Patents

Literature

178results about How to "Reliable joint" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

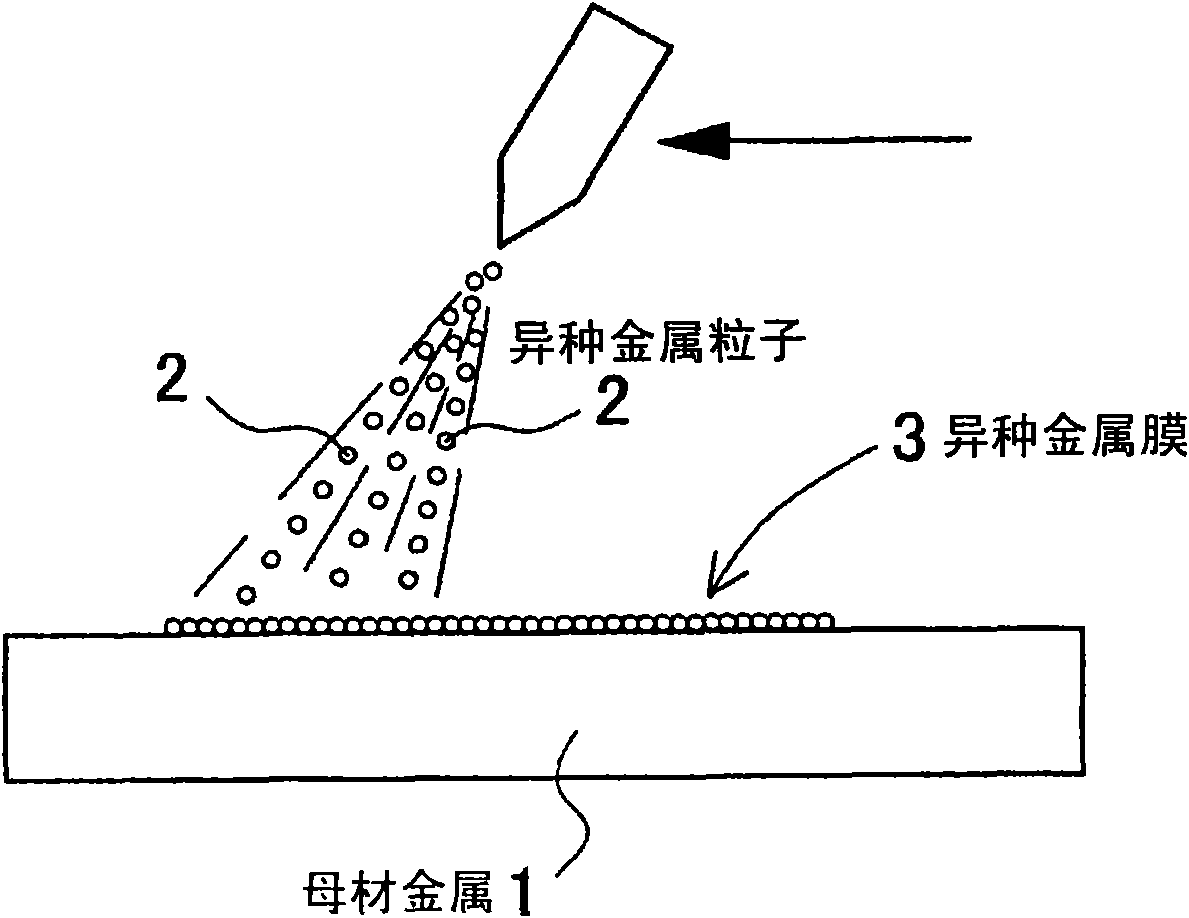

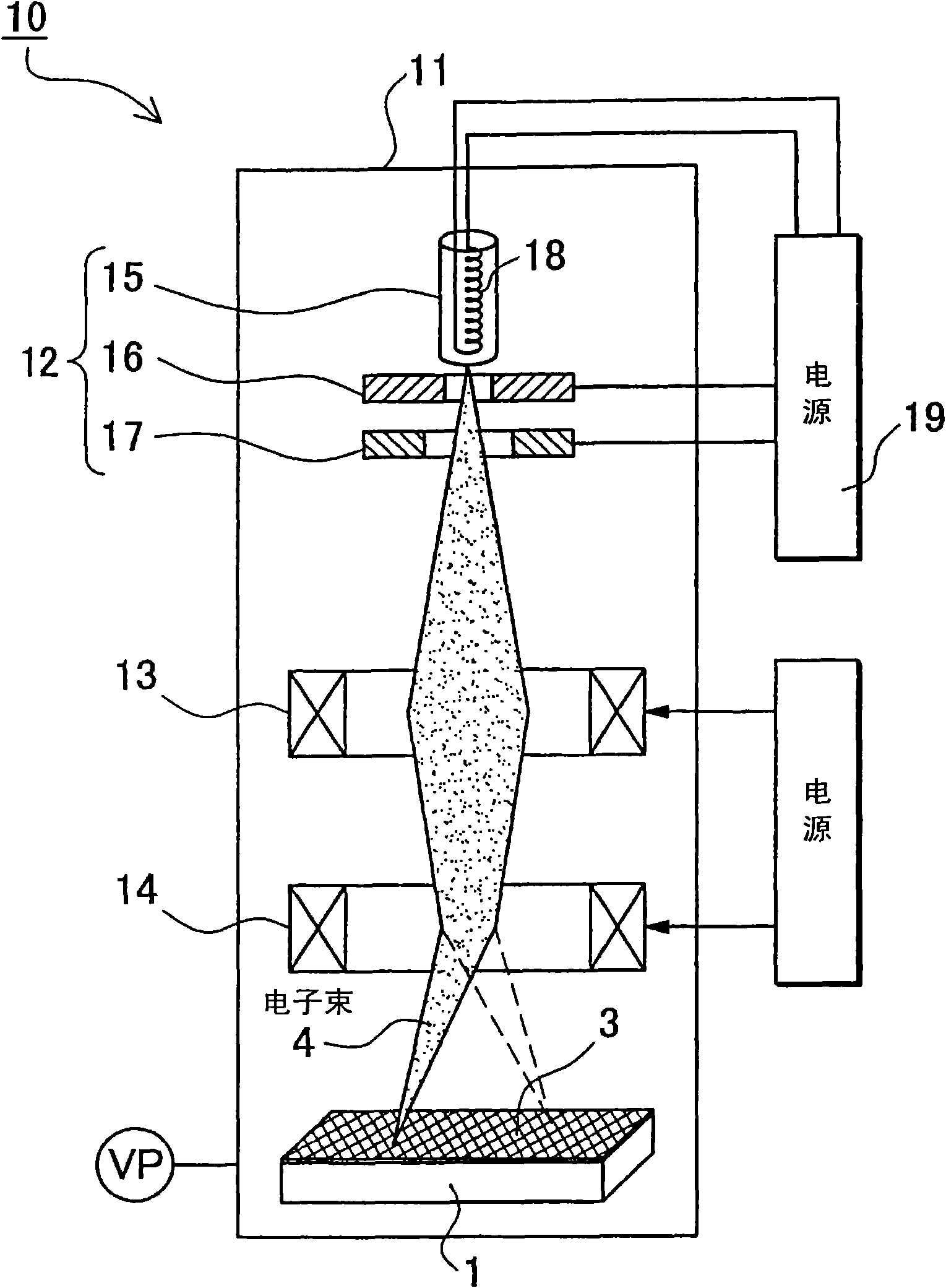

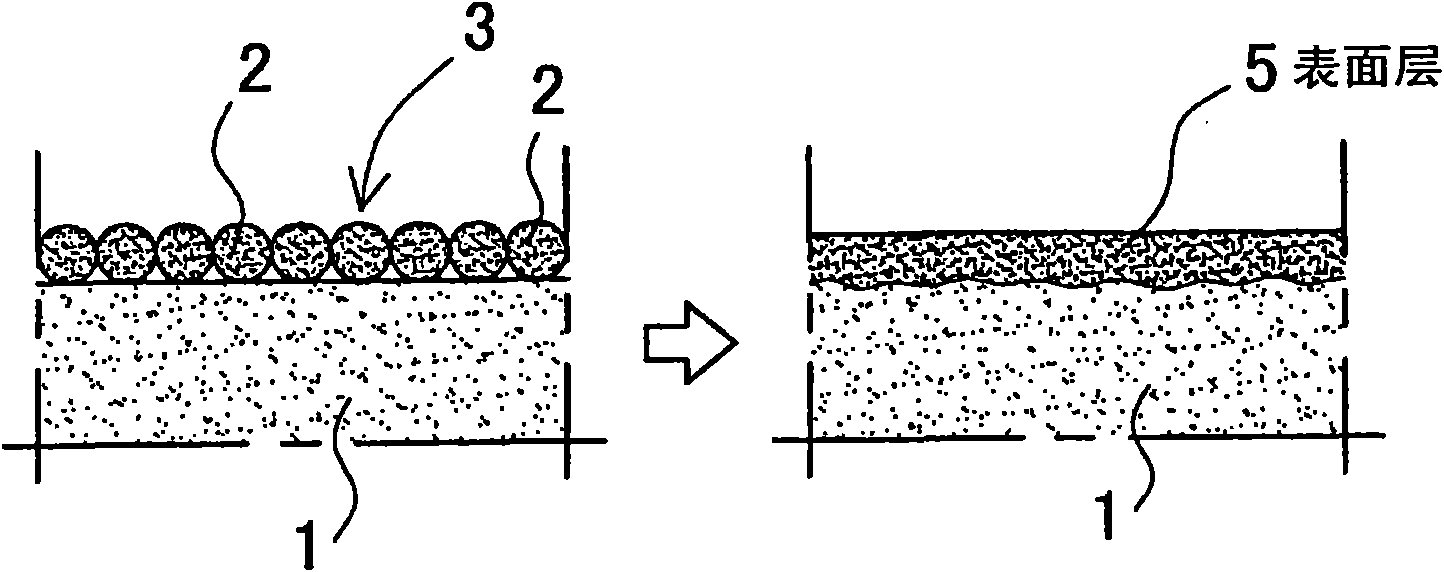

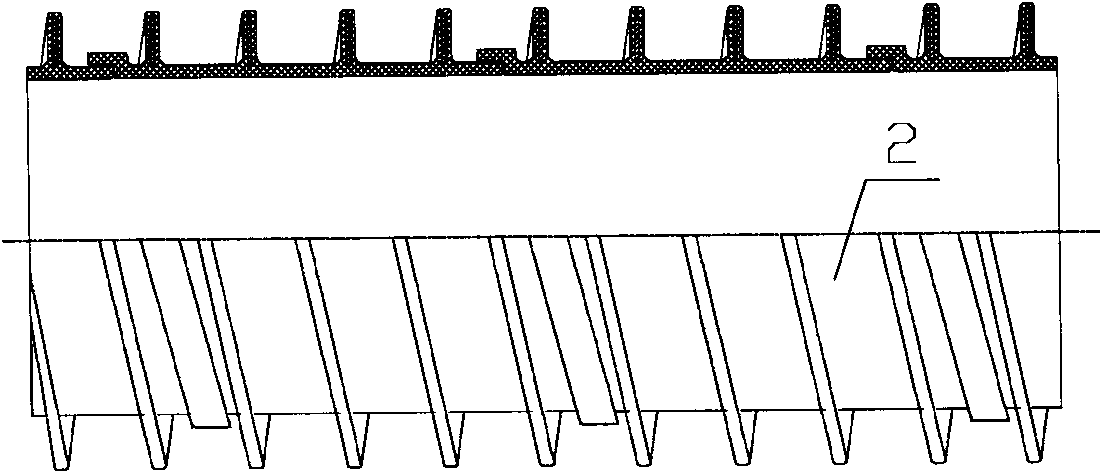

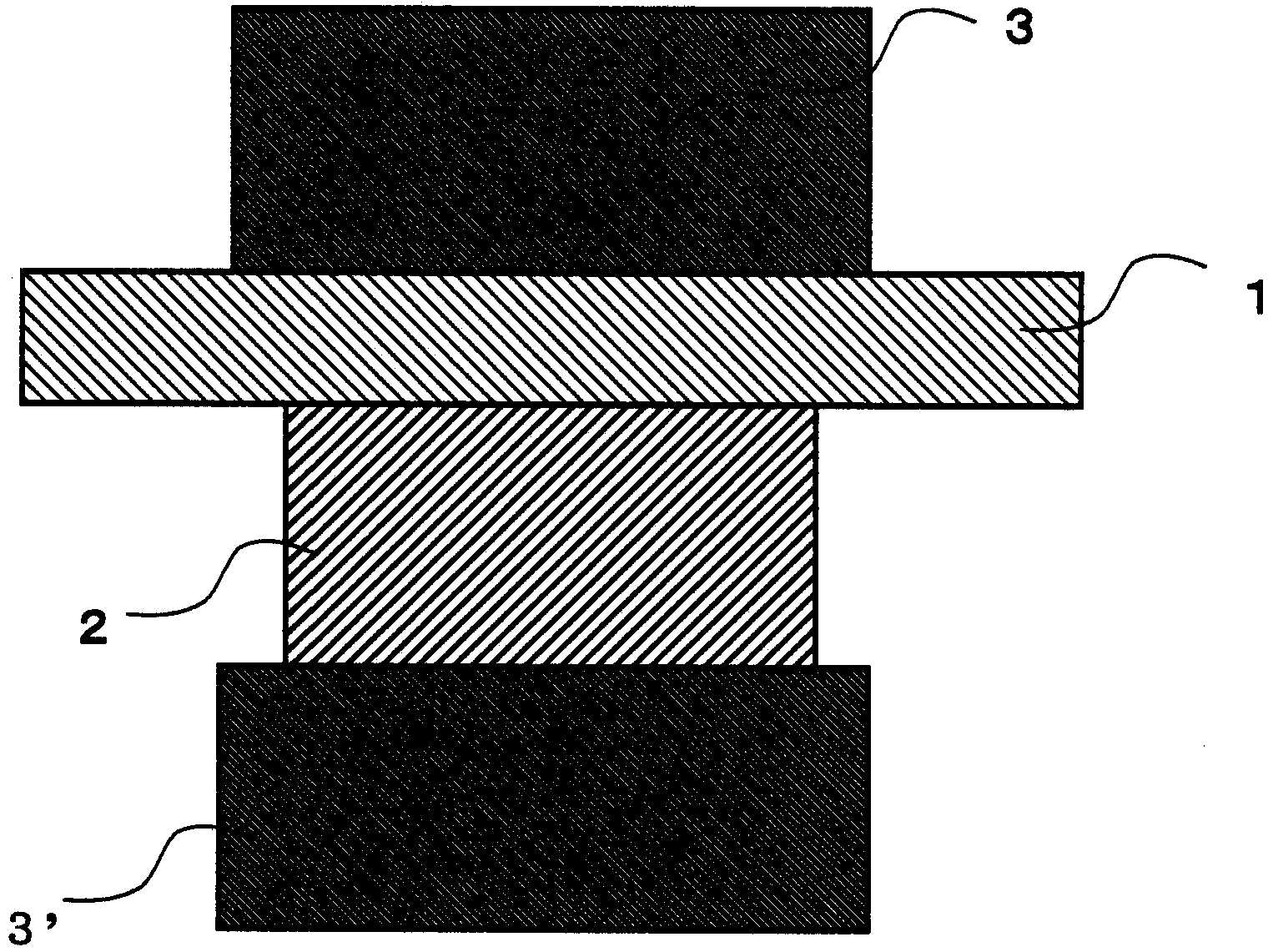

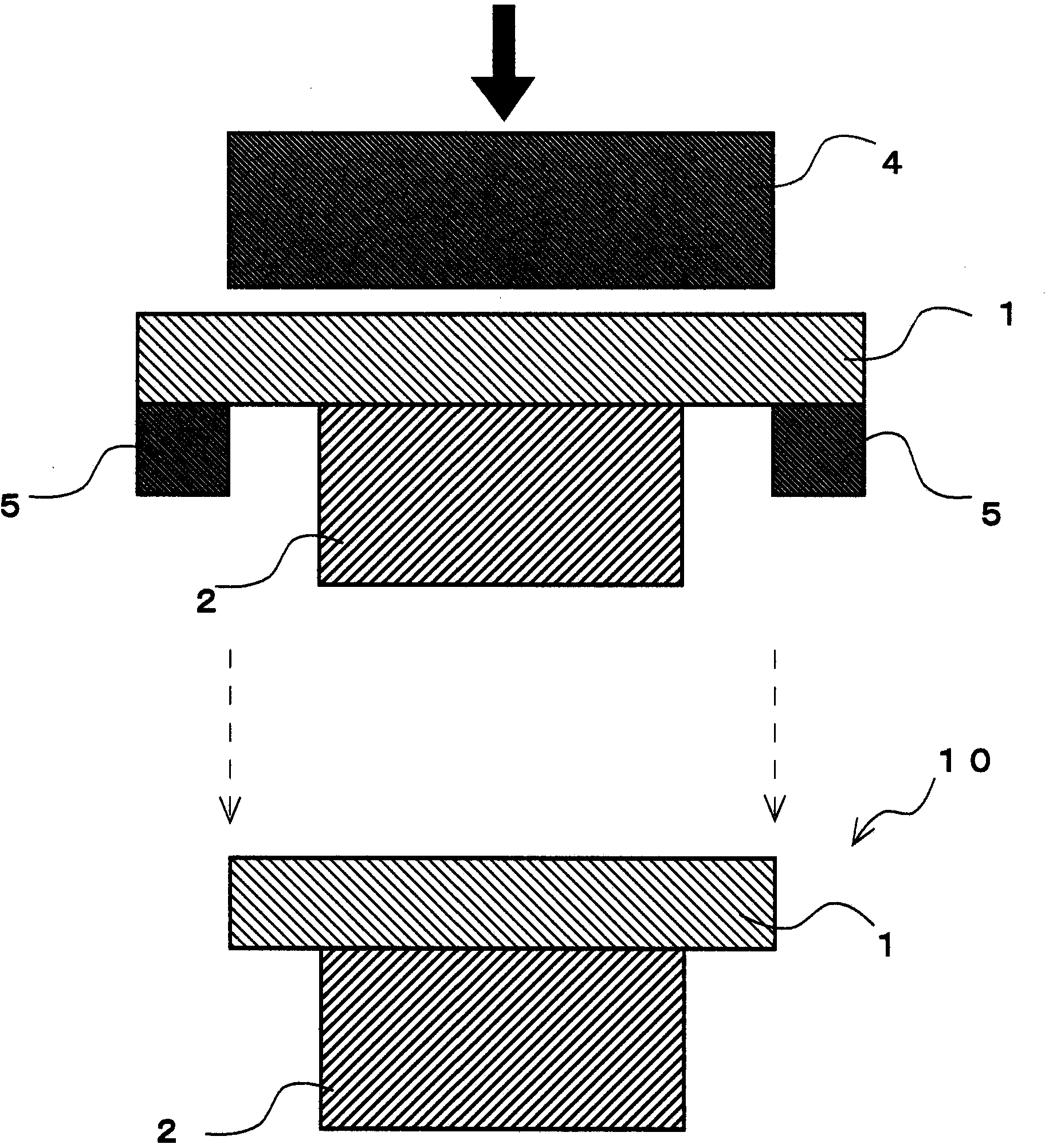

Metal surface treatment method

To reliably bond various metals onto a surface of various parent metals in an alloyed state in a simple, easy and efficient manner. [MEANS FOR SOLVING PROBLEMS] A metal surface treatment method comprising a shot peening step of shot peening dissimilar metal particles (2), which are different from a parent metal (1), on the surface of the parent metal (1) to provide a dissimilar metal film (3) on the surface of the parent metal (1), and an electron beam irradiation step of applying electron beams (4) to the surface of the parent metal (1) with the dissimilar metal film (3) provided thereon by the shot peening step to bond the dissimilar metal film (3) and the parent metal (1).

Owner:LTT BIO PHARMA

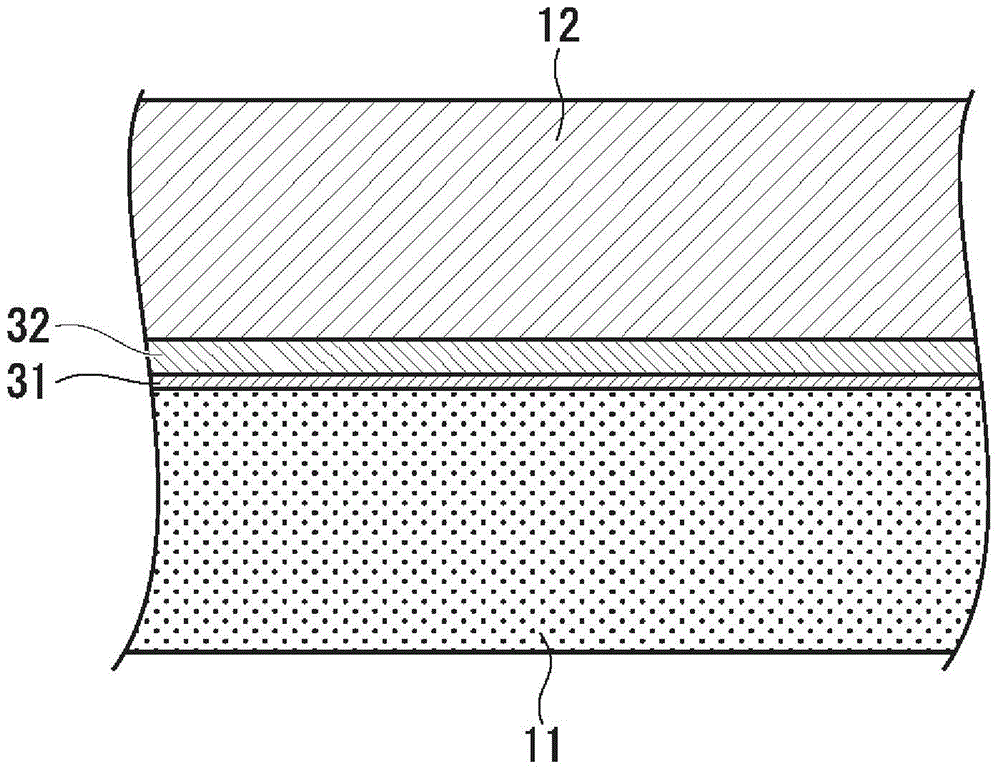

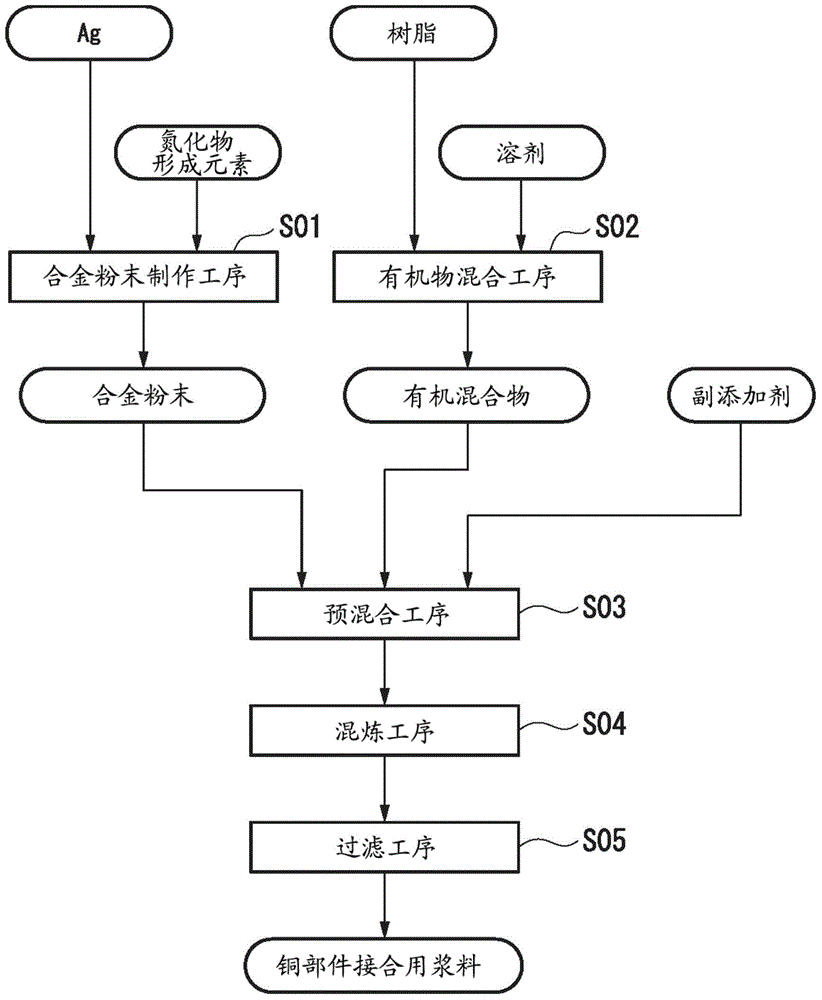

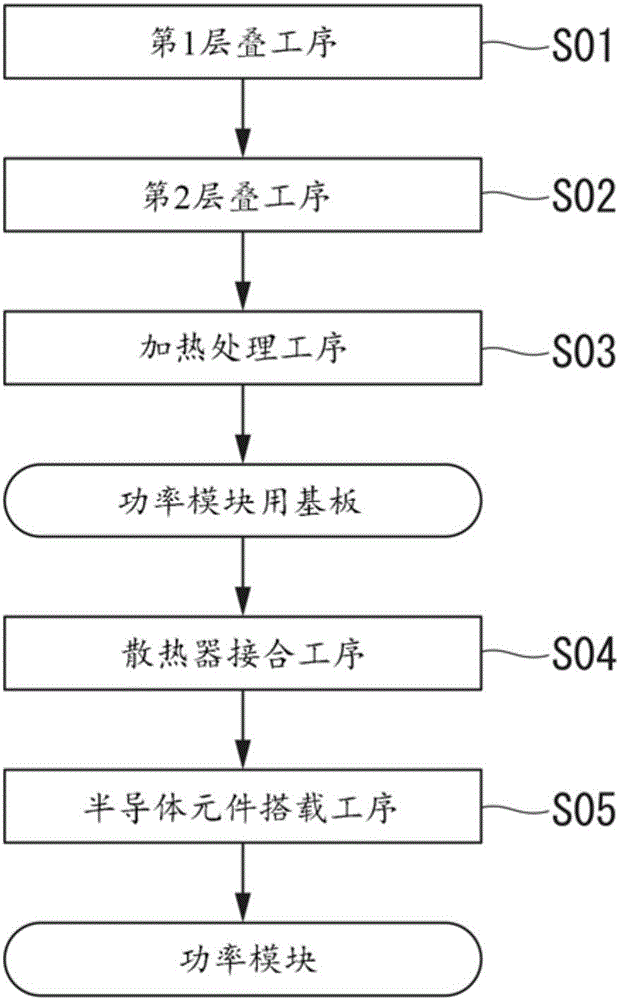

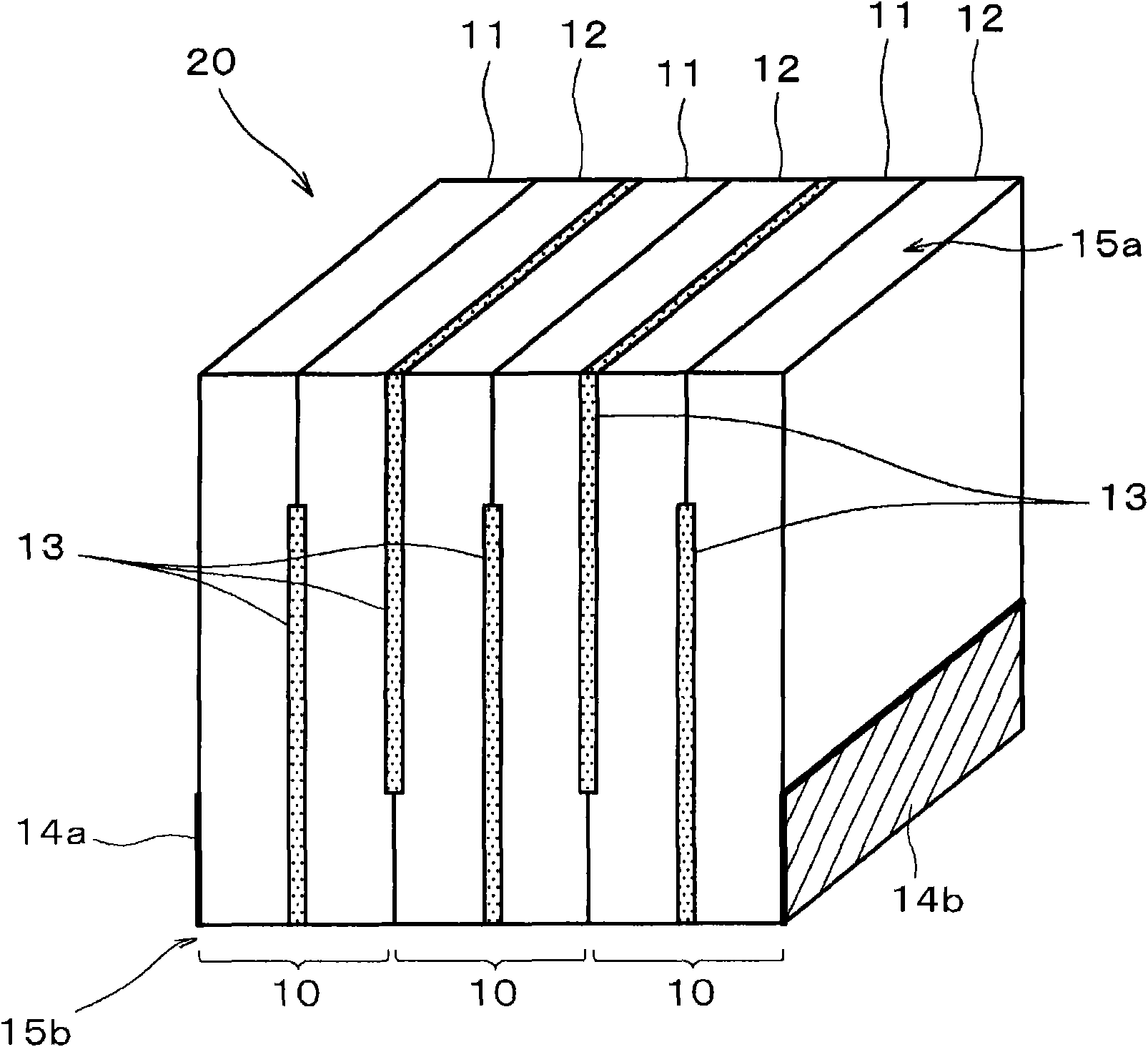

Substrate for power modules, substrate with heat sink for power modules, power module, method for producing substrate for power modules, and paste for bonding copper member

ActiveCN104067386AInhibition of ruptureReliable jointSemiconductor/solid-state device detailsSolid-state devicesComputer moduleNitride

This substrate for power modules is obtained by laminating and bonding a copper plate, which is formed of copper or a copper alloy, onto the surface of a ceramic substrate (11). A nitride layer (31) is formed on the surface of the ceramic substrate (11) between the copper plate and the ceramic substrate (11). An Ag-Cu eutectic structure layer (32) having a thickness of 15 [mu]m or less is formed between the nitride layer and the copper plate.

