A kind of polysulfone aramid fiber, slurry to be spun and manufacturing method thereof

A manufacturing method and slurry technology, applied in spinning solution preparation, single-component copolyamide rayon, wet spinning, etc., can solve the problems of cumbersome post-processing steps, harsh reaction conditions, equipment corrosion, etc., and achieve high strength Enhanced, high solubility, enhanced neutralization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

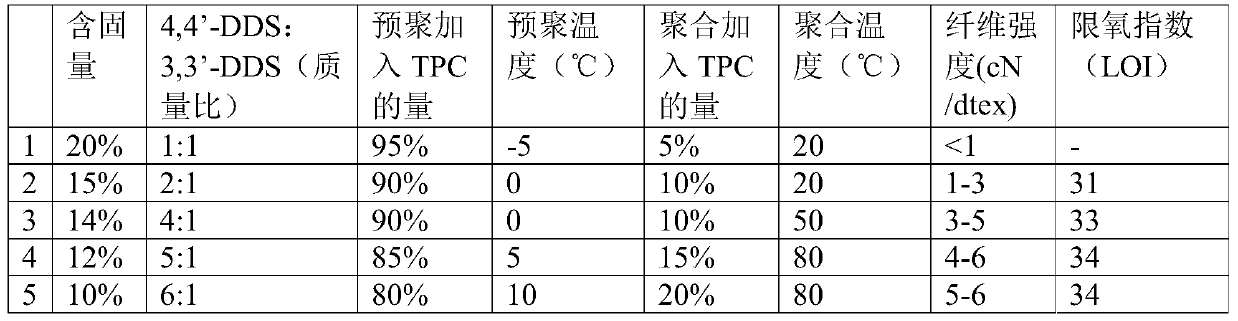

Examples

Embodiment 1

[0040] Add 19.864 grams of 4,4'-diaminodiphenylsulfone (0.08mol) and 4.966 grams of 3,3'-diaminodiphenylsulfone (0.02mol) in sequence to a dry 500mL three-neck flask, add 210mL of anhydrous N,N' - Dimethylacetamide (DMAc), stirred and dissolved to obtain a colorless clear solution; cooled to an internal temperature of 0°C with an ice-water bath, then added 18.272 grams of terephthaloyl chloride (0.09mol), and stirred at 0°C for half an hour Then rise to 20°C and stir for half an hour; then raise the temperature to 50°C and add 2.036 grams of terephthaloyl chloride (0.01mol), and continue stirring at 50°C for 1 hour, then add 70.734 grams of trioctylamine (0.02mol ) neutralization, after stirring at 35° C. for 1 hour, a neutral slurry to be spun was obtained.

[0041] The slurry is spun with wet spinning equipment: the spinning slurry is extruded into the coagulation bath through a spinneret with a diameter of 0.07 mm and a number of holes of 10, and the coagulation bath is com...

Embodiment 2

[0043] Add 20.692 grams of 4,4'-diaminodiphenylsulfone (0.0833mol) and 4.138 grams of 3,3'-diaminodiphenylsulfone (0.0167mol) in sequence to a dry 500mL three-necked flask, and add 235mL of anhydrous N,N' -Dimethylacetamide (DMAc), stirred and dissolved to obtain a colorless clear solution; cooled to an internal temperature of 0°C with an ice-water bath, then added 17.257 grams of terephthaloyl chloride (0.085mol), and stirred at 0°C for half an hour Then rise to 25°C and stir for half an hour; then heat up to 60°C and add 3.045 grams of terephthaloyl chloride (0.015mol), and continue stirring at 60°C for 1 hour, then add 33.45 grams of benzyltrimethylammonium hydroxide ( 0.02mol) neutralized, at 25 ° C, after stirring for 1 hour, a nearly neutral spinning slurry was obtained.

[0044] The slurry is spun with wet spinning equipment: the spinning slurry is extruded into the coagulation bath through a spinneret with a diameter of 0.07 mm and a number of holes of 10, and the coag...

Embodiment 3

[0046] Add 21.279 grams of 4,4'-diaminodiphenylsulfone (0.0857mol) and 3.551 grams of 3,3'-diaminodiphenylsulfone (0.0143mol) in sequence to a dry 500mL three-necked flask, add 280mL of anhydrous N,N' -Dimethylacetamide (DMAc), stirred and dissolved to obtain a colorless clear solution; cooled to an internal temperature of 0°C with an ice-water bath, then added 16.242 grams of terephthaloyl chloride (0.08mol), and stirred at 0°C for half an hour Then rise to 25°C and stir for half an hour; then heat up to 80°C and add 4.060 grams of terephthaloyl chloride (0.02mol), and continue stirring at 80°C for 1 hour, then add 41.866 grams of benzyltriethylammonium hydroxide ( 0.02mol) and neutralized at 45°C to obtain a neutral slurry to be spun after stirring for 1 hour.

[0047] The slurry is spun with wet spinning equipment: the spinning slurry is extruded into the coagulation bath through a spinneret with a diameter of 0.07 mm and a number of holes of 10, and the coagulation bath is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com