Method for preparing fibrous nano magnesium hydrate

A nano-magnesium hydroxide and fibrous technology, which is applied in the field of hydrometallurgy, can solve the problems of inconvenient filtration, easy generation of gel, and difficult filtration and washing of gel, so as to reduce filling volume, reduce energy consumption, and facilitate comprehensive Use the effects of development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

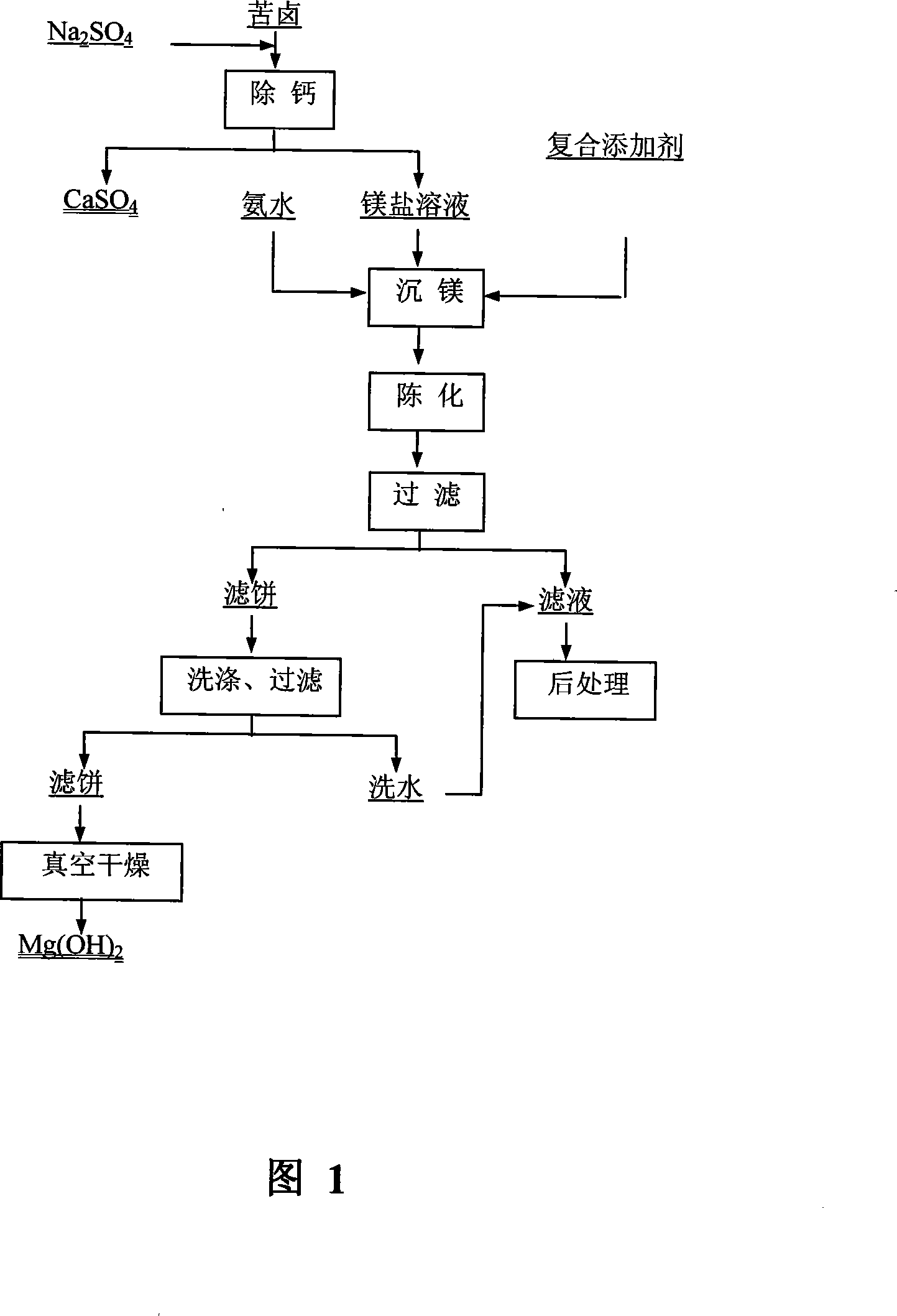

Image

Examples

Embodiment 1

[0021] Example 1: Qinghai Salt Lake bittern was used as raw material, and the contents of main elements were as follows.

[0022] main ion

[0023] Ca 2+ Add 1.5 times the equivalent mole of sodium sulfate into the bitter bittern, raise the temperature to 50°C and continue to stir, and react for 30min, the Ca in the bittern 2+ CaSO 4 The precipitate is removed to obtain a magnesium chloride solution; the magnesium salt solution obtained above is diluted to contain Mg 2+ 80g / l; Get the magnesium salt solution 200ml after this dilution, and add the dehydrated alcohol of 15ml and 10ml gelatin and sodium lauryl sulfate mixed solution (gelatin: sodium lauryl sulfate=1 : 1wt%), make the magnesium salt solution that contains composite dispersant; At room temperature 30 ℃, add 20% ammoniacal solution with the speed of 2ml / min in above-mentioned magnesium salt solution, keep stirring speed simultaneously and be 800r / min, Stop injecting lye until the system pH=9, and obtain...

Embodiment 2

[0025] Ca 2+ Add 1.5 times the equivalent mole of sodium sulfate into the bitter bittern, raise the temperature to 30°C and continue to stir, and react for 60 minutes, the Ca in bitter bittern 2+ CaSO4 The precipitate is removed to obtain a magnesium chloride solution; the magnesium salt solution obtained above is diluted to contain Mg 2+ 50g / l, get the magnesium salt solution 200ml after this dilution, and add the dehydrated alcohol of 10ml and the gelatin of 8ml and sodium lauryl sulfate mixed solution (gelatin: sodium lauryl sulfate=1 : 1wt%), make the magnesium salt solution that contains composite dispersant; At room temperature 15 ℃, add 25% ammonia solution with the speed of 4ml / min in above-mentioned magnesium salt solution, keep stirring speed and be 1000r / min, until System pH = 10, stop injecting lye, and get milky white Mg(OH) 2 suspension; then raise the temperature of the emulsion to 60°C and age for 2 hours; then filter the aged magnesium hydroxide emulsion, wa...

Embodiment 3

[0027] Ca 2+ Add 1.5 times the equivalent mole of sodium sulfate into the bitter bittern, raise the temperature to 40°C and continue to stir, and react for 45 minutes, the Ca in bitter bittern 2+ CaSO 4 The precipitate is removed to obtain a magnesium chloride solution; the magnesium salt solution obtained above is diluted to contain Mg 2+ 10g / l, get the magnesium salt solution 200ml after this dilution, and add the dehydrated alcohol of 6ml and 5ml gelatin and sodium lauryl sulfate mixed solution (gelatin: sodium lauryl sulfate=1 : 1wt%), make the magnesium salt solution that contains composite dispersant; At room temperature 20 ℃, add 10% sodium hydroxide solution with the speed of 8ml / min in above-mentioned magnesium salt solution, keep stirring speed simultaneously and be 1400r / min until the system pH = 10.5 to stop injecting lye, to obtain milky white Mg(OH) 2 suspension; then raise the temperature of the emulsion to 70°C and age for 1 h; then filter the aged magnesiu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com