Owner:MITSUBISHI MATERIALS CORP

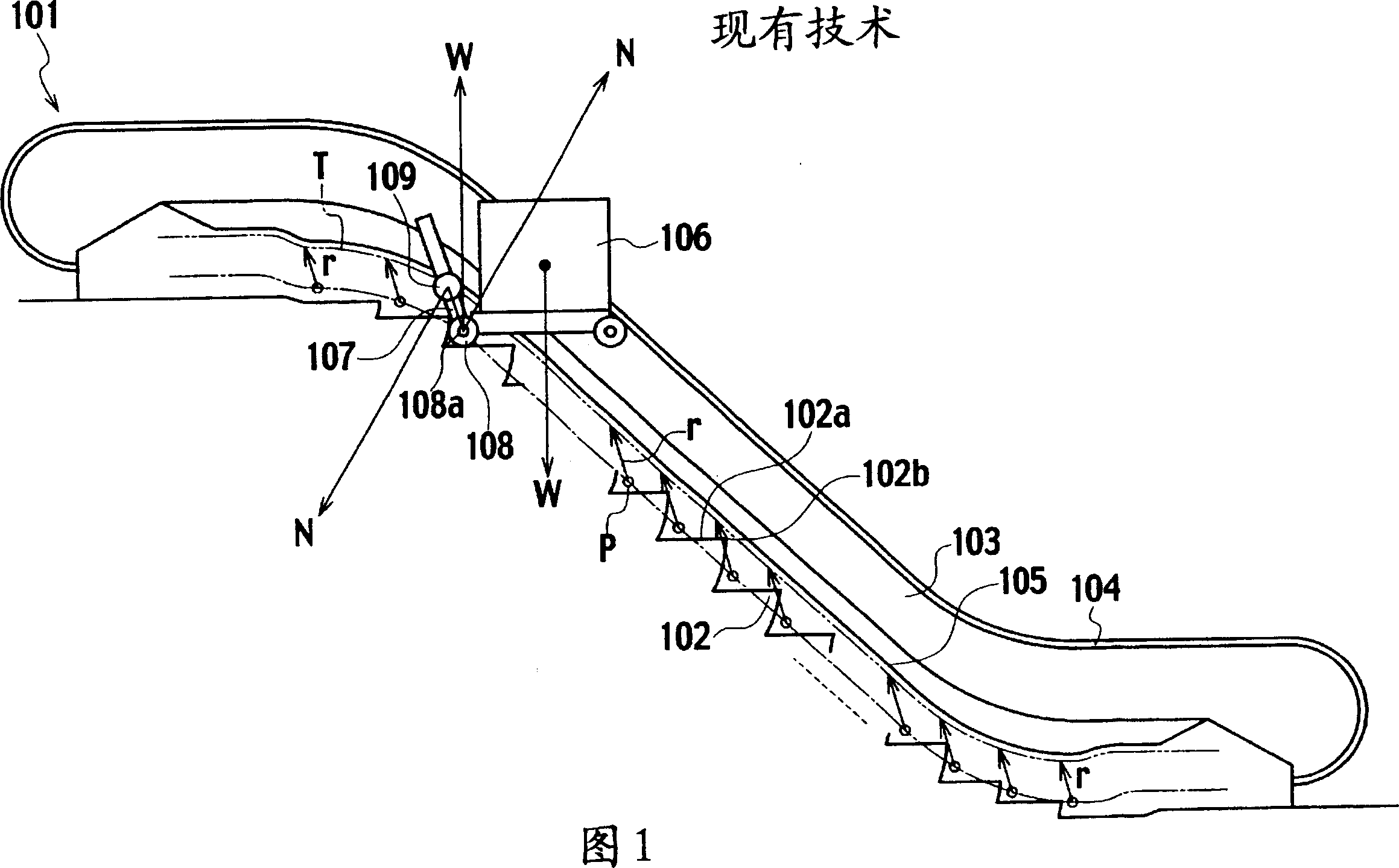

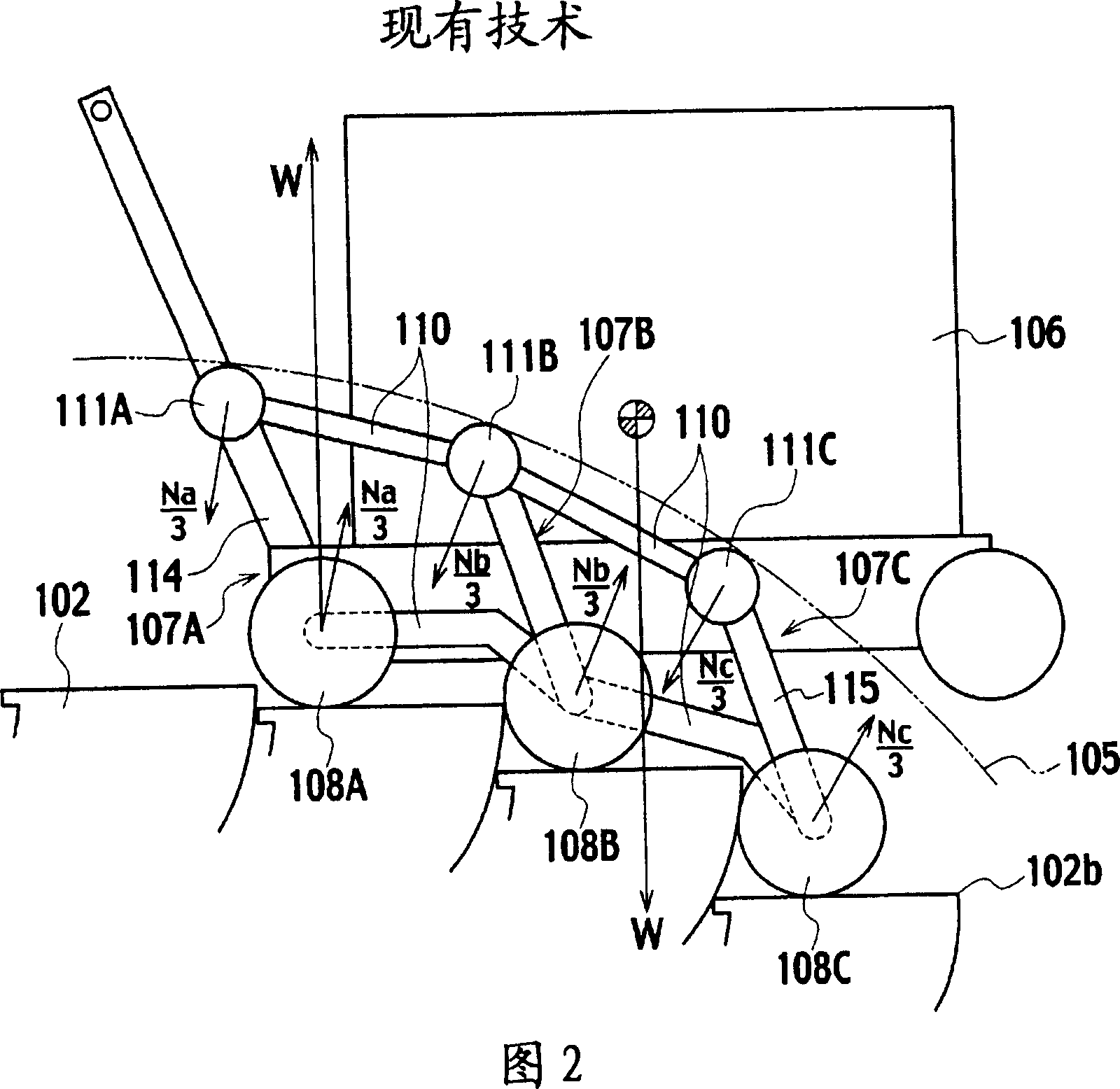

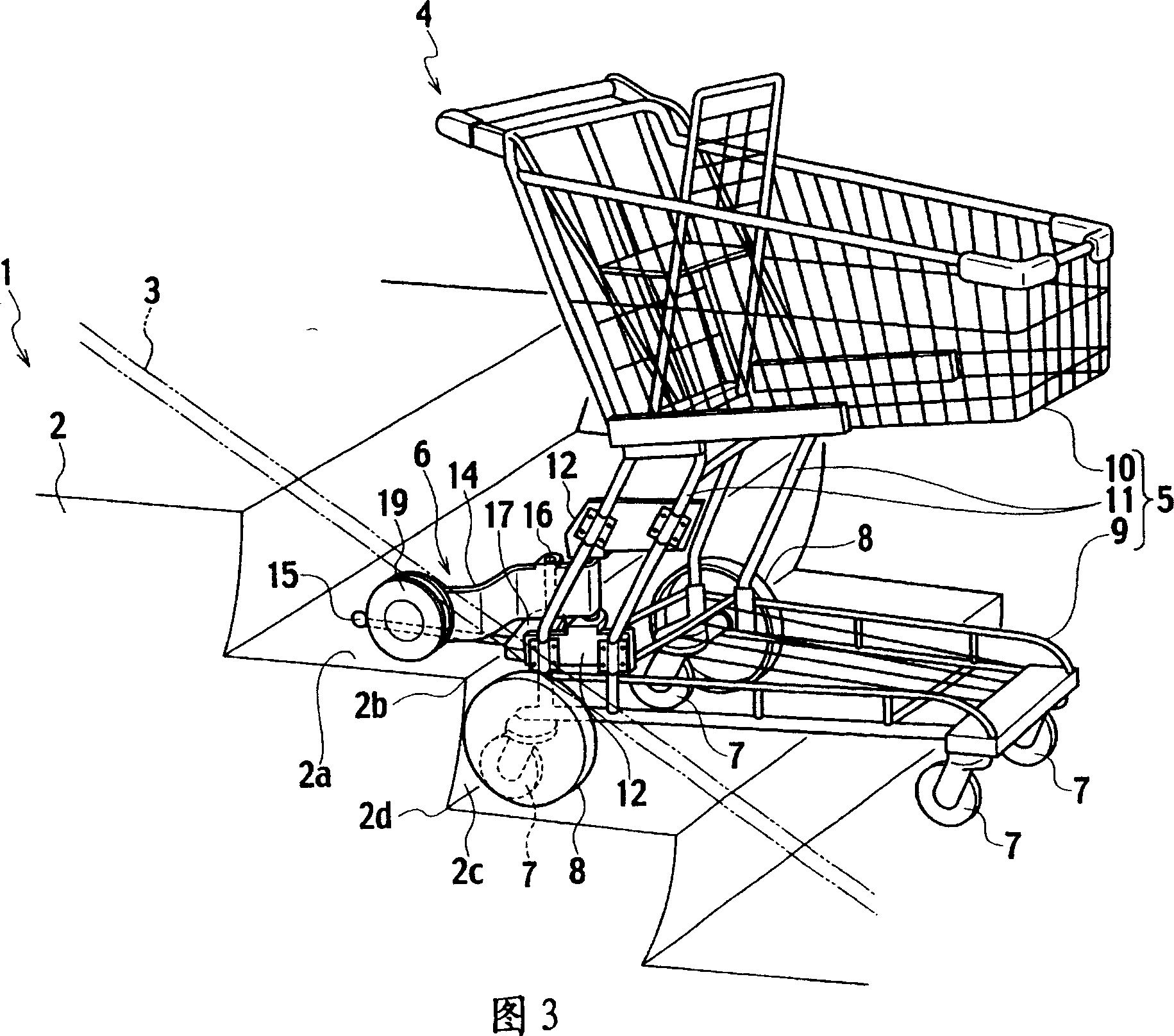

Carriage for escalator and escalator

InactiveCN1976865AReliable jointSmooth and stable rideWheelchairs/patient conveyanceEscalatorsEngineeringCarriage

A cart for an escalator, wherein a cart body (5) comprises caster wheels (7) rotatable in all directions about vertical rotating axes. A copying mechanism (6) is engaged with an escort rail (3) to maintain the cart body (5) in a specified attitude. Contact parts (8) fitted to the cart body (5) are brought into contact with the rise face (2c) of a step (2) to separate the caster wheels (7) from the rise face (2c).

Owner:TOSHIBA ELEVATOR KK

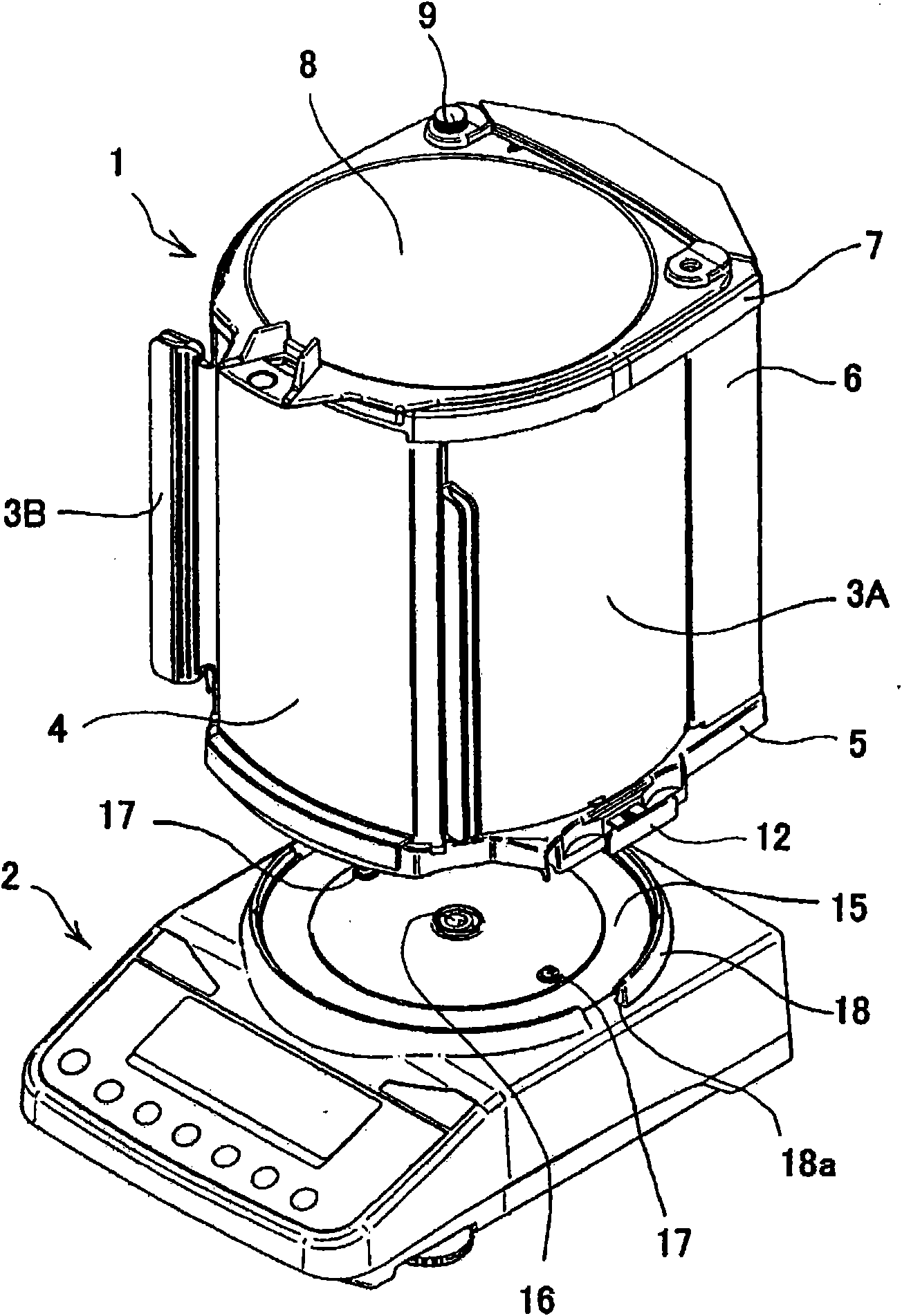

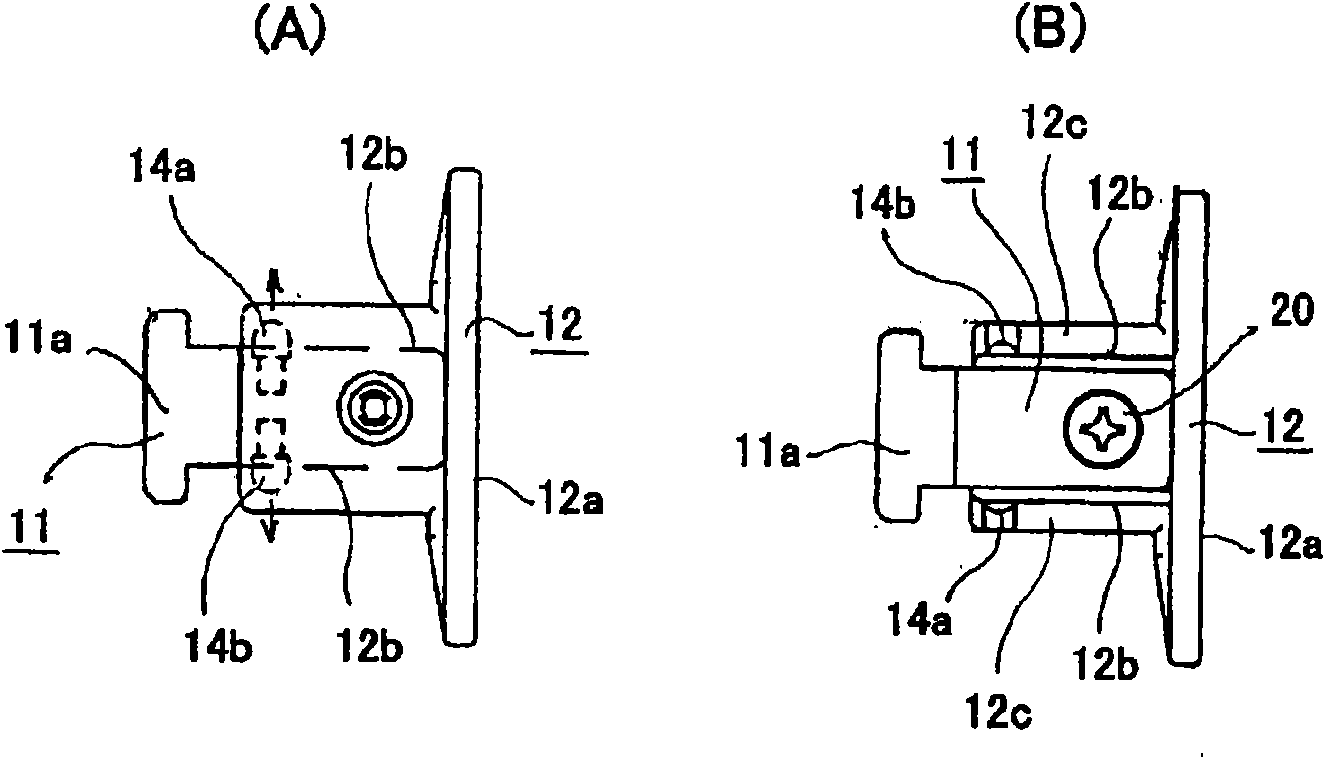

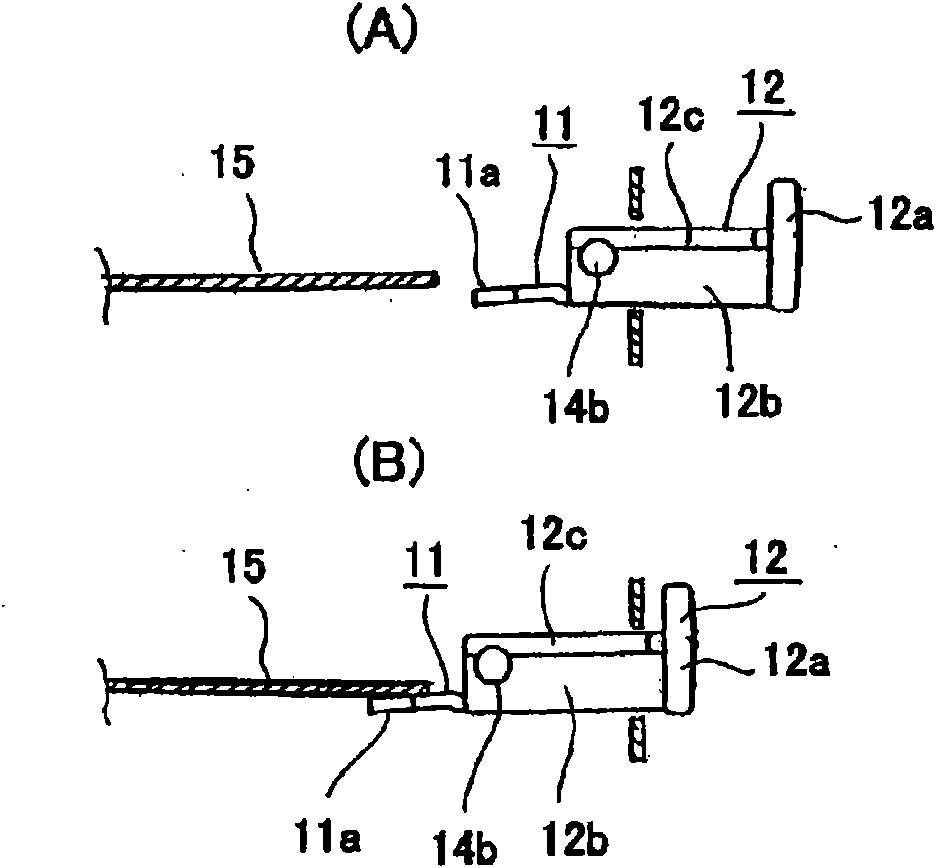

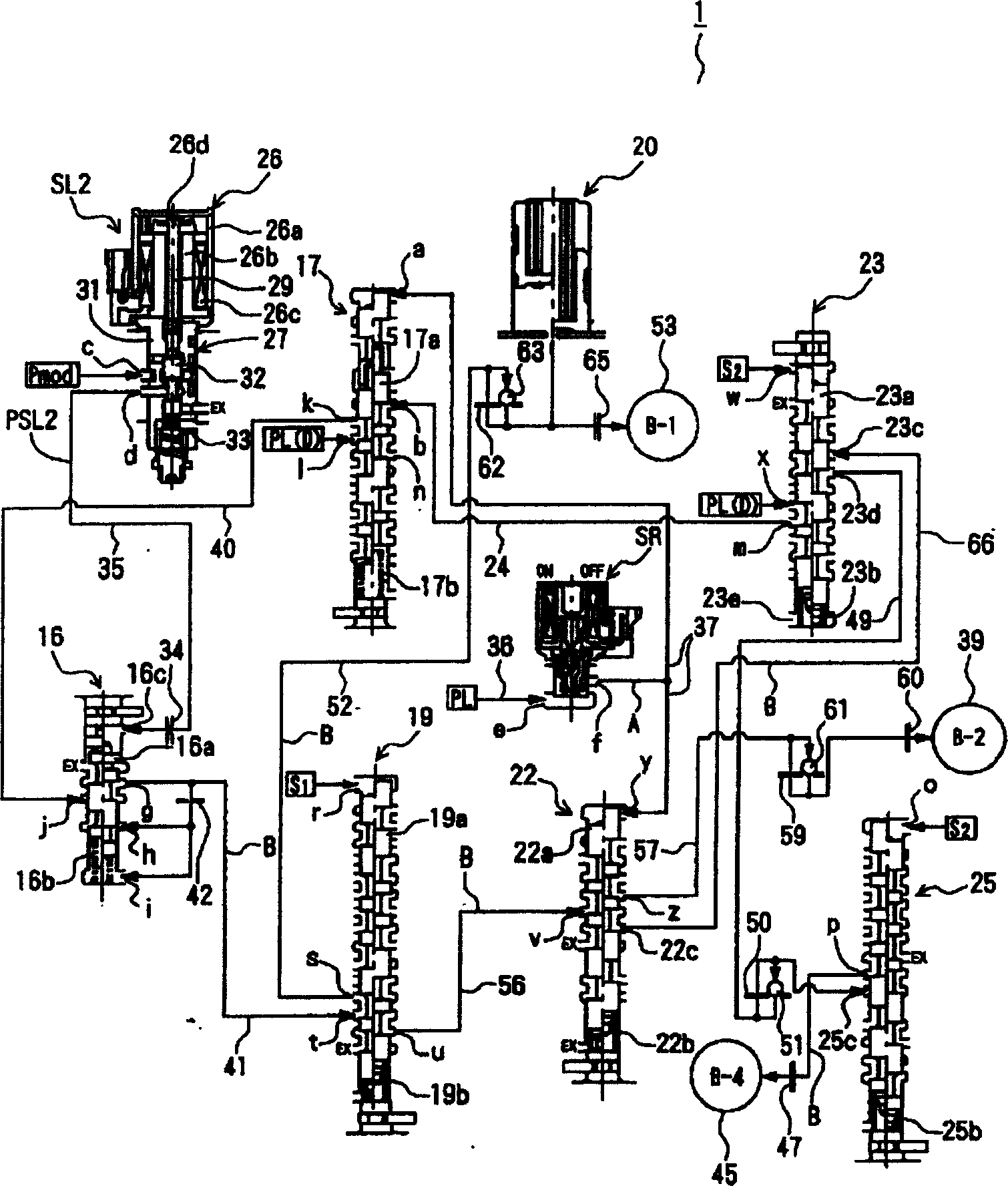

Detachable windshield for weighing device

A detachable windshield provided with attaching and detaching means for strongly fixing the windshield to an electronic scale by just a single touch of a moving member is obtained. A pair of moving members 12 that is moved inside and outside a detachable windshield 1 is provided in a lower frame member 5 of the windshield 1, and an engagement member that is engaged with a backside of a pan floor member 15 of an electronic scale 2 is provided in the moving member 12. The detachable windshield 1 is placed on the electronic scale 2 with the moving member 12 drawn to the outside of the windshield.At this point, the moving members 12 are pushed. As a result, a latch member provided in the moving member 12 is latched in the backside of the pan floor member 15 on the side of the electronic scale2, and the detachable member 1 and the electronic scale 2 are integrally engaged with each other. The moving member 12 is drawn to release the engagement state between the pan floor member 15 and thelatch member, thereby detaching the windshield 1. The windshield 1 can easily and instantaneously be attached and detached by manipulating the moving member 12.

Owner:A&D CO LTD

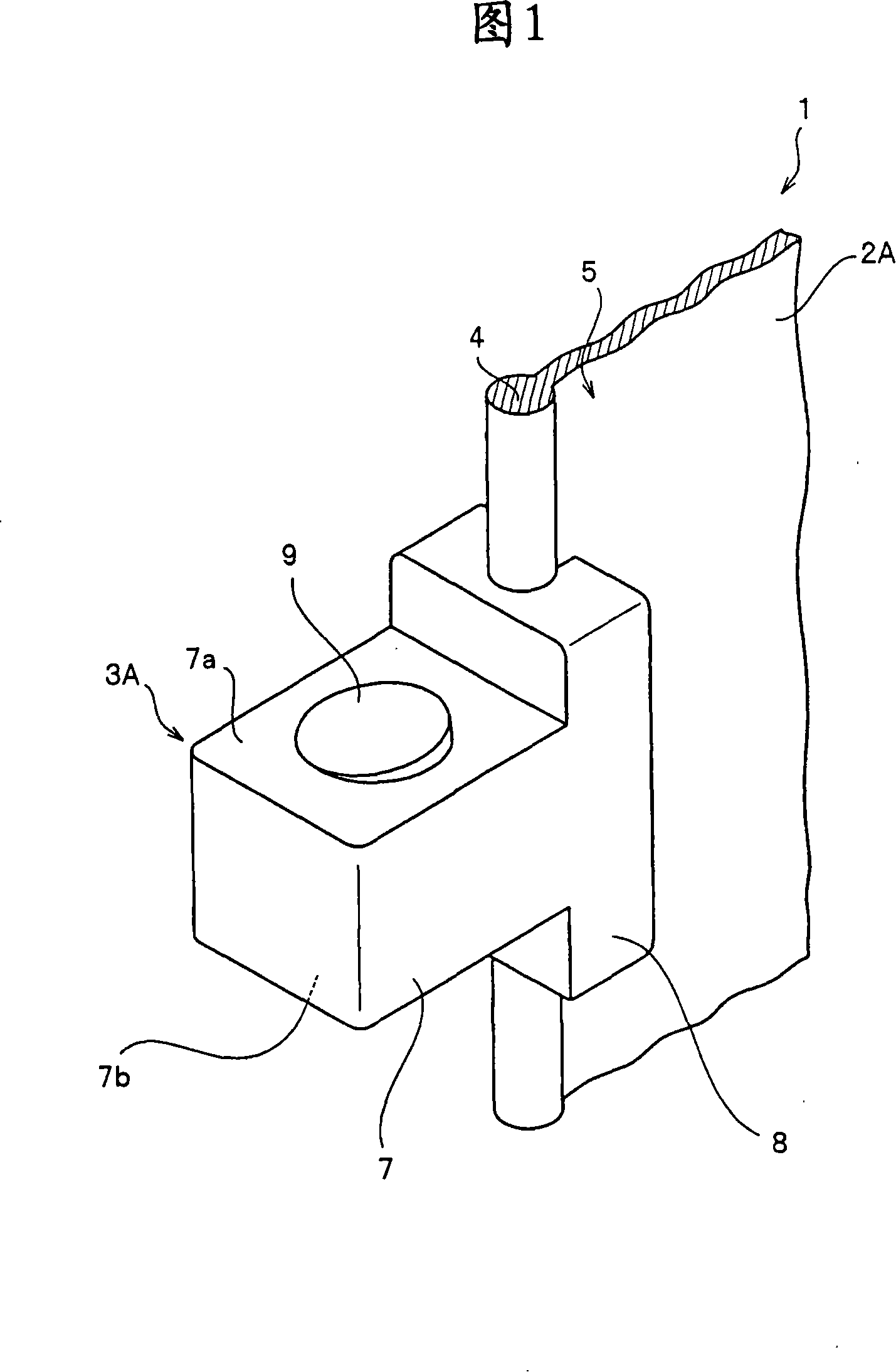

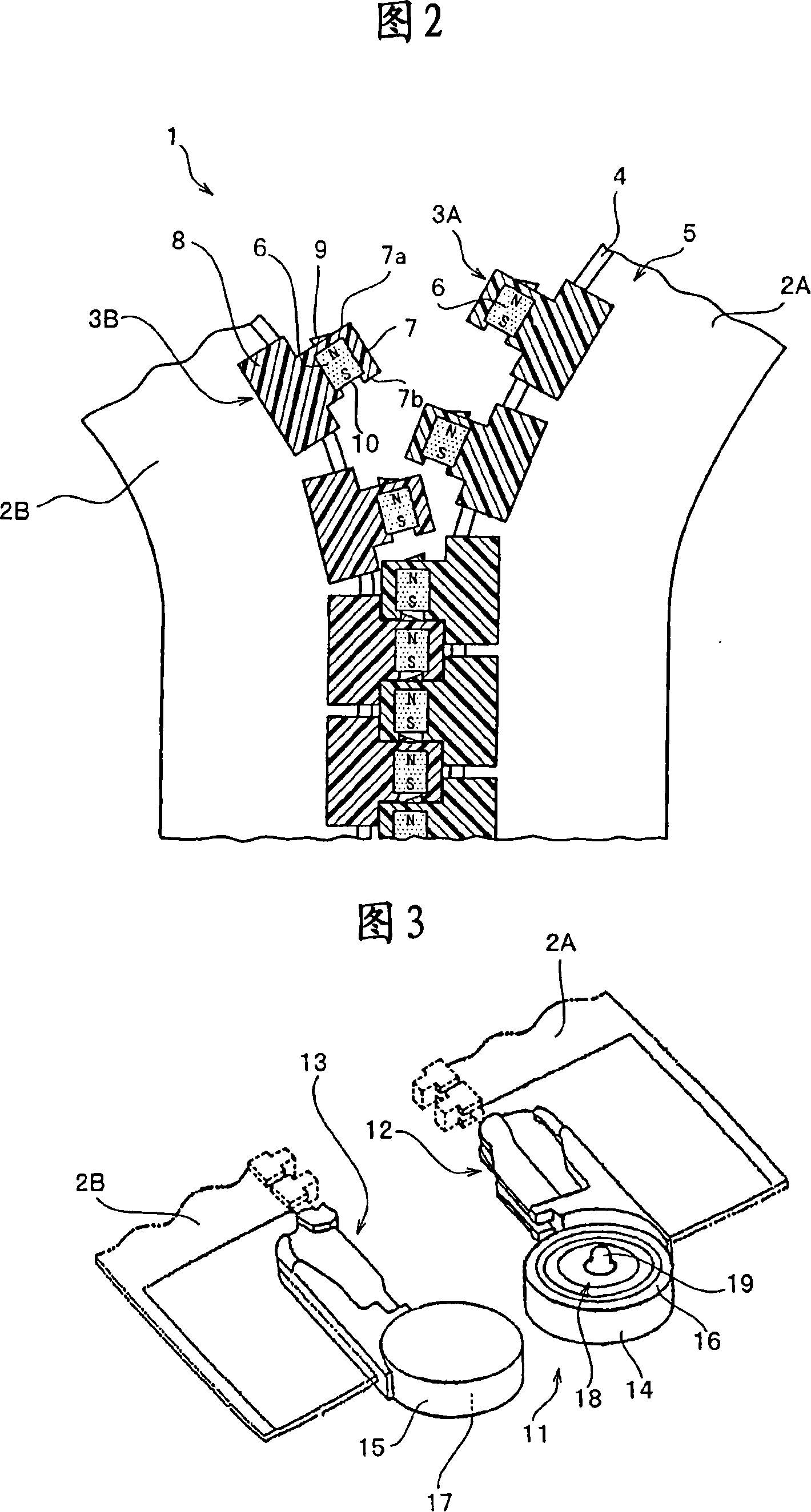

Verschluss

ActiveCN101081115AStay engagedPrevent openingSlide fastenersOther accessoriesMagnetic tension forcePull force

A fastener wherein right and left side edge portions can be engaged using a magnetic force, and which can be applied preferably for plastic article such as clothes and further prevented from being opened carelessly even if a lateral pulling force is applied when right and left elements are engaged. In the fastener, a plurality of first and second magnetic elements(3A,3B) having magnetism are provided in lines on a pair of first and second fastener tapes(3A,3B), the first and second magnetic elements(3A,3B) are adsorbed to each other using a magnetic force, characterized in that the first and second magnetic elements have head portions(7), a leg portion(8), and engagement / disengagement portions(9,10) formed at the head portions and mechanically engaged with or disengaged from each other between the first and second magnetic elements(3A,3B), the first and second magnetic elements are respectively disposed at predetermined intervals, the magnetic elements(3A) of one fastener tape(2A)(3B) are adsorbed to spaces between the adjacent magnetic elements of the other fastener tape(2B), and the first and second magnetic elements(3A,3B) are engaged with each other alternately.

