Patents

Literature

46 results about "Dye penetration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

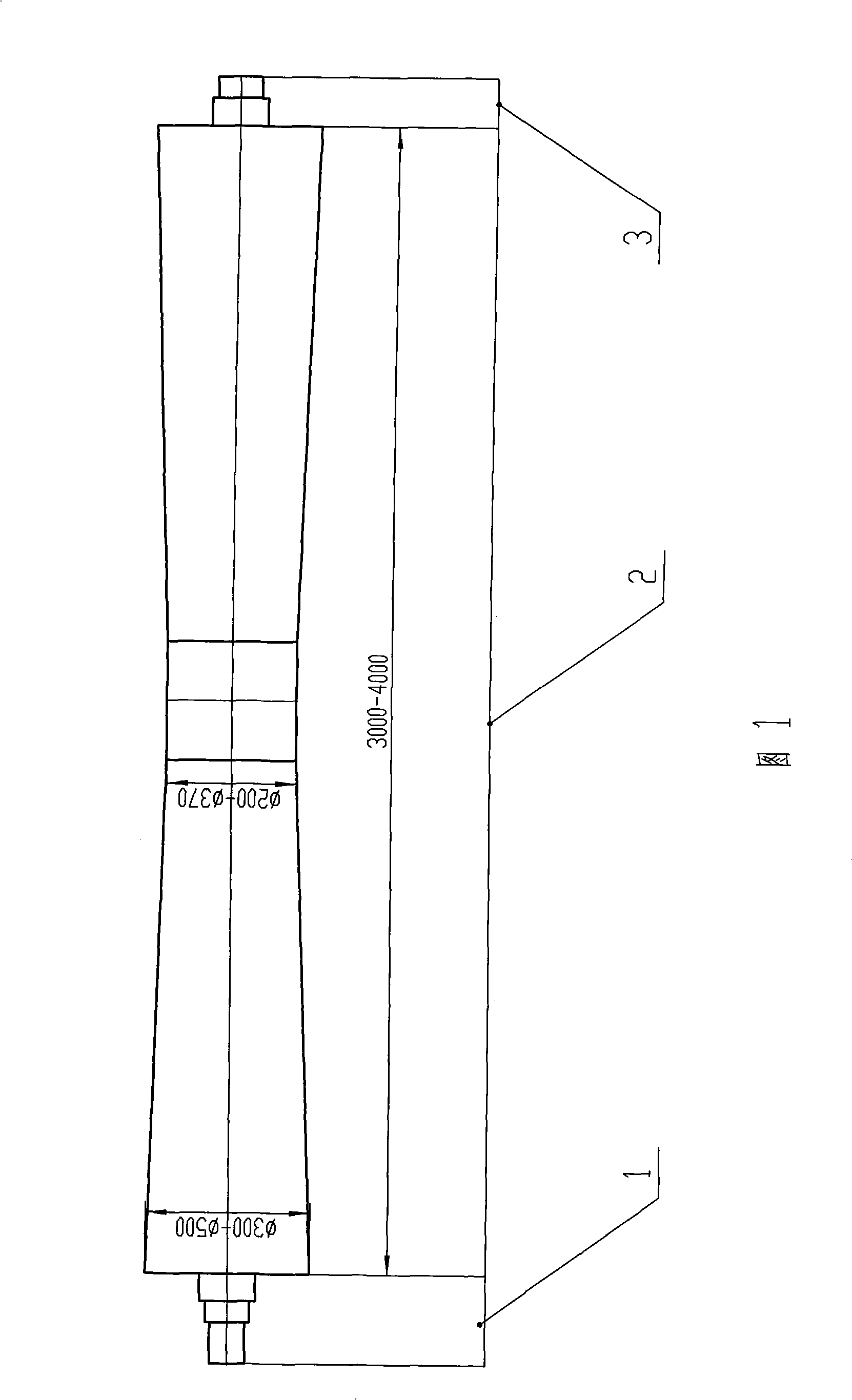

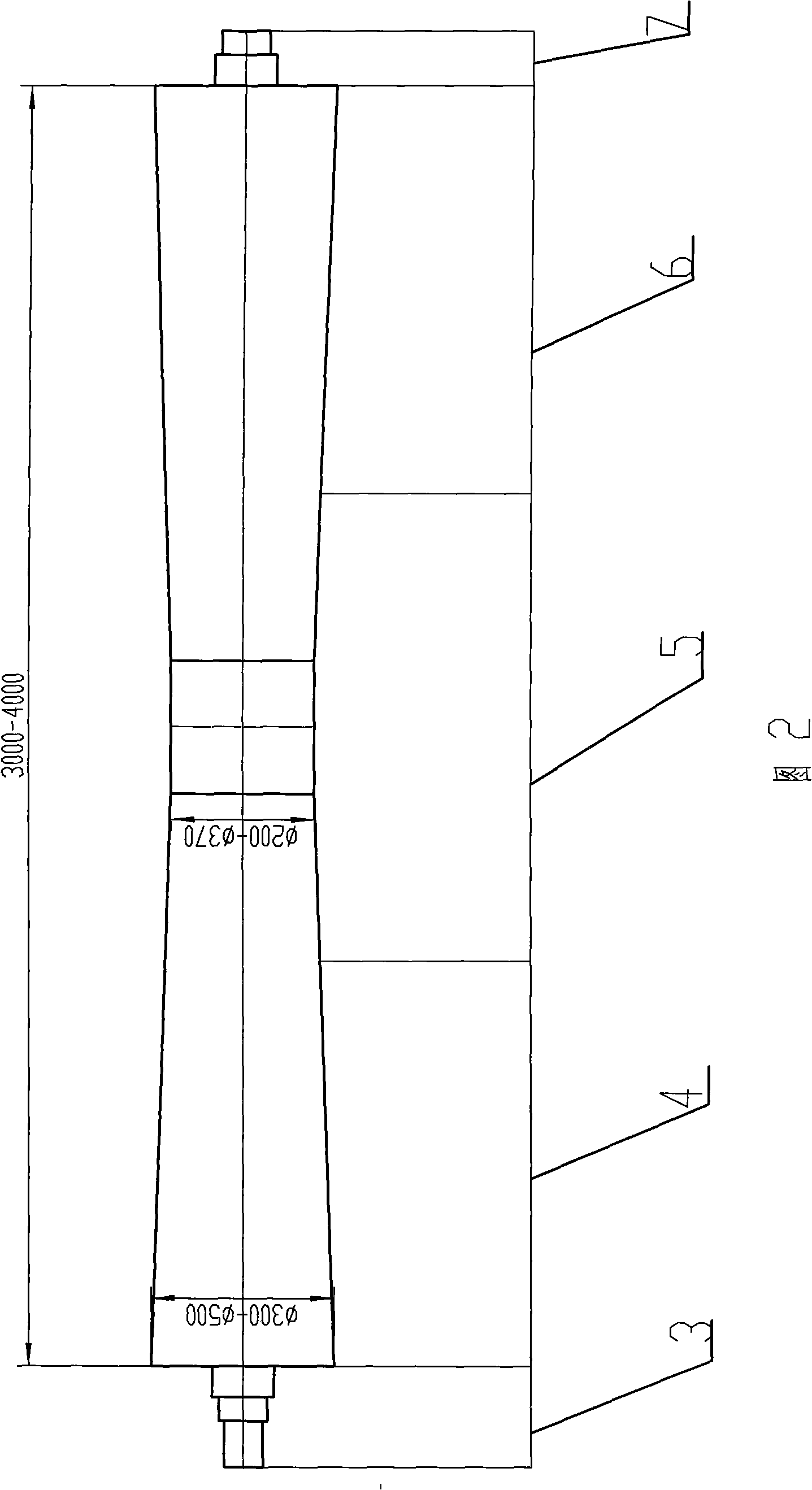

Technique and method for preparing biconical roller of large-sized strip hot-rolling mill transport roller

InactiveCN101358279AConsistency temperatureConsistency depthFurnace typesHeat treatment furnacesManufacturing technologyHeating time

The invention belongs to a roller production technology of a slab band hot milling roll transport roller way. The invention provides a biconical roller production technology of a large-sized slab band hot milling roll transport roller way as follows: forging blank piece normalizing treatment, ultrasonic inspecting, rough machining before thermal refining, thermal refining, semifinishing, roller body surface quenching, tempering, finish machining and inspection of all surface magnetic powder of the roller or dye penetration; in the processes of the roller body surface quenching and the tempering, the biconical roller is divided into different heating sections according to the roller body structural size of the biconical roller, the different sections of the biconical body adopt the mode of different heating strength and same heating time according to different structures of the sections, so that all surfaces of the roller can simultaneously obtain the identical quenching temperature and the identical depth of temperature penetration; in order to obtain the proper quenching hardness and the sufficient hardening layer and simultaneously avoid quenching cracks and reduce quenching deformation, the invention adopts the technique of water-oil double medium quenching.

