Patents

Literature

146 results about "DIAPHENYLSULFONE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

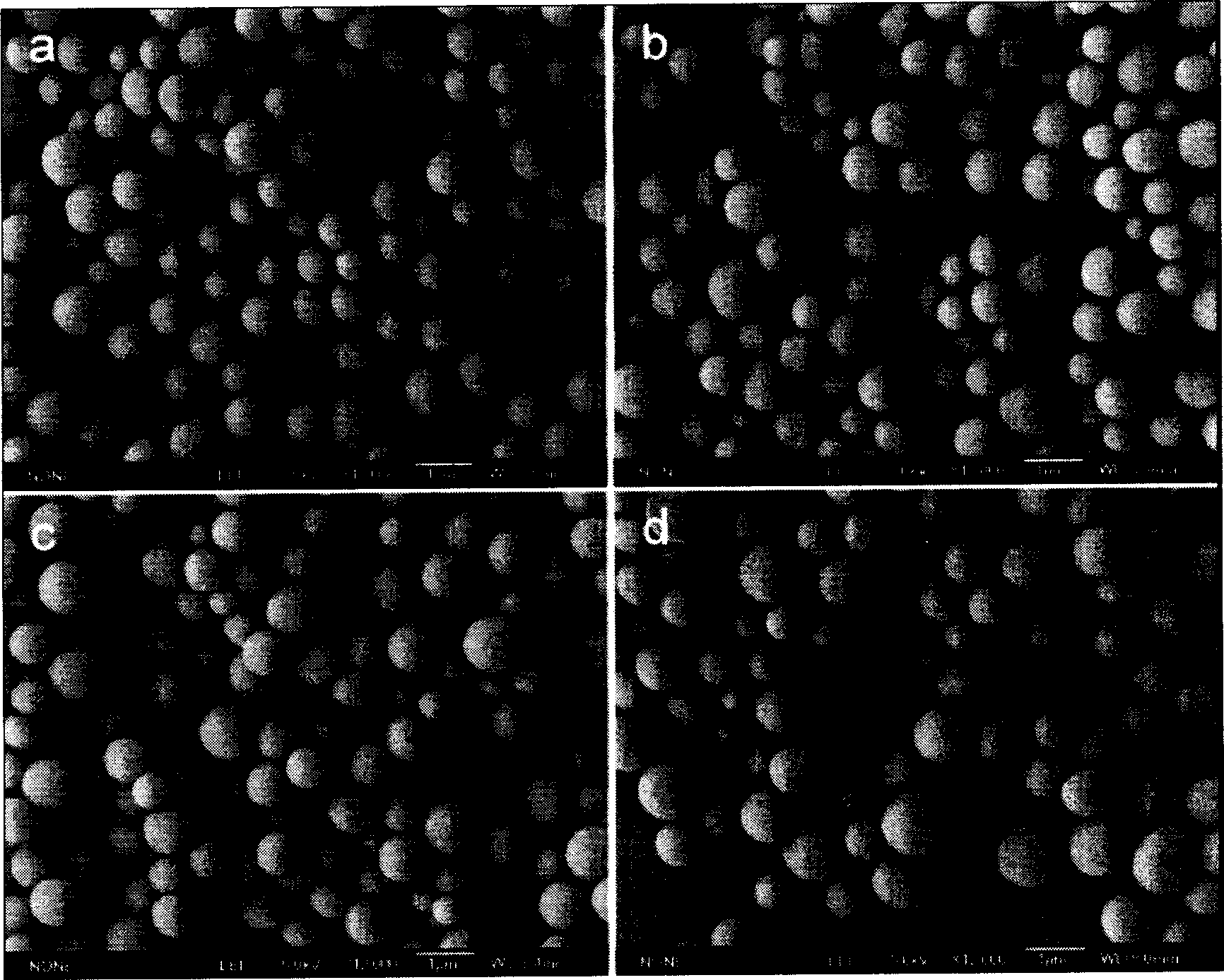

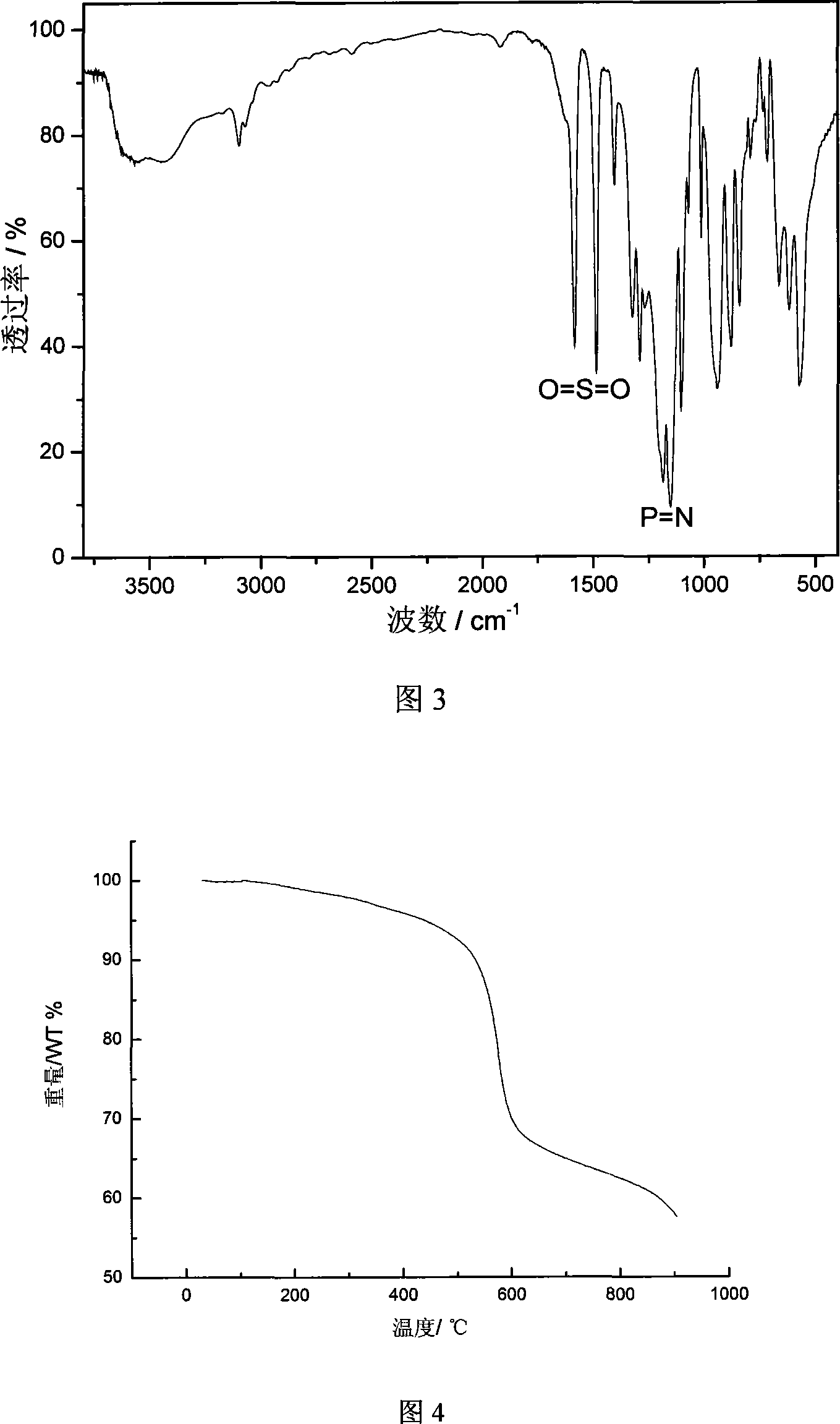

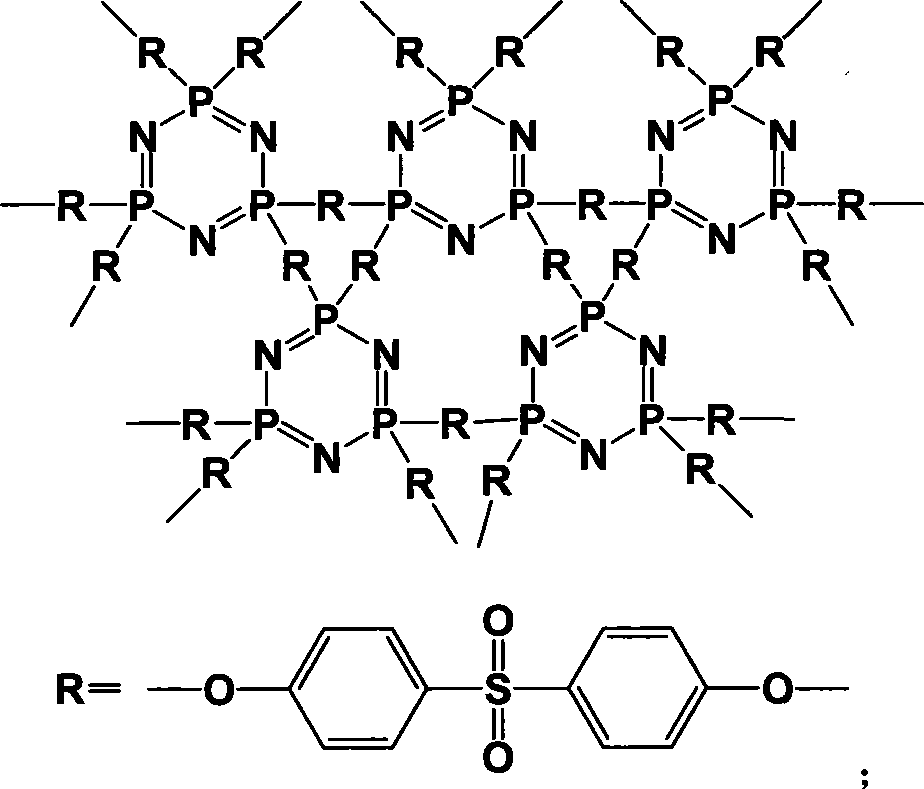

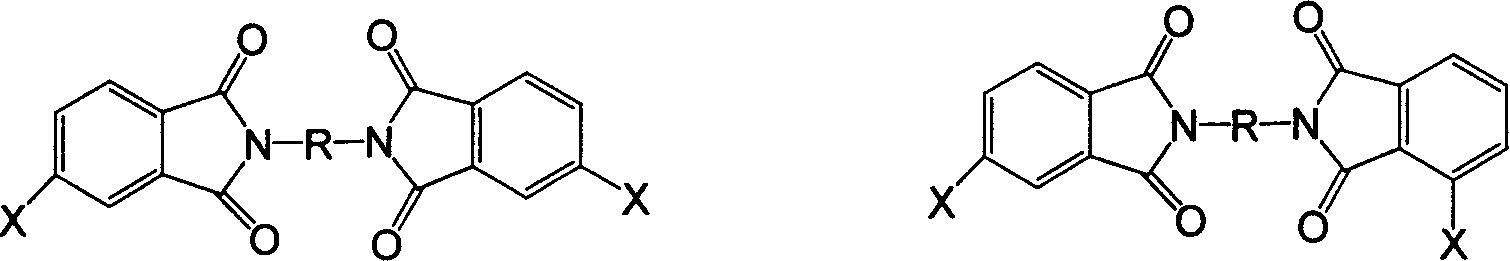

Crosslinking poly(organophosphazenes) microsphere and preparation method thereof

InactiveCN1908033AGood thermal stabilitySimple processCatalyst carriersPharmaceutical non-active ingredientsChemistryChromatography column

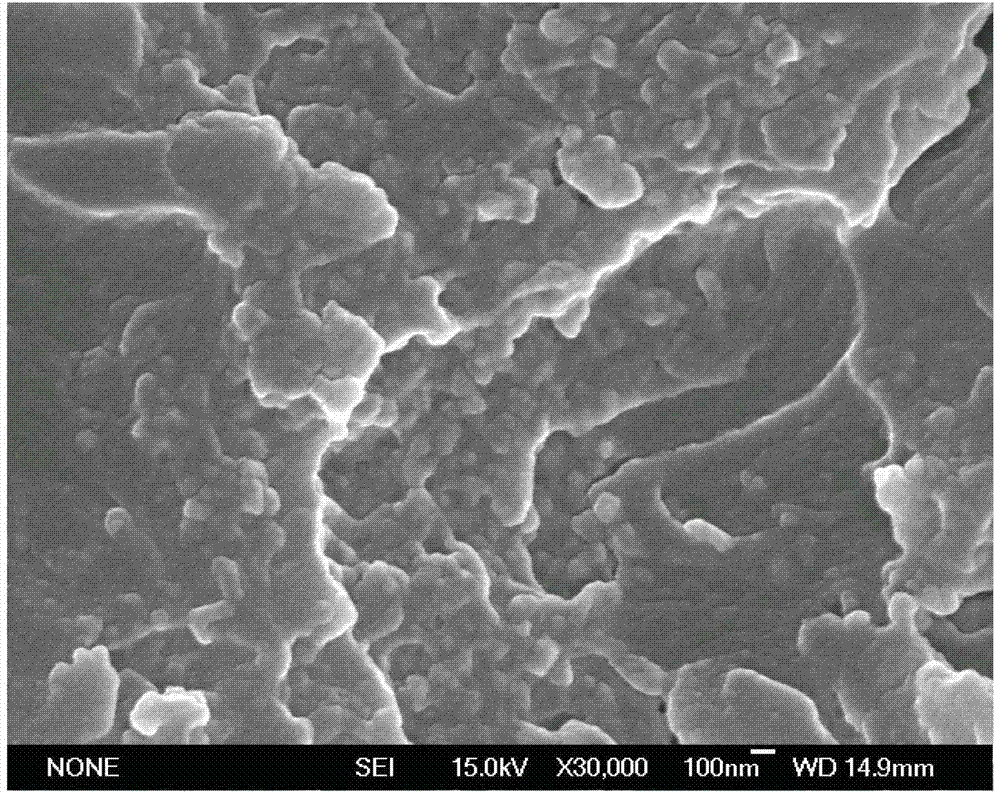

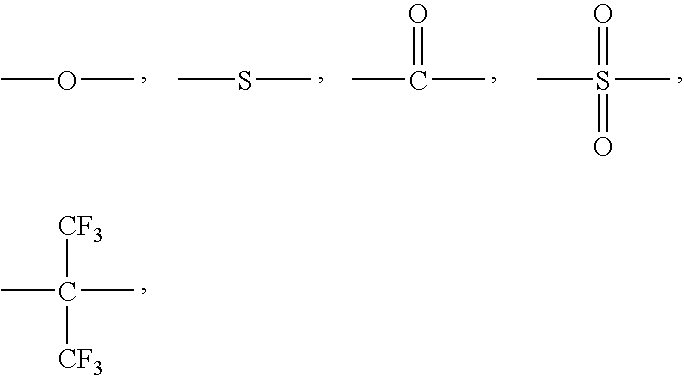

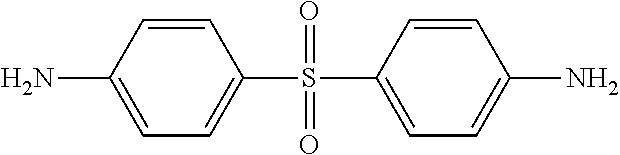

the invention discloses a crosslinking polyphosphine-nitrile microball and preparing method, which is characterized by the following: the diameter is 0.4-5 um ; the chemical structural formula is displayed on the right; the microball surface is flat solid structure, which adopts hexachloride cycotrinitrilephosphine and 4, 4'-dihydroxy diphenyl sulfone to crosslink and condense under the action of trimethylamine.

