes; 2) inoculating the strain in the bacterial cellulose culture fluid, and rocking in a rocker for 12-48 hours; 3) carrying out ultrasonic treatment on a 0.2mg / ml graphene dispersion liquid for 1-3 hours, and adding the graphene dispersion liquid into the bacterial cellulose culture fluid with the strain, wherein the volume ratio of the graphene dispersion liquid to the bacterial cellulose culture fluid is 1:5-1:10; 4) rocking the mixed liquid in the rocker for 12-24 hours; 5) putting the liquid in a 28 DEG C thermostatic oven, and standing for 1-2 weeks to obtain the graphene / bacterial cellulose composite material; and 6) cleaning the graphene / bacterial cellulose composite material, and carrying out freeze-drying. In the composite material, the graphene is evenly distributed on the bacterial cellulose fibers, thereby effectively inhibiting the defect of high agglomeration tendency of graphene particles.

Owner:EAST CHINA JIAOTONG UNIVERSITY

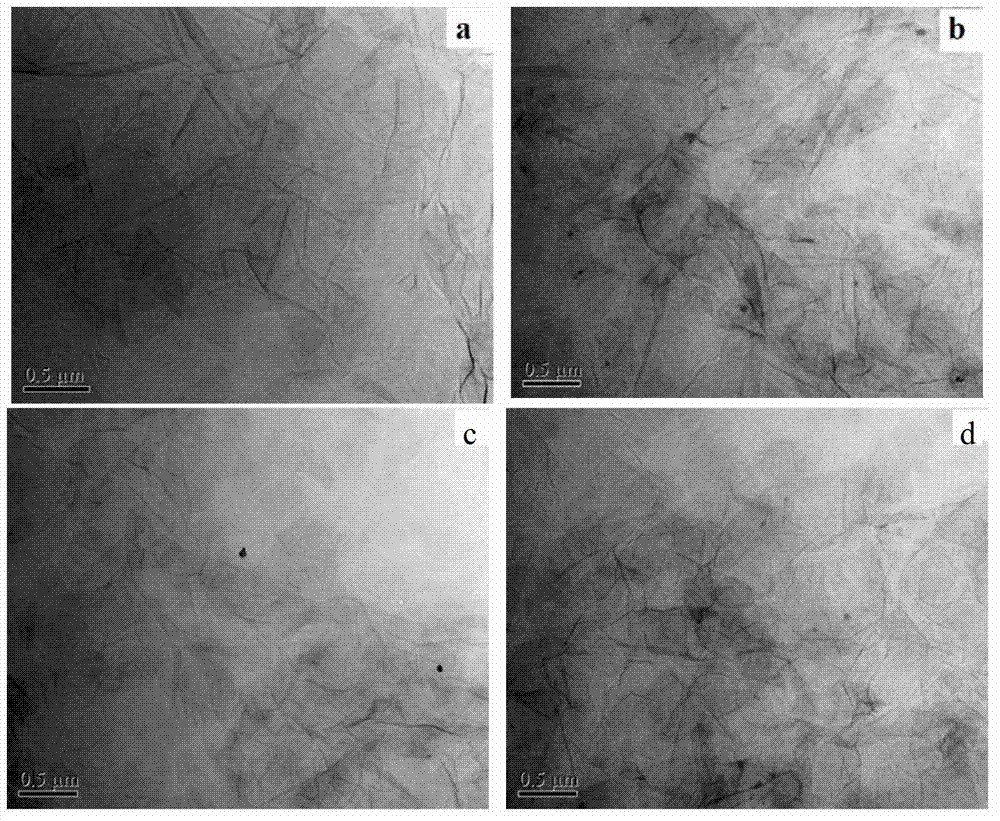

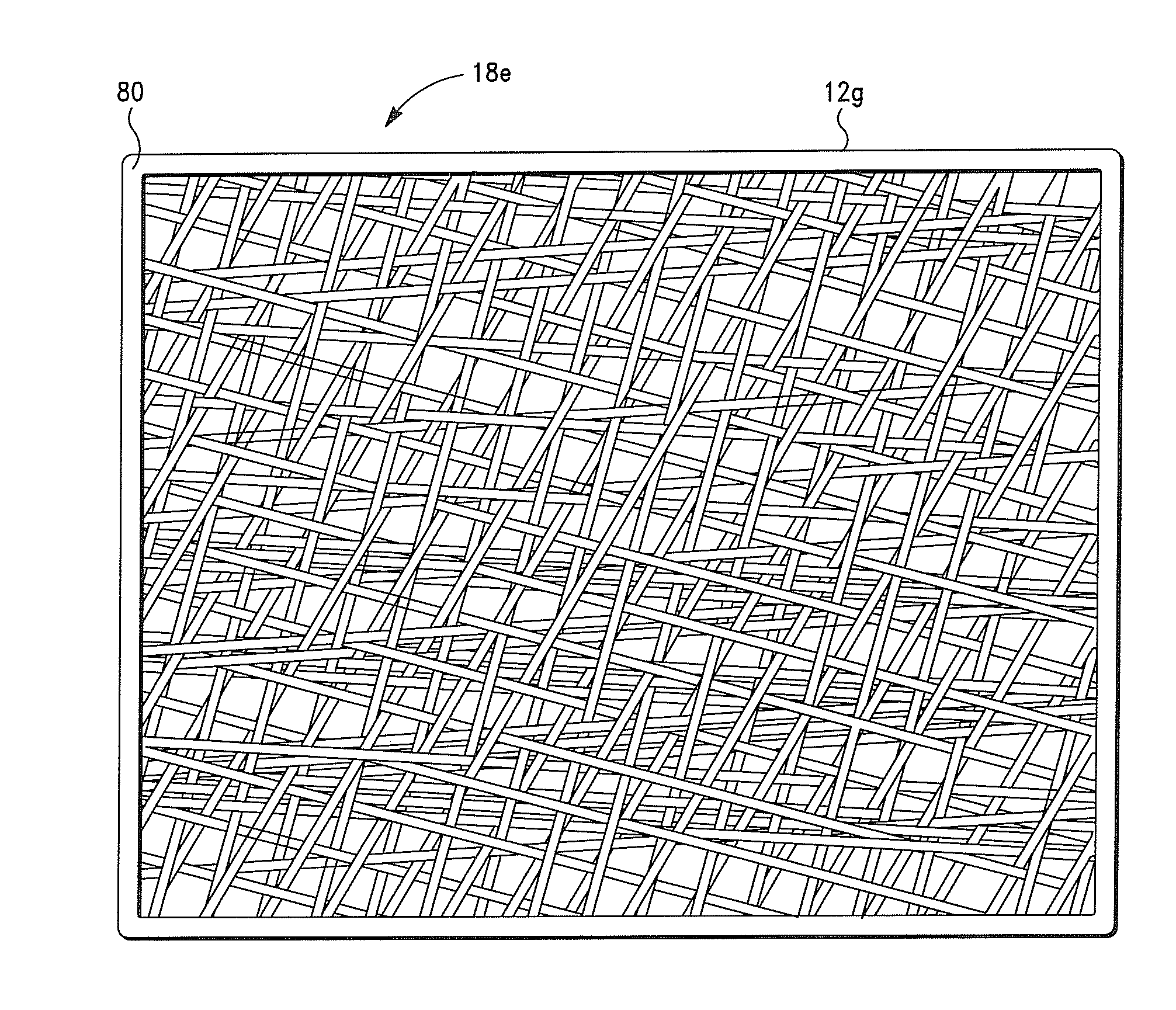

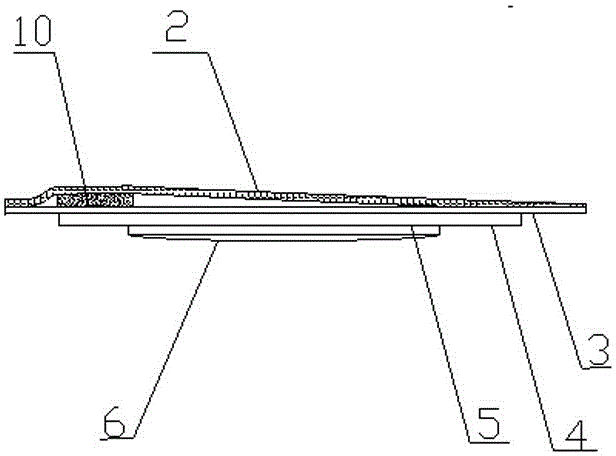

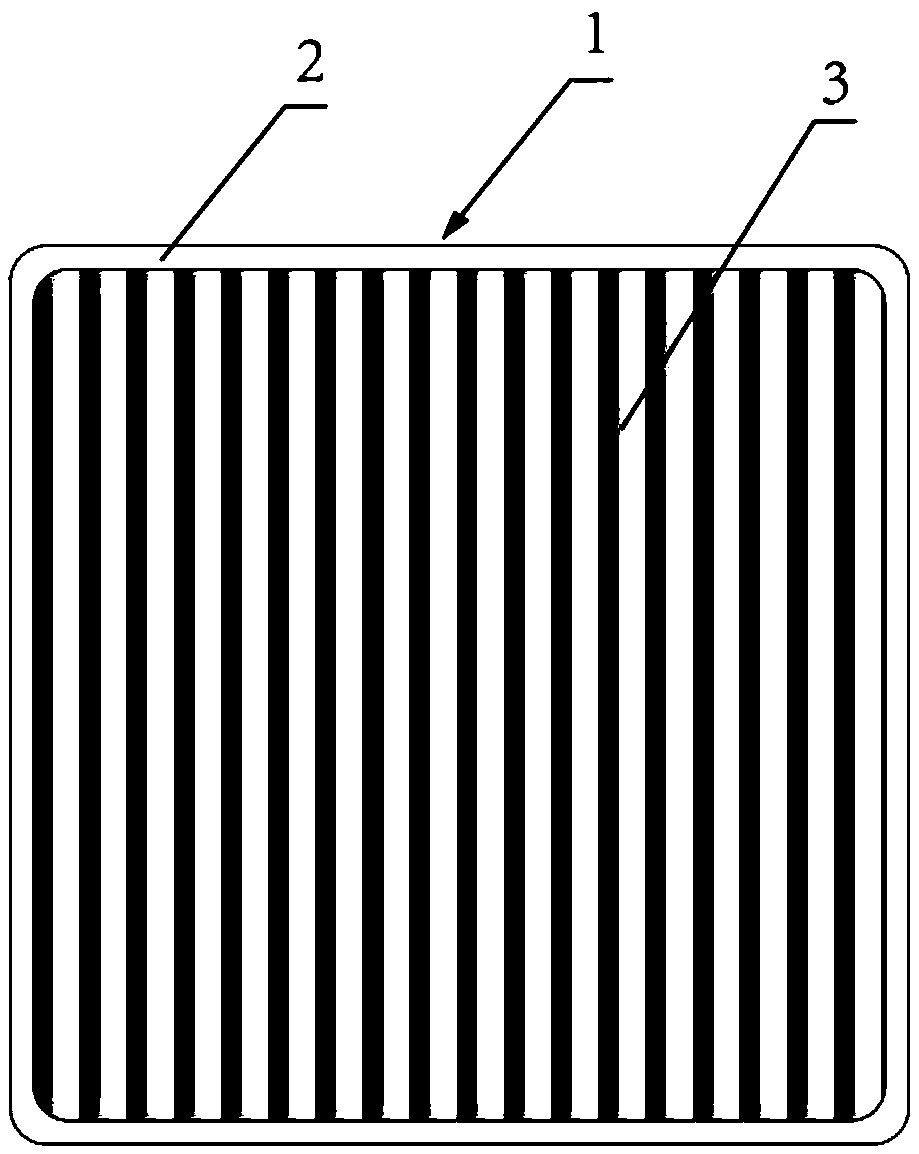

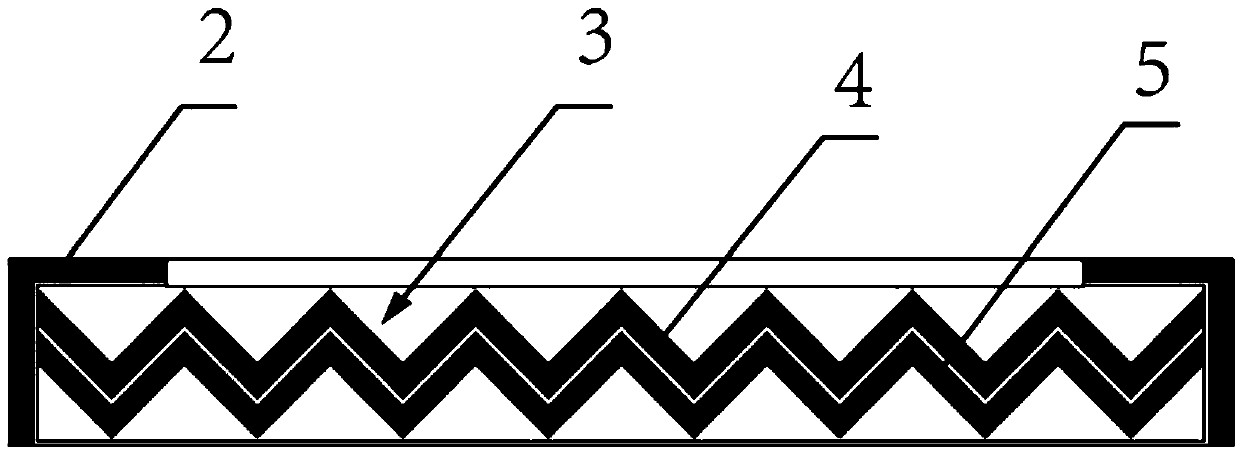

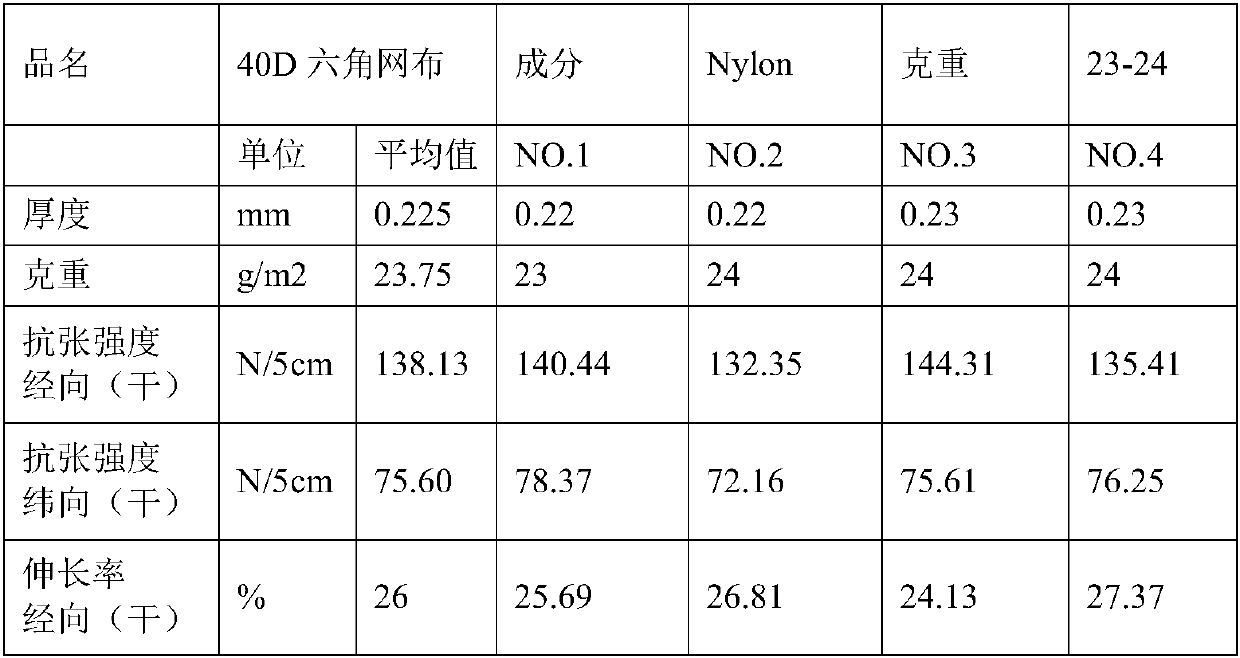

Composite elastic material screen cloth

ActiveCN102975420AIncrease elasticityReduce lossesClimate change adaptationHeat proofingFiberWave shape

The invention discloses a composite elastic material screen cloth which comprises a warp-knitted three-dimensional fabric formed by a top layer, a bottom layer and a connecting layer for connecting the top layer with the bottom layer, wherein a cavity is surrounded by the top layer, the bottom layer and the connecting later, the cavity is internally filled with a composite material capable of being solidified, the connecting layer consists of a plurality of layers of reticular fiber fabrics which are distributed in parallel with one another along the length direction of the screen cloth, each layer of the reticular fiber fabrics is formed by a plurality of alternately woven wave-shaped fibers, each wave peak of each wave-shaped fiber is fixedly connected with a first node, the first nodes fixedly connected with the wave peaks on the wave-shaped fibers are arranged on the same straight line, and 1-5 node(s) arranged between the adjacent two wave peaks of the wave-shaped fibers is / are available. The composite elastic material screen cloth has the advantages that the composite elastic material screen cloth is convenient to use, and convenient to disassemble and transport by workers, and the special material in a reticular composite concrete layer with certain thickness and certain hardness can be formed only by irrigating liquids, such as water, when the screen cloth is used; and the screen cloth is good in comprehensive performance, flexible to use, low in cost, convenient to construct, and high in efficiency, and is environment-friendly.

Owner:蔡晓民 +1

All-natural moisture-retention dust-proof insulation weeding multifunctional environmental material

InactiveCN101230144AKeep moisturePromote growthPlant protective coveringsVegetable oilPulverized fuel ash

The invention relates to environment protection material. Natural multi-purpose environmental protection material with functions of moisturizing, dust prevention, heat preservation and weed eradication is characterized in that the material is made from raw materials of plant material powder, filling material, reticular fiber, foaming agent, binding agent, humectant and vegetable oil, and prepared into s block shape; The occupying mass percent of the raw materials is as follows: 50-65 percent of plant material powder, 10-15 percent of reticular fiber, 5-10 percent of foaming agent, 5-10 percent of binding agent, 5-10 percent of humectant, and 0.5-1 percent of vegetable oil; the plant material powder is admixture of one or two of straw, caving, leaf, tree branch, bark, bamboo, vine, bulrush, aquatic grass, pygmy water lily, water fern, nuphar pumilum, singharanut, lotus flower, loosestrife, common snapdragon, waterweed and hydrilla verticillata which are smashed into powder, and when the plant material powder is admixture of more than any two, the compounding ratio is the non critical ratio; the filling material adopts pulverized fuel ash and clay. The invention has the advantages of low cost, moisturizing, dust prevention, and weed eradication.