Owner:洛阳市双勇机器制造有限公司

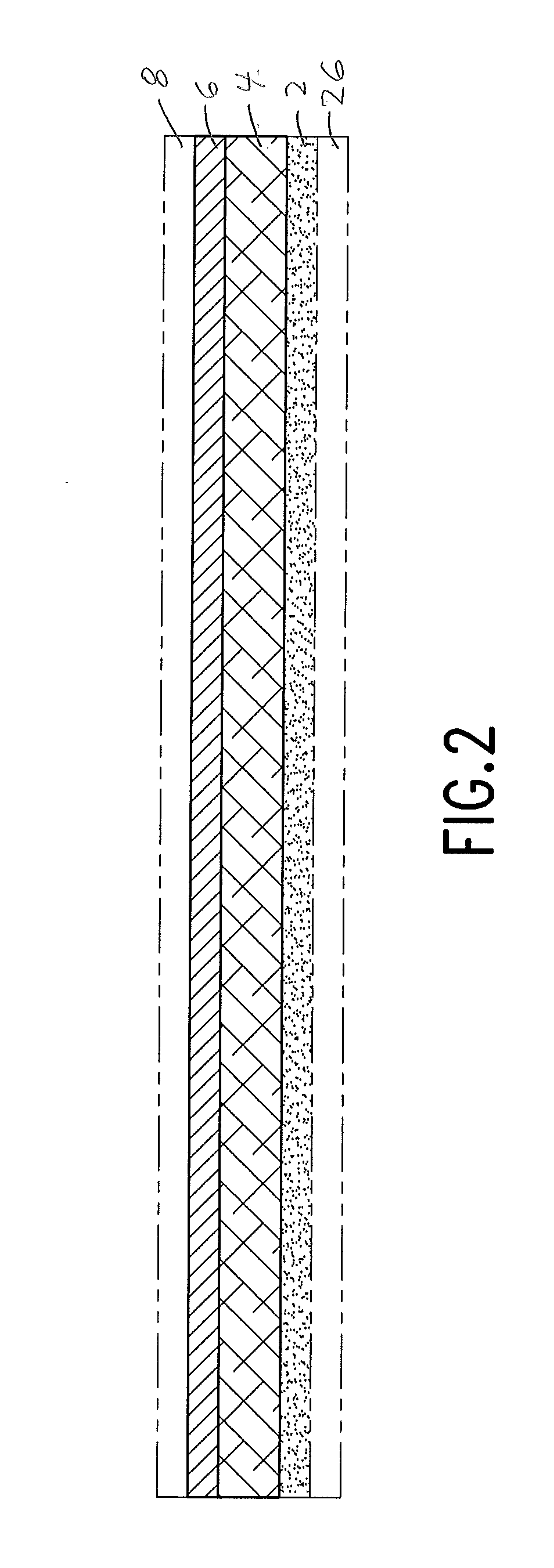

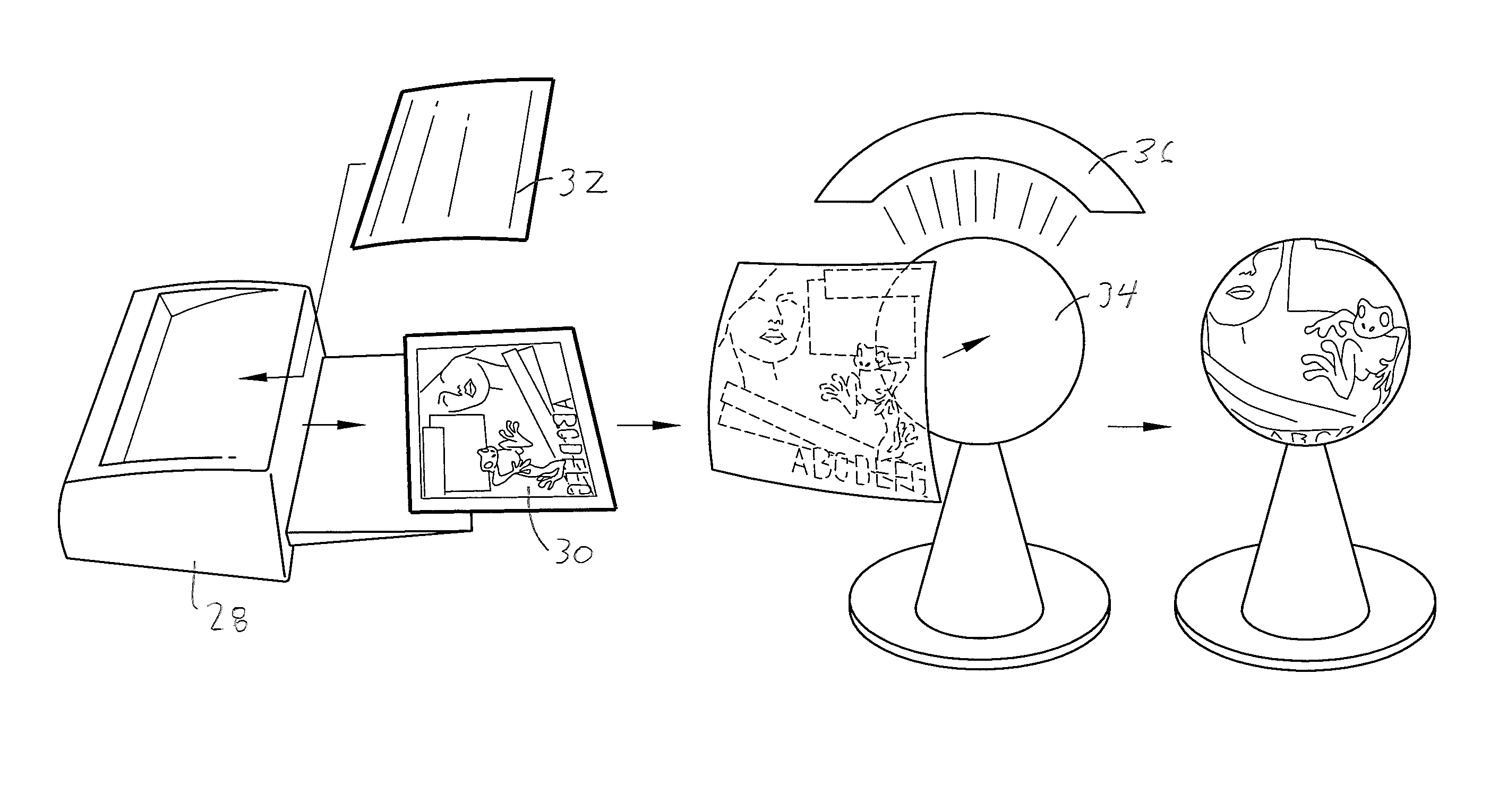

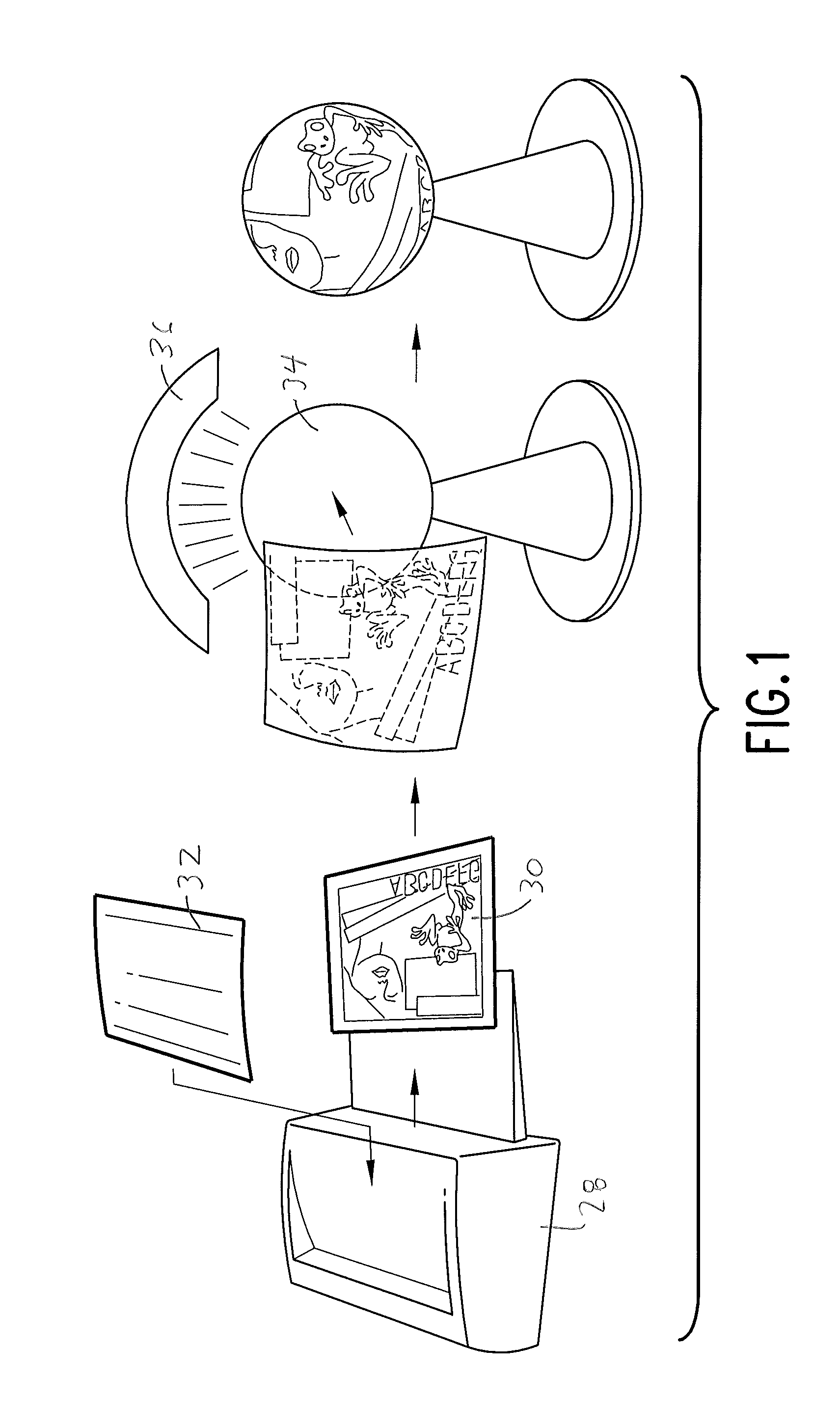

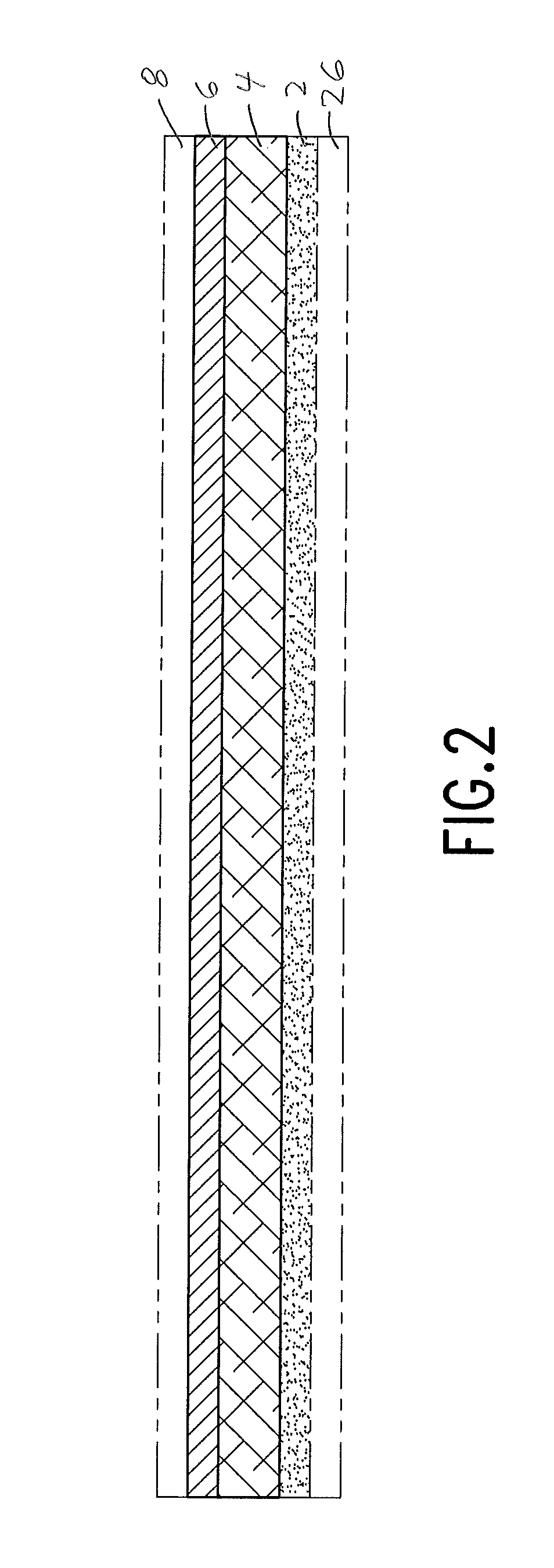

Metalized receiver/transfer media for printing and transfer process

InactiveUS20120044312A1Good release effectMinimal dye penetrationRecording apparatusTransfer printingThin metalEngineering

Media for receiving a printed image during sublimation or heat activated ink printing, and for transferring the image to a final substrate during subsequent heat transfer and activation, and a process of using the media. The media comprises a fibrous sheeting material, which can curve and conform to a three dimensional object to be imaged during the transfer printing process. A thin metal or metalized layer is to be applied onto the fabric / textile sheet shielding the fibrous structure, creating a reflective surface with excellent release properties. This reflective surface allows minimal dye penetration and excellent heat conductivity during heat transfer.

Owner:SAWGRASS TECH INC

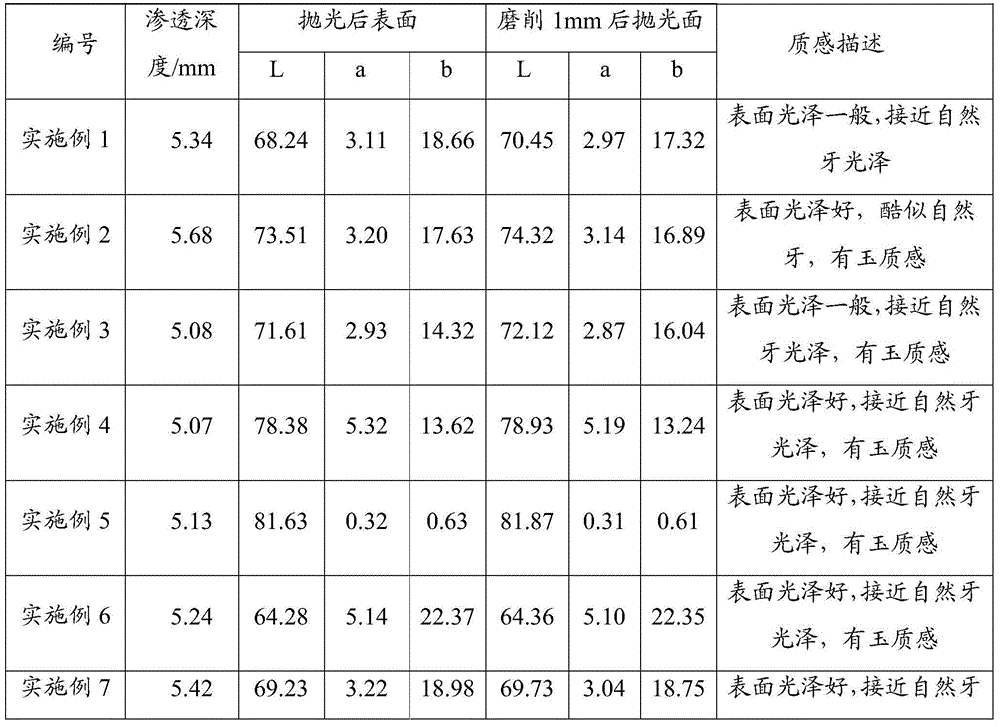

Dyeing liquor for dental ceramics

The invention provides dyeing liquor for dental ceramics. The dyeing liquor for dental ceramics comprises a solvent, a coloring agent and an organic addition agent. Compared with the conventional dyeing liquor in the prior art, the dyeing liquor for dental ceramics, provided by the invention, has the characteristics as follows: (1), the dyeing liquor self needs to be stabilized, is harmless to human bodies or causes less damage; (2), the depth of penetration of the dyeing liquor to dental ceramics needs to be sufficient, and the depth of dyeing penetration to pre-sintering green bodies needs to be greater than 5mm; (3), the dyeing liquor needs to be uniform in dyeing the dental ceramics in the surface or in the direction perpendicular to the surface, that is, the dental ceramics, after being subjected to localized grinding or finishing at different parts with different grinding amounts, can still be uniform in color; (4), at the same time, inorganic ions are added to the dyeing liquor, so that an optical effect of the dental ceramics is obviously improved, and a sense of quality similar to that of natural teeth is achieved.

Owner:NANCHONG THREE CIRCLE ELECTRONICS +1

Multifunctional resin coloring modifier and preparation method thereof

InactiveCN105459239ASolve permeabilitySolve level dyeingWood treatment detailsWood impregnation detailsVolumetric Mass DensityFire retardant

The invention belongs to a multifunctional resin coloring modifier and a preparation method thereof. The multifunctional resin coloring modifier comprises, by weight, 10-35 parts of modified melamine urea formaldehyde resin, 1-10 parts of water soluble dye, 1-10 parts of dyeing assistants, 1-10 parts of fire retardants, and 50-80 parts of water. The modified melamine urea formaldehyde resin is prepared from, by weight, 30-50 parts of formaldehyde, 30-50 parts of melamine, 30-50 parts of methyl alcohol, 10-20 parts of urea, 10-20 parts of polymerization inhibitors, and 40-60 parts of water. According to the multifunctional resin coloring modifier and the preparation method thereof, dyeing and functional modifying of wood materials are integrated, the good modified characteristic of the dyed wood is achieved which the dye penetration, leveling property, color fastness, light resistance and the like are achieved. The multifunctional resin coloring modifier and the preparation method thereof have the advantages that operation is easy, implementation is easy, the production cost is low, a dyed material is large in density, high in strength, stable in dimension, resistant to abrasion, resistant to flame, uniform and rich in color, firm and durable, energy is saved in the production process, and environmental friendliness is achieved.

