Patents

Literature

41results about How to "Stay engaged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

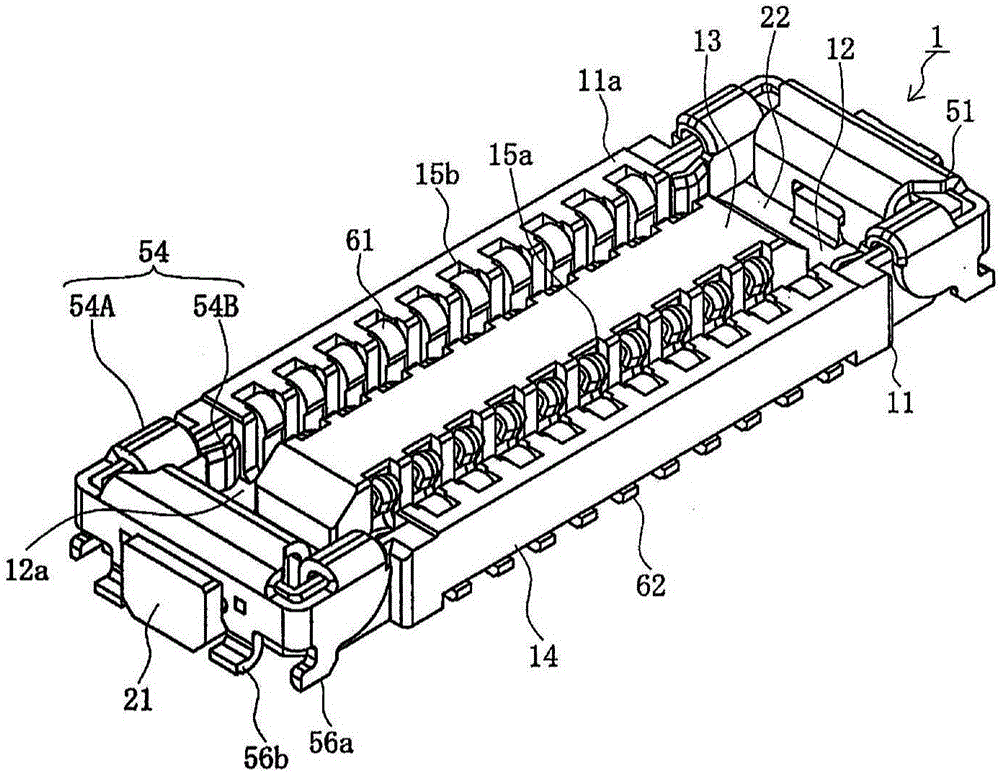

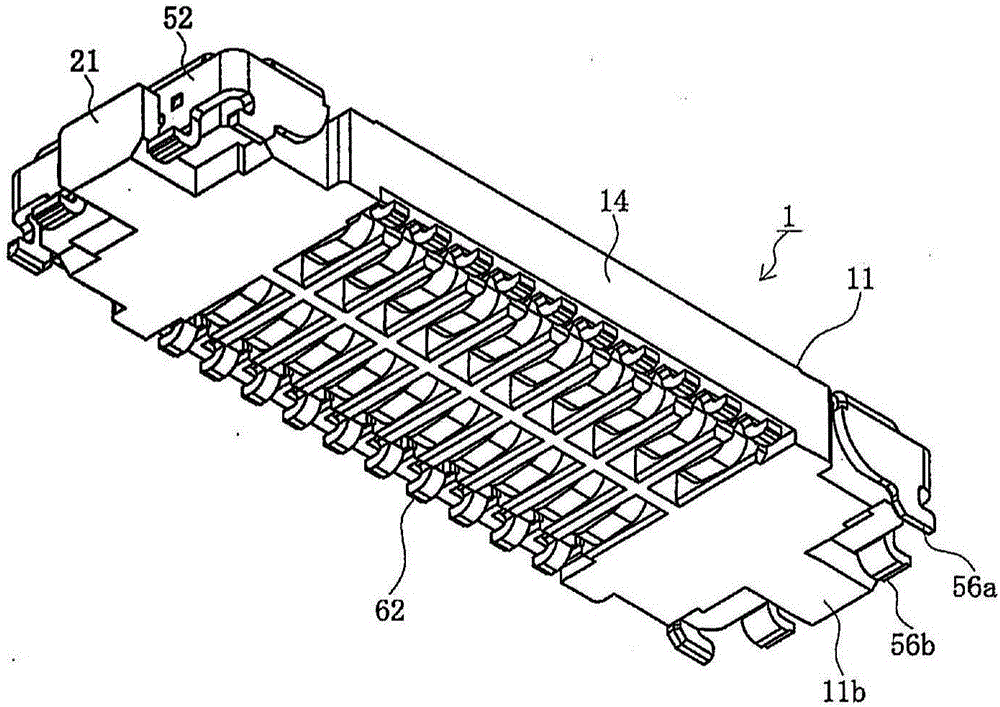

Connector

ActiveCN104682047AEnsure electrical connectionStay engagedCoupling contact membersButt jointElectrical connection