Owner:刘俊松

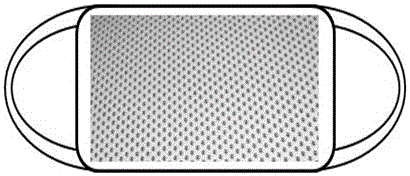

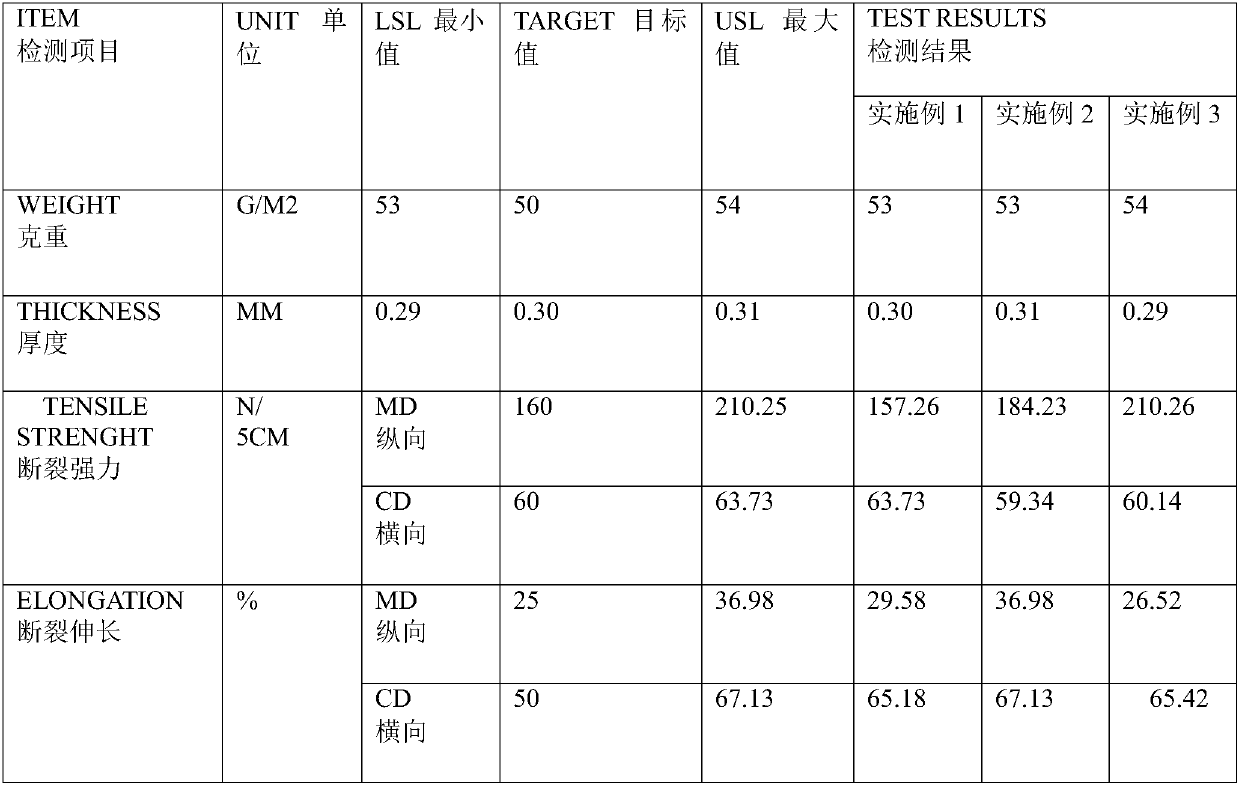

Production process of special non-woven fabric for facial mask

ActiveCN104233628AImprove permeabilityAvoid destructionSucessive textile treatmentsFilament forming substance formingViscous flowMixed materials

The invention discloses a production process of a non special -woven fabric for a facial mask. The production process comprises the following steps that raw materials including dacron, nylon and polyethylene are prepared according to a weight ratio being (10-20):(30-40):(30-50); the dacron and nylon raw materials are uniformly mixed and stirred; the mixed materials are melted and compressed by a screw extrusion machine into viscous flow state melts, and the melts are respectively conveyed to a melt filer through a melt pipeline to be filtered; the filtered raw materials are respectively conveyed into a spinning die head; a fine melt flow is extruded from a spinning hole and is then cooled, drafted and shaped to form fiber through a drafting air passage under the effect of process cooling air; then, through a diffusion air passage, the fiber is uniformly adsorbed onto a net forming conveying belt, and a continuous reticular fiber layer is formed; the continuous fiber nets pass through a hot rolling mill, and the fabric nets form non-woven fabrics; the cloth is subjected to softening treatment through softening agents. The production process has the advantages that no stimulation is generated on the skin, silk protein liquid can be better adsorbed, and meanwhile, the ventilation performance is good.

Owner:ZHEJIANG KEDEBANG NONWOVEN CLOTH

High-efficiency low-resistance nano anti-virus mask and production method thereof

InactiveCN102499493AEasy to makePrevent intrusionSynthetic resin layered productsNon-woven fabricsPolymer dissolutionFiber

The invention relates to a high-efficiency low-resistance nano anti-virus mask and a production method thereof. The nano anti-virus mask comprises a filtering material and is characterized in that the filtering material comprises a base material and a static net spraying film. The production method of the nano anti-virus mask is characterized by comprising the following steps of: dissolving a polymer, adding an inorganic salt, and stirring the mixture to form a uniform spinning solution; and carrying out static net spraying on the obtained spinning solution, depositing the static net spraying film containing two-dimensional reticular fiber and one-dimensional electrospun fiber on a receiving device with the base material attached to obtain a composite structure of the base material and the static net spraying film, and preparing the composite structure into the nano anti-virus mask. The nano anti-virus mask has high virus filtering efficiency and small respiratory resistance.

Owner:DONGHUA UNIV

Novel anti-haze mask

InactiveCN105768276AImprove efficiencyThe principle of dust removal is novel and uniqueProtective garmentEngineeringCotton cloth

The invention discloses a novel anti-haze mask, wherein a binding agent layer absorbent sheet is arranged on the outer layer or inner core of the mask; and the binding agent layer absorbent sheet is made by coating a binding agent on a non-woven fabric or a cotton fabric or silks, which serve as a substrate material, and covering the substrate material with reticular fibers. On the basis of bionic thought, the binding agent layer absorbent layer can promote the coagulation of aerosol, so that the aerosol is turned into large particles, and various particles in air can be bound. The anti-haze mask, which is novel, efficient and cheap, plays an important role in protecting people's health.