Owner:INST OF WOOD INDUDTRY CHINESE ACAD OF FORESTRY

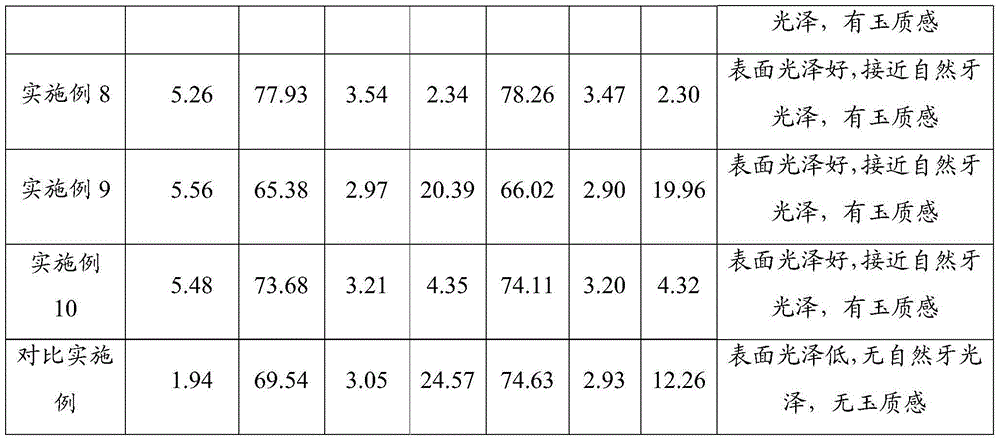

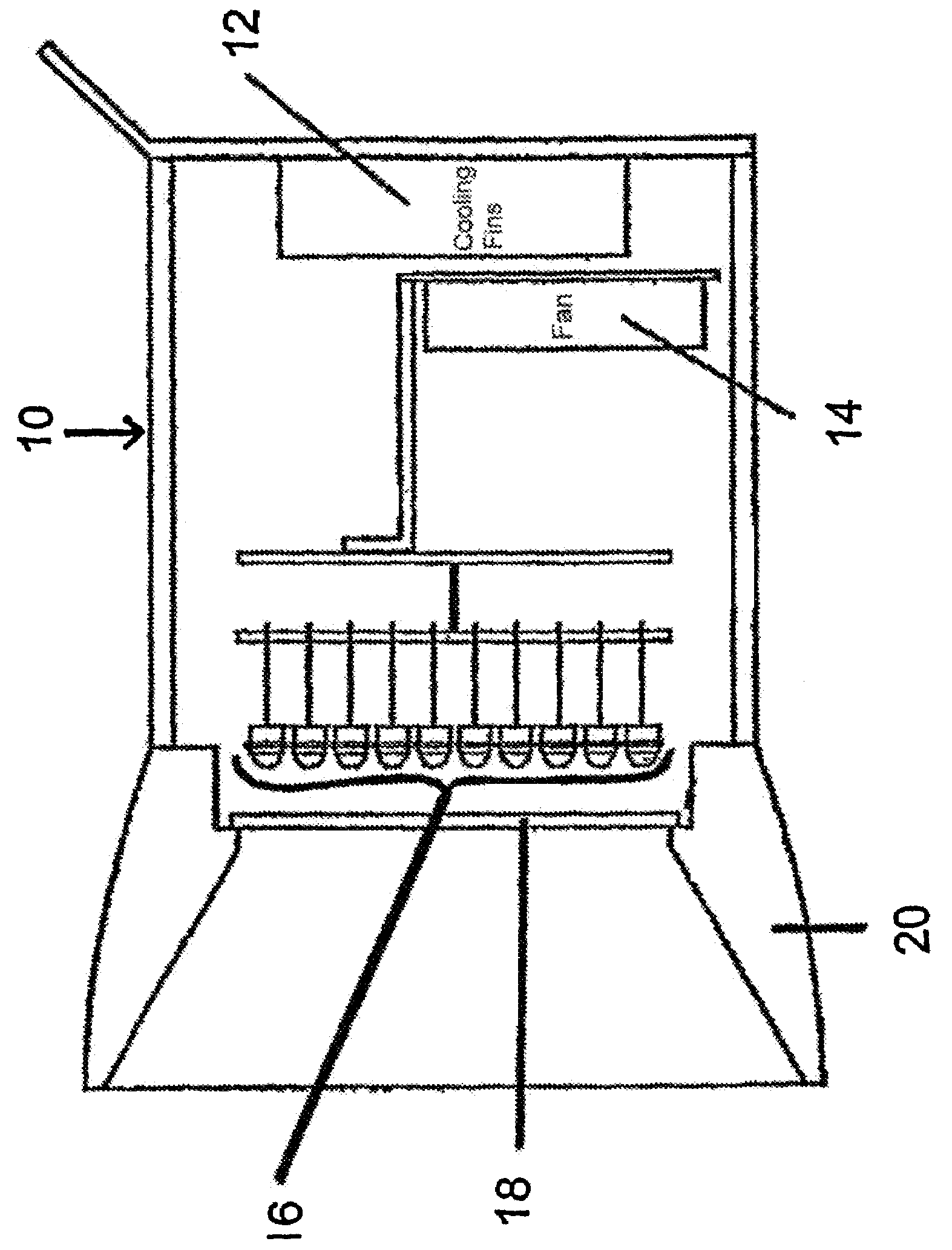

Hand lamp, especially for magnetic crack detection

The invention relates to a manual lamp, especially for optical crack testing according to the magnetic powder testing and dye penetration method. Said manual lamp comprises at least one LED having an emission wavelength located in the UVA range as an illuminating means.

Owner:ILLINOIS TOOL WORKS INC

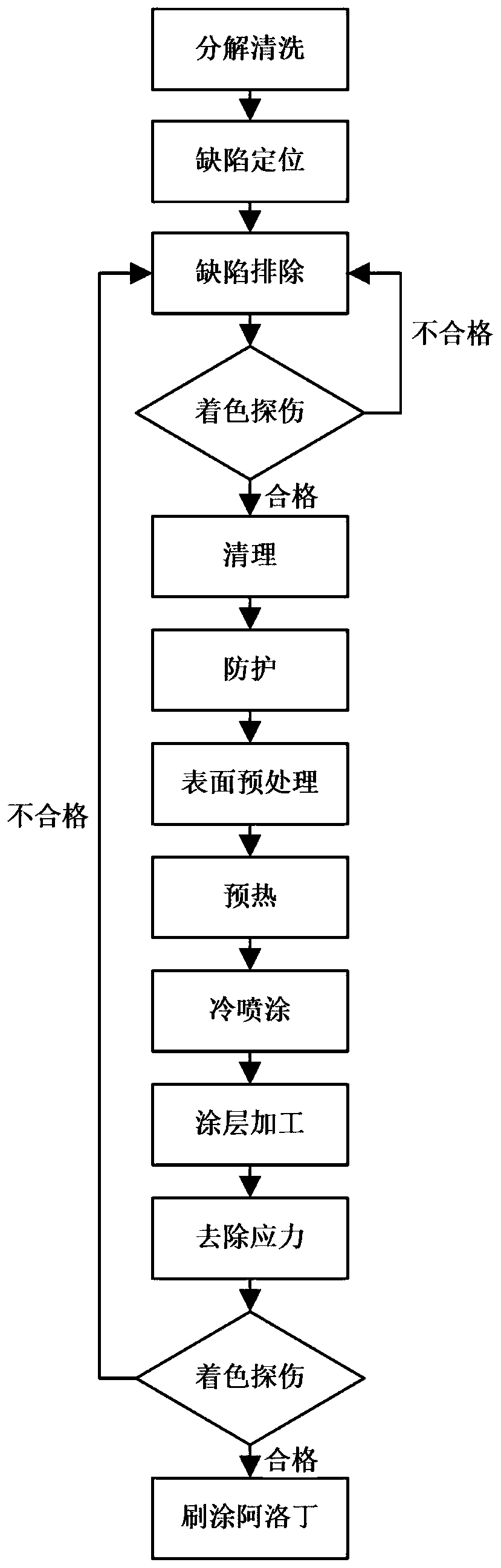

Method for repairing aircraft fuel system aluminum silicon alloy shell casting defects

ActiveCN110480254AAvoid heat cracksAvoids the problem of substrate annealing softeningAircraft componentsAircraft fuel systemDecomposition

The invention relates to the technical field of aircraft fuel system mechanical part accessory repairing, in particular to a method for repairing aircraft fuel system aluminum silicon alloy shell casting defects. The method includes the following steps of S1, decomposition cleaning; S2, defect positioning and removal; S3, dye penetration; S4, cleaning; S5, protection; S6, surface pretreatment; S7,preheating before spraying; S8, cold spraying; S9, coating processing; S10, stress relief treatment; S11, dye penetrant inspection; and S12, anti-corrosion treatment. According to the method for repairing the aircraft fuel system aluminum silicon alloy shell casting defects, the problems of a heat crack of a shell and base material annealing softening caused by large heat input of a traditional surfacing process are effectively avoided, the repairing problem of the aircraft fuel system aluminum silicon alloy shell casting defects is solved, at the same time, casting defect repairing of the shell can be realized under the operation temperature of less than 120 DEG C, the problem of scrapping of a whole part of accessories due to shell damage or secondary damage caused by repairing is avoided, and economic benefits are significant.

