Efficient pouring machine and repair method for highway cracks

A seam filling machine and crack technology, which is applied in the field of highway crack high-efficiency seam filling machine and its repair, can solve the problem that asphalt is not easy to bond into a whole, and achieve the effects of reducing the risk of equipment, easy to absorb, and easy to accept.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

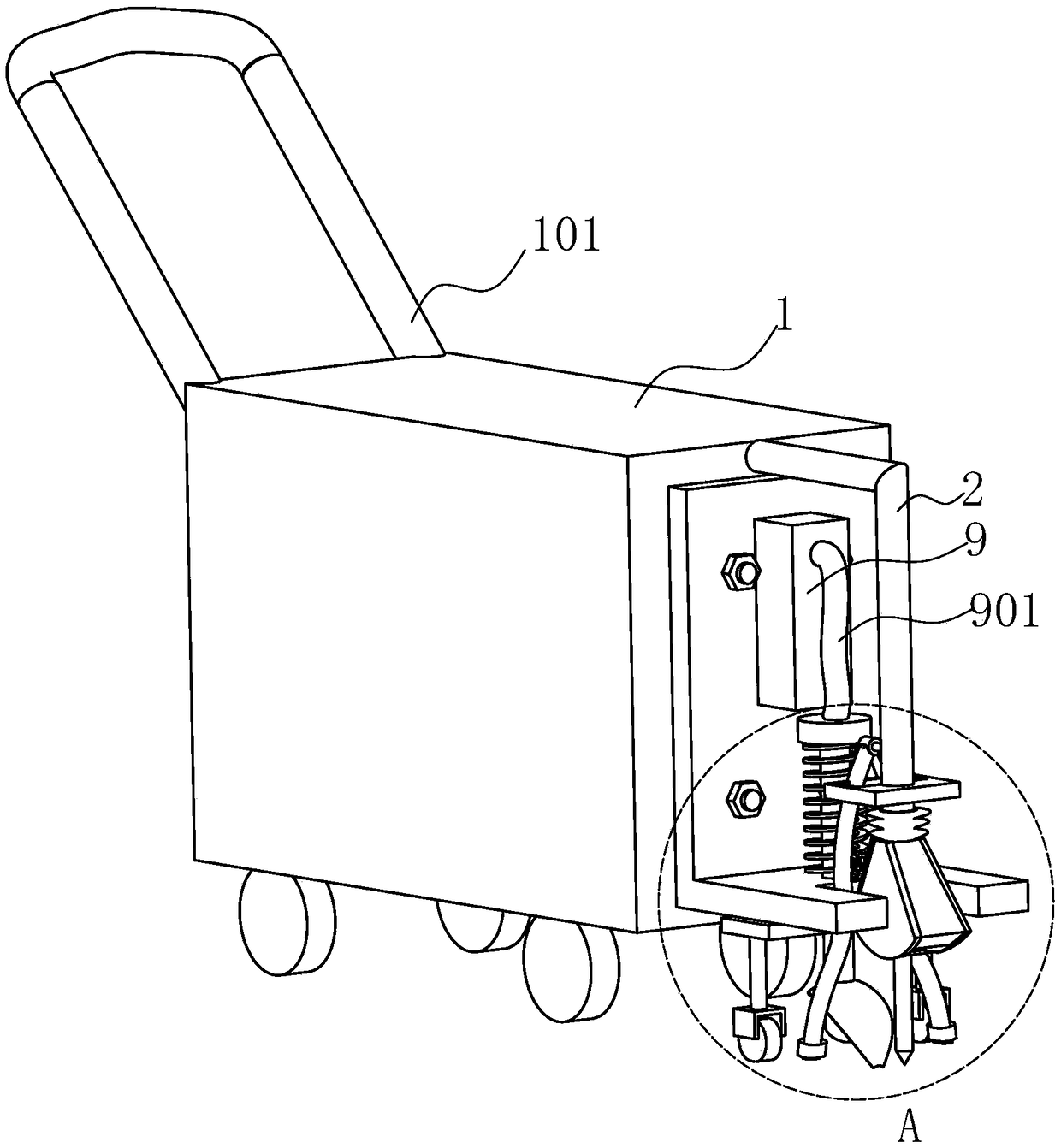

[0044] Such as Figure 1 to Figure 7 As shown, a high-efficiency joint filling machine for road cracks includes a joint filling machine body 1 and an asphalt spray gun 2 used in conjunction with the joint filling machine body 1. The rear end of the joint filling machine body 1 is provided with a handrail 101, and the front end of the joint filling machine body 1 A mounting frame 3 is provided, and the mounting frame 3 is an L-shaped structure composed of horizontal plates and vertical plates.