Owner:刘智懿

Method of recovering and reconstructing vegetation of mining land

InactiveCN101518186AAvoid churnPromote recoveryHorticultureSoil-working methodsRevegetationCrushed stone

The invention relates to a method of recovering and reconstructing vegetation of mining land, which comprises the following steps: clearing float stones and flattening broken stones; laying reticular fiber ecological mats along the slope; and punching holes on the laid ecological mats, mixing and uniformly stirring grass seeds, shrub seeds and loam soil, sowing the mixture into the holes, and then covering the holes by sun-shading nets. The invention can protect water and soil, i.e. prevent soil which is artificially covered on the slope of the broken stones from losing by covering the reticular fiber ecological mats, balance temperature, improve efficiency and prevent sand and dust from blowing.

Owner:蓟县林业调查规划设计所

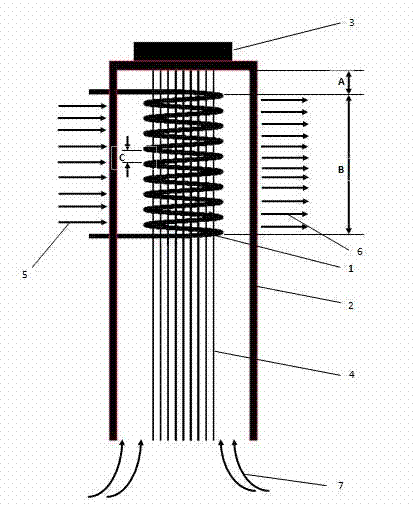

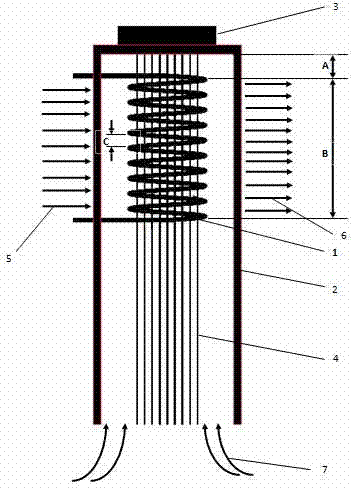

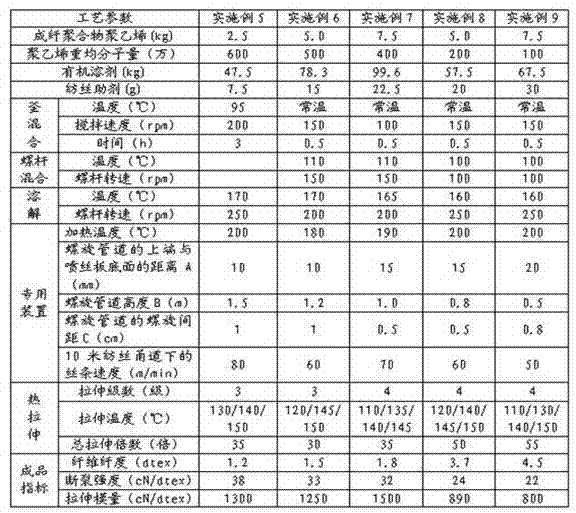

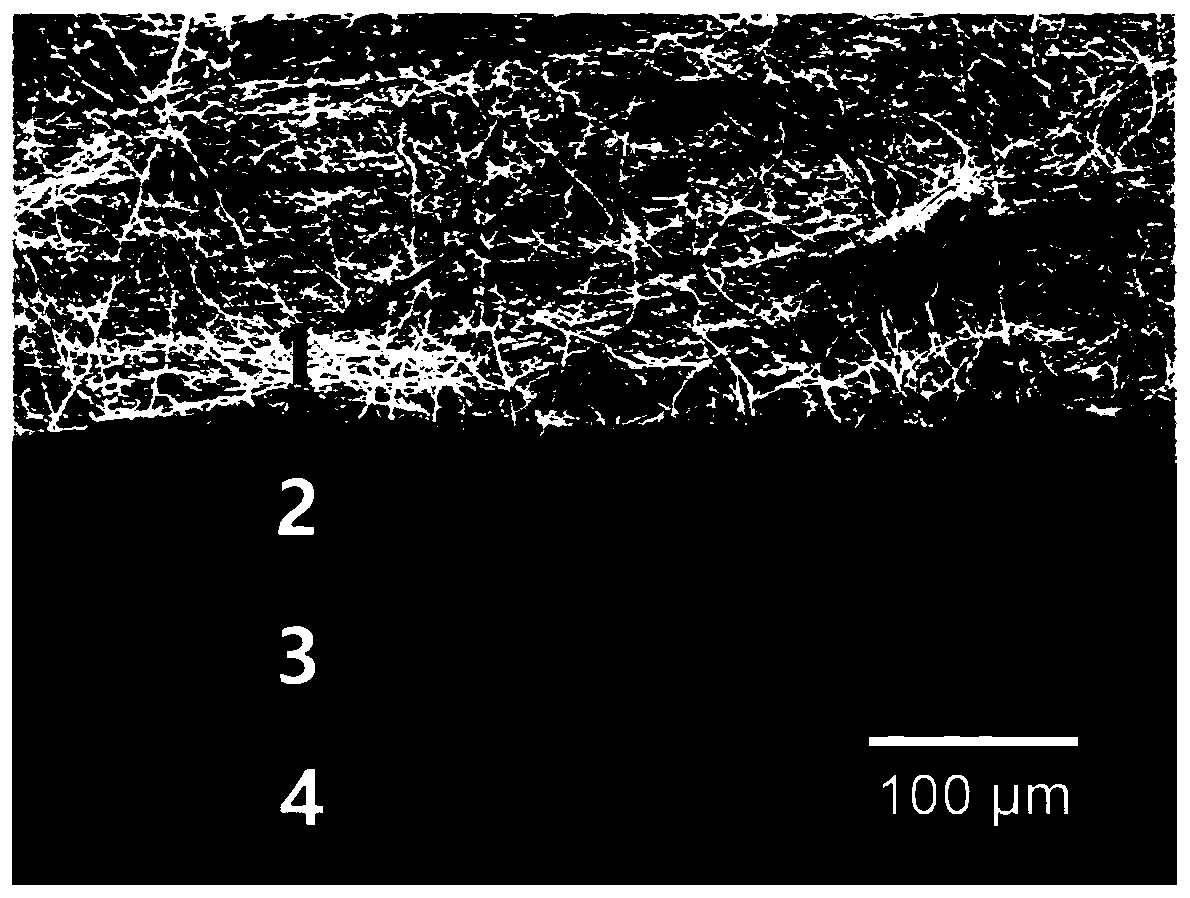

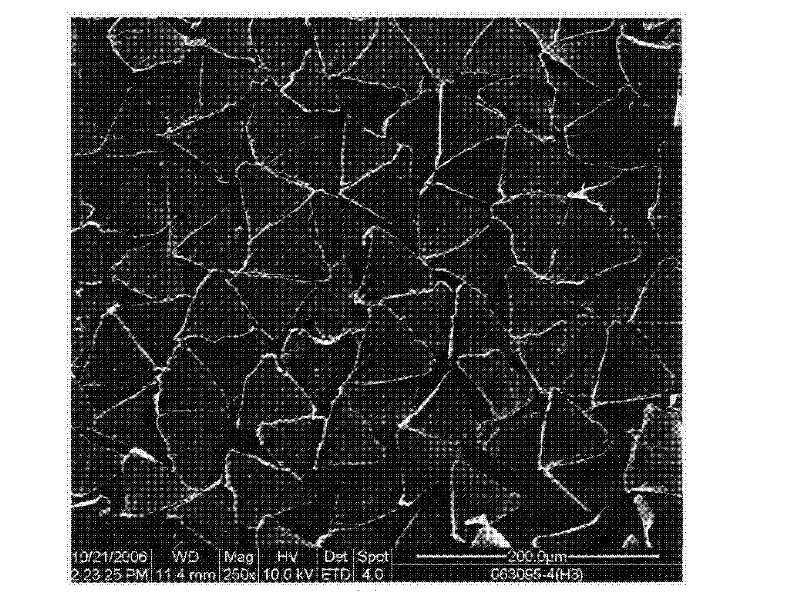

Preparation method of high strength polyethylene fiber and special device thereof

ActiveCN102226300AQuick drawSimple process routeArtificial filament washing/dryingArtificial filament heat treatmentState of artOrganic solvent

The invention provides a preparation method of high strength polyethylene fiber and a special device thereof. The preparation method comprises the following steps: fibre-forming polymer polyethylene and organic solvent are mixed with spinning aid, the mixture is dissolved to form organic solution, then the organic solution is extruded from a spinneret, liquid trickles enter a flashing heating area below the spinneret to ensure that the organic solvent in the liquid trickles is flashed fast, polyethylene is taken from the gap of spiral pipes of the special device arranged in the flashing heating area to form solid precursor with a fibrillated superfine reticular fiber structure; and the precursor performs hot drawing to prepare the high strength polyethylene fiber with the reticular structure. As the preparation method adopts the flashing technology and the special device, the problem of the prior art that the solvent in strand silk is difficult to volatilize owning to thick volatile solvent layer, can be effectively solved; and the process flow is shortened, the industrialized production is easy to realize, the production efficiency is increased and the product quality of the high strength polyethylene fiber can be ensured.

Owner:JIANGSU LIUJIA TECH CO LTD +1

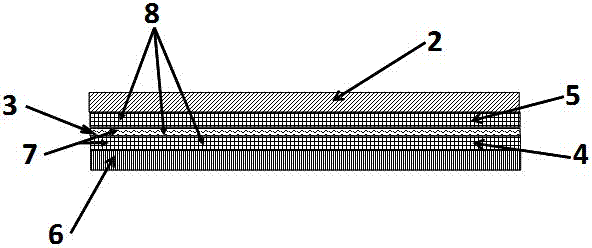

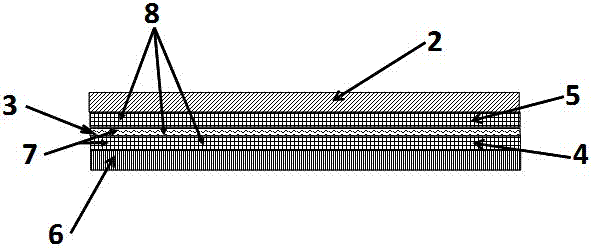

Oriented draining dressing with effect of keeping wound moderate wetting and preparation method thereof

ActiveCN110269749AModerately moistAppropriate moisture absorptionAdhesive dressingsAbsorbent padsMedicineNanofiber

The invention relates to an oriented draining dressing with an effect of keeping a wound moderate wetting and a preparation method thereof. The oriented draining dressing with the effect of keeping a wound moderate wetting has a composite layer structure, and comprises a hydrophilic layer, a moisturizing layer and a volatile layer which are adjacent one another, wherein the hydrophilic layer, the moisturizing layer and the volatile layer have porous structures and gradually reduced pore diameters; and the hydrophilic layer is made of a hydrophilic material having a moisture regain of less than or equal to 5 percent, and the moisturizing layer is made of a hydrophilic material having a moisture regain of more than or equal to 100 percent. The preparation method comprises the following steps: respectively forming a polysaccharide B nanofiber membrane and a hydrophobic layer on two side surfaces of a polysaccharide A non-woven fabric; and forming a bacterial cellulose ultrafine reticular fiber membrane on the surface of the polysaccharide B nanofiber membrane to prepare the oriented draining dressing with the effect of keeping a wound moderate wetting. The oriented draining dressing with the effect of keeping a wound moderate wetting can be used for keeping a wound moderate wetting for a relatively long period, and has an excellent antibacterial effect. The preparation method of the oriented draining dressing with the effect of keeping a wound moderate wetting is relatively low in cost, and has an excellent application prospect.

