Preparation method of high strength polyethylene fiber and special device thereof

A technology of high-strength polyethylene and a manufacturing method, which is applied in the directions of flash spinning, drawing spinning, artificial filament heat treatment, etc., can solve the problem that organic solvents are not easy to volatilize and clean, it is difficult to increase the spinning speed, and the drafting hair is prone to occur. It can shorten the production time, improve the safety and reliability, and save the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

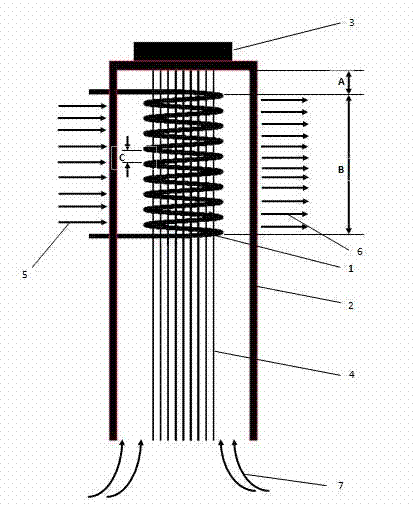

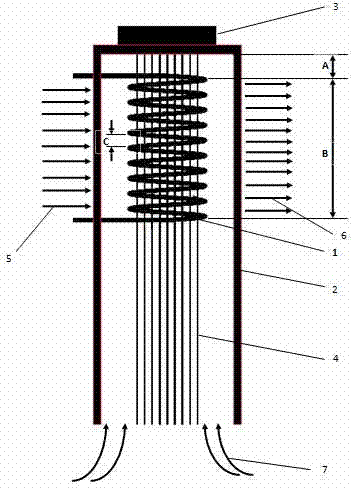

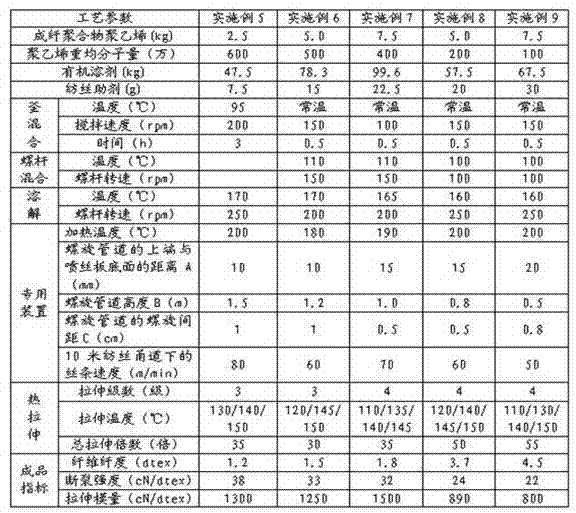

[0027] Example 1: Add 47.5 kg of commercially available decahydronaphthalene solvent (industrial grade) into a stainless steel reactor, turn on the stirring device at a stirring speed of 150 rpm, heat the temperature of the reactor to 90°C, and form a fiber with a molecular weight of 5 million 2.5 kg of polymer polyethylene and 12.5 g of calcium stearate, a spinning aid, were added slowly, stirred and mixed for 2.5 hours; then dissolved and extruded through a twin-screw dissolving machine, the temperature inside the twin-screw was 170°C, and the speed of the twin-screw was 200 rpm minute. After being filtered by the filter, it is pumped into the spinneret 3 by a metering pump, and the formed liquid stream 4 (ie fiber tow) enters the flash heating zone. The special device arranged in the flash heating zone below the spinneret 3 includes a spiral pipeline 1 with circulating heating oil inside; the spiral pipeline 1 is arranged in the spinning shaft 2 below the spinneret 3; the s...

Embodiment 2

[0028] Embodiment 2: 66.4 kilograms of commercially available decahydronaphthalene solvents (technical grade) are added in the stainless steel reactor, the stirring device is turned on, the stirring speed is 250 rpm, and the molecular weight is 3.5 million fiber-forming polymer polyethylene 5 kilograms and spinning Slowly add 25 grams of silk additive calcium stearate, stir and mix for 0.5 hours, then add to the screw mixer, the temperature inside the screw is 100 ° C, the screw speed is 100 rpm, after mixing, a uniform suspension is formed in a container, and then Dissolved and extruded by a twin-screw dissolving machine, the temperature inside the twin-screws is 160°C, and the rotational speed of the twin-screws is 250 rpm. After filtering through the filter, pump it into the spinneret 3 with a metering pump, and the formed liquid trickle 4 enters the flash heating zone; a special device arranged in the flash heating zone below the spinneret 3 (the structure is the same as th...

Embodiment 3

[0029] Embodiment 3: 117.5 kilograms of commercially available decahydronaphthalene solvents (industrial grade) are added in the stainless steel reactor, the stirring device is turned on, the stirring speed is 200 rpm, and the molecular weight is 4 million fiber-forming polymer polyethylene 7.5 kilograms and spinning Slowly add 37.5 grams of calcium stearate as a silk aid, stir and mix for 0.5 hours, then add to the screw mixer, the temperature inside the screw is 110°C, the screw speed is 150 rpm, after mixing, a uniform suspension is formed in a container, and then Dissolved and extruded by a twin-screw dissolving machine, the temperature inside the twin-screws is 165°C, and the rotational speed of the twin-screws is 180 rpm. After being filtered by the filter, pump it into the spinneret with a metering pump, and the formed liquid trickle 4 enters the flash heating zone; the special device (the structure is the same as in Example 1) arranged in the flash heating zone below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com