Owner:YKK CORP

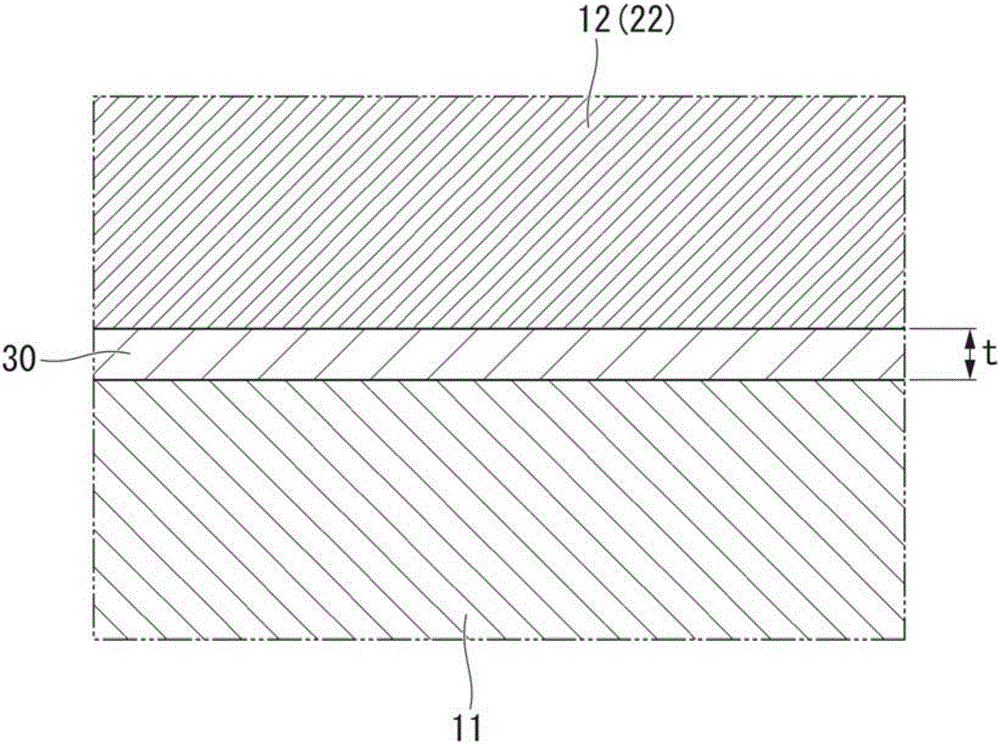

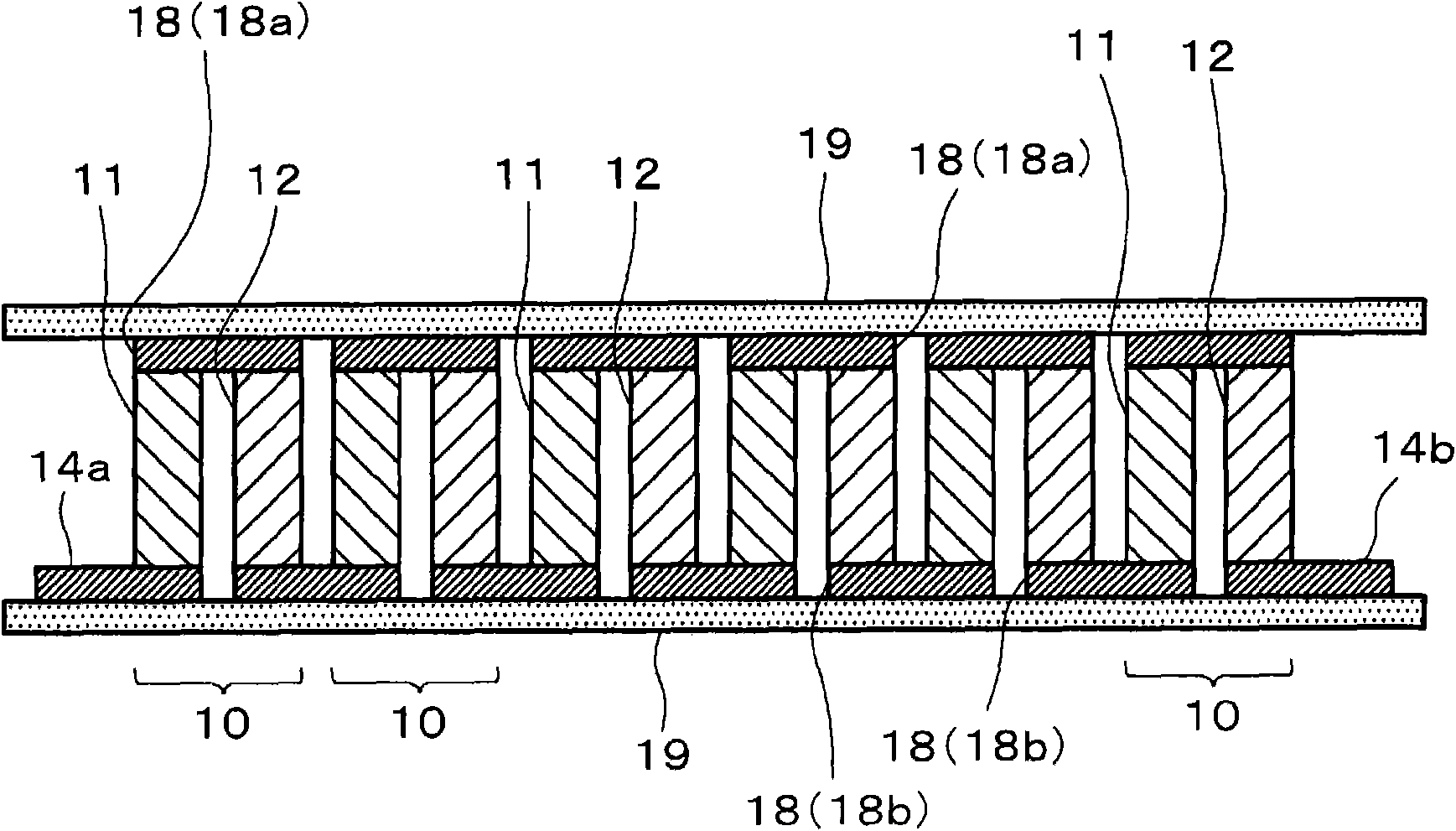

Copper/ceramic bond and power module substrate

ActiveCN105980334AReliable jointSemiconductor/solid-state device detailsSolid-state devicesBond interfaceComputer module

The invention discloses a copper / ceramic bond and a power module substrate. The copper / ceramic bond formed by bonding a copper member (22) comprising copper or copper alloy to a ceramic member (11) comprising nitride ceramic, wherein in a bonded interface of the copper member (22) and ceramic member (11) an active element oxide layer (30) containing an active element and oxygen is formed, and the active element oxide layer (30) has a thickness (t) in the range of 5 to 220 nm.

Owner:MITSUBISHI MATERIALS CORP

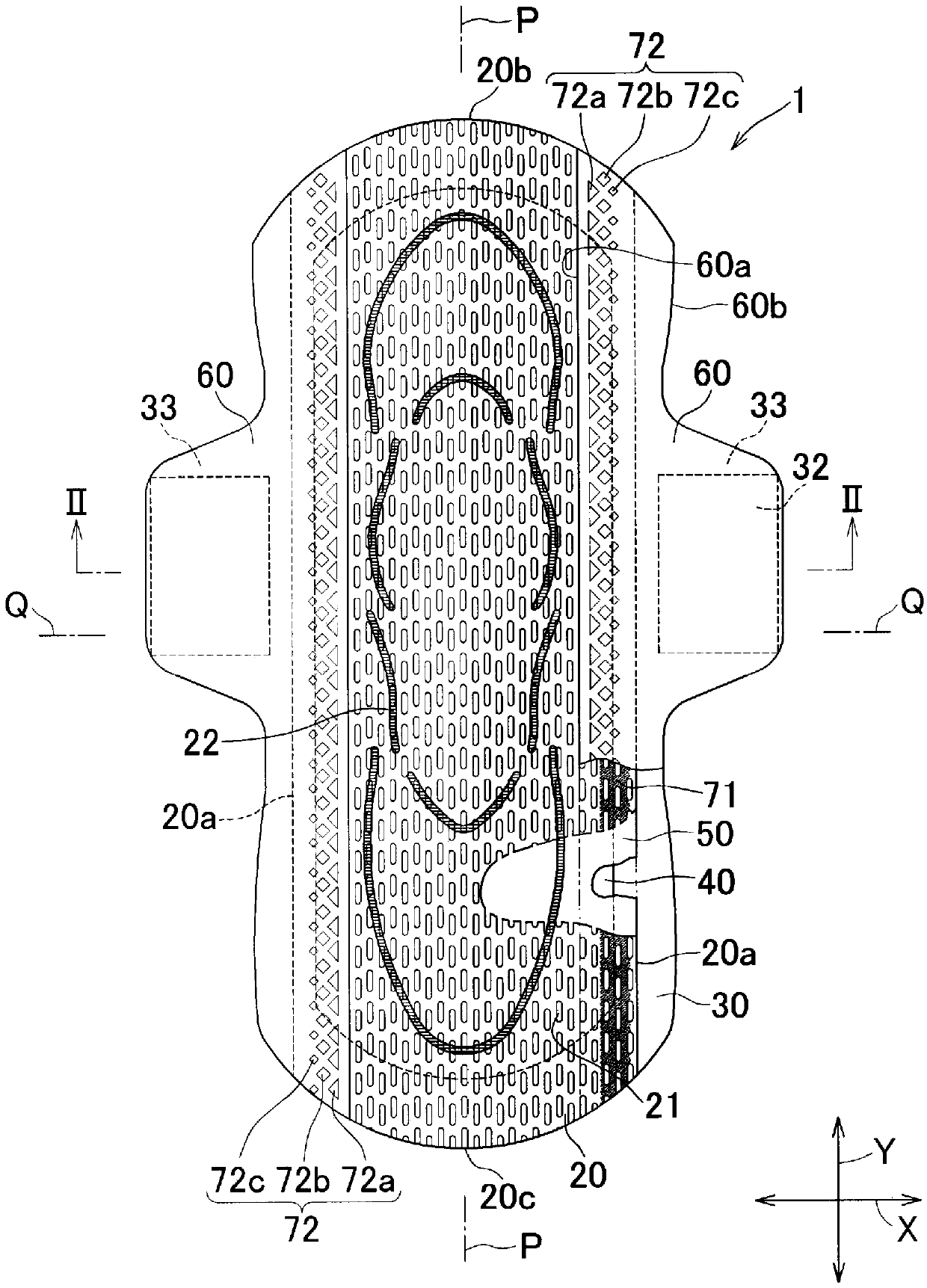

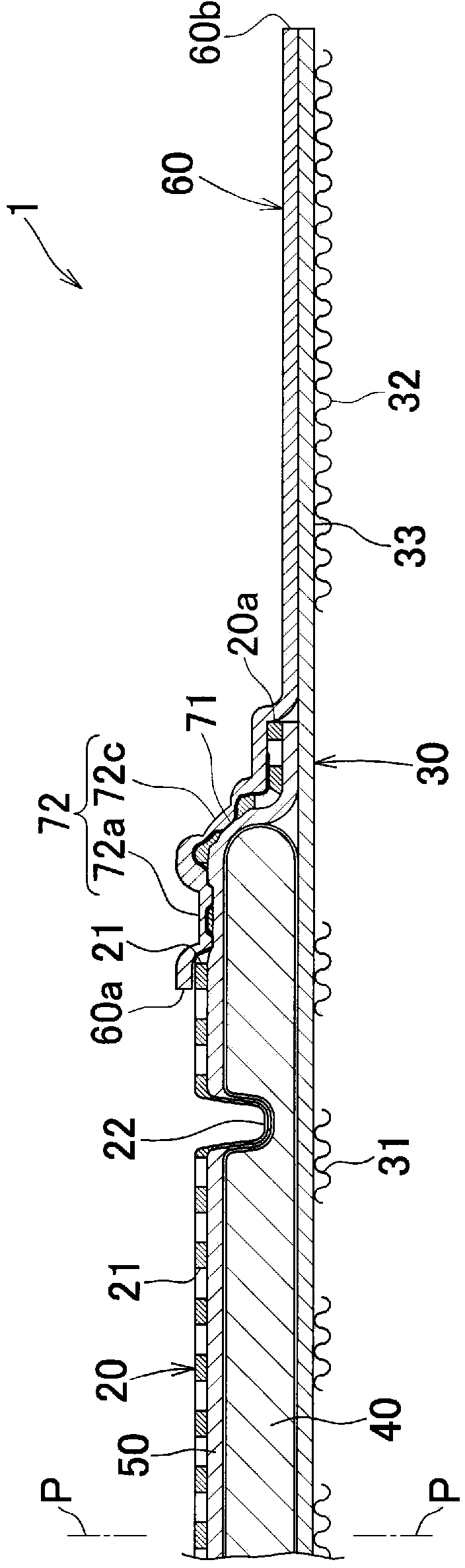

Absorbent article

InactiveCN103826584AReliable jointAvoid peeling off each otherAbsorbent padsBaby linensHot meltNatural fiber

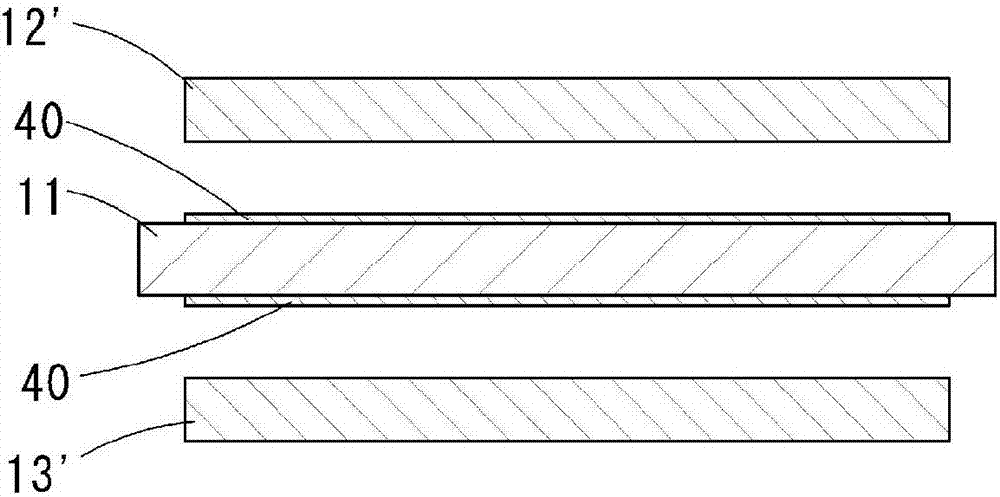

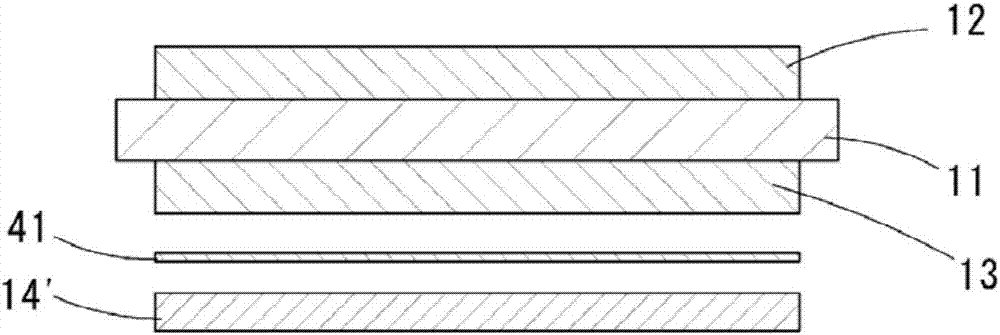

Provided is an absorbent article, wherein the surface sheet, which contains non-heat-meltable fibers, does not peel off easily. The sanitary napkin (1) comprises: a surface sheet (20); a back sheet (30); a body fluid absorbent (40) that is positioned between the surface and back sheets (20, 30); a heat-meltable sheet (50) that is positioned between the surface sheet (20) and the absorbent (40); and a pair of side sheets (60) that are positioned on the skin-facing surface of the surface sheet (20). The heat-meltable sheet (50) and the side sheets (60) are formed using synthetic fiber that contains thermoplastic resin. The surface sheet (20) is formed using cotton fiber, which is a natural fiber. Multiple openings (21), which penetrate in the thickness direction thereof, are formed. The side sheets (60) are attached so as to overlap and cover the two side edges (20a) of the surface sheet (20). Adhesive sections (71) are formed between the surface sheet (20) and the side sheets (60). Welded sections (72) resulting from heating and pressurization are formed between the side sheets (60) and the heat-meltable sheet (50). Portions of the adhesive sections (71) and the welded sections (72) overlap each other.

Owner:UNI CHARM CORP

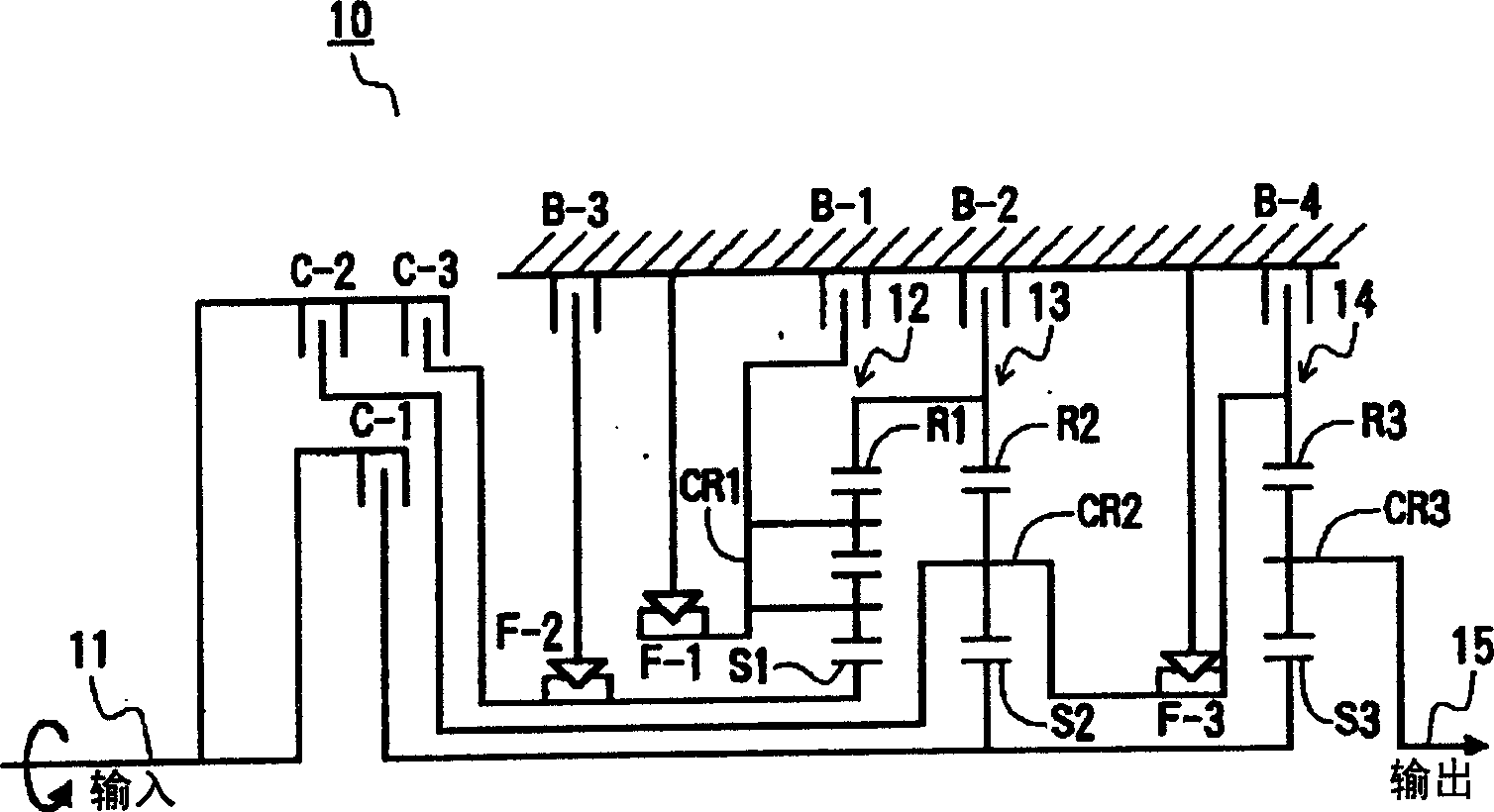

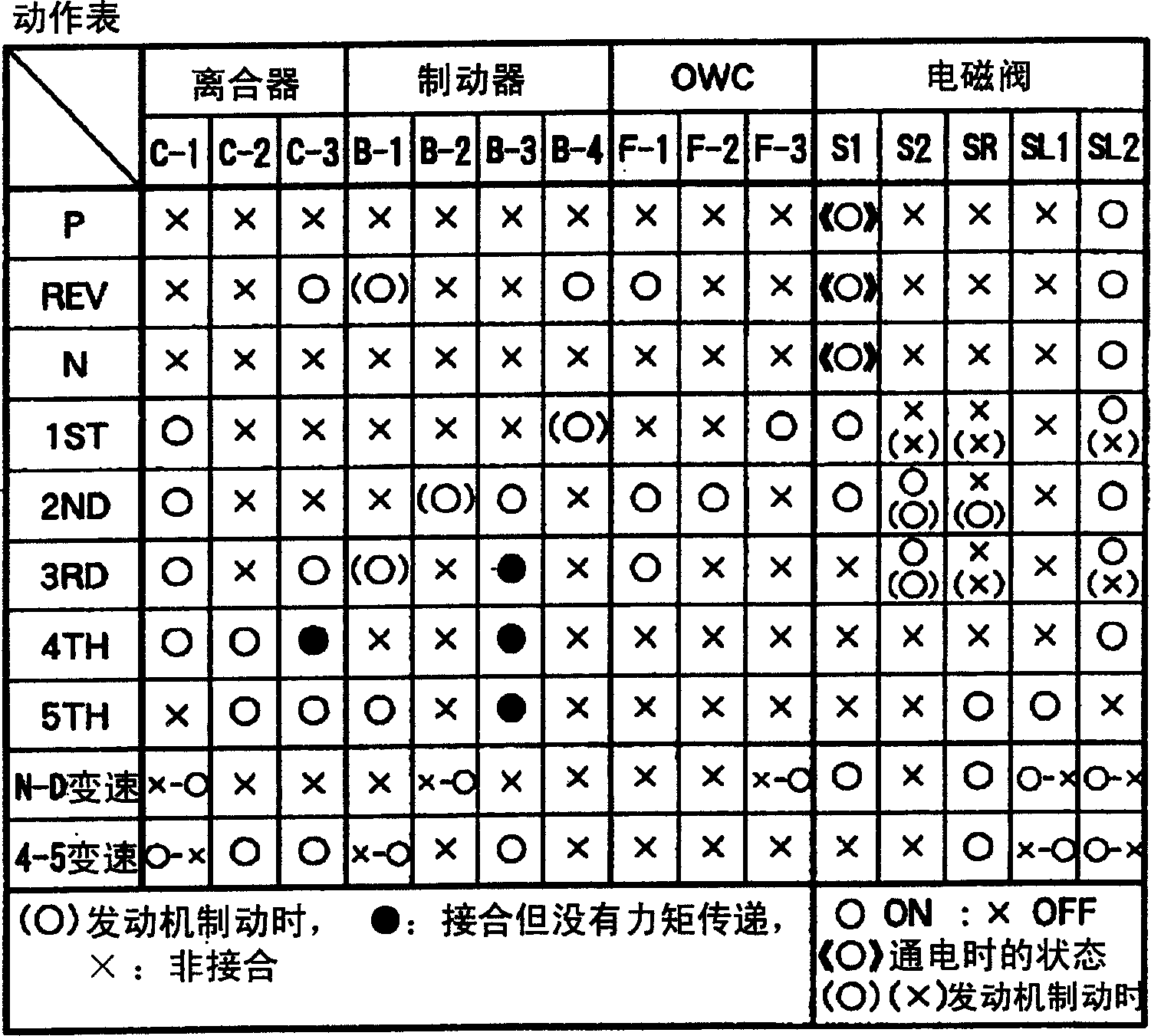

Hydraulic control system for automatic transmission

InactiveCN1501013ASimple compositionCushion the shockGearing controlAutomatic transmissionEngineering

The hydraulic control device 1 of the automatic transmission has a 3-4 shift valve 23 for outputting initial pressure of a first route at a third speed stage lower than a fourth speed stage directly connecting an input shaft 11 and an output shaft 15 of the automatic transmission and a clutch apply control valve 17 for outputting initial pressure of a second route at a fifth speed stage higher than the direct connection stage.Both valves 23 and 17 perform a control to block both initial pressures of the first and second routes at the direct connection stage.

Owner:AISIN AW CO LTD +1

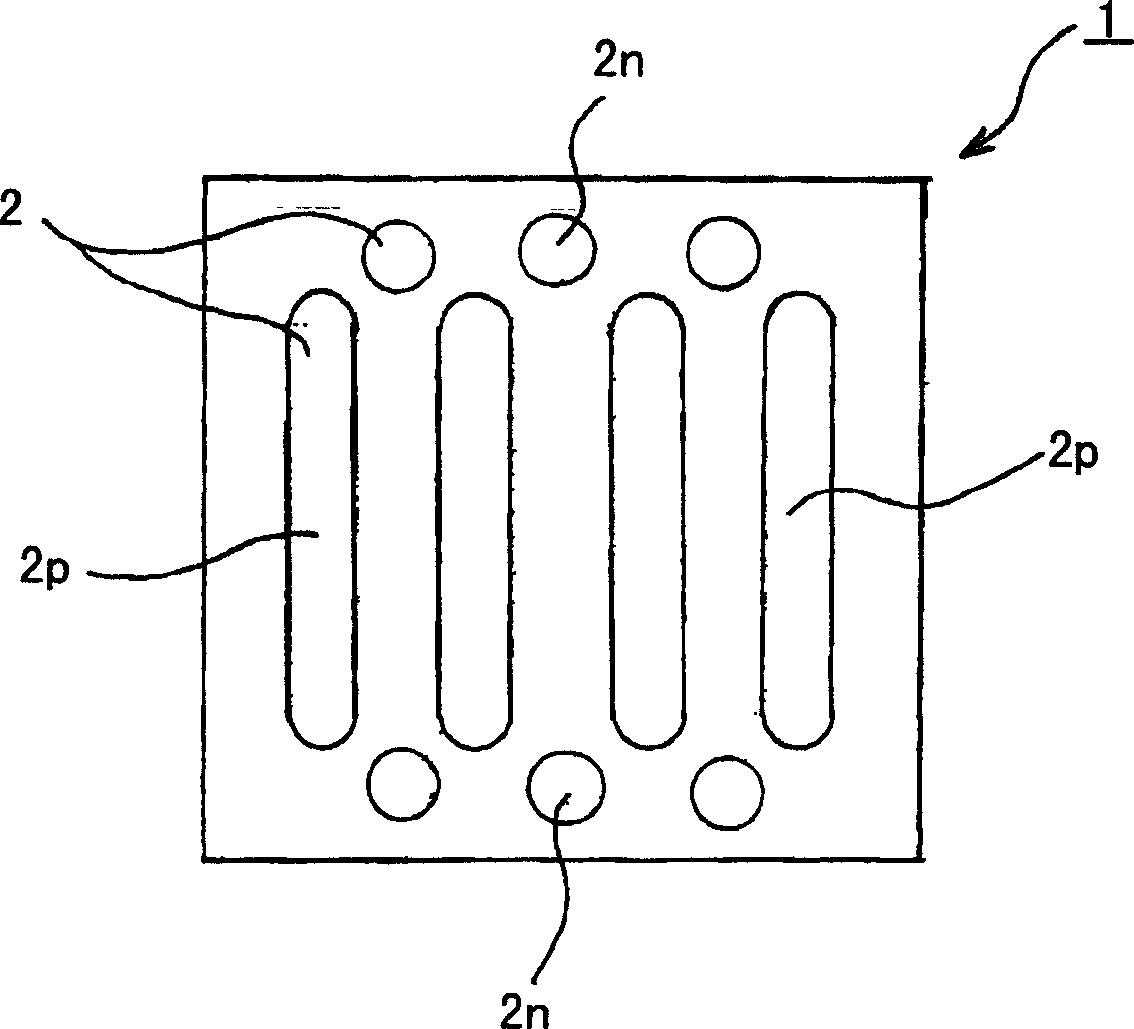

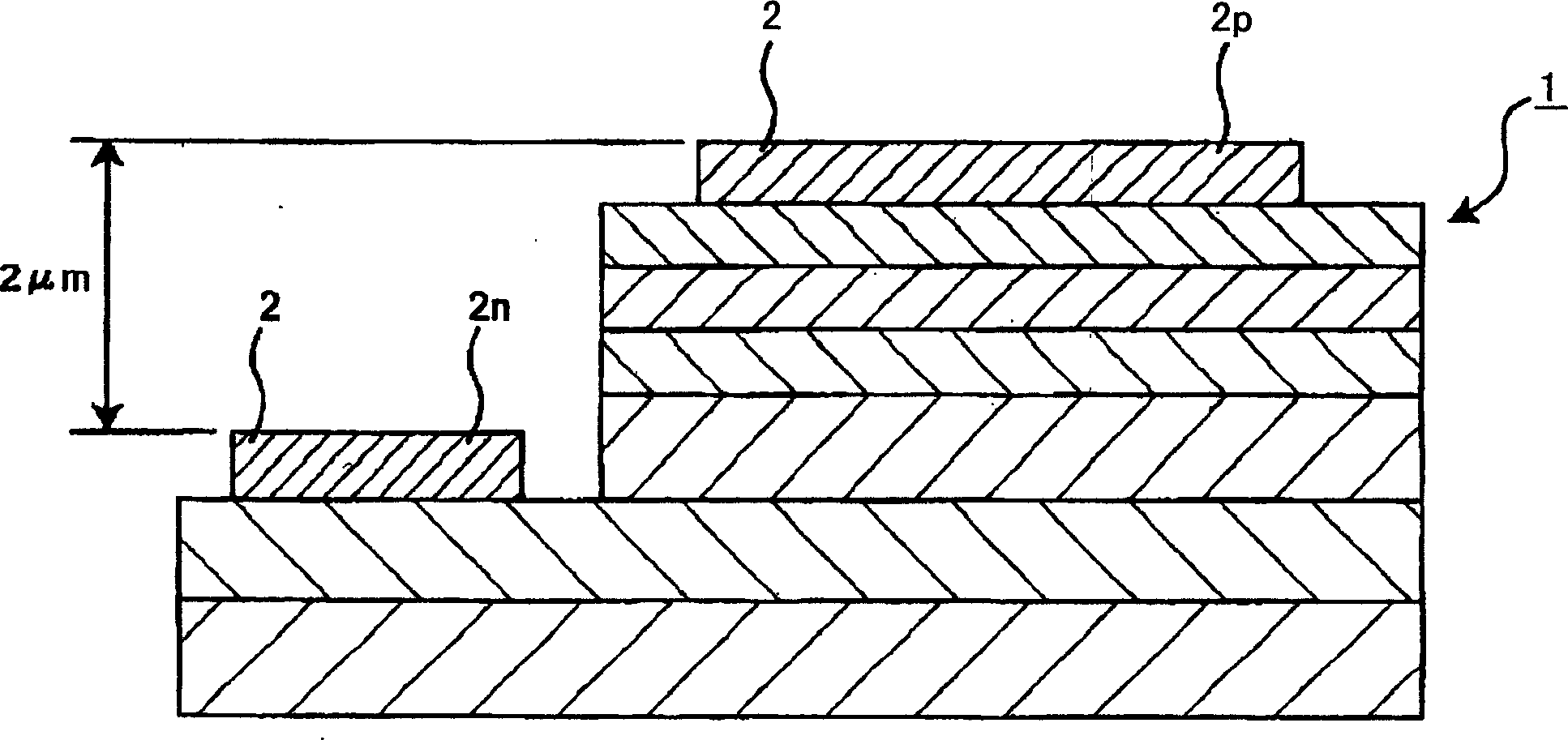

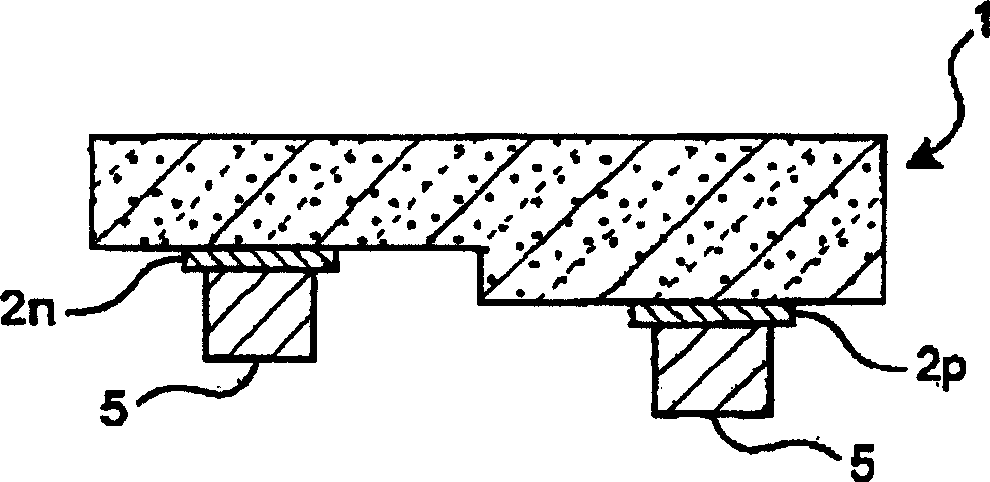

Thermoelectric conversion element, thermoelectric conversion module, and process for producing thermoelectric conversion element

ActiveCN101681977AEasy to shareLower resistanceThermoelectric device with peltier/seeback effectThermoelectric device manufacture/treatmentThermoelectric conversionContact resistance

This invention provides a thermoelectric conversion element, which has low contact resistance between a p-type thermoelectric conversion material and an n-type thermoelectric conversion material and,at the same time, does not cause oxidation-derived deterioration, and can be used even at an elevated temperature, and a thermoelectric conversion module, and a process for producing a thermoelectricconversion element. A material composed mainly of a substance having a layered perovskite structure represented by a compositional formula of A2BO4 (wherein A represents one or a plurality of elementsincluding at least La; and B represents one or a plurality of elements including at least Cu) is used as a p-type oxide thermoelectric conversion material (11). A material composed mainly of a substance having a layered perovskite structure represented by a compositional formula of D2EO4 (wherein D represents one or a plurality of elements including at least one of Pr, Nd, Sm, and Gd; and E represents one or a plurality of elements including Cu) is used as an n-type oxide thermoelectric conversion material (12). The p-type oxide thermoelectric conversion material, the n-type oxide thermoelectric conversion material, and the composite insulating material (13) are cosintered. A glass having a glass softening point of 550 to 750 DEG C or above is used as a glass constituting the composite insulating material.

