High-performance polysulfone resin and synthesis thereof

A polysulfone resin, high-performance technology, applied in the field of high-performance polysulfone resin and its synthesis, can solve the problems that the transparency cannot be improved, the yellowness index of polysulfone resin is high, and there are few research reports, etc., to achieve improvement Transparency and thermal stability, high transparency, and the effect of expanding the application field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

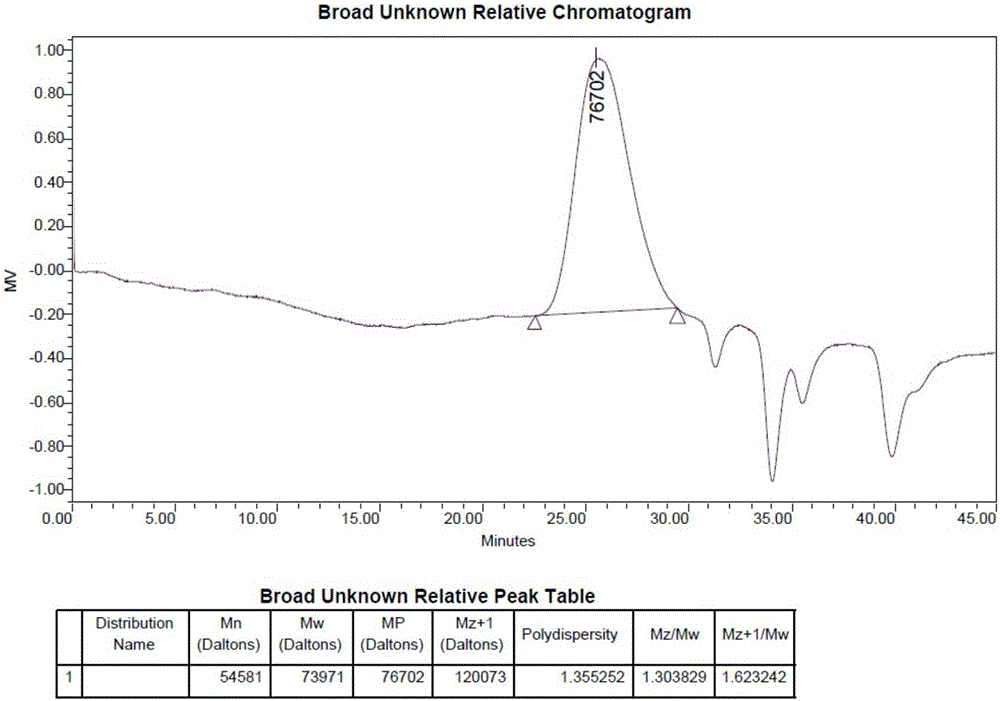

Image

Examples

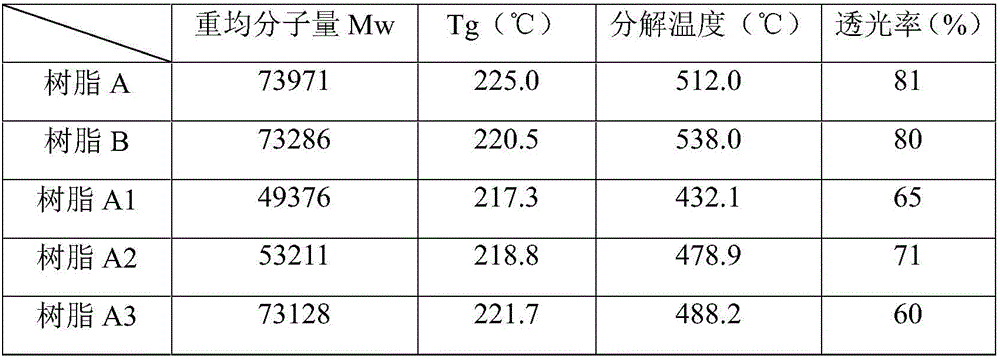

Embodiment 1

[0024] Polymerization reaction: add 50kg 4,4-dichlorodiphenyl sulfone, 34.2kg sodium carbonate, 3.42kg potassium bicarbonate, 0.342kg cesium carbonate, 90kg N,N'-dimethylformamide and 22.5g 3 -Fluoro-4 chlorobenzophenone, then add 43kg of 4,4'-dihydroxydiphenyl sulfone, pump out the air in the kettle to negative pressure -0.05MPa, then feed nitrogen to raise the pressure in the kettle to 3.0MPa; repeatedly extract Vacuum to negative pressure -0.05MPa, then feed nitrogen to raise the pressure in the kettle to 3.0MPa, repeat the operation 5 times, completely replace the air in the kettle; After rising to 250°C for 6 hours of constant temperature reaction, add 127.5g of 3-fluoro-4 chlorobenzophenone, react for 10 minutes, stop the reaction, and obtain polymerized mucus;

[0025] Post-processing: Cool the reacted liquid at a constant temperature of 20°C, then crush and pulverize it, put the solid powder into a washing tank and wash it with deionized water until the ion content in ...

Embodiment 2

[0027] Polymerization: 50kg 4,4-dichlorodiphenyl sulfone, 34.2kg sodium carbonate, 3.42kg potassium bicarbonate, 0.342kg cesium carbonate, 90kg N,N'-dimethylacetamide and 22.5g 3 -Fluoro-4 chlorobenzophenone, then add 32kg of biphenol, pump out the air in the kettle to a negative pressure of -0.05MPa, and then feed nitrogen to raise the pressure in the kettle to 3.0MPa; repeatedly pump the vacuum to a negative pressure of - 0.05MPa, then feed nitrogen to raise the pressure in the kettle to 3.0MPa, repeat the operation 5 times, and completely replace the air in the kettle; heat the temperature in the kettle to 200°C, react at a constant temperature for 1.5 hours, and raise the temperature to a constant temperature of 250°C After reacting for 5 hours, add 127.5g of 3-fluoro-4 chlorobenzophenone, react for 15 minutes, stop the reaction, and obtain polymerized mucus;

[0028] Post-processing: Cool the reacted liquid at a constant temperature of 20°C, then crush and pulverize it, p...

Embodiment 3

[0030] In a 200-liter stainless steel reaction kettle equipped with a nitrogen pipe, a condensation water separator and a high-efficiency stirrer, 35.0kg of 4,4-dichlorodiphenyl sulfone, 22.2kg of biphenol, 14.0KG of sodium carbonate, 58g of 3 -Fluoro-4 chlorobenzophenone, then add 100.00kg N,N'-dimethylformamide. After pumping air to reduce the pressure inside the kettle to -0.09MPa, introduce nitrogen to raise the pressure inside the kettle to 0.01MPa, repeat this process five times to vacuumize and introduce nitrogen to replace the air in the kettle, and finally introduce nitrogen to reduce the pressure in the kettle to 0.01MPa. The pressure was raised to 2.0MPa. Heat to make the temperature in the kettle reach 200°C to form a salt at a constant temperature for 1 hour, then raise the temperature to 210°C and polymerize at a constant temperature for 3 hours, then add 92 g of 3-fluoro-4-chlorobenzophenone, react for 20 minutes, stop the reaction, and obtain a polymerized slim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com