Owner:国营芜湖机械厂

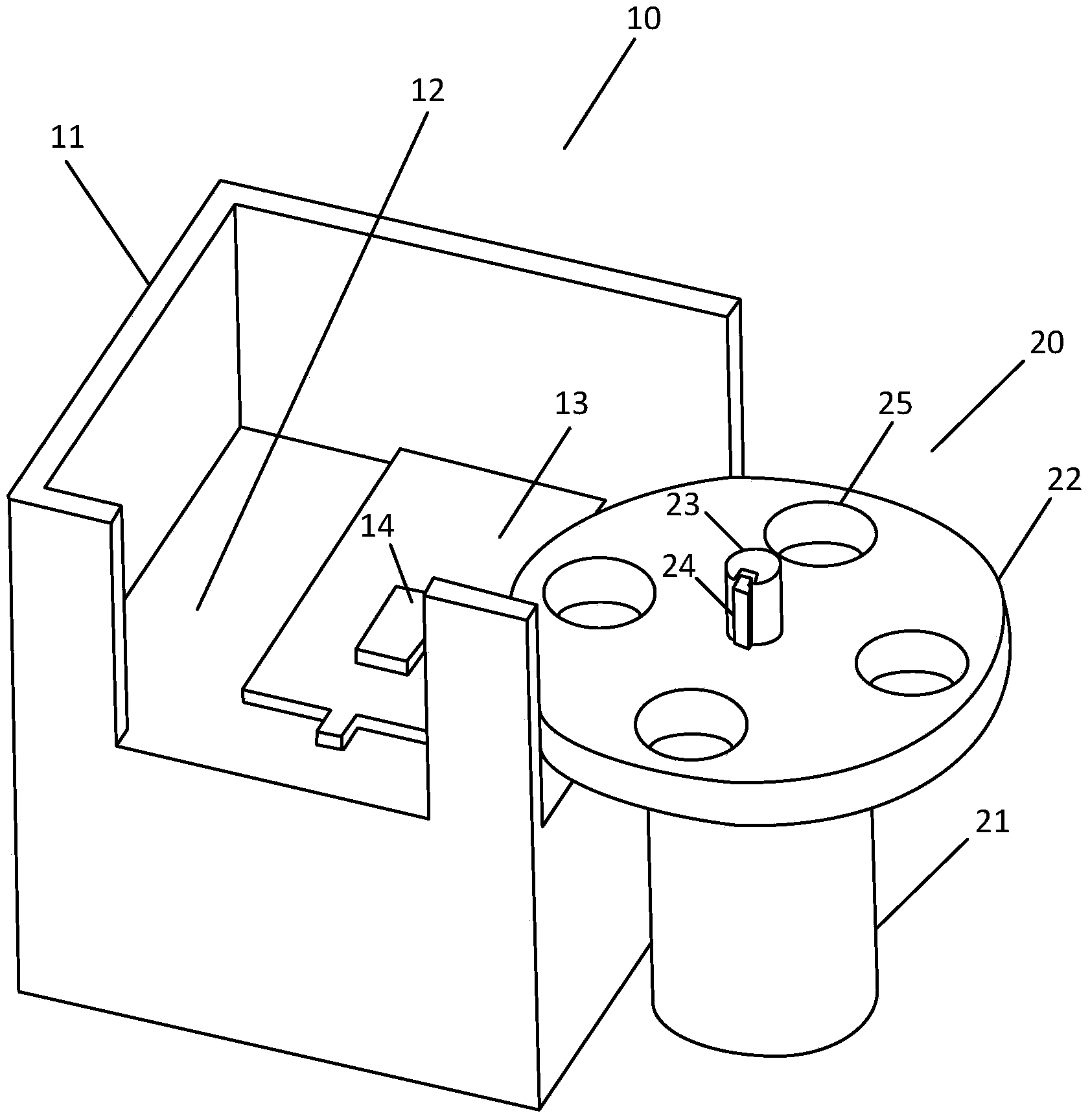

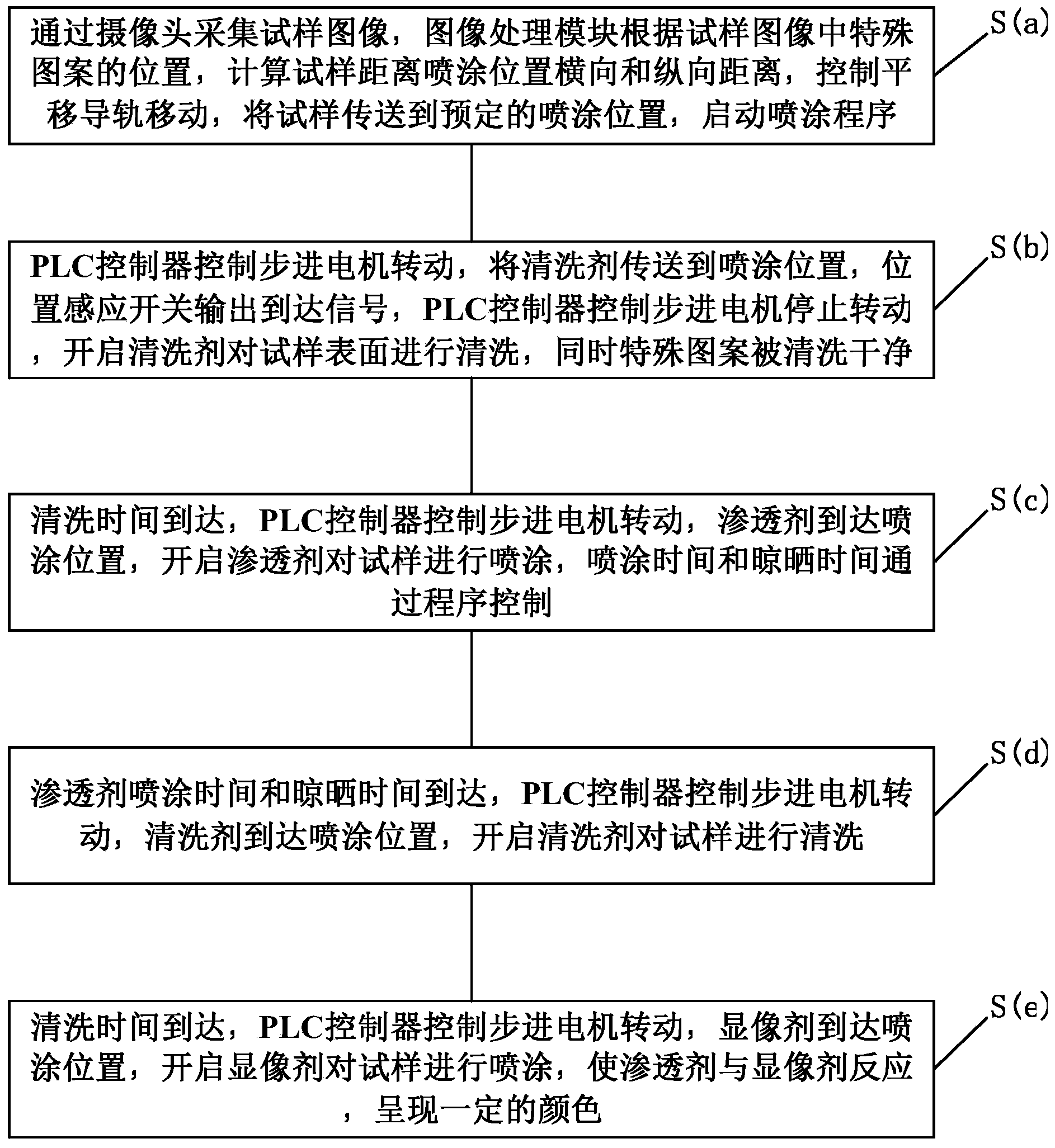

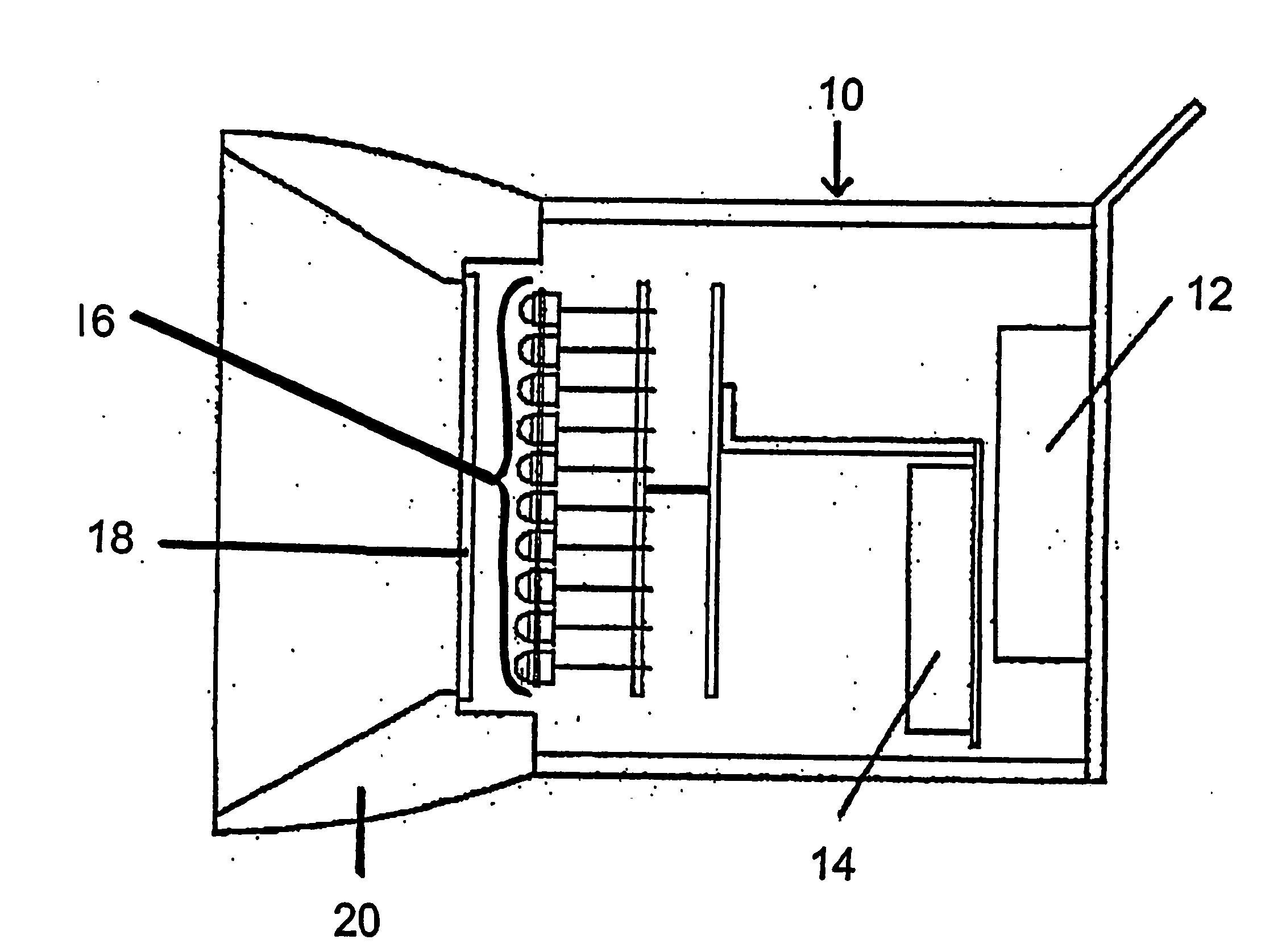

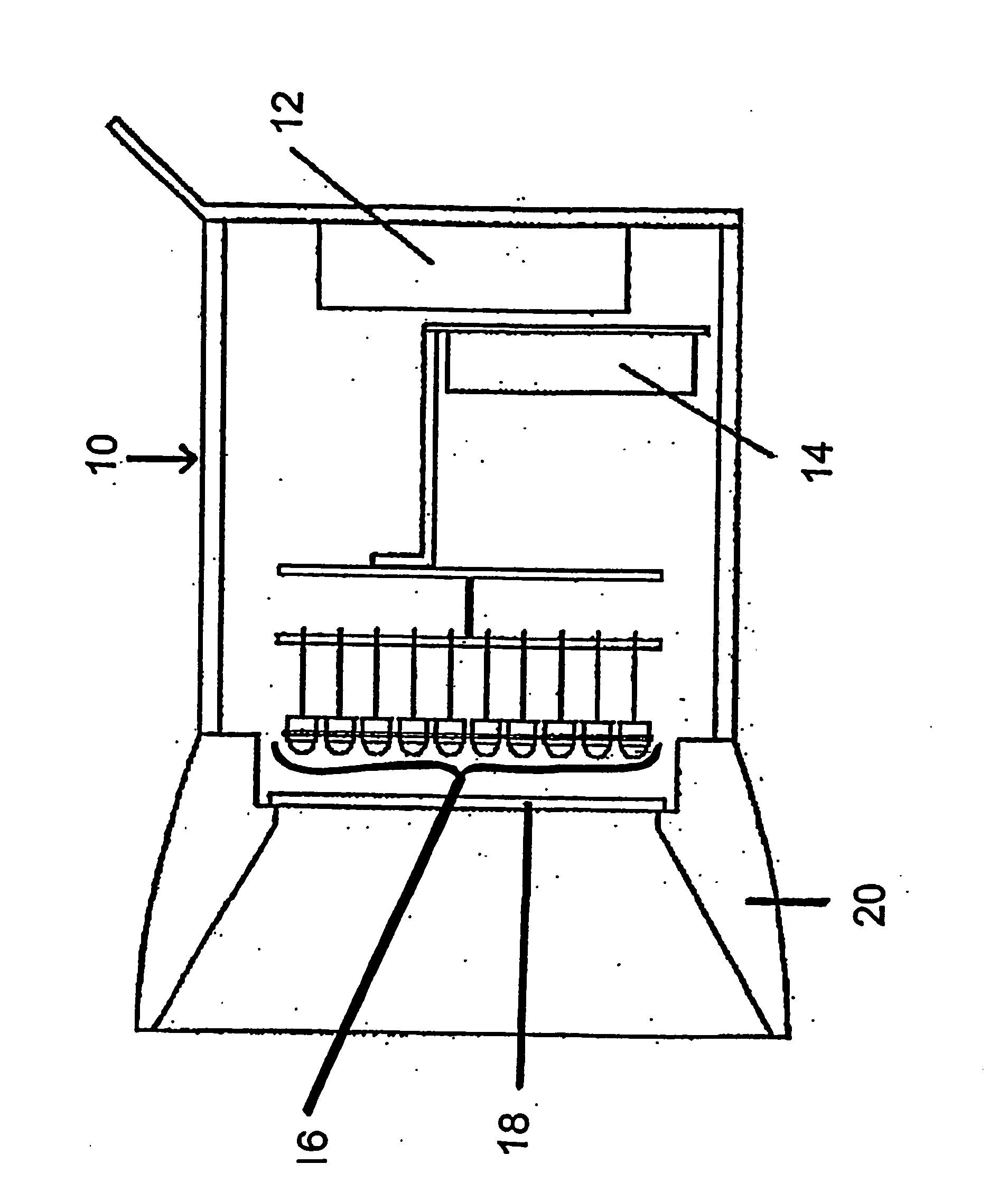

Dye penetration inspection apparatus and dye penetration inspection method

ActiveCN103399019ARealize the automation of colored flaw detectionReduce pollutionOptically investigating flaws/contaminationImaging processingEngineering

The invention provides a dye penetration inspection apparatus and a dye penetration inspection method. The apparatus comprises a workbench and an injection bench; the workbench comprises a peripheral pedestal and a supporting body at the center of the pedestal; the surface of the supporting body is provided with a translational guide rail; a pallet is disposed on the translational guide rail; the injection bench is disposed at the side of the opening of the pedestal, and comprises a rotating disk and a stepping motor; a position sensing switch is disposed on the stepping motor and used to output the position signal of a reagent bottle to a PLC controller controlling the rotation of the stepping motor; a pick-up head is disposed above the supporting body; a cleanable special pattern is coated at the center of the upper surface of a sample; and the pick-up head acquires the image of the sample, an image processing module makes the translational guide rail move according to the position of the special pattern, and thus the sample is sent to a predetermined spraying position. The dye penetration inspection apparatus and the dye penetration inspection method help to realize automation of dye and inspection and reduce pollutions to environment.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