Owner:MURATA MFG CO LTD

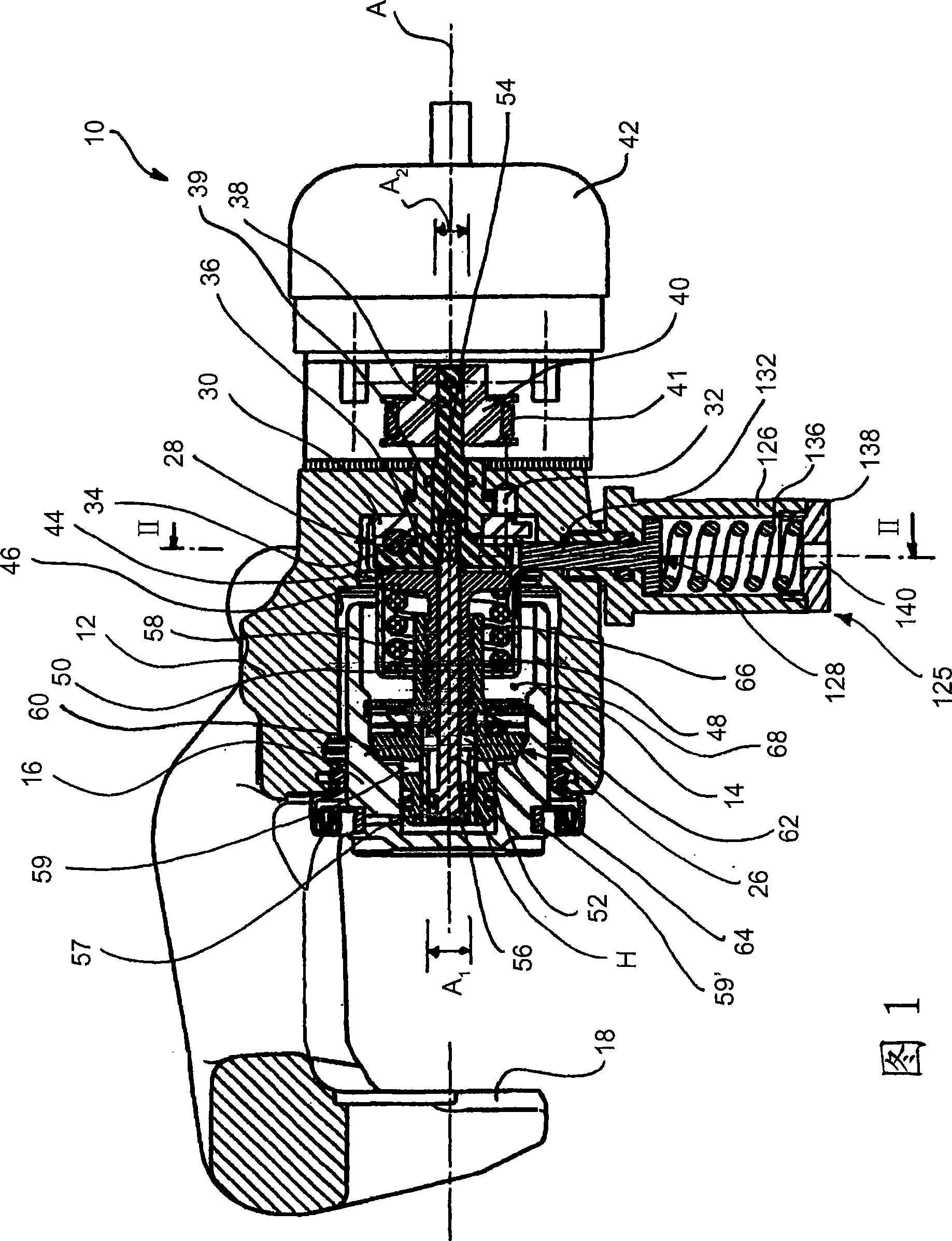

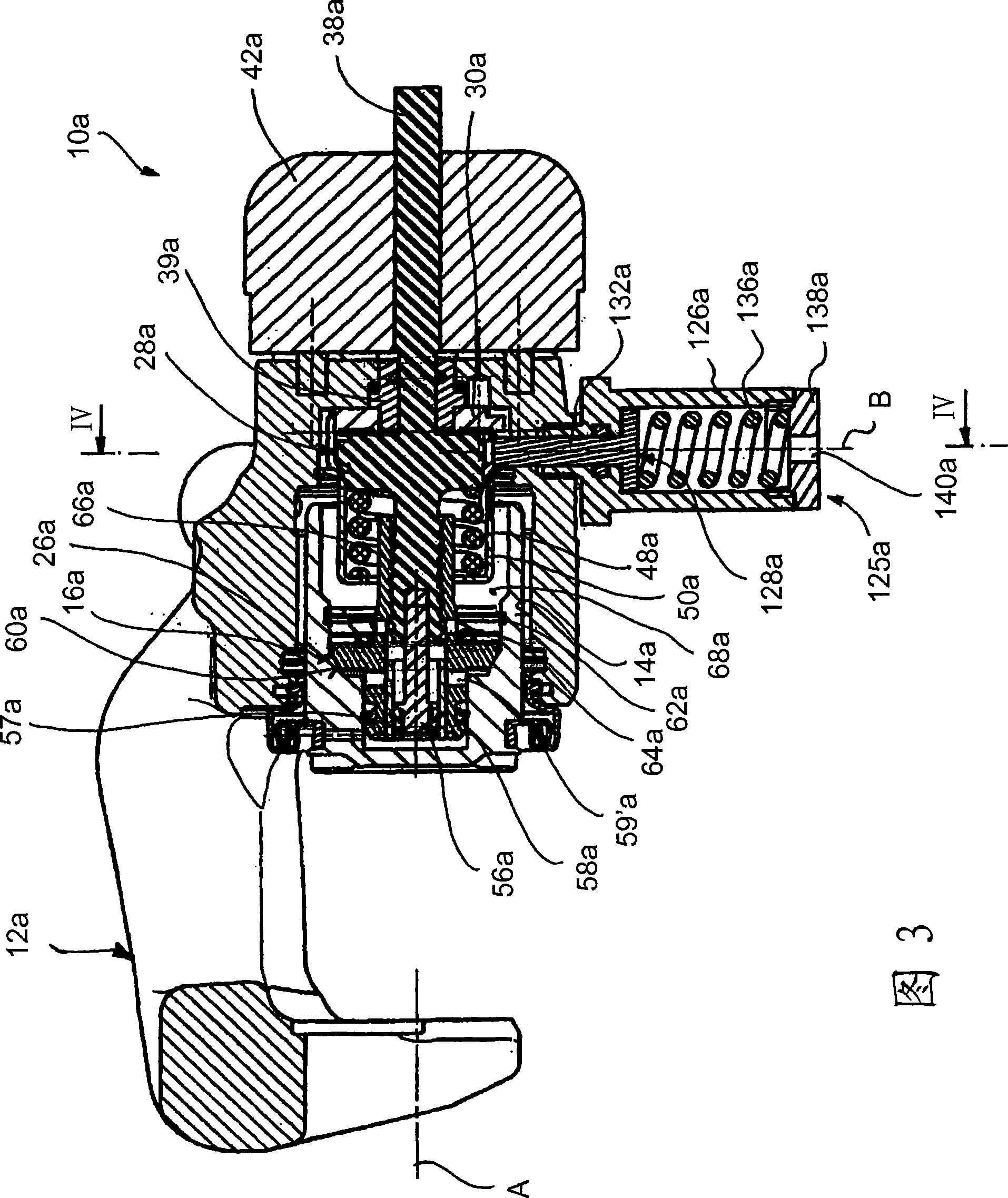

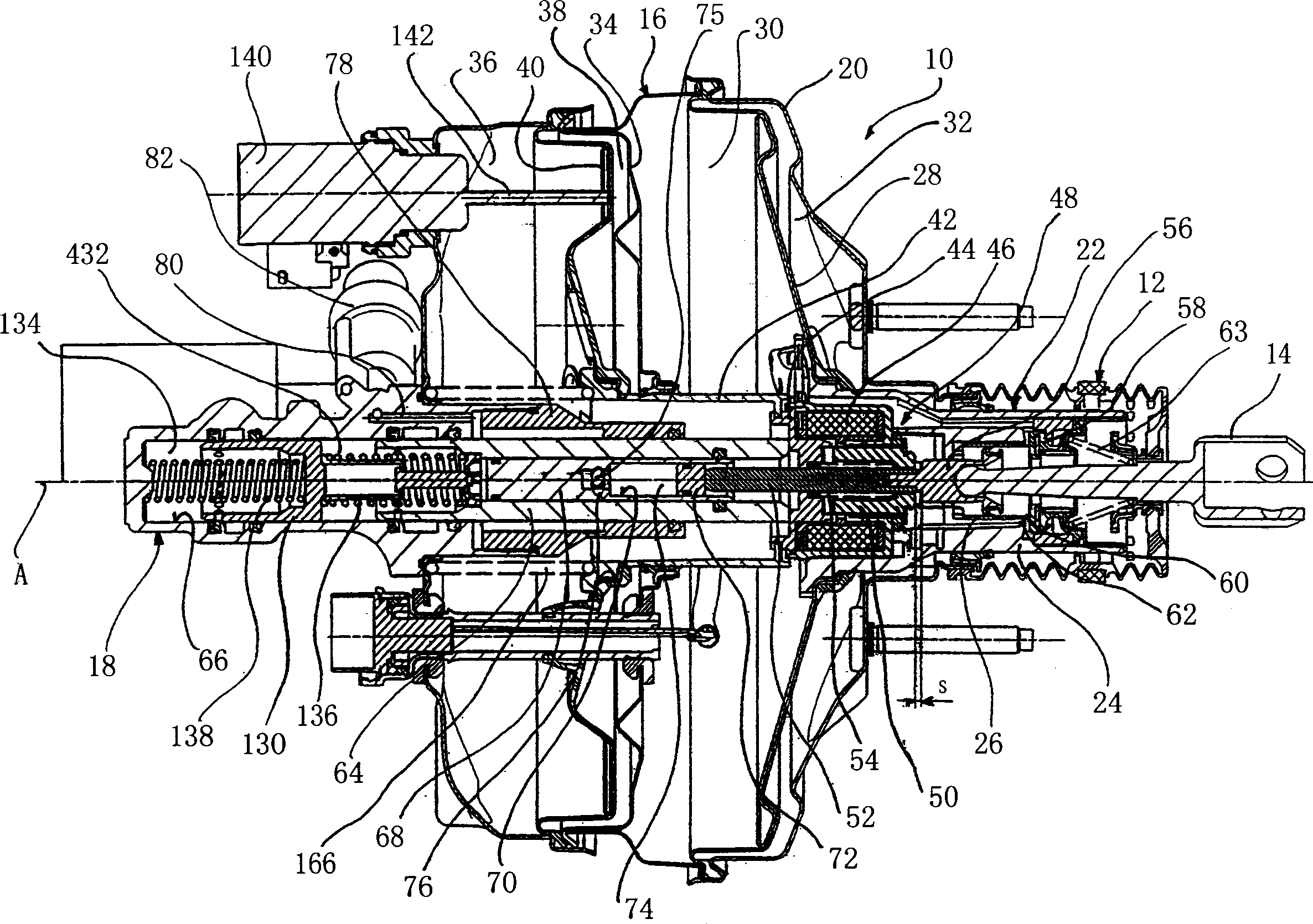

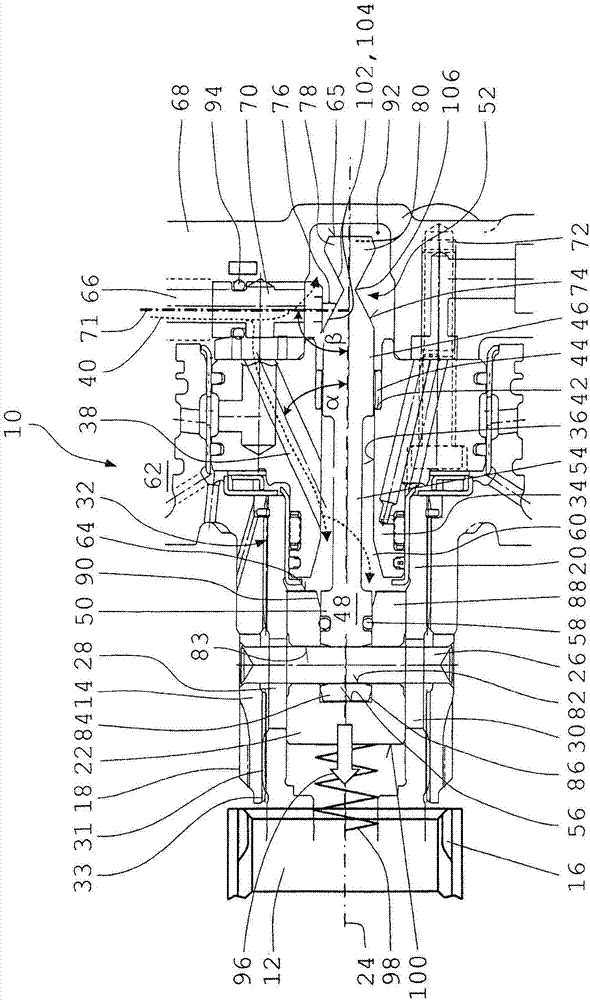

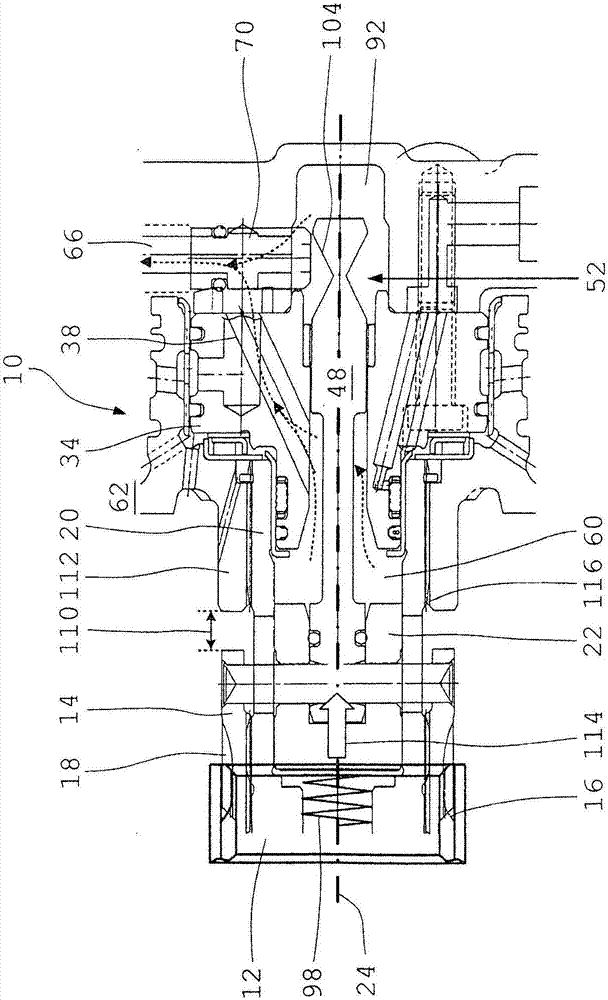

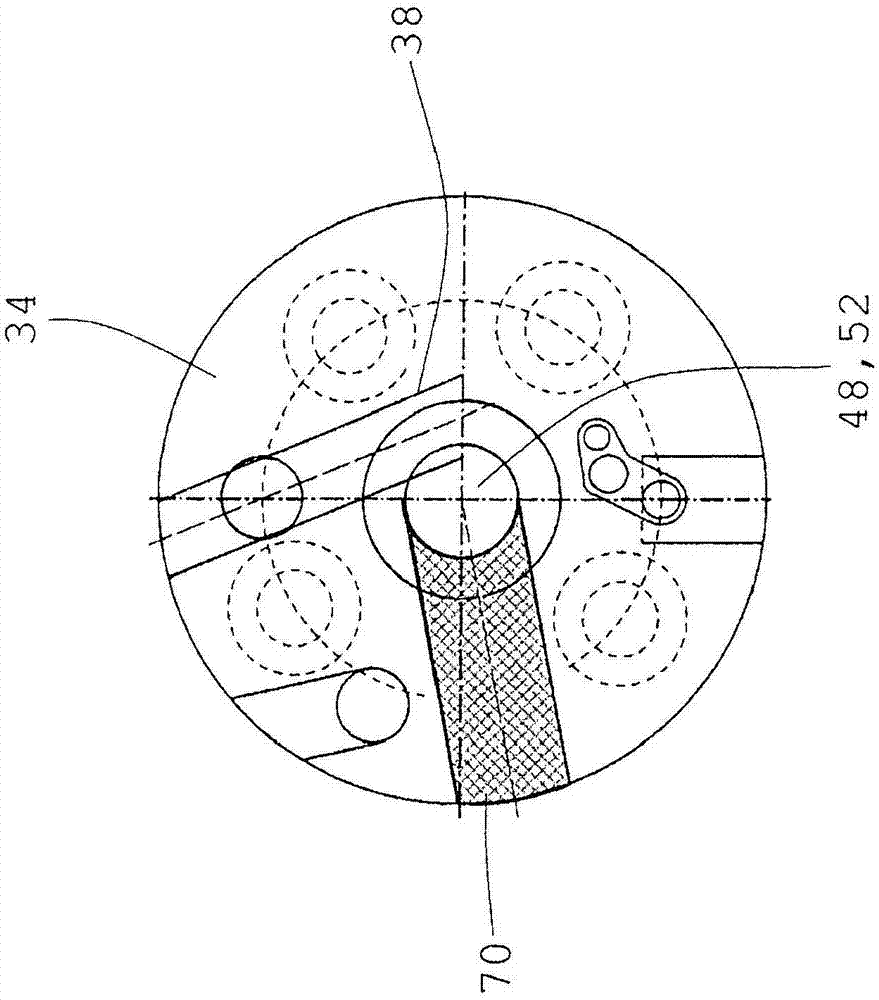

Hydraulically actuable vehicle brake having a locking means

InactiveCN101421534AAchieve compensationReduce reaction forceBrake actuating mechanismsActuatorsHydraulic fluidControl theory

The present invention relates to a vehicle brake (10) having a housing (12), a brake piston (16) which is accommodated in the housing (12) and is coupled to a brake lining (20), a blocking device (26) for locking the brake piston (16) within the housing (12), and an electromechanical actuating device (42) for actuating the blocking device (26) in a parking brake situation, wherein the brake piston (16), together with the housing (12), delimits a fluid chamber (68) which can be loaded with hydraulic fluid, with the result that the brake piston (16) can be displaced hydraulically within the housing (12) along a piston longitudinal axis (A) for actuating the vehicle brake (10).; There is provision in a vehicle brake of this type for the blocking device (26) to be assigned a locking arrangement (125) which acts mechanically on a component (36) of the blocking device (26) in a parking brake situation and blocks a restoring movement of said component (36).

Owner:LUCAS AUTOMOTIVE GMBH

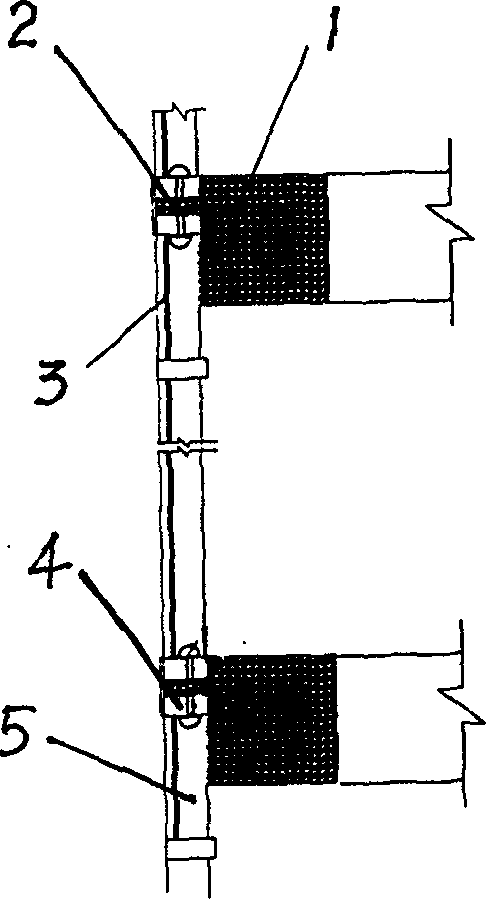

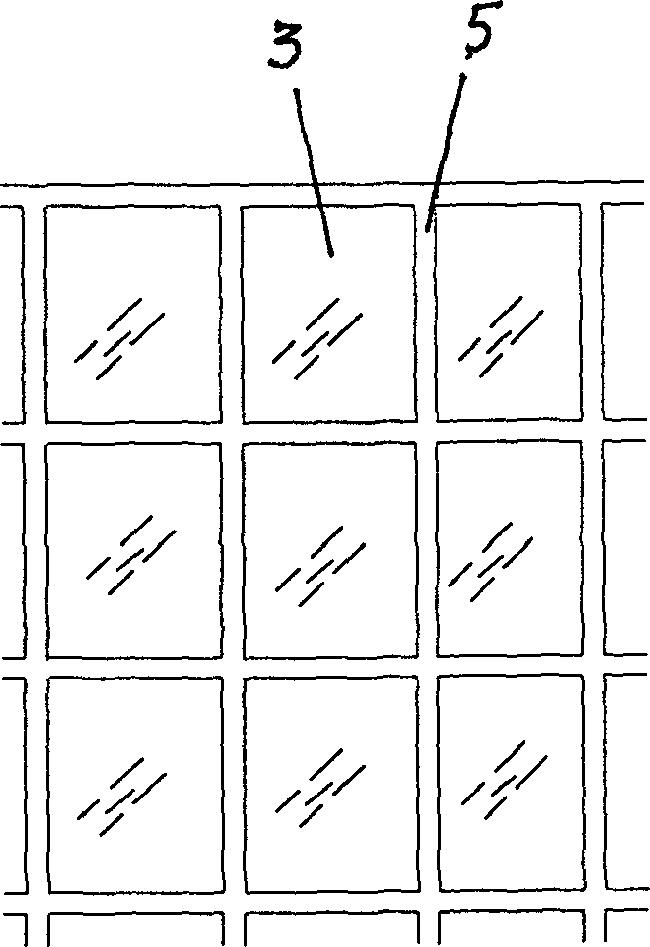

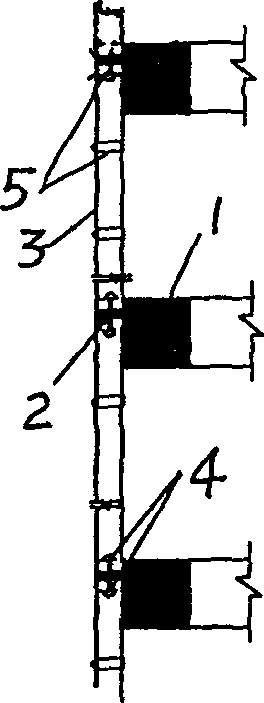

Erection and construction method for glass curtain wall of building

The invention is a method to mount glass curtain wall of building, during building construction, and in the place of building wall to be mounted with glass curtain wall and / or erect surface of the column, setting the supporting structure extending outward in a spacing and layered mode, to mount the frame construction of the curtain wall glass, which is linked with the supporting structure through the linking structure. Its advantages: it can realize the layered processing of structure load of the glass curtain wall, reduce the use number of aluminium alloy connecting and buttoning pieces by a large margin, reduce the fracture surface of the aluminium alloy frame system, and thin the wall thickness properly, and convenient, simple and more safe and reliable to construct, etc.

Owner:安建丞

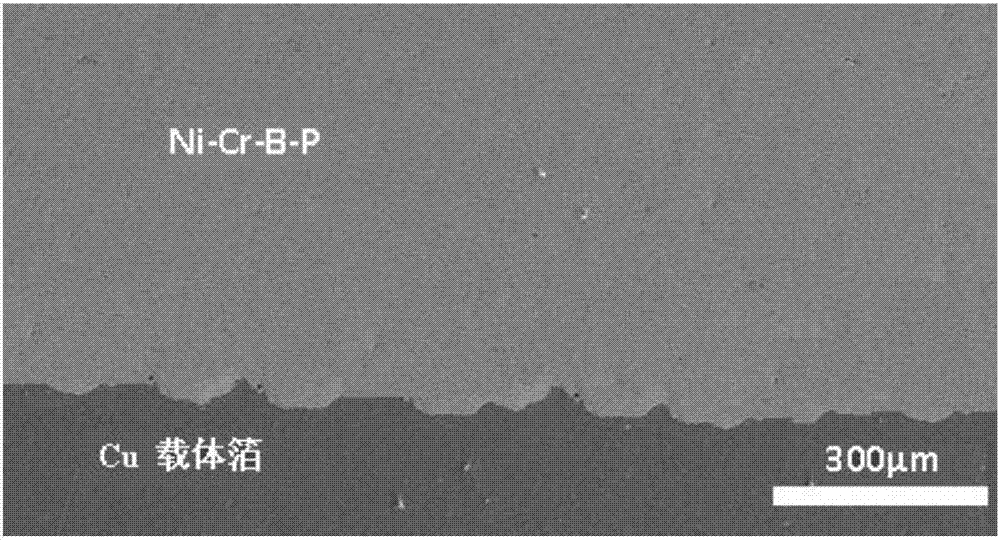

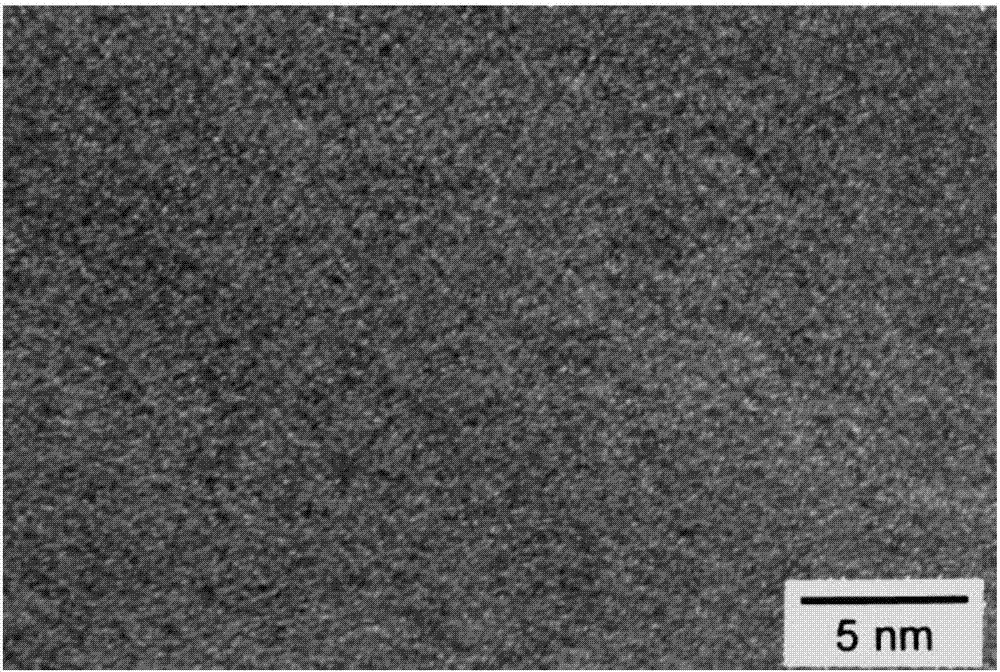

Preparation method for ultrathin copper foil Ni-Cr-B-P stripping layer

ActiveCN107475698AUniform textureStable electrodepositionLiquid/solution decomposition chemical coatingChemical platingCopper foil

The invention discloses a preparation method for an ultrathin copper foil Ni-Cr-B-P stripping layer. The preparation method comprises the following steps that a certain amount of sodium hypophosphite (NaH2PO2.H2O), sodium fluoride, sodium 2-mercaptobenzothiazole and citric acid are dissolved and mixed through distilled water; nickel sulfate NiSO4.6H2O and chromium chloride CrCl3.6H2O are added in sequence under a certain temperature and the stirring effect; the pH value is adjusted to the specified value through a 10% of NaOH solution, and dilution is conducted through water to be the specified volume; a certain concentration of KBH4 is uniformly dripped into a mixture solution to serve as a chemical plating solution; and carrier foil is chemically plated for a certain period, and after a plated part is washed through distilled water and anhydrous ethanol, the ultrathin copper foil Ni-Cr-B-P stripping layer is obtained. The stripping layer obtained through the preparation method presents a uniform single amorphous structure and has good thermal stability after hot press processing, the stripping resistance strength of the stripping layer is more stable, the process is simple, the industrialization cost is low, and the new preparation method for the ultrathin copper foil stripping layer has development prospects.

Owner:ANQING NORMAL UNIV +1

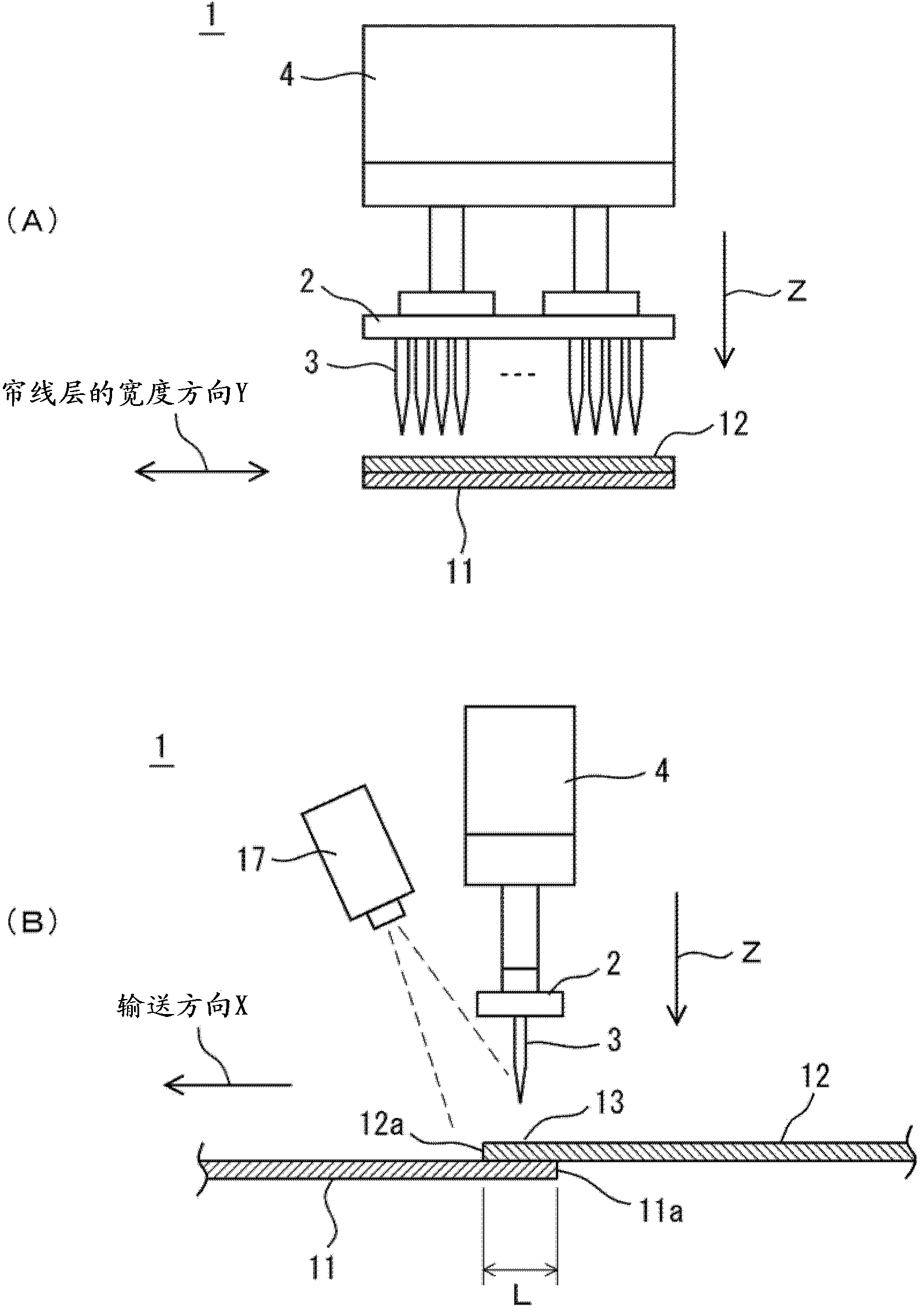

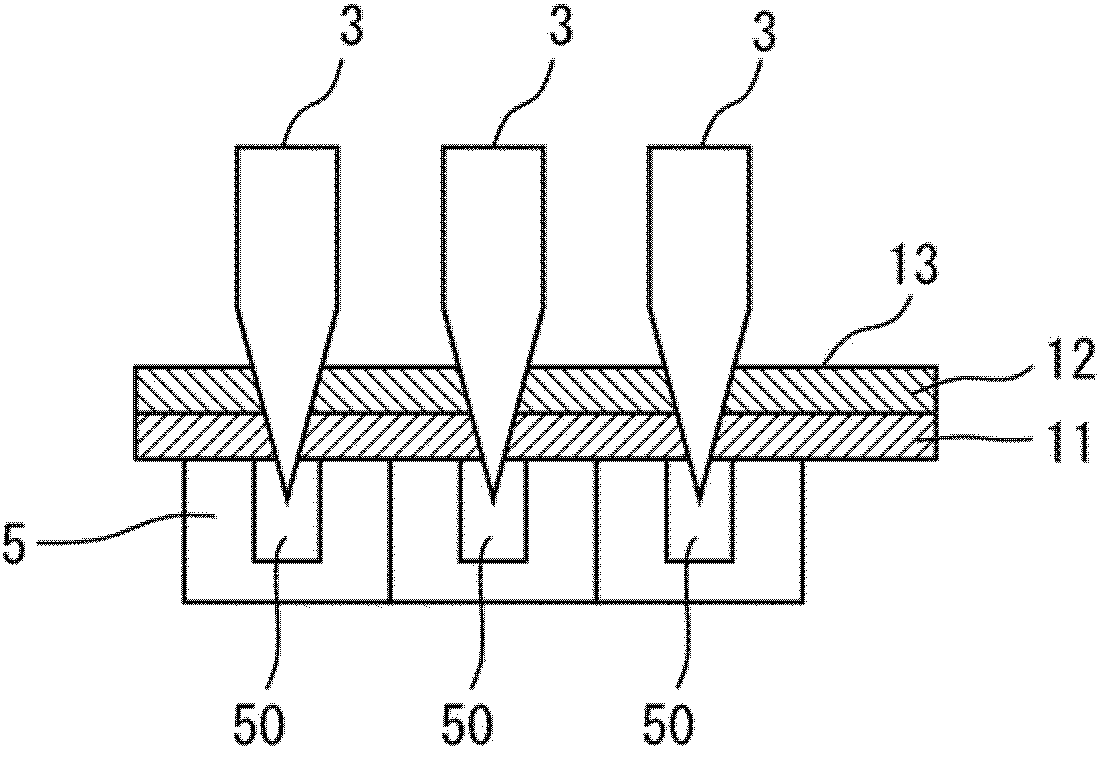

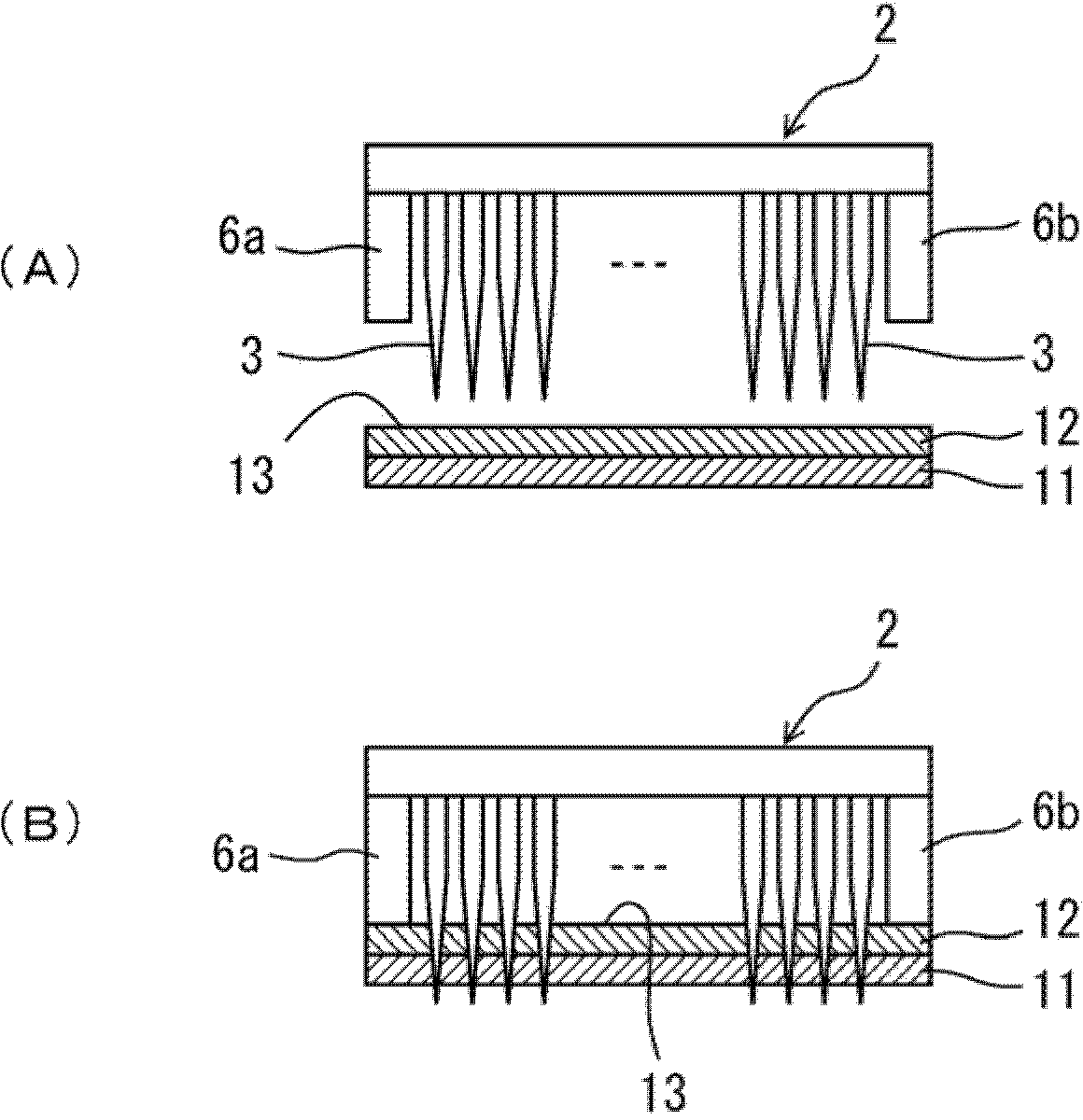

Tyre cord layer jointing device and jointing method

InactiveCN103660294AImprove productivityExcellent high speed uniformityTyresProduction rateEngineering

The invention provides a tyre cord layer jointing device and jointing method. Accordingly, tyres with excellent high-speed uniformity can be manufactured at a high production rate without needing reserving a relatively large amount of rubber among cords or pre-cutting the two edges of each cord layer in a mode that even a relatively small overlapped part can still reliably joint the cord layers with a stable strength. The tyre cord layer jointing device comprises an elevating part and an elevating unit. Needle-shaped projections are distributed on the elevating part at specified intervals along the width direction of the two cord layers. Each of the cord layers is formed by using unvulcanized rubber to cover a cord arrangement body which is formed by parallelly arranging the cords. The elevating unit enables the needle-shaped projections to spur the overlapped part until the front end parts of the needle-shaped projections penetrate through the overlapped part. Moreover, the elevating unit enables the elevating part to lower down to make the unvulcanized rubber of one cord layer invade into the other cord layer and then enables the elevating part to rise up to pull the needle-shaped projections out of the overlapped part after the spurring.

