Patents

Literature

52 results about "White Fiber" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A type of striated skeletal muscle fiber that contracts quickly and contains small amounts of mitochondria, myoglobin and sarcoplasm.

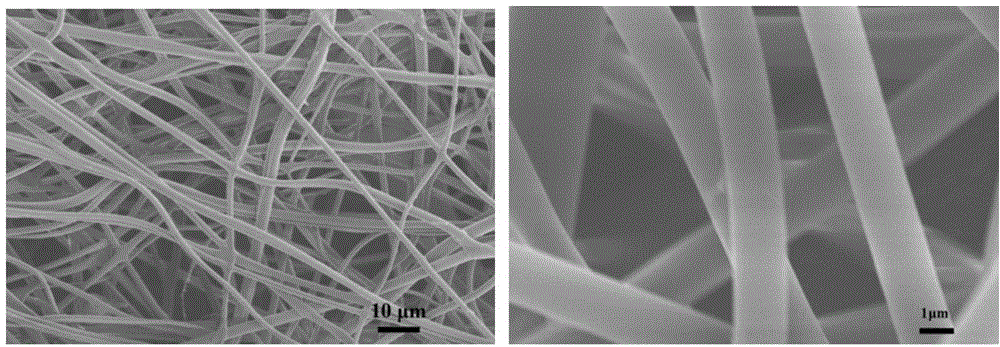

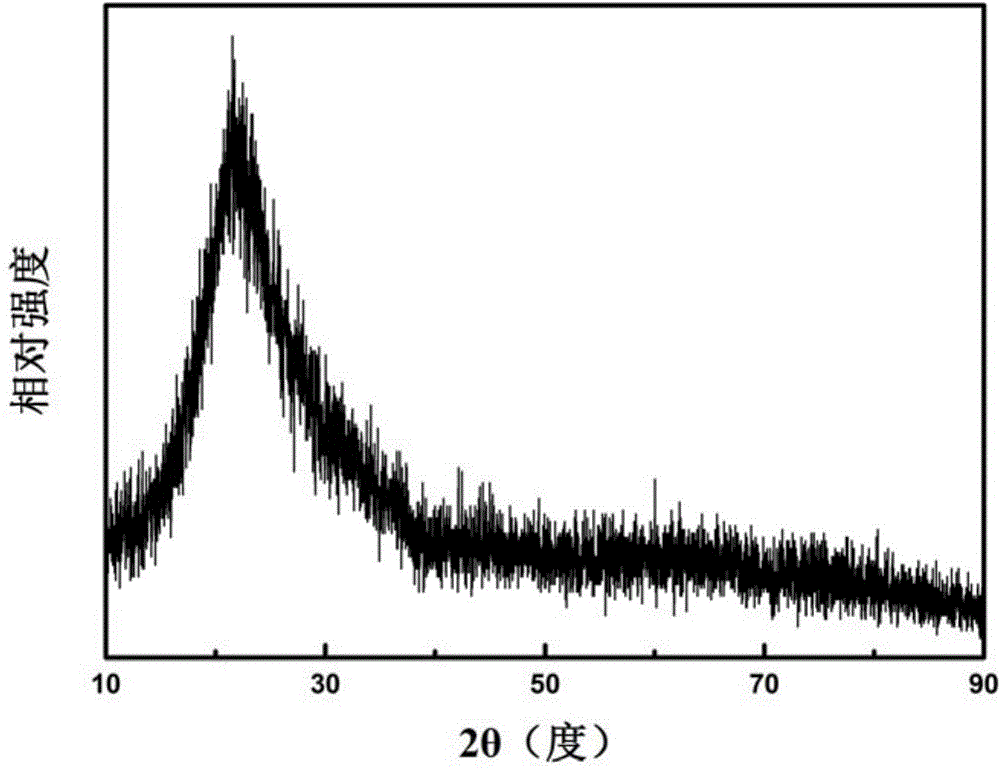

Preparation method of flexible silicon dioxide fiber film

InactiveCN103603136AHigh yieldThe preparation method is simple and feasibleFilament/thread formingFibre chemical featuresFluorescencePhosphoric acid

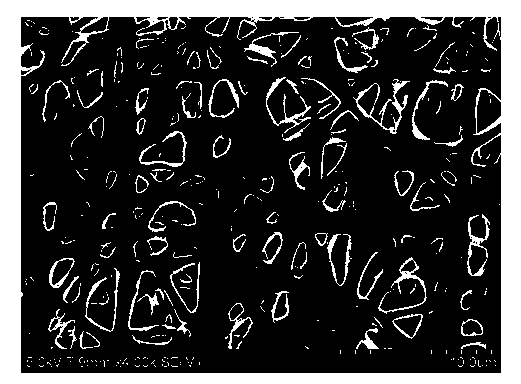

The invention relates to a preparation method of a flexible silicon dioxide fiber film. The method includes: (1) mixing tetraethyl orthosilicate, ultrapure water and phosphoric acid at room temperature to obtain a transparent and clear silicon source solution; (2) dissolving polyvinyl alcohol in the ultrapure water with stirring at the temperature of 80-90 DEG C for 4-5 hours to obtain a polyvinyl alcohol solution; (3) mixing the silicon source solution with the polyvinyl alcohol solution to obtain a colorless clear spinning solution, standing and ageing prior to electrostatic spinning, and collecting a layer of uniform white fiber film; (4) putting the white fiber film in a muffle furnace, heating to 500 DEG C prior to retaining the temperature for 2-4 hours, then heating to 800 DEG C prior to retaining the temperature for 2-3 hours, and finally naturally cooling to obtain the flexible silicon dioxide fiber film. The preparation method is simple, and the prepared silicon dioxide fiber film is resistant to organic solvents and corrosion, has good flexibility after being subjected to high temperature and has potential application in the fields of catalyst loading and fluorescent films.

Owner:DONGHUA UNIV

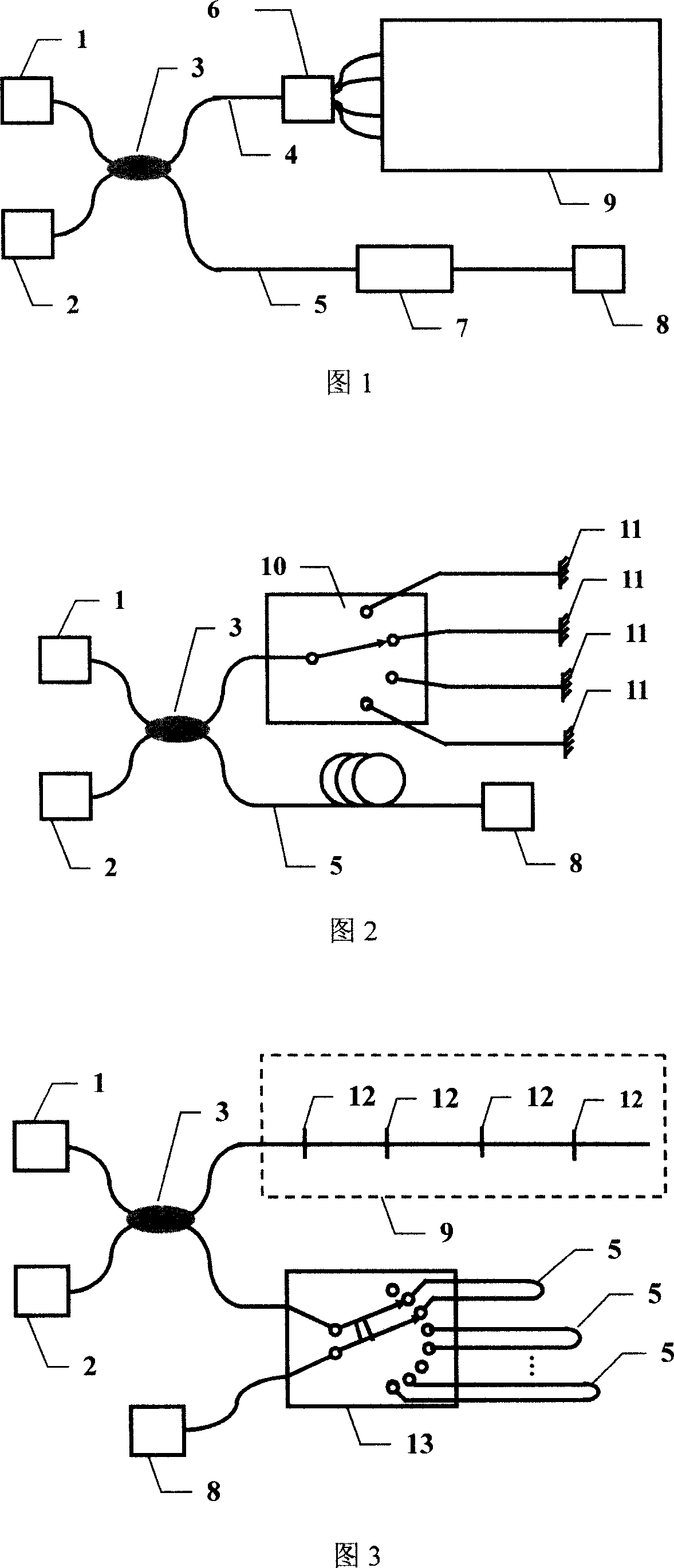

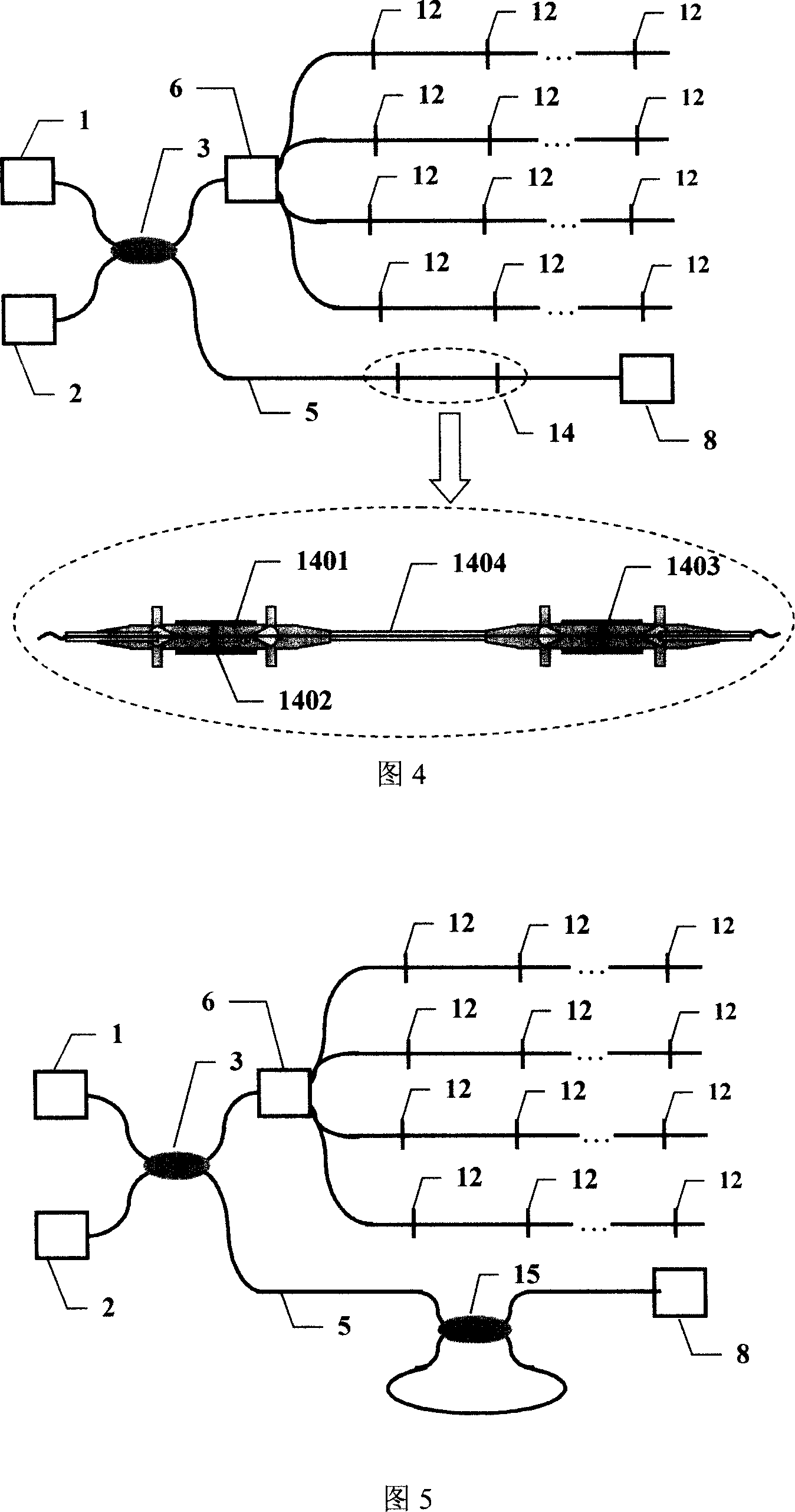

Multiplex fibre optic interferometer and nesting constructing method of the same

InactiveCN1963399ARealize inquiryRealize measurementUsing optical meansConverting sensor output opticallyMultiplexingSensor array

This invention relates to one fiber intervene device based on space-division multiplex principle, which uses imbedded fiber router and light process jump sum optical retard in white light intervene to form the white fiber intervene based on the above technique to realize multiple fiber intervene imbedding and multiplexing. The invention is to solve the multiple path multiplex process of fiber to realize sensor array and internet.

