Fusion gene for regulating and controlling color of cotton fibers and expression vector and application of fusion gene

A technology that integrates genes and cotton fibers, and is applied in the fields of application, fusion peptides, and genetic engineering, and can solve problems that cannot meet the needs of consumers and the diversity of colors in the textile industry.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Acquisition of maize leaf color gene Lc gene, small fragment peptide 2A peptide gene, cotton anthocyanin synthesis regulation gene GhPAP1D

[0034] The small fragment peptide 2A peptide gene and the Lc gene were synthesized by Huada optimized fusion, and the synthesized fragment was used as a template to design primers (Table 1, Lc-2A-U and Lc-2A-D). The 5' of the primer Lc-2A-U A Bam HI restriction site was added to the end, and a 10bp homology arm of the GhPAP1D gene was added to the 5' end of Lc-2A-D. The amplification system is preferably a 10 μl system, including: 2×PrimeSTAR MAX Premix 5 μl, primers Lc-2A-U and Lc-2A-D (5 μmol / L) each 1 μl, template DNA about 60ng, add ddH 2 0 to 10 μl. The amplification program was as follows: pre-denaturation at 98°C for 5 min; then denaturation at 98°C for 30 s, annealing at 56°C for 30 s, extension at 72°C for 60 s, 35 cycles; and finally extension at 72°C for 10 min.

[0035] Using the CDS sequence of Gohir.D7G082100 as a r...

Embodiment 2

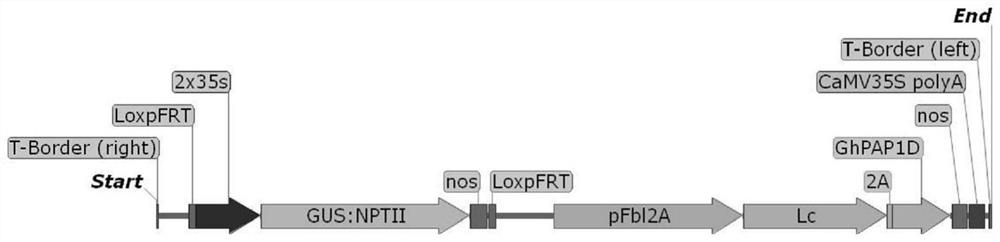

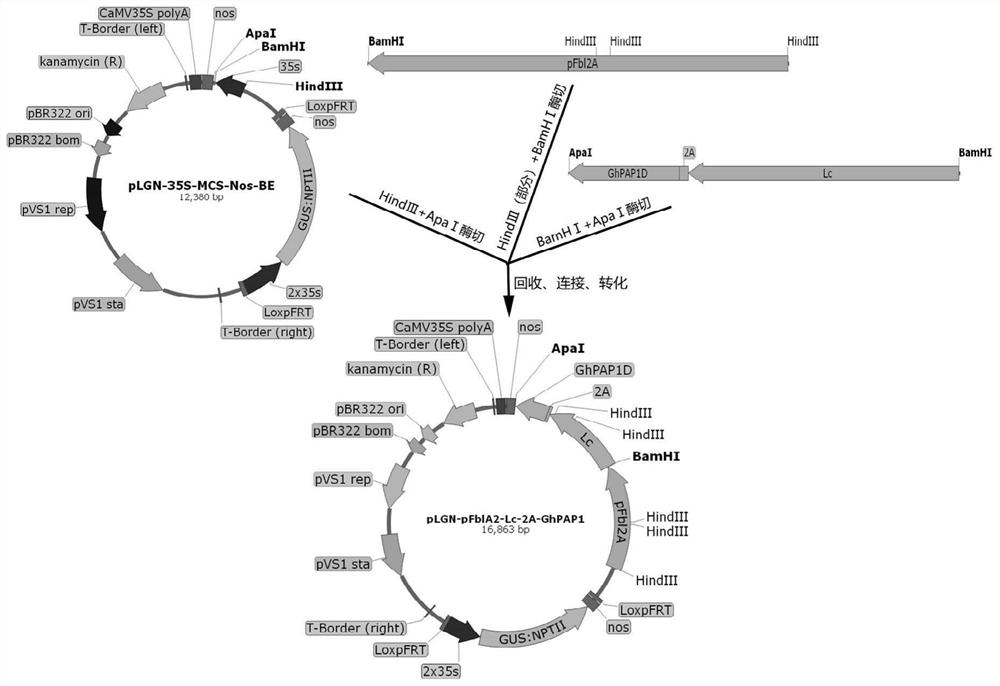

[0040] Construction of a Plant Expression Vector Specifically Expressing Lc and GhPAP1D Fusion Gene During Fiber Secondary Wall Synthesis

[0041] The process of constructing the coding sequences of Lc-2A and GhPAP1D genes into the plant expression vector pLGN is shown in figure 2 . pLGN is a binary plant expression vector transformed from the traditional plant expression vector pBI121. Its T-DNA segment (region between RB and LB, figure 2 ) was replaced by a fusion gene expression cassette of reporter gene GUS and marker gene NPTII controlled by a constitutive 2×35S promoter (2×35S-P). Use primers pFbl2A-F and pFbl2A-R (see Table 1 for the sequence) to amplify and clone the promoter Fbl2A from the genome of the cotton line Jimian No. 14, add a Hind III restriction site to the 5' end of the promoter, and start A BamH Ⅰ restriction site was added to the 3' end of the sub. The amplification system of the present invention is preferably a 10 μl system, including: 5 μl of 2×...

Embodiment 3

[0046] genetic transformation of cotton

[0047] The cotton genetic transformation of the above expression vector was carried out by the method mediated by Agrobacterium tumefaciens, and the medium formula used is shown in Table 2. The specific method is as follows: shell the full cotton seeds of wild type upland cotton YZ-1, put a small amount (about 20 to 40 seeds) of shelled seeds in a sterilized 100mL triangular flask, and first wash them with 75% alcohol Pre-wash the seeds for 1 min, pour off the alcohol and add 0.1% HgCl 2 Sterilize for about 12 minutes (constantly shake the Erlenmeyer flask to sterilize), gently pour out the mercuric chloride, add sterile water to fully rinse the seeds, and rinse for about 10 times. Place the sterilized seeds on the germination medium, and after the radicle grows about 1 cm (about 36-48 hours), gently insert the radicle into the germination medium, and cultivate the hypocotyl in the dark at about 30°C to about 7 cm (about 7 days). Ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com