Verschluss

A technology for zippers and zipper tapes, applied in the field of zippers, which can solve the problems of unintentional opening of the right and left edge parts, and achieve the effects of easy orientation, shortened manufacturing time, and simplified manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

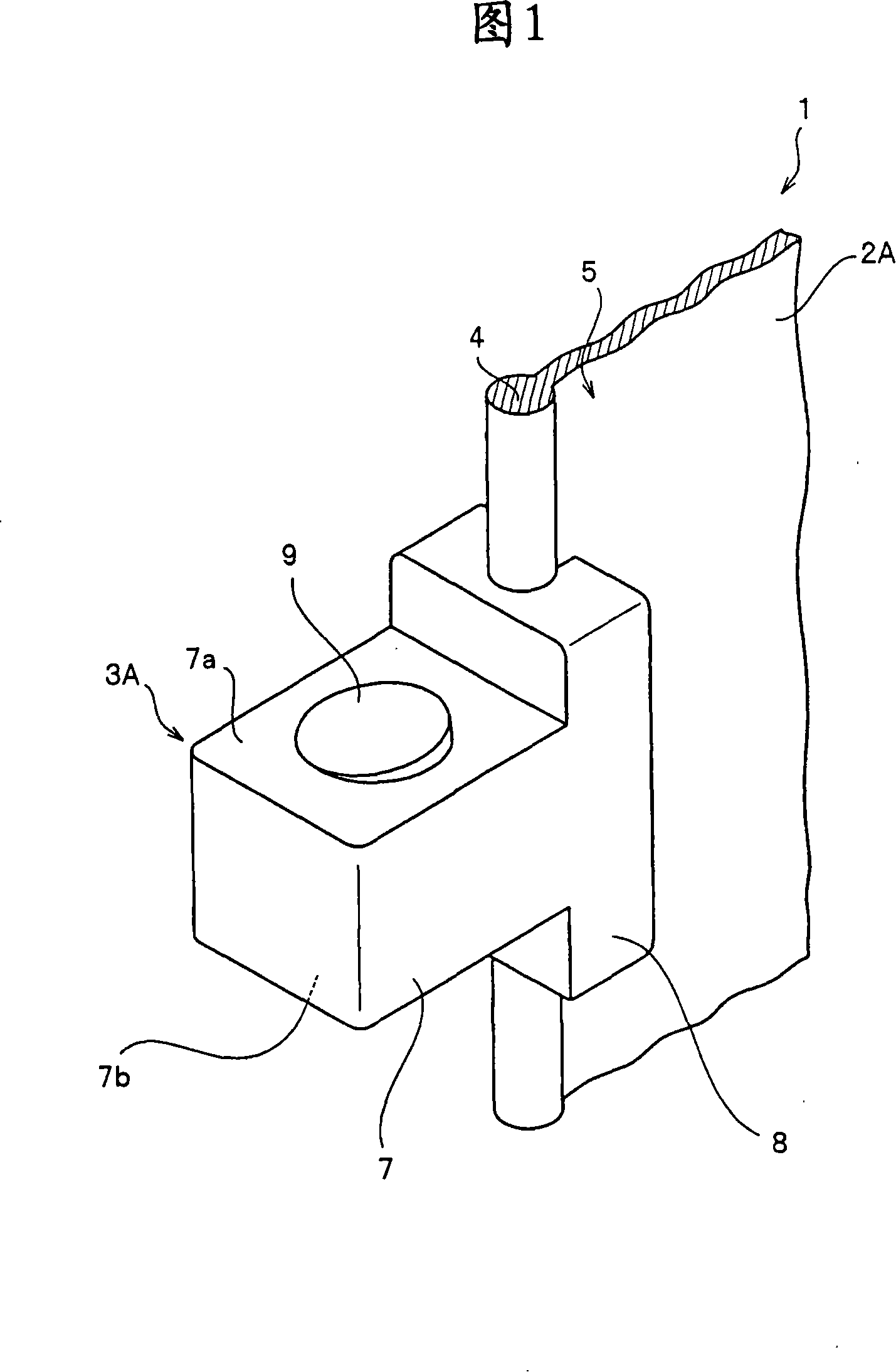

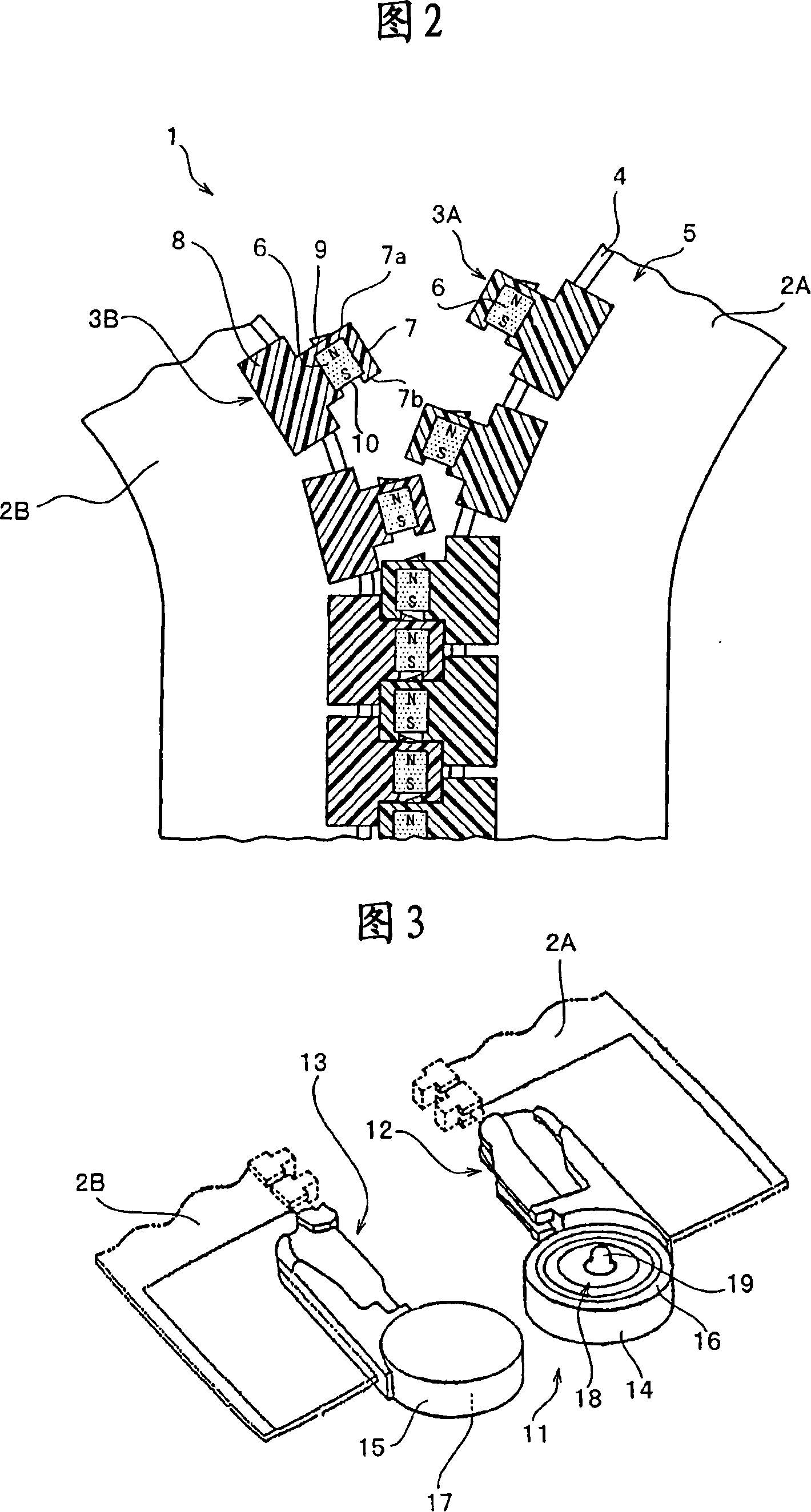

[0052] FIG. 1 is a perspective view showing a magnetic element of a slide fastener according to a first embodiment of the present invention. Fig. 2 is a front view of a part of the slide fastener according to the first embodiment, particularly showing the magnetic element in section. In the following description, in FIG. 1 , one direction (direction upward in the figure) along the longitudinal direction of the fastener tape is defined as the front, and the other direction (direction downward in the figure) is defined as the rear.

[0053] The slide fastener 1 of the first embodiment includes a pair of first and second fastener tapes 2A and 2B and a plurality of first and second magnetic elements 3A and 3B made of synthetic resin. The core part 4 is formed at the opposite side edges of the first fastener tape 2A and the second fastener tape 2B, and a plurality of first magnetic elements 3A and second magnetic elements 3B are formed at constant intervals along the first fastener...

