Substrate with cooler for power modules and method for producing same

A technology of power module and manufacturing method, applied in semiconductor/solid-state device manufacturing, manufacturing tools, printed circuit manufacturing, etc., can solve problems such as deformation of aluminum coolers, and achieve the effect of high bonding reliability and low thermal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

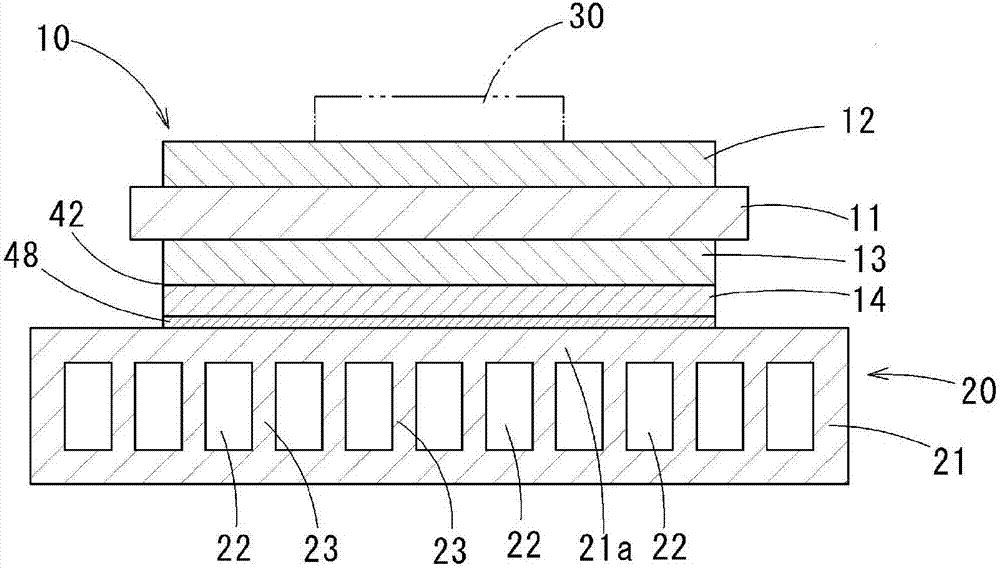

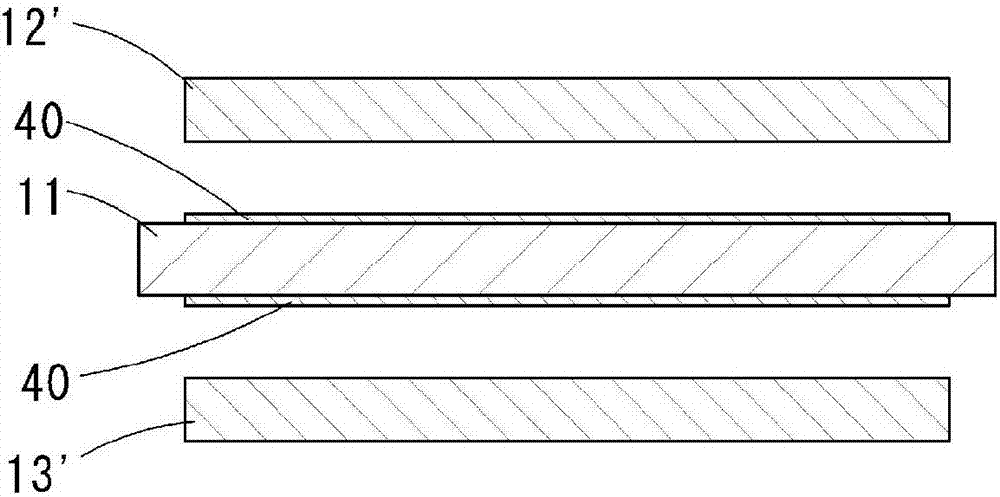

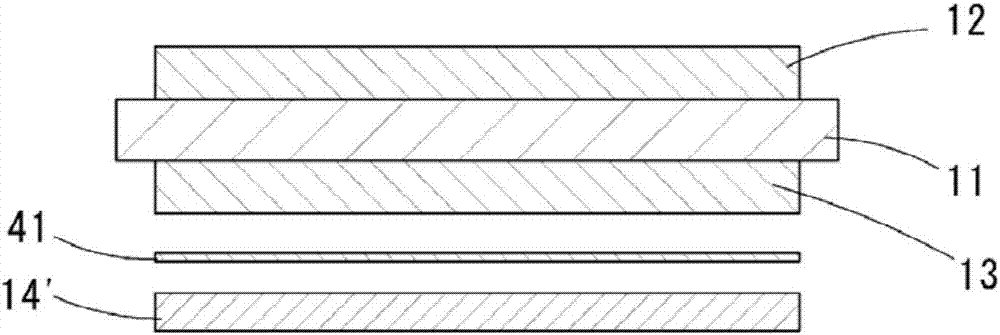

[0038] figure 1 The shown power module substrate 10 with a cooler has: a ceramic substrate 11; a circuit layer 12 bonded to one surface of the ceramic substrate 11; a first metal layer 13 bonded to the other surface of the ceramic substrate 11; The metal layer 14 is bonded to the surface of the first metal layer 13 opposite to the ceramic substrate 11; the cooler 20 is bonded to the second metal layer 14; and the titanium layer 42 is interposed between the first metal layer 13 and the second metal layer 14. figure 1 Indicated at 48 is an adhesive layer which will be described later. And, if figure 1 As shown by the two-dot chain line in , the semiconductor element 30 is bonded on the circuit layer 12 with a solder material to form a power module.

[0039] The ceramic substrate 11 prevents electrical connection between the circuit layer 12 and the first metal layer 13, and it can use aluminum nitride (AlN), silicon nitride (Si 3 N 4 ), alumina (Al2 o 3 ), etc., but among ...

no. 2 Embodiment approach

[0075] Such as Figure 4 As shown, the power module substrate 210 with a cooler according to the second embodiment of the present invention includes: a ceramic substrate 211; a circuit layer 212 bonded to one surface of the ceramic substrate 211 and made of copper or a copper alloy; The metal layer 213 is bonded to the other surface of the ceramic substrate 211 and is made of copper or a copper alloy; the second metal layer 214 is bonded to the first metal layer 213 and is made of nickel or a nickel alloy; and the cooler 20 is bonded to the first metal layer 213. 2. The metal layer 214 is made of aluminum alloy. In addition, as in the first embodiment, part of the double cladding material for brazing the cooler 20 remains between the second metal layer 214 and the cooler 20 as the joining layer 48 .

[0076] In this power module substrate 210 with a cooler, Ni in the second metal layer 214 bonded to the surface of the first metal layer 213 exists in a diffused state, and in t...

no. 3 Embodiment approach

[0080] Such as Figure 5 As shown, the power module substrate 310 with a cooler according to the third embodiment of the present invention includes: a ceramic substrate 311; a circuit layer 312 bonded to one surface of the ceramic substrate 311 and made of copper or a copper alloy; The metal layer 313 is bonded to the other surface of the ceramic substrate 311 and is made of copper or a copper alloy; the second metal layer 314 is bonded to the first metal layer 313 and is made of nickel or a nickel alloy; and the cooler 20 is bonded to the first metal layer 313. The second metal layer 314 is made of aluminum alloy, and also has an aluminum layer 315 interposed between the second metal layer 314 and the cooler 20 . In addition, a part of the double-clad material used to braze and join the cooler 20 remains between the aluminum layer 315 and the cooler 20 as the joining layer 48 similarly to each of the above-described embodiments.

[0081] In this power module substrate 310 wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com