Owner:SUMITOMO RUBBER IND LTD

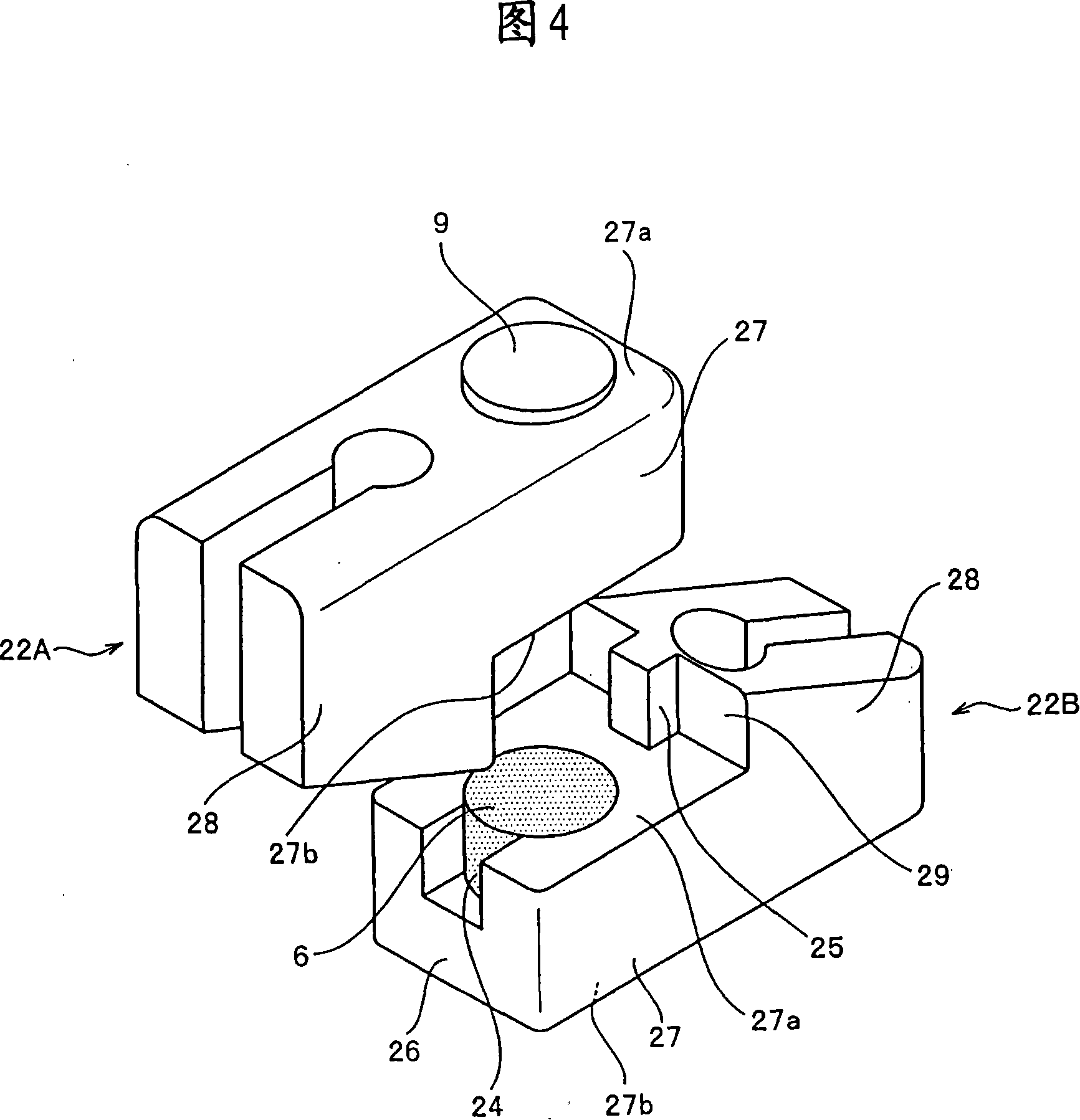

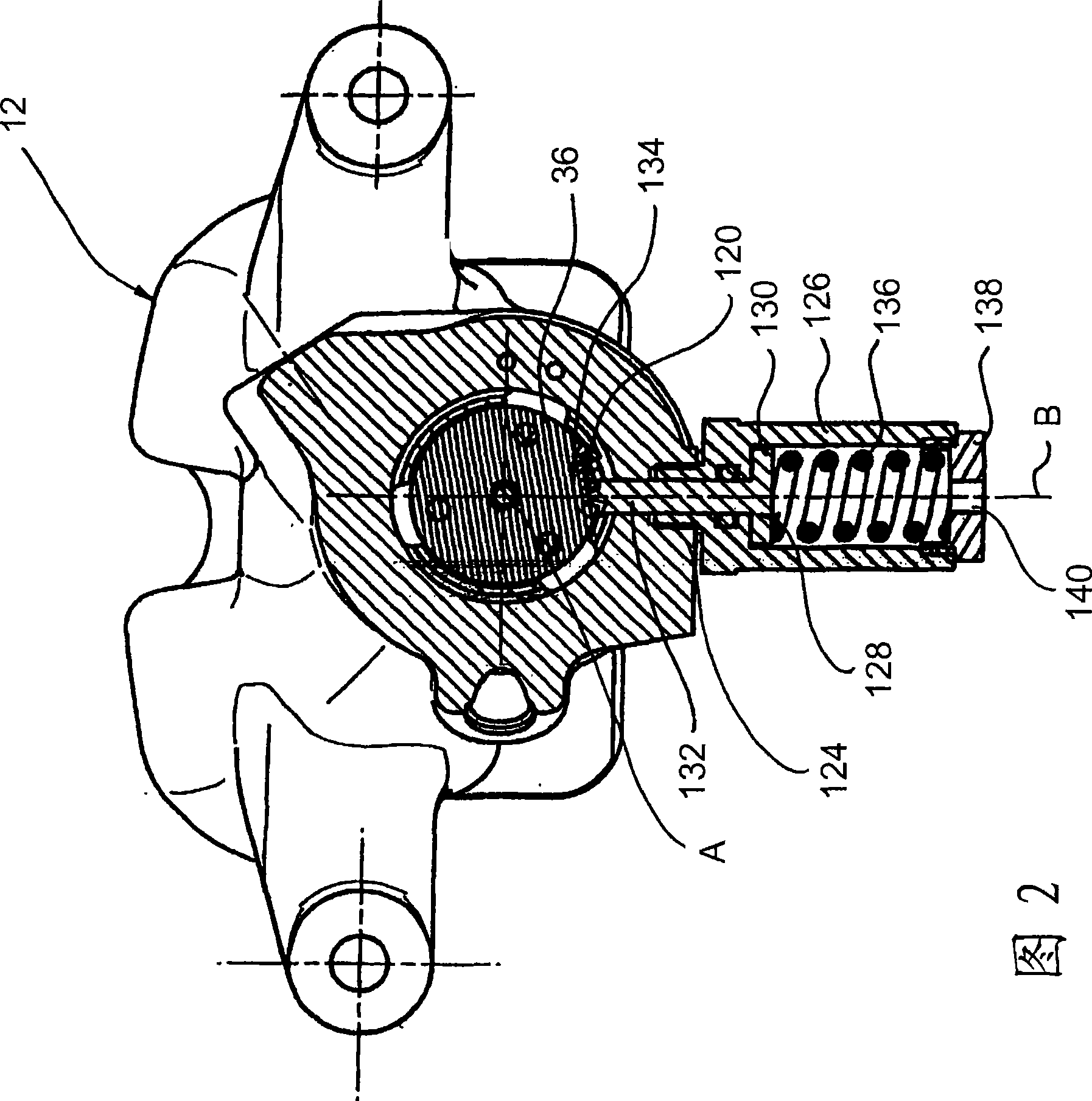

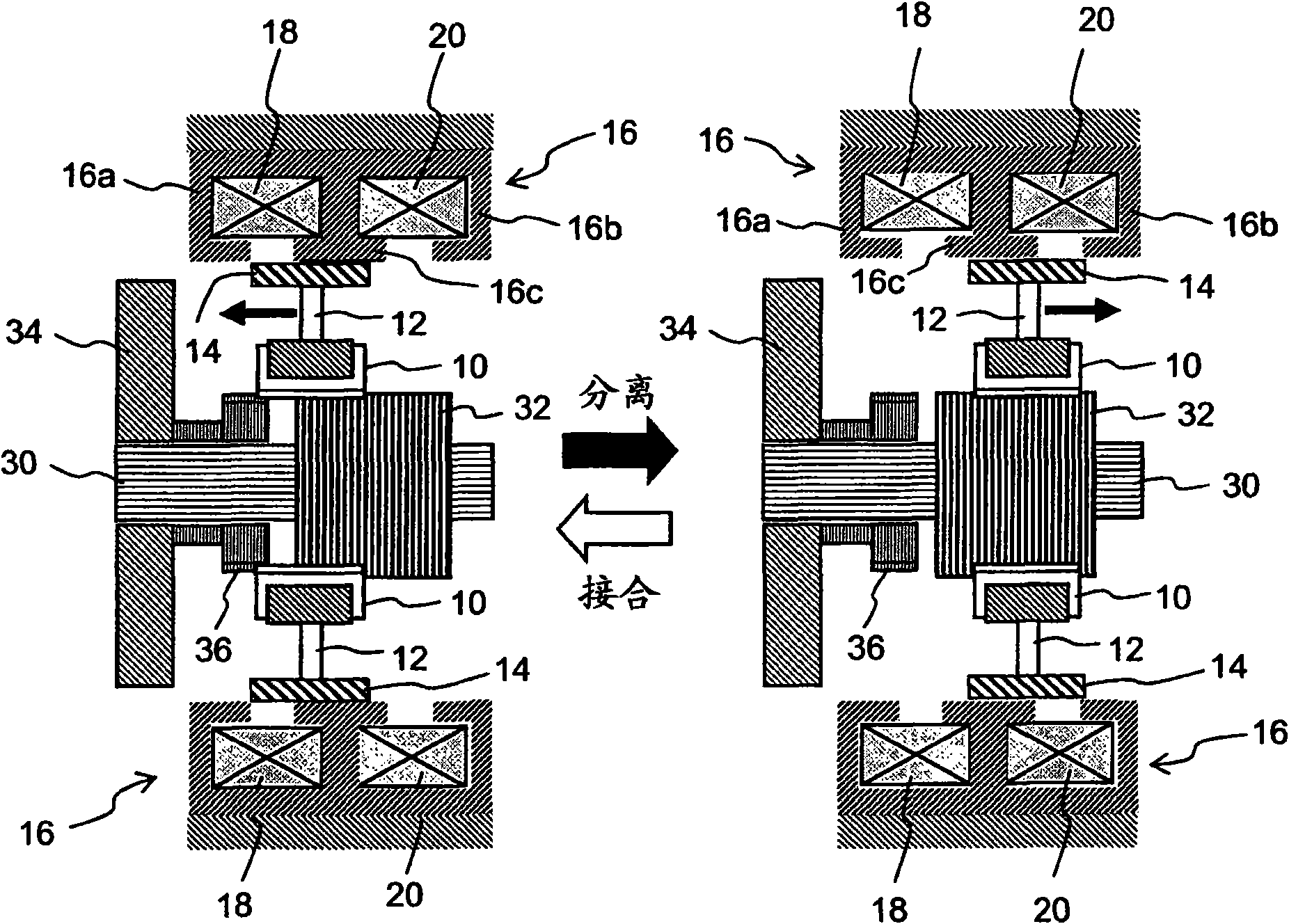

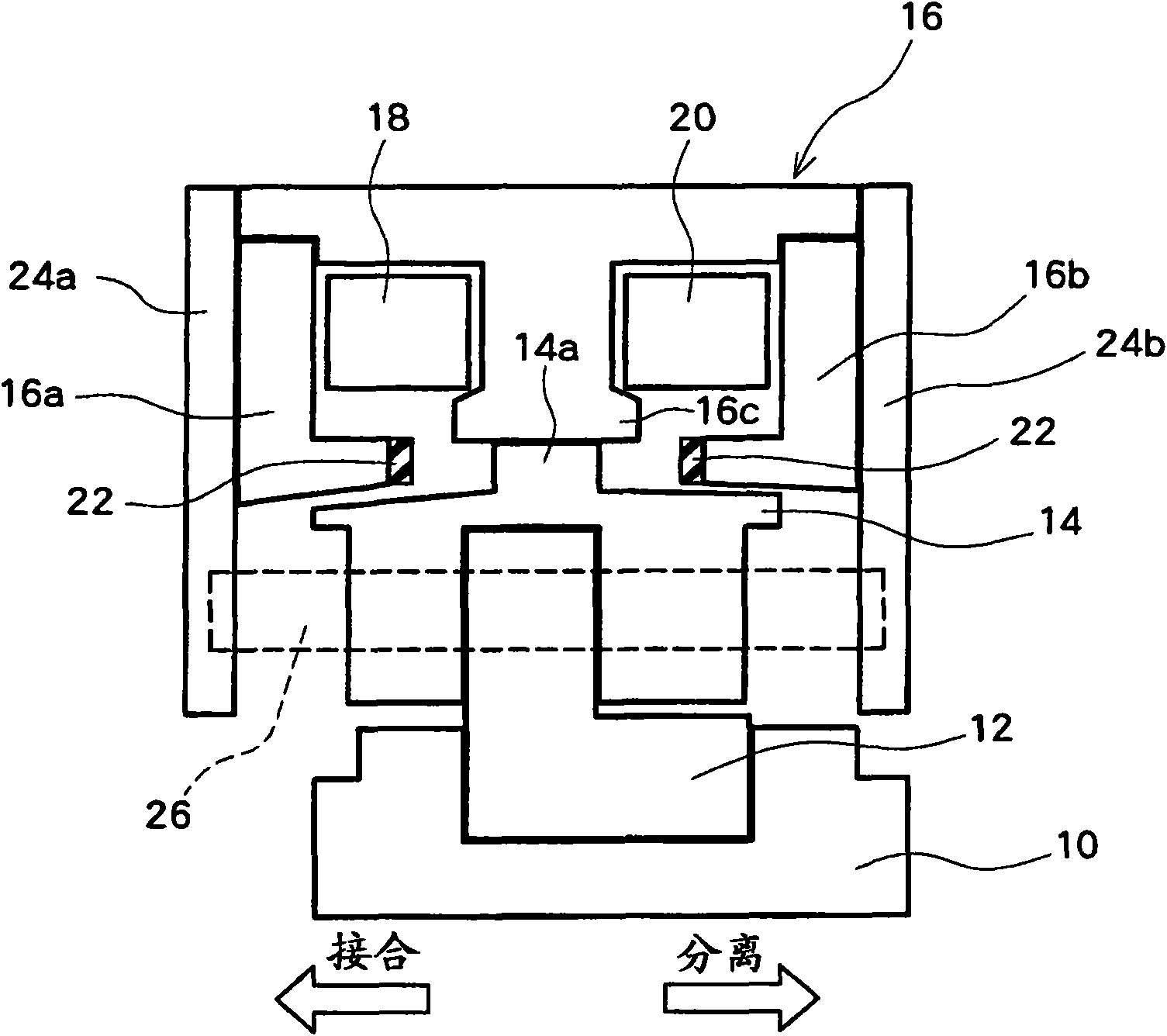

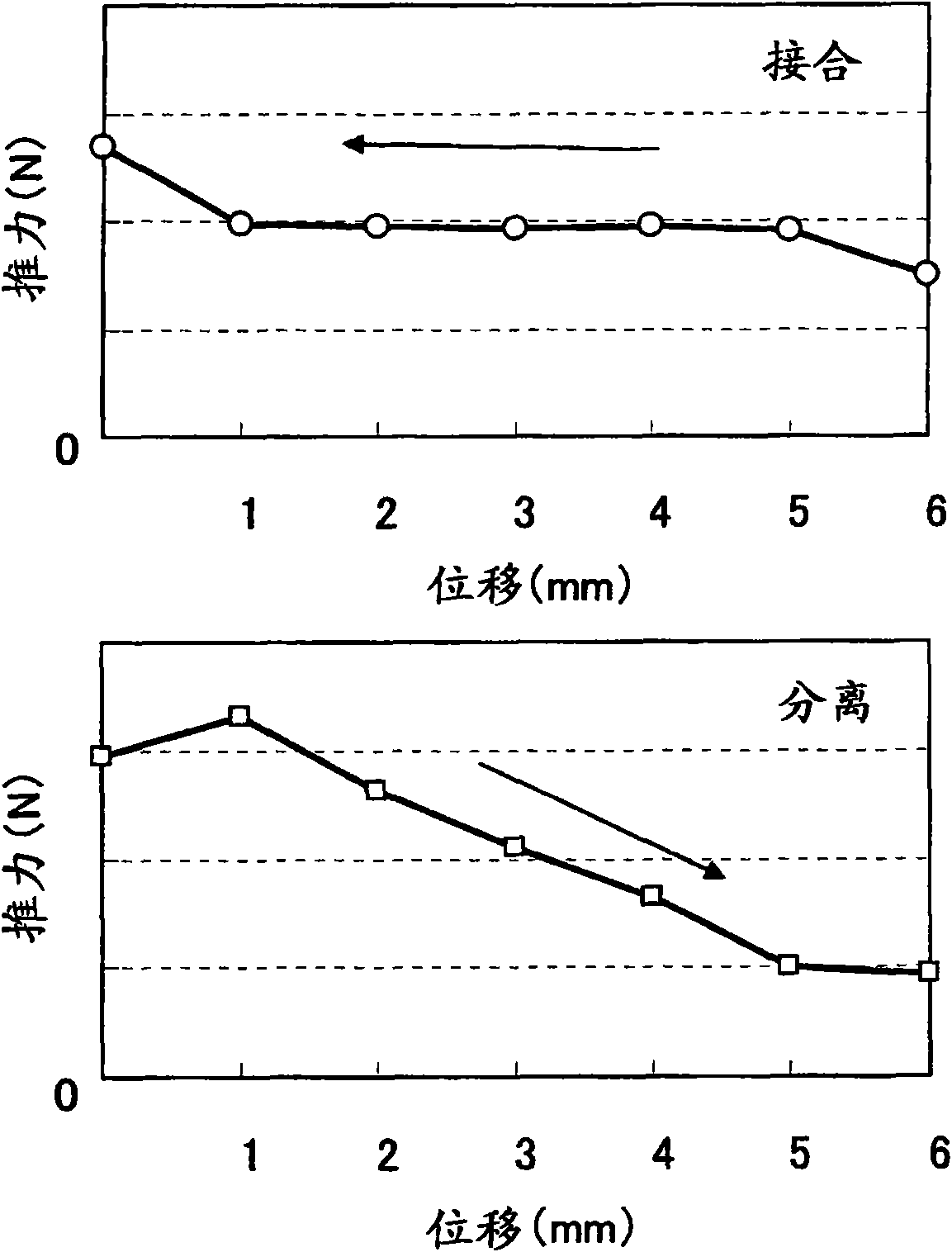

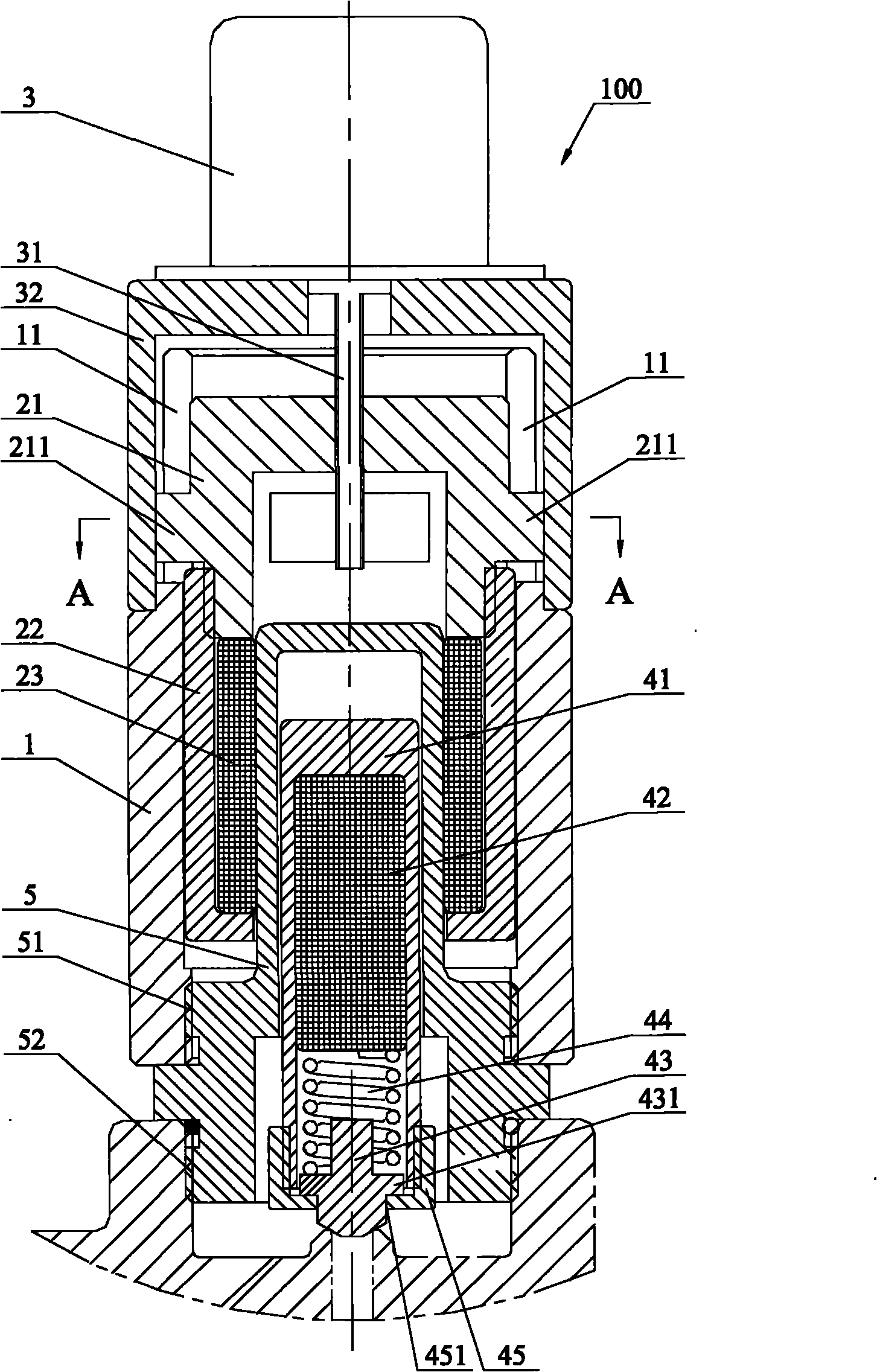

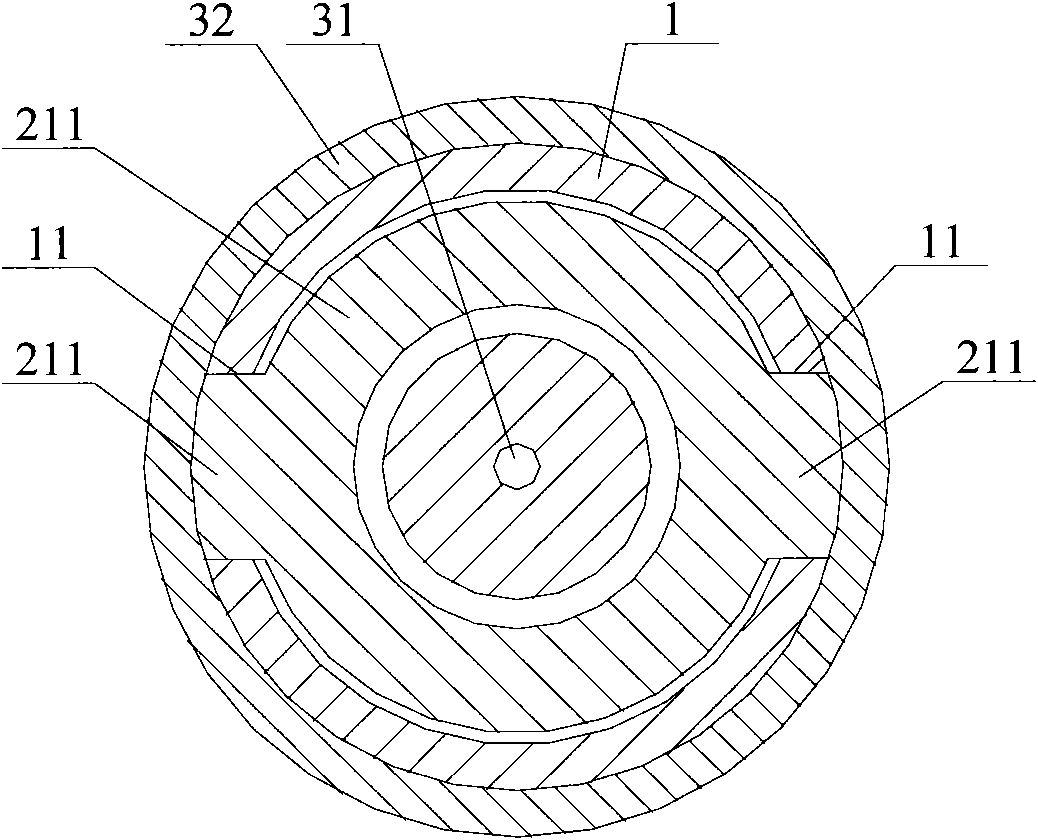

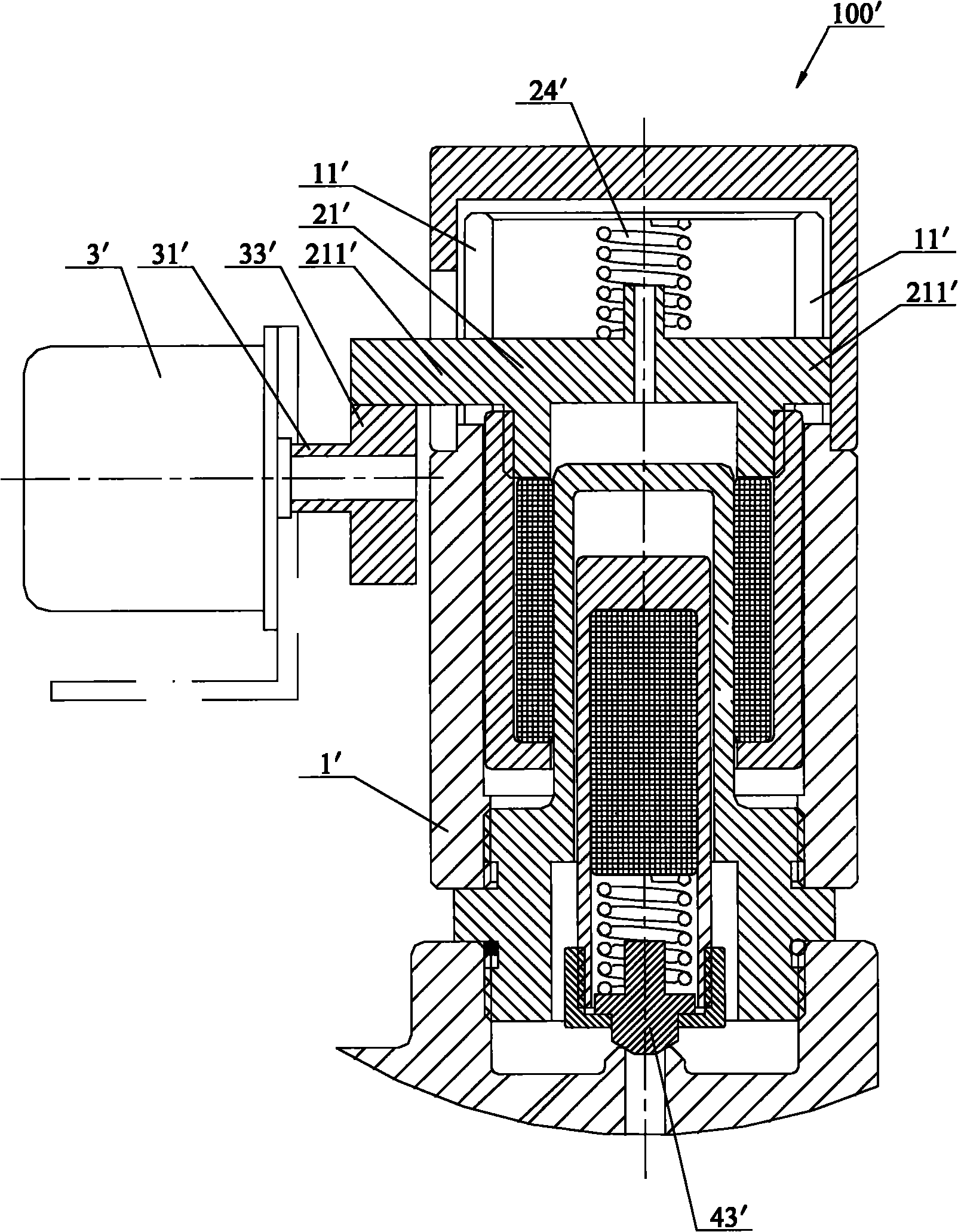

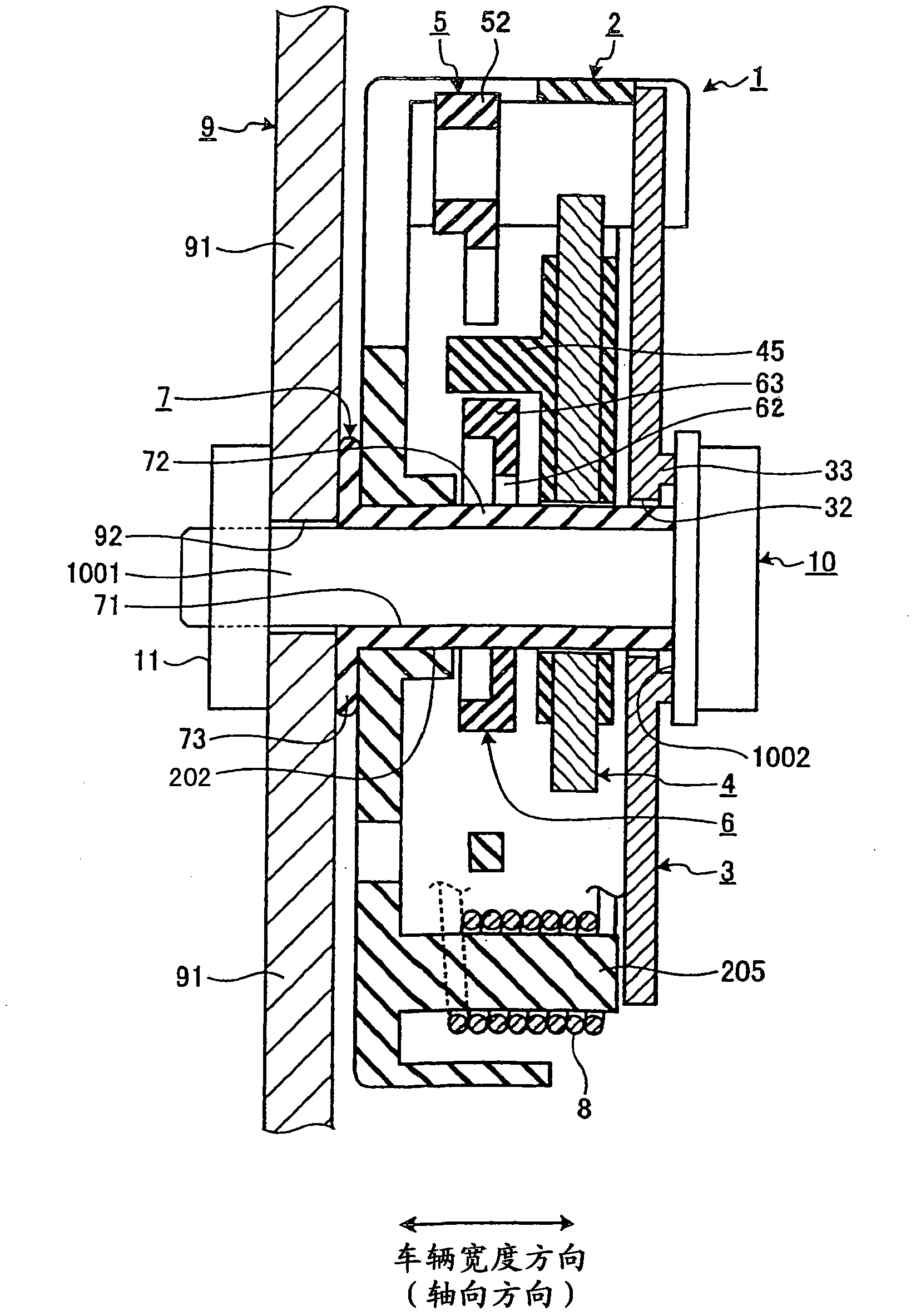

Dog clutch actuator

InactiveCN101657649ASmallEasy to moveMagnetically actuated clutchesInterengaging clutchesEngineeringActuator

Provided is a dog clutch actuator comprising a sleeve (10) having dog teeth made engageable with the dog teeth formed in a power transmission shaft (30) and made movable in the axial direction, and aplunger (14) for moving together with the sleeve (10). The plunger (14) is axially moved through a yoke (16) by electric currents to flow through coils (18 and 20). The dog clutch actuator is so characterized by the shapes of the plunger (14) and the yoke (16) that a sucking force increases in the engaging direction, when the dog clutch is engaged, and decreases in the disengaging direction, whenthe dog clutch is disengaged.