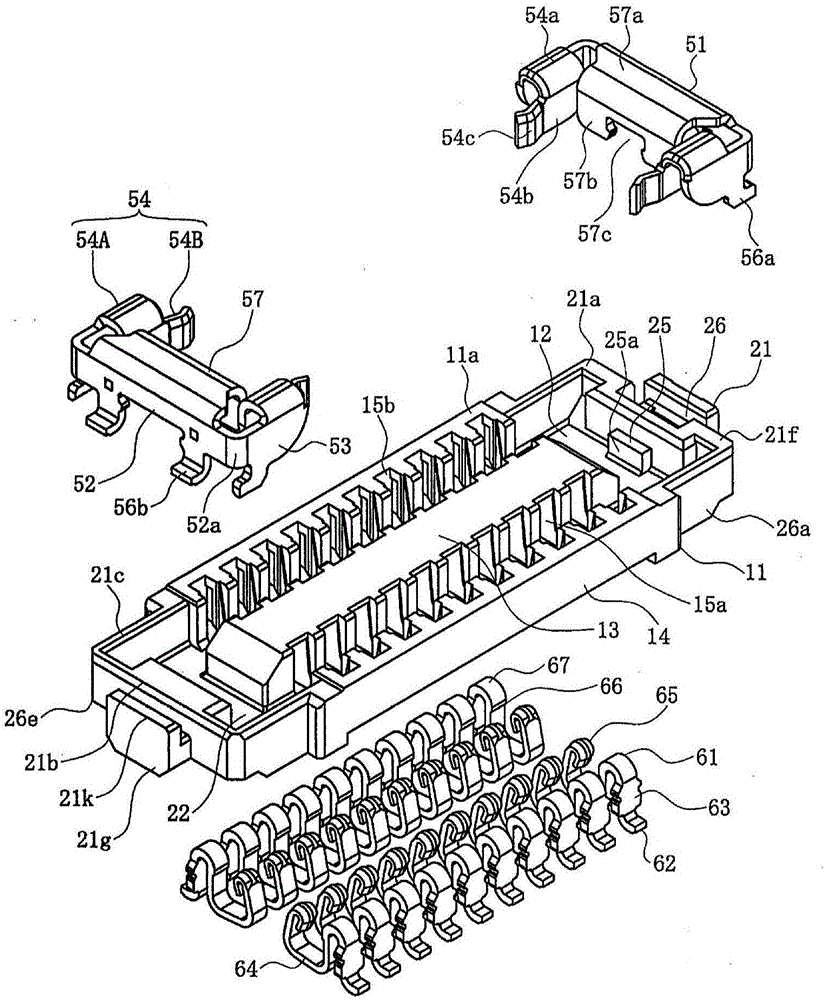

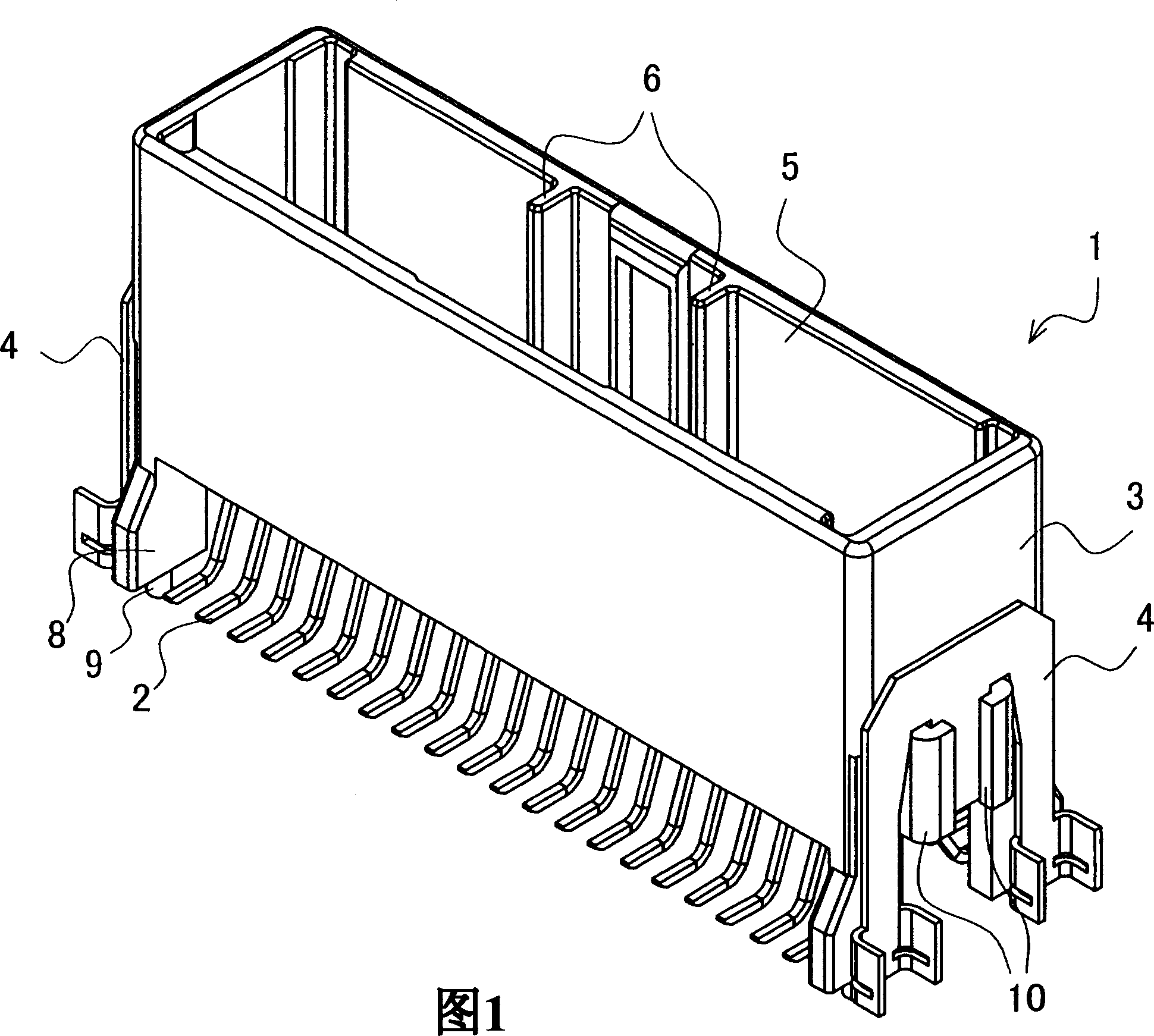

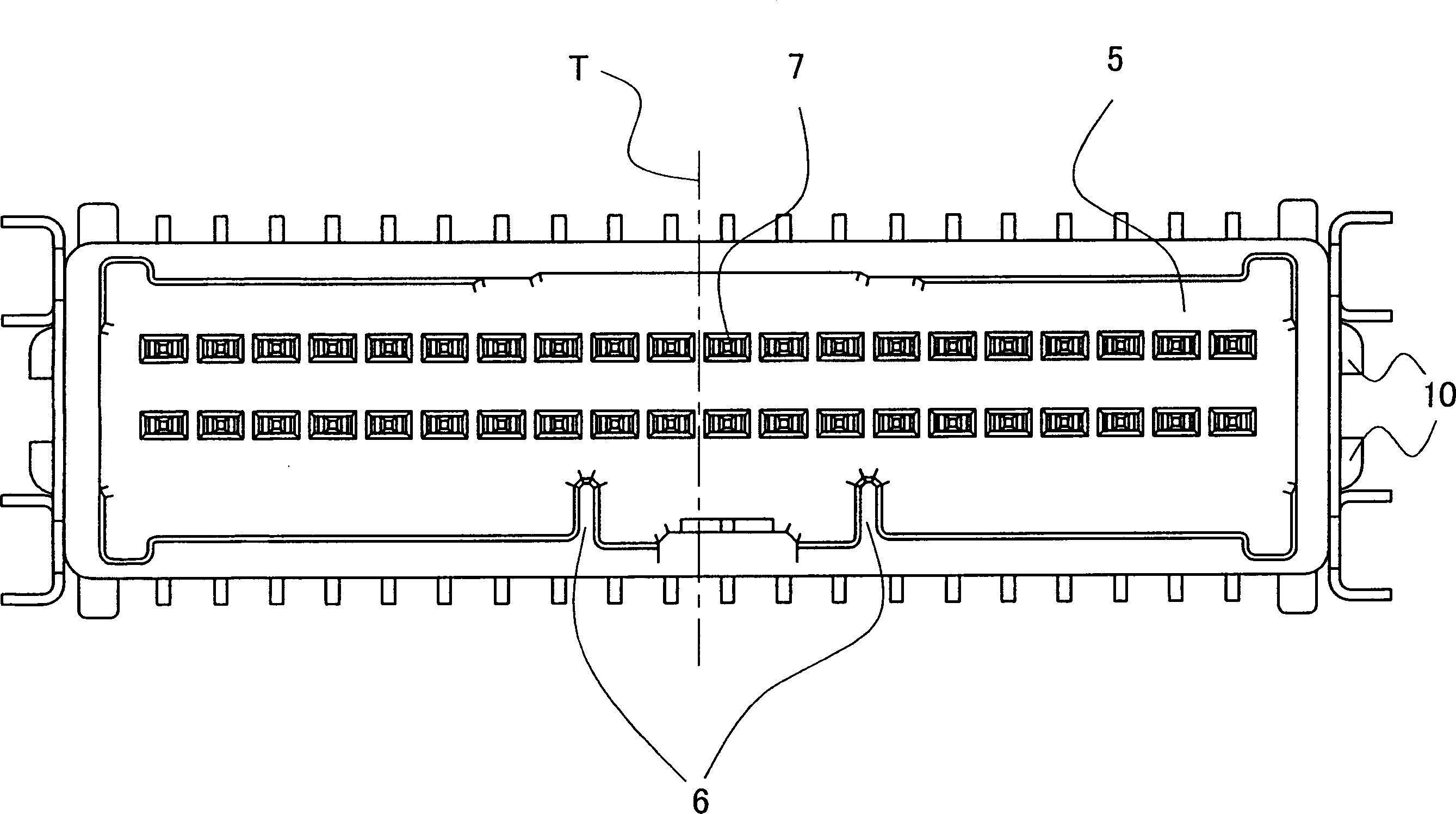

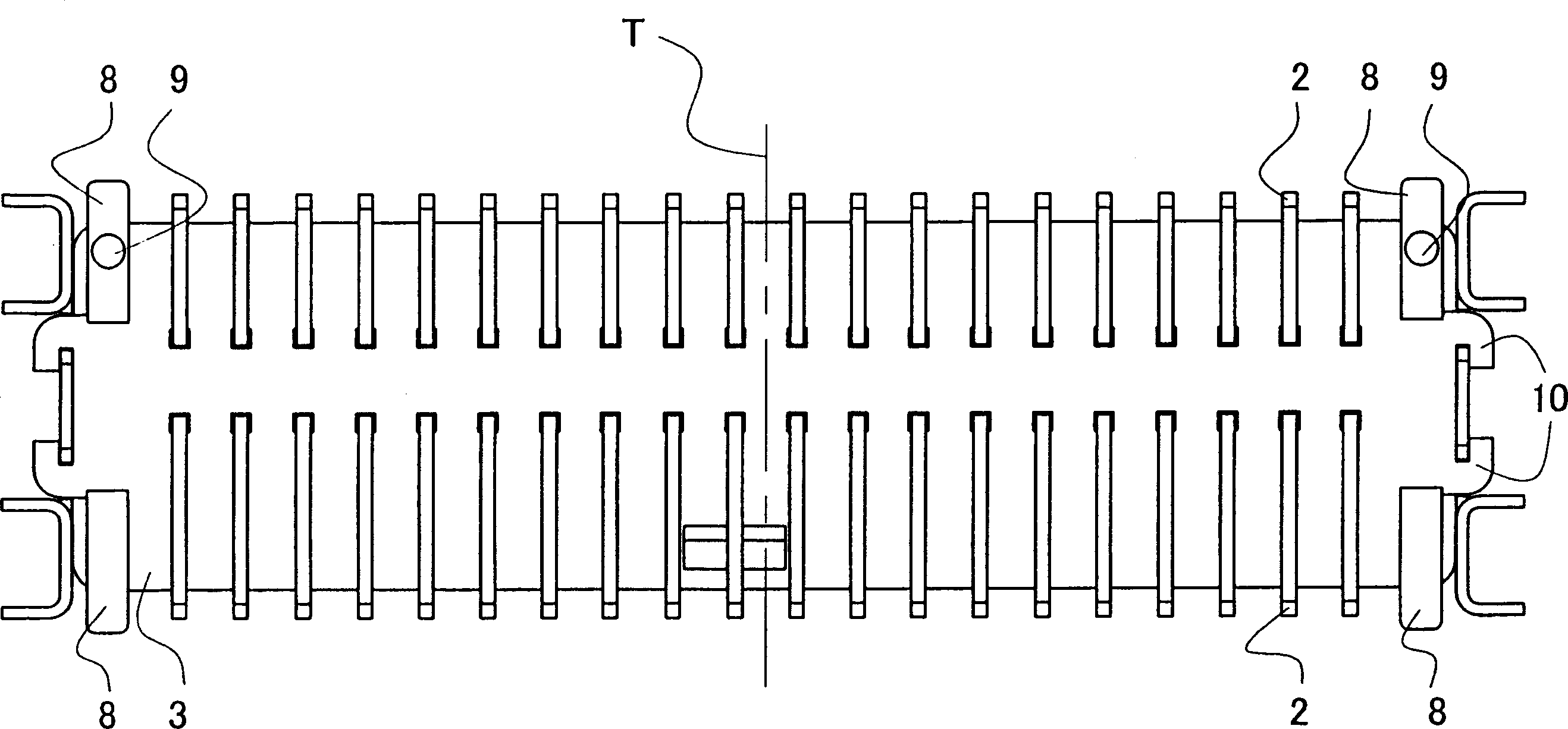

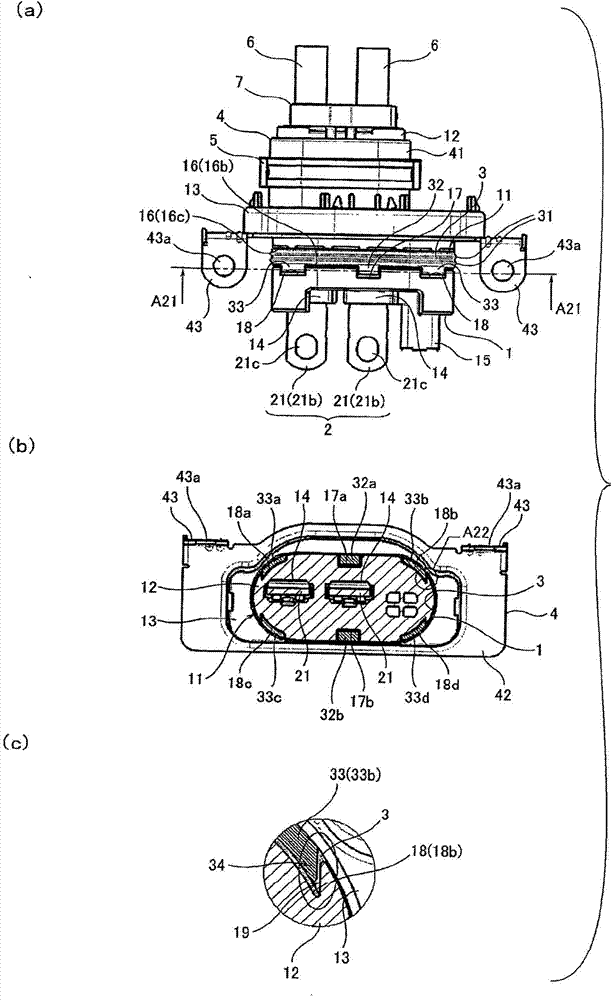

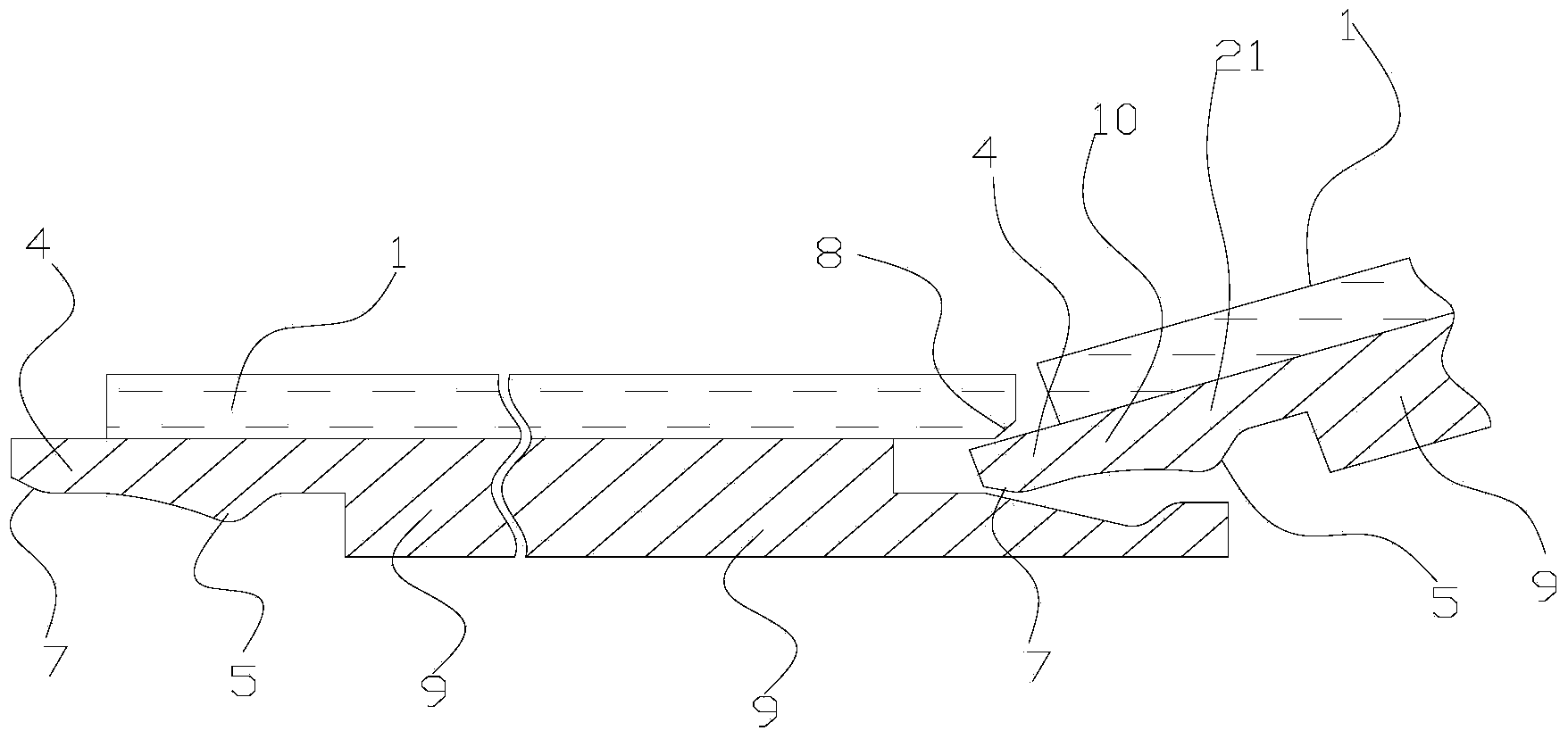

The invention provides a connector. Reinforced metal fittings of the connector can be reliably connected to reinforced metal fittings of another connector, electrical connections between the reinforced metal fittings are maintained, and the connector can be connected to another connector end to end. A connector body includes butt-joint guide portions and reinforced metal fittings. The butt-joint guide portions are formed on two vertical ends of the connector body so that the connector body is butt joint with a connector body of another connector. Each reinforced metal fitting includes a body portion, a side plate portion, and a contact arm portion, wherein the body portion extends transversely along the connector body, the side plate portion is connected to the body portion and extends vertically along the connector body, and the contact arm portion is connected to the side plate portion. The reinforced metal fittings are arranged to the left and to the right of the butt-joint guide portions. Each contact arm portion includes a first contact part and a second contact port that face each other. When the connector body is butt joint with the connector body of another connector, the reinforced metal fittings arranged on another connector body are inserted between the first and second contact parts, and the reinforced metal fittings are maintained by the first and second contact parts on two sides and contact the first and second contact parts.