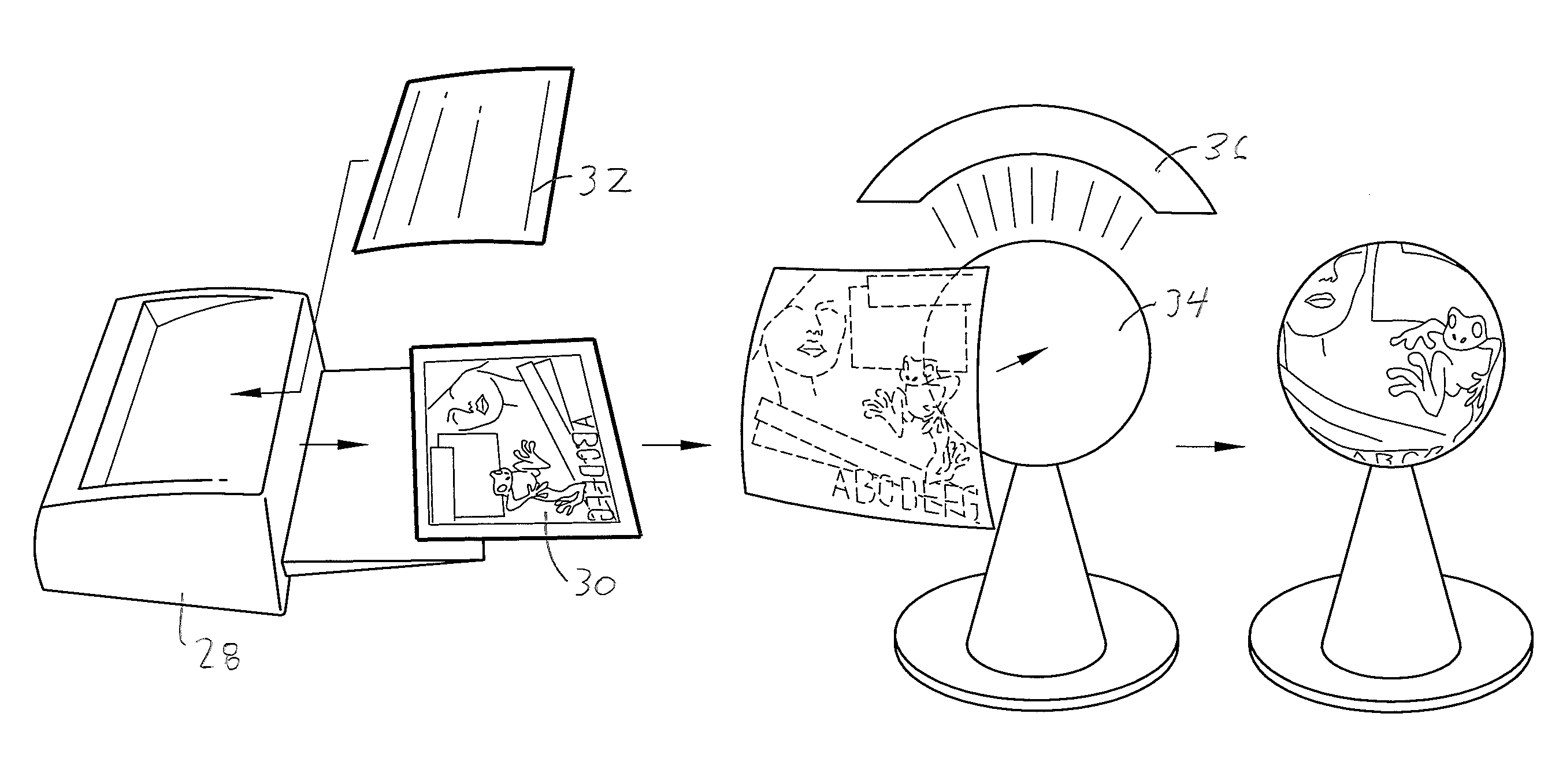

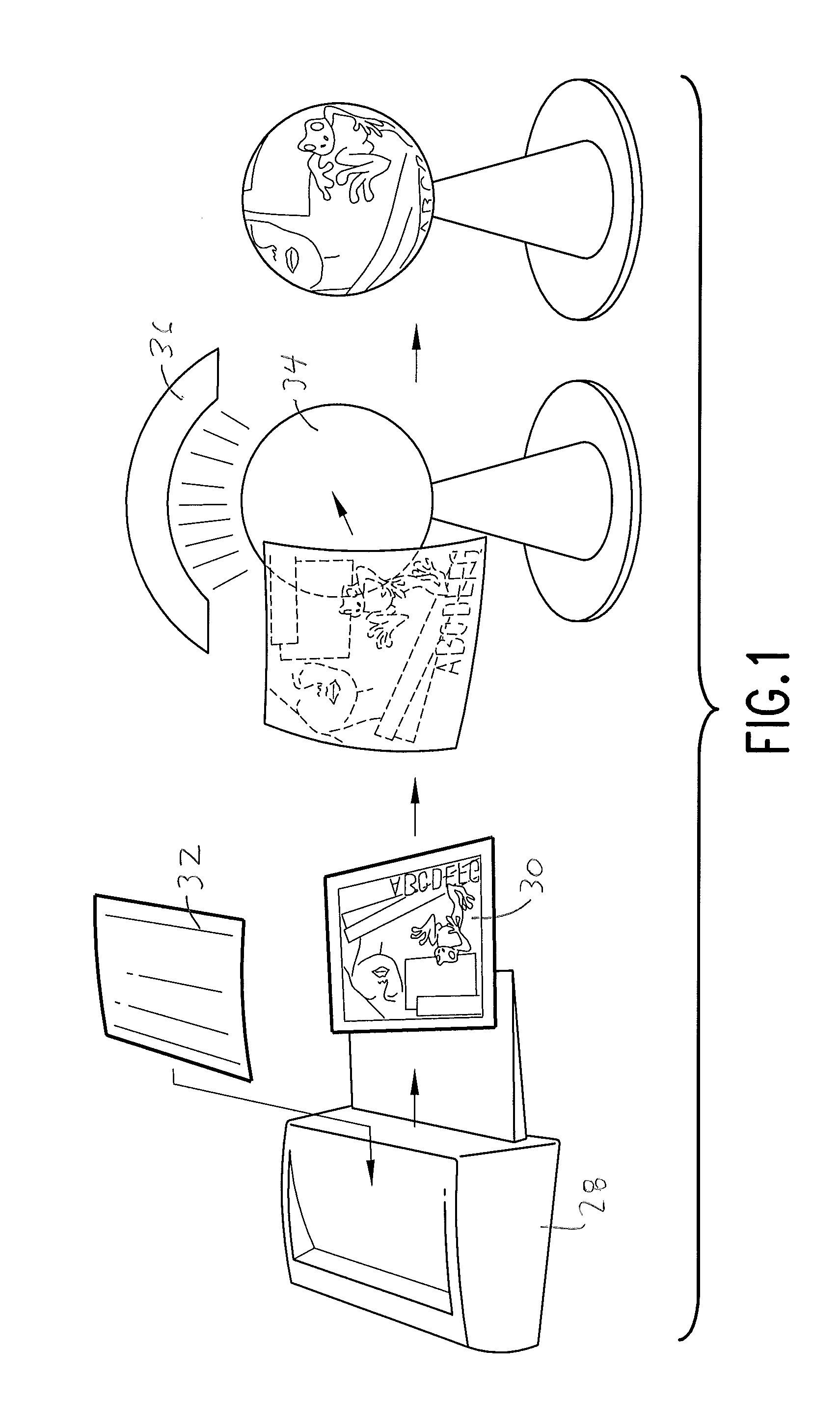

Metalized receiver/transfer media for printing and transfer process

InactiveUS8477163B2Good release effectMinimal dye penetrationRecording apparatusInking apparatusThin metalEngineering

Media for receiving a printed image during sublimation or heat activated ink printing, and for transferring the image to a final substrate during subsequent heat transfer and activation, and a process of using the media. The media comprises a fibrous sheeting material, which can curve and conform to a three dimensional object to be imaged during the transfer printing process. A thin metal or metalized layer is to be applied onto the fabric / textile sheet shielding the fibrous structure, creating a reflective surface with excellent release properties. This reflective surface allows minimal dye penetration and excellent heat conductivity during heat transfer.

Owner:SAWGRASS TECH INC

Processes to pre-treat hair with organic solvents

Owner:NOXELL CORP

Carrier dyeing method of para-aramid fibers

ActiveCN103498214AEasy to dyeGood for adsorption and dyeingCarding machinesDyeing processDye absorptionCarding

The invention discloses a carrier dyeing method of para-aramid fibers. The carrier dyeing method comprises the steps that mechanical carding is conducted on the para-aramid fibers to be dyed; the carded para-aramid fibers are dyed. Mechanical carding has the two functions that firstly, by observing the surface appearances of the fibers through a scanning electron microscope, the facts that after the fibers are carded, under the action of mechanical force, the surfaces become rough, most macromolecular chains are fractured, punctiform pots are produced, and dye absorption and uptake are facilitated can be discovered; secondly, by means of mechanical carding, impurities in the fibers are removed, the fibers become fluffy, the specific surface area of the fibers making contact with dye is increased, and dyeing of the fibers is facilitated. Through research on a dyeing process, the problems that when para-aramid dyeing is conducted at present, the dye-uptake rate is low, dye penetration cannot be achieved, and neutral and deep color dyeing cannot be achieved are solved. Conventional equipment is used in the carrier dyeing method, and the carrier dyeing method has the advantages that processes are simple, environmental friendliness is achieved, procedures are short, and inherent excellent performance of the fibers will not be damaged.

Owner:SHAANXI YUANFENG TEXTILE TECH RES

Aluminum alloy car body coloring pervasion weld seam leakage testing technological process

InactiveCN101303267AHigh sensitivityImprove reliabilityDetection of fluid at leakage pointOptically investigating flaws/contaminationYarnWeld seam

The present invention provides a dye penetration welding line leakage test process for an aluminium alloy car body, comprising the steps of eliminating all of the oxide scale, pocking and dust on the welding line to be tested; washing the oil contamination off the welding line to be tested and cleaning the welding line by a piece of clean cloth or cotton yarn; spraying and coating osmotic agent evenly on the outside of the welding line to be tested every 2 to 3 minutes, making sure that the welding line is wet within 10 to 15 minutes; observing whether leakage exists on the other side of the welding line or not and mending the welding line if leakage exists. Therefore, the probability that the welding line on the car top leaks can be avoided by using the process with high technique sensitivity and reliability surpassing the rain test in the present invention, and the probability of accumulated water pollution caused by the rain test in workshop can also avoided. Furthermore, the quality of the welding line surface on the car top can be ensured through fault detection because the process can be performed easily without any other devices and the result is easy to observe. General process workers can perform the dye penetration welding line leakage test process after a simple training, thus, professional fault detection workers are not necessary.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

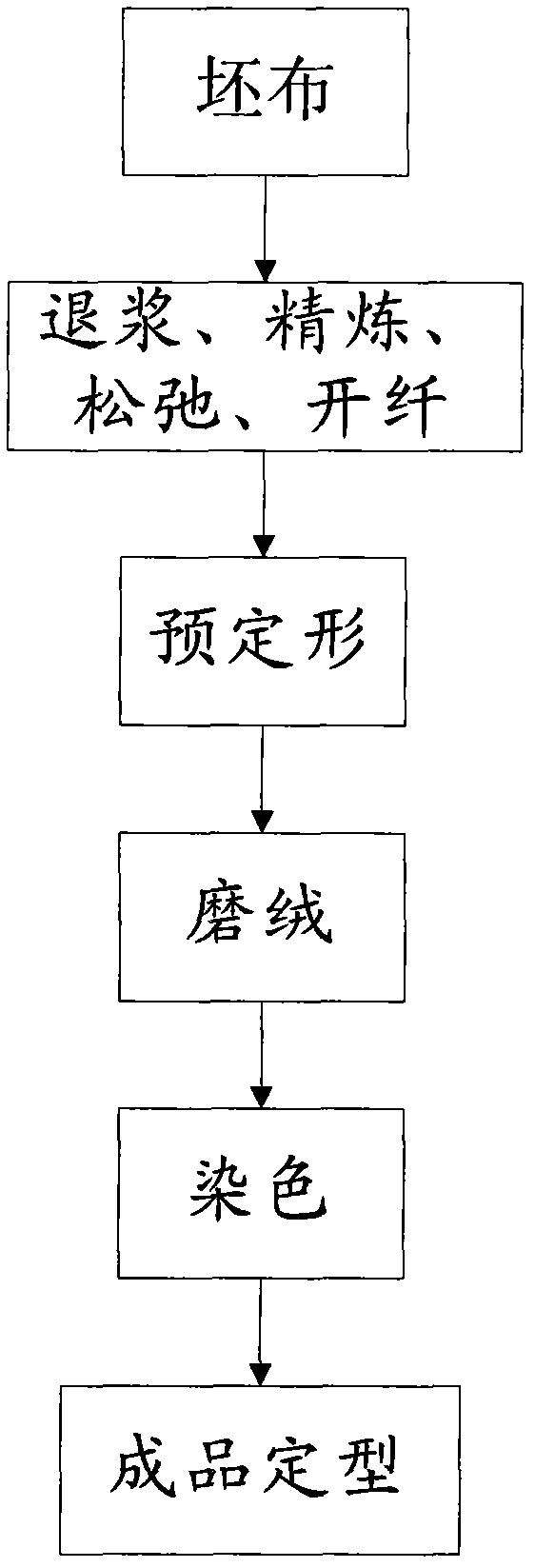

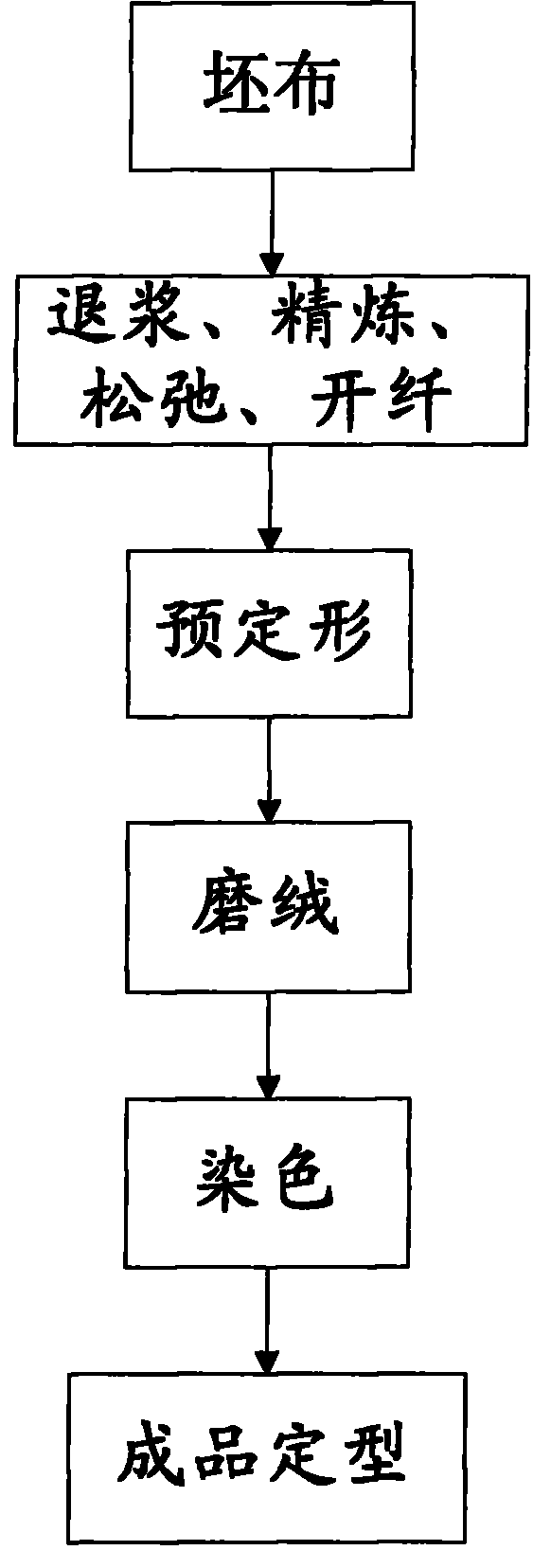

Dyeing and finishing process for suede fabric

InactiveCN102465460AImprove recycling efficiencyMeet the requirements of rapid responseDyeing processEngineeringDye penetration

The invention discloses a dyeing and finishing process for a suede fabric. The dyeing and finishing process comprises the following steps of: desizing, refining, slackening, splitting, presetting, sueding, dyeing a gray fabric; and forming a finished product, wherein the gray fabric is dyed by adopting a supercritical fluid dyeing means in the dyeing step, the dyeing temperature is 90-115 DEG C, the dyeing pressure is 18-25MPa, and the dyeing time is 15-45min. According to the dyeing and finishing process disclosed by the invention, time, labor and energy sources are saved; the environment is protected; and the dyed and finished product has the characteristics of high dyeing firmness, dyeing penetration and isochromatic property.