Owner:SHANGHAI JIAO TONG UNIV

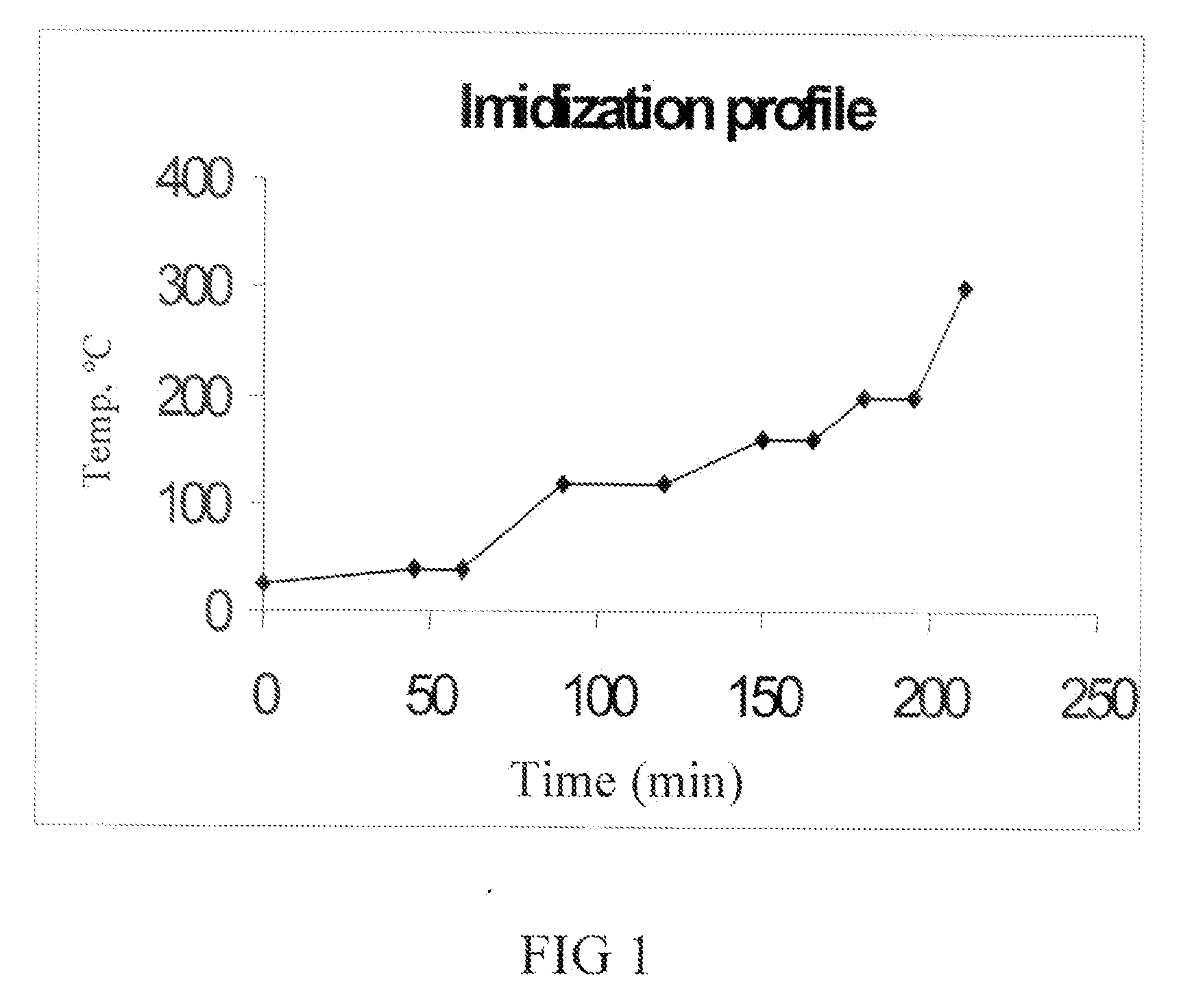

Polyimide solvent cast films having a low coefficient of thermal expansion and method of manufacture thereof

InactiveUS20080044683A1Low thermal expansionSynthetic resin layered productsPrinted circuit aspectsVitrificationMicrometer

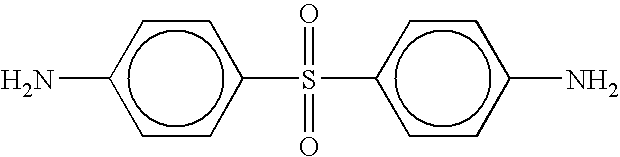

A solvent cast film comprises a polyimide comprising structural units derived from polymerization of a dianhydride component comprising a dianhydride selected from the group consisting of 3,4′-oxydiphthalic dianhydride, 3,3′-oxydiphthalic dianhydride, 4,4′-oxydiphthalic dianhydride, and combinations thereof, with a diamine component comprising 4,4′-diaminodiphenylsulfone; wherein the polyimide has a glass transition temperature from 190° C. to 400° C.; and wherein the film has a coefficient of thermal expansion of less than 60 ppm / ° C., a thickness from 0.1 to 250 micrometers, endless than 5% residual solvent by weight.

Owner:SHPP GLOBAL TECH BV

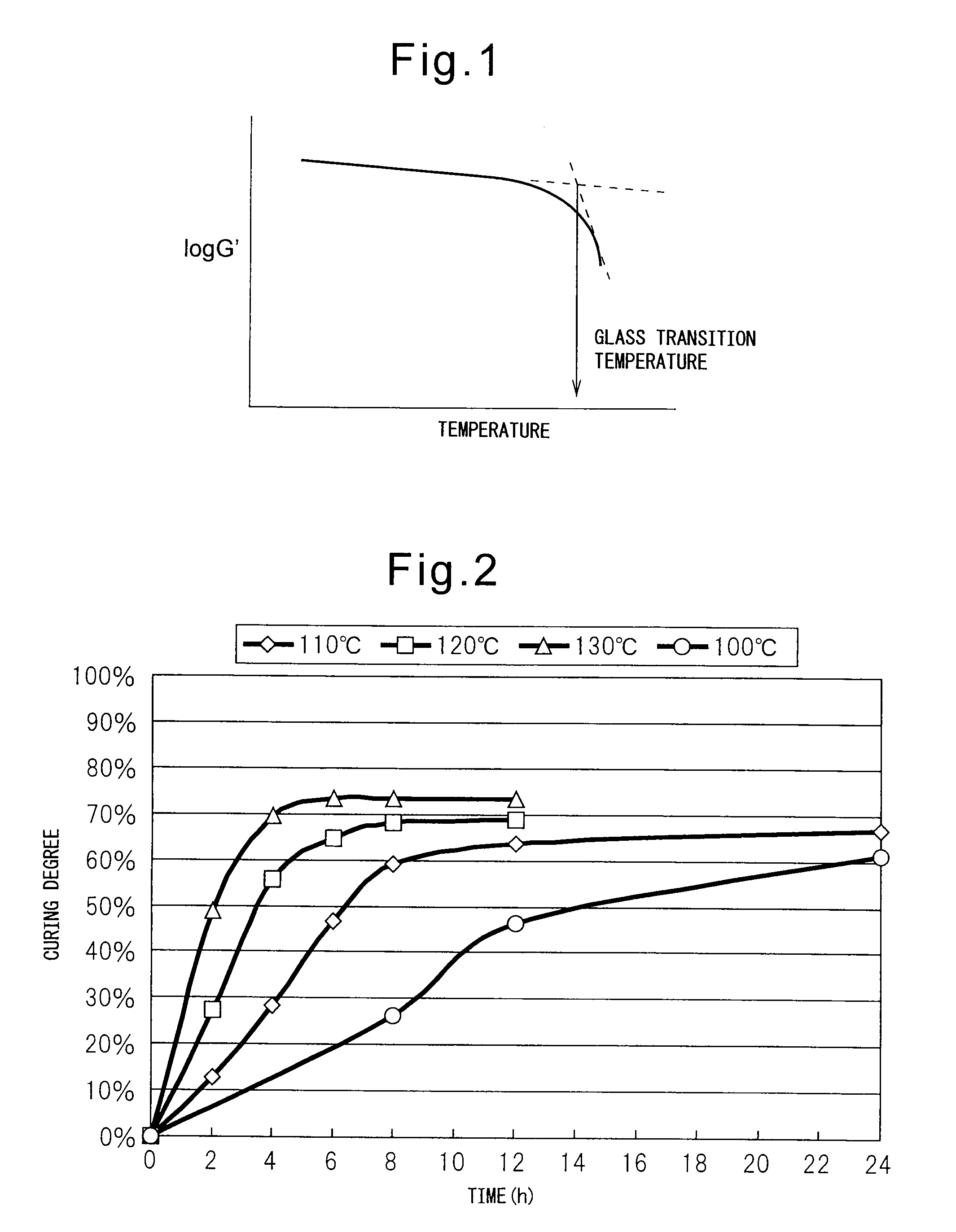

Epoxy resin composition for fiber reinforced composite material, prepreg, and fiber reinforced composite material

ActiveUS20130217283A1Reduced trapped airMinimize amount of water vaporLaminationLamination apparatusEpoxyPolymer science

An epoxy resin composition having components (A), (B), (C), and (D), wherein the epoxy resin composition has a viscosity at 40° C. of about 1×103 to about 1×104 Pa·s, a curing start temperature of about 90 to about 110° C., and a minimum viscosity at the curing start temperature of about 2 to about 20 Pa·s, wherein the components (A), (B), (C), and (D) are as follows: (A) About 60 weight parts or more of a tetraglycidyl amine type epoxy resin per 100 weight parts of the epoxy resin blend; (B) Dicyandiamide; (C) Diaminodiphenyl sulfone and (D) Urea compound.

Owner:TORAY IND INC

Epoxy resin silica sol, epoxy resin organic-inorganic nano hybrid material and preparation method thereof

The invention discloses epoxy resin silica sol which is characterized by being prepared from the following components: epoxy resin, organic silicon, silane coupling agent, organic solvent and ammonia water at a molar ratio of 1:(0.1-2):(0.01-2):(0.9-18):(0.001-0.06). The invention also discloses a preparation method of the epoxy resin silica sol. The invention also discloses an epoxy resin organic-inorganic nano hybrid material adopting the epoxy resin silica sol, which is characterized in that the epoxy resin curing agent is one or more of methylhexahydrophthalic anhydride, methylhexahydrophthalic anhydride acid, 4,4-diaminodiphenylmethane and 4,4-diamino diphenyl sulfone. The invention also discloses a preparation method of the epoxy resin organic-inorganic nano hybrid material. The product provided by the invention has excellent insulating property, and the method is stable and efficient.

Owner:上海上惠纳米科技有限公司

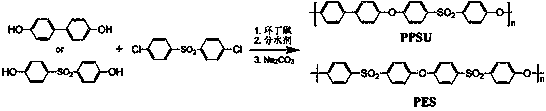

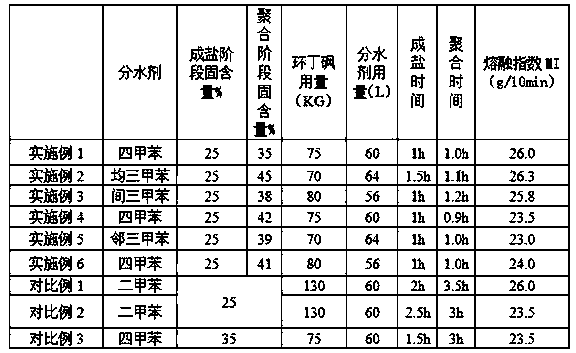

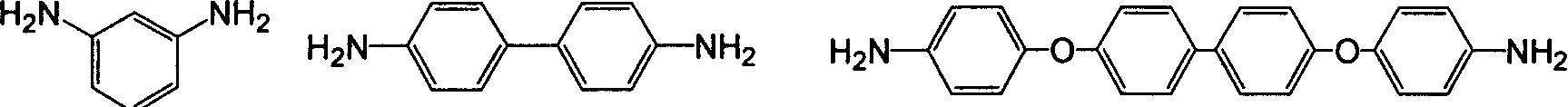

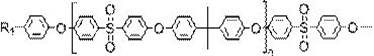

Industrial synthesis method of poly(aromatic ether sulfone) resin with high solid content

The invention discloses an industrial synthesis method of a poly(aromatic ether sulfone) resin with a high solid content. The synthesis method comprises the following steps: taking 4,4'-dichlorodiphenyl sulfone and 4,4'-biphenol or 4,4'-dihydroxyl diphenyl sulfone as the reaction monomers, sulfolane as the solvent, and sodium carbonate as the salt forming agent, adding the solvent into a reactor filled with nitrogen gas, then stirring, heating to a temperature of 60 to 80 DEG C, orderly adding the reaction monomers, fully dissolving the monomers, adding the salt forming agent into the reactor, then adding a water separating agent, keeping on stirring, heating to a temperature of 200 to 210 DEG C, carrying out salt forming reactions for 1 to 2 hours; completely evaporating the water separating agent after the salt forming reactions, then transporting the salt forming reaction products to a polymerization reactor to carry out reactions; wherein the solid content of the system in the salt forming phase is 20% to 25%, and the solid content of the system in the polymerization phase is 35% to 45%; cooling the polymerization sticky liquid after the polymerization reactions, grinding into powder, filtering, then boiling and washing with deionized water to remove the solvent and byproduct namely the salt, and finally drying so as to obtain the target product. The synthesis technology can reduce the using amount of solvent sulfolane, shortens the polymerization time, and increases the output.

Owner:JIANGMEN YOUJU NEW MATERIALS

Method of Producing Rough Strains of Bacteria and Uses Thereof

ActiveUS20090304749A1Redress balance of immuneImprove diseaseAntibacterial agentsBiocideSulfoneMycobacterium

The present invention relates to a method of producing rough strains of a bacterium, such as Mycobacterium obuense, said method comprising exposing said bacterium to a sulfone and / or sulfonamide (such as 4,4′-Diaminodiphenyl sulfone or an analogue thereof). A rough strain of Mycobacterium obuense producible by said method and uses thereof. In particular, uses of a rough strain of Mycobacterium obuense deposited under the Budapest Treaty of NCTC with the accession number NCTC 13365.