Owner:TOYOTA JIDOSHA KK

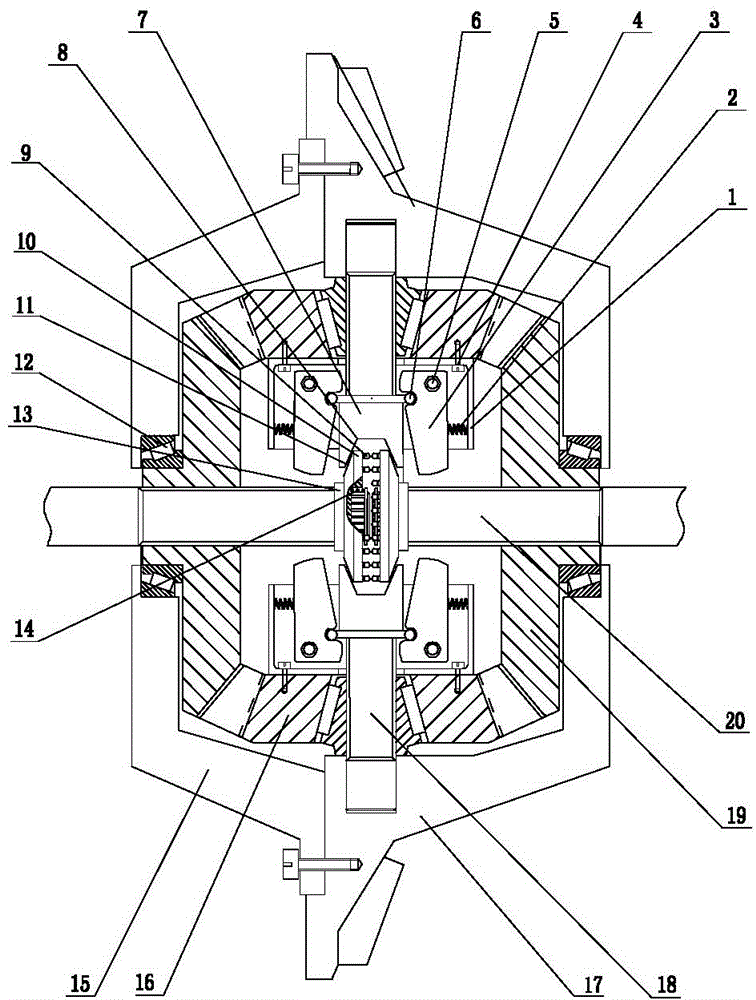

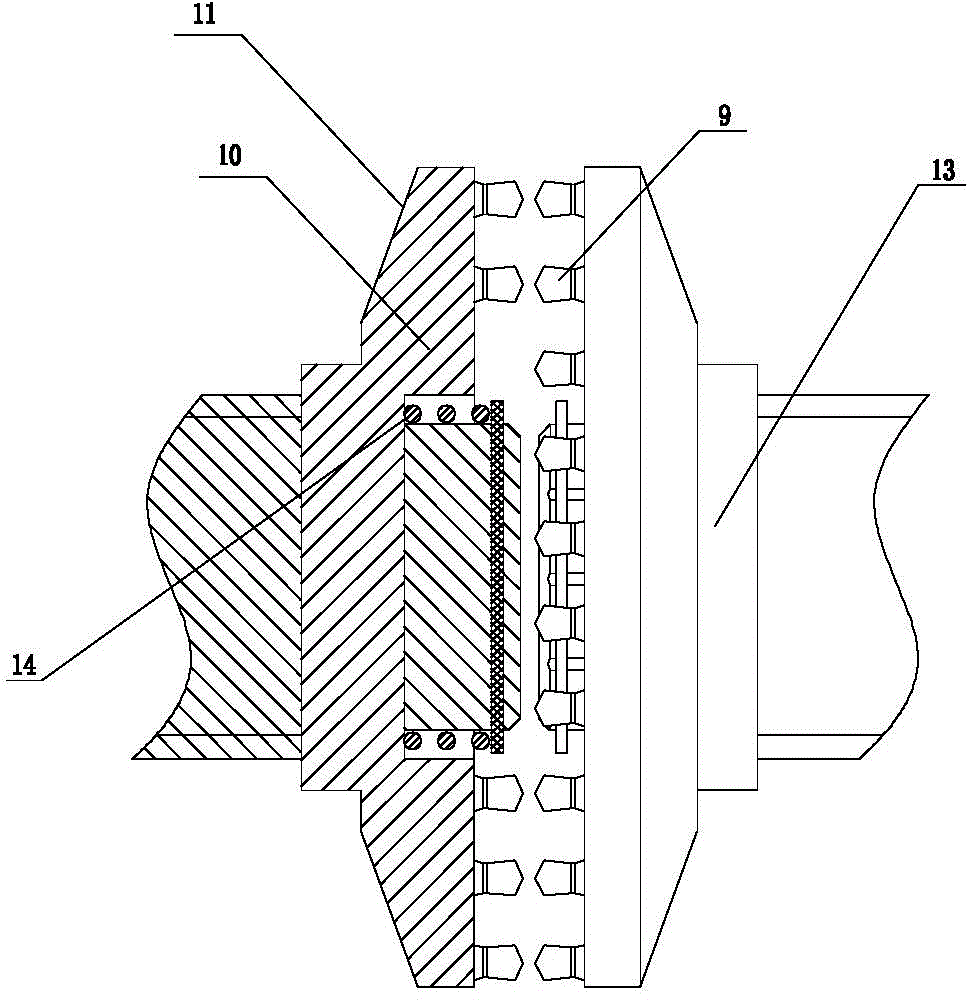

Centrifugal speed limiting differential mechanism

InactiveCN104791452AReduce noiseRealize clutchDifferential gearingsControl devicesDifferential functionLeft half

The invention discloses a centrifugal speed limiting differential mechanism, and belongs to the technical field of automobile differential mechanisms. A planet gear shaft is divided into two sections. The two sections of planet gear shaft are supported and installed at the upper end and the lower end of a planet wheel through conical roller bearings respectively and extend in an inner cavity wall of an outer shell. A lock sleeve and a centrifugal fly weight device are arranged at the two close ends of the two sections of planet gear shaft respectively. A part abutting against the centrifugal fly weight device is arranged on the outer side of the lock sleeve. An engaging fluted disc is arranged on the two close ends of two spline half shafts. A matching structure matched with the lock sleeve is arranged on the outer side of the engaging fluted disc. According to the centrifugal speed limiting differential mechanism, the rotating speed difference of the left half shaft and the right half shaft can be automatically inducted, and the speed limiting differential function is achieved. Centrifugal fly weight type automatic induction is achieved, the structure is simple, and functions are liable. Separation and union of the differential fluted disc is achieved through the friction function, reliable jointing under the high rotating speed is achieved, and meanwhile destructive impact is avoided. The wedge self-locking type engaging fluted disc is adopted, and a certain self-locking function is achieved after jointing.

Owner:HUNAN AGRICULTURAL UNIV

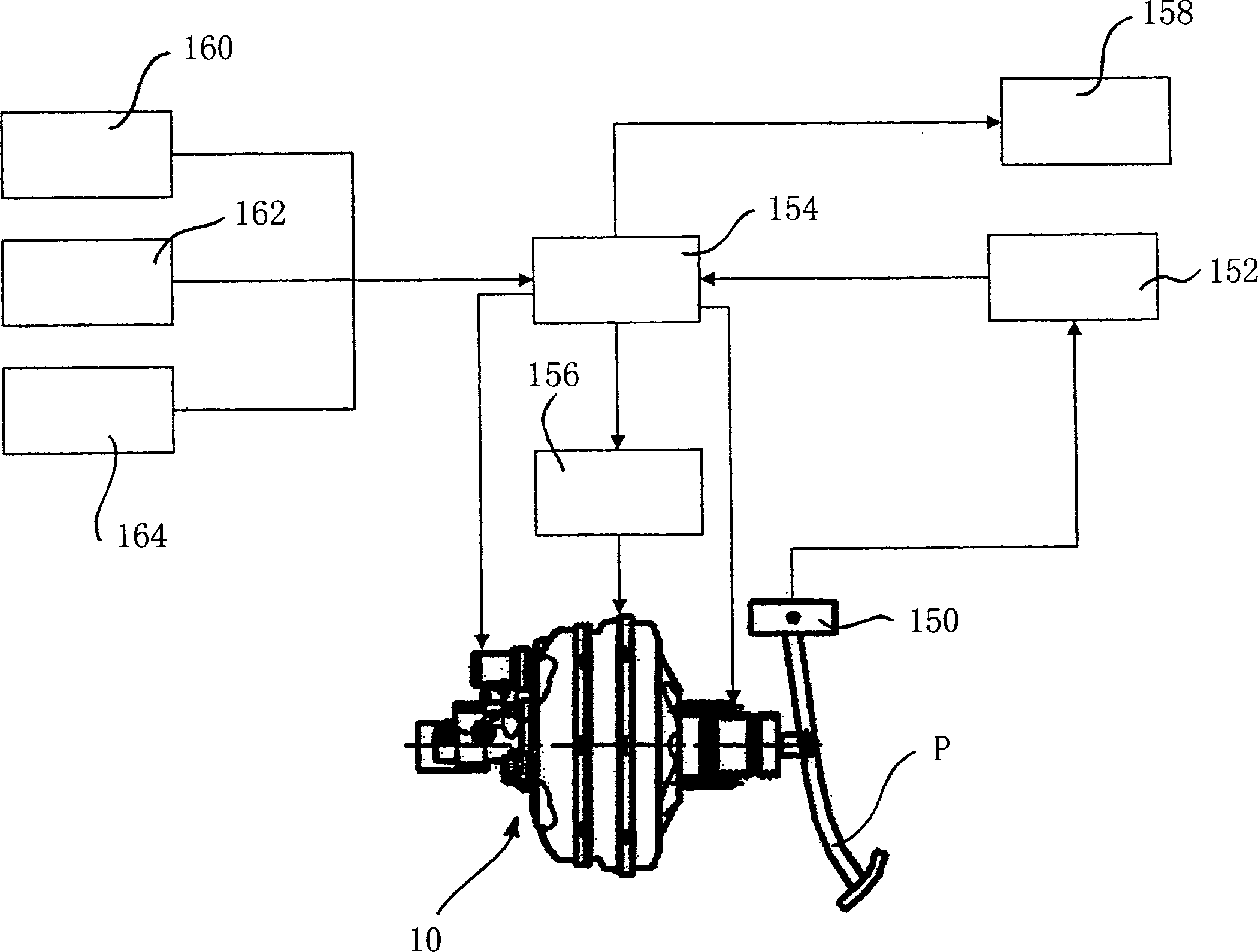

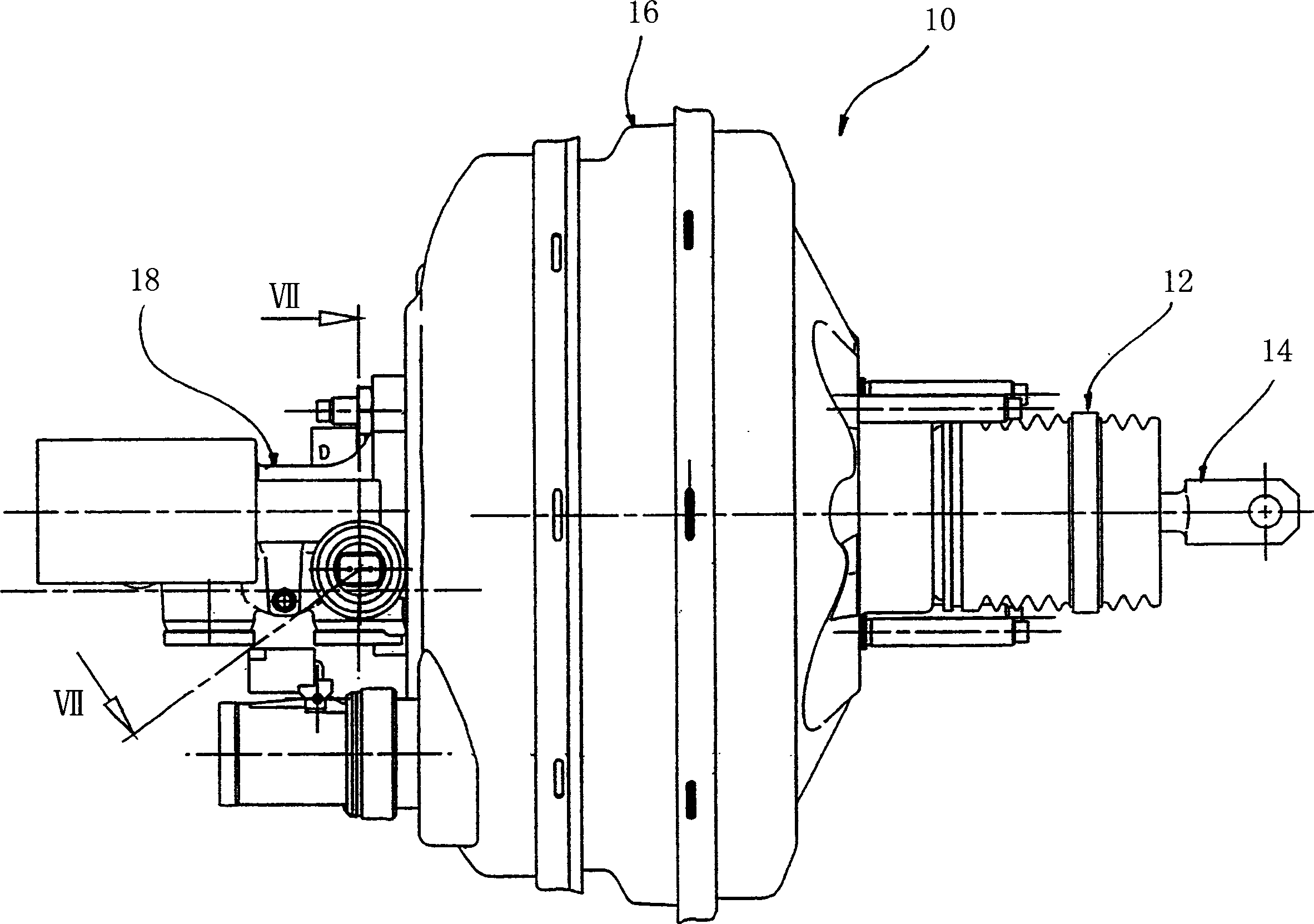

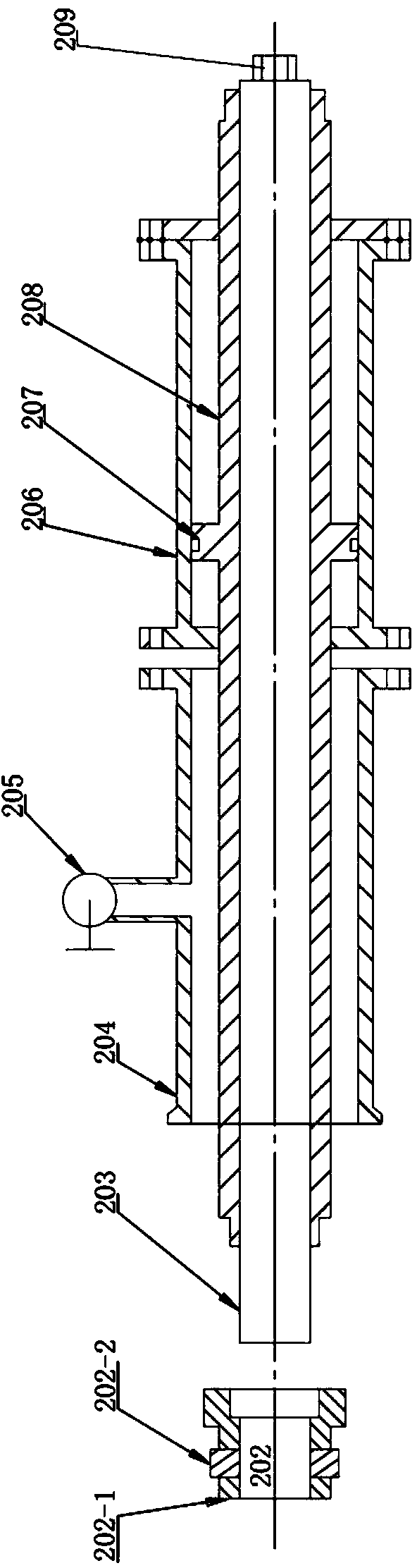

Braking force generator for a hydraulic vehicle braking system

InactiveCN1914078AIncrease motivationIncreased vulnerabilityBraking action transmissionFoot actuated initiationsForce generationEngineering

The invention relates to a braking force generator (10), for a hydraulic vehicle braking system, comprising a force introduction member (14), which is or may be coupled to a brake pedal (P) and which may be mounted in a base housing of the brake force generator (10), a main brake cylinder, in which a primary piston (64), for generation of a hydraulic braking pressure, runs in a displaceable manner, a pedal counter-force simulation device (106), coupled to the force introduction member (14), a pedal operation recording device (150), for recording a pedal operation and an operation force generation device, for exerting an operating force on the primary piston (64), whereby the operating force generation device comprises a control valve (22), a chamber arrangement (16) and an electromagnetic actuator (48). The chamber arrangement (16) is embodied with a vacuum chamber (30) and a working chamber (32), separated from the vacuum chamber (30) by a moving wall (28), in fluid connection to each other by means of the control valve (22) and the control valve (22) is operated according to the recorded pedal operation.

Owner:LUCAS AUTOMOTIVE GMBH

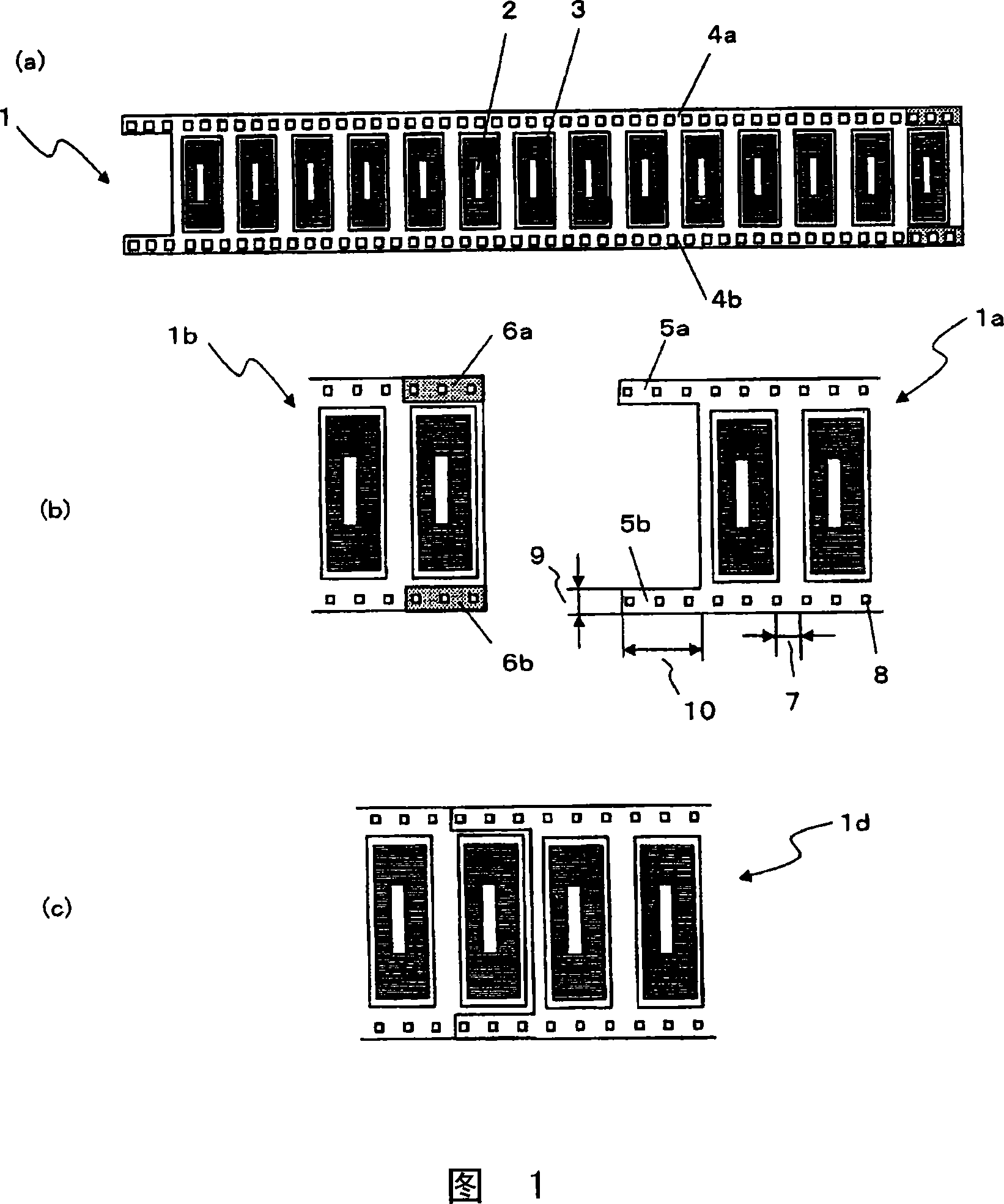

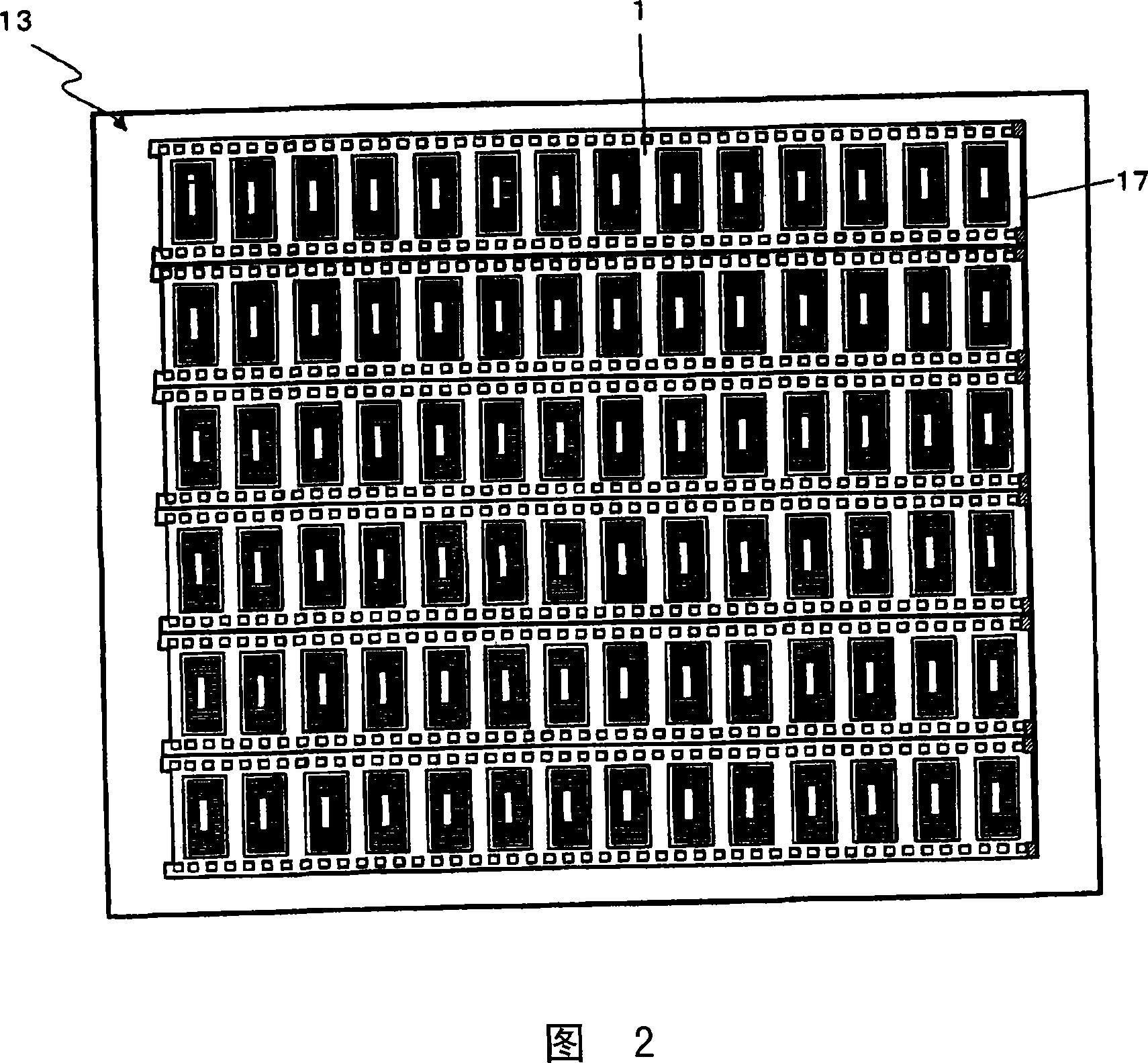

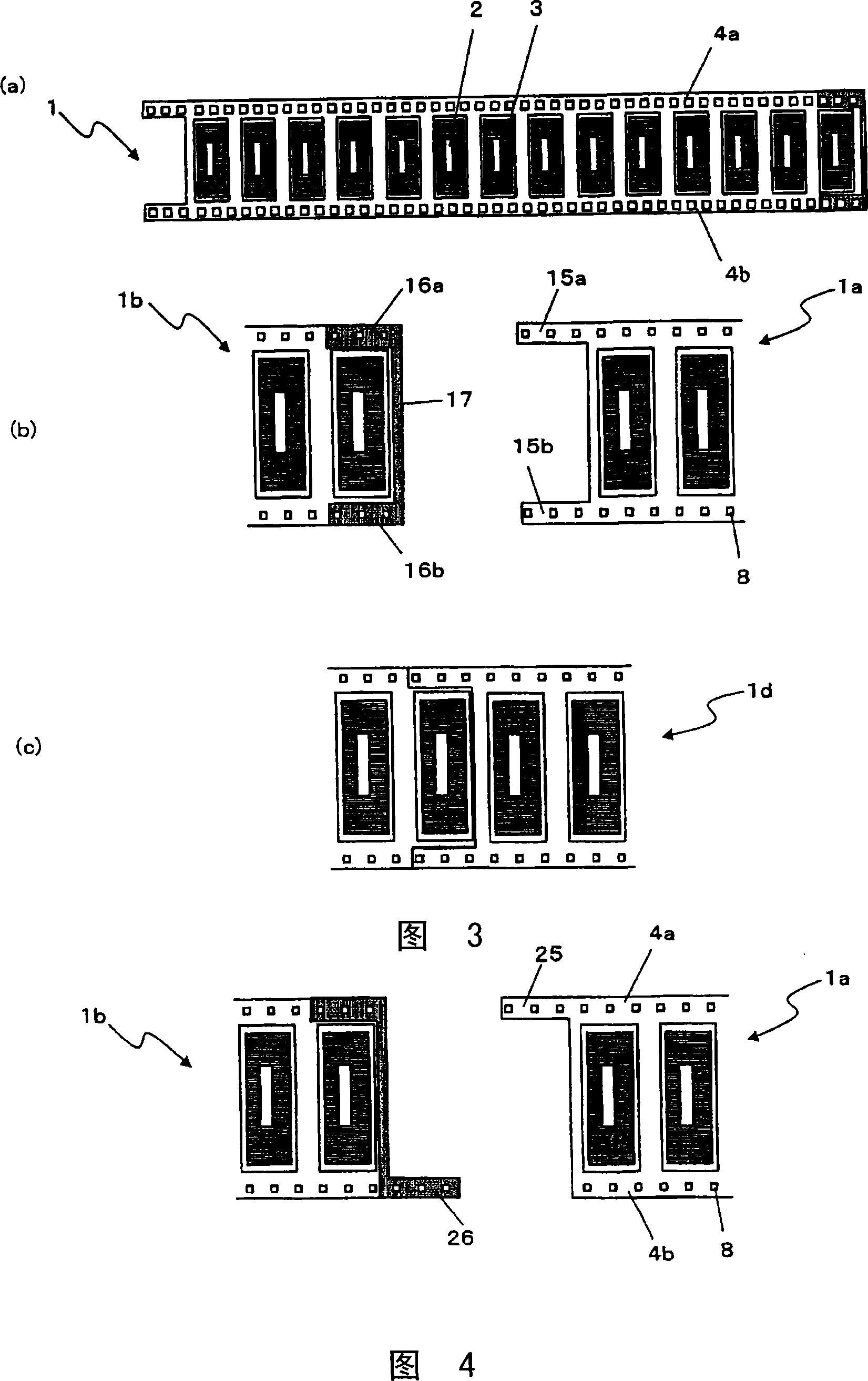

Long film circuit board, and production method and production device therefor

InactiveCN101036422AReliable linkEasy to handlePrinted circuit aspectsAdhesivesFlexible circuitsEngineering

Owner:TORAY IND INC

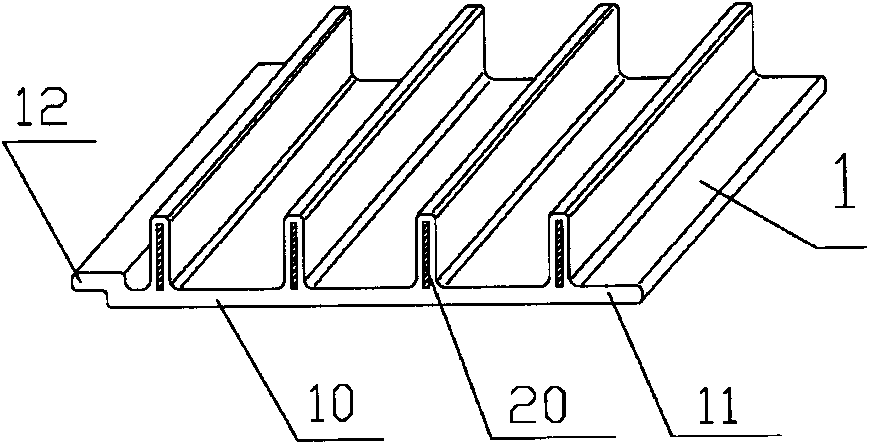

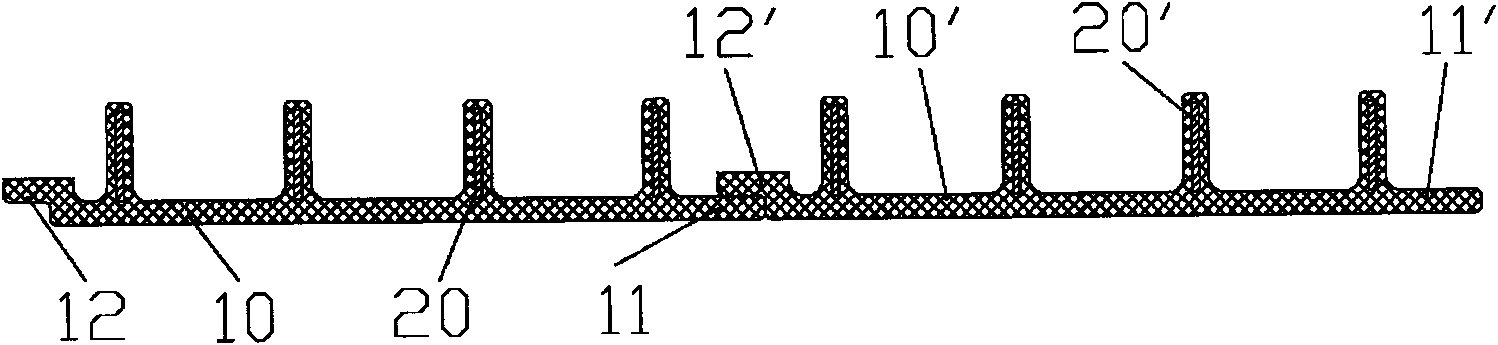

Steel belt reinforced composite lap joint belt material for plastic-steel wound pipe

The invention discloses a steel belt reinforced composite lap joint belt material for a plastic-steel wound pipe. The belt material at least comprises a belt material unit, wherein the belt material unit comprises a substrate and at least one rib plate; the rib plate is arranged vertical to the substrate; a steel belt is arranged on the rib plate; the rib plate is connected to the substrate; and one side of the substrate is provided with a joint part which has a flat structure and is at least provided with a joint bump. The design mode of an occlusal surface is provided, so that belt materials are jointed more stably and reliably, a weld face is prevented from cracking, and welding intensity and the quality of a tubular product are ensured.