Owner:CHANGSHU ZHUOHUI TEXTILE

Method for welding cold-expansion tube production line draw rod

The invention provides a method for welding a pull rod for a production line of cold expansion pipes, which comprises the following steps: preparing before welding; preparing a short joint end of the pull rod; preparing of a long joint end of the pull rod; welding; detecting after the welding, namely, carrying out ultrasonic and dye penetration inspection for the welded joint after the pull rod is welded. The method has the advantages that by adopting an unconventional method to weld and repair the pull rod for the production line of the cold expansion pipes, the method solves the technical problems of integral preheating of the pull rod, heat treating after the welding and welding at low temperature, avoids multiple technical defects, shortens repair time, and reduces loss of oil fields. The pull rod is a key component of production line equipment for the cold expansion pipes in the oil fields, and directly influences production operation after the pull rod is damaged, then the downtime loss is 320, 000 Yuan per hour, and if spare parts are bought abroad, several months are needed. The method generates certain social benefit and larger economic benefit, and provides scientific repair method for guiding production practice for projects in the same field.

Owner:TIANJIN PIPE GROUP CORP

Low-temperature polyester fiber dyeing method based on diethyl phthalate

InactiveCN107059424AHigh strengthGood level dyeingDry-cleaning apparatus for textilesDyeing processFiberPolyester

The invention discloses a low-temperature polyester fiber dyeing method based on diethyl phthalate. According to the low-temperature polyester fiber dyeing method based on diethyl phthalate, a polyester fabric is dyed by using diethyl phthalate as a dyeing auxiliary agent, the dyeing temperature is controlled at 103-105 DEG C, the color depth, the chromatic light, the color fastness and the dyeing penetration of the obtained fabric are the same as the fabric obtained through the traditional high temperature and high pressure dyeing, the mightiness and leveling property of the fabric are improved, and the friction and the soaping fastness achieve the national standard of more than grade 4. Compared to the traditional high temperature and high pressure dyeing method, the low-temperature polyester fiber dyeing method of the present invention has advantages of substantially-reduced dyeing temperature, dyeing time shortening, energy saving, consumption reducing, efficiency improving, and production cost reducing; and the diethyl phthalate adopted as the dyeing auxiliary agent is the environmentally friendly organic ester so as to achieve the environmentally friendly low temperature dyeing.

Owner:JIESHOU HUAYU TEXTILE

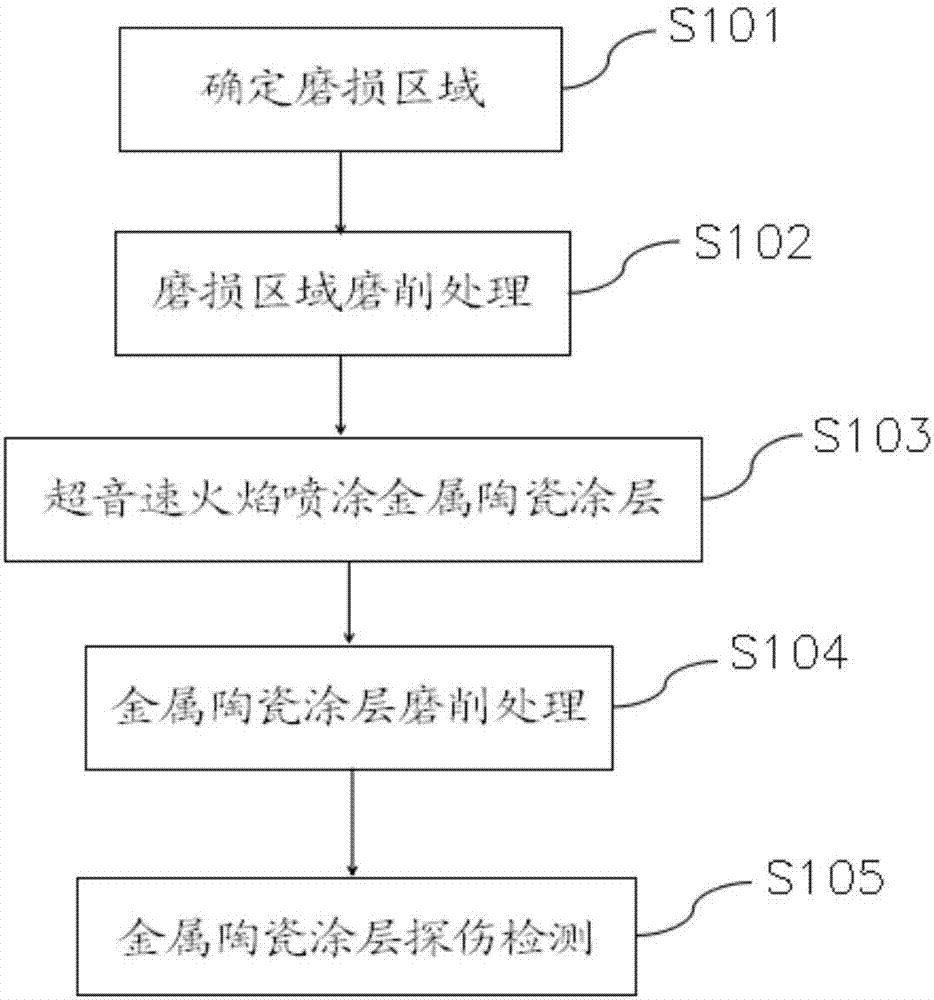

Centrifugal compressor shaft wearing repair method

InactiveCN107299309AReduced risk of deformation and bendingMeet the use requirementsMolten spray coatingHardnessEngineering

The invention relates to a centrifugal compressor shaft wearing repair method which comprises the following steps: determining a wearing region of a centrifugal compressor shaft; carrying out grinding treatment on the wearing region, carrying out dye penetration flaw detection on the ground centrifugal compressor shaft when a hardness value of the wearing region reaches or approaches that of the centrifugal compressor shaft, and stopping grinding to the wearing region after determining no defect after flaw detection; carrying out metal ceramic coating spraying treatment on the wearing region by a supersonic flame spraying gun; carrying out grinding treatment on a metal ceramic coating to enable the size of the diameter of a region shaft after the metal ceramic coating is applied to be the same as an original set size; carrying out the dye penetration flaw detection on the metal ceramic coating subjected to grinding treatment, thus obtaining a finished product after the metal ceramic coating passes through the dye penetration flaw detection. The centrifugal compressor shaft wearing repair method has the advantages of high efficiency, good binding force of the coating and the shaft, energy conservation and environmental protection, and also has the advantages of little heat input and reduction in risk of deformation and bending of the centrifugal compressor shaft.

Owner:大连透平机械技术发展有限公司

Manual lamp, especially for magnetic crack testing

InactiveUS20070014195A1Guaranteed reliabilityReduce intensityCombination recordingLighting elementsDye penetrationLength wave

The invention relates to a manual lamp, especially for optical crack testing according to the magnetic powder testing and dye penetration method. Said manual lamp comprises at least one LED having an emission wavelength located in the UVA range as an illuminating means.

Owner:ILLINOIS TOOL WORKS INC

Thermal transfer powdery coating and preparation method and application thereof

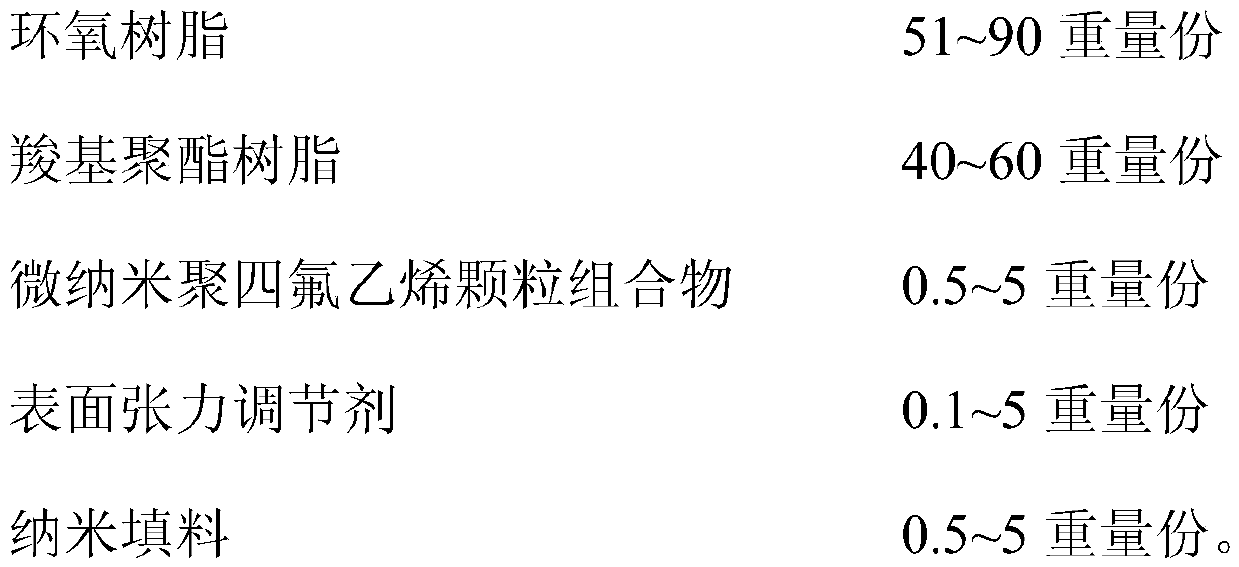

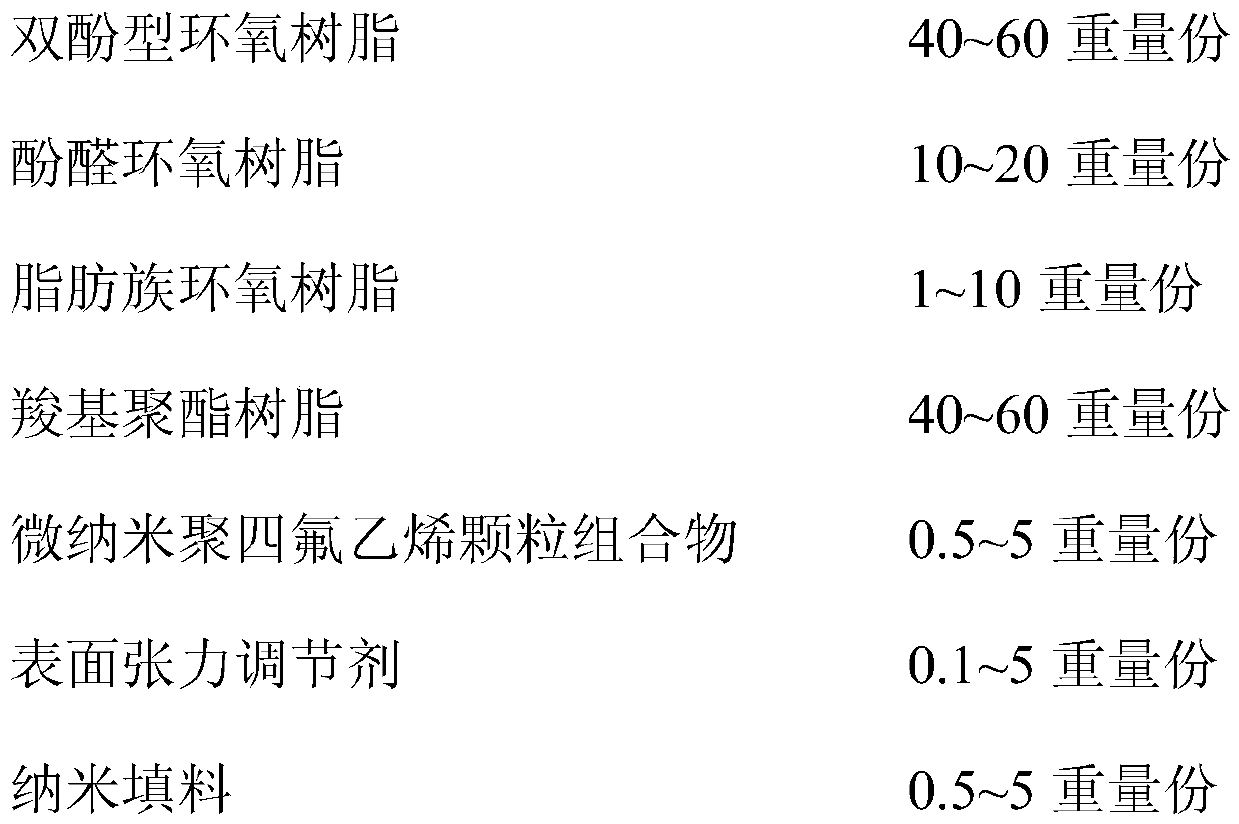

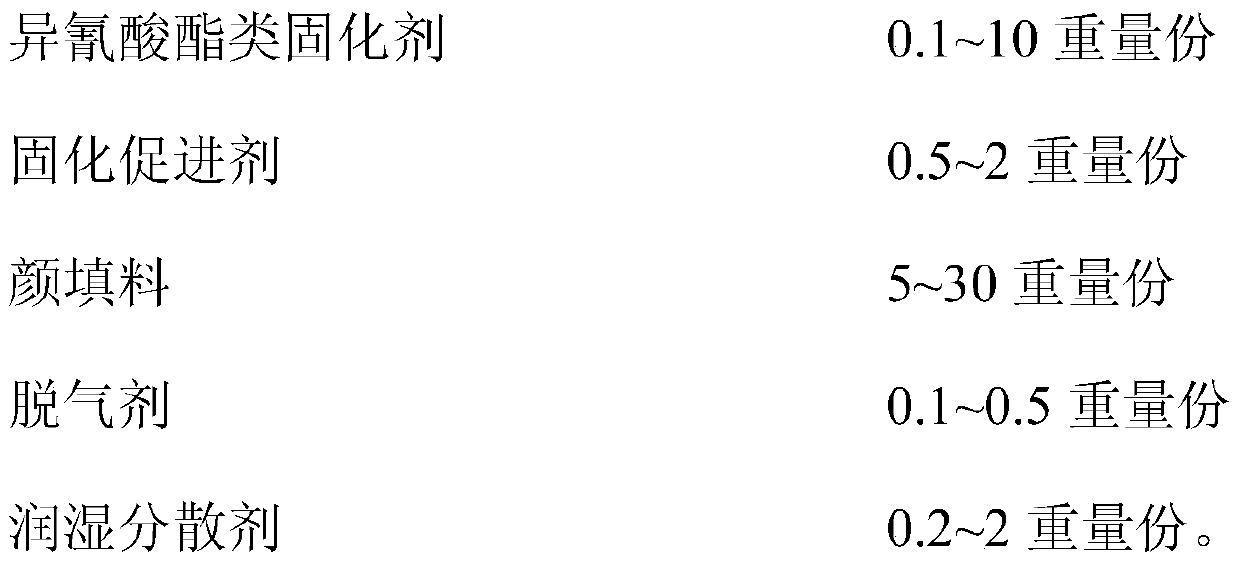

ActiveCN110272677AFast curingImprove infrared absorptionPowdery paintsEpoxy resin coatingsEpoxyMicro nano

