Crack-resistant concrete mix and mixing method thereof

A concrete and admixture technology, applied in chemical instruments and methods, cement mixing devices, clay preparation devices, etc., can solve the problems of high cost of impermeable concrete, reduce engineering construction costs, improve cohesiveness, Addressing the effects of strength and impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

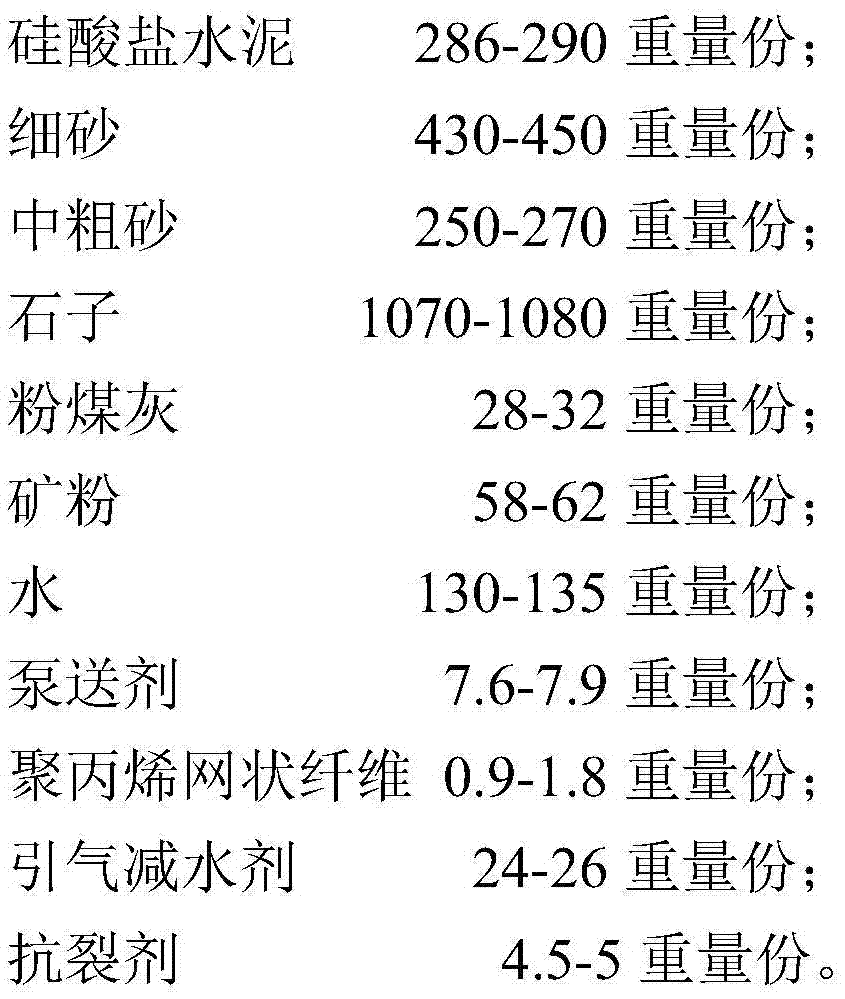

[0020] A kind of anti-cracking concrete mixture, each cubic meter of raw material contains:

[0021]

[0022] The fineness modulus of fine sand is 1-2mm. The fineness modulus of medium and coarse sand is 4-5mm. The particle size of the stone is 5-25mm. Portland cement is P·O42.5 Portland cement. The mineral powder is S95 grade mineral powder. The length of polypropylene mesh fibers is 15-20mm.

[0023] The mixing method of the above-mentioned anti-cracking concrete mixture is to add stones, fly ash, mineral powder, polypropylene mesh fiber, coarse sand and fine sand successively while stirring, and stir for 2 minutes to make the polypropylene mesh fiber fully Open it, then add Portland cement, water, air-entraining superplasticizer, anti-cracking agent and pumping agent, and stir evenly. Show through many experiments and studies, adopt the C30 / P6 impervious concrete of the present invention's preparation, 7d compressive strength is 22.7Mpa, 28d compressive strength is ...