Owner:HUAHAN SCI & TECH

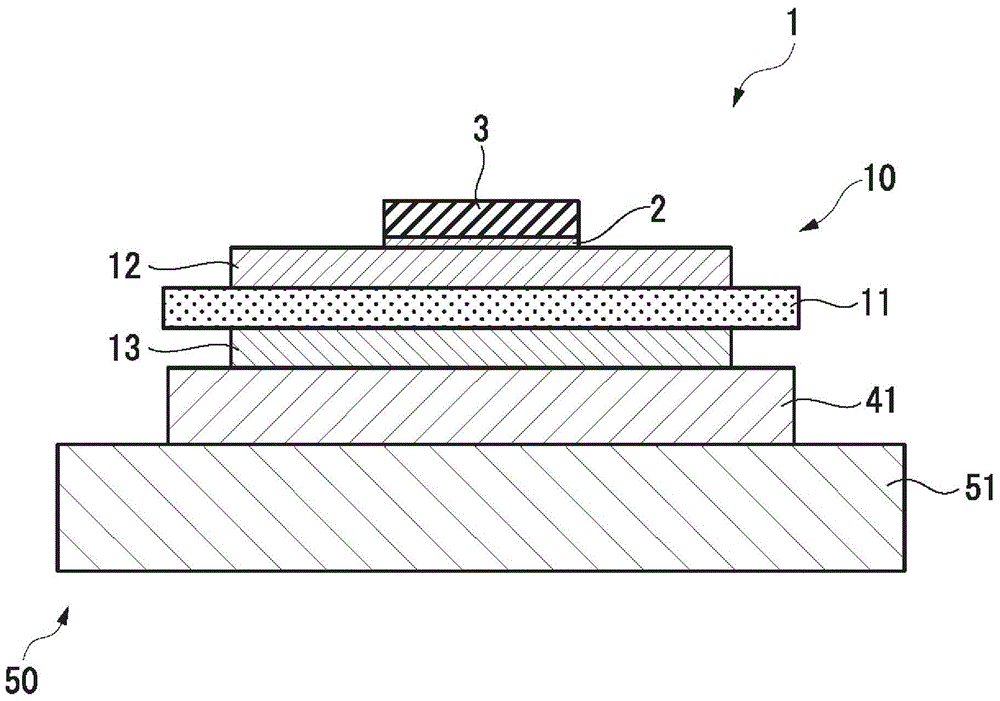

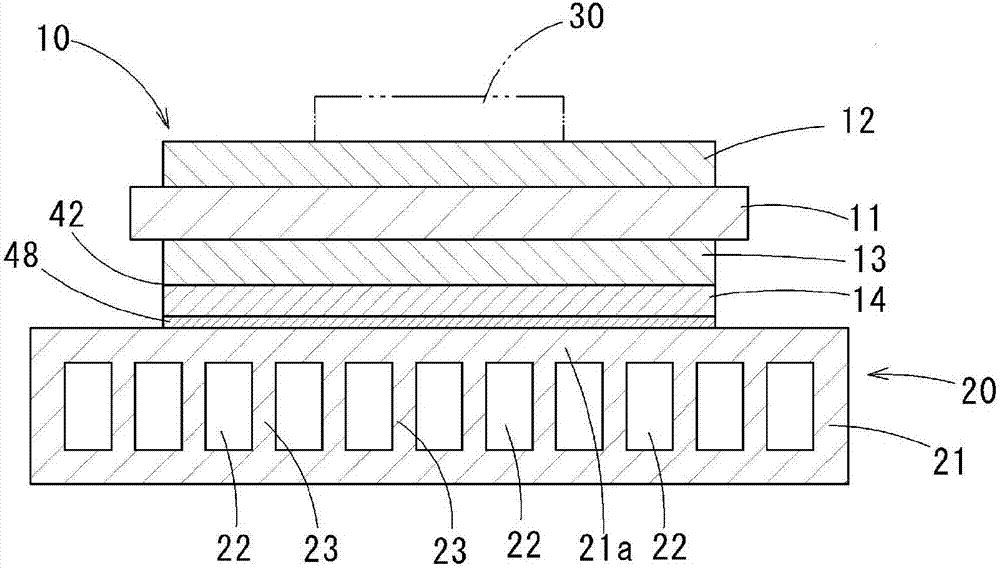

Substrate with cooler for power modules and method for producing same

InactiveCN107112298AReduce thermal resistanceImprove joint reliabilitySemiconductor/solid-state device detailsSolid-state devicesSolid phasesMetal

Provided is a substrate with a cooler for power modules, which is prevented from the occurrence of deformation during brazing of a metal layer that is formed from copper or a copper alloy to a cooler that is formed from aluminum, and which has low thermal resistance and high bonding reliability. A circuit layer that is formed from copper or a copper alloy is bonded to one surface of a ceramic substrate, while bonding a metal layer that is formed from copper or a copper alloy to the other surface of the ceramic substrate. A second metal layer that is formed from aluminum or an aluminum alloy is bonded to the metal layer by solid-phase diffusion, and a cooler that is formed form an aluminum alloy is joined to the second metal layer by brazing with use of an Mg-containing Al-based brazing filler material.

Owner:MITSUBISHI MATERIALS CORP

Control valve and valve with same

InactiveCN101782149AAchieve closureSolve wasteOperating means/releasing devices for valvesLift valveDrive motorEngineering

The invention discloses a control valve. A magnetic ring component is arranged in a valve body sleeve and is connected with an output shaft of a driving motor; a magnetic core component is embedded on the inner side of the magnetic ring component, the lower end part of the magnetic core component is used for pressing against or separating from an overflow channel between a valve inlet and a valve outlet to realize the opening and closing of the valve; and under the action of the driving motor, the magnetic ring component moves in the sleeve axially and drives the magnetic core component to move axially. The invention also discloses a valve. A valve body is provided with a separation part which divides an inner chamber of the valve body into an inlet chamber and an outlet chamber; the side wall of the inlet chamber and the outlet chamber of the valve body at a position connected with the separation part is provided with a valve port; the opening end on the lower part of a valve cover is sealed and connected with the outer surface of the valve body at the periphery of the valve port; a piston is arranged in a valve cover accommodating chamber; the control valve is fixedly arranged on the valve cover; a second overflow channel is arranged between the outlet chamber of the valve body and the valve cover accommodating chamber above the piston; and the lower end part of the magnetic core component of the control valve is used for pressing against or separating from the second overflow channel.

Owner:HAILIN ENERGY TECH

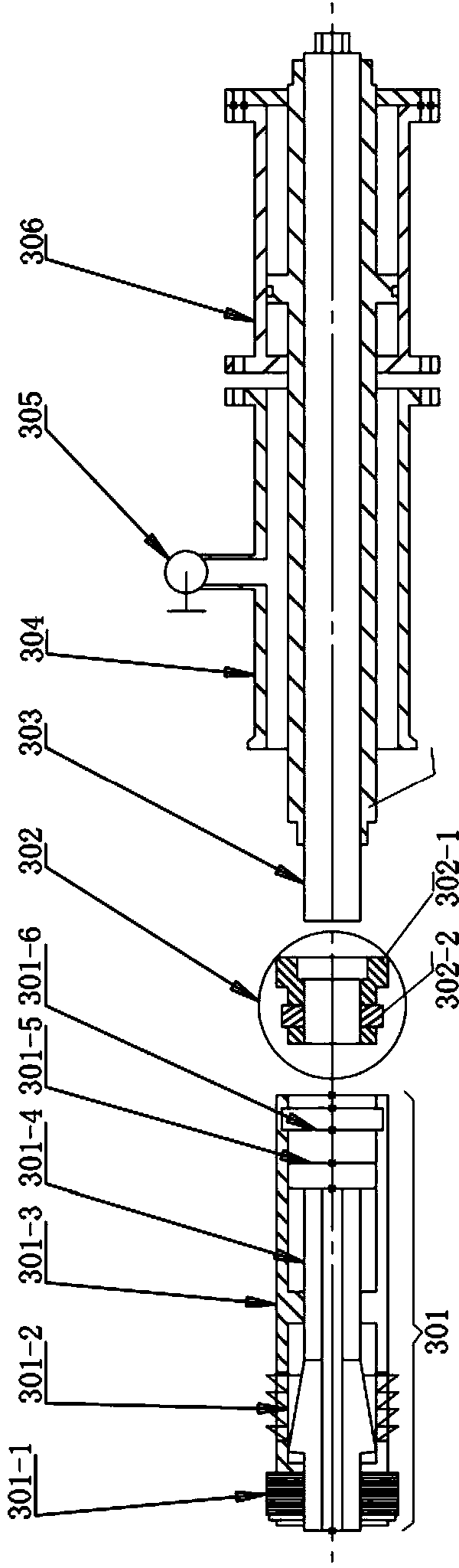

Device capable of replacing valve under pressure

ActiveCN103742710AReliable stuckEnsure construction safetyValve arrangementsPipe elementsHydraulic cylinderInternal pressure

The invention provides a device capable of replacing a valve under pressure. The device comprises a plugging device, a combining part, a blowout prevention pipe, a hydraulic cylinder, a piston rod and an operating rod. One end of the combining part is detachably connected to the plugging device, and the blowout prevention pipe contains the plugging device and the combining part and is connected with the hydraulic cylinder. The plugging device is mainly composed of a sealing rubber sleeve, a slip bowl seal assembly, a differential pressure type piston and slips, the slips can be automatically unfolded through fluid pressure, and thus safe bowl seal is achieved. One end of the combining part is connected with the hydraulic cylinder through the piston rod and the operating rod which penetrate through the blowout prevention pipe. The invention further provides a method for replacing a valve under pressure with the device capable of replacing a valve under pressure. The device achieves seal, bowl seal, seal removal and internal pressure balance of a tool, the complex functions can be continuously and automatically completed in one travel, and thus the device is easier and more reliable to operate. Uncertainty caused by manual operation is reduced, safety in the construction process is guaranteed, no pollution will be caused to the environment, and construction cost is greatly reduced.

Owner:袁占良

Knotting device and creel

ActiveCN107010485APhysically effortlessReliable jointFilament handlingAuxillary apparatusYarnEngineering

Owner:KARL MAYER ROTAL SRL

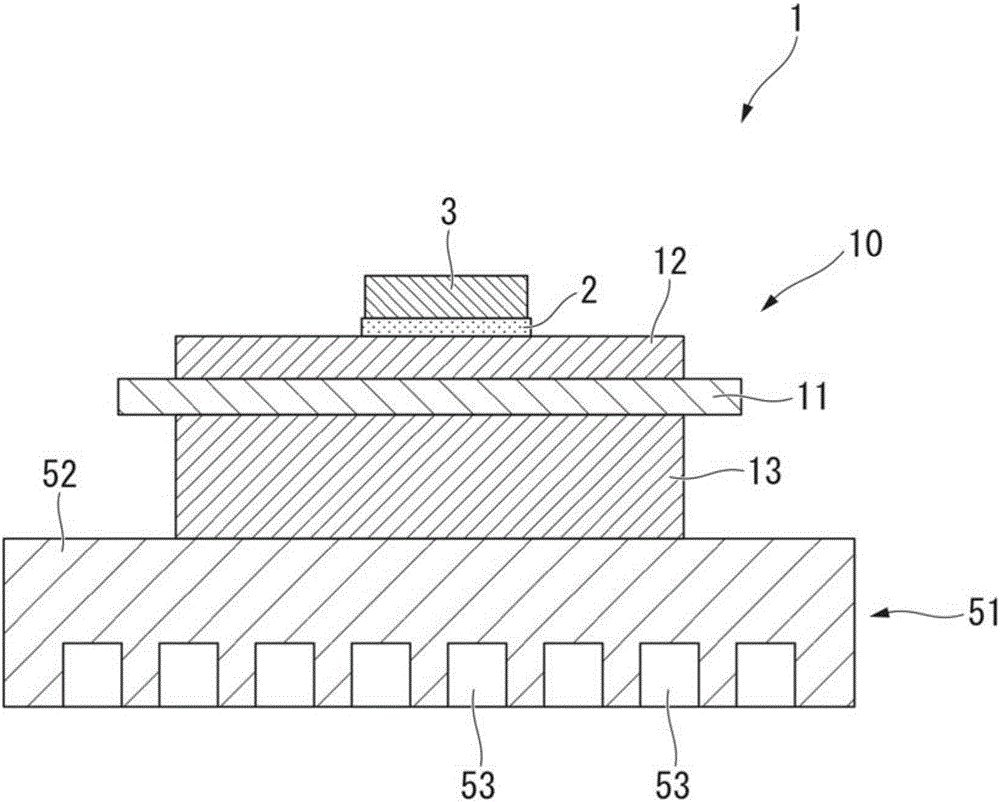

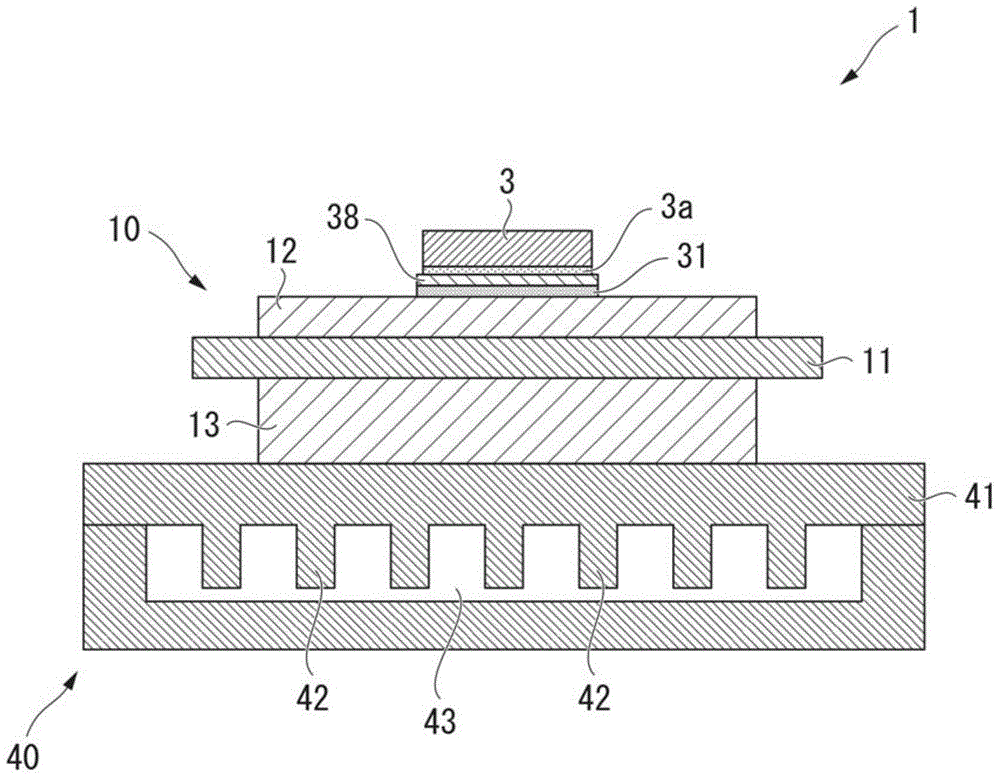

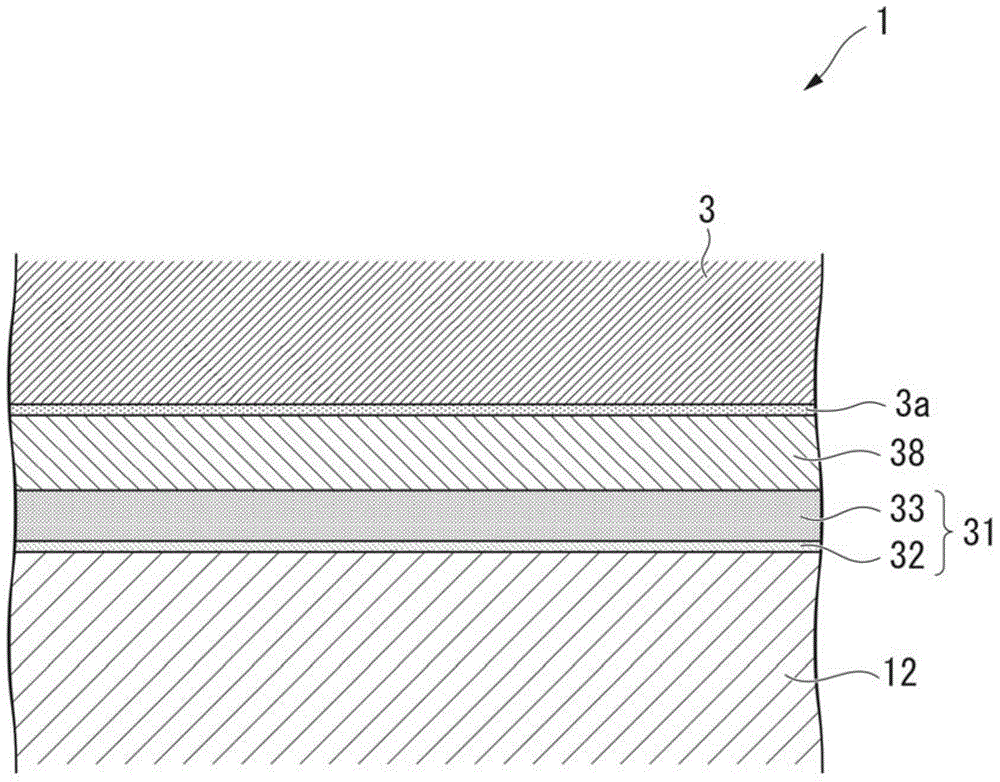

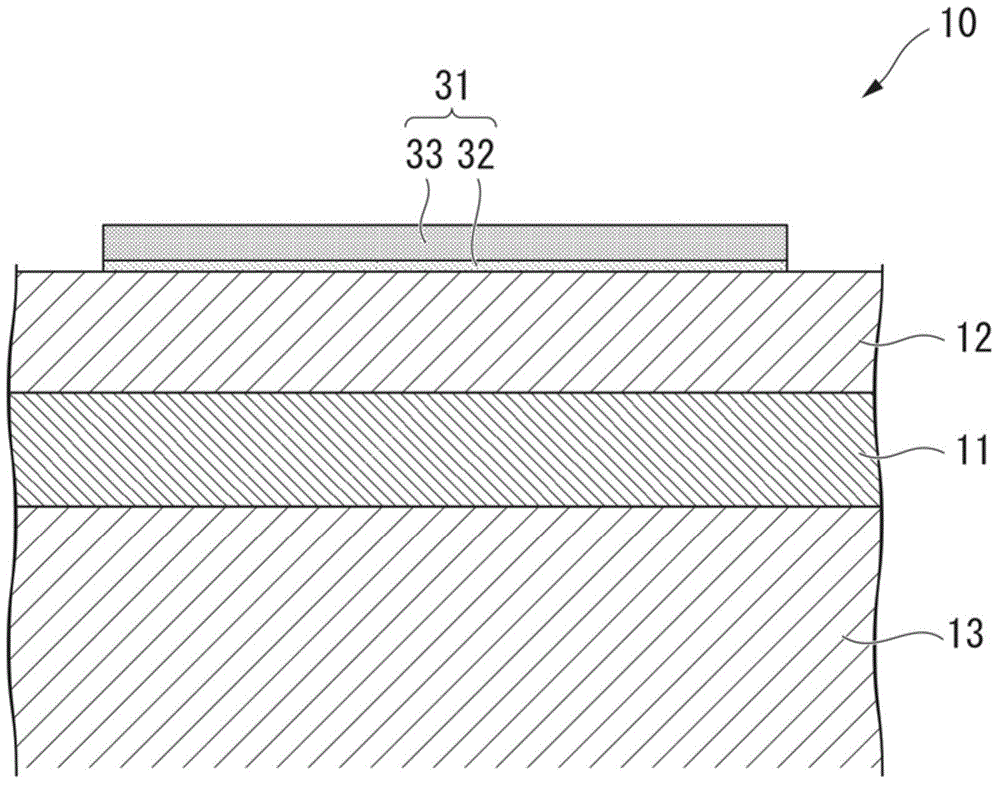

Semiconductor device, ceramic circuit board, and semiconductor device manufacturing method

ActiveCN104704618AEfficient deliveryReliable jointSemiconductor/solid-state device detailsSolid-state devicesPorosityPower semiconductor device

A semiconductor device (1) of the present invention is provided with a circuit layer (12) formed of a conductive material, and a semiconductor element (3) mounted on the circuit layer (12). On one surface of the circuit layer (12), a base layer (31) having a porosity within a range of 5-55 % is formed, and on the base layer (31), a bonding layer (38) is formed, said bonding layer being formed of a fired body of a bonding material containing metal particles and / or metal oxide particles, and an organic material. The circuit layer (12) and the semiconductor element (3) are bonded to each other with the base layer (31) and the bonding layer (38) therebetween.

Owner:MITSUBISHI MATERIALS CORP

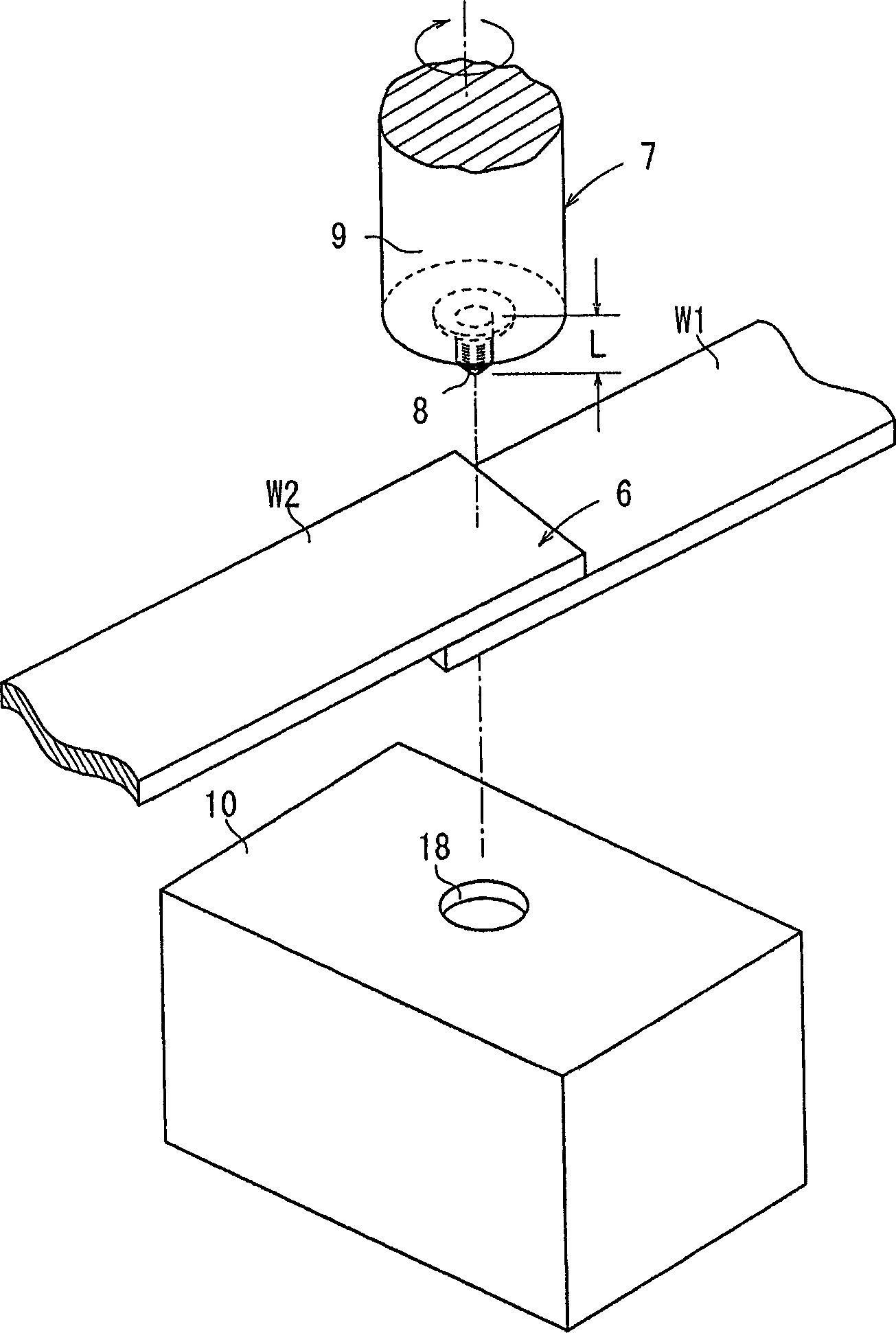

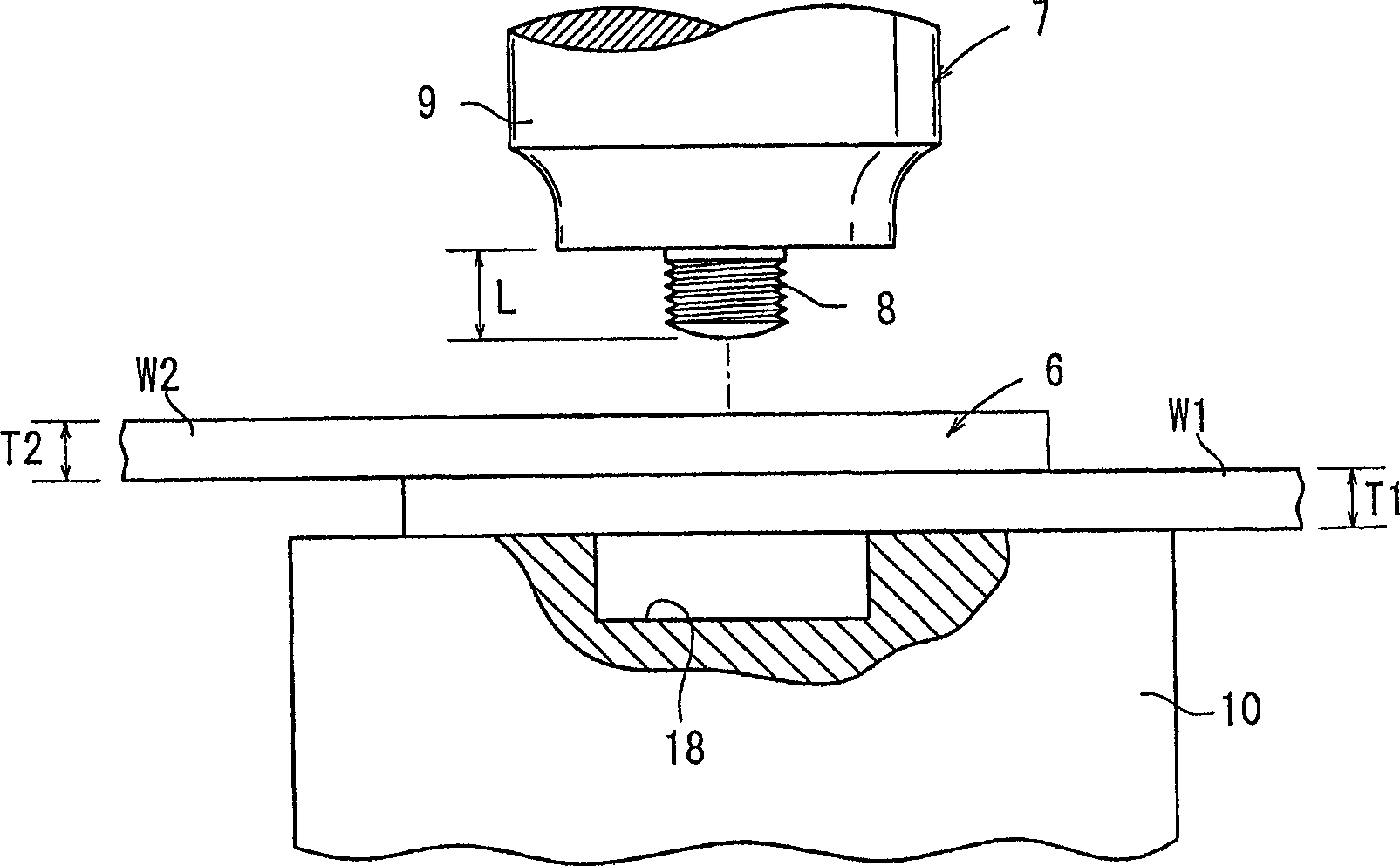

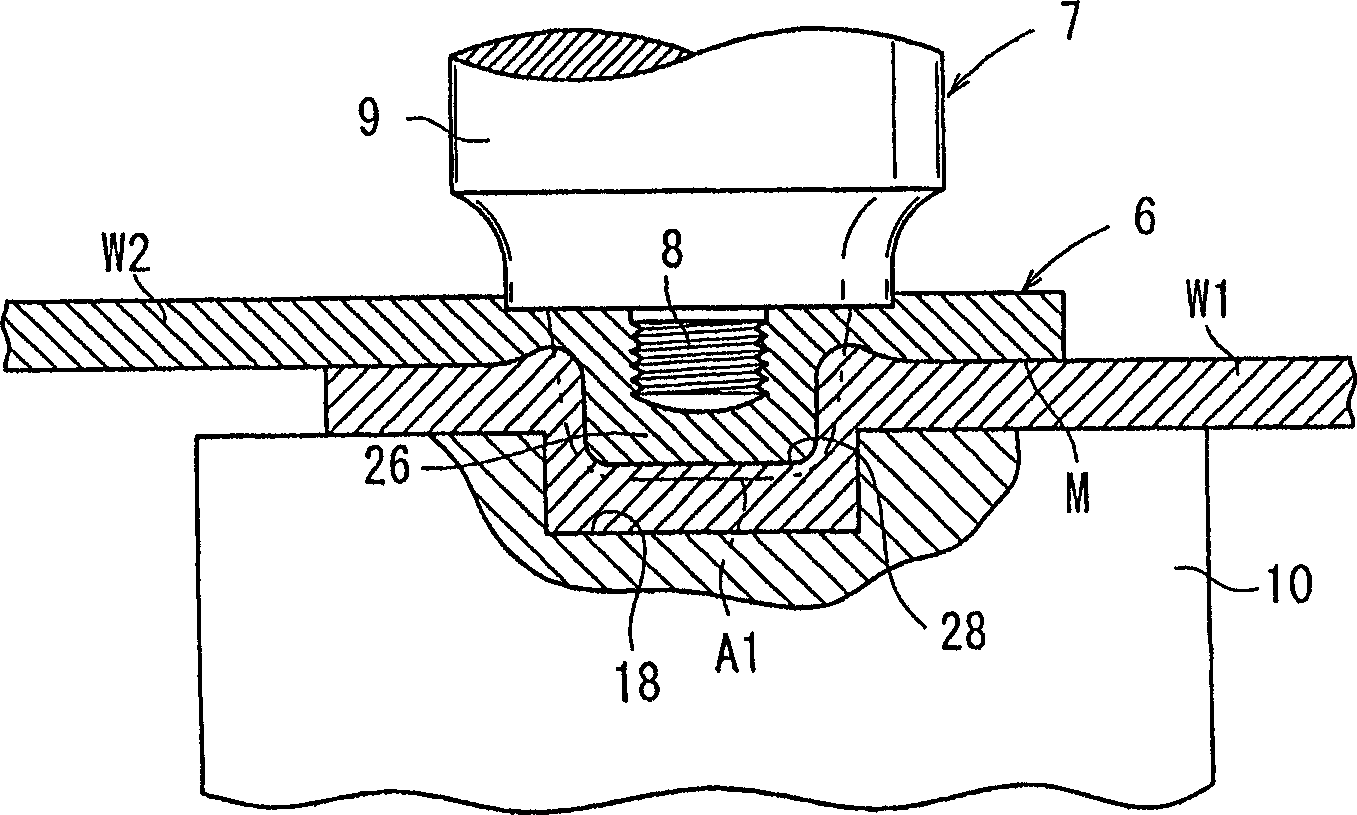

Method for friction stir welding, jig therefor, member with friction stir-welded portion, and tool for friction stir welding

InactiveCN1839011AImprove joint strengthStir wellNon-electric welding apparatusFriction weldingEngineering

A recess portion (18) with a substantially circular horizontal cross-section is provided in the upper end surface of a supporting jig (10). When a probe (8) of a device (7) for friction stir welding is buried in the upper end surface of a layered portion (6), material in the vicinity of the buried portion flows plastically. This causes the plastically flowed material to flows into the recess portion (18), and as a result, the material is stirred in a relatively large region. When the material flowed into the recess portion (18) is cooled and solidified, a friction stir-welded portion-possessing member (42) having a projection portion (44) is obtained.