Owner:DONGHUA UNIV

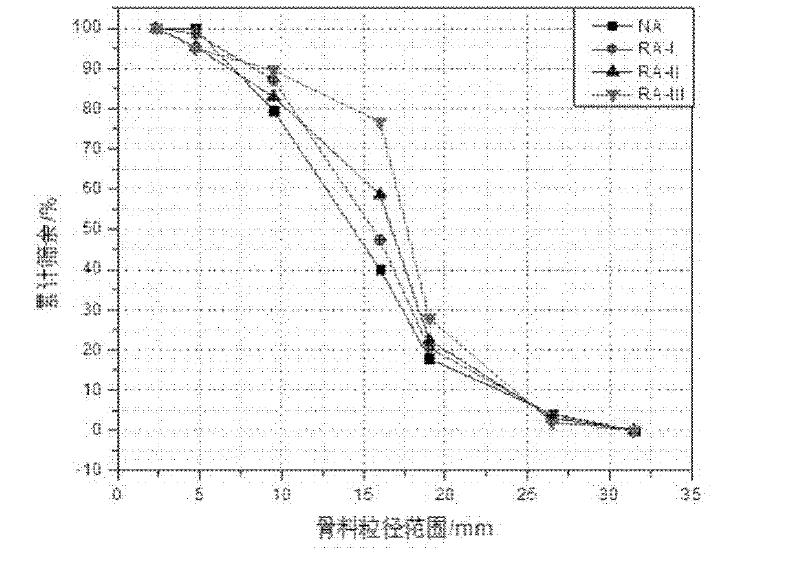

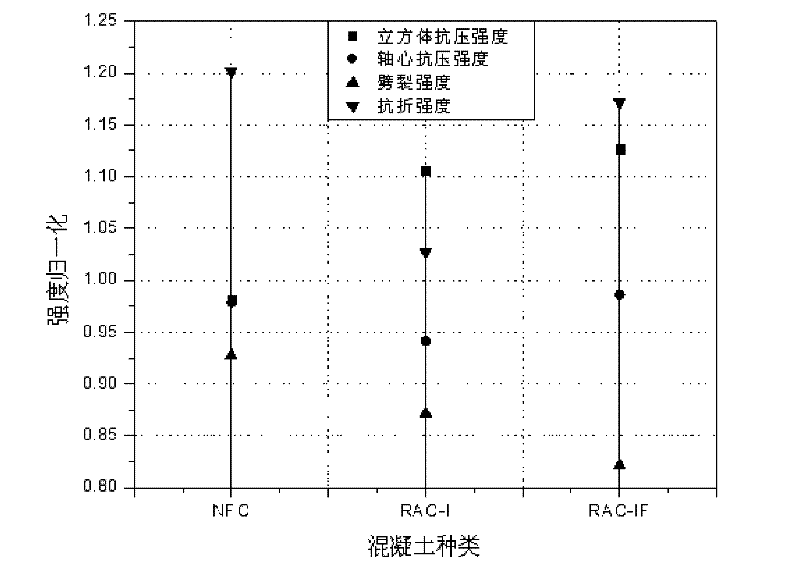

Low elastic modulus fiber-enhanced recycled concrete preparation method

InactiveCN102531494AImprove performanceInterface initial defect crack improvementSolid waste managementPortland cementMechanical property

The invention discloses a low elastic modulus fiber-enhanced recycled concrete preparation method. The method is characterized in that crushed waste concrete is used as a portion of coarse aggregate of concrete; and low elastic modulus fiber is doped in the recycled concrete to improve performance of the recycled concrete. The low elastic modulus fiber-enhanced recycled concrete contains, calculated by 100 weight parts per cubic meter concrete, 32.5R ordinary portland cement 20 to 21 parts, fine aggregate 18 to 20 parts, natural coarse aggregate 34 to 36 parts, recycled coarse aggregate 14 to26 parts, polypropylene three-branch anti-aging reticular fiber 0.03 to 0.05 parts, and water 8 to 10 parts. Based on the tension resistance, the polypropylene three-branch anti-aging reticular fibercan prevent the development of an interface initial defect crack between fresh mortar and fresh coarse aggregate in the concrete, and can remarkably improve the interface crack between fresh mortar and old mortar of the recycled concrete. The preparation method is simple, and the recycled concrete has reliable mechanical property and wide commercial application prospect.

Owner:XIAN COAL CONSTR ENG

Grouting material for expressway bridge bearings and preparation method thereof

The invention discloses a grouting material for expressway bridge bearings, which comprises the following components in parts by weight: 400-500 parts of cement, 300-450 parts of quartz sand, 10-20 parts of fly ash, 2-4 parts of a water reducing agent, 1-1.5 parts of a coagulation accelerator, 1-4 parts of an expander, 1-3 parts of a retarder, 2-3 parts of a defoamer, 2-5 parts of a thickener, and1-1.5 parts of polypropylene reticular fibers. The invention further discloses a preparation method of the grouting material for expressway bridge bearings. The cement uses in the grouting material adopts sulphoaluminate cement and ordinary portland cement, which not only realizes the characteristics of early strength, but also avoids the problem of strength substantial decline caused by the useof the ordinary portland cement alone. The raw materials of the grouting material have a wide range of sources and low price. The preparation method is simple, and suitable for large-scale promotion,and the grouting material has good construction performance, can realize self-flow leveling, has long operation time, and has a smooth surface after being poured, and the shortcomings of traditional mortar such as irregularity, easy cracking, easy stripping and easy dusting can be overcome.