Owner:IMMODULON THERAPEUTICS

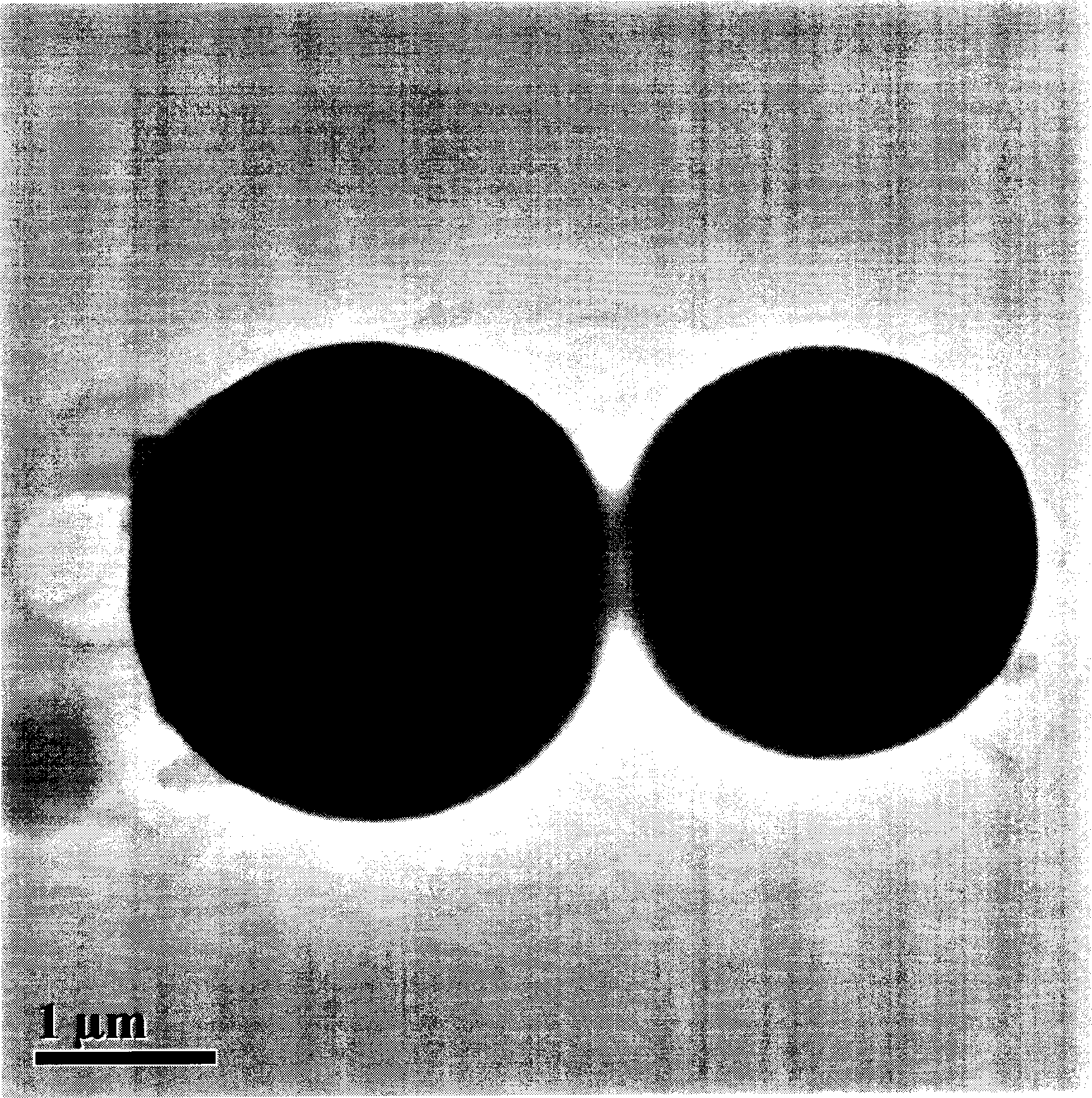

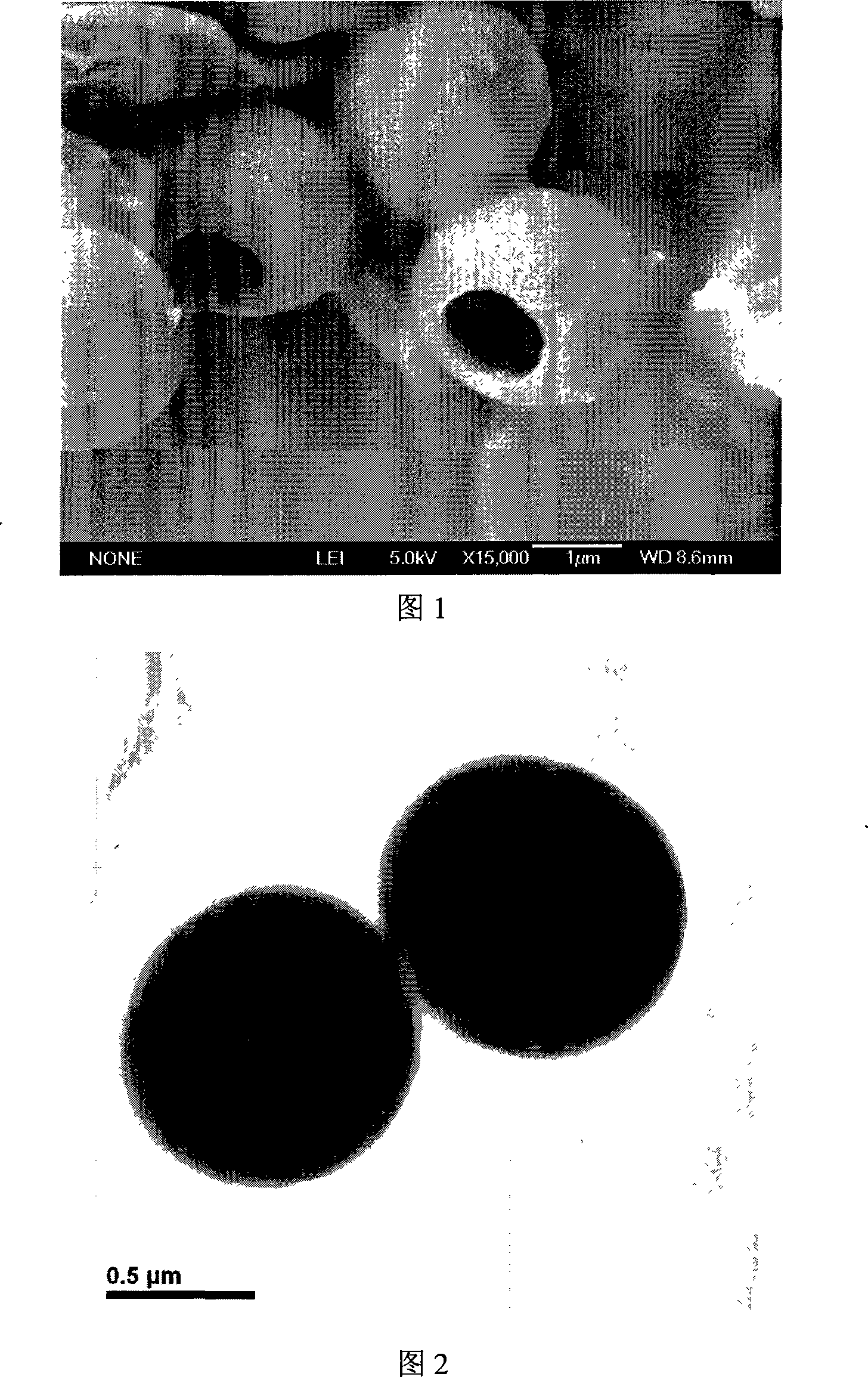

Hollow micro-ball containing phosphazene and preparing method

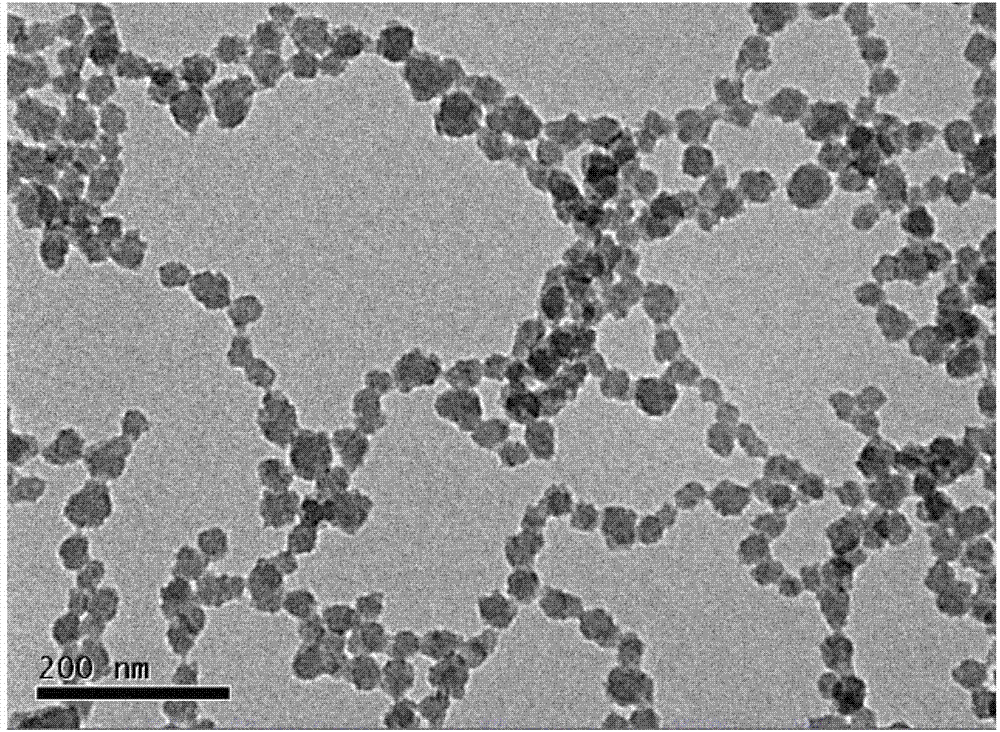

InactiveCN101070389ALoose internal structureDense surface structurePharmaceutical non-active ingredientsPolymer sciencePtru catalyst

The present invention discloses a kind of phosphazenes-containing hollow microsphere as shown in the following figure, and its preparation method; specifically, the diameter of the hollow microsphere is 0.3-2.0mu m, and the internal hollow diameter of the hollow microsphere is 100-800 nm. The phosphazenes-containing hollow microsphere which has a body-type crosslinking structure, can be produced by crosslinking condensation reaction under the function of acid binding agent, and controllable hydrolysis, in sequence, between hexachlorocyclotriphosphazene and 4, 4'-dihydroxy diphenyl sulfone; the preparation method is novel, simple and feasible, which can be large scale prepared in industrial applications.The phosphazenes-containing hollow microsphere can be used in controlling drug release, efficient catalyst carriers, new photoelectric material, flame retardant materials, etc.

Owner:SHANGHAI JIAO TONG UNIV

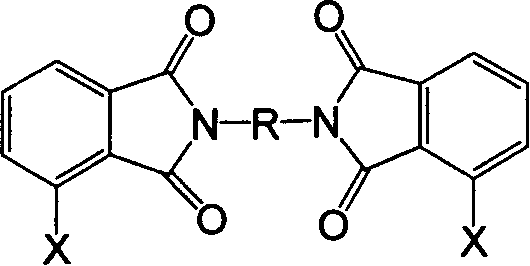

Method for preparing polyether imide copolymer by bisubstituted compound and bisphenol

The disclosed polyetherimide copolymer is copolymerized in dichloro-benzenes with the material with disubstituted phthalimide, diamine as NH2-R-NH2 and proper NH2-R-NH2 and 4, 4-dichlorodiphenyl sulfone. This invention reduces cost, simplifies process, and can recover the solvent conveniently.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method of making bisimides

The present invention provides a method for preparing relatively insoluble bisimides under conditions which afford high imidization reaction rates and which permit the monitoring and adjustment of reactant stoichiometry at any stage of the reaction. The bisimides provided by the present invention are prepared either by reaction of a diamine such as 4,4′-diaminodiphenylsulfone (DDS) with an anhydride, for example 3-chlorophthalic anhydride (3-ClPA) in the presence of a solvent at a pressure greater than one atmosphere and at a temperature above the normal boiling point of the solvent, or by reaction of a monoamine with a dianhydride under the same conditions. In one embodiment, the relatively insoluble product bisimides provided by the present invention have a solubility in ortho-dichlorobenzene of less than about 10 percent by weight at a temperature of about 180° C.

Owner:SHPP GLOBAL TECH BV

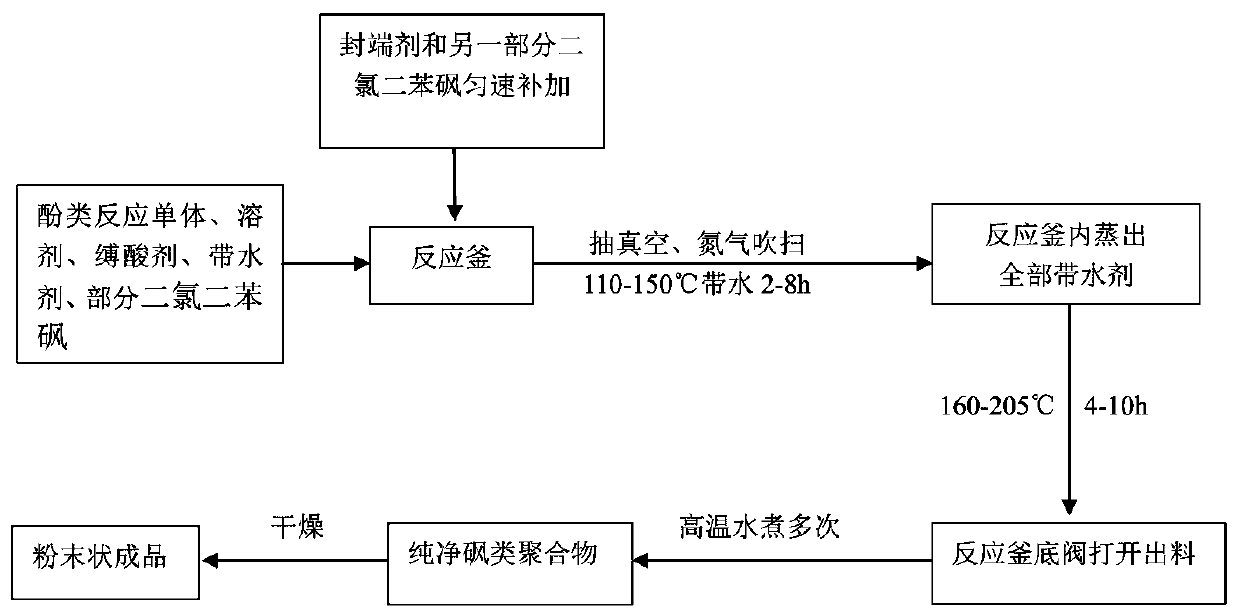

Preparation method of polysulfone resin material with low cyclic dimer content

The invention relates to a preparation method of a polysulfone resin material with low cyclic dimer content, belonging to the technical field of polysulfone resin. The preparation method of the polysulfone resin material with the low cyclic dimer content in the invention comprises the following steps: with a phenolic substance and a part of 4,4'-dichlorodiphenyl sulfone used as reaction monomers,adding an aprotic exchange solvent, an acid-binding agent and a water-carrying agent, adding an end-capping reagent and the other part of 4,4'-dichlorodiphenyl sulfone at a constant speed in a water-carrying reaction period, then evaporating out the water-carrying agent, continuing to conduct polymerization, and then carrying out post-treatment to obtain the polysulfone resin material with the lowcyclic dimer content. The target polysulfone resin material prepared by using the method is high in purity and stable in performance.

Owner:FUHAI (DONGYING) ADVANCED MATERIAL TECH CO LTD

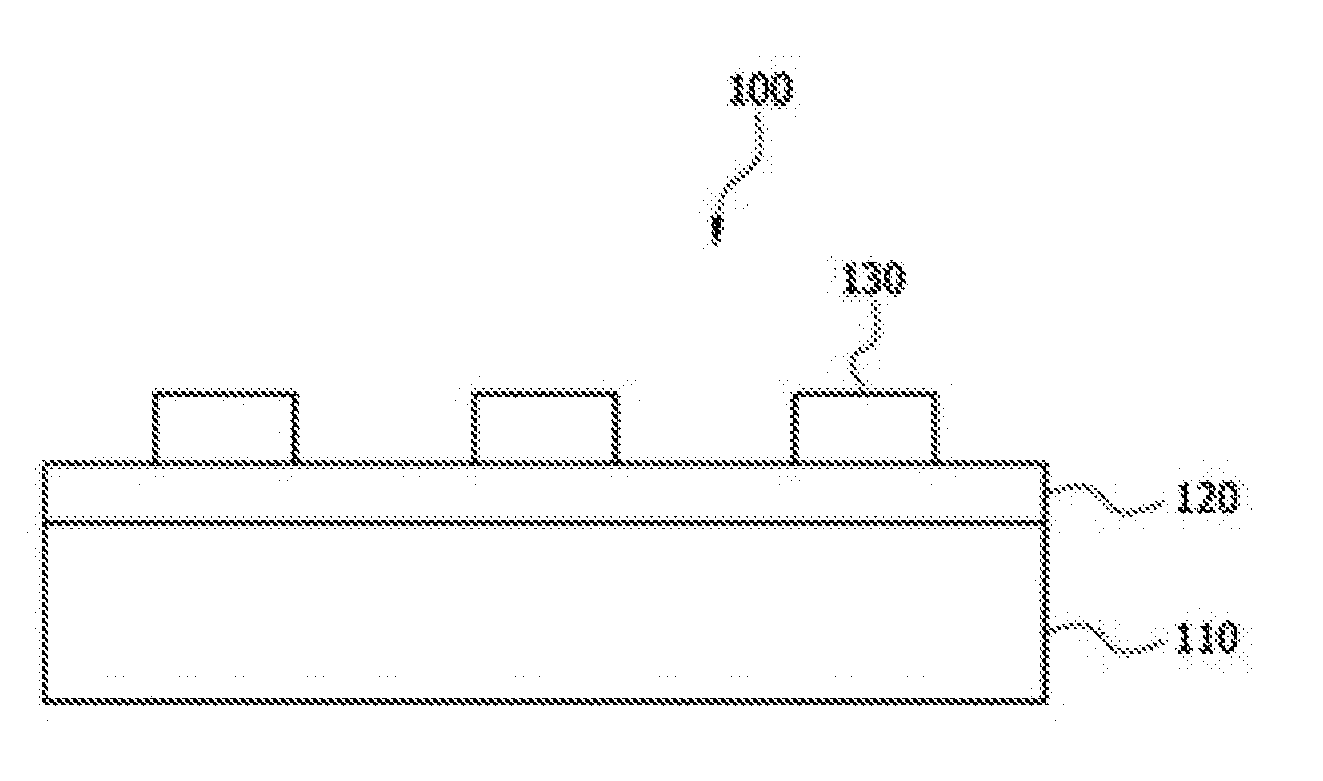

Resin composition, and printed circuit board using same

ActiveUS20150319855A1Improve thermal conductivityImprove cooling effectPrinted circuit aspectsCircuit susbtrate materialsPolymer scienceFirming agent

According to one embodiment of the present invention, an epoxy resin composition comprises: a resin including an epoxy compound, triethylenediamine, diphenylphosphine and / or tetraphenylborate; a curing agent including diaminodiphenylsulfone, ethylenediamine, diaminopropane, methanediamine, phenylenediamine and / or triethanolamine; and an inorganic filler, wherein the inorganic filler includes at least two alumina (Al2O3) groups classified by particle size.

Owner:LG INNOTEK CO LTD

Preparation method of flame-retardant aqueous polyurethane coating

The invention discloses a preparation method of a flame-retardant aqueous polyurethane coating. The method comprises the following steps: mixing borophenylic acid with hexamethylene diisocyanate in the presence of a catalyst, performing stirring reaction at 60-90 DEG C, adding tri(2,3-dibromo)propyl borate into a reaction system, and performing stirring reaction at 50-80 DEG C for 20-60 minutes to obtain a polyurethane prepolymer; adding a chain extender and acetone into the polyurethane prepolymer, performing stirring reaction at 70-85 DEG C for 1-3 hours, adding triethylamine, performing neutralization reaction for 10-40 minutes, adding water for emulsifying to form aqueous polyurethane, adding a dispersion solution A, 3,3'-diamino-4,4'-dihydroxy diphenyl sulfone, 1-sulfolane-3-ethoxycarbonyl-5-hydroxyl pyrazole and 1,4-bis(hydroxydimethylsilyl)benzene into aqueous polyurethane, and performing shear stirring for 40-80 minutes under the condition that the pH value is 7 to obtain the flame-retardant aqueous polyurethane coating. The obtained polyurethane coating is greatly improved in flame retardance and mechanical performance.

