Composite elastic material screen cloth

A technology of elastic materials and composite materials, which is applied in building thermal insulation materials, hydraulic material layered products, building components, etc., can solve the problems of inconvenient transportation of raw materials, high labor intensity of workers, low work efficiency, etc. Penetration into the ground, ease of handling and transportation, effect of small water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

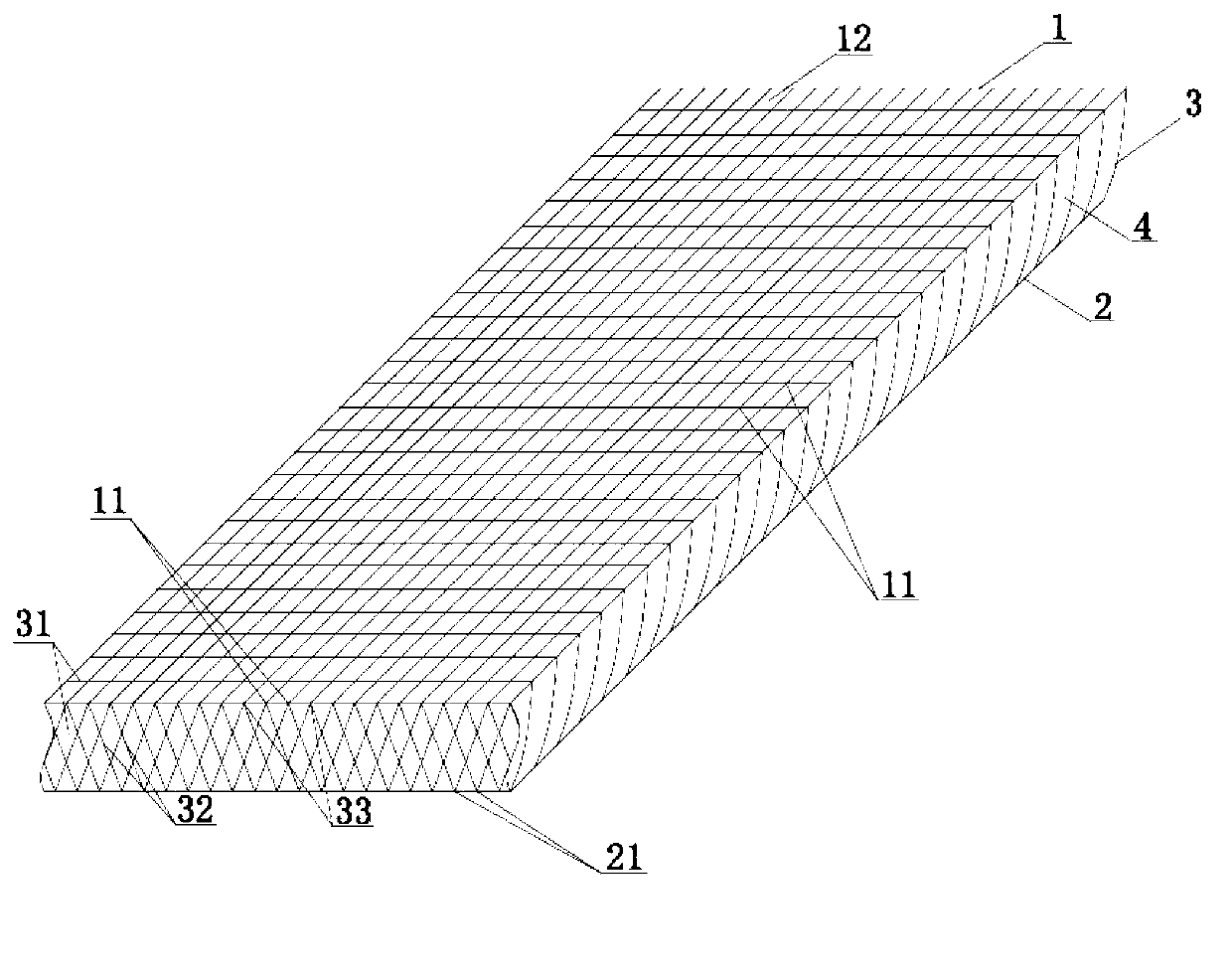

[0016] Such as figure 1 Shown, a kind of composite elastic material mesh cloth, comprises the three-dimensional warp knitted fabric that is made up of top layer 1, bottom layer 2 and connecting layer 3 that connects top layer 1 and bottom layer 2, and top layer 1, bottom layer 2 and connecting layer 3 are mesh fabrics , a plurality of first nodes 11 are uniformly arranged on the top layer 1, and a plurality of second nodes 21 are uniformly arranged on the bottom layer 2, the top layer 1 and the connection layer 3 are fixed through the first nodes 11, and the bottom layer 2 and the connection layer 3 Affixed by the second node 21, the top layer 1, the bottom layer 2 and the connection layer 3 enclose a cavity 4, and the cavity 4 is filled with a curable composite material 5 (not shown in the figure), and the connection layer 3 is composed of mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com