Owner:HONDA MOTOR CO LTD

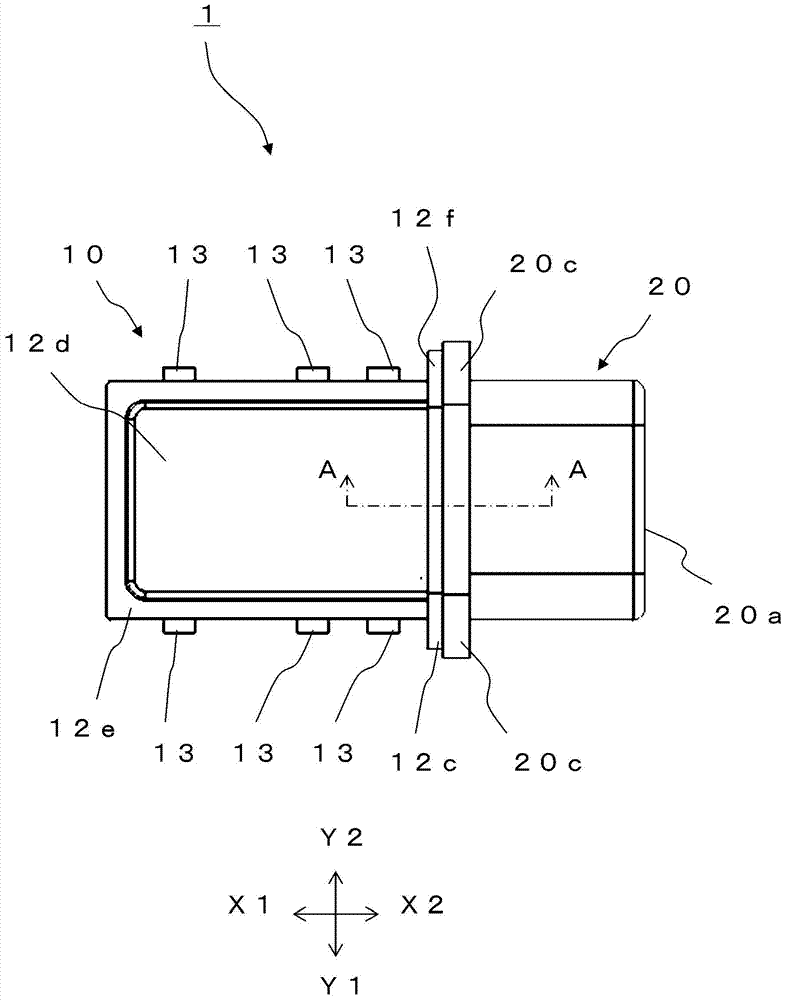

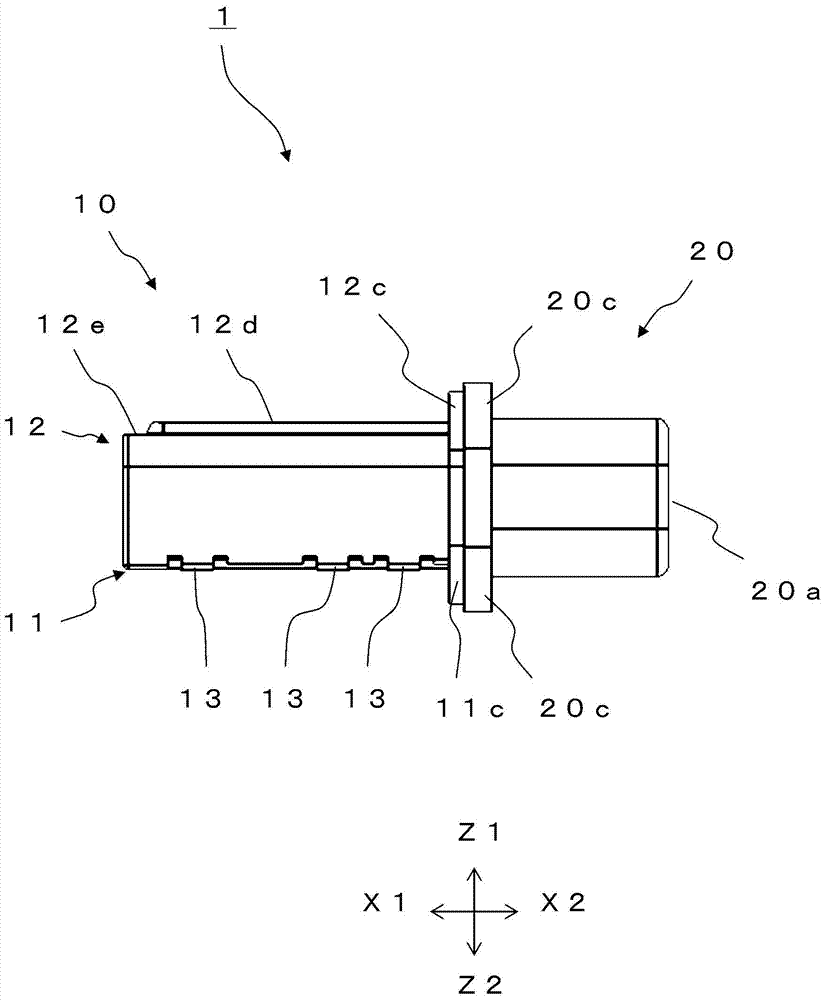

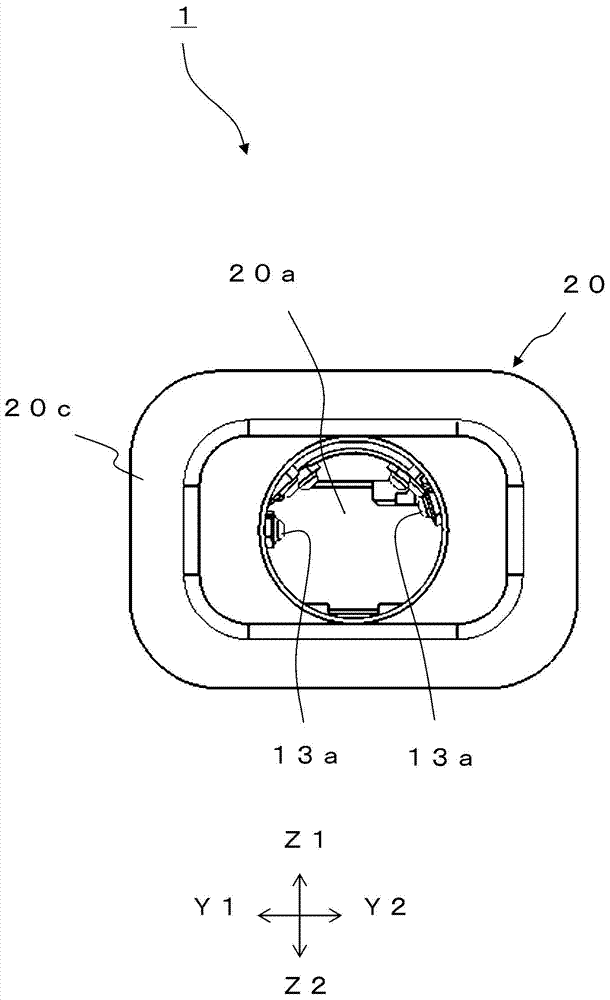

Waterproof connector

Provided is a waterproof connector which realizes miniaturization and reliable connection. The waterproof connector (1) comprises a lower shell (11), an upper shell (12), a cover (20) and terminal parts (13), the lower shell is formed by light-absorption materials, the upper shell is formed by transmittance materials, laser welding portions (a shell welding portion (31) and a flange welding portion (32)) obtained by laser connection of the lower shell and the upper shell are formed, a lower flange portion (11c) is arranged around a side opening portion (10b) of the upper shell (11), an upper flange portion (12c) is arranged at a side of the upper shell (12), a cover side flange portion (20c) is arranged at a position of the cover opposite to a shell side flange portion (10c) formed by the lower flange portion and the upper flange portion, and an ultrasonic welding portion (33) is formed by ultrasonic connection of the shell side flange portion and the cover side flange portion.

Owner:ALPS ALPINE CO LTD

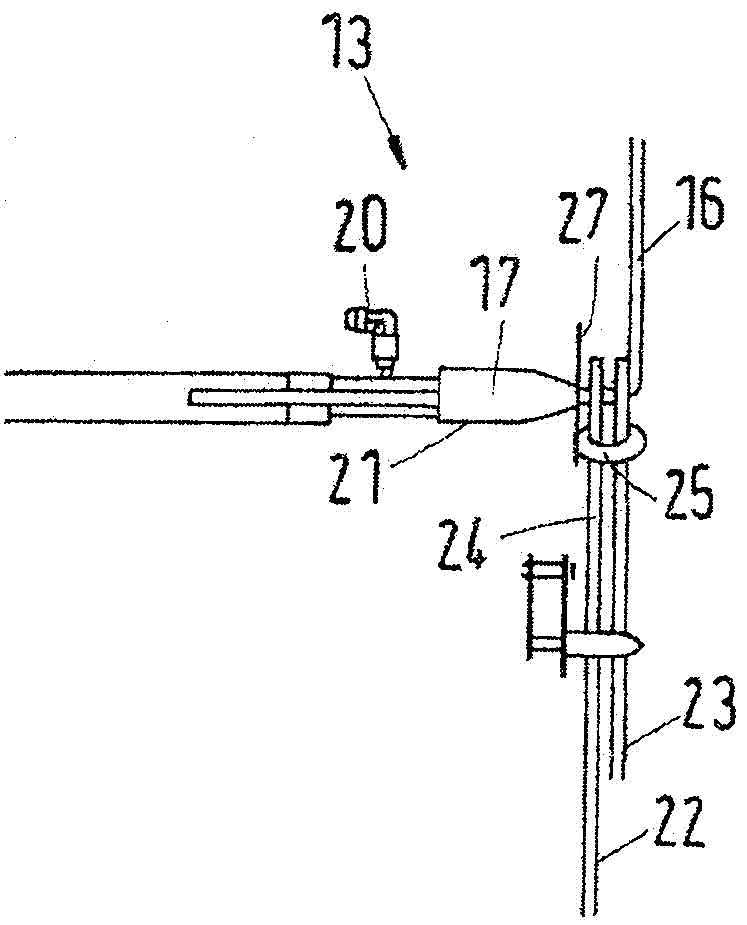

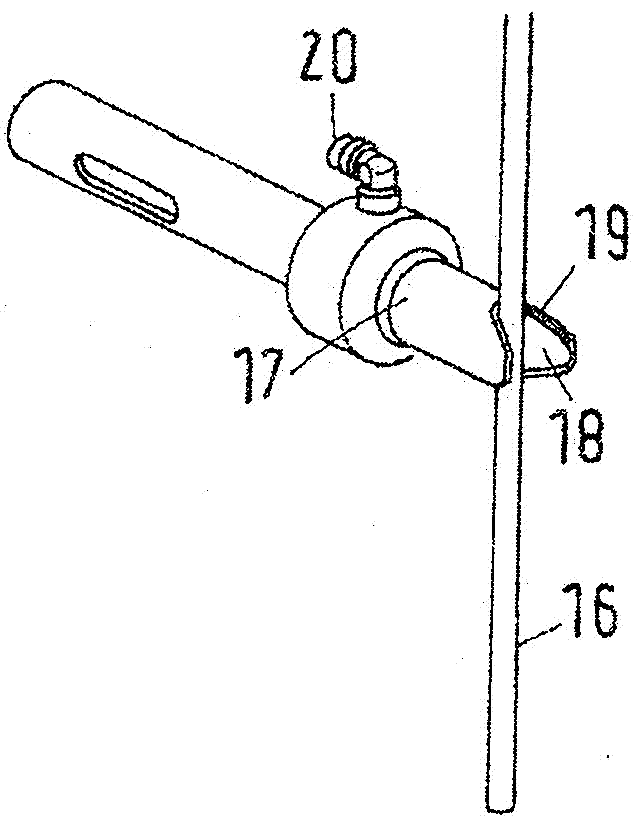

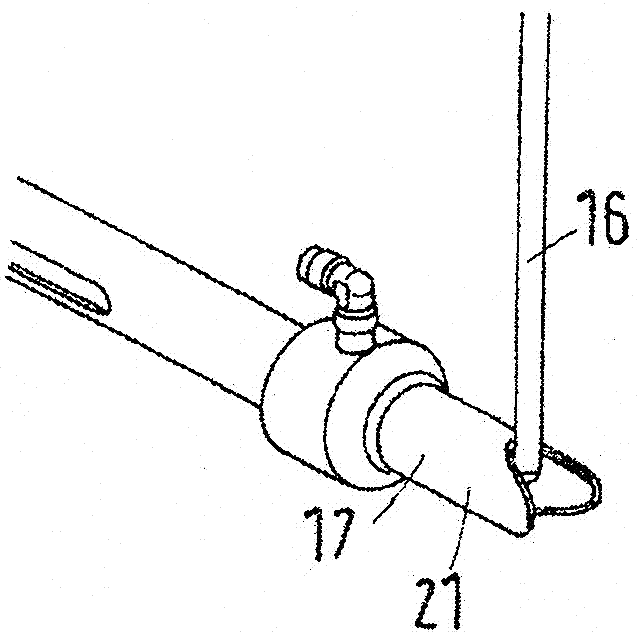

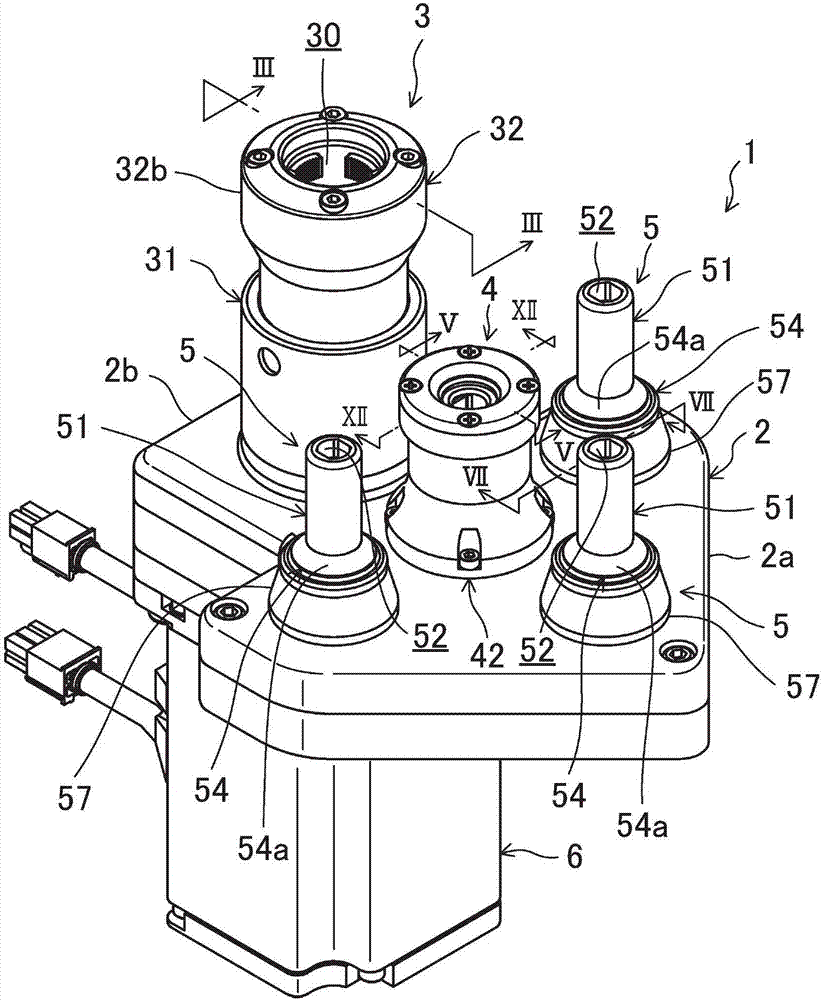

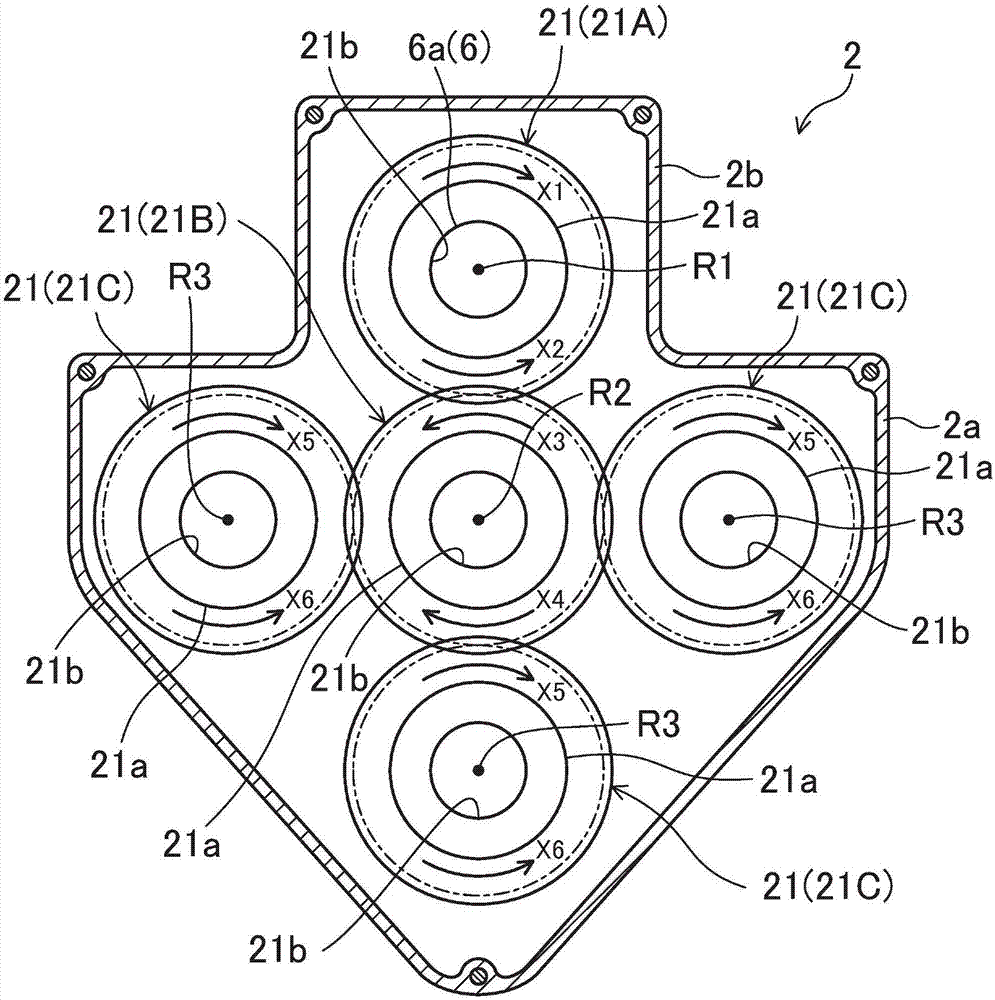

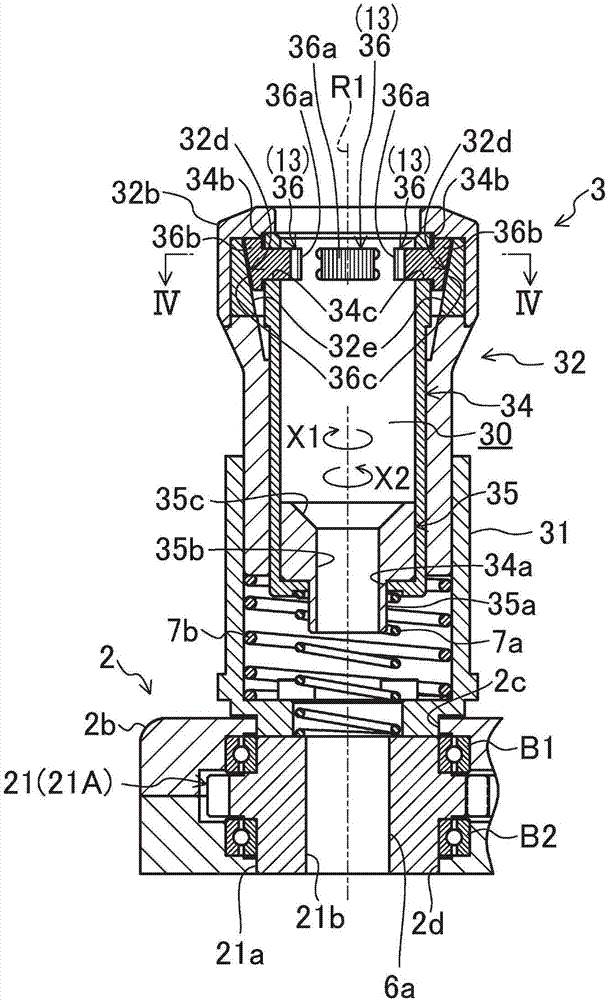

Rotating replacement device

ActiveCN107107245AAvoid breakingReliable assembly and disassemblySleeve/socket jointsTool changing apparatusEngineeringMechanical engineering

A rotating replacement device is provided with, on the inside peripheral surface of a first rotor (41) that forms a through hole (41a), a positioning means (13) that comes in contact with the outer peripheral surface of a contact tip (12) accommodated in the through hole (41a) so as to make a center axis of the contact tip (12) be aligned with or brought closer to a rotational center (R2) of the rotor.

Owner:TIPMAN

Clad electrode for spark plug and method for manufacturing same

InactiveCN103765708AReliable jointAchieve long lifeSparking plugs manufactureDiffusion layerHeat treated

Owner:TANAKA PRECIOUS METAL IND

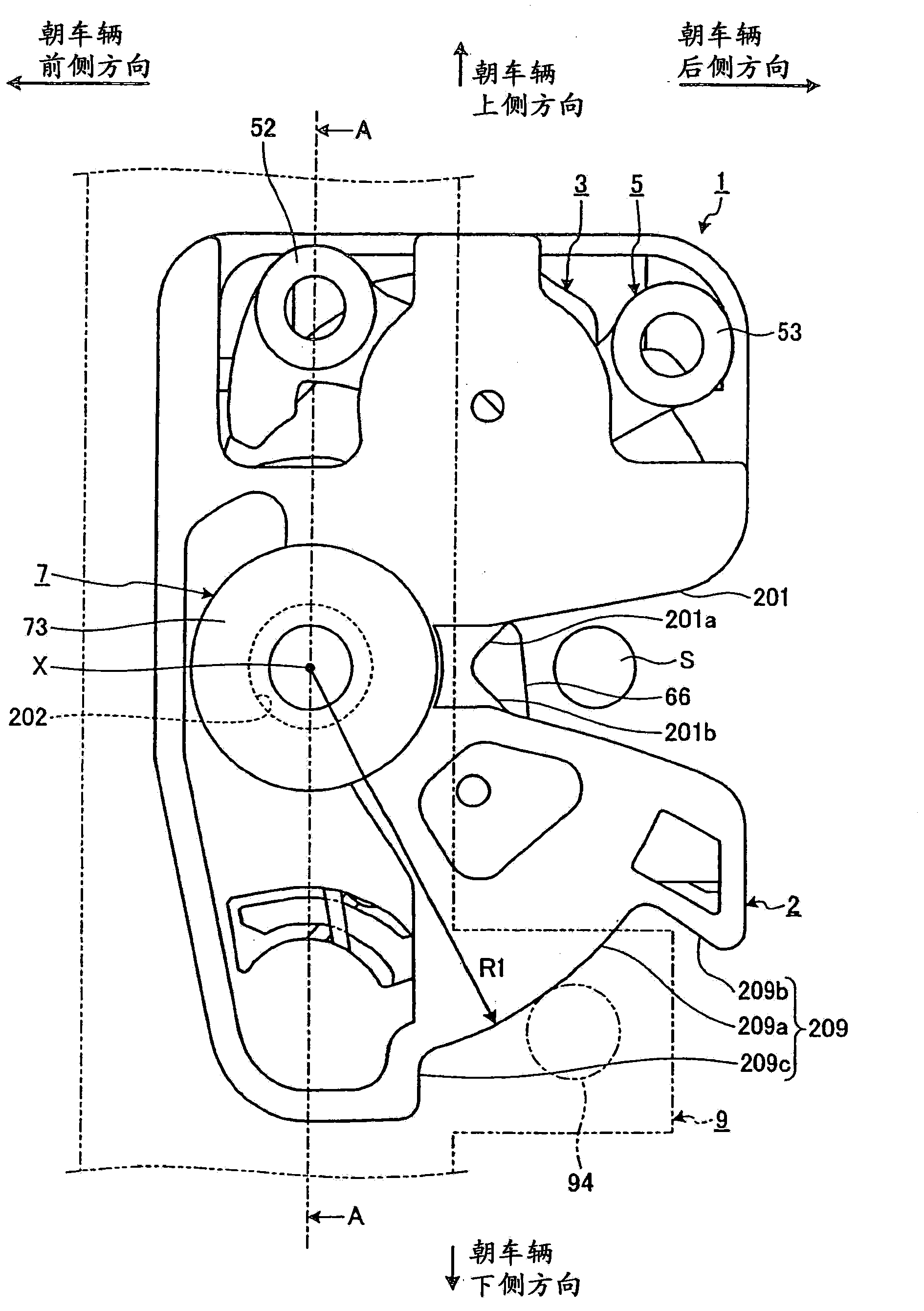

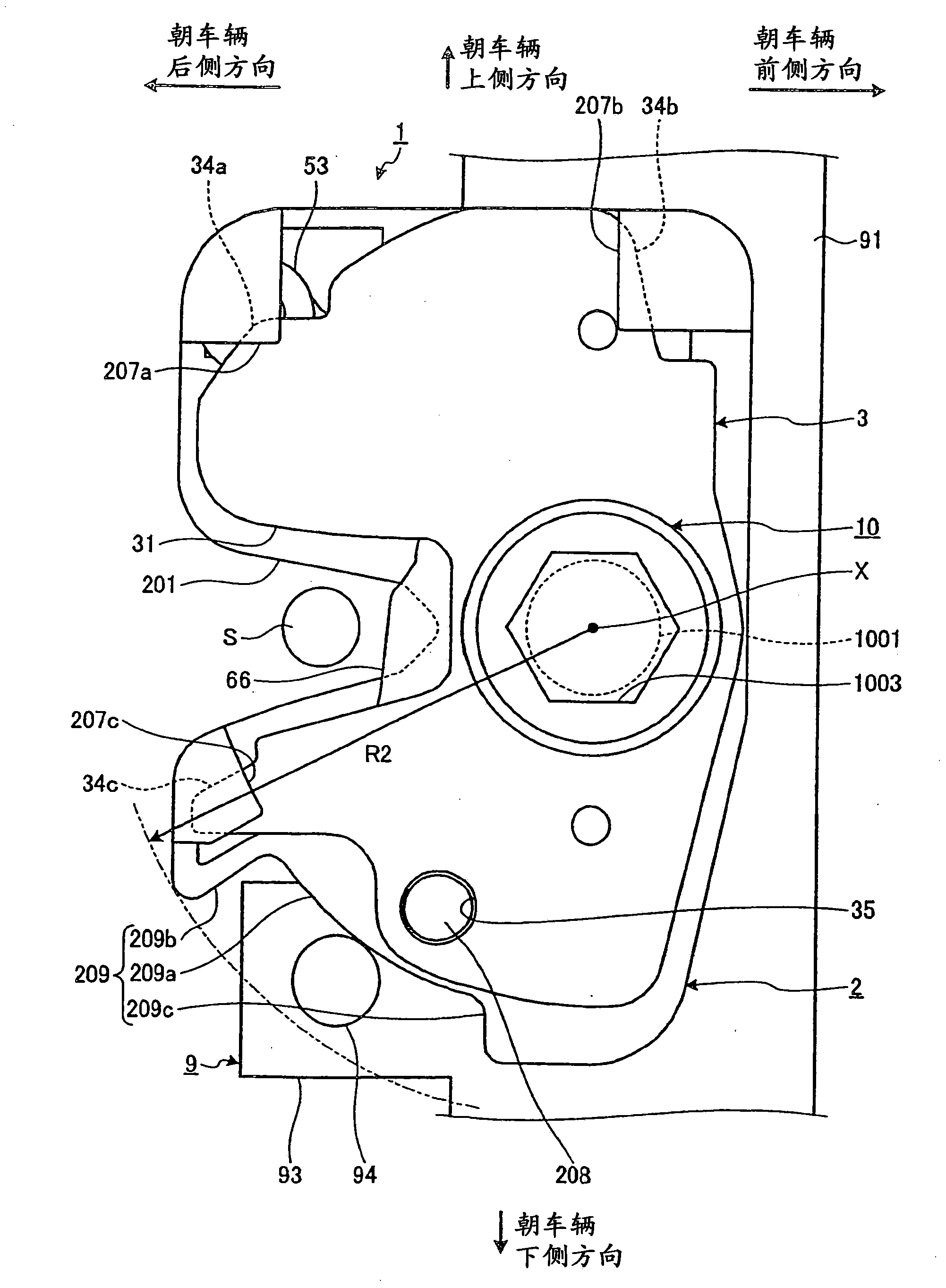

Locking device

Owner:MITSUI KINZOKU ACT

Semiconductor element mounting method and mounting substrate

InactiveCN1606143AControl supplyShape stableSemiconductor/solid-state device detailsSolid-state devicesEngineeringUltrasonic vibration

The bonding member formed by the gold nano paste is arranged between the above-mentioned each element electrode and the above-mentioned each substrate electrode, and the above-mentioned each element electrode is connected to the above-mentioned each substrate electrode by means of the above-mentioned each bonding member. Each bonding member imparts ultrasonic vibrations to bond the respective bonding members to the respective substrate electrodes and the respective element electrodes.

Owner:PANASONIC CORP

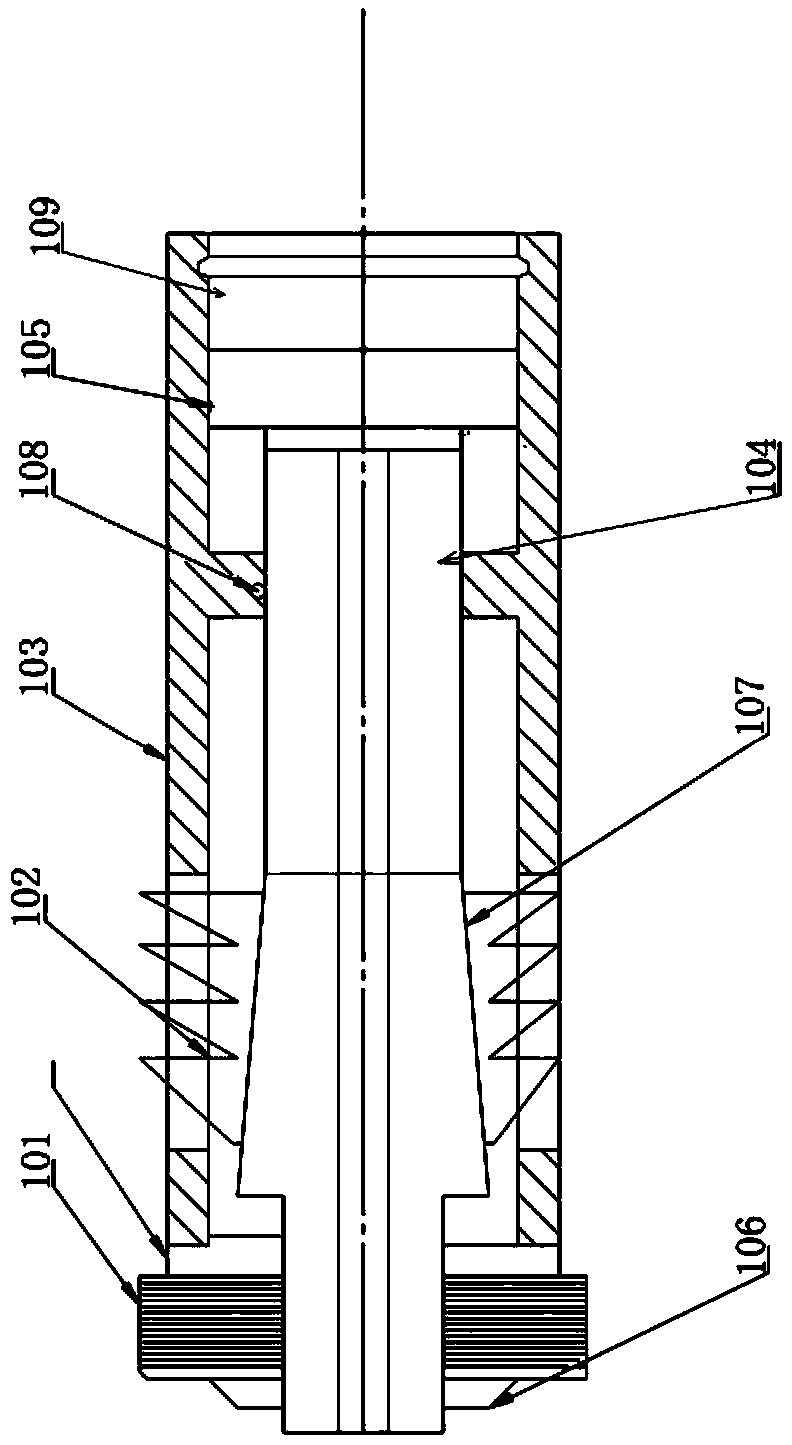

Jaw clutch

ActiveCN107110240ASecurity exclusionTilt safetyFluid actuated clutchesInterengaging clutchesEngineeringPosition sensor

The invention relates to a jaw clutch (10) having an axially static clutch part (12) and having an axially movable clutch part (14), wherein the axially static clutch part (12) and the axially movable clutch part (14) are of sleeve-shaped form and are arranged coaxially with respect to one another, wherein the axially movable clutch part (14) can, in order to produce a positively locking connection to the axially static clutch part (12), be displaced axially by way of a piston (22) that can be actuated by pressure medium, wherein the piston (22) is arranged in longitudinally displaceable fashion in a cylinder housing (20) which, radially on the outside, bears the axially movable clutch part (14), wherein the piston (22) is connected by way of a piston pin (26) to the axially movable clutch part (14), and wherein pressure medium (40) can be supplied to the cylinder chamber (60) of the cylinder housing (20) via a supply duct (38), the piston (22) being fixedly connected, at one axial end, to a coaxially oriented sensor pin (48), and the sensor pin (48), in the region of its free axial end (78) remote from the piston, being formed, at a sensor section (52), as an encoder element for a position sensor (70).

Owner:ZF FRIEDRICHSHAFEN AG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com