Owner:HARBIN ENG UNIV

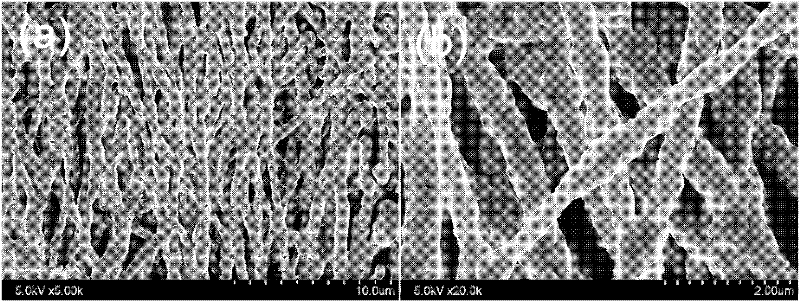

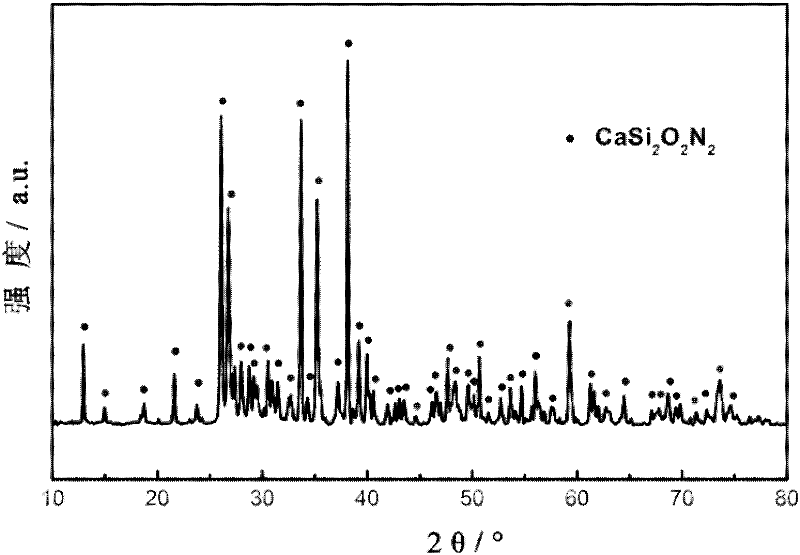

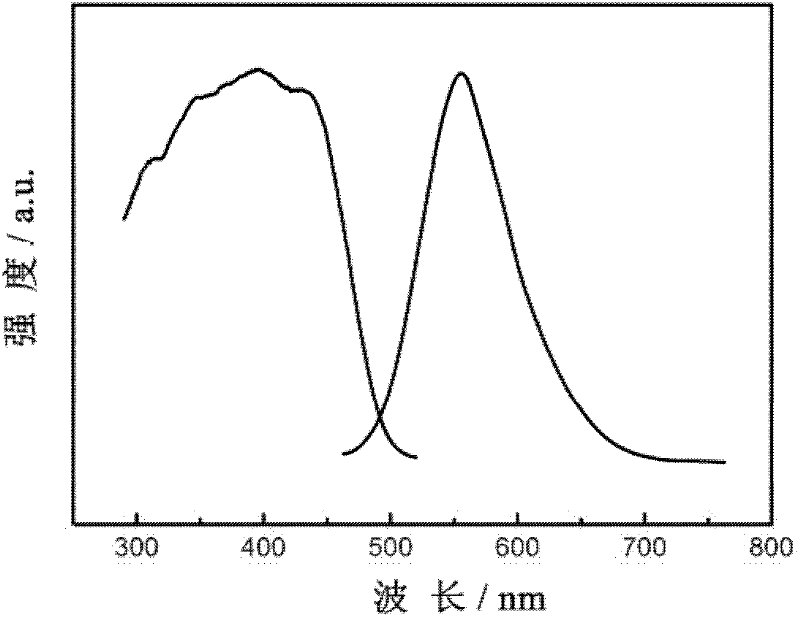

Preparation method for CaSi2O2N2:Eu<2+> fluorescence nano-fiber

InactiveCN102358963AGood fiber shapeSimple methodFilament/thread formingArtificial filament heat treatmentFluorescenceSolvent

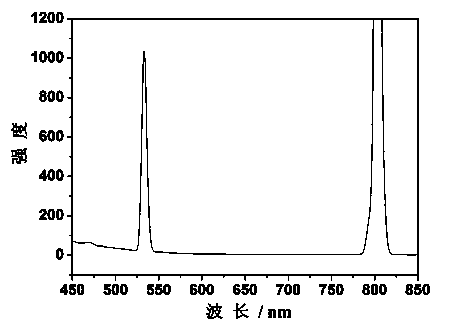

The present invention relates to a preparation method for CaSi2O2N2:Eu<2+> fluorescence nano-fiber. The method comprises the following steps: (1) dissolving calcium nitrate and europium nitrate in a mixed solvent comprising alcohol and water; adding tetraethyl orthosilicate while stirring; adding polyvinylpyrrolidone after stirring; continuously stirring to obtain a spinning liquid; (2) pouring the spinning liquid into a syringe, carrying out electrostatic spinning to collect a layer of uniform white fiber on receiving aluminum foil; (3) placing the white fiber into a high-temperature tubularatmosphere furnace to carry out a heat treatment; finally carrying out cooling along with the furnace to obtain the CaSi2O2N2:Eu<2+> fluorescence nano-fiber. The method of the present invention has characteristics of simpleness, low nitridation temperature and short time. The prepared CaSi2O2N2:Eu<2+> phosphor has good fiber morphology so as to contribute to improvement of the luminescent property and the later package in the LED, and has a good application prospect.

Owner:DONGHUA UNIV

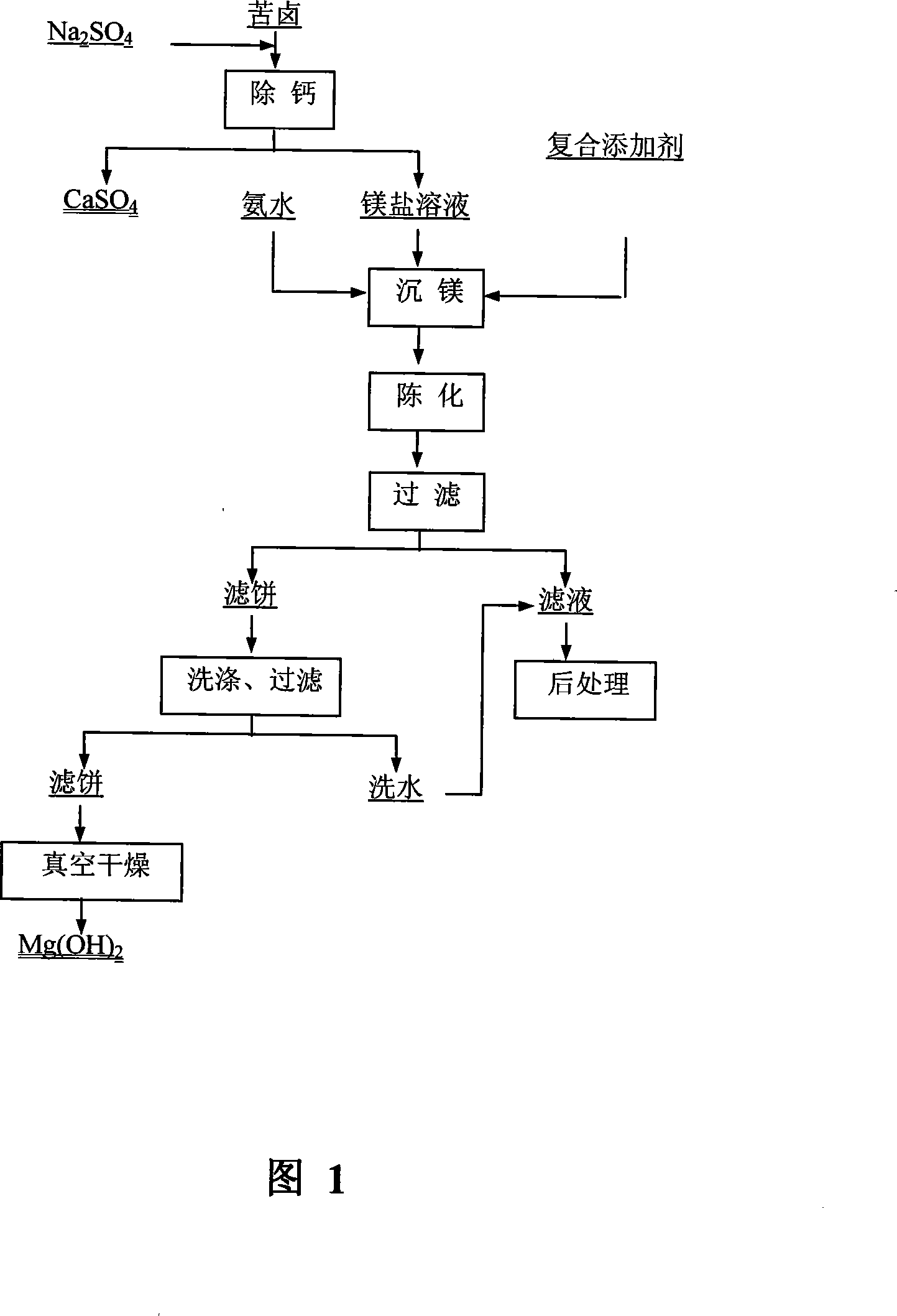

Method for preparing fibrous nano magnesium hydrate

InactiveCN101177289AReduce energy consumptionReduce fillingNanostructure manufactureMagnesium hydroxideReaction temperaturePotassium

The invention relates to a preparation method of a fiber-shaped nanometer magnesium hydroxide. The bitter brine of the discharge liquid after extraction of potassium, lithium, boron and other elements from the salt lake water is used as the raw material; the ammonia liquor or the sodium hydroxide solution is taken as the precipitant; the mixed solution of absolute ethanol, gelatin and lauryl sodium sulfate is used as the compound dispersing agent; the technological proposal is that the precipitation reaction is carried out at room temperature; through a serial procedures of heating and aging, washing in the dilute ammonia liquor, filtering, drying in the vacuum and grinding, the pure-white fiber-shaped nanometer magnesia powder is prepared with an average size of 30 to 80nm in diameter and 200 to 500nm in length. When the fiber-shaped nanometer magnesia powder is used as an inorganic flame retardant, the filling amount needed decreases significantly and the fiber-shaped nanometer magnesia powder can reinforce and toughen the polymer materials; the reaction temperature is the normal temperature, which reduces the energy consumption significantly; the fiber-shaped nanometer magnesia powder also develops a new method for comprehensive utilization of the salt lake resources.