Owner:LESCENT CHINA ADVANCED MATERIALS CO LTD

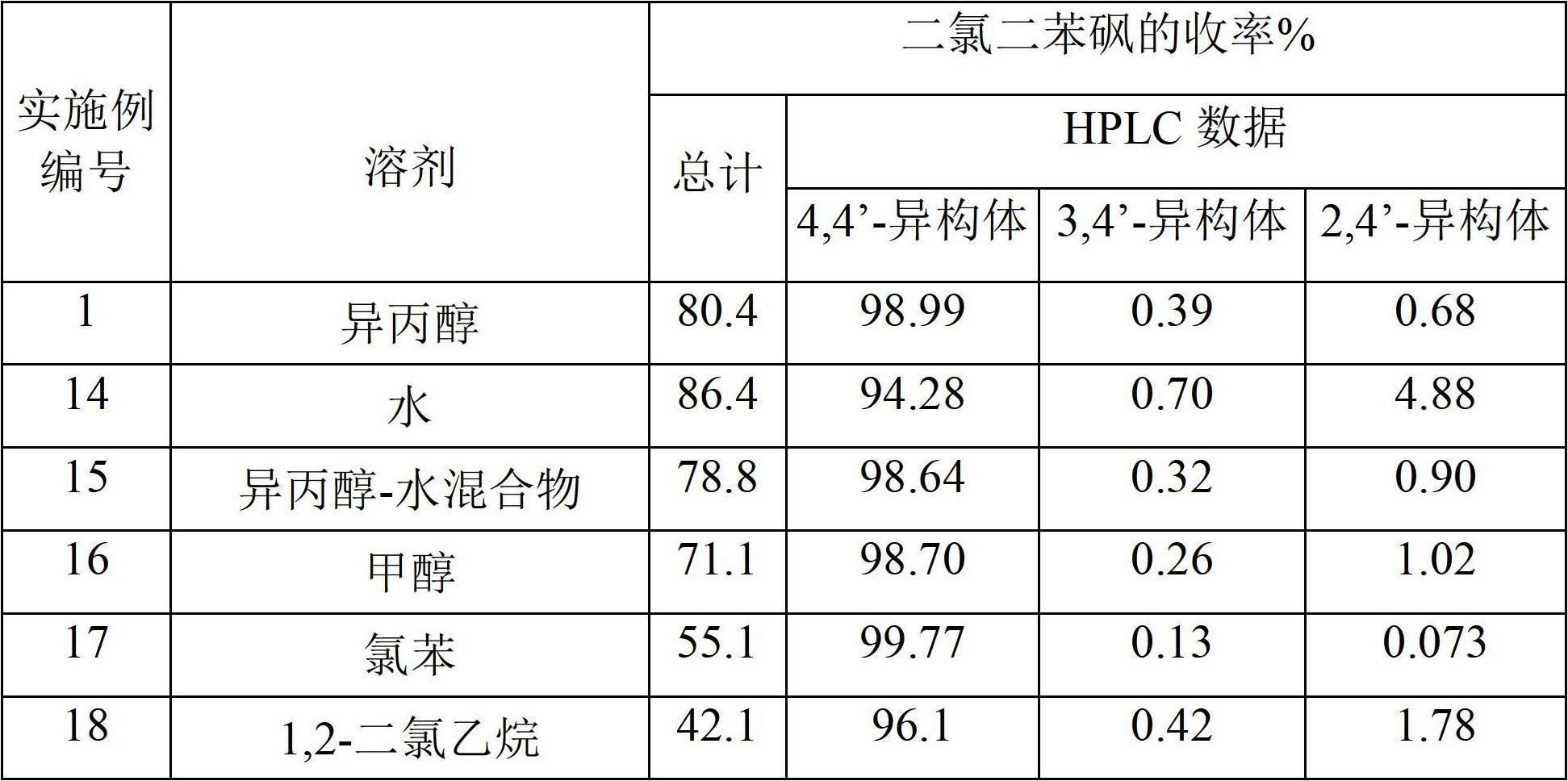

Process for the production of a sulfone monomer

The present invention provides an economic and environmentally friendly method for the preparation of polymer grade 4,4'-dichlorodiphenyl sulfone which is substantially free of 2,4' and 3,4'-isomers of dichlorodiphenyl sulfone with yield of over 90%, with substantially reduced reaction times without the use of impregnated catalysts. Further no toxic byproducts such as dimethyl pyrosulfate are formed thereby reducing the load on effluent treatment with the added advantage of substantially recycling the reactants and byproducts. Further the present invention discloses a process is disclosed in which isomeric mixture of 4,4'-, 3,4'-, and 2,4'-dichlorodiphenyl sulfone produced during the preparation of 4,4'-dichlorodiphenyl sulfone is converted to value added products such as diphenyl sulfone, 2,4'-dihydroxydiphenyl sulfone, 4,4'-dihydroxydiphenyl sulfone and 2-aminodiphenyl sulfone.

Owner:H R 班多德卡尔 +1

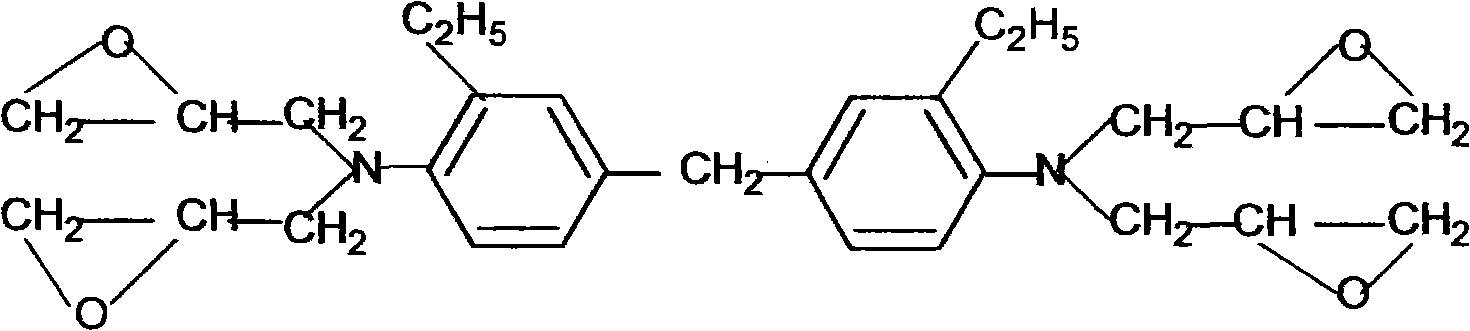

Preparation method of tetraglycidyl-3,3'-diethyl-4,4'-diaminodiphenyl-methane

ActiveCN101665475AImprove catalytic performanceThe source is not easyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsEpoxyPotassium carbonate

The invention relates to a preparation method of tetraglycidyl-3,3'-diethyl-4,4'-diaminodiphenyl-methane, which comprises the following steps: mixing 1 mol of 1,3,3'-diethyl-4,4'-diaminodiphenyl-methane, 5-10 mol of epoxy chloropropane, 0.5-1.0 percent by weight of Alpha-halogenated carboxylate catalyst (based on the weight of the 3,3'-diethyl-4,4'-diaminodiphenyl-methane), 70-85g of polyol and 40-50g of water in a reaction container, dissolving, and then raising the temperature to 50-70 DEG C, maintaining the temperature for 4-7h, continuously adding 320g of acetone and 373-412g of 30 percentby weight of sodium hydroxide water solution or 30 percent by weight of potassium carbonate or mixture of the 30 percent by weight of sodium hydroxide water solution and the 30 percent by weight of potassium carbonate for reacting for 3-5h at a temperature of 50-60 DEG C; adding 800-1,000ml of methylbenzene for extracting a target product, and evaporating the methylbenzene, wherein the product isa bit red liquid resin, the epoxy value of the resin is 0.70-0.74equivalent / 100g, the viscosity 25 DEG C is 0.40-0.51Pa.s, the heat deflection temperature of the resin after being cured by 4,4'-diaminodiphenylsulfone is 182.1 DEG C, the Rockwell hardness E is 85, and the impaction modulus is 3.2 Gpa.

Owner:SHANGHAI PLASTICS RES INST CO LTD

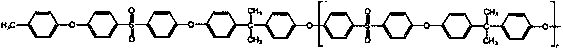

Preparation method of double-terminated polysulfone

The invention belongs to the technical field of high polymer materials, and particularly relates to a preparation method of double-terminated polysulfone, thepreparation method comprises the following steps: taking bisphenol A and 4, 4 '-dichlorodiphenyl sulfone as reaction monomers, adding an end-capping reagent A with activity lower than that of the bisphenol A, a salt-forming agent and a solvent for reaction until the molecular weight reaches the target molecular weight, adding an end-capping reagent B with activity higher than that of the bisphenol A for continuous reaction, and after the reaction is finished, carrying out post-treatment to obtain the double-terminated polysulfone. The end-capping reagent A with activity lower than that of bisphenol A is added in the early stage of the reaction to reduce the low molecular weight polymer part in the final product so that the mechanical property, heat resistance, thermal stability and other properties of the product are improved. When the reaction is about to be finished, the end-capping reagent B with higher activity than bisphenol A is added so that the molecular weight is controlled through rapid end capping, the performance of products in different batches can be more stable, and the method is more suitable for the field of preparation of hollow fiber membranes.

Owner:FUHAI (DONGYING) ADVANCED MATERIAL TECH CO LTD

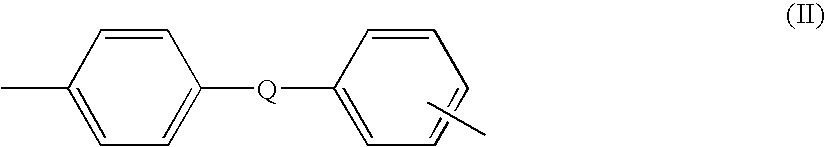

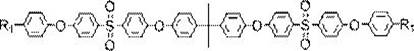

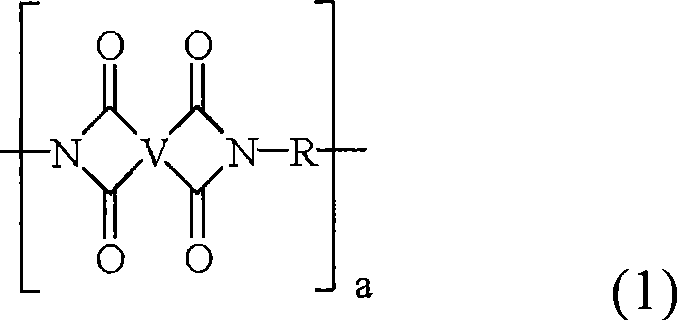

Copper foil with primer resin layer and laminated sheet using the same

InactiveUS20100233476A1Small shrinkage stressHigh bonding strengthPlastic/resin/waxes insulatorsPrinted circuit aspectsPolymer scienceNaphthalenetetracarboxylic dianhydride

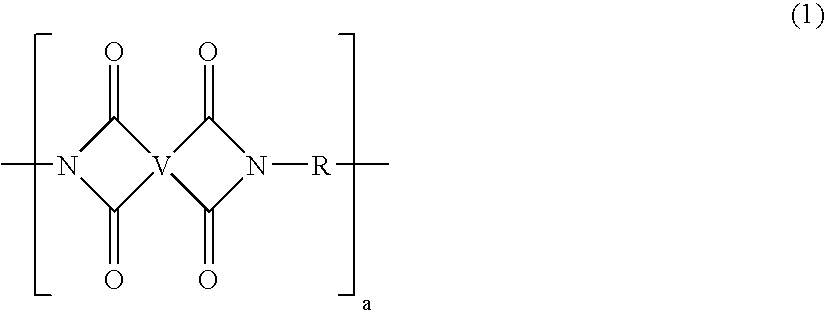

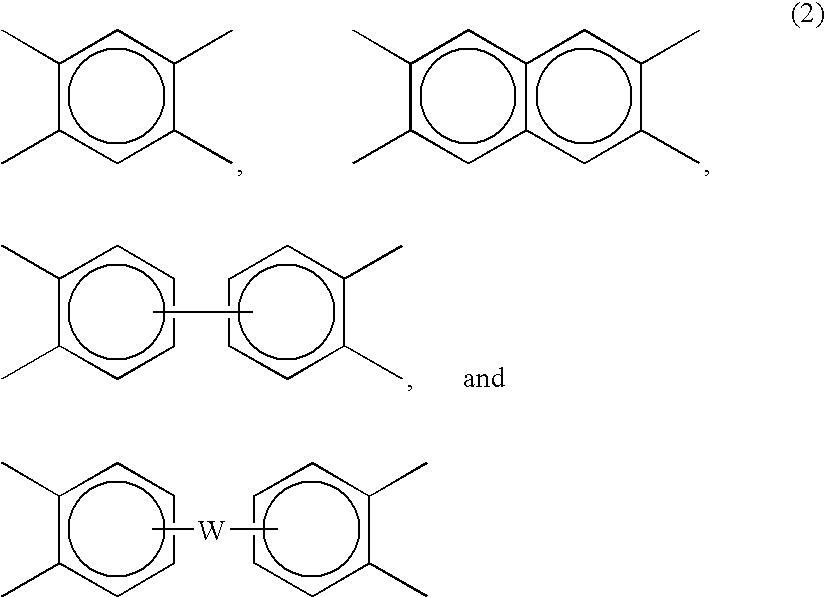

The present invention relates to a copper foil having a primer resin layer which improves the adhesive strength between a copper foil surface without roughening treatment and a substrate resin and a laminated sheet using the same and is characterized by using a polyimide represented by the following formula (1):(wherein, R1 represents a quadrivalent aromatic group which is a residual group of a dicarboxylic acid dianhydride ingredient (pyromellitic acid anhydride, 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride, 3,3′,4,4′-benzophenontetracarboxylic acid dianhydride or 2,3,6,7-naphthalenetetracarboxylic acid dianhydride), R2 represents a divalent aromatic group which is a residual group of a diamine ingredient (1,3-bis-(3-aminophenoxy)benzene, 3,3′-diamino-4,4′-dihydroxydiphenylsulfone or / and 4,4′-diamino-3,3′,5,5′-tetraethyldiphenylmethane), and n1 represents a repeating number) as a primer resin; and copper foils and laminated sheets having said polyimide layer as a primer have high adhesive strength and are suitable for flexible printed wiring boards.