Owner:石家庄国辰知识产权服务有限公司

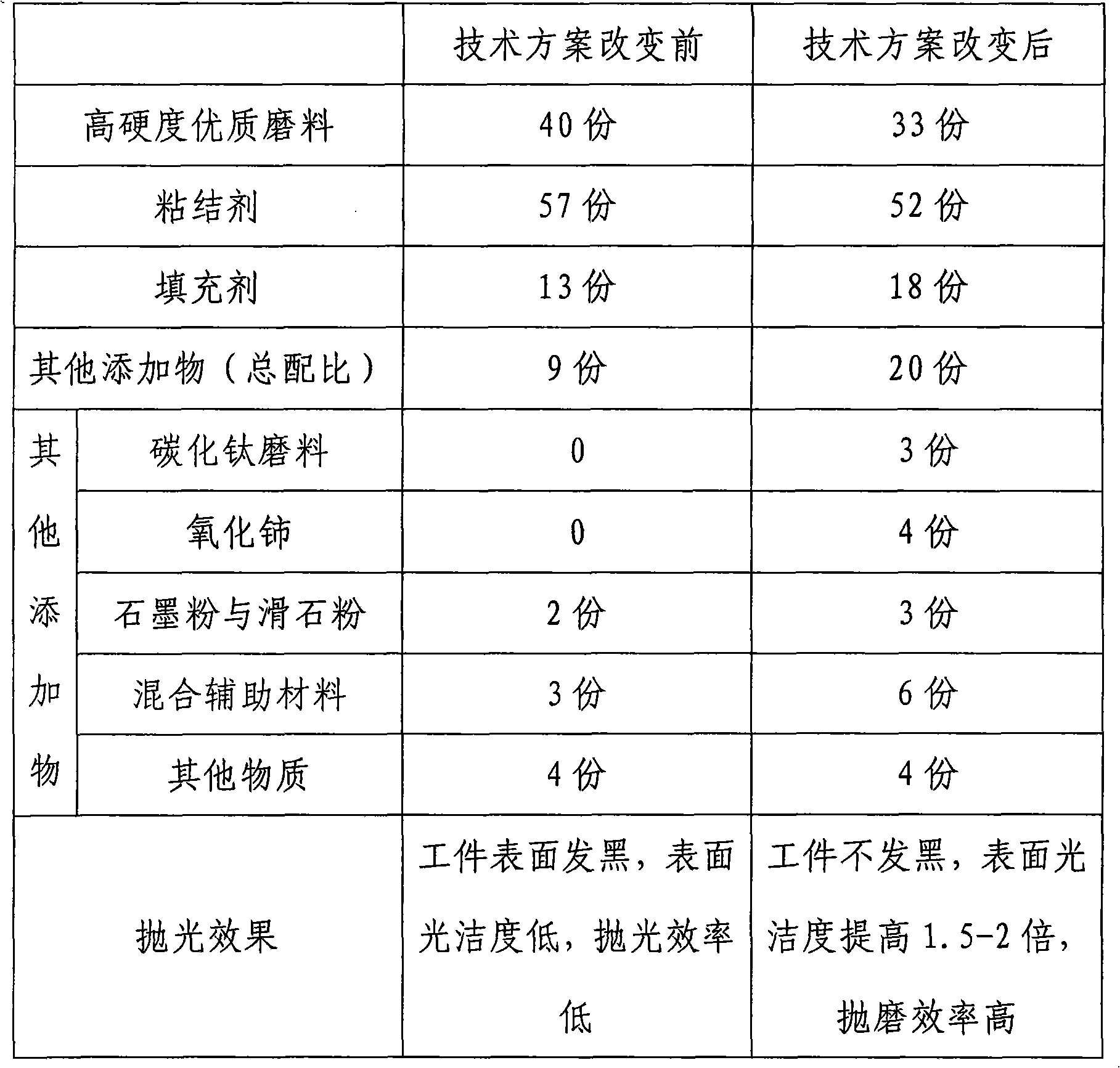

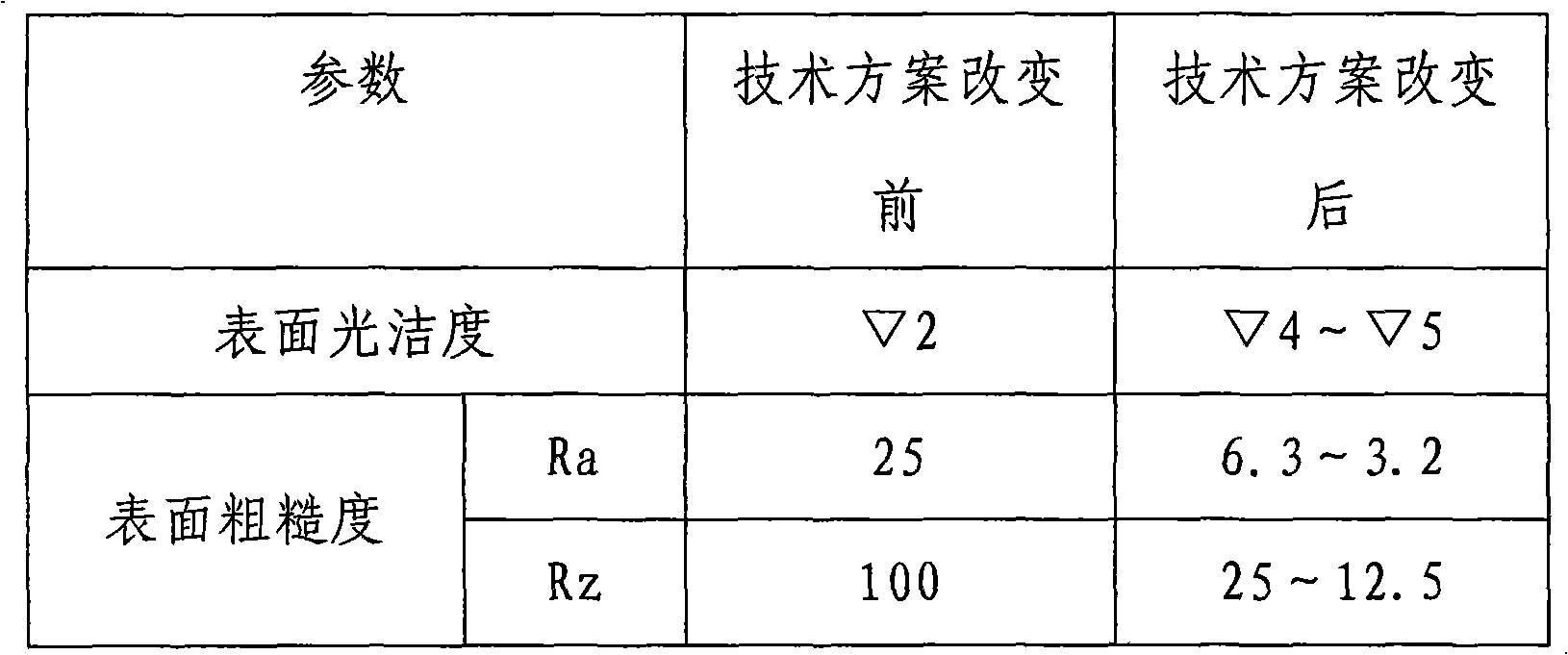

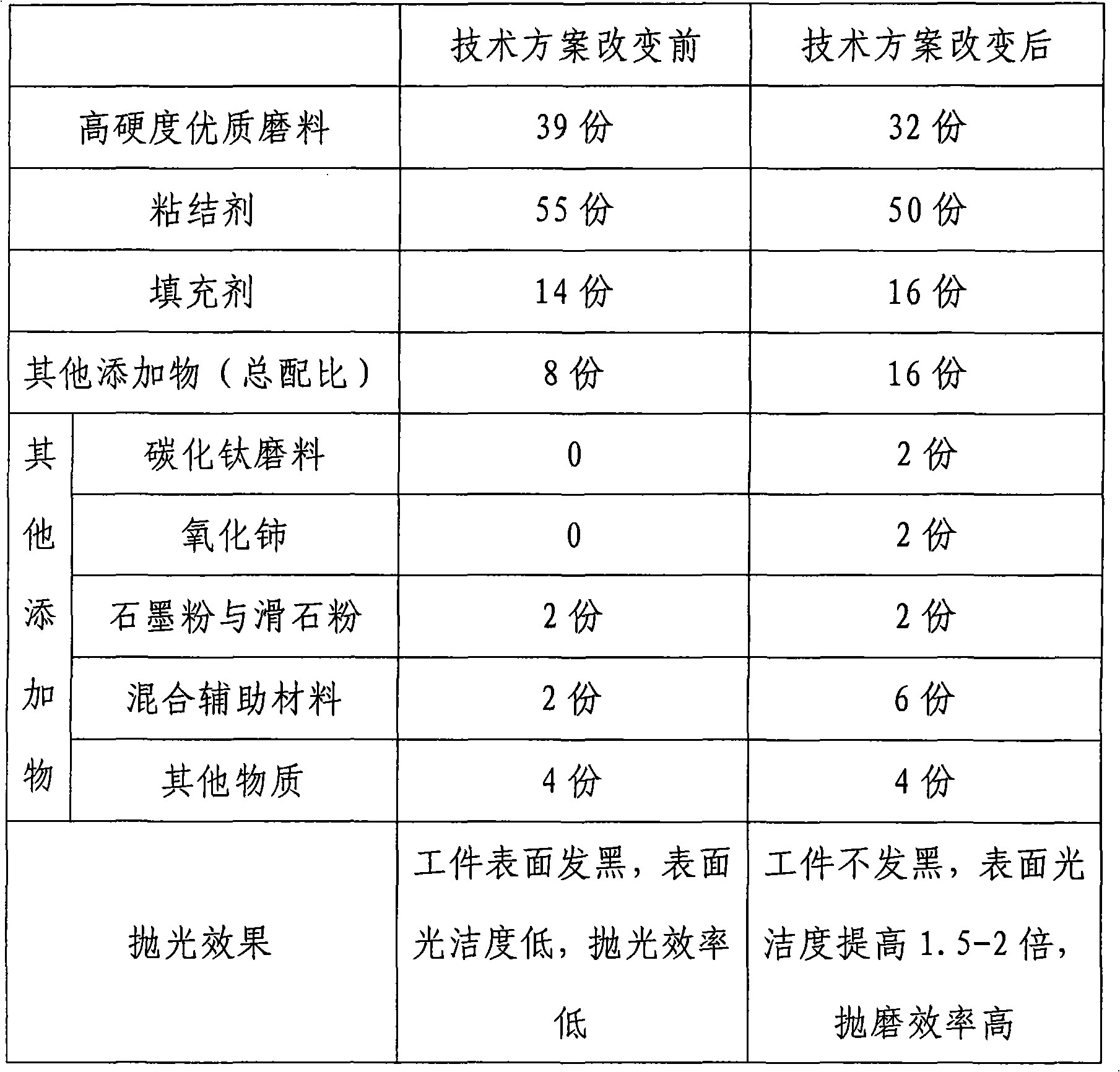

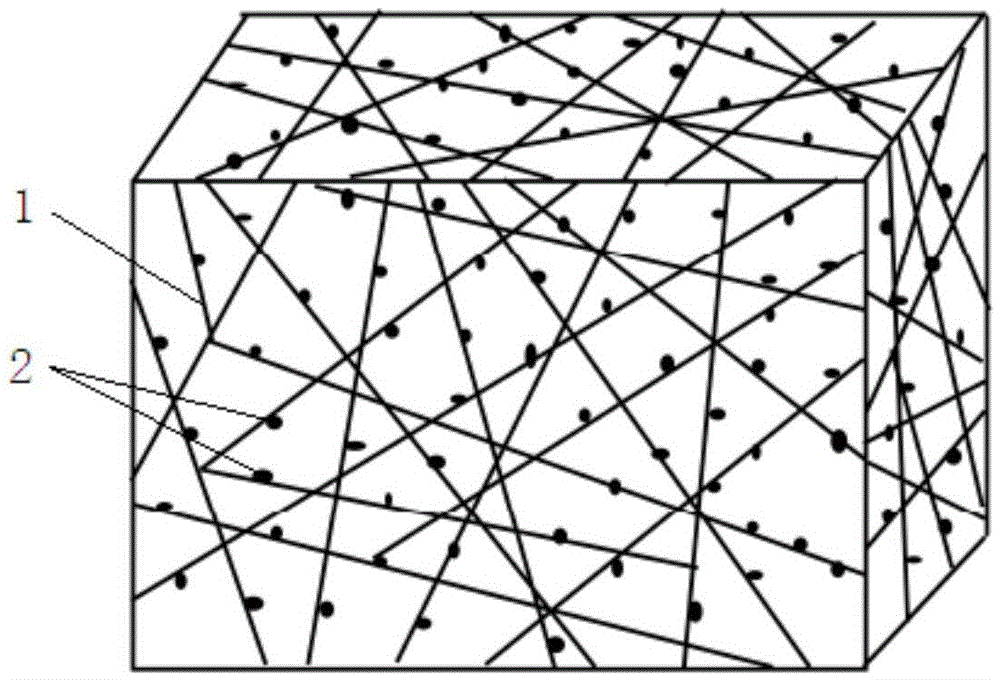

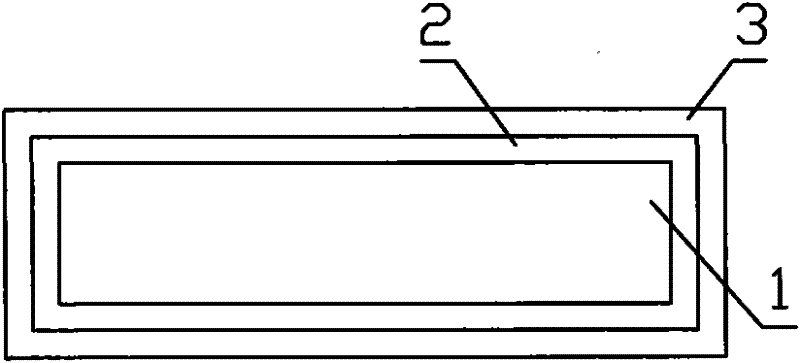

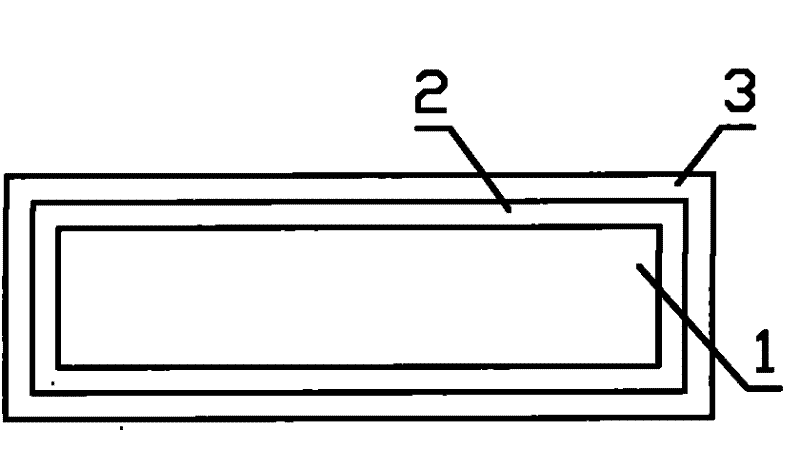

Nylon wheel and preparation method thereof

InactiveCN101570005AGood self-sharpeningGood polishing effectOther chemical processesFlexible-parts wheelsSurface finishPolymer science

The invention relates to a nylon wheel and a preparation method thereof. The nylon wheel comprises a nylon fiber silk screen (1) with a reticular fiber structure and a working layer (2) poured in the nylon fiber silk screen (1), wherein the working layer (2) is a mixture prepared from a high-hardness high-quality grinding material, a binding agent and a filling agent, and the weight proportion of the nylon fiber silk screen (1) to the mixture is 1:5-7. The method for preparing the nylon wheel comprises the following steps: 1) adding the high-hardness high-quality grinding material and the filling agent into the binding agent in an agitator tank in turn according to the sequence, stirring the mixture evenly under a condition of heating; 2) pouring the liquid mixture obtained in the step 1) into the nylon fiber silk screen, and performing an extrusion process so that the material is evenly distributed in the nylon fiber silk screen; and 3) according to the diameter and the thickness of the nylon wheel to be produced, performing laminating processing on the nylon fiber silk screen, cutting off and processing the nylon fiber silk screen into required shapes after standing, and performing hot working under a condition of heating to obtain the finished product. The nylon wheel has the advantages of low cost, long service life, capability of improving the surface finish quality of a workpiece, and high polishing efficiency. The method for preparing the nylon wheel has convenient manufacture and high production efficiency.

Owner:YANGJIANG WEIYI POLISHING MATERIAL

Impervious freezing-and-thawing-resistant concrete mix and mixing method thereof

InactiveCN106915934AImprove impermeability and freeze-thaw resistanceImprove adhesionCement mixing apparatusFiberCrack resistance