Owner:MOLEX INC

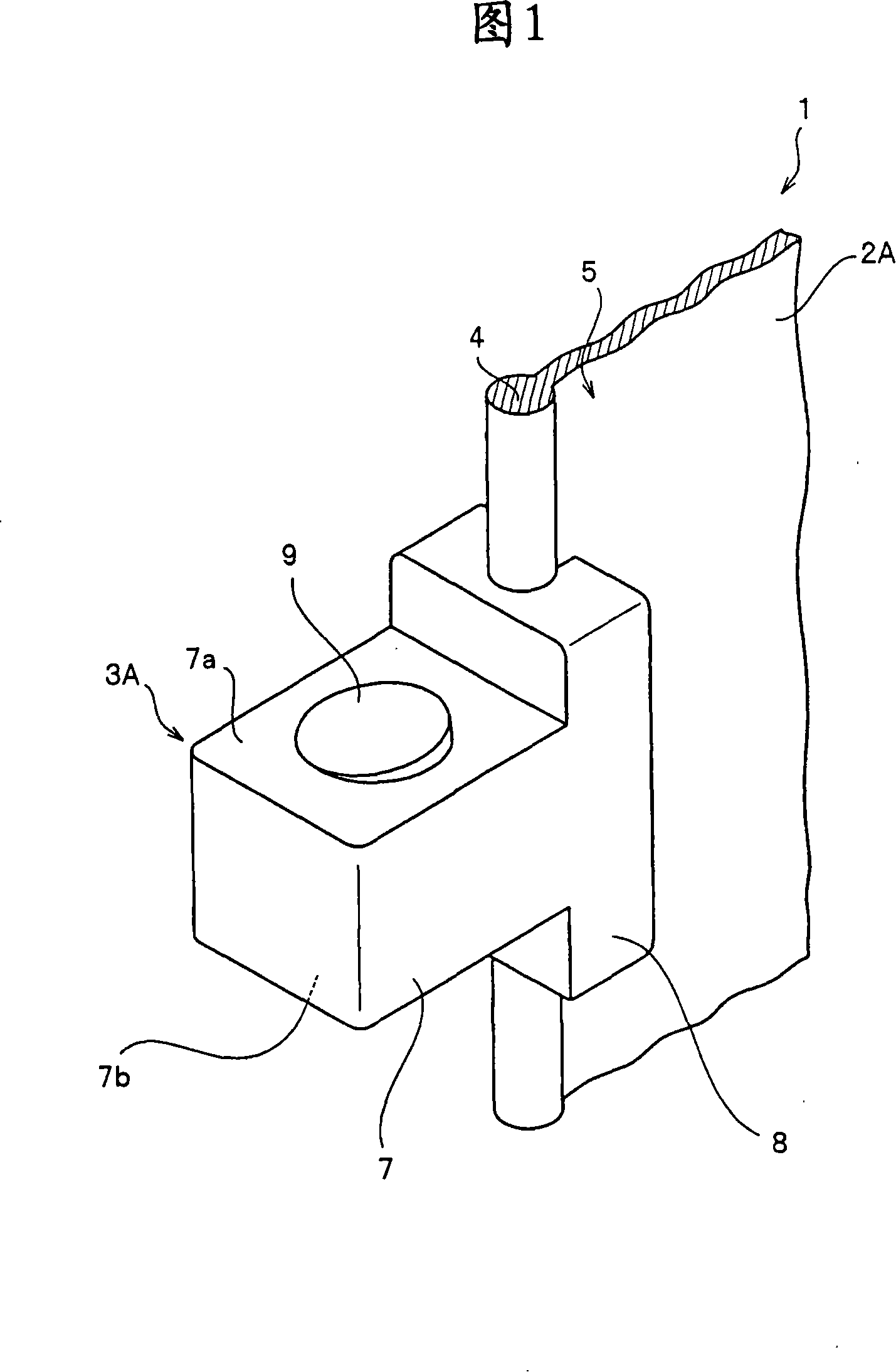

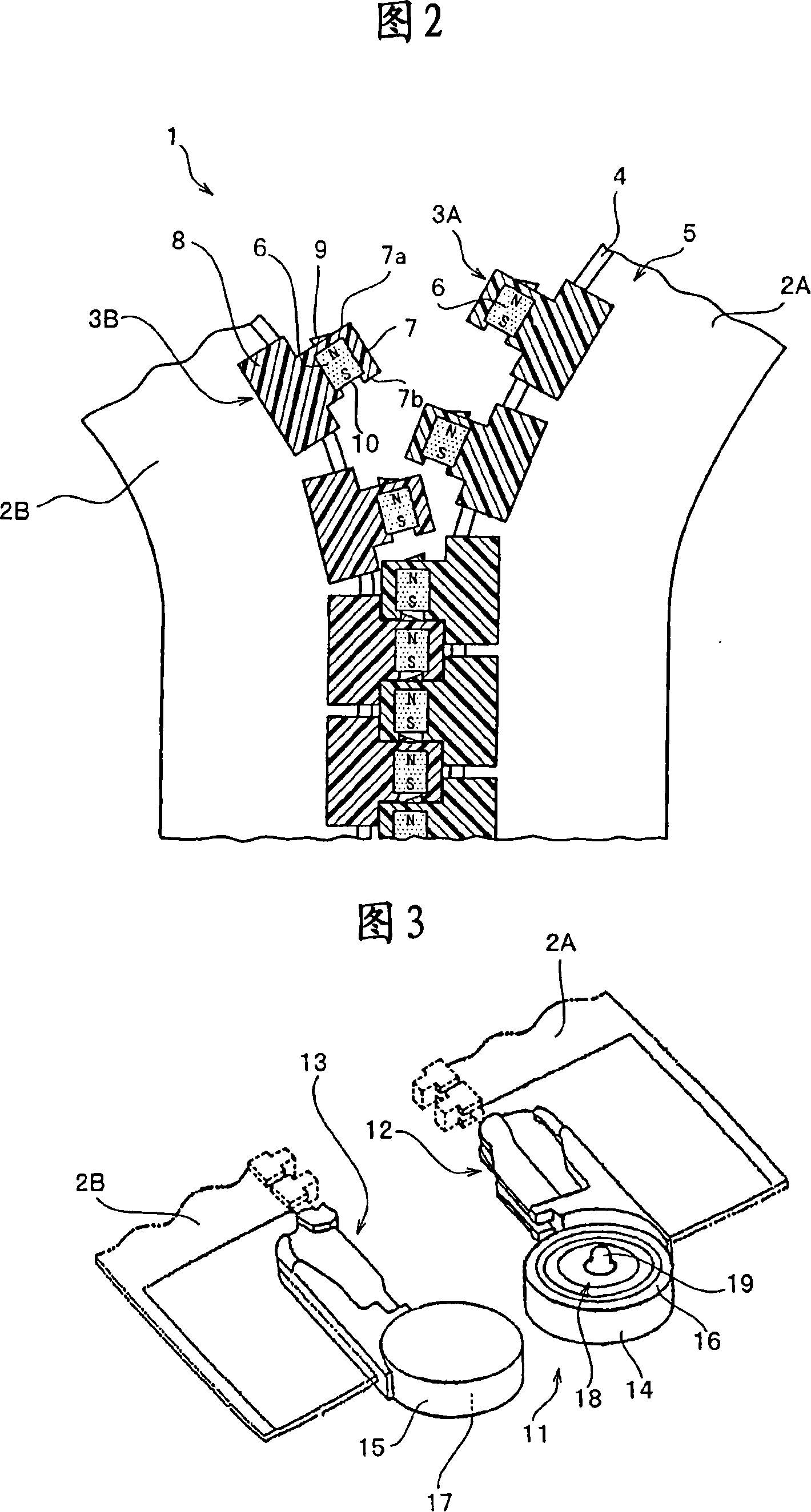

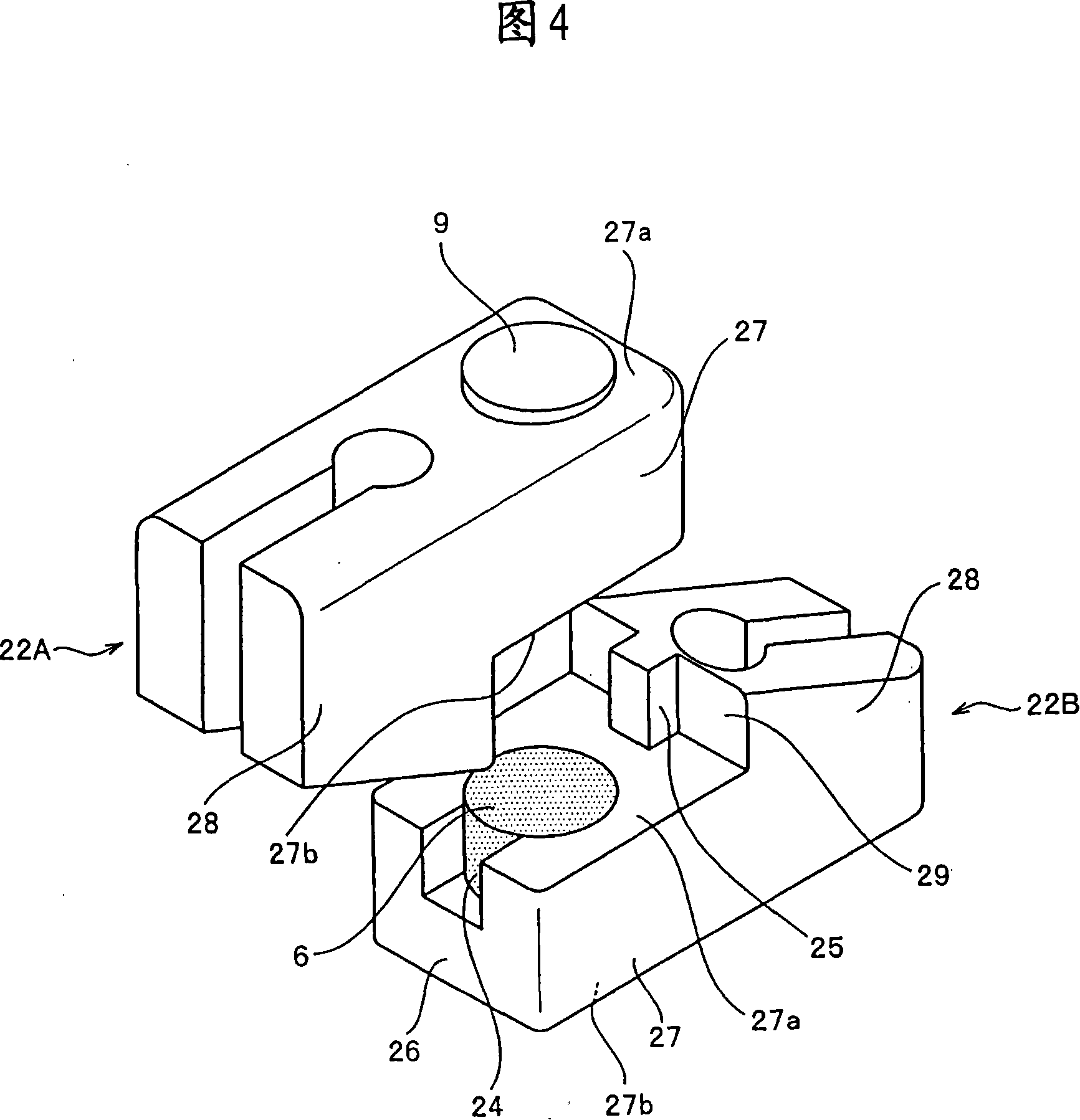

Verschluss

ActiveCN101081115AStay engagedPrevent openingSlide fastenersOther accessoriesMagnetic tension forcePull force

A fastener wherein right and left side edge portions can be engaged using a magnetic force, and which can be applied preferably for plastic article such as clothes and further prevented from being opened carelessly even if a lateral pulling force is applied when right and left elements are engaged. In the fastener, a plurality of first and second magnetic elements(3A,3B) having magnetism are provided in lines on a pair of first and second fastener tapes(3A,3B), the first and second magnetic elements(3A,3B) are adsorbed to each other using a magnetic force, characterized in that the first and second magnetic elements have head portions(7), a leg portion(8), and engagement / disengagement portions(9,10) formed at the head portions and mechanically engaged with or disengaged from each other between the first and second magnetic elements(3A,3B), the first and second magnetic elements are respectively disposed at predetermined intervals, the magnetic elements(3A) of one fastener tape(2A)(3B) are adsorbed to spaces between the adjacent magnetic elements of the other fastener tape(2B), and the first and second magnetic elements(3A,3B) are engaged with each other alternately.