Owner:NIPPON KAYAKU CO LTD

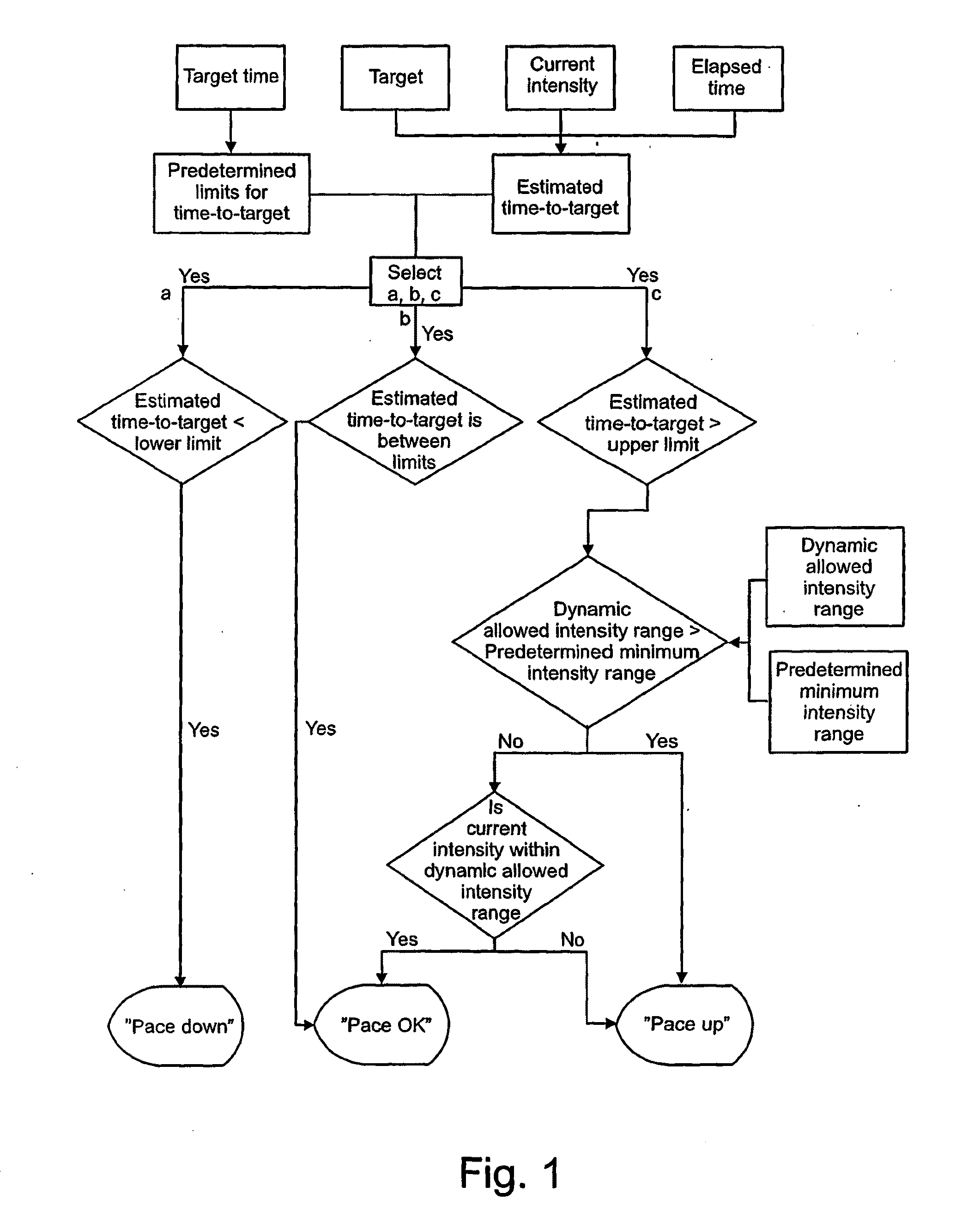

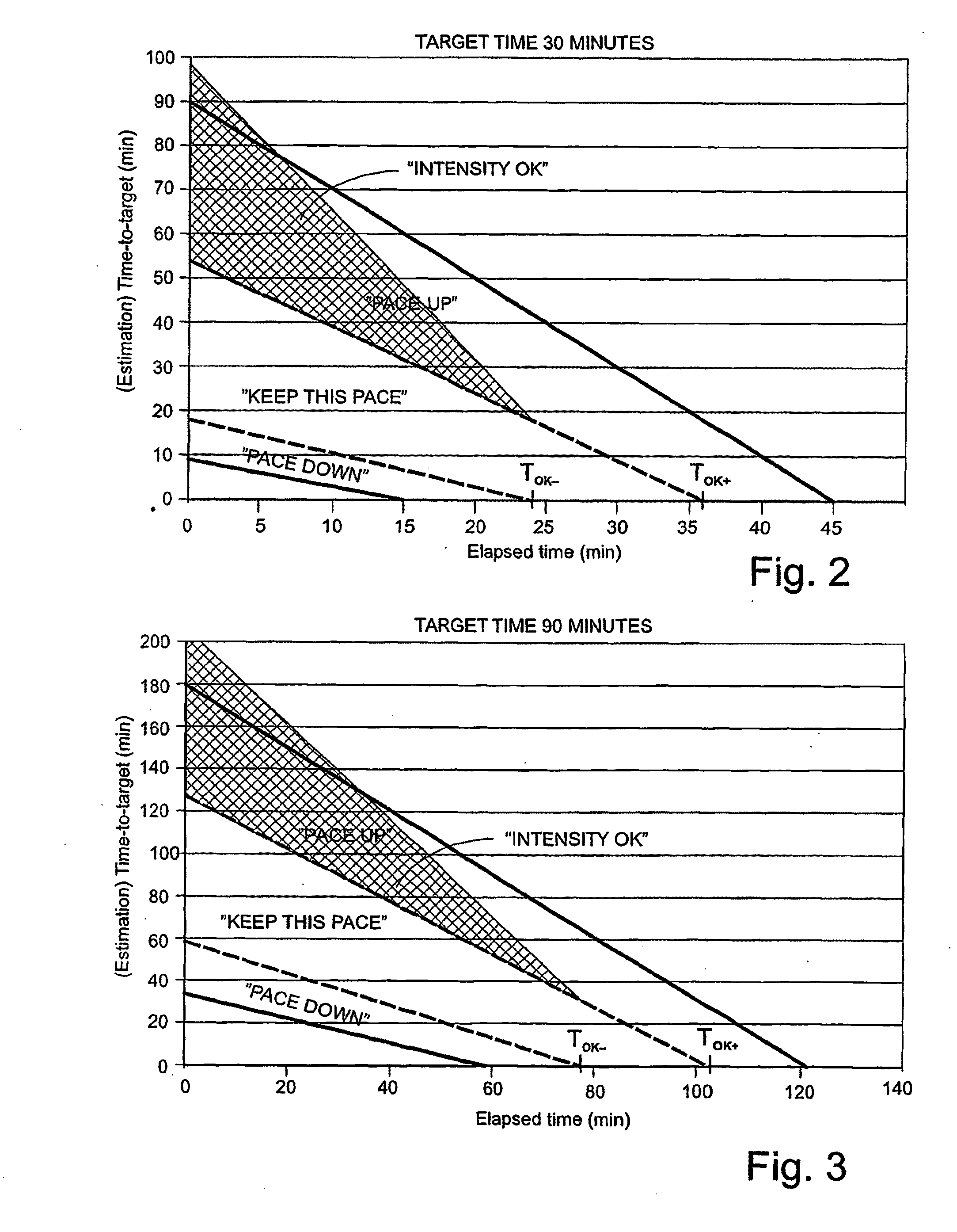

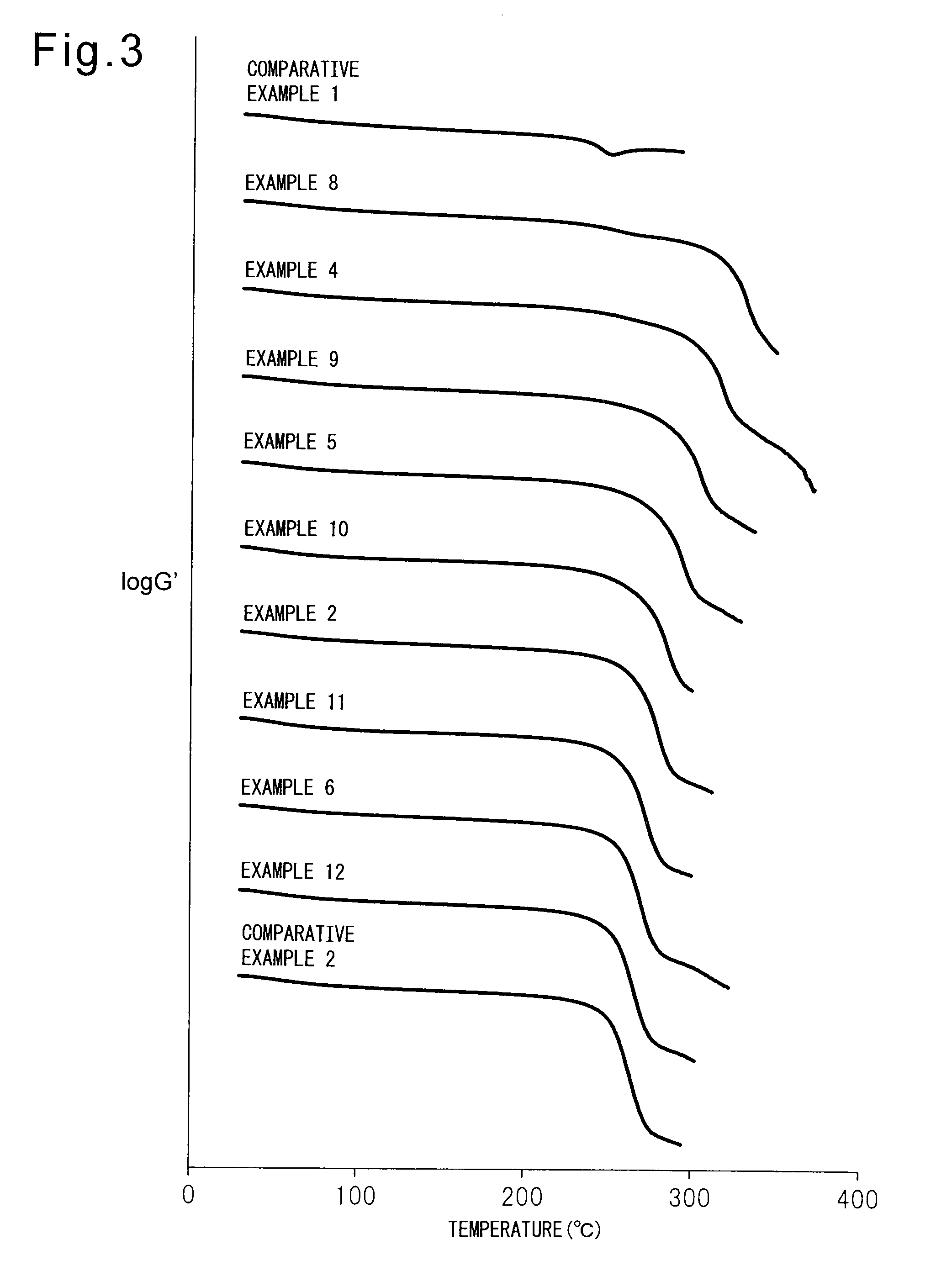

Method for producing fiber-reinforced composite material, and heat-resistant mold material and heat-resistant structural material using the fiber-reinforced composite material

ActiveUS20120231687A1High heat resistanceHigh mechanical propertySynthetic resin layered productsPretreated surfacesGypsumFibre reinforcement

A method for producing a fiber-reinforced composite material having high mechanical properties and high heat resistance, and allowing the use of a gypsum die in primary curing, wherein a fiber-reinforced prepreg, obtained by impregnating reinforcing fibers with an epoxy resin composition comprising a triphenylmethane-type epoxy resin, N,N,N′,N′-tetraglycidyldiaminodiphenylmethane (B) and diaminodiphenylsulfone (C), is subjected to primary curing at 110-130° C., and then to secondary curing at a temperature which is at least as high as the primary curing temperature.

Owner:MITSUBISHI CHEM CORP

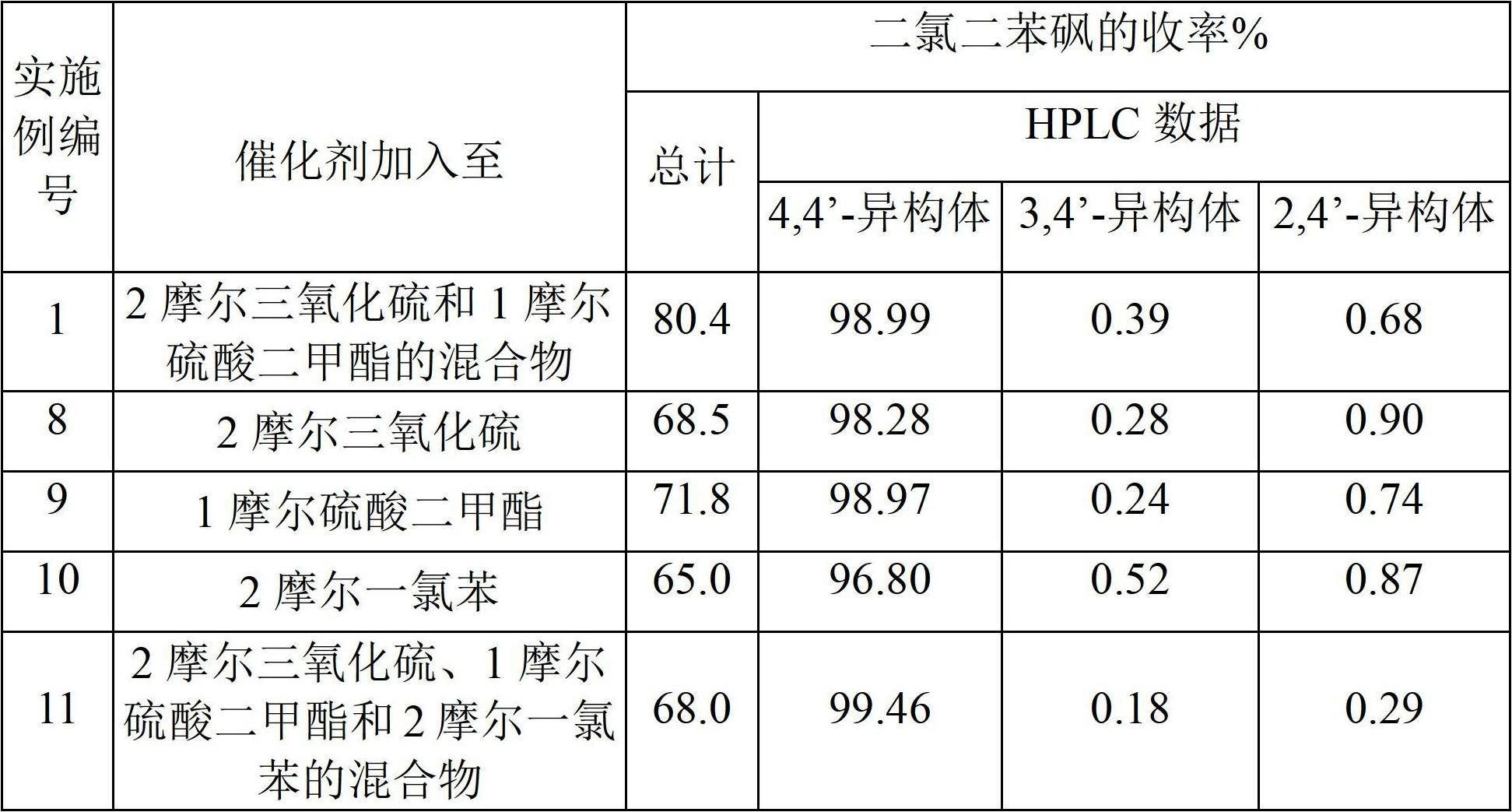

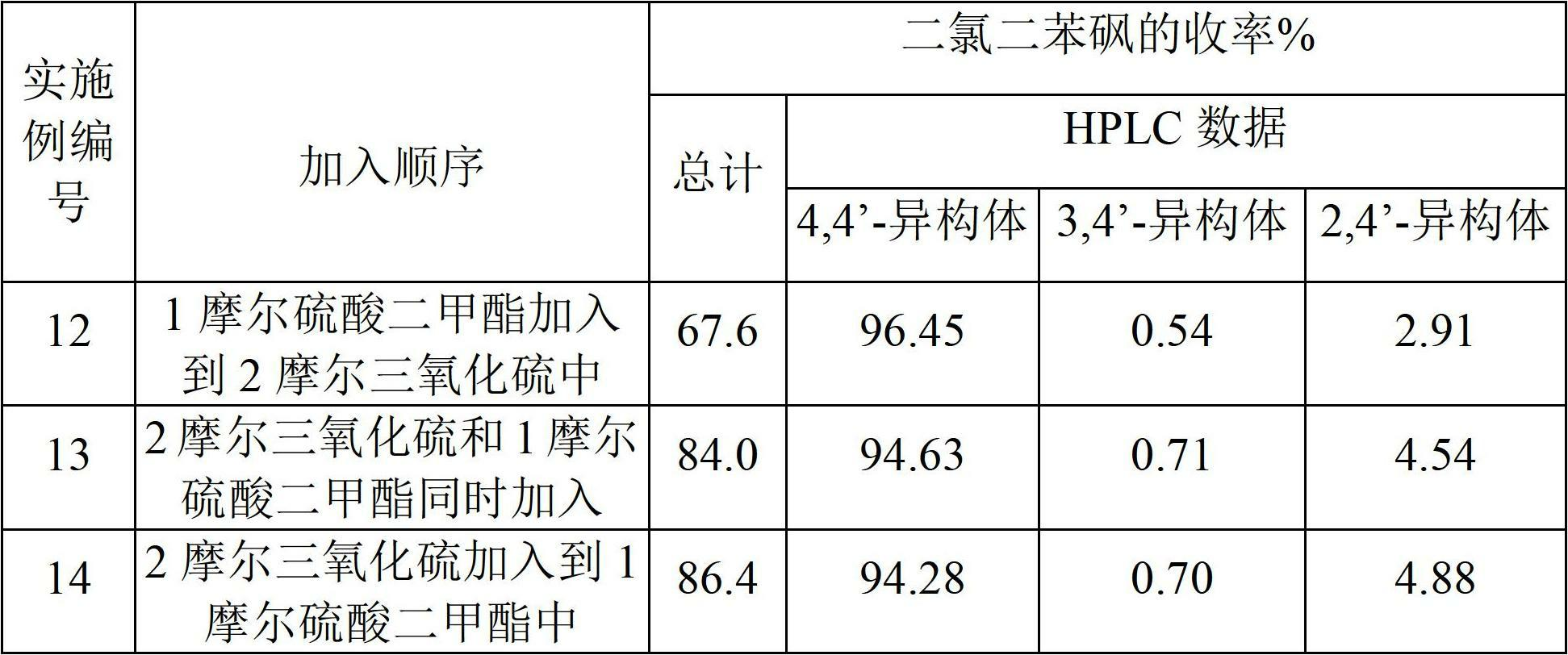

Preparation method for catalytic synthesis of 4,4'-dichlorophenylsulfone

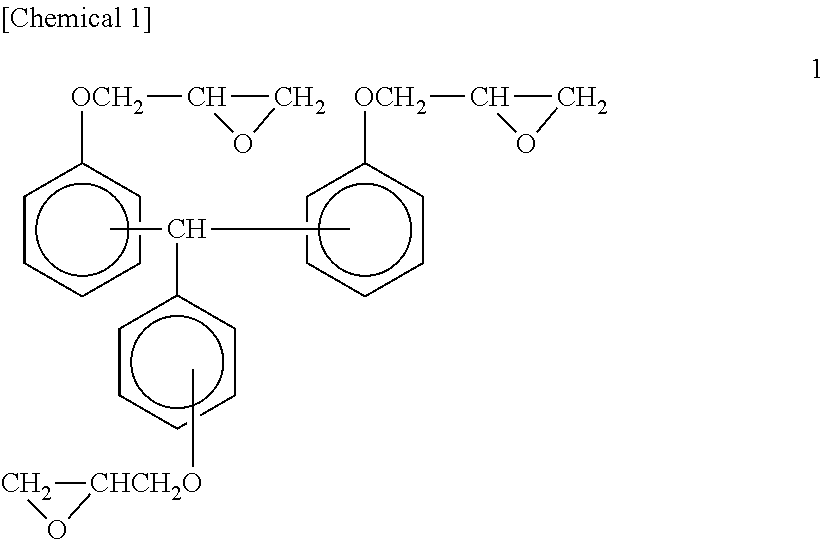

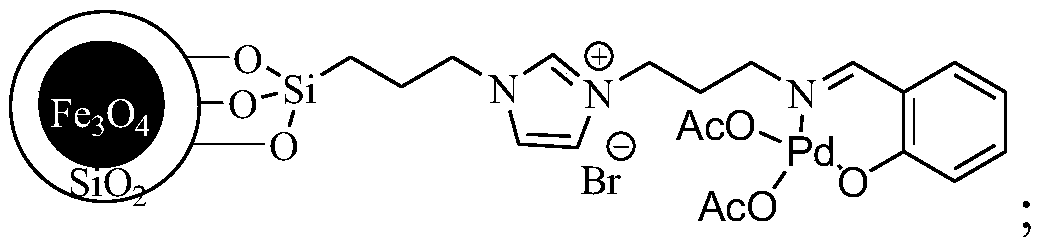

InactiveCN111302983AHigh catalytic activityEasy to recycleOrganic chemistryOrganic compound preparationSodium bicarbonateChlorobenzene

The invention discloses a preparation method for catalytic synthesis of 4,4'-diaminostilbene. The preparation method comprises the following steps: with a superparamagnetic nanoparticle loaded ionic liquid as a catalyst, subjecting chlorobenzene and thionyl chloride to a Friedel-Crafts reaction under the action of the catalyst, after the reaction is completed, additionally adding a catalyst recovered by a magnetic field, pouring out a reaction solution, dropwise adding a saturated sodium bicarbonate solution into the reaction solution until the pH value of the solution is adjusted to be neutral, then carrying out stirring, filtering the material liquid while the material liquid is hot, cooling a filtrate to 0-5 DEG C for crystallizing, carrying out filtering so as to obtain 4,4'-dichlorodiphenyl sulfoxide, dissolving the 4,4'-dichlorodiphenyl sulfoxide into glacial acetic acid, adding hydrogen peroxide for an oxidation reaction, carrying out cooling after the reaction is finished, andcarrying out filtering so as to obtain 4,4'-dichlorodiphenyl sulfone. According to the invention, the chlorobenzene is used as a reaction raw material and a solvent; no solvent impurities are not mixed; meanwhile, simple process, low cost and few impurities are achieved; an obtained product is high in purity and has a content of 99.2% or above; the content of a 2,4'-isomer is smaller than 0.1%; the yield reaches 90% or above; and the preparation method provided by the invention is good in economic benefit and applicable to industrial production.

