Method for efficiently dispersing carbon nano-tubes

A technology of carbon nanotubes and nanotubes, which is applied in the field of preparation of carbon nanotube dispersions, can solve the problems of easy aggregation of carbon nanotubes, low dispersion concentration, poor electrical and thermal conductivity, and other problems, so as to overcome anisotropy and improve Mechanics, Effects on Solving Agglomeration and Stacking Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] In terms of mass fraction, 1 part of multi-walled carbon nanotube (CNT-E3010, Zhongshan Carnet Plastic Co., Ltd.), 0.5 part of carboxylated carbon nanotube (carboxyl molar content is 1%, XF022, Nanjing Xianfeng Nano Material Technology Co., Ltd. Co., Ltd.), 120 parts of water were mixed evenly, and the pH was adjusted to 8 with aqueous sodium bicarbonate solution, and a stable dispersed carbon nanotube dispersion was obtained after ultrasonic dispersion for 1 hour in an ultrasonic cleaning machine with a power of 100W.

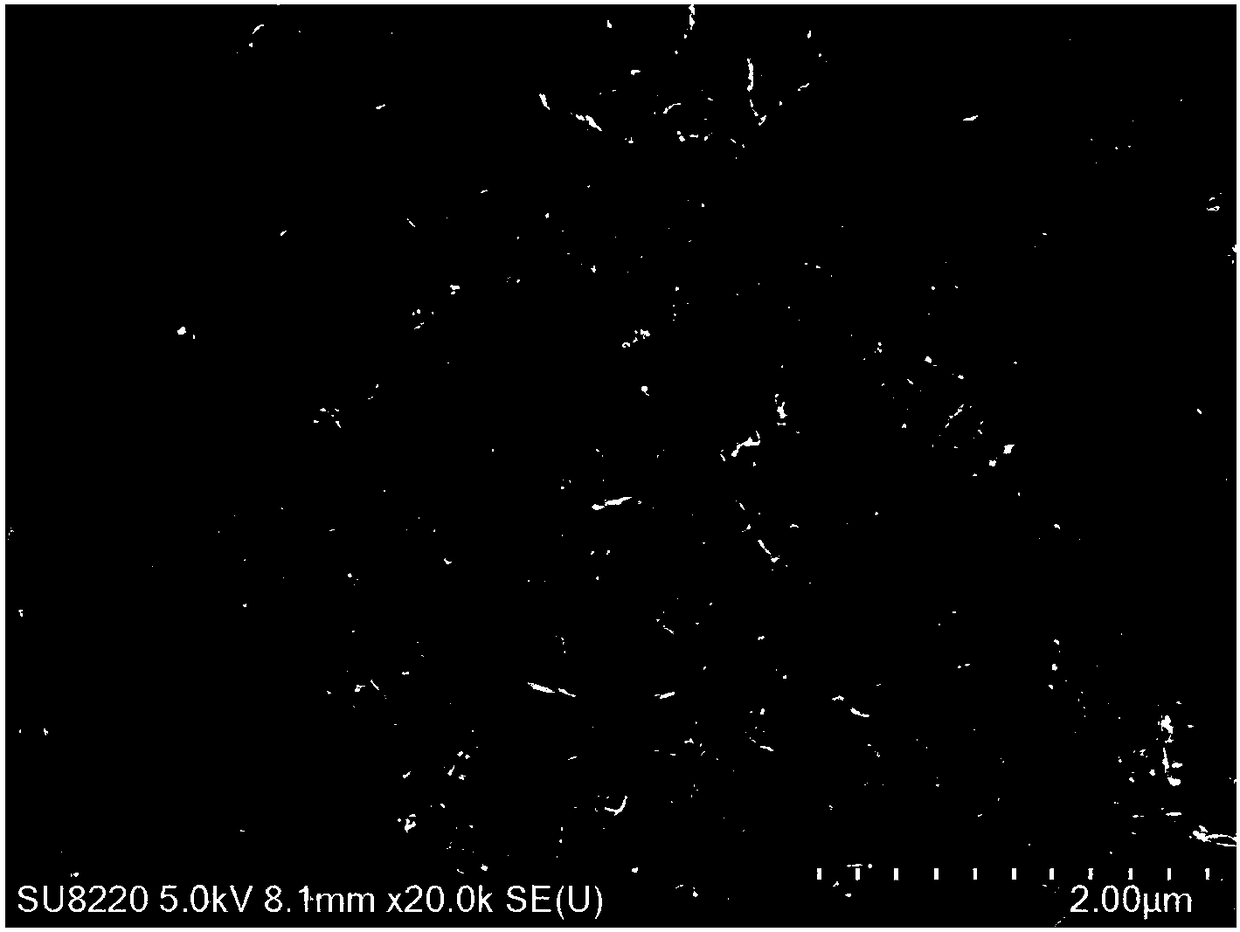

[0037] figure 1 In order to use scanning electron microscopy (FE-SEM, SU-8200, Japan) to obtain the microcosmic dispersion state of the dispersion (stable dispersed carbon nanotube dispersion) of functional carbon nanotube dispersed carbon nanotube in embodiment 1, the high-magnification scanning of characterizing Electron microscope picture. It can be seen from the figure that carbon nanotubes can basically form a single-layer dispersed state, but the...

Embodiment 2

[0044] In terms of mass fraction, 2 parts of multi-walled carbon nanotubes (CNT-E3010, Zhongshan Carnet Plastic Co., Ltd.), 2 parts of hydroxylated carbon nanotubes (the molar content of hydroxyl is 1.5%) (XF021, Nanjing Xianfeng Nanomaterials Co., Ltd. Technology Co., Ltd.) and 800 parts of acetone were mixed evenly, and the pH was adjusted to 8 with aqueous sodium bicarbonate solution, and a stable dispersed carbon nanotube dispersion was obtained after ultrasonic dispersion in an ultrasonic cleaning machine with a power of 100W for 1 hour.

[0045] The apparent color of the obtained carbon nanotube dispersion was dark black, and the concentration was 5 g / L. After measurement, the Zeta potential of the dispersion was -60.8mV, and the hydrated particle size was 583.2nm. No precipitation was found in a centrifuge at 5000r / min for 15 minutes, which proved that the carbon nanotube aqueous dispersion was stable.

[0046] In the present invention, the E44 epoxy resin and the obtai...

Embodiment 3

[0048] In terms of mass fraction, 1 part of single-walled carbon nanotubes (CNT-E3010, Zhongshan Carnet Plastic Co., Ltd.), 0.2 parts of hydroxylated carbon nanotubes (the molar content of hydroxyl is 1.5%) (XF021, Nanjing Xianfeng Nanomaterials Co., Ltd. Technology Co., Ltd.) and 500 parts of ethanol were mixed evenly, and the pH was adjusted to 9 with aqueous sodium hydroxide solution, and a stable dispersed carbon nanotube dispersion was obtained after ultrasonic dispersion for 3 hours in an ultrasonic cleaning machine with a power of 100W.

[0049] The apparent color of the obtained carbon nanotube dispersion was dark black, and the concentration was 0.24 g / L. After measurement, the Zeta potential of the dispersion was -48.8mV, and the hydrated particle size was 600.2nm. No precipitation was found in a centrifuge at 5000r / min for 15 minutes, which proved that the carbon nanotube aqueous dispersion was stable.

[0050] In the present invention, the E44 epoxy resin and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com