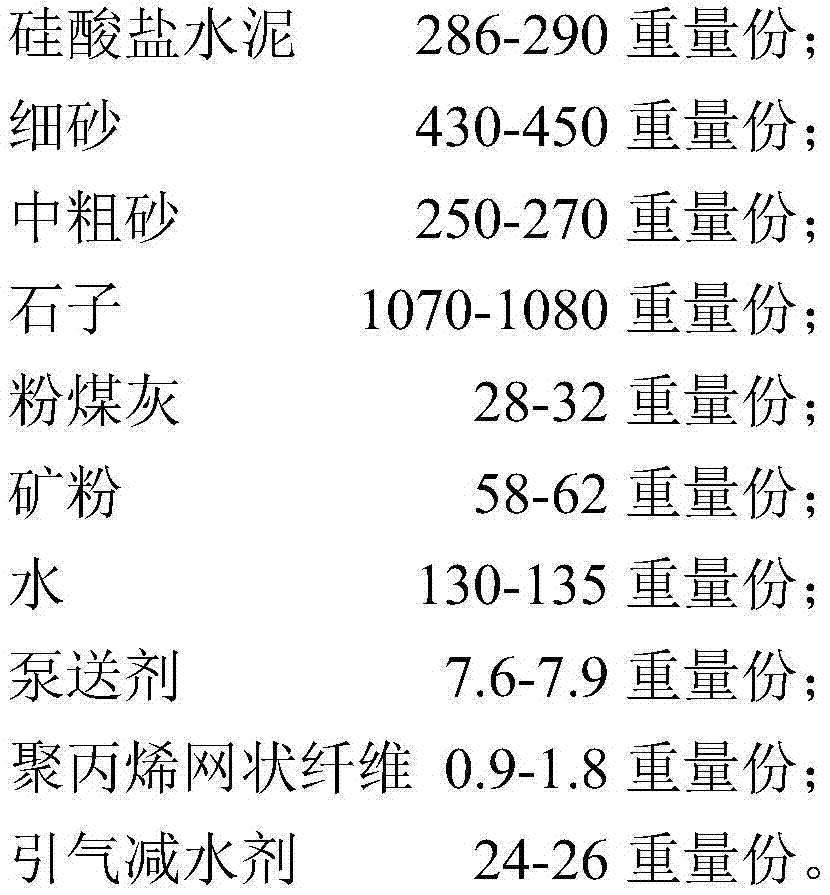

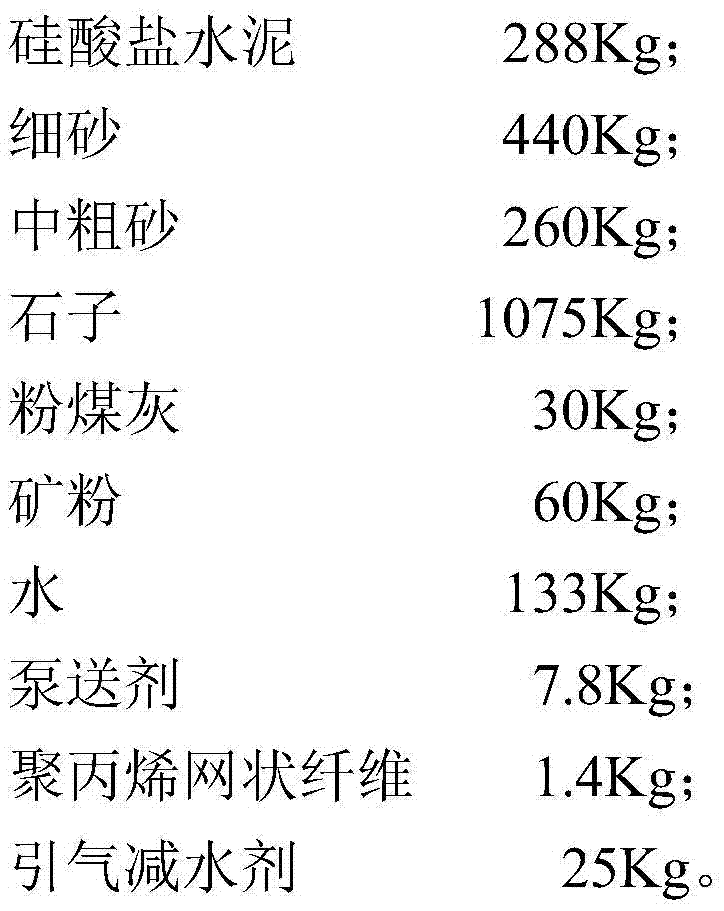

The invention relates to an impervious freezing-and-thawing-resistant concrete mix. The concrete mix comprises, by weight, 286 to 290 parts of Portland cement, 430 to 450 parts of fine sand, 250 to 270 parts of medium coarse sand, 1070 to 1080 parts of cobblestone, 28 to 32 parts of fly ash, 58 to 62 parts of mineral powder, 130 to 135 parts of water, 7.6 to 7.9 parts of a pumping agent, 0.9 to 1.8 parts of polypropylene reticular fibers and 24 to 26 parts of an air-entraining and water-reducing agent. According to the invention, aggregate grading is optimized, a sand rate and a water-cement ratio are controlled, and the superfine polypropylene reticular fibers are added, so organic combination of the superfine polypropylene reticular fibers with the fine sand is realized, bonding between the fine sand and other ingredients is improved, the problem of reduction in strength, impermeability, durability, crack resistance and workability during preparation of concrete from ultrafine sand is effectively overcome, and cost for engineering construction is substantially reduced; meanwhile, the air-entraining and water-reducing agent is used so as to improve the anti-permeability and freezing-and-thawing resistance of concrete.

Owner:TIANJIN ZEYUAN CONCRETE CO LTD

Crack-resistant concrete mix and mixing method thereof

InactiveCN106915935AImprove crack resistanceImprove freeze-thaw resistanceCement mixing apparatusFiberCrack resistance

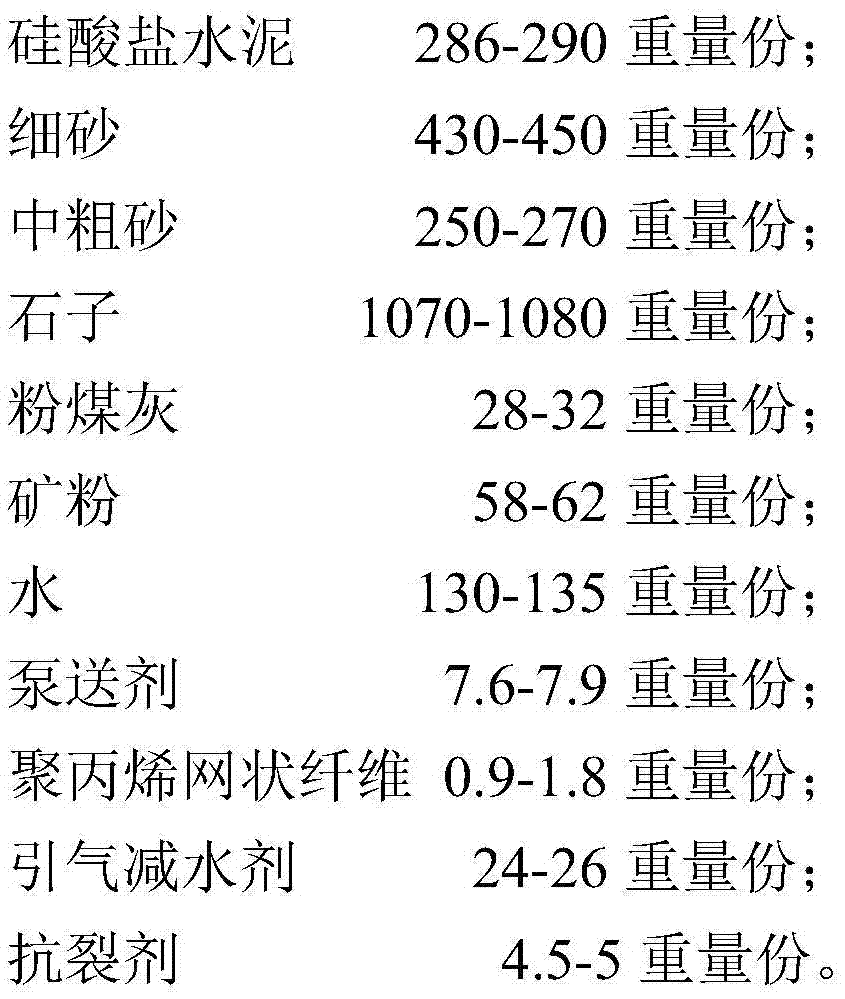

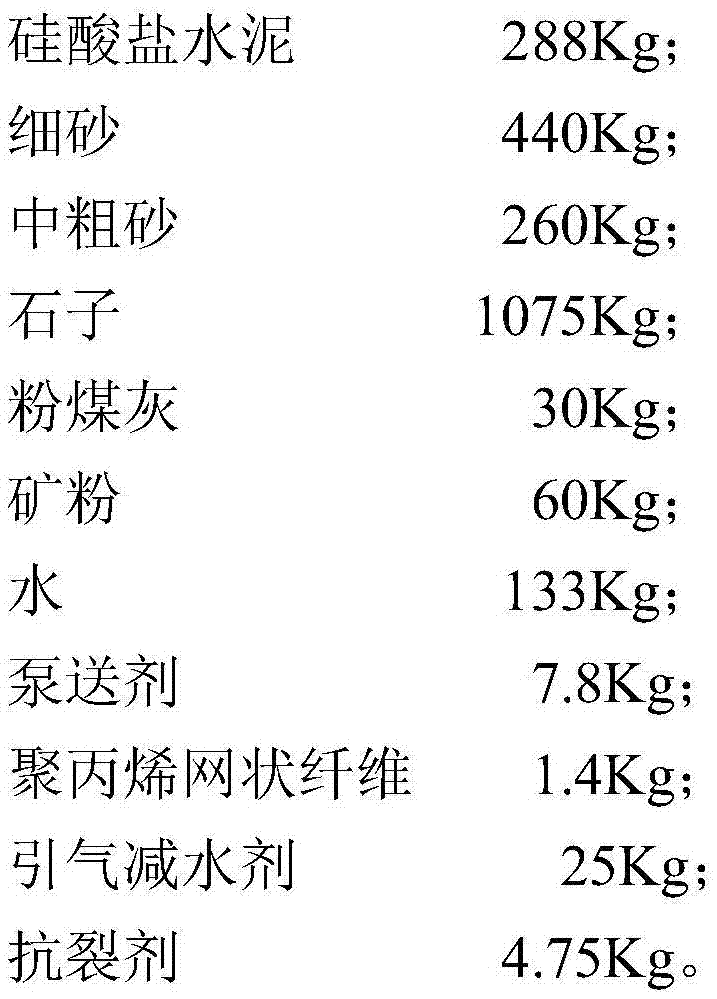

The invention relates to a crack-resistant concrete mix. The concrete mix comprises, by weight, 286 to 290 parts of Portland cement, 430 to 450 parts of fine sand, 250 to 270 parts of medium coarse sand, 1070 to 1080 parts of cobblestone, 28 to 32 parts of fly ash, 58 to 62 parts of mineral powder, 130 to 135 parts of water, 7.6 to 7.9 parts of a pumping agent, 0.9 to 1.8 parts of polypropylene reticular fibers, 24 to 26 parts of an air-entraining and water-reducing agent, and 4.5 to 5 parts of a crack-resistant agent. According to the invention, aggregate grading is optimized, a sand rate and a water-cement ratio are controlled, and the superfine polypropylene reticular fibers are added, so organic combination of the superfine polypropylene reticular fibers with the fine sand is realized, bonding between the fine sand and other ingredients is improved, the problem of reduction in strength, impermeability, durability, crack resistance and workability during preparation of concrete from ultrafine sand is effectively overcome, and cost for engineering construction is substantially reduced; meanwhile, the air-entraining and water-reducing agent and the crack-resistant agent are used so as to improve the crack resistance and freezing-and-thawing resistance of concrete.

Owner:TIANJIN ZEYUAN CONCRETE CO LTD

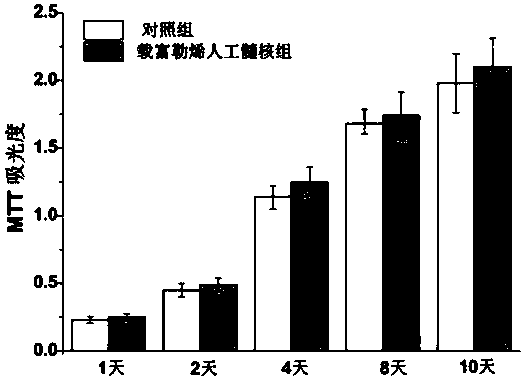

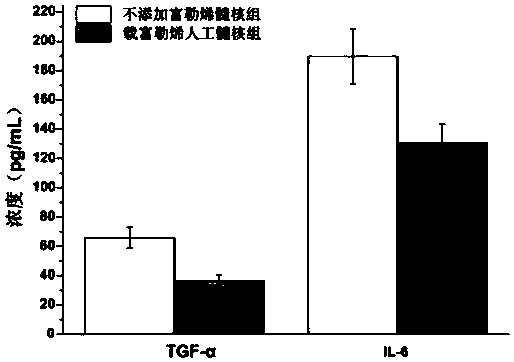

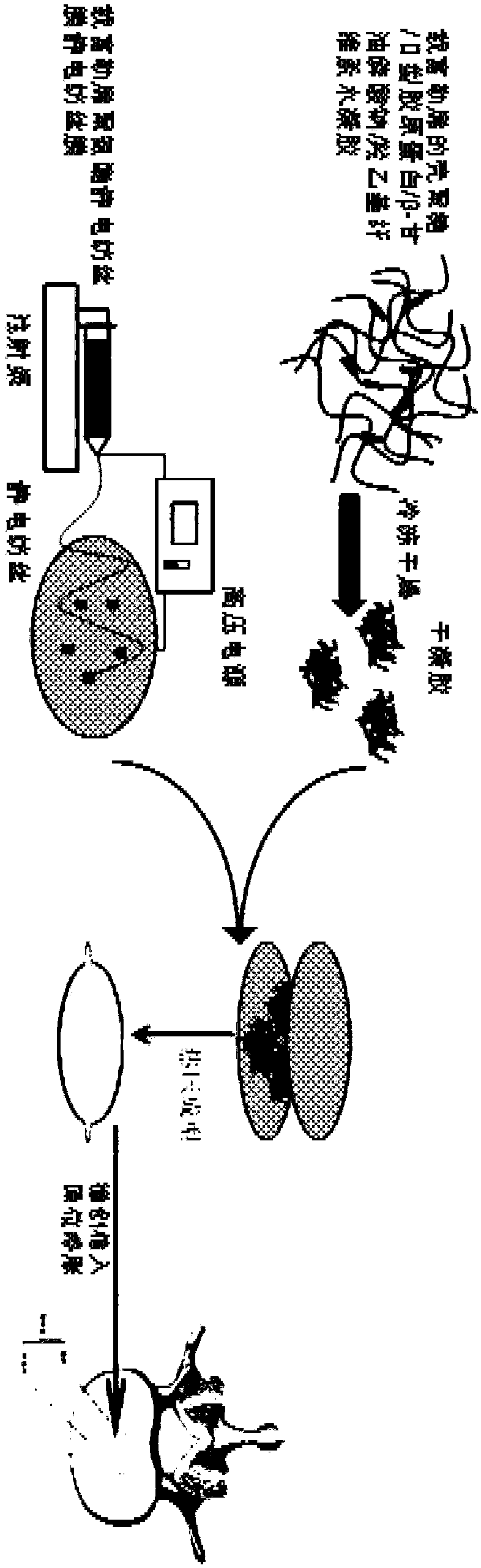

Preparation method of artificial fullerene-carried nucleus pulposus

ActiveCN108498857AReduce displacementReduce degradationFilament/thread formingTissue regenerationFiberStructure of the Earth

The invention relates to the preparation field of artificial nucleus pulposus, in particular to a preparation method of artificial fullerene-carried nucleus pulposus. According to the preparation method of the artificial fullerene-carried nucleus pulposus, a semi-molding design concept is adopted, the fullerene nucleus pulposus can be implanted into an affected part with low invasiveness, and surgery risks and postoperative shifting problems are reduced; by adding fullerene into the artificial nucleus pulposus, the content of free radials in the nucleus pulposus can be reduced, and the purposeof decelerating degeneration of the intervertebral disc is achieved. By designing the artificial nucleus pulposus into a structure with an inner layer containing xerogel and an outer layer provided with an electrostatic spinning membrane, on the one hand, a three-dimensional reticular fiber membrane of the outer layer can be utilized to wrap the xerogel of the inner layer without influencing hydration and expansion of the xerogel, shifting of the xerogel is also avoided, and the overflow risk is reduced; on the other hand, the mass of the filling xerogel and the diameter of the fiber membranecan be adjusted according to actual demands to achieve a better filling effect and better recover the structure of the intervertebral disc. Moreover, the artificial nucleus pulposus is a dry solid and is easy to preserve and long in storage life.

