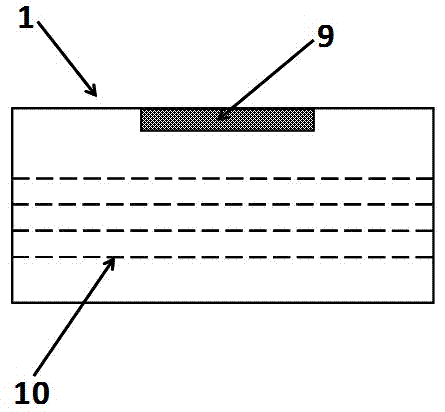

High-efficiency low-resistance nano anti-virus mask and production method thereof

A production method and anti-virus technology, applied in chemical instruments and methods, protective clothing, layered products, etc., can solve the problems of reducing the protective performance of masks, the attenuation of electret charge, and the inability to achieve high-efficiency filtration of germs, etc., to achieve light weight , good air permeability, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

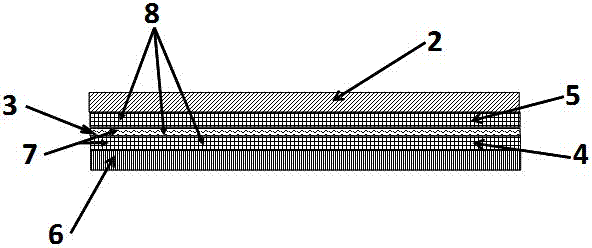

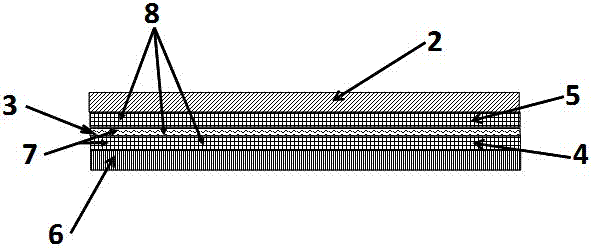

Embodiment 1

[0028] (1) At room temperature, add 0.5 g of nylon 6 to 9.5 g of formic acid solvent, then add 0.01 g of sodium chloride, and stir on a magnetic stirrer at a speed of 50 rpm for 10 h until a uniform spinning solution is obtained. Silk solution to obtain a nylon 6 spinning solution containing sodium chloride with a mass fraction of 5%.

[0029] (2) At room temperature and a relative humidity of 20%, the prepared nylon 6 solution was sent to the spinneret at a delivery speed of 0.5mL / h, and the spinneret was connected to a 10 kV high-voltage electrostatic generator for Electrostatic spray net effect, finally use the conductive flat plate with melt-blown polypropylene non-woven fabric to receive the nylon 6 electrostatic spray net film containing two-dimensional mesh fiber and one-dimensional electrospun fiber electrostatic spray net film, the receiving distance is 5cm, Form the composite structure 7 of electrostatic spun mesh and non-woven fabric;

[0030] (3) Attach another me...

Embodiment 2

[0033](1) At room temperature, add 2 g of nylon 66 to 7.85 g of formic acid solvent, add 0.15 g of potassium chloride, and stir on a magnetic stirrer at a speed of 100 rpm for 12 h until a uniform spinning solution, the obtained mass fraction is 20% nylon 66 solution containing potassium chloride.

[0034] (2) At room temperature and a relative humidity of 25%, the prepared nylon 66 solution was sent to the spinneret at a delivery speed of 1 mL / h, and the spinneret was connected to a 30 kV high-voltage electrostatic generator for Electrostatic spray net effect, finally use the conductive roller with spunbonded polypropylene non-woven fabric to receive the nylon 66 electrostatic spray net film containing two-dimensional mesh fiber and one-dimensional electrospun fiber electrostatic spray net film, the receiving distance is 15 cm , forming a composite structure 7 of electrostatically spun mesh and non-woven fabric;

[0035] (3) Attach another spunbonded polypropylene nonwoven f...

Embodiment 3

[0038] (1) At room temperature, add 0.7 g of polyurethane to 9.25 g of N-N-dimethylformamide solvent, then add 0.05 g of sodium chloride, and stir on a magnetic stirrer at 200 rpm for 15 h until A spinning solution with uniform properties was obtained, and a polyurethane solution containing sodium chloride with a mass fraction of 7% was obtained.

[0039] (2) At room temperature and a relative humidity of 25%, the prepared polyurethane solution was sent to the spinneret at a delivery speed of 5 mL / h, and the spinneret was connected to a 40 kV high-voltage electrostatic generator for electrostatic Spray net effect, and finally use the conductive roller attached to the melt-blown polyethylene terephthalate non-woven fabric to receive the polyurethane electrostatic spray net film containing the electrostatic spray net film of two-dimensional mesh fiber and one-dimensional electrospun fiber, The receiving distance is 20 cm, forming a composite structure of electrostatic spun mesh ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com