Glowing nanometer fibre with biocompatibility and preparation method of glowing nanometer fibre

A biocompatibility and nanofiber technology, which is applied in the preparation of fluorescent nanofibers, luminescent nanofibers and its preparation, can solve the problems that fluorescent nanofibers are not suitable for the biological field and do not have biological safety, so as to facilitate later observation , good biocompatibility, and the effect of luminescent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] 1) Dissolve 0.5 g, 100 nanometer carbon nanoparticles in 10 ml of water under ultrasonic conditions for 0.5 hours to make the mass concentration 0.05 g / ml. Under stirring conditions, 1 g of polyvinylpyrrolidone was added and stirred for 1 hour to finally obtain a uniform spinning solution.

[0023] 2) Pour the above spinning solution into the syringe, adjust the voltage to 10 kV, the solution flow rate is 0.1 ml / h, and the receiving distance is 10 cm. A uniform layer of white fiber is collected on the receiving aluminum foil.

[0024] 3) Put the white fibers in a high-temperature tubular atmosphere furnace, ventilate nitrogen, increase the temperature to 600°C, keep the temperature for 3 hours, and finally decrease the temperature to room temperature to obtain luminescent nanofibers containing carbon nanoparticles.

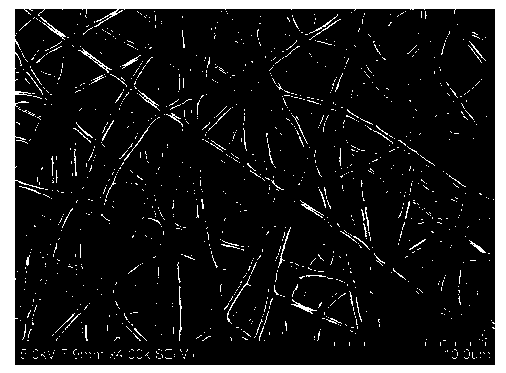

[0025] figure 1 Scanning electron micrograph of the prepared nanofiber membrane. It can be seen from the figure that the diameter of the nanofiber is 500 nanomet...

Embodiment 2

[0027] 1) Dissolve 1 gram of 300-nanometer carbon nanoparticles in 10 ml of 1:1 ethanol / chloroform under ultrasonic conditions for 1 hour to achieve a mass concentration of 0.1 g / ml. Under stirring conditions, 0.5 g of polylactic acid was added and stirred for 2 hours to finally obtain a uniform spinning solution.

[0028] 2) Fill the above-mentioned spinning solution into the syringe, adjust the voltage to 15 kV, the solution flow rate is 0.1 ml / h, and the receiving distance is 10 cm. A uniform layer of white fiber is collected on the receiving aluminum foil.

[0029] 3) Put the white fibers in a high-temperature tubular atmosphere furnace, blow in nitrogen, raise the temperature to 800°C, keep the temperature for 2 hours, and finally lower the temperature to room temperature to obtain luminescent nanofibers containing carbon nanoparticles.

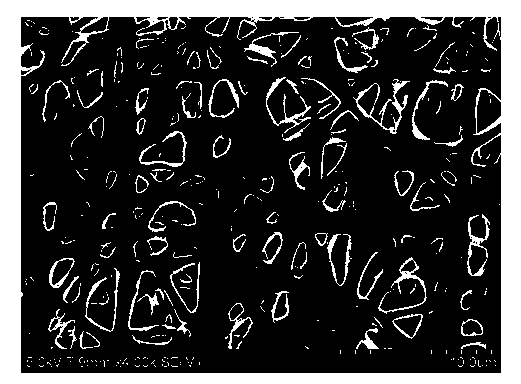

[0030] figure 2 Scanning electron micrograph of the prepared nanofiber membrane. It can be seen from the figure that the diameter of the nan...

Embodiment 3

[0032] 1) Dissolve carbon nanoparticles of 0.1 g and 200 nanometers in 10 ml of ethanol under ultrasonic conditions for 1 hour to make the mass concentration 0.01 g / ml. Under stirring conditions, 0.2 g of chitosan was added and stirred for 3 hours to finally obtain a uniform spinning solution.

[0033] 2) Fill the above-mentioned spinning solution into the syringe, adjust the voltage to 20 kV, the solution flow rate is 0.2 ml / h, and the receiving distance is 15 cm. A uniform layer of white fiber is collected on the receiving aluminum foil.

[0034] 3) Put the white fibers in a high-temperature tubular atmosphere furnace, blow in nitrogen, increase the temperature to 600°C, keep the temperature for 2 hours, and finally decrease the temperature to room temperature to obtain luminescent nanofibers containing carbon nanoparticles.

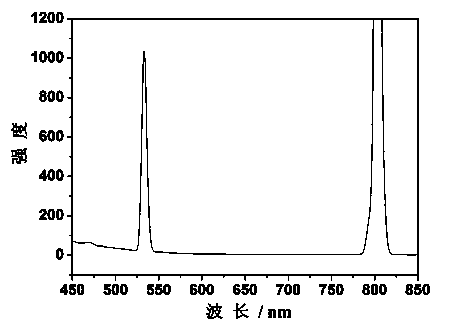

[0035] image 3 It is the emission spectrum of nanofiber membrane with 800 nm as the excitation wavelength. It can be seen from the figure that the emission...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com