Owner:九江中星医药化工有限公司

Environment-friendly fireproof coating and preparation method thereof

InactiveCN111995922AShort processEasy to operateFireproof paintsAnti-corrosive paintsPhosphoric Acid EstersPolymer science

The invention discloses an environment-friendly fireproof coating, the coating is prepared from the following components in parts by weight: 10-20 parts of vinyl-modified hyperbranched polyphosphate,5-10 parts of acrylate-modified p-aminophenyl calixpyrrole, 50-70 parts of 1, 3-bis (oxiranylmethyl)-5-(2-propenyl)-1, 3, 5-triazine-2, 4, 6 (1H, 3H, 5H)-triketone / 3, 3 '-diamino-4, 4'-difluorodiphenyl sulfone polycondensate, 0.5-1.5 parts of an initiator, 15-25 parts of an inorganic filler, 1-3 parts of a defoamer and 1-3 parts of a dispersant. The invention also provides a preparation method ofthe environment-friendly fireproof coating. The environment-friendly fireproof coating disclosed by the invention is good in comprehensive performance, remarkable in fireproof and flame-retardant effects, good in water resistance, decoration and storage stability, environment-friendly and pollution-free.

Owner:邵敏

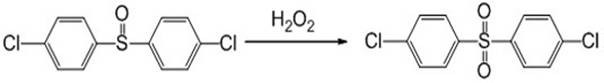

Method for synthesizing 4, 4 '-dichlorodiphenyl sulfone by using sulfoxide oxidation method

InactiveCN112608258AReduce usageImprove efficiencyOrganic chemistryOrganic compound preparationDichloropropanePolymer science

The invention relates to a method for synthesizing 4, 4 '-diaminodiphenyl sulfone by a sulfoxide oxidation method. The method is characterized by comprising the following steps: putting 4, 4 '-dichlorodiphenyl sulfone, dichloropropane, water and a phase transfer catalyst into a reactor, heating to 50-95 DEG C after feeding is finished, slowly dropwise adding hydrogen peroxide, continuously reacting for 3-7 hours, cooling to 0-5 DEG C, filtering, washing a filter cake with water, and drying to obtain the finished product 4, 4'-dichlorodiphenyl sulfone. The method is short in reaction time, thorough in material reaction, high in product yield and low in production cost.

Owner:JIANGSU AOLUNDA HIGH TECH IND

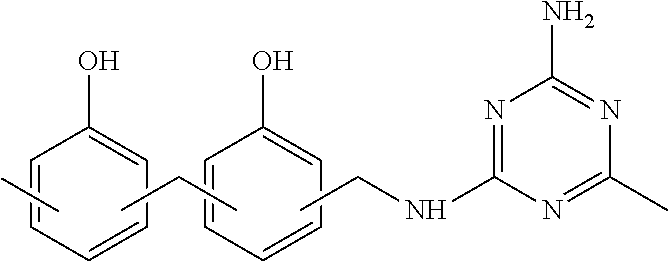

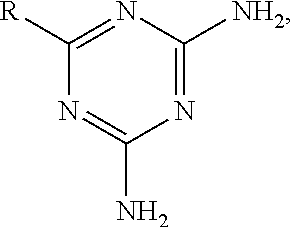

Epoxy resin composition, and prepreg and printed circuit board using the same

ActiveUS8748513B2Superior of processibilityMaintain good propertiesPrinted circuit aspectsSynthetic resin layered productsEpoxyTriazine

Disclosed is an epoxy resin composition for printed circuit board, which includes (A) an epoxy resin; (B) a composite curing agent, including amino-triazine-novolac resin and diaminodiphenylsulfone mixed in a certain proportion; (C) a curing accelerator; and (D) an optional inorganic filler.

Owner:TAIWAN POWDER TECH CO LTD

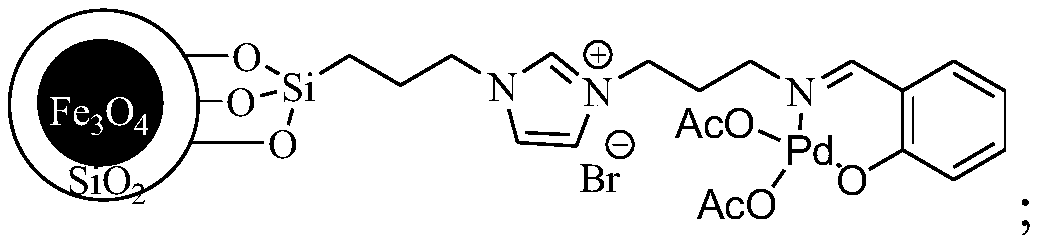

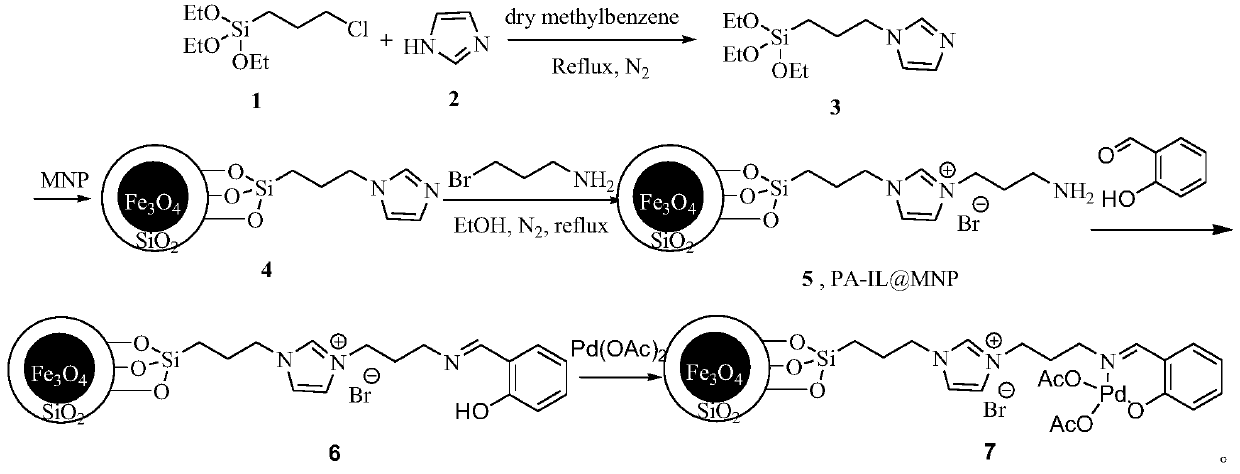

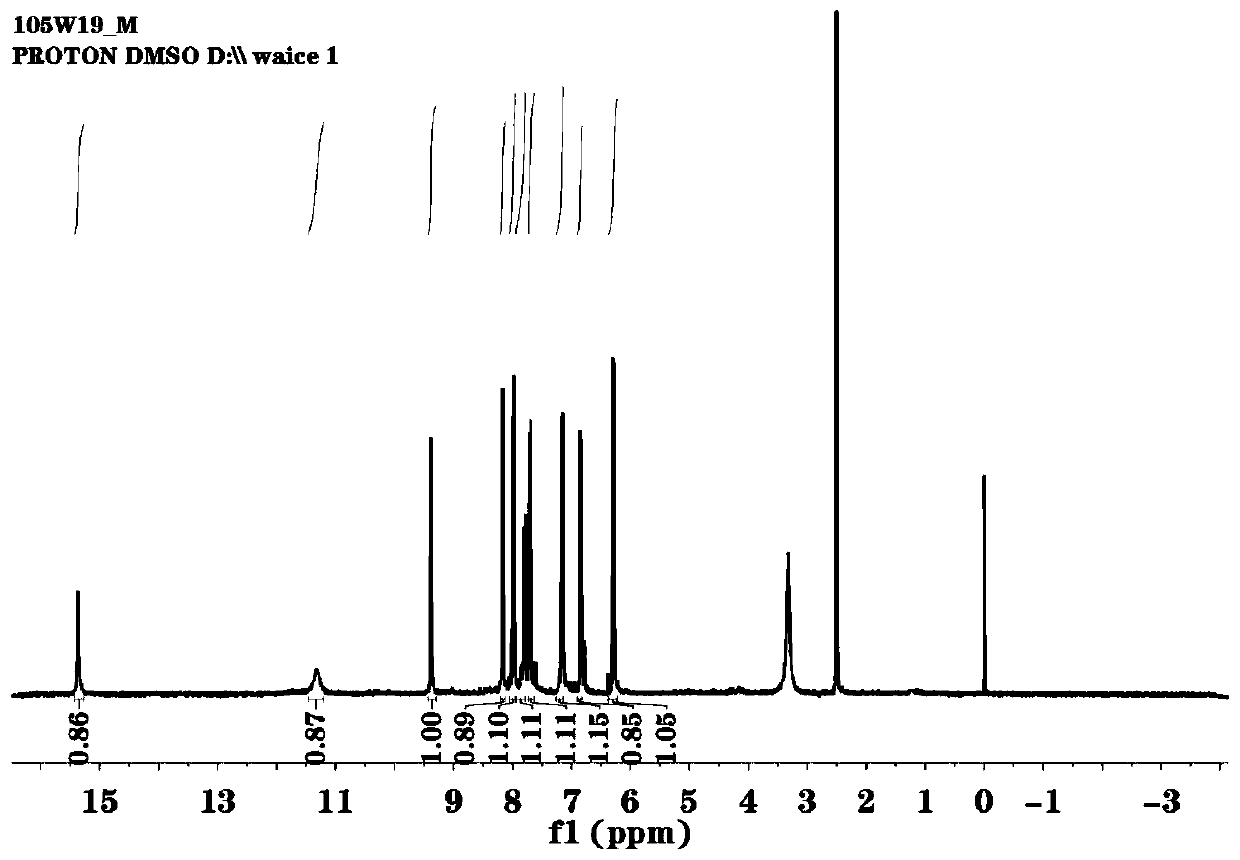

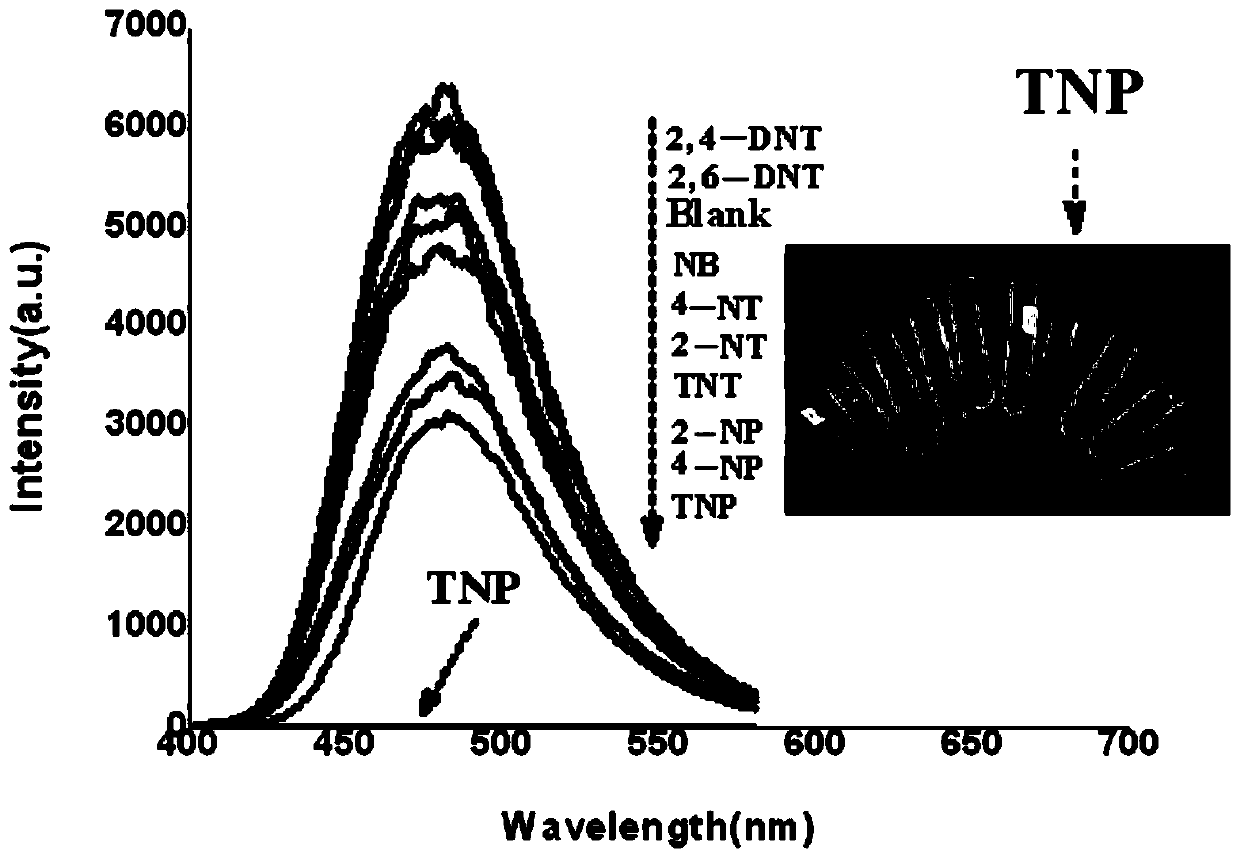

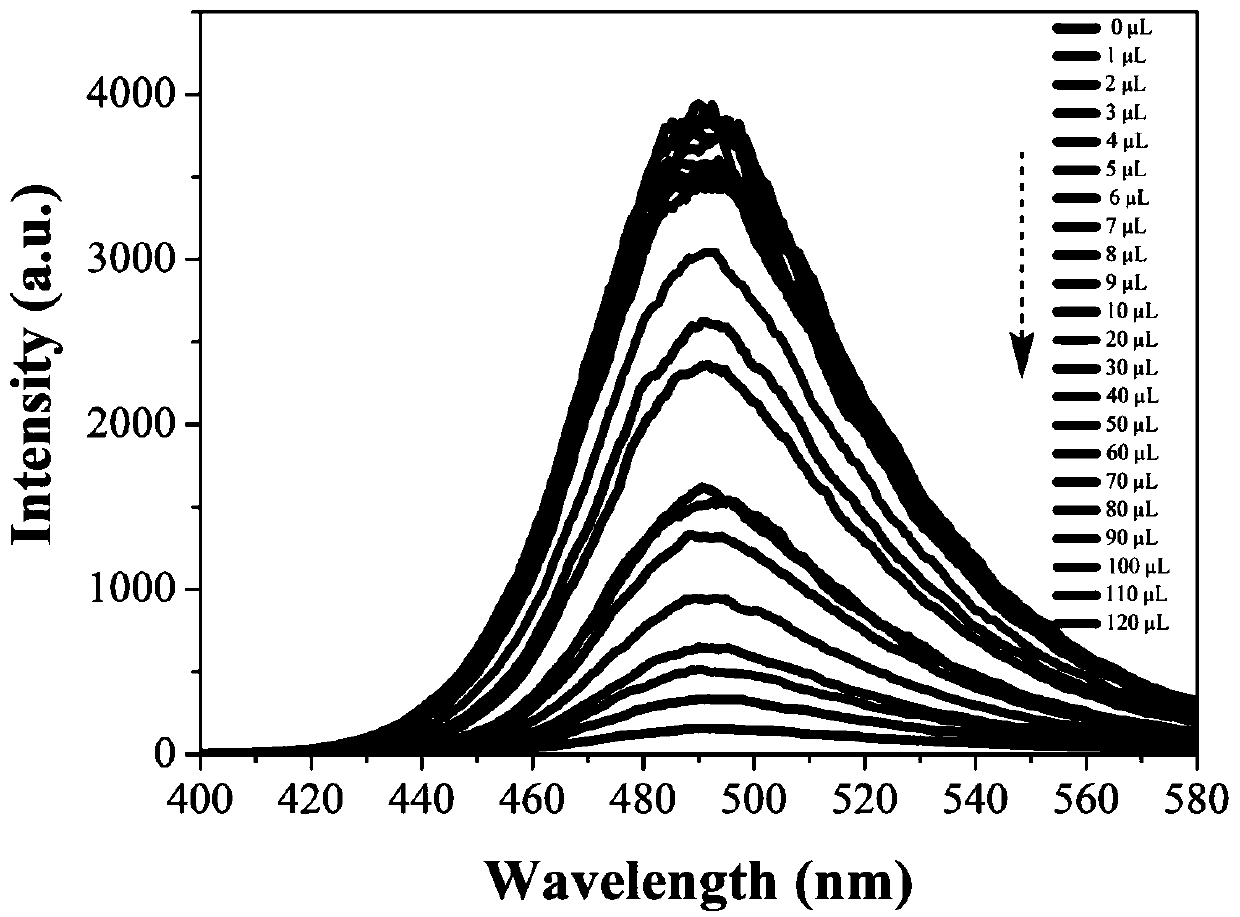

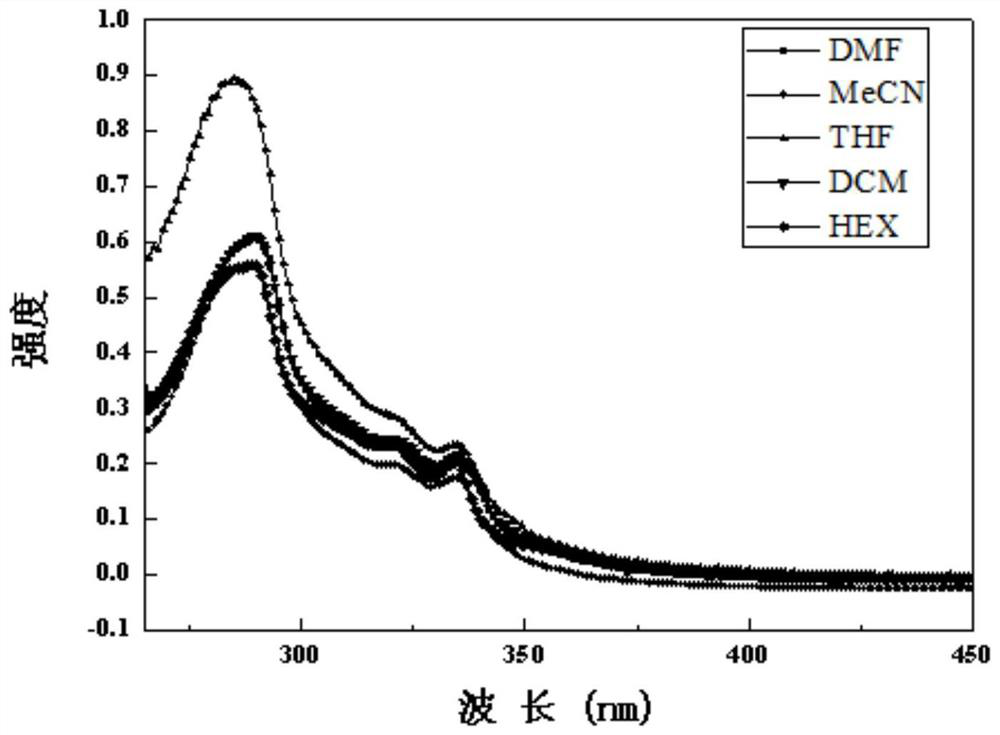

Fluorescent probe for rapidly identifying 2, 4, 6-trinitrophenol and preparation method thereof