Embodiment 2

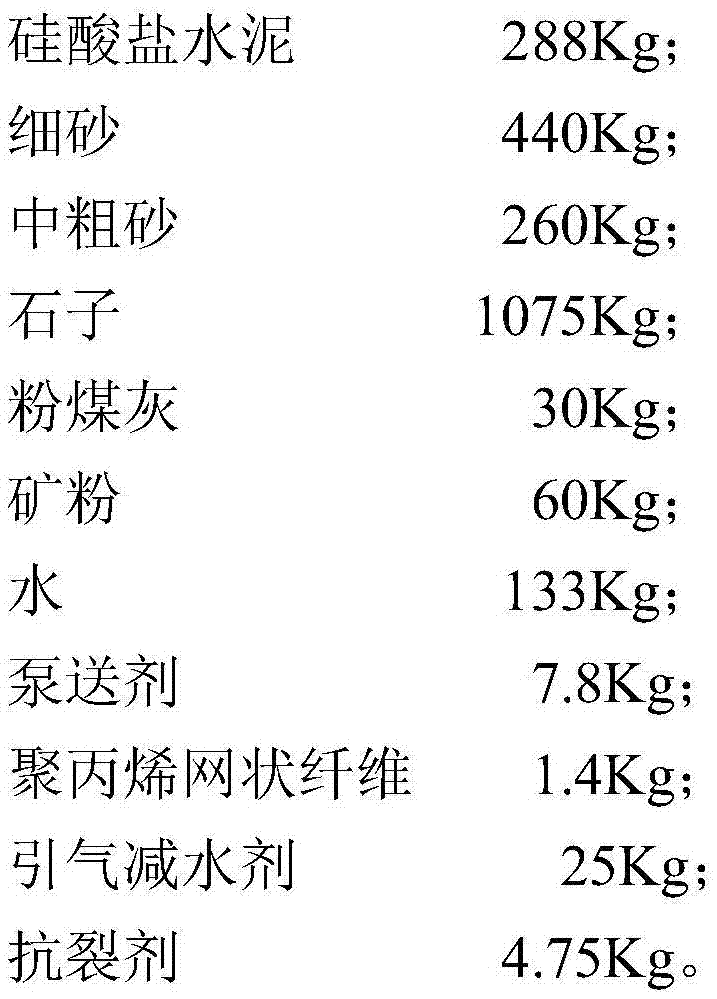

[0025]

[0026]

[0027] The fineness modulus of fine sand is 1-2mm. The fineness modulus of medium and coarse sand is 4-5mm. The particle size of the stone is 5-25mm. Portland cement is P·O42.5 Portland cement. The mineral powder is S95 grade mineral powder. The length of polypropylene mesh fibers is 15-20mm.

[0028] The mixing method of the above-mentioned anti-cracking concrete mixture is to put in stones, fly ash, polypropylene mesh fiber, coarse sand and fine sand successively while stirring, and stir for 2 minutes to fully open the polypropylene mesh fiber, silicon Salt cement, water, air-entraining superplasticizer, anti-cracking agent and pumping agent, just stir evenly. Show through many tests and studies, adopt the C30 / P6 impervious concrete of the present invention's preparation, 7d compressive strength is 21.5Mpa, 28d compressive strength is 31.5Mpa, its strength and impermeability, durability, abrasion resistance, Various properties such as drying shri...

Embodiment 3

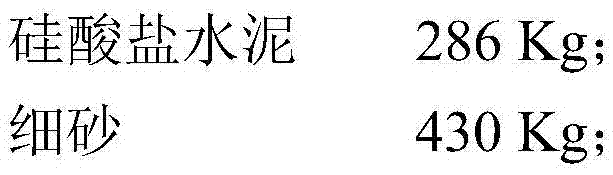

[0030] A kind of anti-cracking concrete mixture, each cubic meter of raw material contains:

[0031]

[0032]

[0033] The fineness modulus of fine sand is 1-2mm. The fineness modulus of medium and coarse sand is 4-5mm. The particle size of the stone is 5-25mm. Portland cement is P·O42.5 Portland cement. The mineral powder is S95 grade mineral powder. The length of polypropylene mesh fibers is 15-20mm.

[0034] The mixing method of the above-mentioned anti-cracking concrete mixture is to put in stones, fly ash, polypropylene mesh fiber, coarse sand and fine sand successively while stirring, and stir for 2 minutes to fully open the polypropylene mesh fiber, silicon Salt cement, water, air-entraining superplasticizer, anti-cracking agent and pumping agent, just stir evenly. Show through many experiments and studies, adopt the C30 / P6 impervious concrete of the present invention's preparation, 7d compressive strength is 23.3Mpa, 28d compressive strength is 34.8Mpa, its ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com