Jellyfish collagen and method for preparing the same

A technology of jellyfish collagen and collagen, which is applied to the preparation method of peptides, chemical instruments and methods, protein food components, etc., can solve problems such as large salt, difficulty in salt recovery, and the impact of jellyfish collagen extraction, and achieve good storage and purity high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 120g of salted jellyfish, soak in 100ml of 0.2M sodium hydroxide solution for 2 hours, the pH of the solution after soaking is 6.5, ammonia gas will be generated during alkali washing, and the bubbles will be obvious, which can remove ammonia ions and impurities. The jellyfish skin changes from white opaque to transparent (similar to frozen dehydrated jellyfish), and the middle glue layer can be clearly seen. Remove the upper and lower cortex, slice the white middle layer and store in the freezer.

[0026] Take the above-mentioned medium rubber layer, grind it, add 20ml of 0.1M acetic acid, and add 600mg of pepsin (Huamei, Sina-American Biotec, pepsin 1:3000), stir and dissociate at room temperature for 30h.

[0027] Ultrafiltration membrane filter is used to control the membrane inlet pressure at 1-2kg / cm 2 , and adopt an external electric field of 10-70V / cm, intercept concentrated molecular weight at 100,000-300,000 Daltons of collagen, and its interception rate...

Embodiment

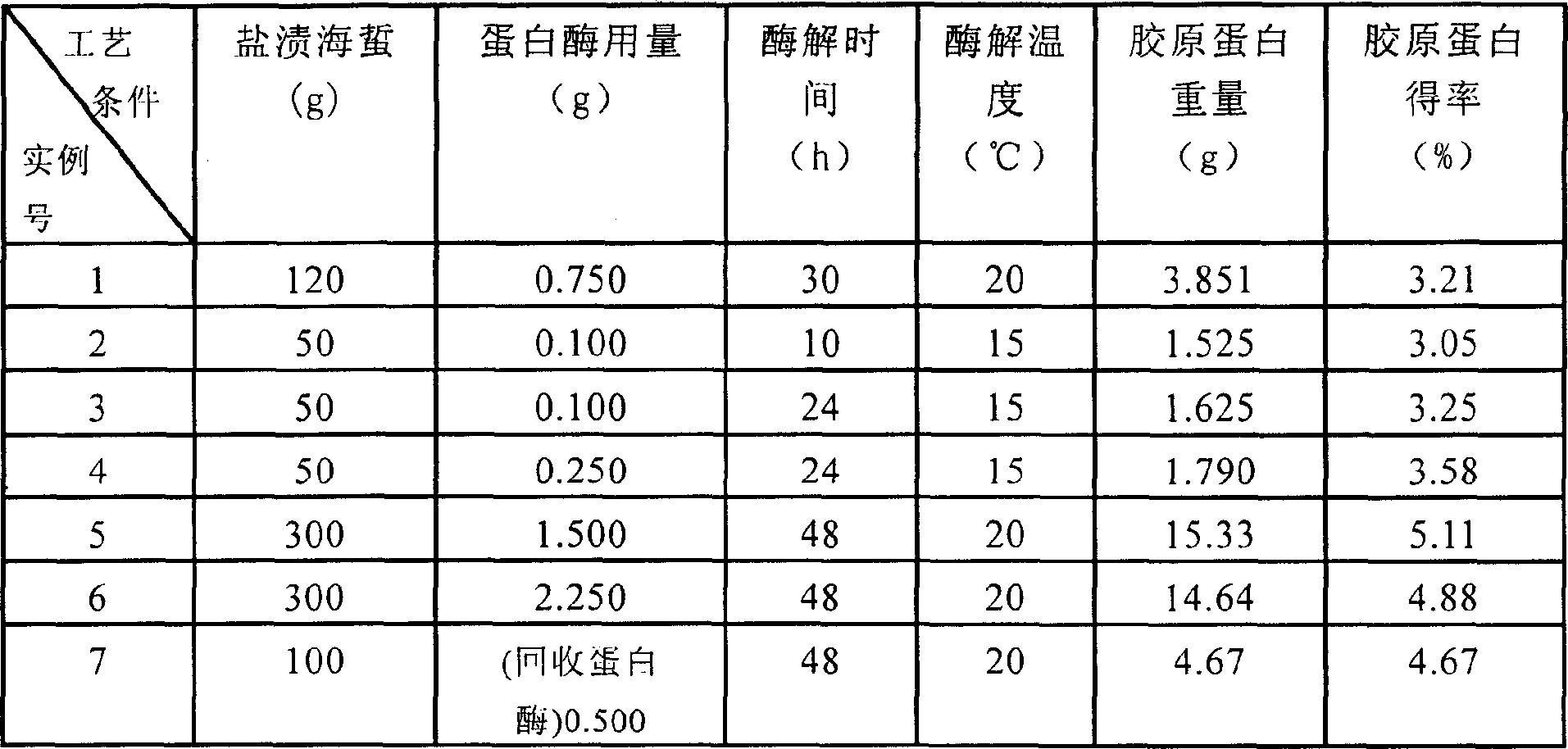

[0032] Embodiment (1)-(7) concrete process conditions and results are shown in Table 1:

[0033]

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com