The invention provides a thermal transfer powdery coating and a preparation method and application thereof. The thermal transfer powdery coating comprises, by weight, 51-90 parts of epoxy resin, 40-60 parts of carboxyl polyester resin, 0.5-5 parts of micro-nano polytetrafluoroethylene particle composition, 0.1-5 parts of a surface tension regulator and 0.5-5 parts of a nano filler. The thermal transfer powdery coating is prepared by dispersing, mixing and extruding all the components and then tabletting and crushing the components. The provided thermal transfer powdery coating can be rapidly cured at the low temperature and can be used for coating the surfaces of heat-sensitive substrates such as wood, glass, paper and plastic; a cured coating film has high crosslinking density and hardness, excellent solvent resistance and great substrate adhesion; the surface roughness and surface tension of the powdery coating are suitable for rapid and clear low-temperature thermal transfer, and the dye penetration degree is high.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

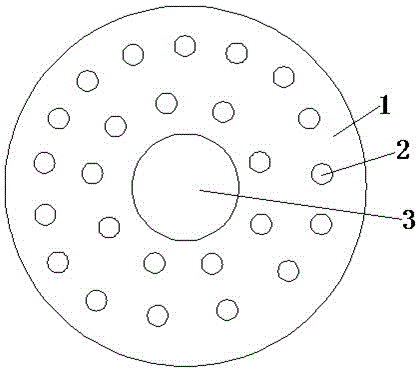

Separator plate disk for textile printing and dyeing machinery

InactiveCN106048947AFlow fastPoor wear resistanceTextile treatment machine arrangementsTextile printerDye penetration

The invention discloses a separator plate disk for textile printing and dyeing machinery. The separator plate disk includes a separator plate disk main body, a first wear-resisting reinforcing layer, a second wear-resisting reinforcing layer, dye penetration holes and plate disk main body fixing holes. The internal surface and the external surface of the separator plate disk main body are respectively provided with the first wear-resisting reinforcing layer and the second wear-resisting reinforcing layer. The separator plate disk main body is evenly provided with the dye penetration holes. The center of the separator plate disk main body is provided with the plat disk main body fixing holes. Through the aforementioned method, according to the invention, the separator plate disk has excellent wear-resisting property, long duration and strong penetration, allows a dye liquid to flow rapidly in a radioactive manner, and enables uniform dyeing.

Owner:蒋萍

Ultra-soft fast soluble film and preparation method thereof

InactiveCN106521935ASolve the problem of long chemical timeShorten the chemical timeFibre treatmentEthylenediamineStaining

Belonging to the textile industry, the invention in particular relates to an ultra-soft fast soluble film and a preparation method thereof specific to textile dyeing and finishing technology. The ultra-soft fast soluble film provided by the invention comprises the following components by weight percentage: 60-80% of stearic acid, 6-15% of diethylenetriamine, 2-5% of triethylene tetramine, 2-6% of triethanolamine, 3-6% of hydroxyethyl ethylenediamine, 2-7% of dimethyl sulfate, 0.1-1.2% of p-toluenesulfonic acid, 8-15% of fatty alcohol polyoxyethylene ether, 1.5-3.5% of a dispersing agent, 1-4% of a swelling agent, 1-3% of a leveling agent, 1-4% of a softening agent, and 2-6% of an efficient defoaming agent. The ultra-soft fast soluble film provided by the invention not only has good dye penetration and excellent dispersion properties, but also has strong acid and alkali resistance and dielectric resistance, can make the fabric fuller, smoother and more resilient, and has the advantages of no yellowing, no fading and no staining, etc.

Owner:江苏海云花新材料有限公司

Polyester cheese dyeing method

InactiveCN106521849APrevent penetrationMeet production dyeing needsSucessive textile treatmentsDyeing processPolyesterEngineering

The invention discloses a polyester cheese dyeing method which comprises the steps of grey yarn preparation, yarn loosening, dyeing, postprocessing, dehydration and spooling. The polyester cheese dyeing method further comprises the steps of boiling off and dehydration and yarn loosening and tipping after the yarn loosening step but before the dyeing step. The polyester cheese dyeing method is different from a traditional polyester yarn production process, and the purposes of yarn shrinkage at different degrees and oil removal through preprocessing can be achieved by adopting boiling off and tipping and then cooperating with appropriate boiling-off temperature and time. The tipping is performed after boiling off and dehydration, the process actions of repeatedly performing the preprocessing are omitted, it is ensured that no shrinkage situation occurs in the high-temperature dyeing process, and blocked dye penetration is avoided. By the adoption of the polyester cheese dyeing method, the problems of dyeing defects, chromatic aberration and the like in polyester yarn dyeing and the dyeing rate are obviously improved, the color stability is good, and the demands for production and dyeing of different polyester yarns can be met.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Preparation method of sodium alginate printing gum for pure cotton knitted fabric

InactiveCN109797577AImprove neutralization efficiencyImprove uniformityDyeing processAlginic acidDye penetration

The invention discloses a preparation method of sodium alginate printing gum for pure cotton knitted fabric, and relates to the technical field of printing gum. The preparation method comprises the following steps: irradiating, adding water and soaking, washing, digesting, diluting, filtering, calcifying, decalcifying, and dehydrating to obtain alginic acid, adding sodium hexametaphosphate to thealginic acid, and adding sodium carbonate, performing a solid-phase neutralization reaction to obtain sodium alginate, pelletizing, drying, smashing, adding an auxiliary material, mixing and finally packaging to obtain a finished product. The printing gum prepared by the method is capable of improving uniformity of the product, improving product storage time and a product dye penetration percentage, and enabling dye to be uniformly dyed on cloth, uniform in printing color, clear in outthread, and bright in color, and reducing production cost.

Owner:江苏明月海洋生物科技有限公司

Leather treatment

An improved method for dyeing leather wit propylene glycol monomethyl ether (PGME) systems comprising adding polyacrylate resins base, C-3 and C-4 alcohols, and n-butyl acetate and negating the need for aqueous compositions, Teflon dispersions, dibutyl phthalate, and improves the dye penetration, hastens the flash times, improves the dust free time, and improves the tape time.

Owner:AUTOMOTIVE TECH INT

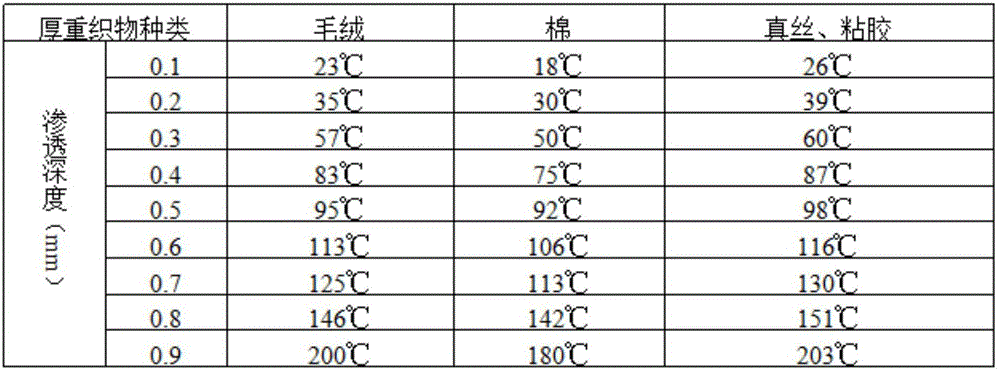

Inkjet printing method ensuring dye penetration effect of heavy fabric

InactiveCN106626850ASolve the problem of poor penetrationReduce difficultyDuplicating/marking methodsPrinting after-treatmentEngineeringDye penetration

The invention discloses an inkjet printing method ensuring the dye penetration effect of heavy fabric. After the heavy fabric is subjected to sizing, drying and rolling, inkjet printing is conducted; after inkjet printing is conducted, the fabric enters a roller press to be subjected to roll compacting and finally enters a drying machine to be dried; and the dried heavy fabric is subjected to dye color fixing, washing and sizing, and the heavy fabric is obtained. Compared with the prior art, the problem that penetration of inkjet printing of heavy fabric is poor is thoroughly solved, the equipment is simple, operation is convenient, and the quality is particularly easy to control. Compared with the prior art, the difficulty of inkjet printing of the heavy fabric is greatly lowered, the yield is greatly increased, and the equipment investment is also greatly reduced; and particularly, common inkjet printing equipment can be used for conducting inkjet printing on the heavy fabric, the equipment utilization rate is increased, in addition, the method has a very good effect on plush fabric, and the history that the plush fabric cannot be subjected to inkjet printing is over.

Owner:刘静

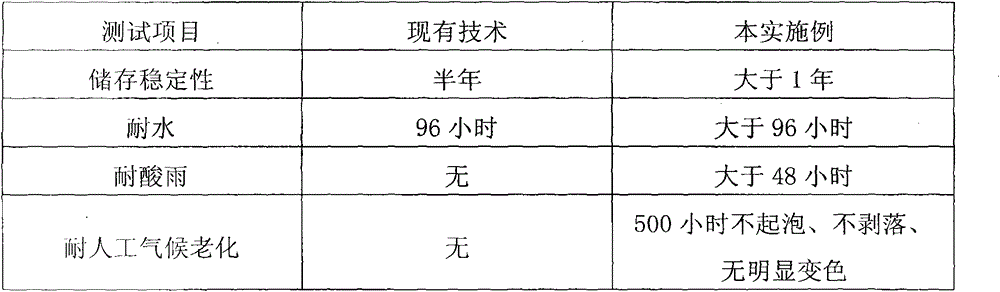

Liquid granite coating

The invention discloses a liquid granite coating, comprising the following components in percentage by mass: 40%-50% of a non-ionic protective colloid solution, 30%-40% of a silicone acrylic emulsion, 20%-30% of a base paint, 2%-5% of a thickening agent and 5%-10% of water. The liquid granite coating disclosed by the invention is good in weather fastness, good in stability, high in fidelity, and free of the problems such as post-thickening, color interference and dye penetration after being stored for more than half a year.

Owner:赵立平

Leather treatment

InactiveUS20030221264A1Pre-tanning chemical treatmentLayered productsPolymer chemistryPolytetrafluoroethylene

An improved method for dying leather with propylene glycol monomethyl ether (PGME) systems comprising adding polyacrylate resin base, C3 and C4 alcohols, and n-butyl acetate and negating the need for teflon dispersions, dibutyl phthalate, and improves the dye penetration, hastens the flash times, improve the dust free time, and improves the tape time.

Owner:AUTOMOTIVE TECH INT

Mechanical real wax cotton print production process

A mechanized process for producing real wax floral cloth, which is characterized by spraying paraffin on the pattern of mechanical cylinders and rollers, using the cylinders and rollers to transfer the paraffin pattern to the cloth, printing and dyeing indigo in the space of the paraffin pattern, and printing The cloth with paraffin pattern is shaken to make the pattern form natural cracks before drying, then put the cloth in the dyeing tank of the desired color, let the dye penetrate into the cracks of the paraffin pattern, and finally dissolve the paraffin with hot water for washing. It can leave a hairline effect formed by the natural crack marks of the paraffin pattern on the cloth surface. It solves the problem of the high cost of batik using rosin and the failure to achieve the effect of hair batik, and is suitable for use on various types of fabric batik.