Owner:KUNMING UNIV OF SCI & TECH

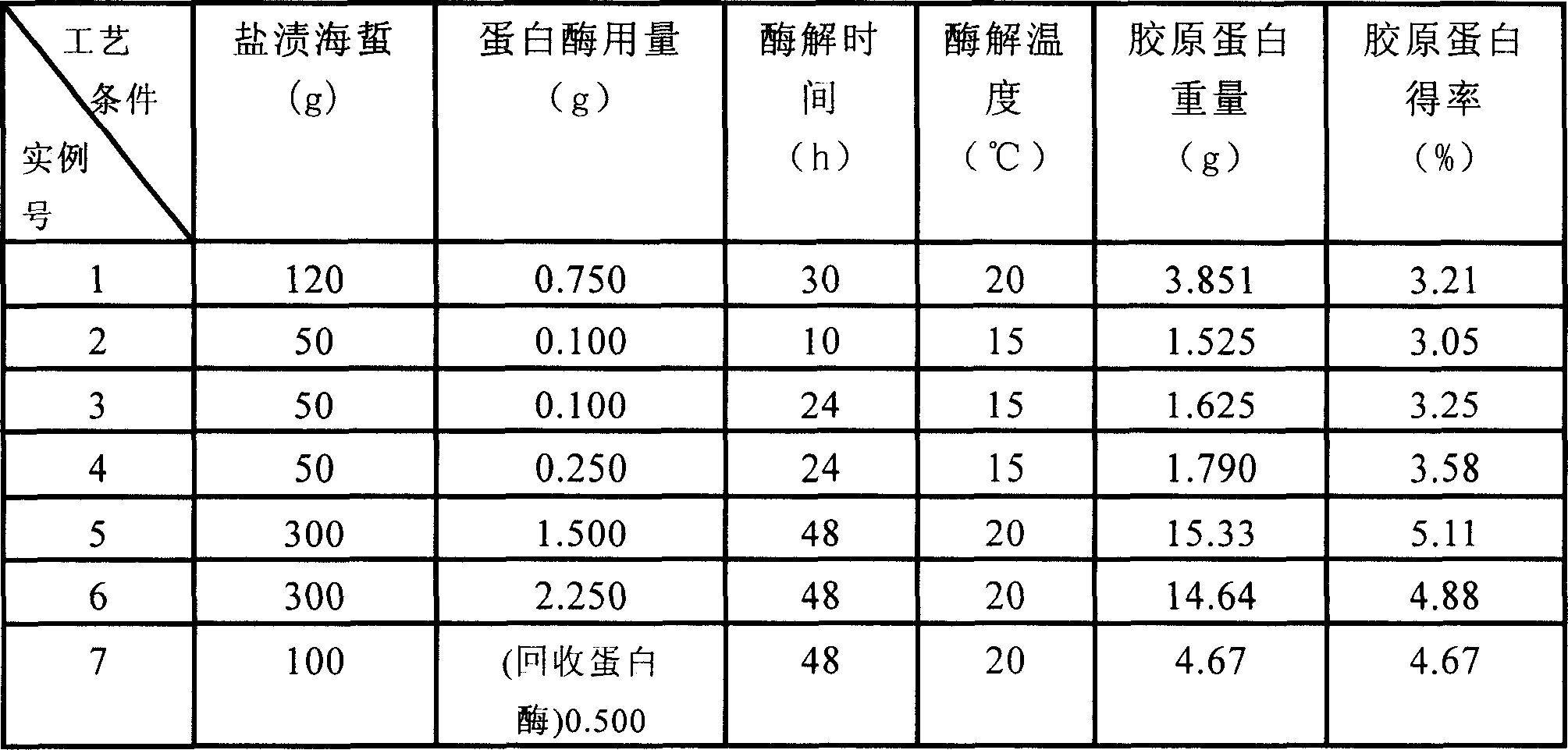

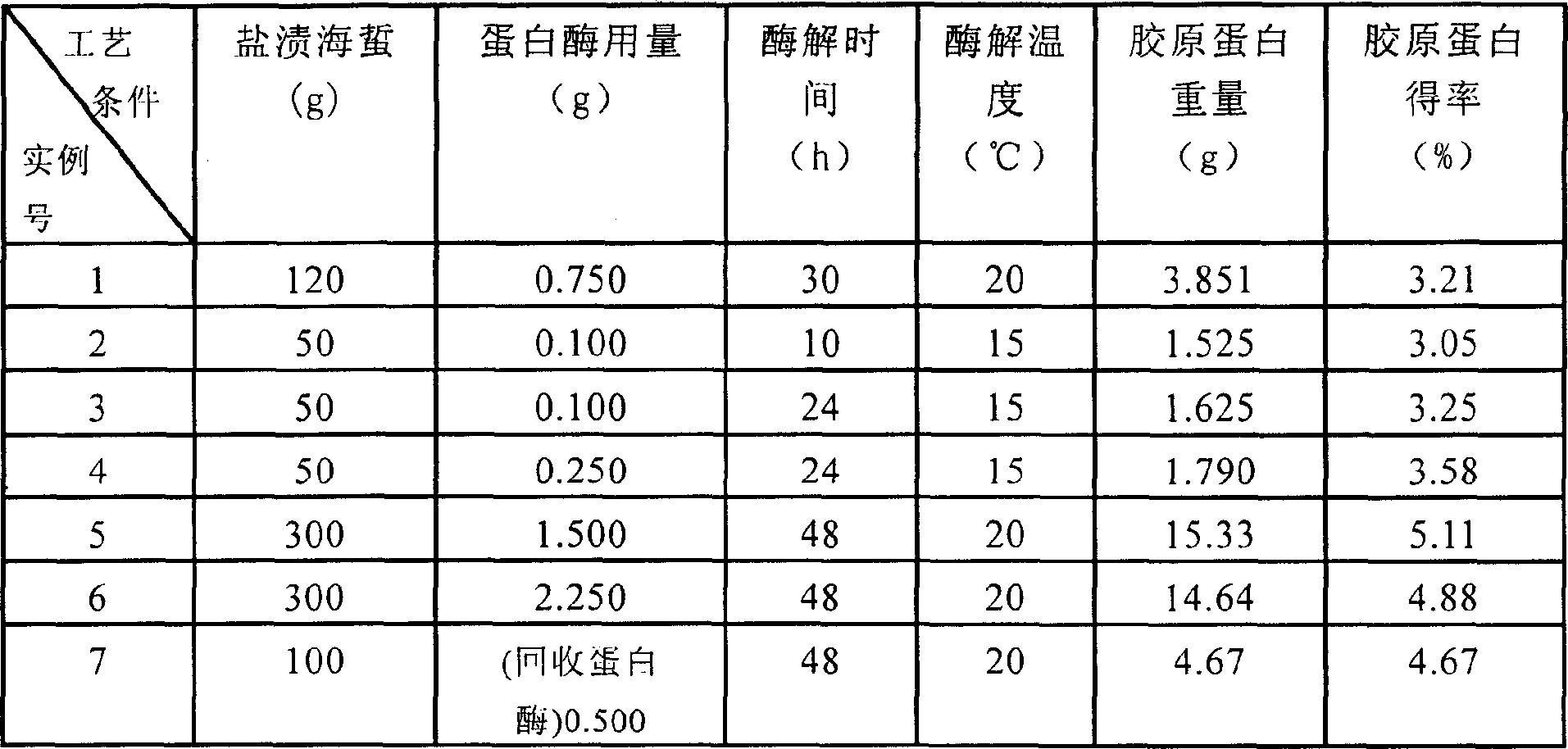

Jellyfish collagen and method for preparing the same

InactiveCN1803836ARestore activityRetain activityProtein composition from fishPeptide preparation methodsThreonineRhopilema esculentum

The disclosed collagen extracted from jellyfish mesoglea belongs to white fiber solid or light-yellow solid powder with bulk density as 0.110-0.645g / ml, shows clear liquid after dissolving in acidic solution completely; has single-bond molecular weight as 100-300 thousands dalton, sugar content as 2.5-5%, amino acid content as 80-95%mg / 100mg with 7.9-8.3% aspartic acid, 10.0-12.9% glutamic acid, 3.5-4.0% threonine, 3.5-3.9% valine, 2.2 -2.5% isoleucine, 3.4-3.8% lycine, and 2.0-2.7% hydroxylysine. Besides, the opposite preparation method comprises: (1) selecting salinized or fresh jellyfish; (2) pre-treating; (3) separating the mesoglea; (4) dissociating mesoglea; (5) ultrafiltrating, separating, and condensing. This invention has trapping rate as 95-98% and high product purity.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

Microwave-assisted preparation method of bagasse bleached pulp

InactiveCN104005247AObvious advantagesHigh whitenessCellulose material pulpingAnthraquinonesSodium hydroxide

The invention discloses a microwave-assisted preparation method of bagasse bleached pulp, which is a method for clean and high-efficient preparation of bagasse bleached pulp by microwave radiation technology. The method comprises: performing microwave heating and water extracting treatment of air-dried bagasse raw materials, repeatedly soaking and cleaning the treated materials with deionized water to be neutral, then performing dehydration and dispersion, rapidly determining the water content of the dispersed materials, then performing delignification treatment of the materials with a known water content by sodium hydroxide / hydrogen peroxide / anthraquinone, finally soaking, dispersing and washing the treated pulp to be neutral, removing excessive water, and sealing to obtain the bagasse bleached pulp. The bagasse bleached pulp prepared by the method is milk white or in a white fiber form, low in paper pulp kappa number, high in whiteness, and moderate in viscosity.

Owner:KUNMING UNIV OF SCI & TECH

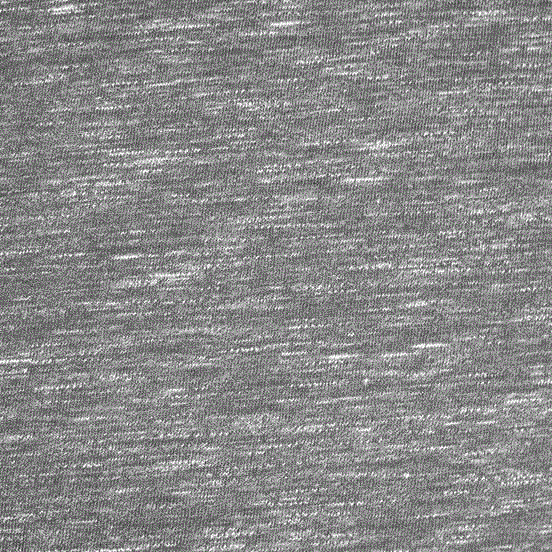

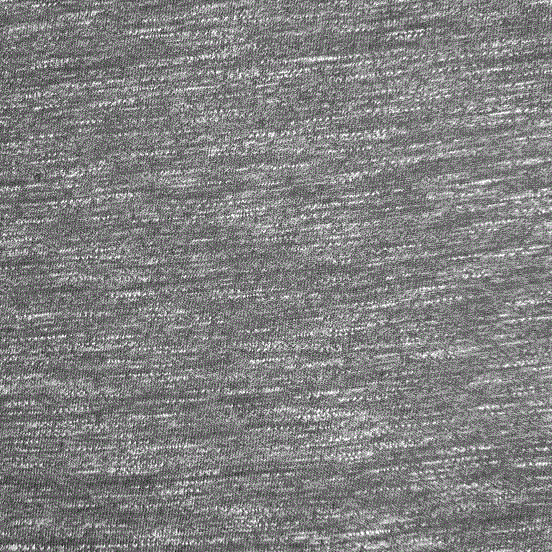

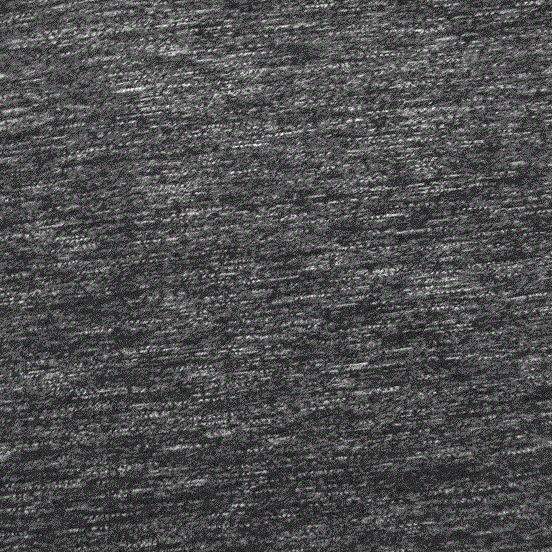

A method of preparing a color-mixed colorized pattern-carrying fabric based on color matching of primary color fibers

A method of preparing a color-mixed colorized pattern-carrying fabric based on color matching of primary color fibers is disclosed. The method includes: forming four fiber primary colors by adopting yellow, pinkish red, green, black and white fibers as raw materials, and blending and weaving fibers having at least three colors from the yellow, pinkish red, green, black and white fibers of the same kind, or fibers having at least three colors from yellow, pinkish red, green, black and white fibers of the different kinds. The color-mixed colorized pattern-carrying fabric shows randomness and irregularity in appearance and styles to a larger degree, and is enhanced in color layering sense and novel in style. The method can reduce reserves of dye varieties and color fiber varieties, thus reducing overstocked funds, and facilitating management.

Owner:泰州吉泰毛纺织染厂 +2

Production method for fiber color art paper

ActiveCN103074808AStrong binding strengthHigh bonding strengthSpecial paperPaper/cardboardOperabilitySlurry

The invention relates to a production method for fiber color art paper, which comprises the following steps: preparing and dyeing basic slurry, preparing fiber slurry and mixing the slurry, wherein the step of dyeing the basic slurry is completed by adding dyes into a dosing jar so as to form deep-color basic slurry in single color; during a drifting process of the dyed basic slurry, mixing the prepared fiber slurry with the dyed basic slurry, wherein the fiber slurry is added into a drifting pipeline in front of a pressure screen of a paper machine; after mixing the dyed basic slurry with white fiber slurry, adding dispersing agents; making paper with pulp on a paper machine; and after putting onto a net and dewatering, shaping, drying and reeling, forming the fiber color art paper with excellent natural texture and with white fibers distributed in deep-color backing paper. The fiber color art paper has the advantages that the processing and manufacturing are easy, the production technology is reliable, the operability is strong, the fiber bonding strength is excellent, the color is rich and various and the paper surface has natural textures. The fiber color art paper is mainly applied to the packaging of special products, various certificates, book covers, restaurant menus, wine lists, and the like.