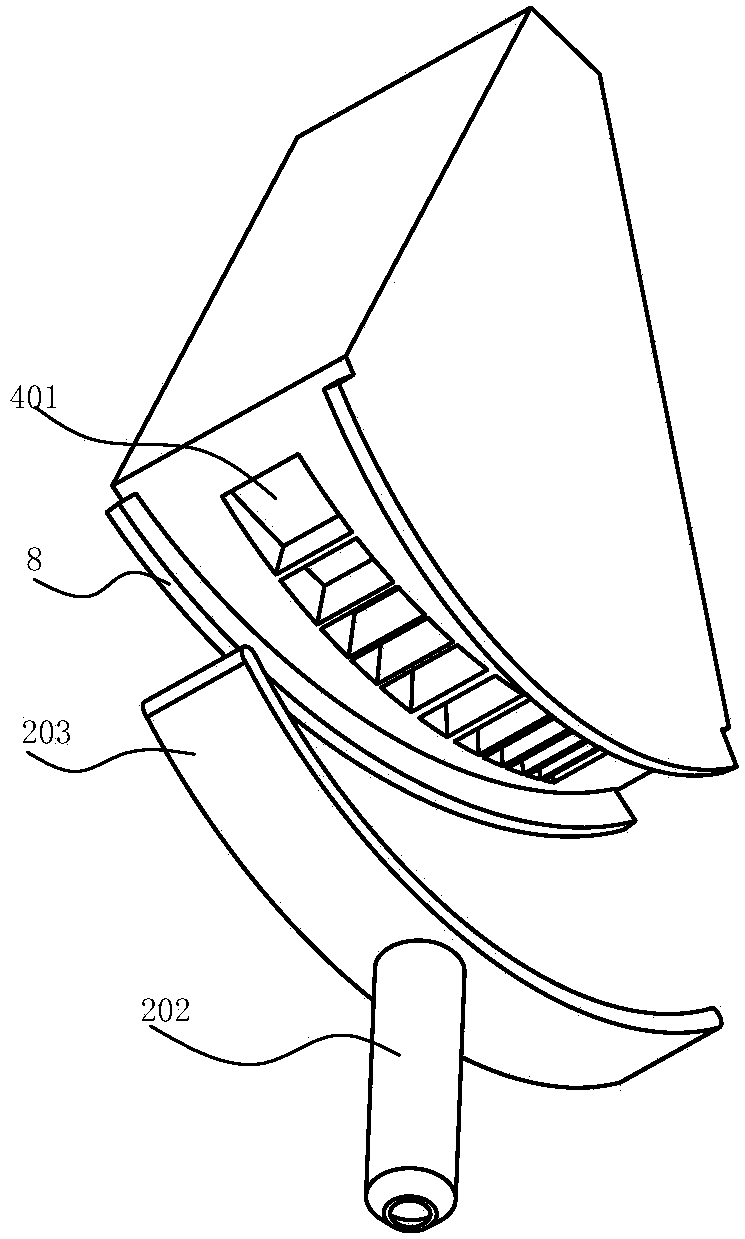

[0045] The asphalt spray gun 2 includes a feed pipe 201 and a gun head 202. The connection between the feed pipe 201 and the gun head 202 is provided with a pressure-rotation conversion channel group 4. The overall shape of the pressure-rotation conversion channel group 4 is similar to a wedge, and its width is from front to back. Gradually, the pressure-to-rotation conversion channel group 4 is distributed with a plurality of channels 401 for conveying asphalt, and the internal size of...