Owner:SHANGHAI NINTH PEOPLES HOSPITAL SHANGHAI JIAO TONG UNIV SCHOOL OF MEDICINE

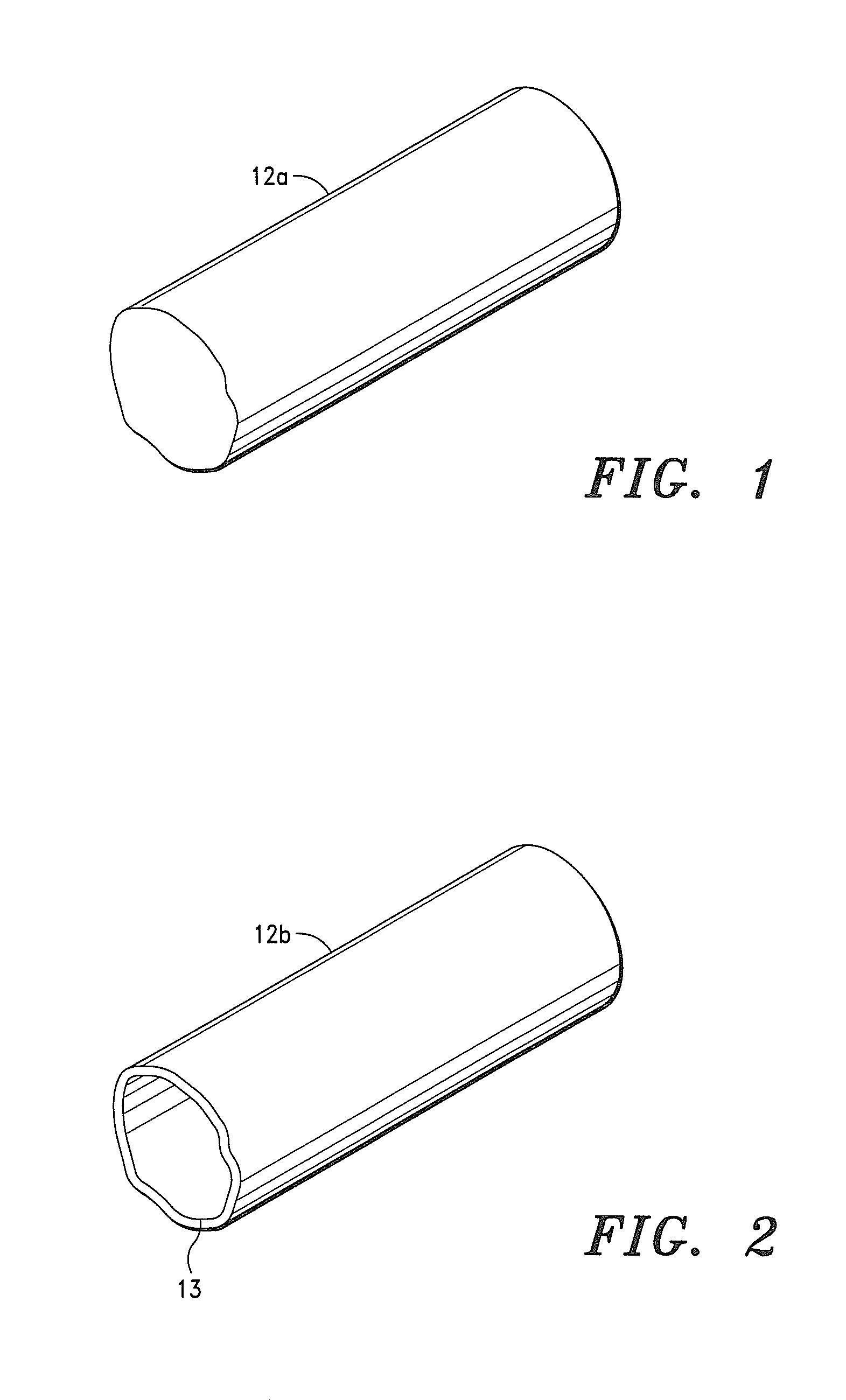

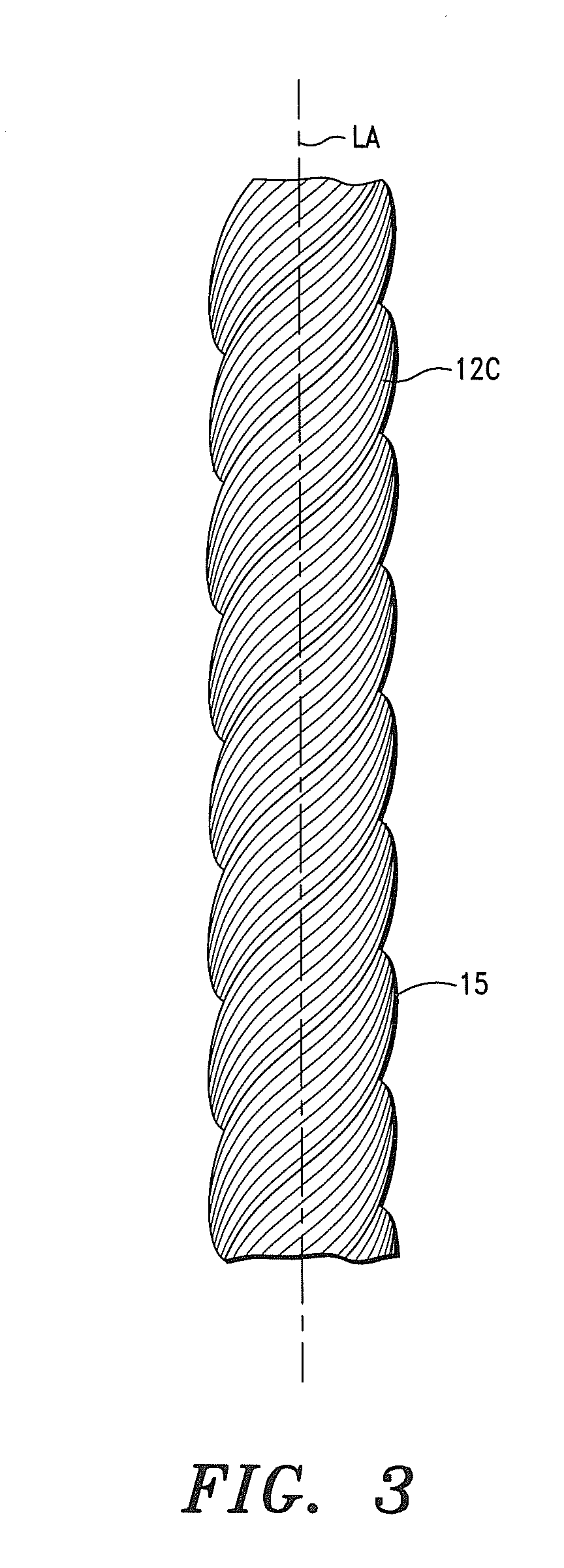

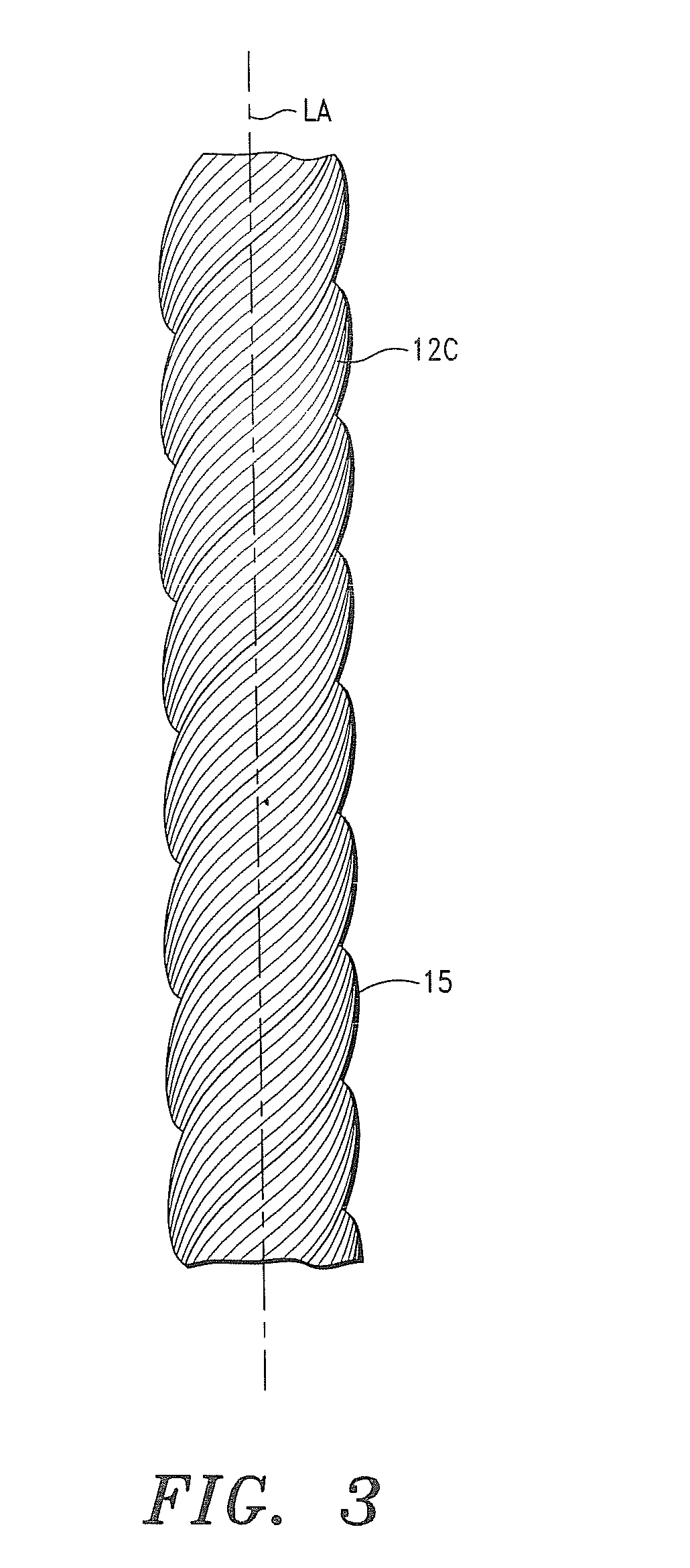

Mesh Fiber Members and Methods for Forming and Using Same for Treating Damaged Biological Tissue

A mesh fiber member having a plurality of biodegradable fibers, the mesh fiber member being configured to induce modulated healing of damaged biological tissue when deployed proximate thereto. The strands comprise an extracellular matrix (ECM) composition or an ECM-mimicking biomaterial composition, such as poly(glycerol sebacate) (PGS), and can include a biodegradable ECM, polymeric or ECM-mimicking biomaterial composition coating.