ActiveCN111285830ARealize detectionHigh selectivityOrganic chemistryGeneral water supply conservationFluoProbesFluorescence

The invention belongs to the field of fluorescent probe preparation technology and application, and particularly relates to a fluorescent probe for rapidly identifying 2, 4, 6-trinitrophenol moleculesand a preparation method thereof. The structural formula of the fluorescent probe molecule L is shown in the specification, and the fluorescent probe molecule L is obtained by reacting 8-formyl-7-hydroxycoumarin with 3, 3'-diamino-4, 4'-dihydroxy diphenyl sulfone. The fluorescent probe disclosed by the invention has relatively good selectivity and visual color change on 2, 4, 6-trinitrophenol (TNP), the detection limit is 1.2*10<-7>mol / L, and the fluorescent probe has a very good application prospect.

Owner:ANHUI UNIV OF SCI & TECH

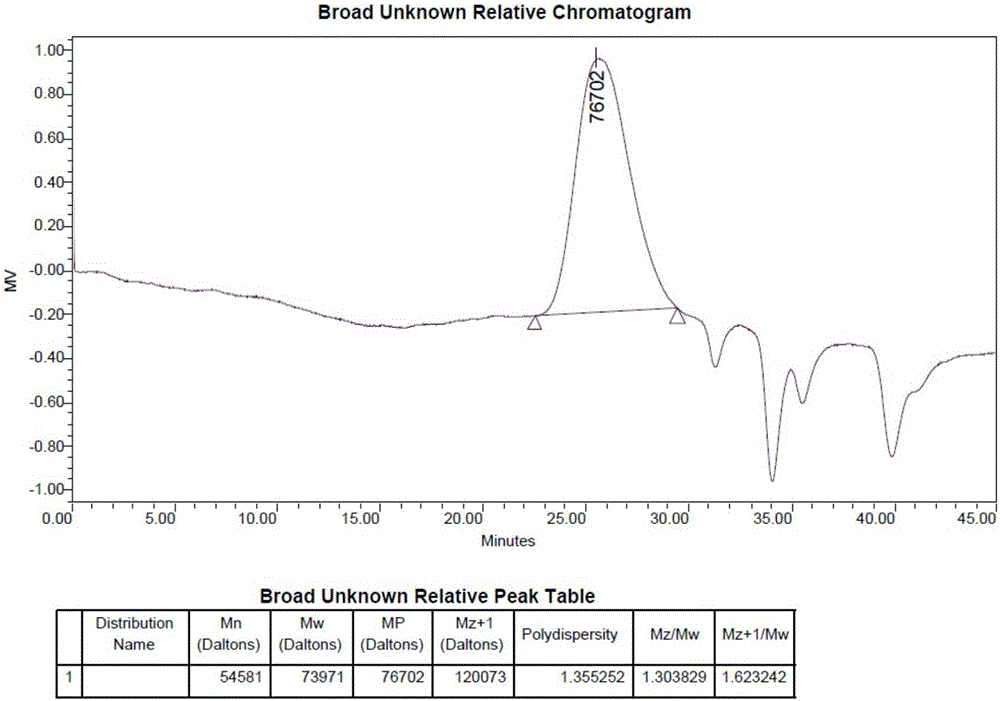

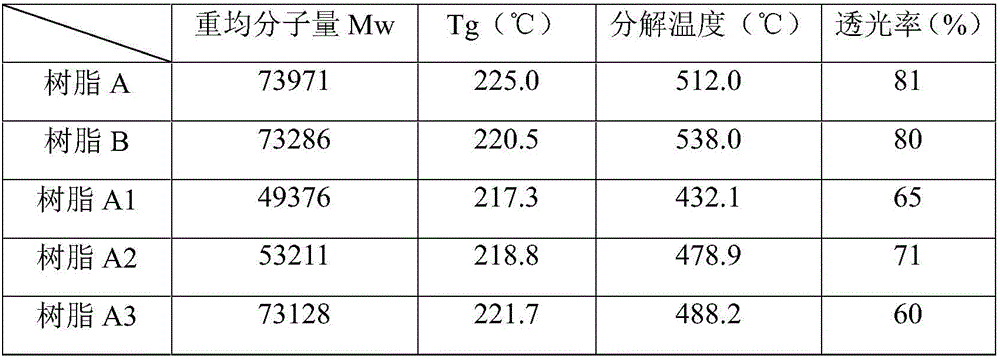

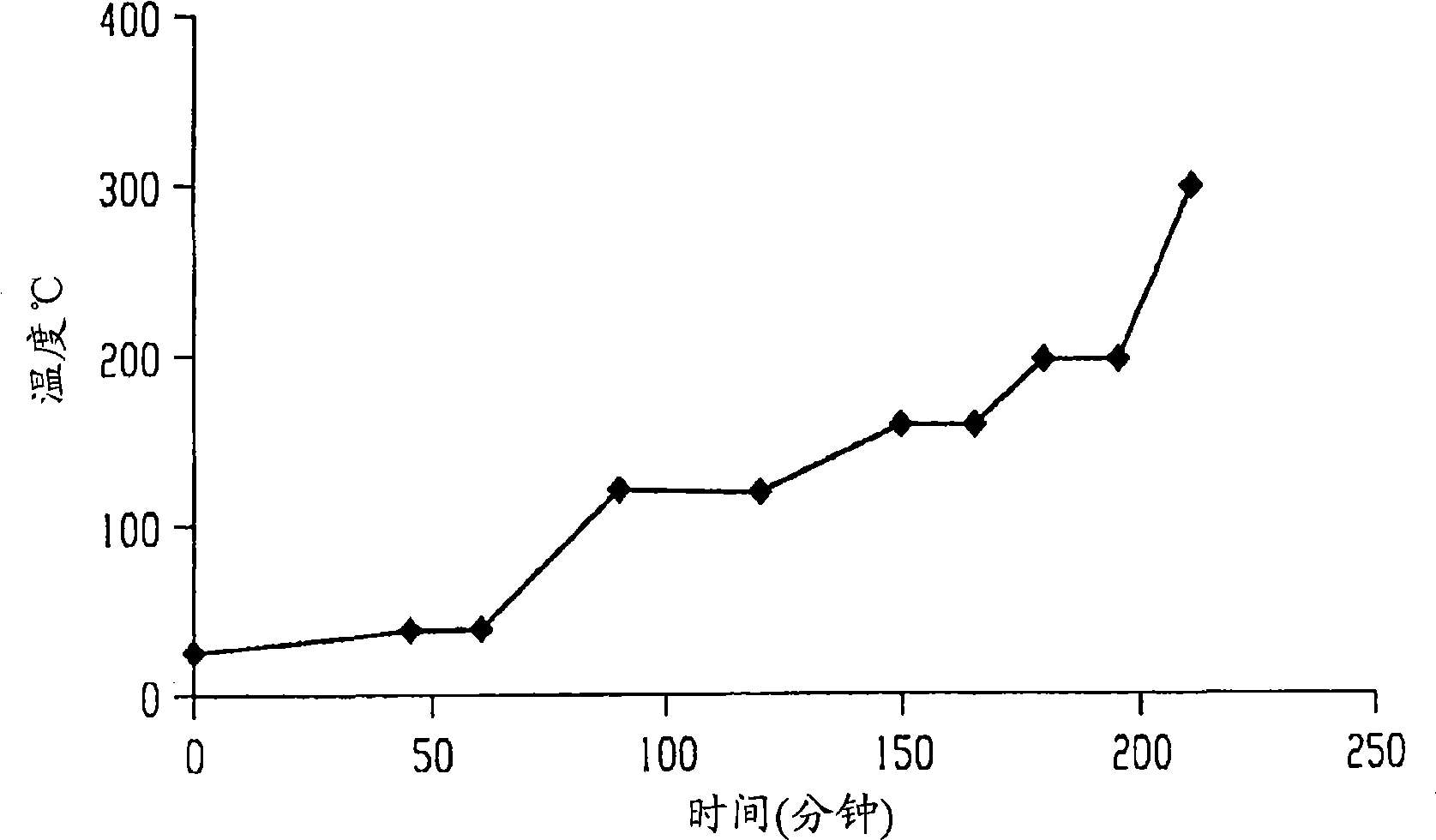

High-performance polysulfone resin and synthesis thereof

The invention provides a preparation method of high-performance polysulfone resin. The preparation method includes adding 45-55 parts of 4,4-dichlorodiphenylsulfone, 35-40 parts of salt-forming agent, 80-100 parts of low boiling point organic solvent and 0.01-0.04 parts of 3-fluoro-4-chlorobenzophenone into the reactor, and then 20-60 parts of 4,4'- -dihydroxydiphenylsulfone or bisphenol, injecting nitrogen gas and heating until the temperature inside the reactor rises to 200-210 DEG C, maintaining reaction at constant temperature for 1 to 2 hours, and after the temperature rises to 240-260 DEG C for 4 to 7 hours, adding 0.09-0.16 parts of 3-fluoro-4-chloro benzophenone, reacting 10-20 minutes, then stopping reactor and treating the reactant to obtain high-performance polysulfone resin. The polysulfone resin prepared by the method has high molecular weight, good transparency and heat resistance.

Owner:FOSHAN POLIMA ADVANCED TECH & SUPPLIES CO LTD +1

Polyimide solvent cast films having a low coefficient of thermal expansion and method of manufacture thereof

A solvent cast film comprises a polyimide comprising structural units derived from polymerization of a dianhydride component comprising a dianhydride selected from the group consisting of 3,4'-oxydiphthalic dianhydride, 3,3'-oxydiphthalic dianhydride, 4,4'-oxydiphthalic dianhydride, and combinations thereof, with a diamine component comprising 4,4'-diaminodiphenylsulfone; wherein the polyimide has a glass transition temperature from 190 DEG C. to 400 DEG C.; and wherein the film has a coefficient of thermal expansion of less than 60 ppm / DEG C., a thickness from 0.1 to 250 micrometers, and less than 5% residual solvent by weight.