Owner:SHANDONG KAILI SPECIAL PAPER

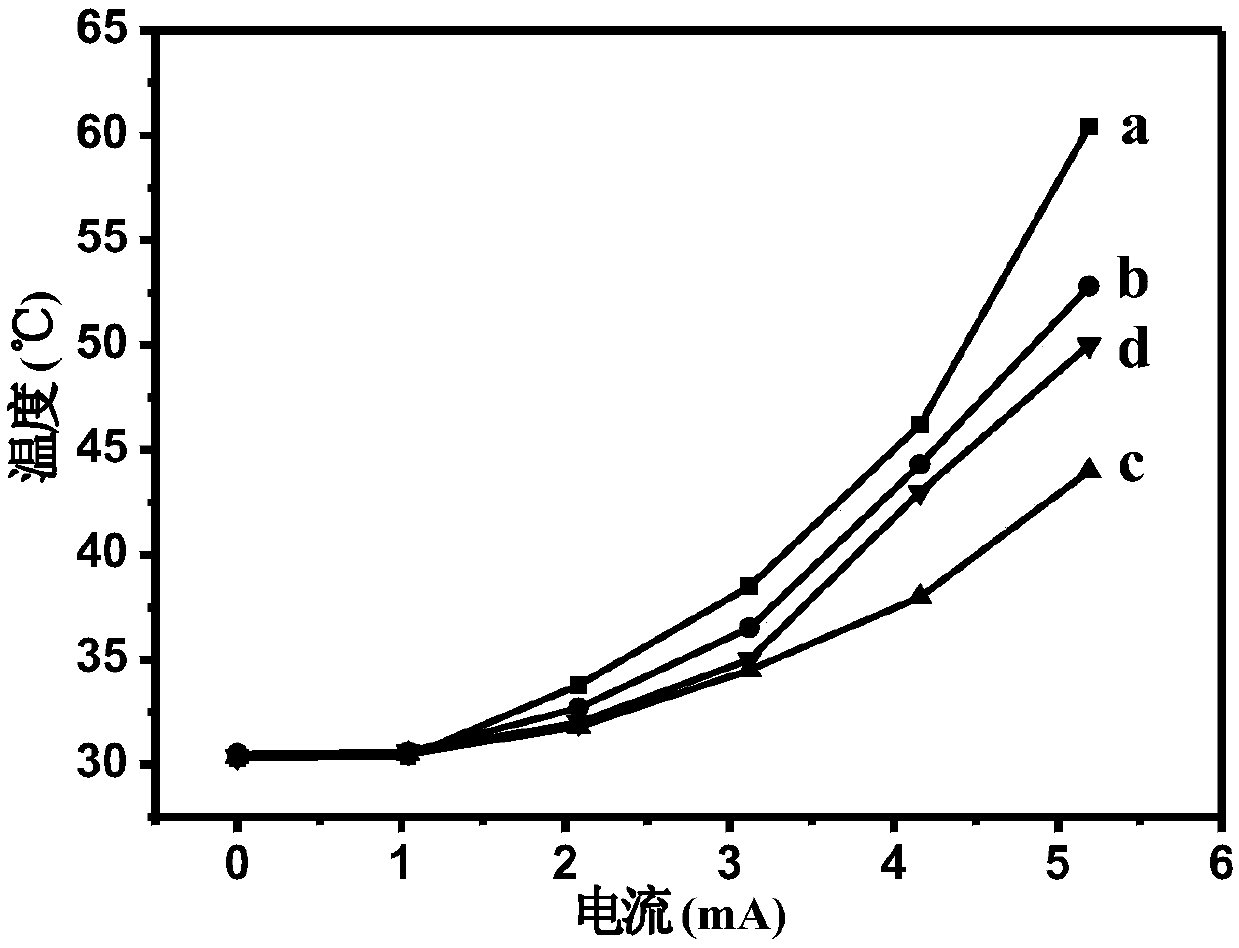

Electrochromic yarn and preparation method thereof

The invention relates to an electrochromic yarn and a preparation method thereof. The preparation method of the electrochromic yarn comprises the following steps: 1, cleaning a fiber roving strip, andthen immersing the fiber roving strip in a dispersed aqueous solution of a carbon nanotube to obtain a carbon nanotube / fiber roving strip; 2, carrying out spinning by utilizing the carbon nanotube / fiber roving strip so as to obtain a carbon nanotube / fiber composite yarn; 3, winding white fibers on the surface of the carbon nanotube / fiber composite yarn so as to obtain a carbon nanotube wrapped yarn; and 4, coating thermochromic ink on the surface of the yarn and carrying out air cooling at a room temperature so as to obtain the electrochromic yarn. The preparation method is simple and low inpreparation cost, and is capable of reducing the electric resistance of the yarn to 300 omega / cm at the minimum; and the thermochromic ink is used for coating on the surface layer of the wrapped fibers, so that the change effect of the yarn can be changed through changing the type of the thermochromic ink. According to the preparation method, white color-changing yarns can be obtained, and the colors of the color-changing yarns are not affected by the natural colors of the yarns.

Owner:WUHAN TEXTILE UNIV

Air-jet vortex spinning fancy yarns and production technology thereof

InactiveCN109972254AOvercome limitationsImprove stylingContinuous wound-up machinesOpen-end spinning machinesYarnPolymer science

The invention relates to air-jet vortex spinning fancy yarns and a production technology thereof. Fancy yarn bodies are involved, each fancy yarn body comprises mixed fibers composed of at least two types of colored fibers or one or more types of colored fibers and raw white fibers, and the production technology comprises the following steps that step one, the colored fibers with the fiber fineness of at least 3D are subjected to pure spinning to obtain thick yarns; step two, one or more types of colored fibers with the fiber fineness between 1D-2D or the mixed fibers composed of one or more types of colored fibers and the raw white fibers are prepared into drawing slivers; step three, the thick yarns prepared in the step one and the drawing slivers prepared in the step two are prepared into the air-jet vortex spinning yarns. The technology solves the problem of limitation of the air-jet vortex spinning yarn style and adds styles of air-jet vortex spinning products, and products whichhave diversified colors and rich cloth cover effects and can meet the requirements of consumers for individuation and fashion-orientation are produced.

Owner:DEZHOU FUHUA ECOLOGY TECH

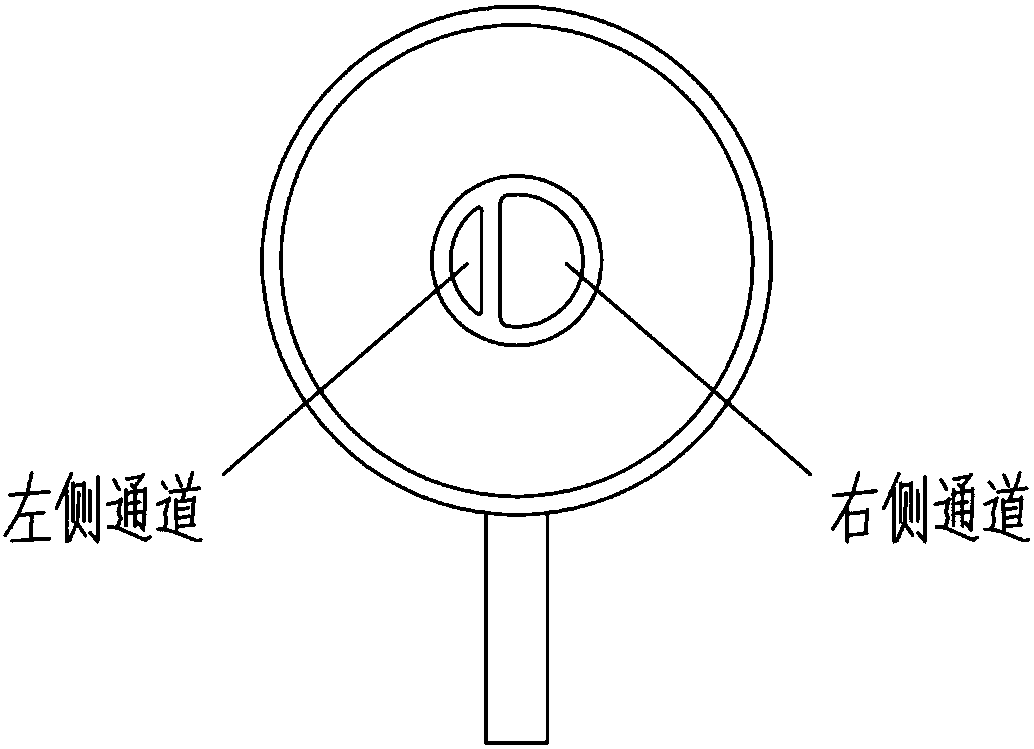

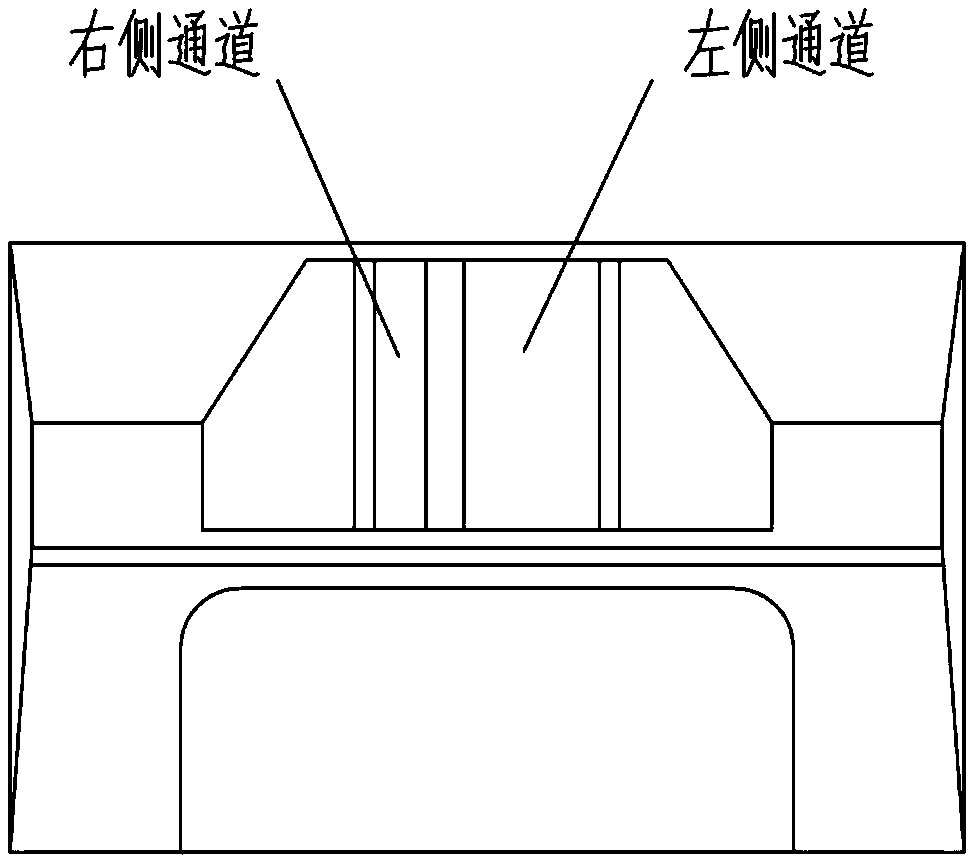

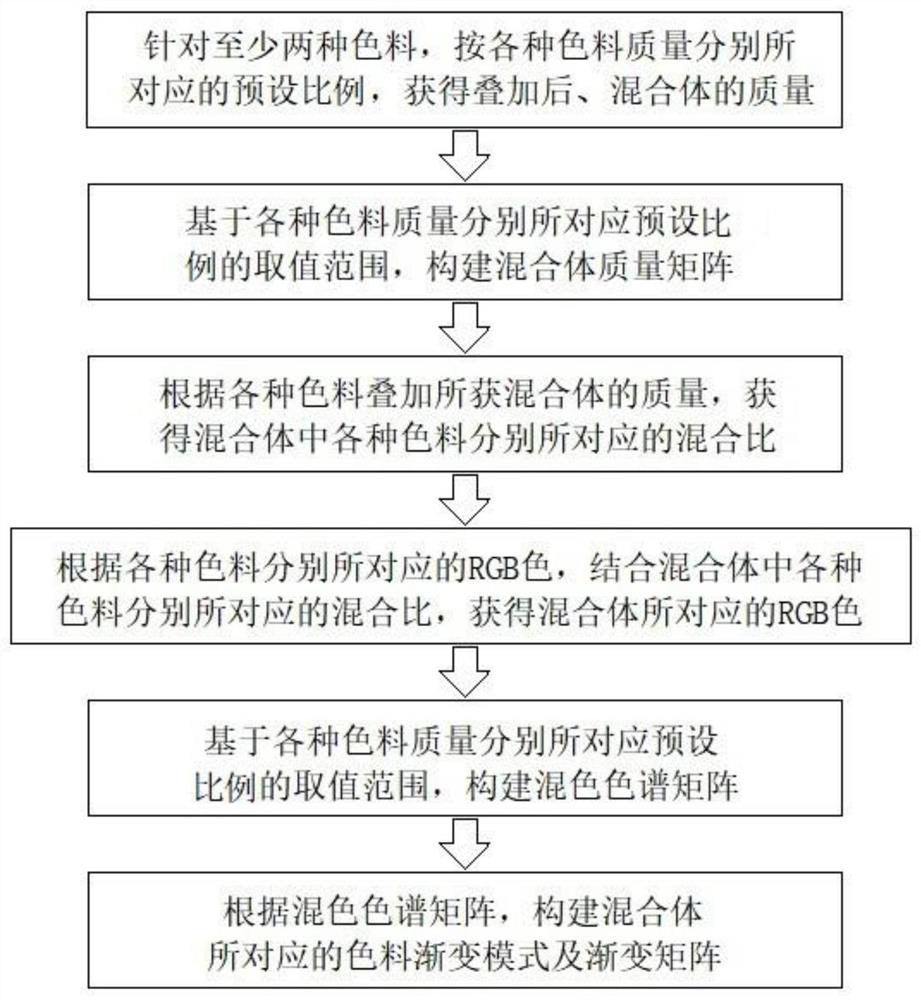

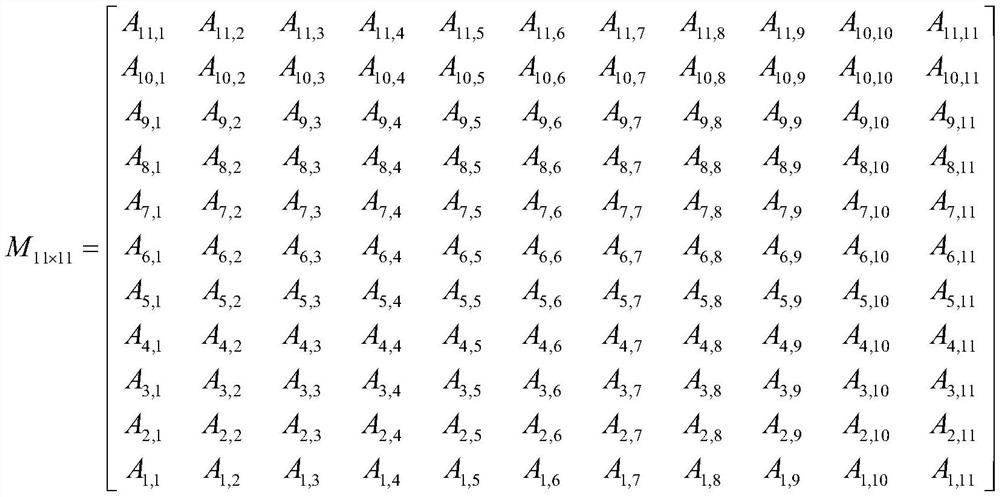

Construction and application of multi-dimensional superimposed color mixing model and gradient chromatographic matrix algorithm