Owner:CORMATRIX CARDIOVASCULAR INC

Lightweight high-strength concrete composite insulation board and preparation method thereof

InactiveCN106587792APerformance is not affectedImprove early strengthSynthetic resin layered productsWater-setting substance layered productFoam concreteHigh strength concrete

The invention discloses a lightweight high-strength foam concrete composite insulation board. A foam concrete slab is used as a main board, a sandwich in the middle is rigid foam polyurethane, and the foam concrete slab comprises the following components in parts by weight: 20-35 parts of ordinary Portland cement, 2-4 parts of ultrafine fly ash, 4-10 parts of ultrafine mineral powder, 40-60 parts of broken stones, 50-70 parts of medium sand, 1-2 parts of tri-isopropanolamine, 0.5-2.5 parts of calcium oxide, 1-3 parts of polypropylene reticular fiber, 0.8-1.6 parts of an organic additive, 3-5 parts of an HTQ-1 type foaming agent, 1-2 parts of an MPS foam stabilizer, 1.5-3 parts of a polycarboxylate superplasticizer, and 15-30 parts of water, wherein the organic additive is prepared by virtue of a dropwise adding reaction of an anionic polymer, a soluble metal salt, and soluble alkali metal silicate. The foam concrete composite insulation board is good in thermal insulation property, good in impact resistance, high in toughness, high in compression strength and low in preparation cost, and is energy-saving and environment-friendly.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

Method for preparing multielement assorted-fibred reinforced recycled concrete with low elasticity modulus

InactiveCN102584137AImprove performanceImprove physical and mechanical propertiesSolid waste managementPolypropyleneMechanical property

The invention discloses a method for preparing multielement assorted-fibred reinforced recycled concrete with low elasticity modulus. Cracked waste concrete is adopted as partially recycled coarse aggregate of the concrete; nylon fiber extracted from waste tyres, modified polypropylene coarse TANK fiber and polypropylene three-branched anti-aging reticular fiber are added to improve the mechanical property of the recycled concrete; in terms of 100 parts by weight, the concrete comprises 21 parts of 32.5R common portland cement, 20 parts of fine aggregate, 25-35 parts of natural macadam, 15-25parts of recycled coarse aggregate, 0.01-0.02 part of nylon fiber, 0.01-0.02 part of modified polypropylene coarse TANK fiber, 0.01-0.02 part of polypropylene three-branched anti-aging reticular fiber and 9 parts of water per cubic meter. The method is simple in preparation, solves the environmental problems caused by construction waste and black pollution and has wide economic and promotion values and social benefit.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Mesh Fiber Members and Methods for Forming and Using Same for Treating Damaged Biological Tissue

A mesh fiber member having a plurality of biodegradable fibers, the mesh fiber member being configured to induce modulated healing of damaged biological tissue when deployed proximate thereto. The strands comprise an extracellular matrix (ECM) composition or an ECM-mimicking biomaterial composition, such as poly(glycerol sebacate) (PGS), and can include a biodegradable ECM, polymeric or ECM-mimicking biomaterial composition coating.

Owner:CORMATRIX CARDIOVASCULAR INC

Preparation method for multielement mixed regenerated fiber enhanced regenerated concrete

InactiveCN102584135ATake advantage ofImprove physical and mechanical propertiesSolid waste managementPolypropyleneMechanical property

The invention discloses a preparation method for multielement mixed regenerated fiber enhanced regenerated concrete. According to the method, crushed waste concrete is used as partial generated coarse aggregate of the regenerated concrete, nylon fibers and radial line steel fibers extracted from waste tires are added, and low elasticity modulus polypropylene reticular fibers are also added to improve the mechanical property of the generated concrete. In per cubic meter of concrete, metered by 100 weight parts, the concrete comprises the following substances of 21 parts of 32.5R ordinary portland cement, 20 parts of fine aggregate, 25-35 parts of natural macadam, 15-25 parts of generated coarse aggregate, 0.01-0.02 part of nylon fiber, 0.01-0.02 part of radial line steel fiber, 0.01-0.02 part of polypropylene three-principal anti-aging reticular fiber and 9 parts of water. The preparation method is simple in preparation, can generally meet the requirements of conventional concrete of medium and low grades, can improve the performance of the generated concrete, particularly the fracture resistant performance, and has considerable economic benefit and environmental benefit.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Method for preparing reticular fiber reinforced hollow fiber membrane of polyvinylidene fluoride

InactiveCN100393397CAperture size controllableStrong blast resistanceSemi-permeable membranesBursting strengthHollow fibre membrane

Owner:TIANJIN UNIV

SIS (small intestinal submucosa) medicine carrying patch as well as preparation method and application thereof

The invention discloses an SIS (small intestinal submucosa) medicine carrying patch. A microstructure of the SIS medicine carrying patch comprises an SIS collagenous fiber skeleton and icariin supported on the SIS collagenous fiber skeleton, wherein the SIS collagenous fiber skeleton adopts a reticular fiber structure; icariin is granular and attached to the SIS collagenous fiber skeleton, and the attaching amount of icariin is 20-80 mu g / cm <2>. According to the SIS medicine carrying patch, granular icariin is attached to the SIS collagenous fiber skeleton, a stable medicine release system is established, two potential bone tissue engineering elements, namely, the SIS collagenous fiber skeleton and icariin, are combined, formed SIS medicine carrying patch composite is reliable and stable, characteristics such as safety, economy, stable chemical property, excellent bone regeneration promoting capability, vascular regeneration promotion capability and the like of icariin are sufficiently utilized, the SIS medicine carrying patch has very high bone regeneration promoting capability and has a wide application prospect in the bone regeneration field, and the preparation method is simple.

Owner:NINGBO UNIV

Orange essential oil dust mask and preparation method thereof

InactiveCN104522912ASimple structureImprove breathabilityGarment special featuresProtective garmentPolyesterFiber

The invention provides an orange essential oil dust mask and a preparation method thereof. The preparation method comprises the following steps: soaking a melt-blown fabric with a reticular fiber structure in orange essential oil for 5-10 minutes, taking out the melt-blown fabric, and drying the melt-blown fabric to obtain orange essential oil filter cloth, respectively arranging two layers of non-woven fabrics above and below the orange essential oil filter cloth, clamping an orange essential oil filtering layer between the two layers of non-woven fabrics, and pressing a mask filtering layer by using a high temperature sealing machine, wherein pure cotton cloth is used on the surface, close to human skin, of the mask, the outermost layer of the mask is made of white cotton cloth, cotton print, cartoon polyester cloth or chiffon, the filtering layer is located in the middle, and the orange essential oil dust mask is prepared by adopting a conventional mask preparation process. The dust healthcare mask provided by the invention is harmless to human bodies, simple, simple in structure, high in breathability and good in dustproof effect, and the dust healthcare mask further has the functions of dispersing aroma, preventing dizziness and vomit, effectively relaxing and relieving pressure, relieving fatigue, and the like.

Owner:晋江市科创源专利服务有限公司

Cushion

InactiveCN101744470AHigh strengthIncrease elasticityStuffed mattressesSpring mattressesHuman bodyEmulsion

The invention discloses a cushion, which comprises an inner core. The inner core comprises a palm fiber layer and an emulsion layer combined on the outer surface of the palm fiber. The emulsion layer is subjected to sulfur treatment to be combined on the outer surface of the palm fiber layer. The inherent three-dimensional reticular fiber structure of the natural wild palm fibers is sufficiently used, and the natural emulsion has high elasticity, thus, the cushion has good ventilation property, prevents insect and germs, is neither too hard nor too soft, and has comfortable feeling for the human body.

Owner:张顺民

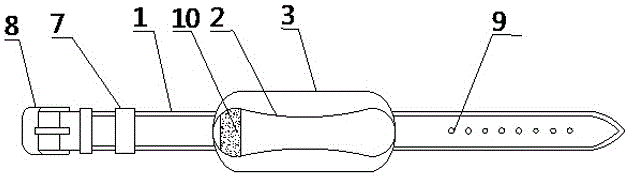

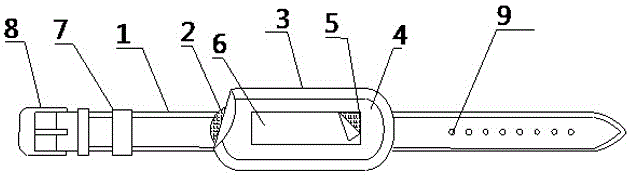

Elastic bleeding-stopping absorbent dressing fixing band

InactiveCN105997185AFlexible adjustment of pressing positionHas anti-inflammatory and analgesic effectsNon-adhesive dressingsPlastersAdhesiveHematoma

The invention discloses an elastic bleeding-stopping absorbent dressing fixing band which comprises a fixing band body. The elastic bleeding-stopping absorbent dressing fixing band is characterized in that the middle of the fixing band body is provided with a bleeding-stopping absorbent dressing, and the bleeding-stopping absorbent dressing comprises five layers including the compressing layer serving as the first layer, the self-sticking layer serving as the second layer, the absorbing layer serving as the third layer, the isolating layer serving as the fourth layer and the bleeding stopping layer serving as the fifth layer, wherein the compressing layer is an adhesive-free non-woven fiber base material layer, the self-sticking layer is a non-woven fiber base material layer with a single-sided adhesive, the absorbing layer is a synthetic fiber layer, the isolating layer is a reticular fiber layer, and the bleeding stopping layer is a protein fiber layer and is attached with an inflammation diminishing, bleeding stopping and pain easing drug. According to the elastic bleeding-stopping absorbent dressing fixing band, the functions of bleeding stopping, inflammation diminishing, pain easing, isolating, absorbing and protecting are integrated into a whole, the pressing part can be flexibly adjusted according to the puncture part and the size of a puncture point, the pressing strength is visible, the conditions such as blood exudation and hematoma complications which are caused by improper pressing are reduced, the problem that medical workers or family members are prone to be contaminated by exudative blood when the medical workers or the family members compress the puncture point with a cotton swab to stop bleeding is solved, and the inflammation diminishing and pain easing effects are achieved.

Owner:SHANDONG UNIV QILU HOSPITAL

Automotive filter for filtering PM2.5 air particles and preparation method

ActiveCN105498389AEvenly distributedImprove adsorption capacityDispersed particle filtrationTransportation and packagingFiberAdhesive

The invention discloses an automotive filter for filtering PM2.5 air particles and a preparation method. The automotive filter is mainly used for filtering PM2.5 air particles in an automobile. A filtration material of the filter includes a base layer and an adsorption layer, wherein the base layer is made of a reticular fiber layer non-woven fabric base layer material formed by using a carding machine to comb short fibers, a reticular fiber layer is provided with an irregular surface, and the adsorption layer is formed by adopting an electrostatic spraying method to spray a diatomite adsorbent on an adhesive on the irregular surface of the base layer. The automotive filter can effectively adsorb PM2.5 particles entering the automobile through an air conditioning system and can also make air resistance not increase obviously. The electrostatic spraying method is adopted to spray diatomite on the surface of the base layer material and can make diatomite distribution uniform, and the thickness is controlled to ensure adsorption capacity under the condition of minimum resistance.

Owner:YINGKOU XIAOJIAZU IND

Composite cloth of superfine denier viscose fiber and elastic mesh cloth and preparation process thereof

ActiveCN109576908ADelicate surface styleFast water absorptionPhysical treatmentNon-woven fabricsYarnSlurry

The invention relates to a composite cloth of superfine denier viscose fiber and elastic mesh cloth, wherein the composite cloth is made of a reticular fiber layer and a base cloth, the mass ratio ofthe reticular fiber layer to the base cloth is 52:48, and the reticular fiber layer is formed by a superfine denier viscose fiber slurry by a wet method; and the base cloth is elastic mesh cloth. In the first step, the process step of processing the superfine viscose fiber into dry paper is changed to the wet paper-making process, the forming step is accelerated, and the formed superfine viscose fiber is uniform and flat in whole. The two main raw material parts can be fully and compositely linked by combining the hydroentangled composite process part. The composite cloth finished product prepared by the composite cloth of superfine denier viscose fiber and elastic mesh cloth and the preparation process thereof has a weight of 55-65g / m2 and a thickness of 0.32-0.34mm after being compounded, has fine and compact surface style, is soft and strong in cotton, only shows the characteristics of yarns after being soaked in water in a semitransparent state, and has the advantages of quick water absorption, good mildew-proof and moth-proof effects, excellent air permeability and hygroscopicity, good moisture persistence and has the properties of thick cotton texture and the like.

Owner:FUYANG WEIYE BASE CLOTH CO LTD

Method for producing cushion

InactiveCN101744471ACome and go freelyHigh strengthStuffed mattressesSpring mattressesHuman bodyEmulsion

The invention discloses a method for producing a cushion, which comprises the following steps: (a) selecting and laying natural wild palm fibers and pressing the natural wild palm fibers into a palm fiber layer; (b) spraying an emulsion layer on the outer surface of the palm fiber layer; (c) putting the palm fiber layer sprayed with the emulsion layer in a sulfating tank to carry out sulfur treatment to lead the emulsion layer and the palm fiber layer closely to be combined with each other; and (d) cutting the combined palm fiber layer and emulsion layer into the cushion shape and sewing the outside layer. The method adopts the green raw materials of the natural wild palm fibers and the natural emulsion to produce the cushion by the high-temperature and high-pressure technology and sufficiently uses the inherent three-dimensional reticular fiber structure of the natural wild palm fibers, and the natural emulsion has high elasticity, thus, the cushion has good ventilation property, prevents insect and germs, is neither too hard nor too soft, and has comfortable feeling for the human body.

Owner:张顺民

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com