Owner:SABIC INNOVATIVE PLASTICS IP BV

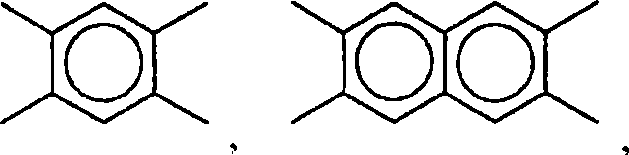

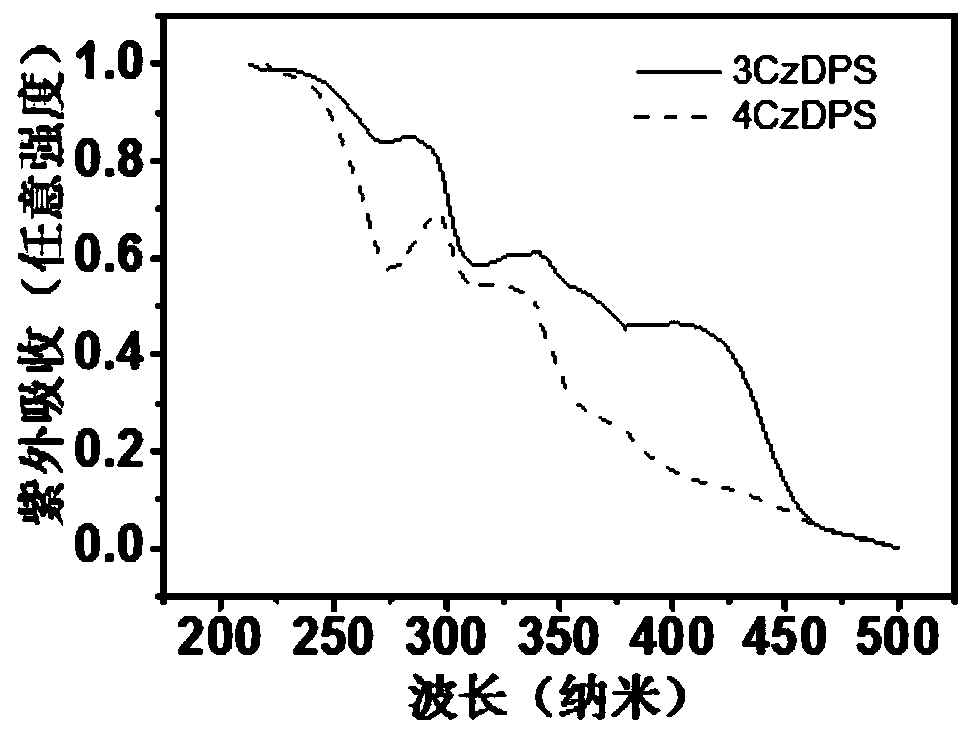

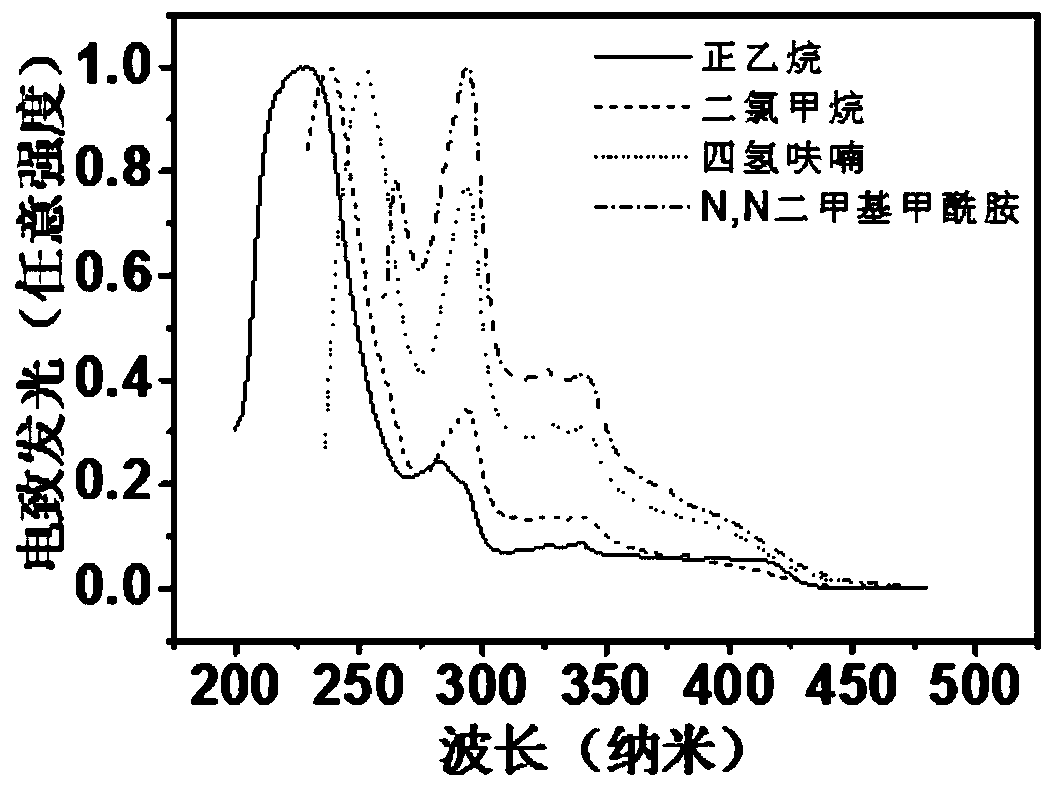

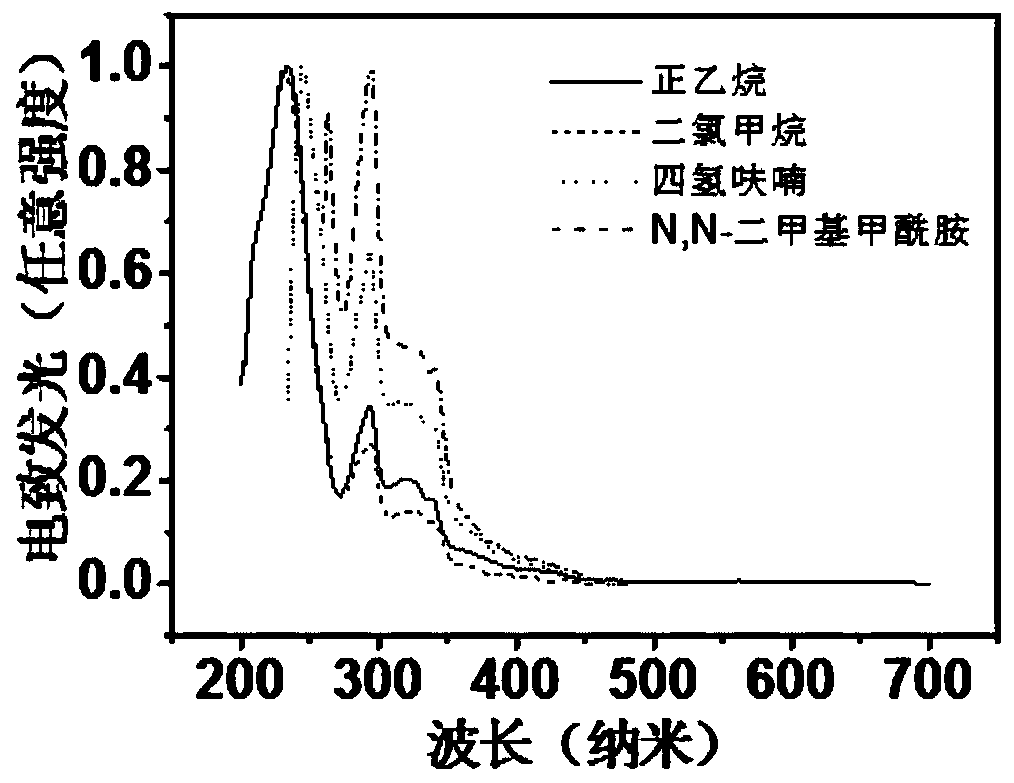

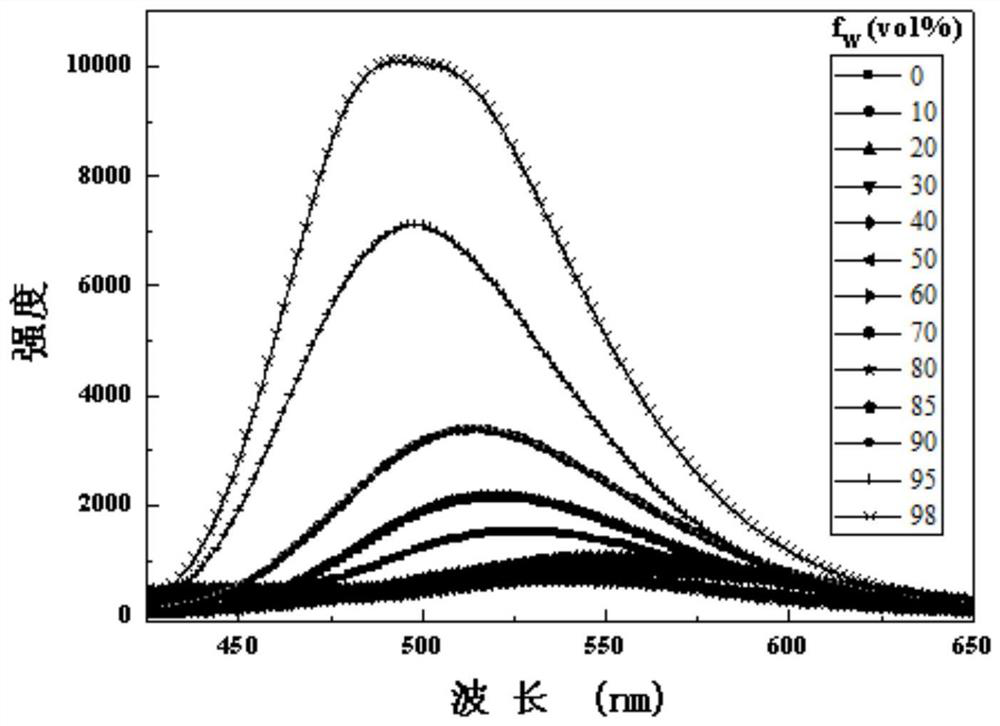

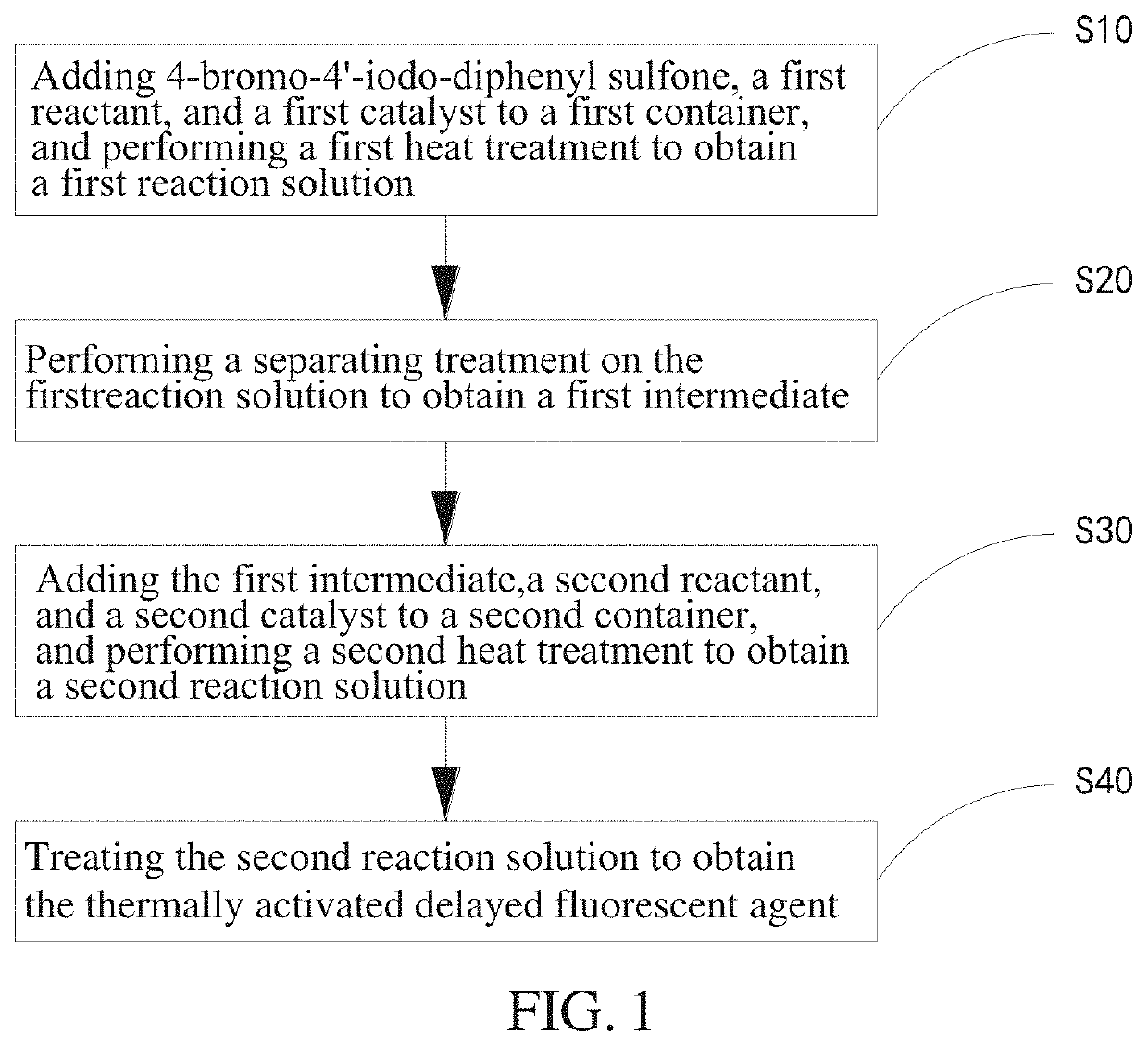

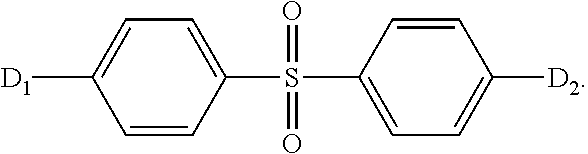

D-A type TADF material, preparation method and application thereof

ActiveCN110511177AGood film formation and shape stabilityGood carrier transport abilityOrganic chemistrySolid-state devicesFluorescenceChemistry

The invention discloses a D-A type TADF material, a preparation method and application thereof. The D-A type TADF material has a structural general formula shown as the specification, wherein A represents a receptor unit, D represents a donor unit, and by changing the linkage position of the donor unit on the receptor unit diphenyl sulfone, specifically two linking modes, i.e. three positions (m1,m2 and m2') and four positions (m1, m2, m1' and m2') respectively, two D-A type TADF materials can be obtained. The two materials have high fluorescence quantum efficiency, good film-forming properties and morphology stability; the good carrier transport capacity facilitates the injection and transport of carriers; at the same time, the materials have appropriate HOMO and LUMO energy levels, so that the device energy level can be better matched. The material has good application prospects in OLED, and the synthesis method of the material is simple, the operability is strong and the synthesiscost is low.

Owner:NANJING UNIV OF POSTS & TELECOMM

Polysulfone resin preparing method with microwaves as heat source

The invention discloses an efficient polysulfone resin preparing method with microwaves as a heat source. The preparing method includes the steps that 4,4'-dichloro(di)phenyl sulfone and bisphenol A serve as initial raw materials, carbonate with the mole number two times that of the bisphenol A is added to serve as alkali, and the mixture is heated and reacted for 2 hours to 5 hours through a microwave reactor in high-boiling-point aprotic polar solvents; then the reaction liquid is slowly poured into deionized water, white fiber-shaped polymers are obtained, then the polymers are soaked for 5 hours to 10 hours under the 60-DEG-C-to-80-DEG-C condition, the process is repeated three times to five times, filtering and drying are carried out, and polysulfone resin is obtained through vacuum drying. By means of the preparing method, the reaction time is shortened to a great degree, energy consumption is reduced, the cost for the production technology is reduced accordingly, and the working efficiency is improved.

Owner:SHANDONG JINLAN SPECIAL POLYMER CO LTD

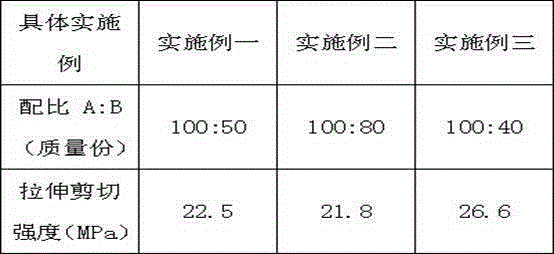

Epoxy resin AB glue used in high-temperature environment and manufacturing and use methods thereof

ActiveCN104987849AImprove thermal stabilityImprove aging resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesHydantoin derivativesPolyamide

The invention discloses an epoxy resin AB glue used in high-temperature environment and manufacturing and use methods thereof. The epoxy resin AB glue used in high-temperature environment comprises components A and B, wherein a main body of the component A is bisphenol epoxy resin, and hydantoin epoxy resin is added to the component A; and a main body of the component B is low molecular polyamide, and 4,4'-diamino diphenyl sulfone is added to the component B. The components A and B are mixed and cured when in use, and thermal stability and aging resistant performance of the epoxy resin AB glue are improved by a joint action of hydantoin epoxy resin and 4,4'-diamino diphenyl sulfone.

Owner:ZHUZHOU SHILIN POLYMER

Addition compound of anhydride elacostearic acid /4,4 diaminodiphenyl sulphone and application

InactiveCN1310883CSolve the "sticky film" problemSufficient printing fastnessOrganic chemistryOrganic compound preparationResistEmulsion

The present invention discloses an eleostearic acid anhydride / 4,4'-diaminodiphenylsulfone addition product, also discloses its production method and also discloses its application. Said addition product can be used as epoxy resni solidifying agent, can be used in water-emulsion type cylinder mould photosensitive resists.

Owner:SHANGHAI ZHONGDA TECHNOLOGY DEVELOPMENT CO LTD +1

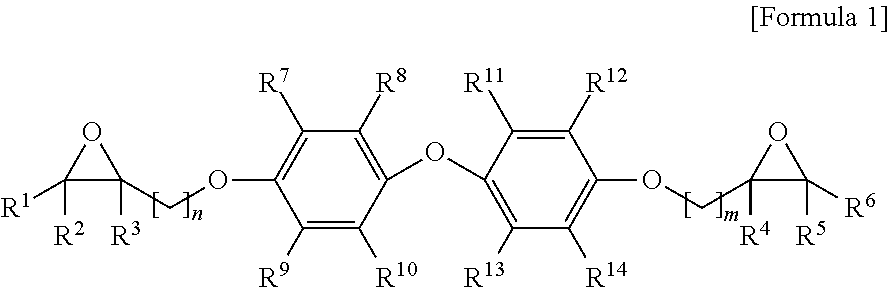

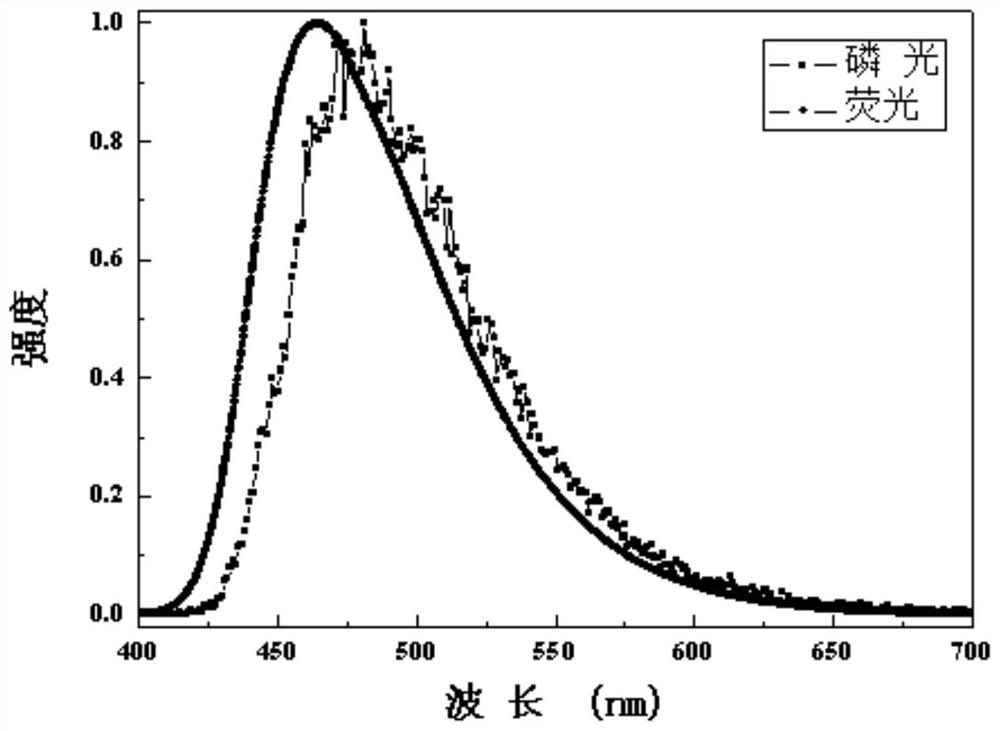

Compound containing diphenyl sulfone skeleton and preparation method and application thereof

ActiveCN113429391AImprove thermal stabilityImprove luminous efficiencyOrganic chemistrySolid-state devicesBenzoic acidChlorobenzene

The invention provides a compound containing diphenyl sulfone as a skeleton and a preparation method and application thereof, and the name of the compound is 10-(4-((3, 5-bis (9H-carbazole-9-yl) phenyl) sulfonyl) phenyl)-9, 9-dimethyl-9, 10-dihydroacridine. The preparation method comprises the following steps: carrying out a carbon-carbon coupling reaction on 9, 9'-(5-bromo-1, 3-phenylene) bis (9H-carbazole) and 4-chloro-1, 2-dimercaptobenzene to synthesize 9, 9'-(5-((4-chlorphenyl) sulfo)-1, 3-phenylene) bis (9H-carbazole); oxidizing the 9, 9'-(5-((4-chlorphenyl) sulfo)-1, 3-phenylene) bis (9H-carbazole) by using m-chloroperoxybenzoic acid to obtain 9, 9'-(5-((4-chlorphenyl) sulfonyl)-1, 3-phenylene) bis (9H-carbazole); finally, enabling the 9'-(5-((4-chlorphenyl) sulfonyl)-1, 3-phenylene) bis (9H-carbazole) and 9, 10-dihydro-9, 9-dimethyl acridine to be subjected to a Ullmann coupling reaction, and obtaining the target compound. The compound has excellent thermal stability, electrochemical stability, charge transfer performance and luminescence performance, and can be used as a blue organic electroluminescent material.

Owner:SHANXI UNIV

Thermally activated delayed fluorescent and synthesizing method thereof

ActiveUS11279873B2Improve luminous efficiencyImprove luminous performanceOrganic chemistryLuminescent compositionsPtru catalystPhotochemistry

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com