ActiveCN112733079ARealize digital virtual color matchingIntuitive color matchingTextile treatment machine arrangementsManufacturing computing systemsYarnHue

The invention relates to construction and application of a multi-dimensional superimposed color mixing model and a gradient chromatography matrix algorithm. A brand-new digital color matching logic design is adopted to construct a pigment discrete color mixing model and a visualization algorithm of a color mixing chromatography of the pigment discrete color mixing model, and digital virtual color matching of color yarns is realized. In actual application, standard color mixing chromatography can be constructed by combining and blending five primary color fibers such as yellow, cyan, fuchsin, black and white fibers, a reference basis can be provided for color matching of color yarns, and a digital model of pigment color matching is specifically constructed; an algorithm and chromatographic big data of serialized mixed chromatography based on pigment blending are constructed, and a complete hue based on pigment color blending and a full chromatographic system with different lightness and saturability are included; a color gradient mode based on pigment blending and gradient chromatography big data are constructed; and compared with a traditional color matching scheme, the obtained color matching is visualized, and the working efficiency of actual chromatography construction is improved.

Owner:YUYUE HOME TEXTILE

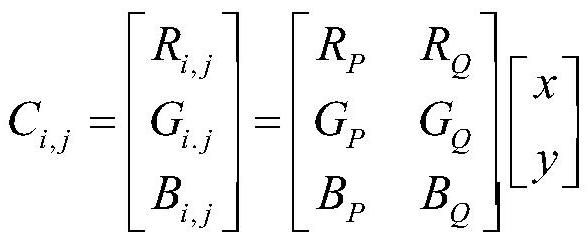

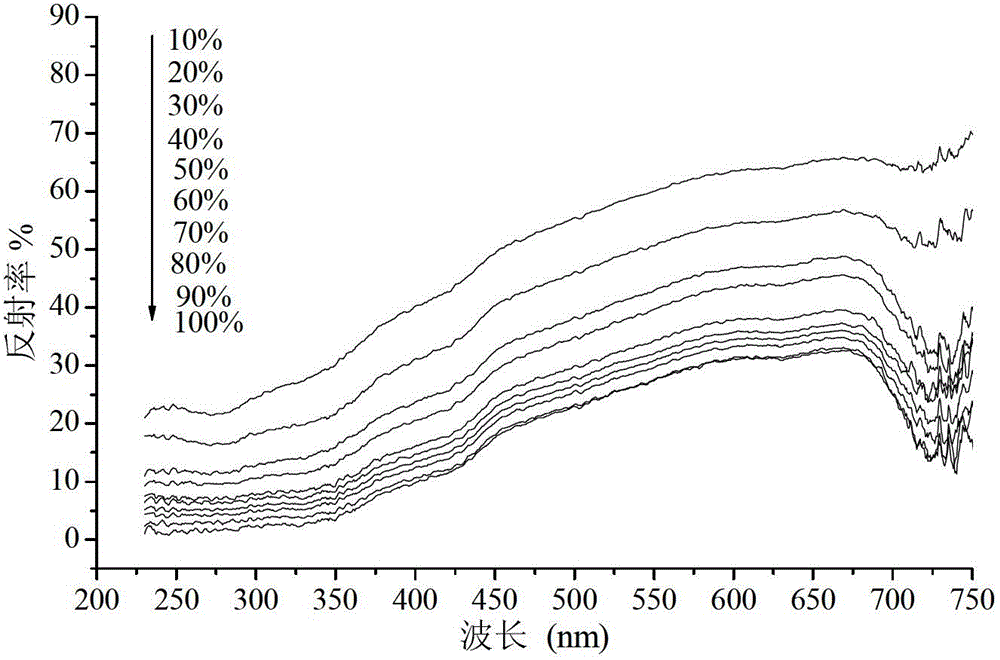

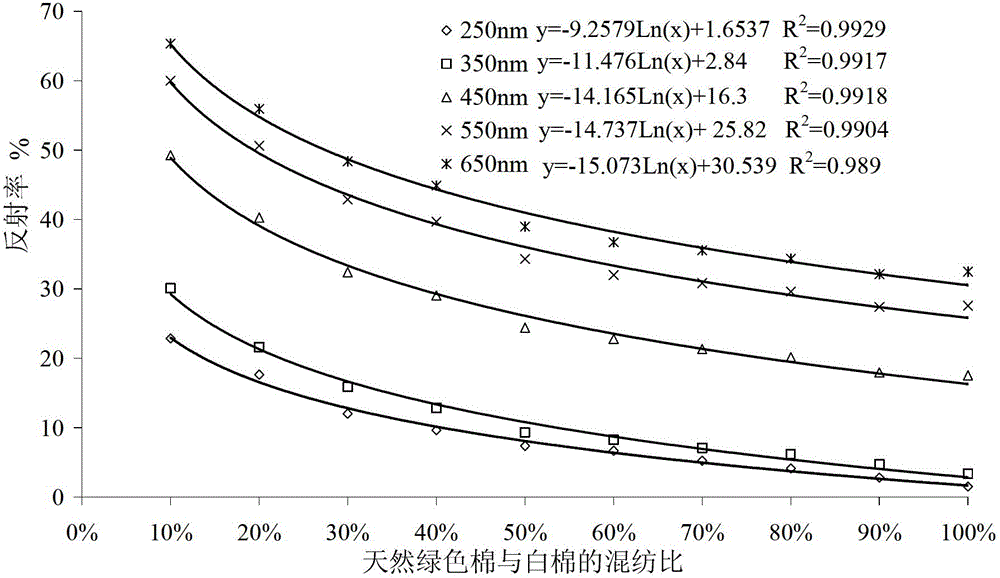

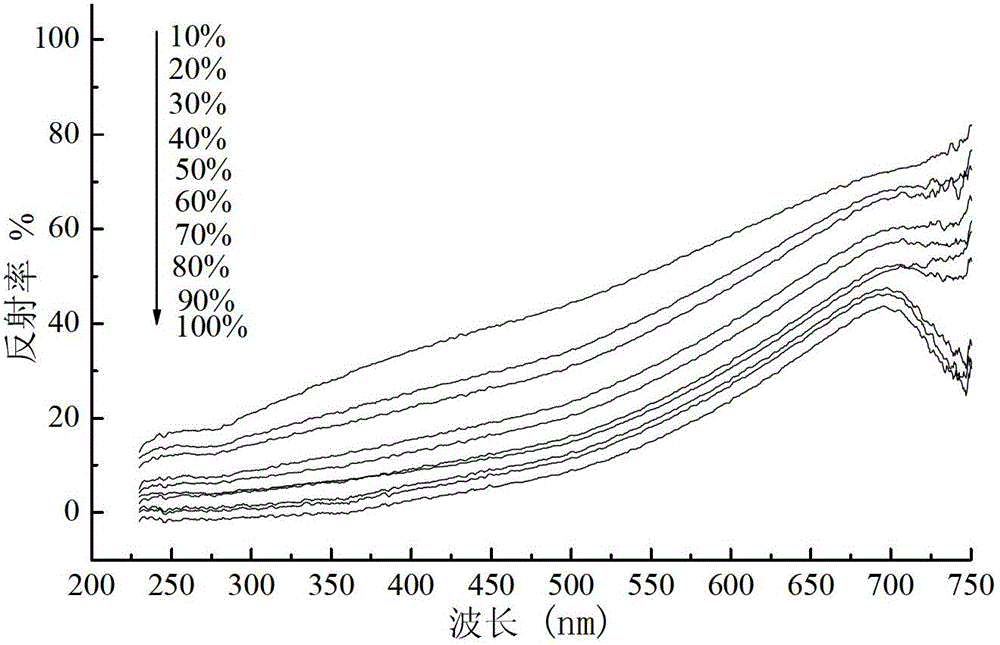

Quantitative determination method for natural colored cotton fiber blending ratio

ActiveCN103063578AEfficient detectionReduce the number of timesColor/spectral properties measurementsQuantitative determinationUltraviolet

The invention discloses a quantitative determination method for natural colored cotton fiber blending ratio and uses a blending product composed of a natural colored cotton fiber and a white fiber as object to be tested. The method comprises the following steps: (a), respectively smashing the natural colored cotton fiber and the white fiber; and (b), mixing evenly the powder of the natural colored cotton fiber and the powder of the white fiber according to echelonment proportion; and (c), performing ultraviolet diffuse reflection spectrometry on mixture with different fiber blended ratio and powder of pure natural colored cotton fiber, so that the corresponding graph-of-relation of reflectivity and wavelength is established; and (d) analyzing the correlation of reflectivity and fiber blended ratio under different wavelengths, so that the quantitative calculation model of correlation quantitation is established; and (e), selecting a characteristic wavelength; and (f) using the selected characteristic wavelength to determinate the ultraviolet diffuse reflectance of the object to be tested, and calculating the blended ratio of the object to be tested through the selected quantitative calculation model.

Owner:ZHEJIANG SCI-TECH UNIV

A method of preparing a homogeneous plain-color fabric based on color matching of primary color fibers

A method of preparing a homogeneous plain-color fabric based on color matching of primary color fiber is disclosed. The method adopts yellow, pinkish red, green, black and white fibers as raw materials, and includes steps of determining a blending ratio of four primary-color fibers and the white fiber according to a target color through computerized color matching, and homogenizing by adoption of a blending technology in conventional spinning methods to obtain the homogeneous plain-color fabric. Appearance of the plain-color fabric is similar to that of slub dyeing or piece dyeing plain-color fabrics, but the plain-color fabric shows multi-color fiber in the micro scale. The plain-color fabric is obtained by blending and weaving yellow, pinkish red, green, black and white fibers of the same kind, or different kinds. The method can reduce reserves of dye varieties and color fiber varieties, thus facilitating management, and can effectively overcome the problem that a plurality of kinds of fiber blended fabrics which are conflict in dyeing conditions are difficult in piece dyeing.

Owner:泰州吉泰毛纺织染厂 +2

Glowing nanometer fibre with biocompatibility and preparation method of glowing nanometer fibre

InactiveCN103806115AGood biocompatibilityBoth luminousNew-spun product collectionArtificial filament physical treatmentPolymer scienceSpinning

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Raw tipping paper with high quality and good breaking resistance degree and preparation method thereof

ActiveCN104005298AImprove the level ofImprove spicy tasteFlexible coversWrappersMolecular sieveFluff pulp

The invention discloses raw tipping paper with high quality and good breaking resistance degree. The raw tipping paper is characterized by being prepared from following raw materials in parts by weight: 45-48 parts of pine pulp, 53-56 parts of fluff pulp, 4-6 parts of phoenix tree barks, 1-2 parts of gelonium, 2-3 parts of polyvinylpyrrolidone, 1-2 parts of alums, 2-3 parts of calcium carbonate, 2-4 parts of a zeolite molecular sieve, 1-3 parts of silicone rubber, 0.8-1 part of beta-carotene, 1-2 parts of lithopone, 2-3 parts of carboxymethylcellulose, 1-2 parts of an auxiliary agent and suitable amount of water. According to the raw tipping paper, prepared phoenix tree bark fibers are added into papermaking pulp so that a product has white fibers which are uniformly distributed; a paper sheet is firm and durable, has good breaking resistance degree and is smooth and fine; the raw tipping paper has a good printing ink leveling performance; the auxiliary agent is added so that the raw tipping paper has a certain adsorption effect, has a pleasant aroma and can be used for improving the spicy taste of smoke.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

Preparation technology of 'weaving and then dyeing' normal pressure one-bath dyeing multi-color fabric

ActiveCN110205731AComfort moisture wicking functionReduce manufacturing costWeft knittingWarp knittingYarnPolyester

The invention discloses a preparation technology of a 'weaving and then dyeing' normal pressure one-bath dyeing multi-color fabric, relates to the technical field of spinning and mainly solves problems in the preparation process of a traditional multi-color fabric. The technology includes the steps: preparing a white gray fabric woven with various fibers with different dyeing performances; dyeingthe white gray fabric. The various fibers with the different dyeing performances comprise at least one of NECDP (novel easy cationic dyeable polyester) profiled fibers or NEDDP (novel easy disperse dyeable polyester) profiled fibers. A previous 'weaving and then dyeing' yarn-dyed weaving production technical idea is newly explored and developed, only several limited white fibers need to be prepared, the complexity of inventory increase due to dyeing of past 'weaving and then dyeing' yarn-dyed fabrics into multi-color yarns according to different designs and colors before weaving is omitted, and production cost and management trouble can be greatly reduced.