Embodiment 2

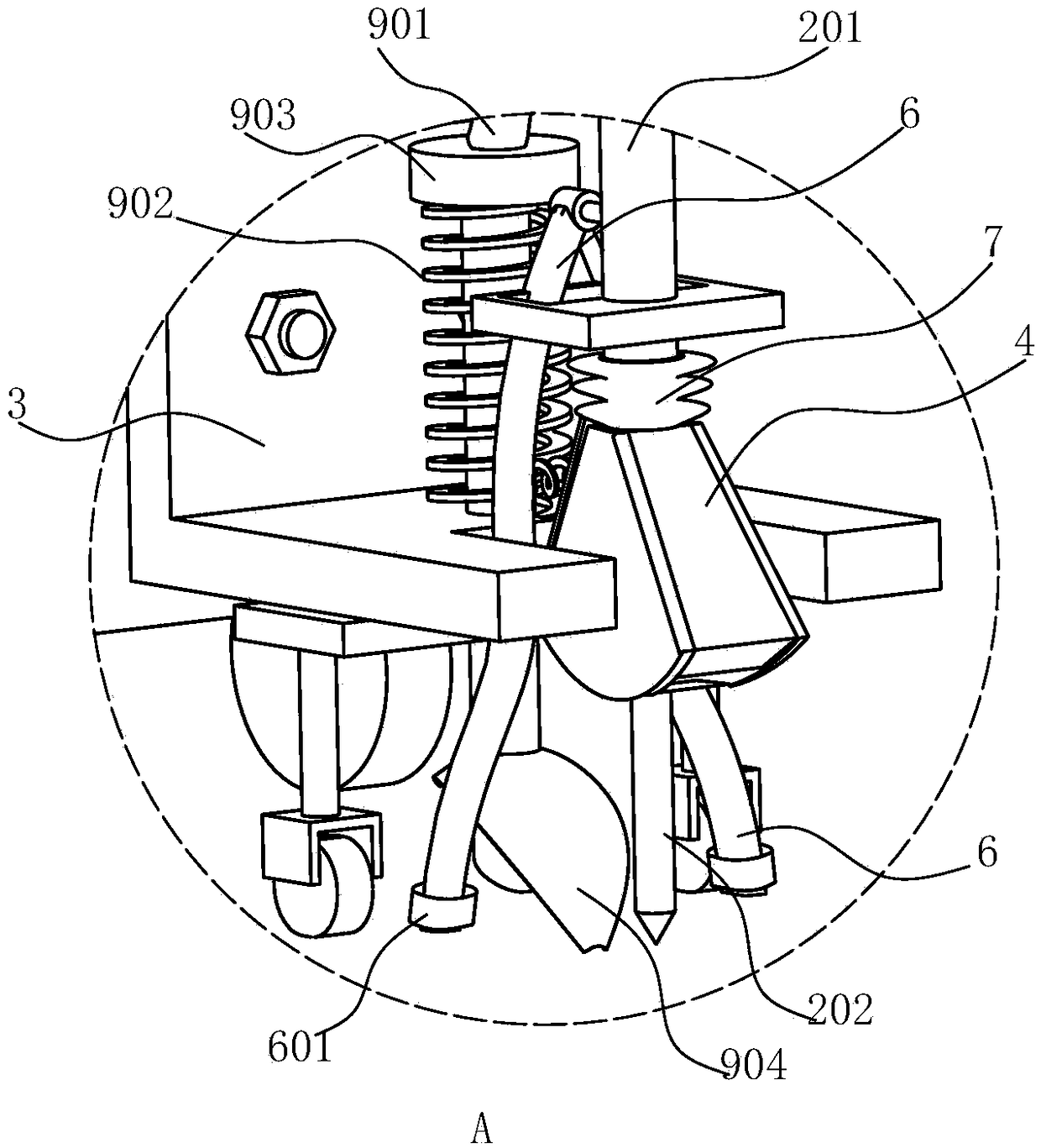

[0055] On the basis that the basic technical solution of Embodiment 1 remains unchanged, a vacuum cleaner 9 and a dust suction pipe 901 communicating with the vacuum cleaner 9 are provided on the caulking machine body 1, and the lower end of the dust suction pipe 901 extends to the bottom of the gun head 202. On the rear side, the particles and impurities in the cracks are sucked out in advance. The way of dust suction is more environmentally friendly than the way of blowing dust, but the requirements for the vacuum cleaner 9 are higher, because the negative pressure reduction rate of the vacuum cleaner is very high, and it is far away from the dust suction. The dust and particles exceeding 50mm in the pipe 901 are almost not affected by the negative pressure, so a special structure must be adopted to ensure the absorption effect. Specifically, the lower end of the dust suction pipe 901 is covered with an arc-shaped dust cover 904, and the dust cover 904 is used to cover Live i...

Embodiment 3

[0059] On the basis that the basic technical solution of Embodiment 1 or 2 remains unchanged, in S step 4, the dimensions of the several channels 401 in the pressure-to-transformation channel group 4 along the transverse direction in the horizontal plane are all the same, and the longitudinal dimensions in the horizontal plane are the same as before. Gradually decrease backwards to ensure that the two track bars 8 can be parallel to each other, so that the slide plate 203 with constant width slides stably in the track bar 8 all the time, and the gun head 202 uses the slide plate 203 at its upper end to slide and fit in the pressure-rotation conversion channel group. 4 On the track bar 8 provided on the lower end surface, the front and rear parts of the slide plate 203 are used to block the channel 401 that is not connected to the gun head 202.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com