Owner:黄培

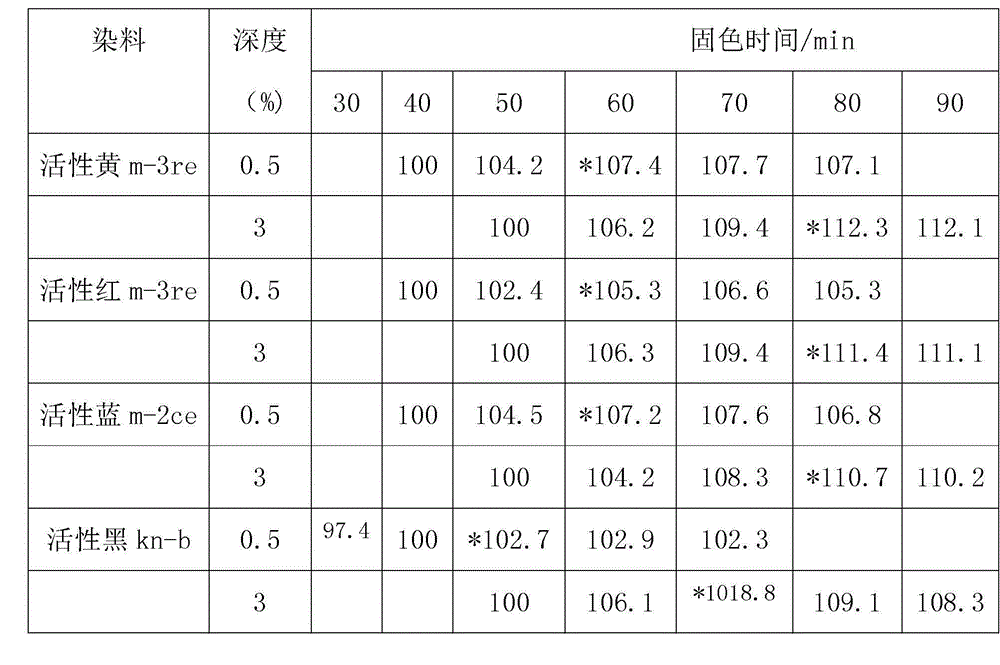

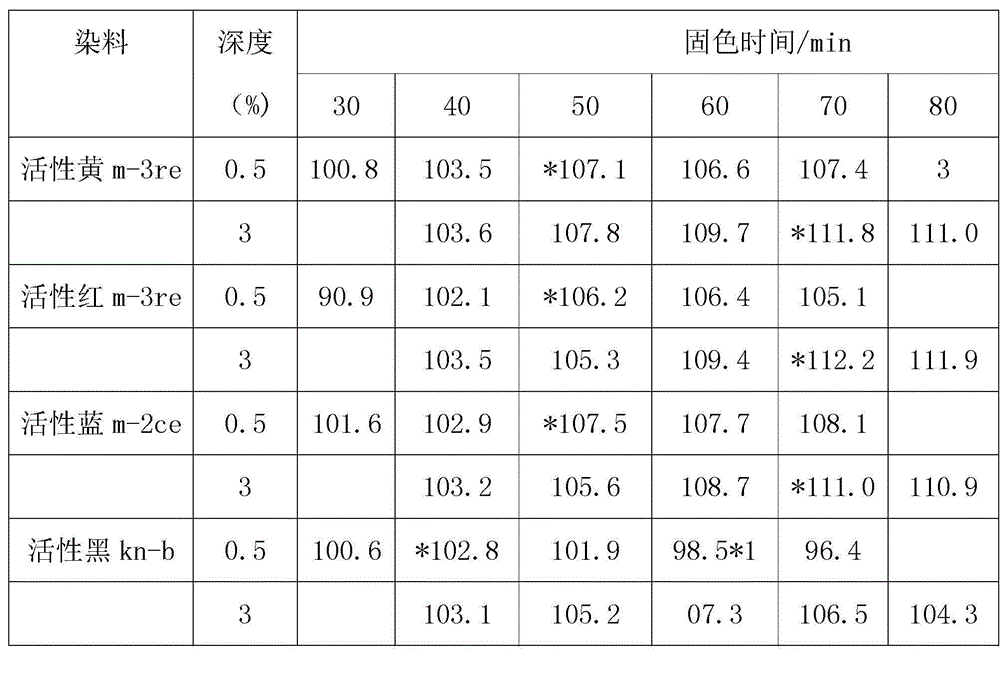

Fabric dyeing depth difference processing method

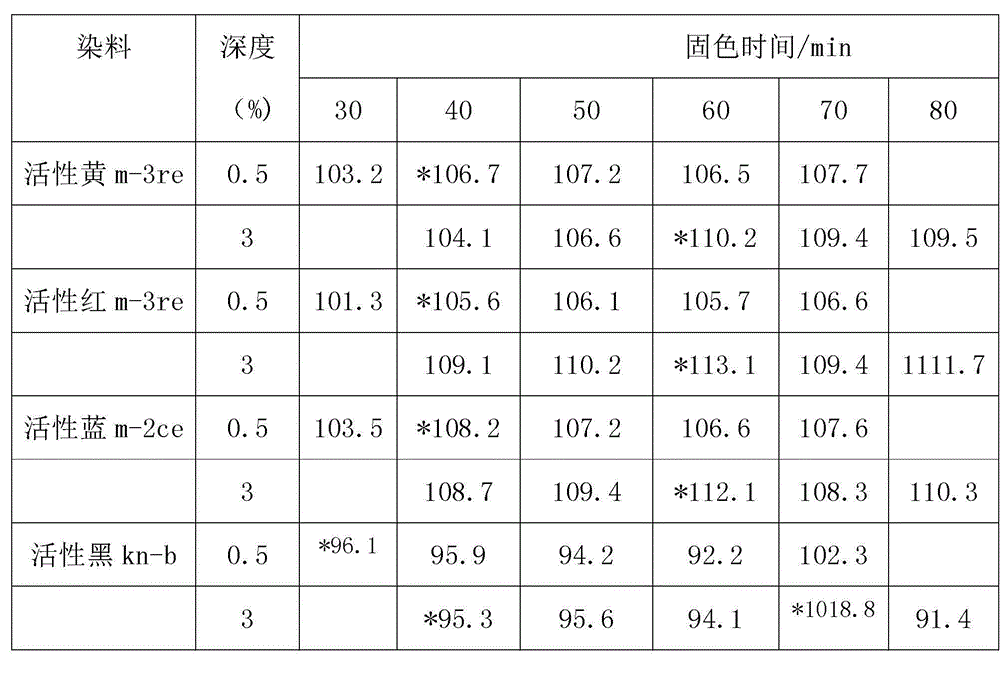

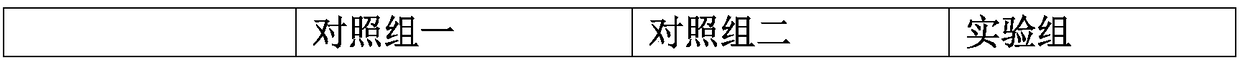

The invention discloses a fabric dyeing depth difference processing method. The method is characterized in that a medium temperature reactive dye dip-dyes at 60DEG C, and a long dye fixation time (60-80min) is needed to realize dyeing balance. The sample dyeing time is prolonged, and the proofing efficiency decreases. The increase of the dyeing temperature effectively shortens the dyeing balance time, the acceleration of the dye up-take rate affects the level dyeing and dye penetration effects, and the acceleration of the hydrolysis rate reduces the depth of the obtained color. Experiment results show that the practical dip-dyeing temperature of a common medium temperature reactive dye is controlled in a range of 65-70DEG C, so the dyeing balance time is shortened, good color depth and level dyeing and dye penetration effects can be obtained, and a vinyl sulfone reactive dye dip-dyes at 65DEG C. When the medium temperature reactive dye is used to dip-dye a sample, recommended conditions are characterized in that dye up-take is carried out for 30min and alkali dye fixation is carried out for 40min at 65-70DEG C to obtain a light color, and dye up-take is carried out for 40min and alkali dye fixation is carried out for 60min at 65-70DEG C to obtain a dark color.

Owner:冒玉兰

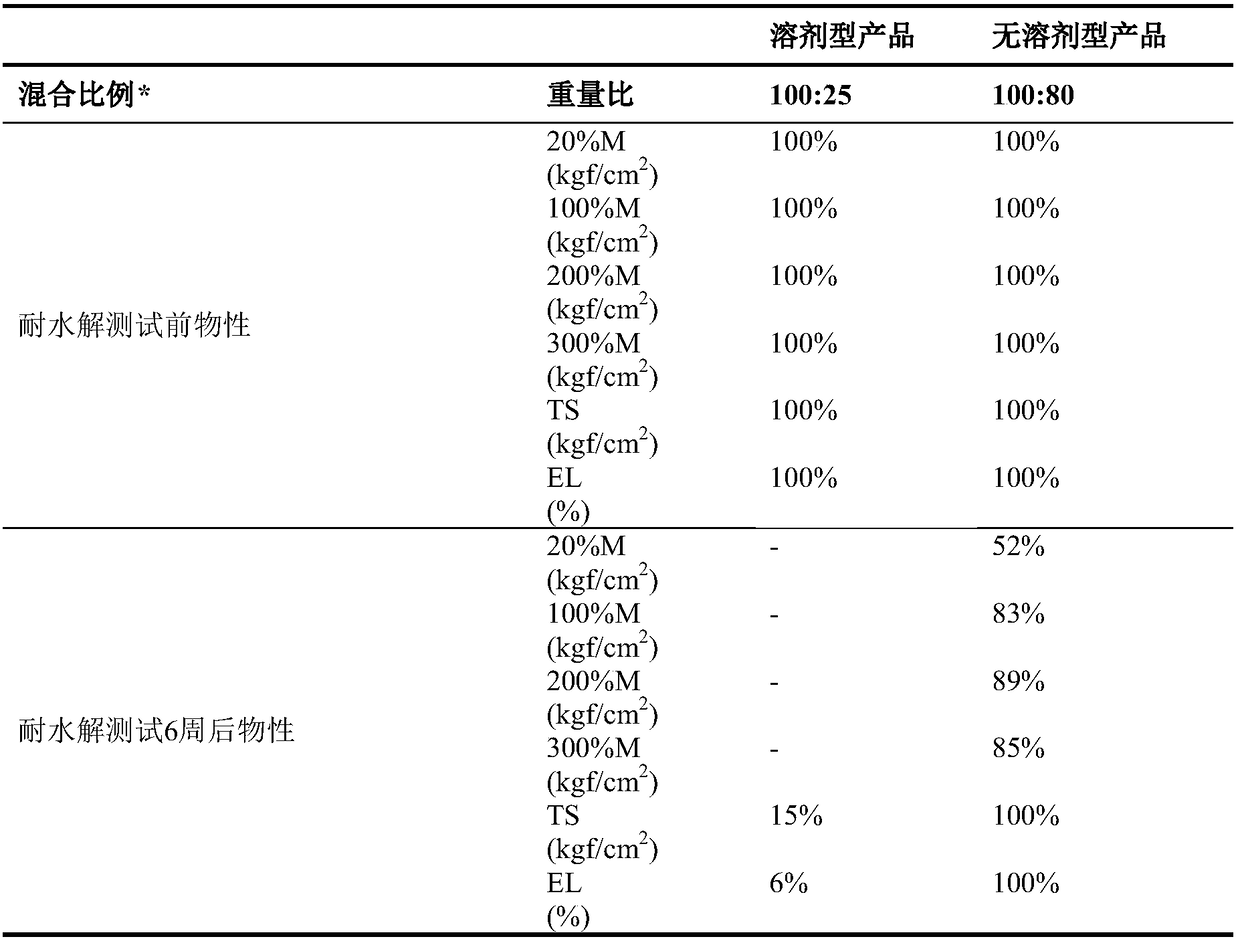

Method for preparing solvent-free polyurethane resin adhesive and use thereof

InactiveCN109251712AImprove permeabilityImprove dyeing effectPolyureas/polyurethane adhesivesPolymer scienceOrganic solvent

The invention discloses a method for preparing a solvent-free polyurethane resin adhesive and use thereof. The solvent-free polyurethane resin adhesive is obtained by reacting modified isocyanate prepared by ethers or ester polyols and ethers or ester polyols. The solvent-free polyurethane resin adhesive of the invention improves the dyeability by introducing a group which can be combined with a dye in the preparation process, and selects an appropriate ether polyol or a small molecule alcohol substance to enhance the effect of dye penetration; In addition, an organic solvent is not used in the preparation process, and the finished product has no solvent release and no solvent residue, and is environmentally friendly; compared with the solvent-based PU resin, the product has the advantagesof better dyeability, hydrolysis resistance, and the like.

Owner:高鼎精细化工(昆山)有限公司

Aqueous acid-and-alkali-resistant digital imaging coating

InactiveCN103757978AImprove liquidityImprove water resistanceDefoamers additionCoatings with pigmentsDigital imagingStrong acids

The invention discloses an aqueous acid-and-alkali-resistant digital imaging coating. The aqueous acid-and-alkali-resistant digital imaging coating comprises 10-20wt% of water, 20-22wt% of an elastic emulsion, 20-25wt% of a fluorocarbon emulsion, 0.8-1.6wt% of a wetting agent, 0.7-0.9wt% of a dispersant, 3-5wt% of titanium dioxide, 7-9wt% of nanometer silica, 6-8wt% of an opaque polymer, 16-18wt% of light calcium carbonate, 0.05-0.7wt% of an antifoaming agent, 0.05-0.1wt% of a film forming assistant and 1-3% of a cationic color fixing agent. A film obtained through using the coating has the advantages of good ink fixing performance, good water resistance, unlikely color change and dye penetration, strong acid and alkali resistances, low softness, good elasticity, and suitable smoothness and glossiness.

Owner:QINGDAO YIQUN PANT GRP

Anti-fading textile dye and preparation method thereof

InactiveCN109487590ANot easy to decolorizeImprove permeabilityDyeing processMichler's ketoneDimethylaniline N-oxide

The invention discloses an anti-fading textile dye and a preparation method thereof. According to the preparation method of the anti-fading textile dye, applied polyoxyethylene lauryl ether sodium sulfate belongs to anionic surfactants and can avoid damage skin when applied to the textile dye; camphor leaf extract, belvedere fruit extract and myrica rubra leaf extract are natural plant extracts and contain volatile plant oils such as eugenol and 1, 8-cineole, which can effectively inhibit bacteria breeding; besides, gentian violet prepared from Michler's ketone, N, N-dimethylaniline, phosphorous oxychloride, sodium carbonate and diluted hydrochloric acid can improve the affinity between the textile dye and textile fabric and further avoid dye fading; bentonite endows the textile fabric with a soft and fluffy feeling, thereby facilitating rapid dyeing and improving dye penetration; by combining with pentanediol, cyclohexanol acetate, ethyl cellulose, laurinol, sodium salicylate, sulfonated oil and deionized water, the prepared anti-fading textile dye has the advantages of being less prone to color fading, high in penetration effects and high in dyeing speed.

Owner:GUANGDONG JINGYING TEXTILE GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com