Owner:青岛新维纺织研究院有限公司

Polysulfone resin preparing method with microwaves as heat source

The invention discloses an efficient polysulfone resin preparing method with microwaves as a heat source. The preparing method includes the steps that 4,4'-dichloro(di)phenyl sulfone and bisphenol A serve as initial raw materials, carbonate with the mole number two times that of the bisphenol A is added to serve as alkali, and the mixture is heated and reacted for 2 hours to 5 hours through a microwave reactor in high-boiling-point aprotic polar solvents; then the reaction liquid is slowly poured into deionized water, white fiber-shaped polymers are obtained, then the polymers are soaked for 5 hours to 10 hours under the 60-DEG-C-to-80-DEG-C condition, the process is repeated three times to five times, filtering and drying are carried out, and polysulfone resin is obtained through vacuum drying. By means of the preparing method, the reaction time is shortened to a great degree, energy consumption is reduced, the cost for the production technology is reduced accordingly, and the working efficiency is improved.

Owner:SHANDONG JINLAN SPECIAL POLYMER CO LTD

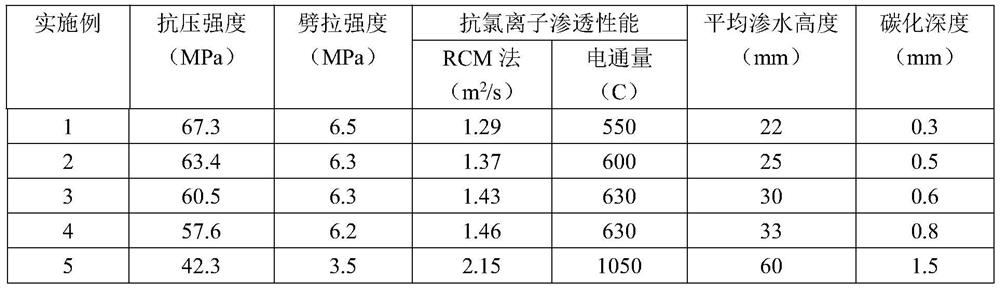

White fiber high-performance C50 pump concrete

The invention discloses white fiber high-performance C50 pump concrete, which comprises the following components: cement, fly ash, slag micro-powder, silica fume, basalt fiber, quartz sand, macadam, an additive, mixing water and titanium dioxide pigment. The white fiber high-performance fair-faced concrete prepared by the invention has the following characteristics: the white fiber high-performance fair-faced concrete has relatively strong tensile strength and ductility, the appearance is white and does not change along with time, the surface performance of fair-faced concrete is realized, bubbles are few, and color is uniform. The concrete disclosed by the invention is used as a concrete base material for a structure, mainly plays roles in pressure resistance, crack resistance, permeationresistance and attractiveness, and has a relatively high application value in the field of building and bridge structure concrete.

Owner:HEFEI UNIV OF TECH +1

Making method of colored spun yarn supportive of being used for jean water-washing

The invention discloses a making method of colored spun yarn supportive of being used for jean water-washing. The colored spun yarn with specific style is made from active indigo-series dyed fiber andcommon white fiber. Jean fabric with washed-old or locally-washed-white style can be obtained by adopting jean water-washing methods like common washing, snow washing, monkey washing and spraying decoration after the colored spun yarn is woven. The colored spun yarn made by the method is stable and controllable in color depth and color tone, high in friction color fastness and capable of servingas a prime raw material for processing jean knitted casual wear, children's jeans and jean woven garments.

Owner:BROS EASTERN

Low-cost anti-microbial flexible fabric

The invention relates to a low-cost antibacterial flexible fabric, which includes an inner layer, a waterproof layer and a surface layer. The waterproof layer is provided with air holes, and the waterproof layer faces the surface layer and the inner layer. A diversion groove one and a vertically arranged diversion groove two. The back side of the inner layer is provided with a lining fabric layer, and the lining fabric layer includes a radiation-proof layer, a water-absorbing layer and a water-permeable layer. The radiation-proof layer is the surface layer, the water-absorbing layer is the inner layer, and the water-permeable layer is the bottom layer. The radiation-proof layer It consists of warp yarns and weft yarns, the warp yarns are composed of silver fibers and filament fibers alternately, and the weft yarns are composed of carbon fibers and filament fibers alternately. The invention has good waterproof performance, antibacterial effect and soft surface. The invention has low cost.

Owner:陆秋亚

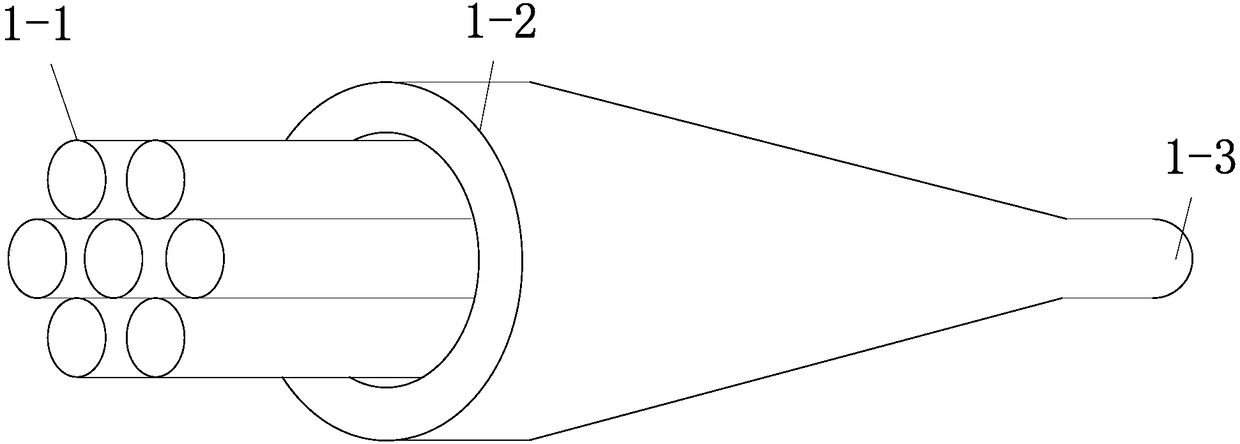

Clustered plastic fiber lantern

InactiveCN108107464AGood flexibilityIncreased durabilityX-ray spectral distribution measurementUnderwaterRefractive index

The invention discloses a clustered plastic fiber lantern which belongs to the field of astronomical photonics. The clustered plastic fiber lantern comprises a plastic fiber bundle, a plastic sleeve and a single fiber port. One end of the plastic fiber bundle is inserted into the plastic sleeve. The single fiber port is a single fiber which is formed through inserting the plastic fiber bundle intothe plastic sleeve and tapering by a plastic fiber tapering device. The plastic fiber bundle is composed of a plurality of plastic fibers with the same parameter. The refractive index of the plasticsleeve is lower than that of the plastic fiber. The diameter of the plastic fiber bundle is same with the internal diameter of the plastic sleeve. The diameter of the single fiber port is same with that of a white fiber. Compared with the prior art, the plastic fiber has advantages of high flexibility, high durability and low cost. Furthermore the clustered plastic fiber lantern satisfies requirements for spatial resolution and energy resolution and can be used for detecting an optical signal underwater.

Owner:HARBIN ENG UNIV

A kind of spinning method of segment color slub yarn

The invention is suitable for the technical field of spinning, and provides a spinning method of a sectionally colored bunchy yarn. The sectionally colored bunchy yarn is spun by a rough yarn as a basic yarn and a rough yarn as a decorative yarn on a spinning frame. The spinning method comprises the following steps of: during spinning, feeding the basic yarn from an inlet of a middle roller in the spinning frame; and feeding the decorative yarn from an inlet of a rear roller of the spinning frame. The sectionally colored bunchy yarn produced by the spinning method provided by the invention is strong in evenness irregularity, and is in particular more in hair and remarkable in color in parts attached by white fiber. Spun fabric is three-dimensional in grain of cloth cover and unique in style, so that the sectionally colored bunchy yarn can better satisfy the demand of consumers.

Owner:BROS EASTERN

Diatom ooze coating

The invention relates to a diatom ooze coating. The diatom ooze coating is prepared via uniform mixing of following raw materials, by weight, 215 to 235 parts of diatomite, 40 to 60 parts of heavy calcium carbonate, 40 to 60 parts of talcum powder, 40 to 60 parts of titanium dioxide, 65 to 85 parts of latex powder, 2 to 6 parts of hydroxypropyl methyl cellulose, 180 to 220 parts of white cement with strength grade of 42.5, 20 to 40 parts of mica powder, 10 to 20 parts of wood white fiber, 3 to 7 parts of bentonite, 290 to 295 parts of snow white colored sand, 1 to 3 parts of a water reducer, 0.5 to 1.5 parts of stretch-proof fiber, and 0.2 to 0.8 part of a negative ion powder. The diatom ooze coating is convenient for construction, is nontoxic, is odourless, is excellent in durability, and is suitable to be used in northwest regions with dry climate; and no pollution is caused.

Owner:甘肃连心涂料有限责任公司

Technology for preparing calcium sulfate whisker from dimethyl cyanoamino di-tyiocarbonate wastewater

The invention discloses a technology for preparing calcium sulfate whisker from dimethyl cyanoamino di-tyiocarbonate wastewater. The technology comprises the following steps: pretreating at the temperature of 70-90 DEG C; distilling organic impurities out of wastewater by azeotropic distillation; adding 0.1-1% of crystallization director in the wastewater; heating to 90-105 DEG C; stirring for 10-30 minutes to separate out white fiber-shaped solids; performing reflux for 1-3 hours; cooling to 20-30 DEG C; aging for 2-3 hours; and performing centrifugal drying to obtain a calcium sulfate whisker product with length of 50-300 micrometers and diameter of 1-20 micrometers. According to the method, the organic impurities in the wastewater are removed by azeotropic distillation, so that the influences of the impurities on the morphology of the calcium sulfate whisker are reduced.

Owner:南京科硕生化科技有限公司

Jellyfish collagen and method for preparing the same

InactiveCN100369929CHigh purityHigh yieldProtein composition from fishConnective tissue peptidesThreonineRhopilema esculentum

The disclosed collagen extracted from jellyfish mesoglea belongs to white fiber solid or light-yellow solid powder with bulk density as 0.110-0.645g / ml, shows clear liquid after dissolving in acidic solution completely; has single-bond molecular weight as 100-300 thousands dalton, sugar content as 2.5-5%, amino acid content as 80-95%mg / 100mg with 7.9-8.3% aspartic acid, 10.0-12.9% glutamic acid, 3.5-4.0% threonine, 3.5-3.9% valine, 2.2 -2.5% isoleucine, 3.4-3.8% lycine, and 2.0-2.7% hydroxylysine. Besides, the opposite preparation method comprises: (1) selecting salinized or fresh jellyfish; (2) pre-treating; (3) separating the mesoglea; (4) dissociating mesoglea; (5) ultrafiltrating, separating, and condensing. This invention has trapping rate as 95-98% and high product purity.