no. 2 example

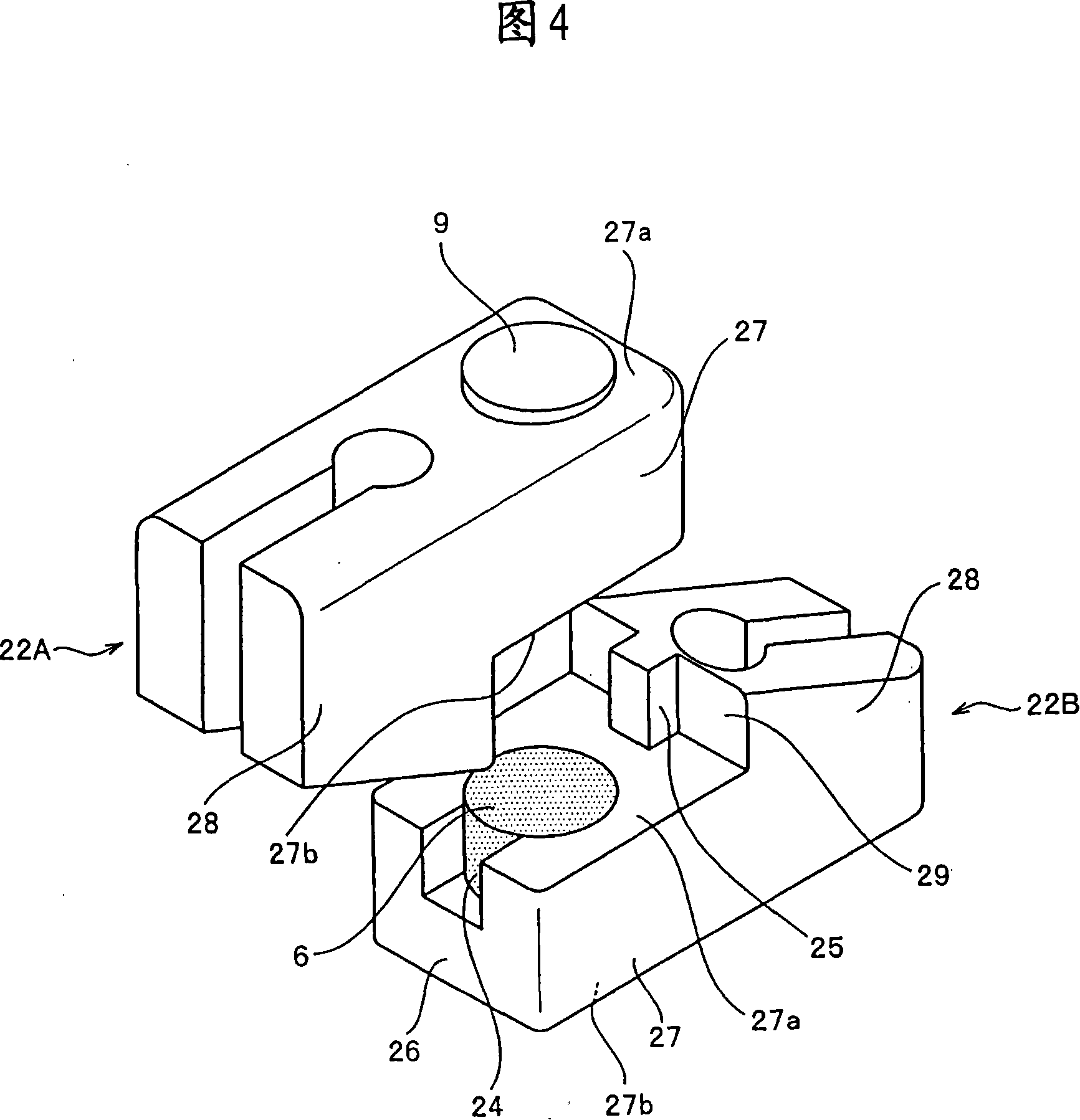

[0065] Next, a slide fastener according to a second embodiment of the present invention will be described. In the description of the second embodiment and the following, components having the same configuration as those of the first embodiment are denoted by the same reference numerals, and descriptions thereof are omitted. FIG. 4 is a perspective view showing a magnetic element of a slide fastener according to a second embodiment, and FIG. 5 is a front view showing a part of the slide fastener of the second embodiment.

[0066] The slide fastener 21 according to the second embodiment includes a pair of first fastener tape 2A and second fastener tape 2B and a plurality of element attachment edge portions 5 corresponding to the first fastener tape 2A and second fastener tape 2B arranged in a row at constant intervals. The first magnetic fastener element 22A and the second magnetic fastener element 22B are provided.

[0067] The first magnetic fastener element 22A and the secon...

no. 3 example

[0076] Next, a slide fastener according to a third embodiment of the present invention will be described. Fig. 8 is a perspective view showing a magnetic element of the slide fastener of the third embodiment. Fig. 9 is a front view showing a part of the slide fastener of the third embodiment. In FIG. 9 , the illustration of the fastener tape is omitted.

[0077] The slide fastener 31 of the third embodiment includes a pair of first and second fastener tapes and a plurality of first magnetic elements arranged in a row at constant intervals along the element attachment edge portions of the first and second fastener tapes. 32A and the second magnetic element 32B.

[0078] Each magnetic fastener element 32A, 32B includes a magnetic head portion 37 and a tooth leg portion 38 , wherein the magnet 6 is embedded in the head portion 37 . The magnet 6 is embedded in the first opposing surface 37a and the second opposing surface 37b of the dental bag portion 37, thereby exposing the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com