Air-jet vortex spinning fancy yarns and production technology thereof

A production process and fancy yarn technology, which can be applied to spinning machines, open-end spinning machines, and continuously wound spinning machines, etc. Clothing personalization, fashion requirements and other issues, to achieve the effect of various colors, increasing styles, and rich cloth effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

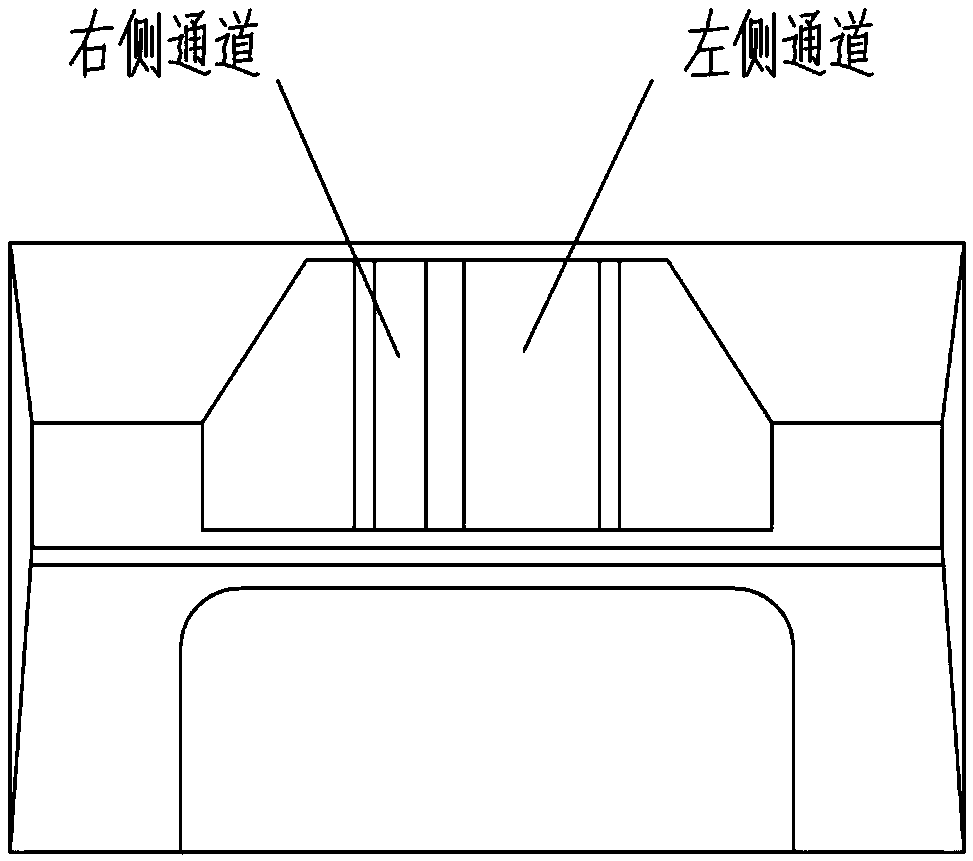

[0062] According to attached figure 1 Shown: an air-jet vortex spinning fancy yarn, including a fancy yarn body, and the fancy yarn body includes:

[0063] The first black polyester fiber, the fiber fineness is 3D;

[0064] The second black polyester fiber, the fiber fineness is 1.5D;

[0065] White viscose fiber, fiber fineness is 1.5D.

[0066] A production process of air-jet vortex spinning fancy yarn, comprising the following steps:

[0067] Step 1: Purely spinning the first black polyester fiber with a fiber fineness of 3D to make a roving, including:

[0068] Step 1.1: Fiber pretreatment, weigh the fiber raw material, then add 10% of the weight of the fiber raw material in water and 4‰ of the fiber raw material weight in the measuring cup, mix evenly to obtain the mixed reagent, and then use a spray device to mix The reagent is evenly sprayed on the pre-laid fiber raw material, and then the fiber raw material is wrapped in a sealed and airtight environment for pre-st...