Owner:THE FIRST INST OF OCEANOGRAPHY SOA

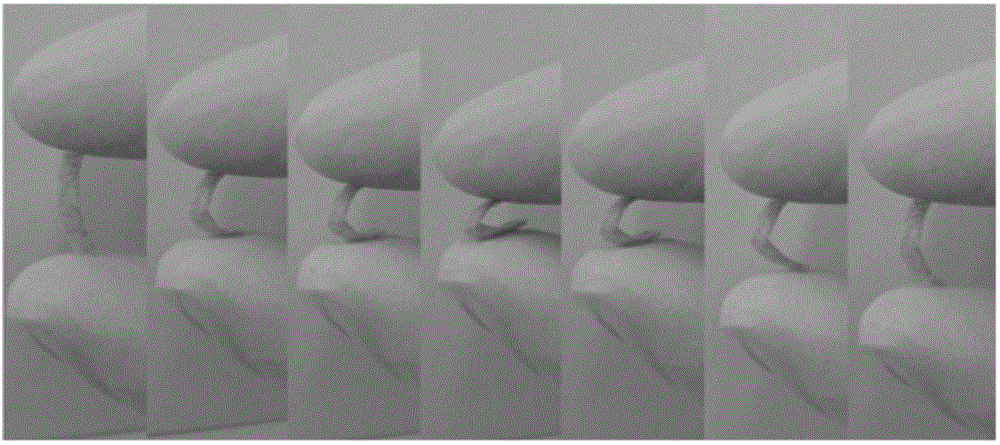

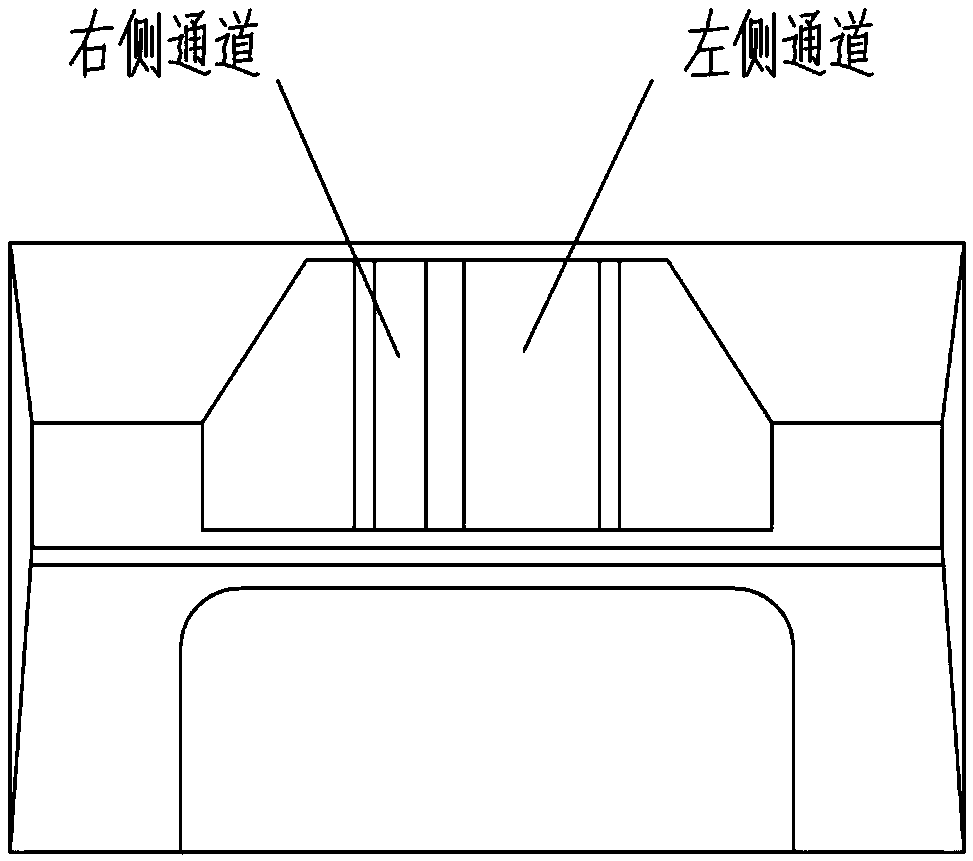

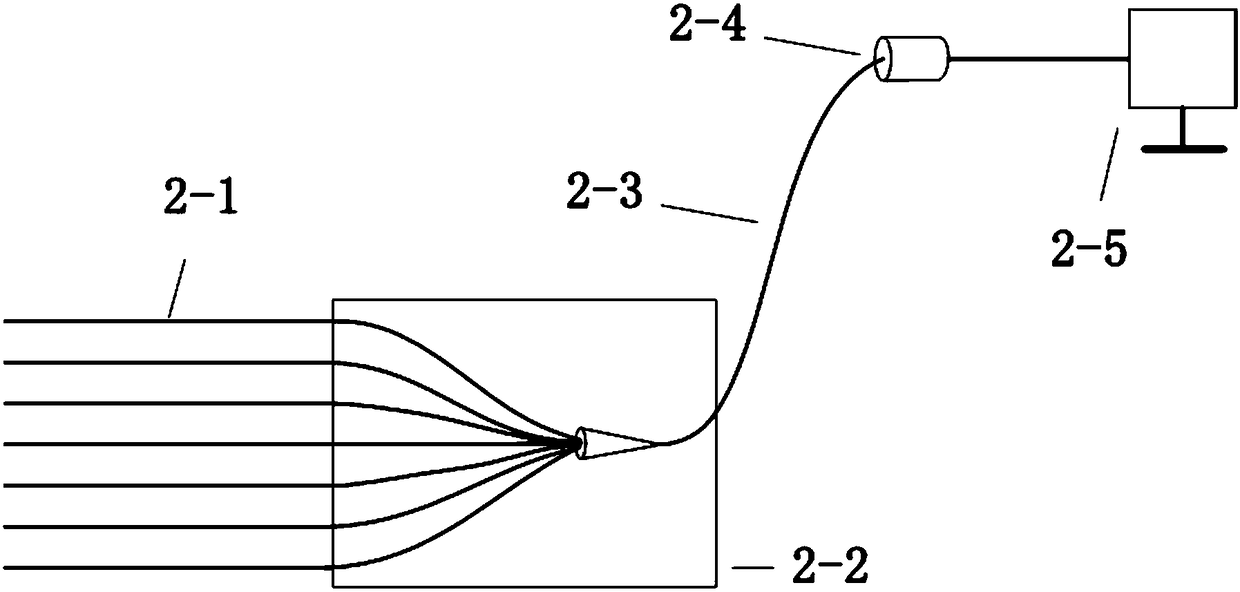

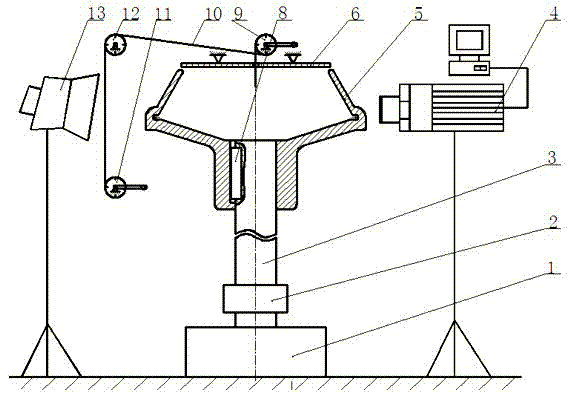

Measurement device for yarn movement in shear flow field in high-speed spinning cup

InactiveCN103245333AContrasting colorsThe experimental device is goodPicture taking arrangementsTextiles and paperYarnMeasurement device

The invention discloses a measurement device for yarn movement in a shear flow field in a high-speed spinning cup. A motor is connected with one end of a rotary shaft through a coupler; the other end of the rotary shaft is connected with the spinning cup through a key; a spinning cup cover is fixed on the wall surface and is positioned at the upper end of the spinning cup; a yarn conveying hole is formed in the center of the spinning cup cover; a yarn conveying wheel is arranged right above the center of the spinning cup cover; a high-speed camera is arranged on one side of the outer part of the spinning cup; a supporting wheel, a yarn storage wheel and a lighting lamp are arranged on the other side of the outer part of the spinning cup; and yarns are stored on the yarn storage wheel, pass through the supporting wheel, the yarn conveying wheel and the yarn conveying hole, and enter the spinning cup. The spinning cup is made of transparent organic glass and can be used for optical measurement; the length of the yarn entering the spinning cup can be accurately controlled according to the scale of the yarn conveying wheel; black and white fibers are distributed at intervals of 2mm to form a sharp color contrast; the movement of the yarn in the high-speed spinning cup is shot by using the high-speed camera; the movement mechanism of the yarn in the shear flow field in the high-speed spinning cup can be researched; and a good experimental device and a testing method are provided for subsequent research.

Owner:ZHEJIANG SCI-TECH UNIV

Production method of plant dye dyed colored spun yarn towel

InactiveCN108824023ABeneficial to human healthConserve waterDyeing processChemistryEnvironmentally friendly

The invention discloses a production method of a plant dye dyed colored spun yarn towel. The production method comprises following steps: step one, picking materials, wherein the ground warps and wefts of the towel are undyed hydrophilic bleached cotton, nap warps of the towel are plant dye dyed spun yarns, the ground warps and the nap warps are all plied yarns, and the plant dye dyed spun yarns are composed of 1 to 30 wt% of hydrophilic plant dyed fibers and 70 to 99 wt% of hydrophilic white fibers; step two, weaving; and step three, finishing. During the whole production, no chemical dye isused, a natural plant dye is adopted, and the towel has a natural antibacterial function, is beneficial for the health of human body, and is very environmentally friendly. The ground warps and the napwarps are all piled yarns, weaving can be carried out without sizing, desizing finishing can be eliminated, the amount of used water is largely reduced, energy is saved, and the cost is reduced. Thelooped piles of produced light color towels, plaid towels, and dark towels are tidy and uniform, and the towel quality is good.

Owner:杭州彩润科技有限公司

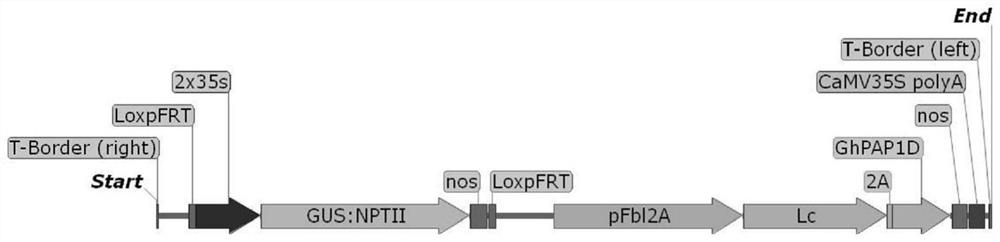

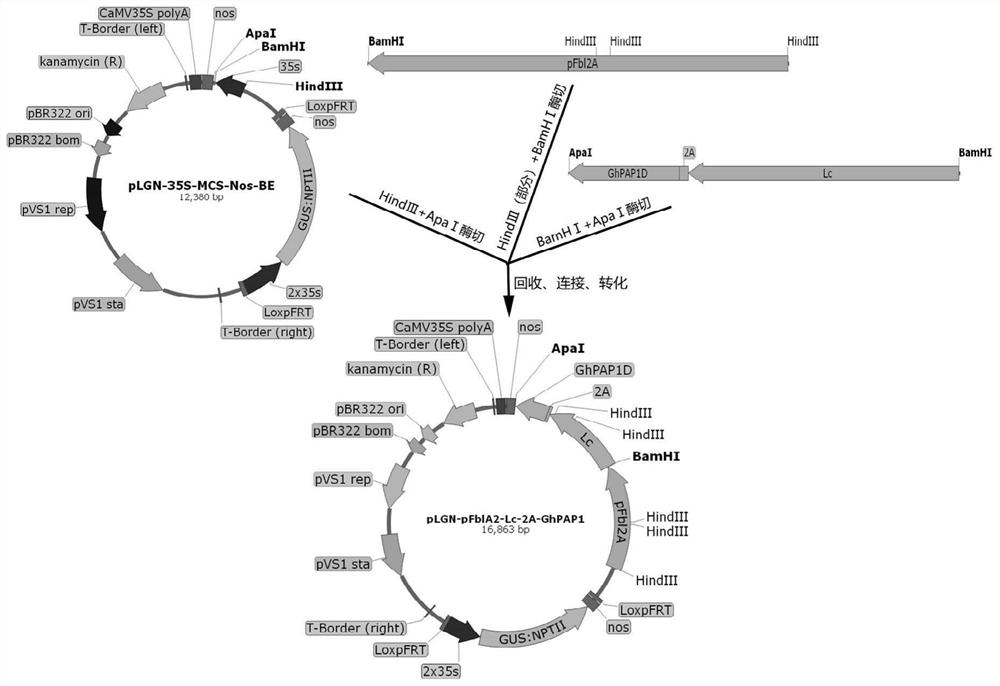

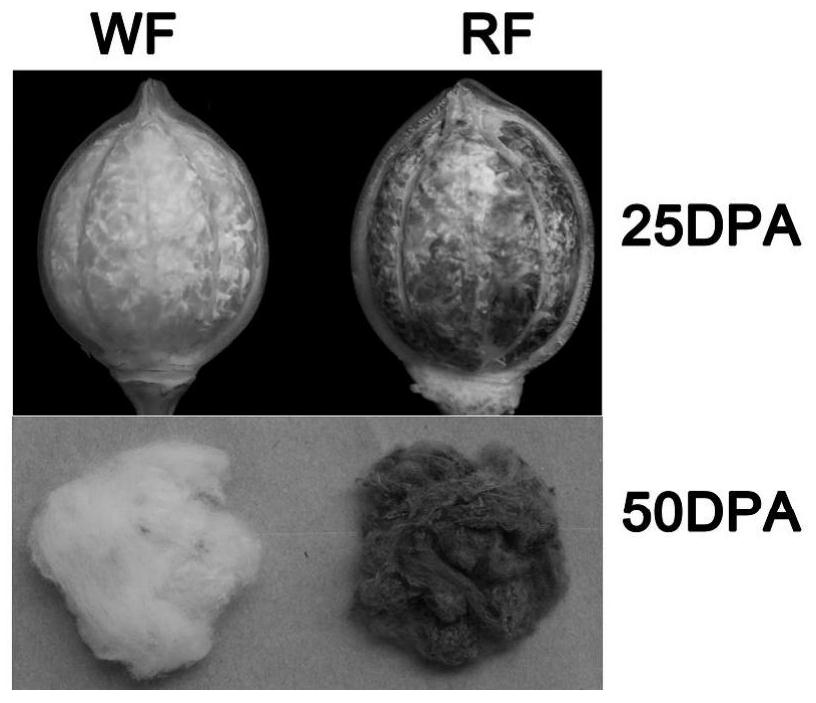

Fusion gene for regulating and controlling color of cotton fibers and expression vector and application of fusion gene

The invention provides a fusion gene for regulating and controlling color of cotton fibers and an expression vector and application of the fusion gene, and relates to the technical field of transgenicbreeding of plants. A 2A peptide capable of being self-cracked into small-fragment peptides is utilized, Lc and GhPAP1 genes are synthesized into the fusion gene, a fiber secondary wall specific promoter pFbl2A is adopted to start excessive expression of the fusion gene in the cotton fibers, and the anthocyanin content of the obtained transgenic cotton fibers is remarkably increased compared withthat of white fibers; the total anthocyanin content in the transgenic fiber is increased by 4093 times compared with that in the white fiber, so that the transgenic cotton generates purple red fibers, and the color range of the mature fibers is obviously expanded.

