Preparation method of sodium alginate printing gum for pure cotton knitted fabric

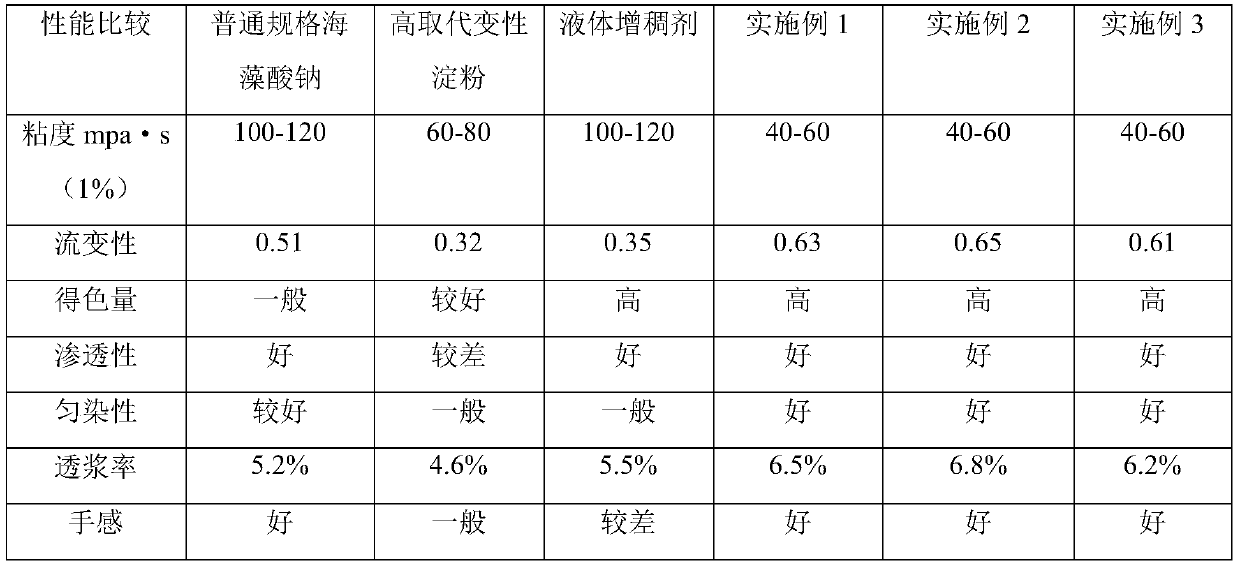

A technology of sodium alginate and printing paste, which is applied in dyeing, textiles and papermaking, etc. It can solve the problems of low printing penetration rate, not bright enough color, and easy hydrolysis, so as to improve the penetration rate and reduce sewage treatment cost, the effect of increased dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) select the Ascophyllum nodosum whose M / G ratio is 1.5-3.0, and irradiate for 2 hours with the energy of gamma rays produced by the radioactive isotope (Co-60), and the soaking time is 8 hours;

[0028] (2) adding sodium carbonate to Ascophyllum nodosum for digestion reaction, wherein, 75kg of Ascophyllum nodosum, 25kg of sodium carbonate, the digestion reaction temperature is 50°C, and the reaction time is 8h;

[0029] (3) After the digestion reaction, add water to dilute to obtain the glue, the dilution factor is 40, and the dilution time is 90s;

[0030] (4) separate and filter after dilution, then add calcium chloride solution for calcium precipitation, add hydrochloric acid after calcium precipitation for decalcification, squeeze and dehydrate to obtain alginic acid, and the moisture content of alginic acid after dehydration is 70%;

[0031] (5) In the stirring tank, add 85kg of alginic acid after dehydration and 2kg of sodium hexametaphosphate, then add 13kg of...

Embodiment 2

[0036] A method for preparing a sodium alginate printing paste for pure cotton knitted fabrics, the preparation steps comprising:

[0037] (1) choose the dried sea-tangle that M / G ratio is 1.5-3.0, irradiate 3 hours by the energy of the gamma ray that radioactive isotope (Co-60) produces, soaking time is 4h;

[0038] (2) add sodium carbonate to dry sea-tangle and carry out digestion reaction, wherein dry sea-tangle 80kg, sodium carbonate 30kg, digestion reaction temperature is 40 ℃, and reaction time is 5h;

[0039] (3) After the digestion reaction, add water to dilute to obtain the glue, the dilution factor is 30, and the dilution time is 100s;

[0040] (4) separate and filter after dilution, then add calcium chloride solution for calcium precipitation, add hydrochloric acid after calcium precipitation for decalcification, squeeze and dehydrate to obtain alginic acid, and the moisture content of alginic acid after dehydration is 65%;

[0041] (5) In the stirring tank, add 85...

Embodiment 3

[0046] A method for preparing a sodium alginate printing paste for pure cotton knitted fabrics, the preparation steps comprising:

[0047] (1) Select macroalgae with an M / G ratio of 1.5-3.0, irradiate for 4 hours with the energy of gamma rays produced by radioactive isotopes (Co-60), and soak for 24 hours;

[0048] (2) add sodium carbonate to dry sea-tangle and carry out digestion reaction, wherein dry sea-tangle 80kg, sodium carbonate 30kg, digestion reaction temperature is 40 ℃, and reaction time is 5h;

[0049] (3) Dilute with water after the digestion reaction to obtain the glue, the dilution factor is 20, and the dilution time is 80s;

[0050] (4) separate and filter after dilution, then add calcium chloride solution for calcium precipitation, add hydrochloric acid after calcium precipitation for decalcification, squeeze and dehydrate to obtain alginic acid, and the moisture content of alginic acid after dehydration is 68%;

[0051] (5) In the stirring tank, add 85kg of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com