Embodiment 2

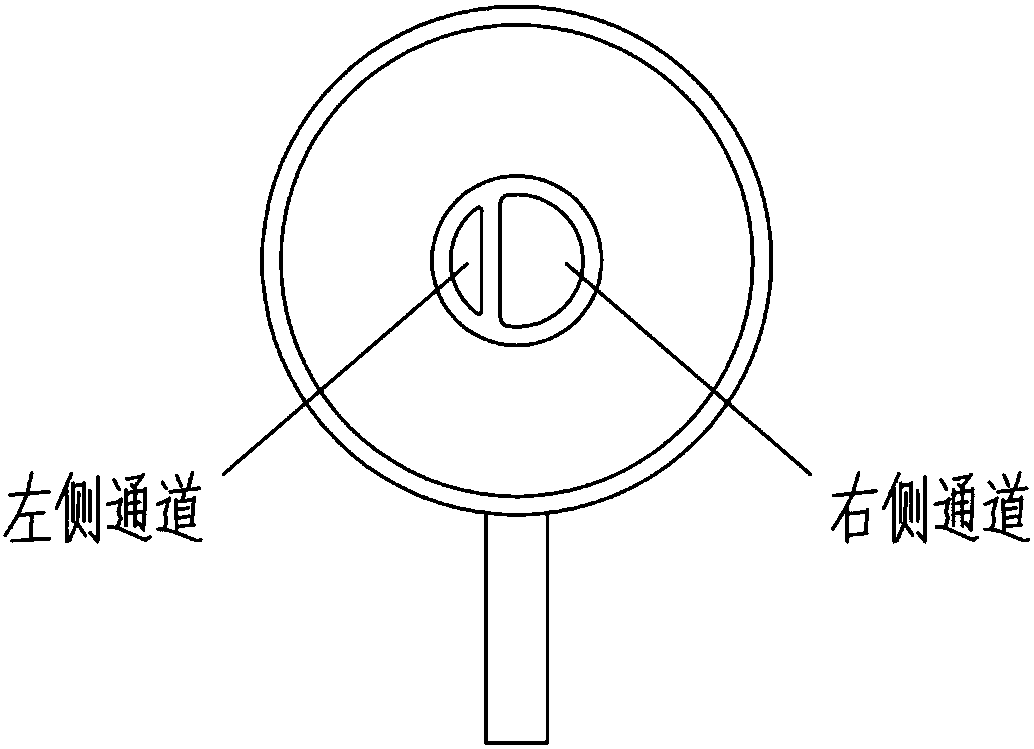

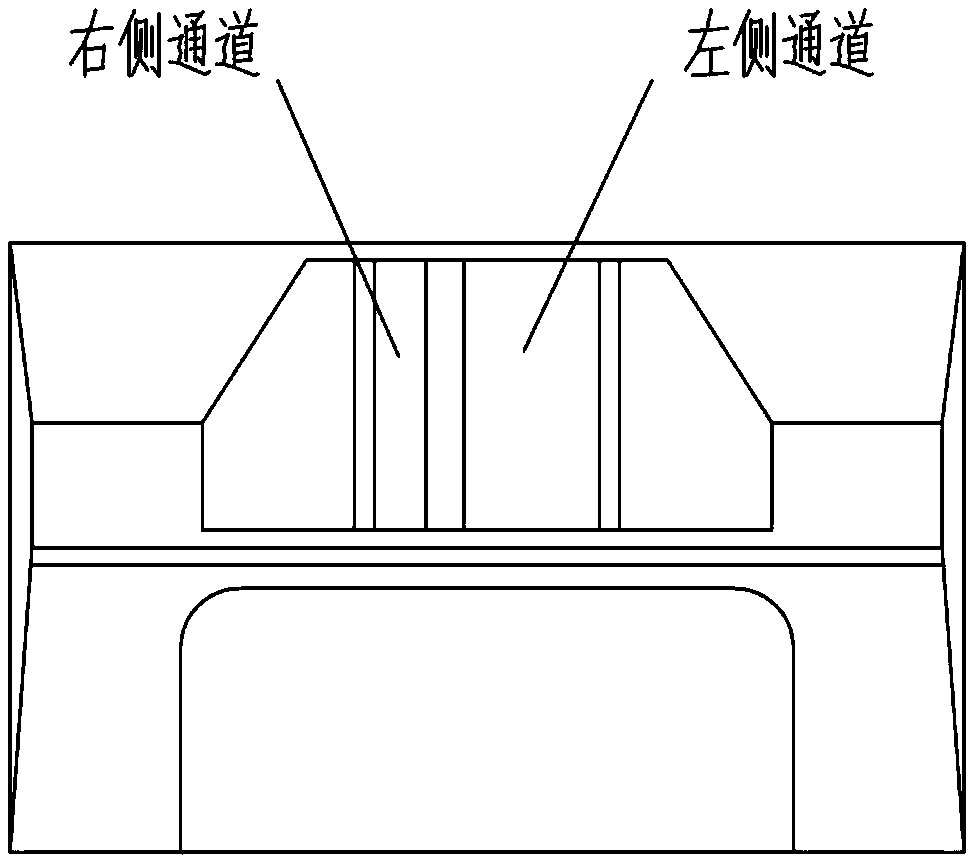

[0101] According to attached figure 2 Shown: an air-jet vortex spinning fancy yarn, including a fancy yarn body, and the fancy yarn body includes:

[0102] The first black polyester fiber, the fiber fineness is 3D;

[0103] The second black polyester fiber, the fiber fineness is 1.5D;

[0104] White viscose fiber, fiber fineness is 1.5D.

[0105] A production process of air-jet vortex spinning fancy yarn, comprising the following steps:

[0106] Step 1: Purely spinning the first black polyester fiber with a fiber fineness of 3D to make a roving, including:

[0107] Step 1.1: Fiber pretreatment, weigh the fiber raw material, then add 10% of the weight of the fiber raw material in water and 4‰ of the fiber raw material weight in the measuring cup, mix evenly to obtain the mixed reagent, and then use a spray device to mix The reagent is evenly sprayed on the pre-laid fiber raw material, and then the fiber raw material is wrapped in a sealed and airtight environment for pre-s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com