Owner:SOUTHWEST UNIVERSITY

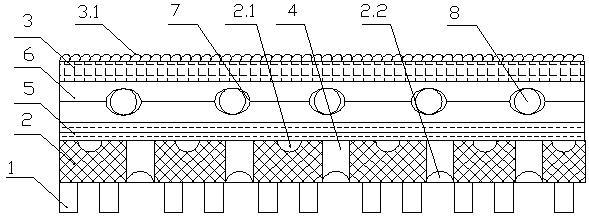

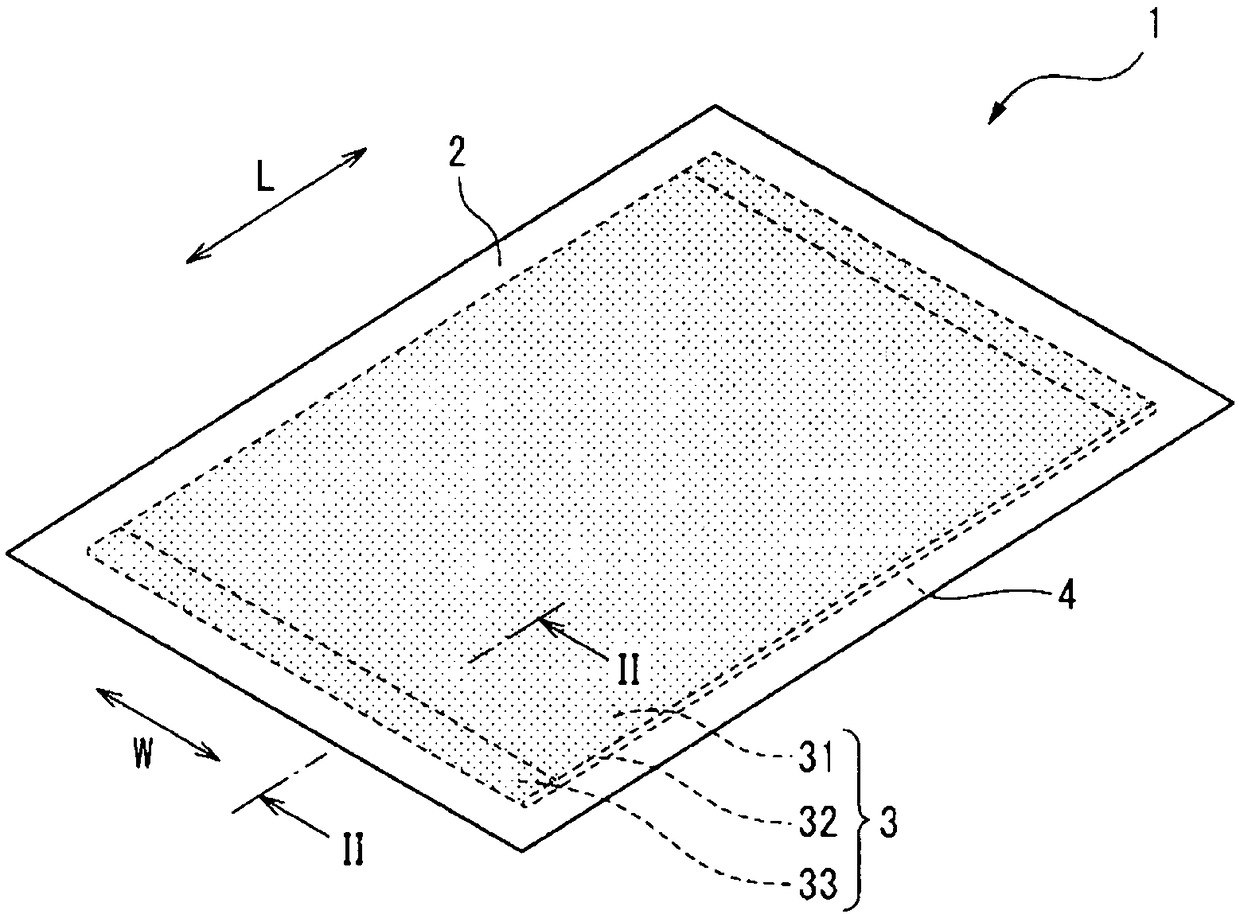

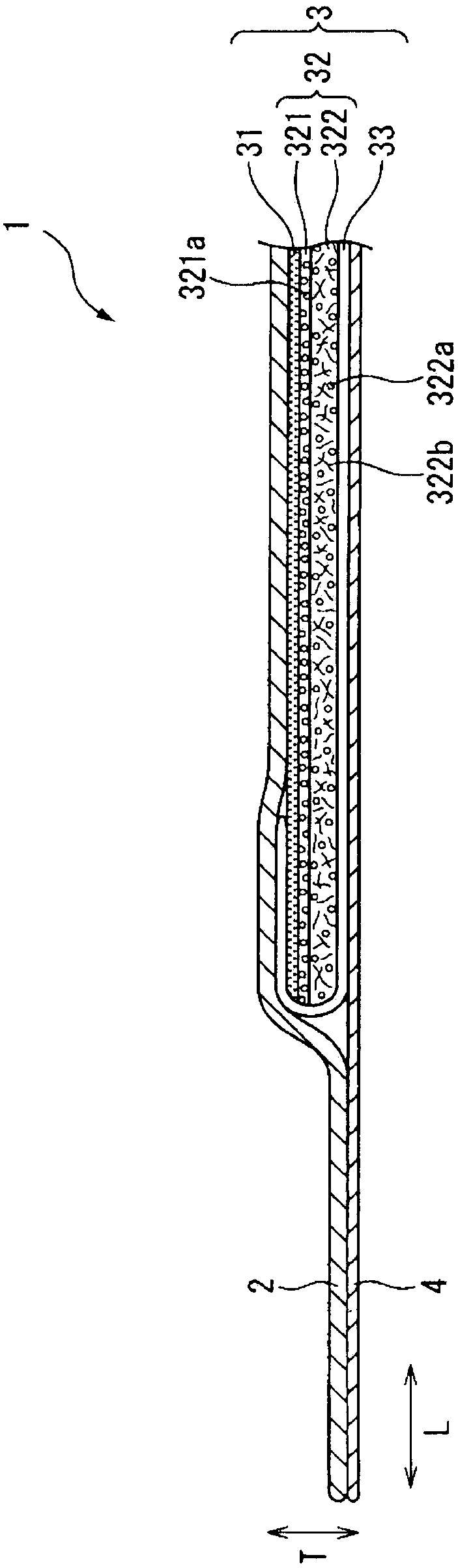

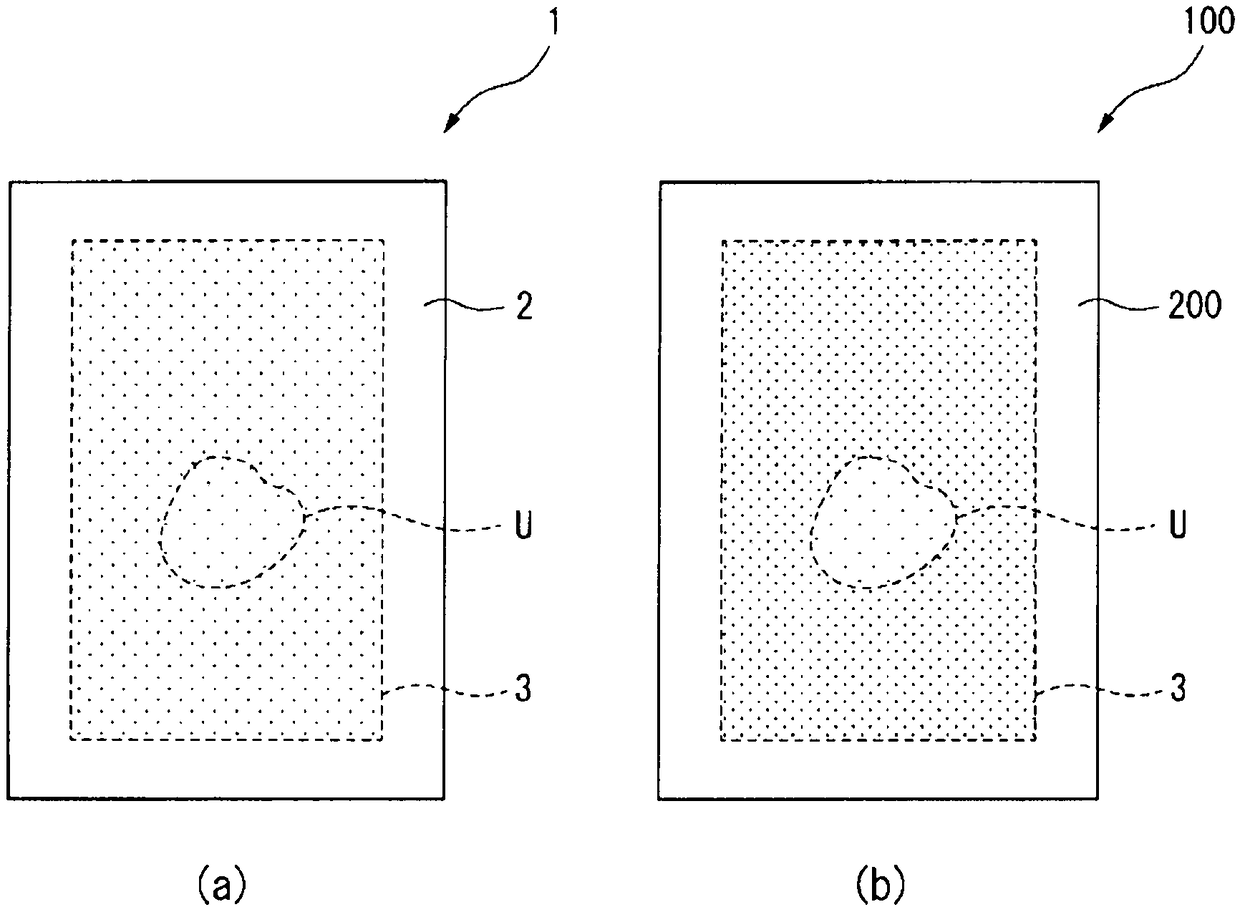

Excrement disposal sheet for animals

InactiveCN108135146AHigh strengthReliable jointAnimal housingAbsorbent padsEngineeringAbsorbent material

The present invention addresses the problem of providing an excrement disposal sheet for animals, of which a surface sheet can exhibit sufficiently superior and enough concealing performance without any structural constraint. The excrement disposal sheet for animals (1) according to the present invention is provided with a liquid-permeable front surface seat (2) composed of white fibers, a liquid-impermeable back surface sheet (4) and an absorbent material (3) arranged between these sheets, wherein the front surface seat (2) has a first surface that is a surface onto which excrement is to be supplied and a second surface that is opposed to the first surface, and the first surface in the front surface sheet (2) has an average absorbance of 700 or more, a floc average value of 6.0 or less and a floc ratio of 0.6 to 1.7.

Owner:UNI CHARM CORP

Novel vortex spinning colorful spun yarn and production process

PendingCN112941688AImprove antibacterial propertiesReduce breedingContinuous wound-up machinesDyeing processTextile fiberPolyester

The invention discloses a novel vortex spinning colorful spun yarn and a production process, and relates to the technical field of spinning. Now the following scheme is provided: the novel vortex spinning colorful spun yarn includes the following steps that S1, fiber selection: selecting common textile fibers such as polyester fibers, wherein the diameter of the selected polyester fibers is 0.6-0.8 mm; S2, diameter changing treatment: after the polyester fibers in the S1 are subjected to high-temperature stretching forming, performing equal-distance compression diameter changing treatment on the diameters of the polyester fibers which are formed just now; S3, dyeing: carrying out dyeing treatment on the treated polyester fibers; and S4, mixing with original white fibers. According to the production process, diameter changing treatment is carried out on the polyester fibers, so that the breathability of spun yarn of the polyester fibers can be improved, the comfort degree of people wearing the spun yarn is improved, meanwhile, hemp fibers and micro silver particles can improve the antibacterial performance of a textile and reduce breeding of bacteria in the spun yarn, and therefore, health of people is better protected.

Owner:滁州霞客无染彩色纺有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com