Owner:YKK CORP

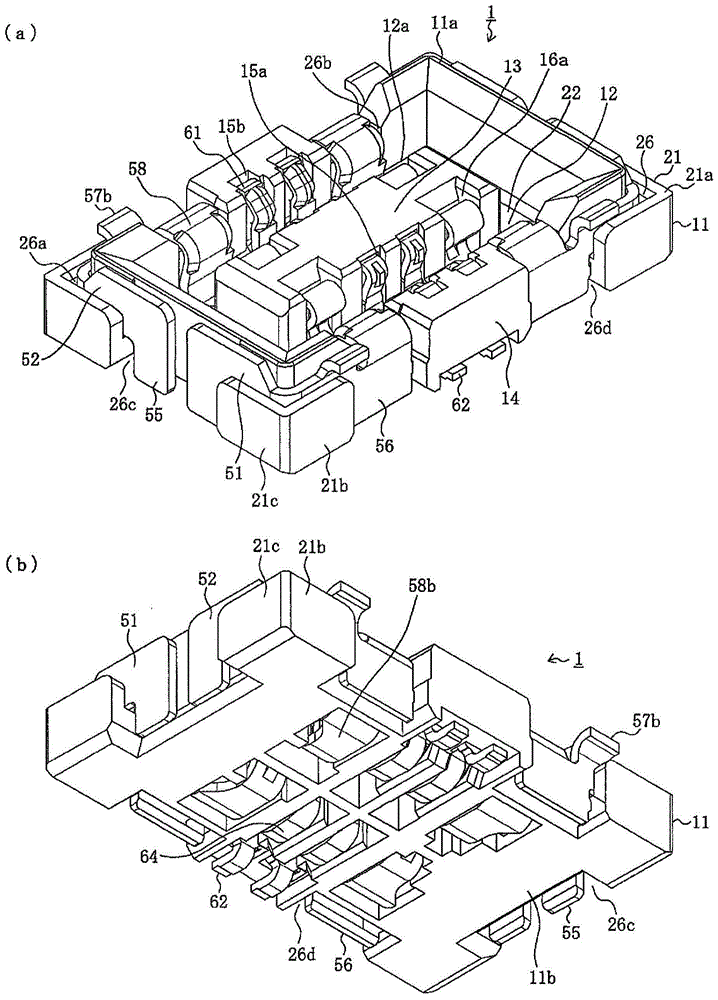

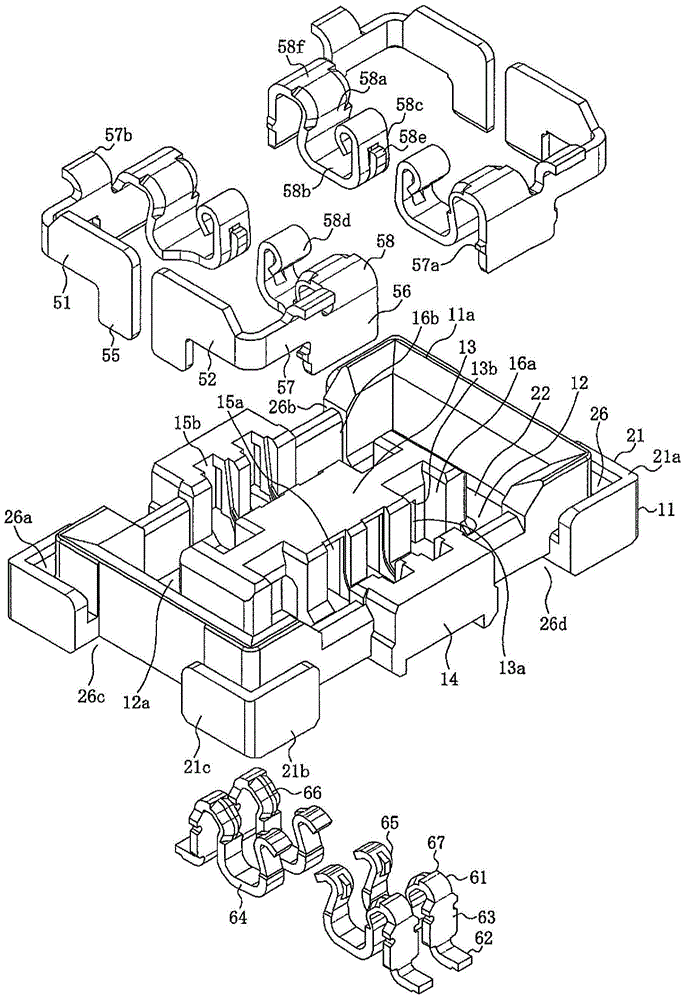

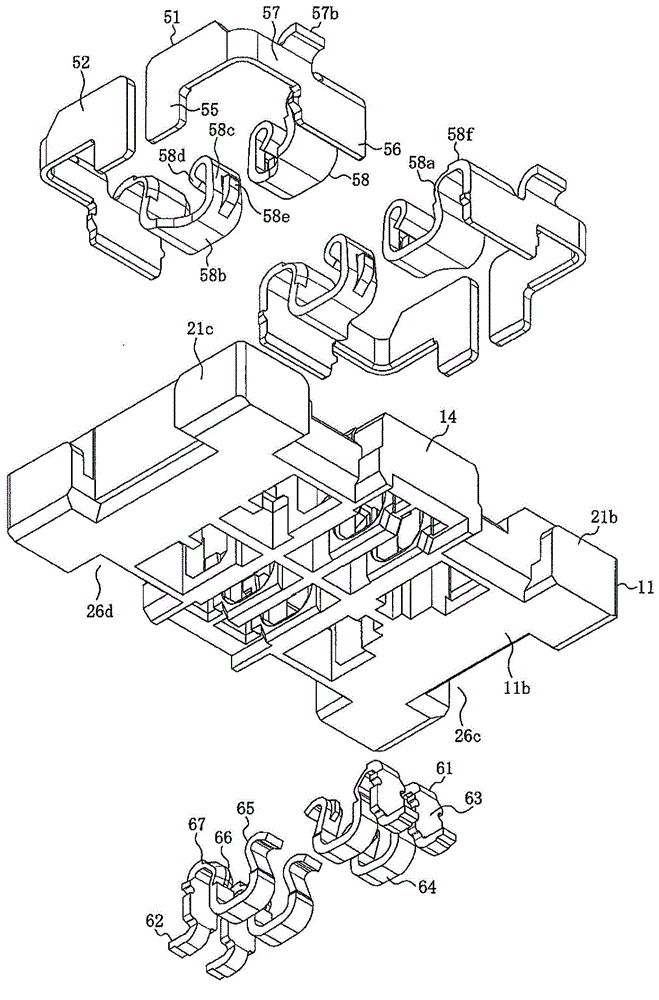

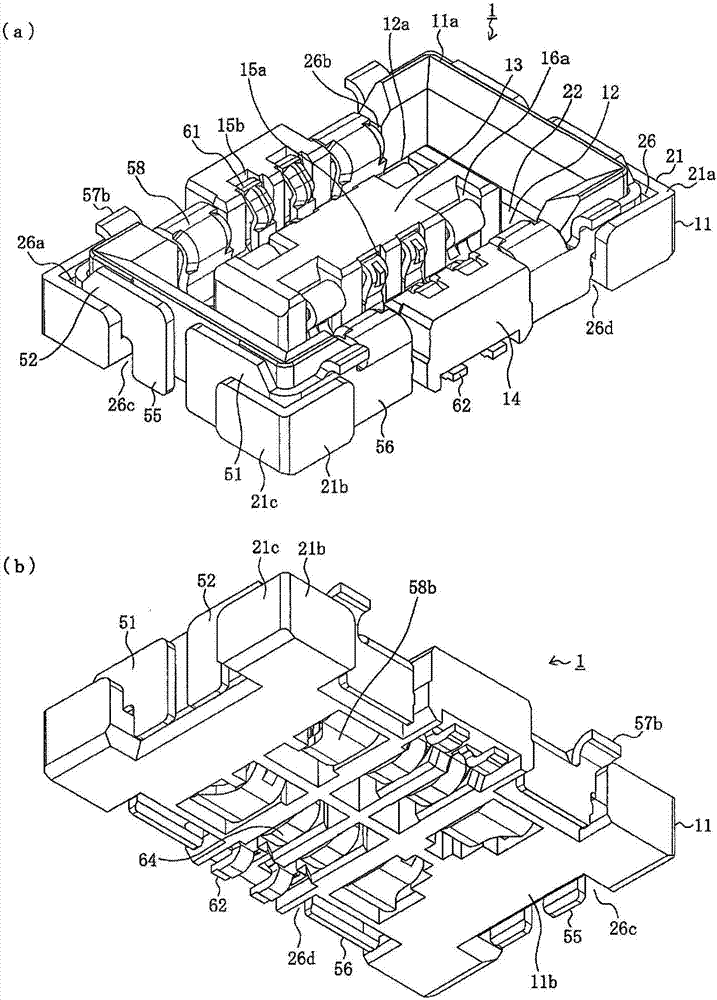

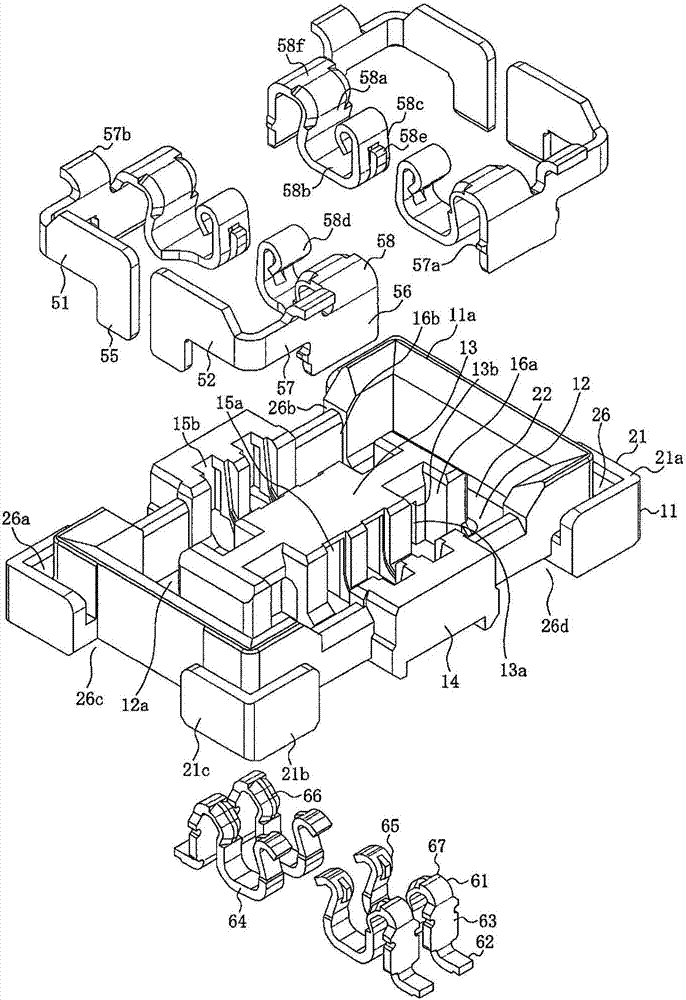

Connector

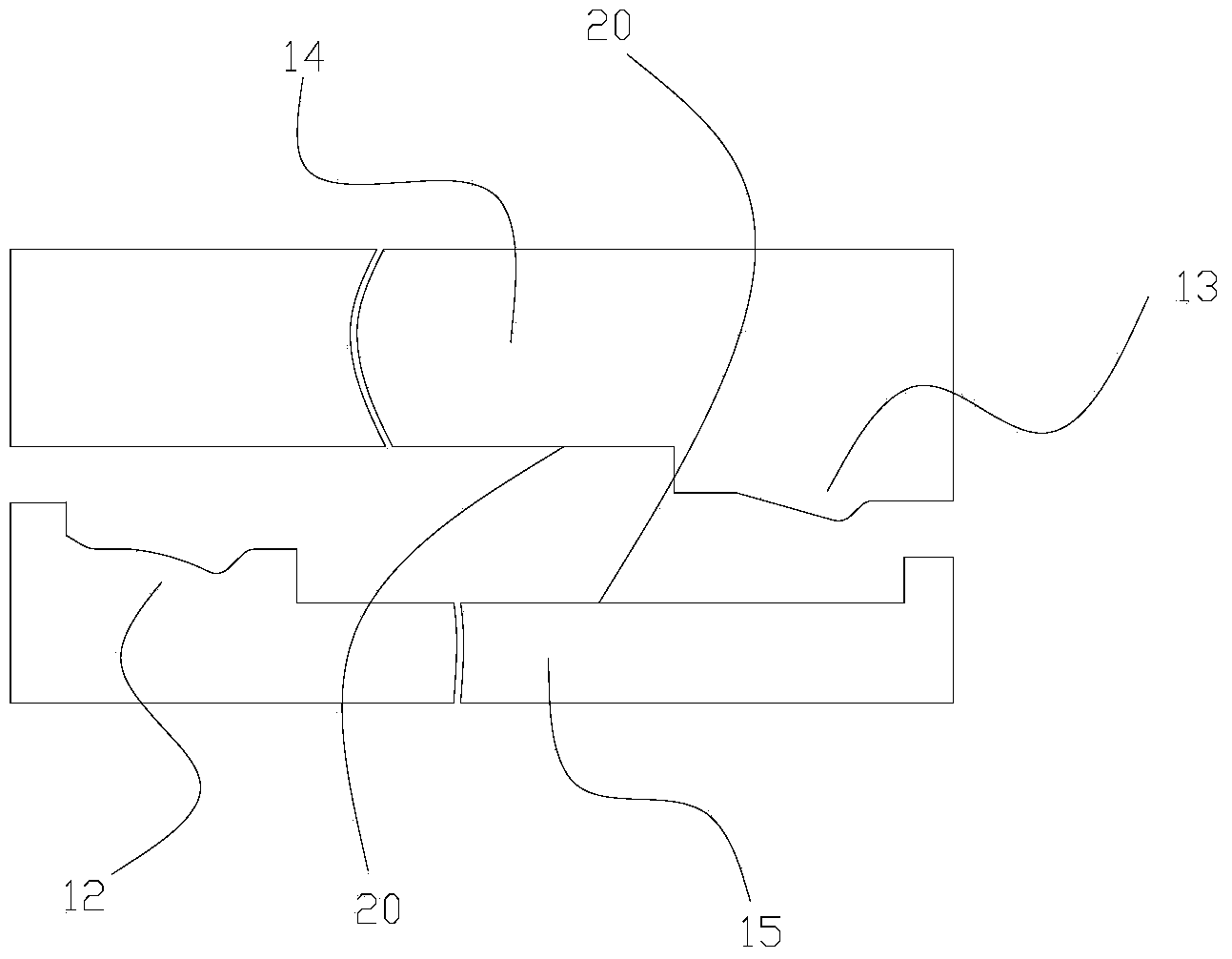

ActiveCN106067623AStay engagedEnsure electrical connectionCoupling contact membersFixed connectionsElectrical connectionEngineering

A connector is provided which includes a main body, terminals mounted in the body, and a reinforcing metal fitting mounted in the body. The fitting includes a body secured to the mating guide portion, a pair of left and right connecting arm portions connected to the base end of the body, and a pair of left and right contact arm portions connected to the base end of the connecting arm portions. The fitting further includes a first connecting leg portion connected to a connecting pad on a board being connected at the upper end of the first connecting leg portion to the lower end or base end of each contact arm portion so as to have a substantially L-shaped profile when viewed from a side of the connector.The resilient length can be extended to a portion in contact with the other reinforcing metal fitting so as to more reliably maintain the mutual engagement and the electrical connection between the reinforcing metal fitting and the other reinforcing metal fitting.

Owner:MOLEX INC

Headrest moving device

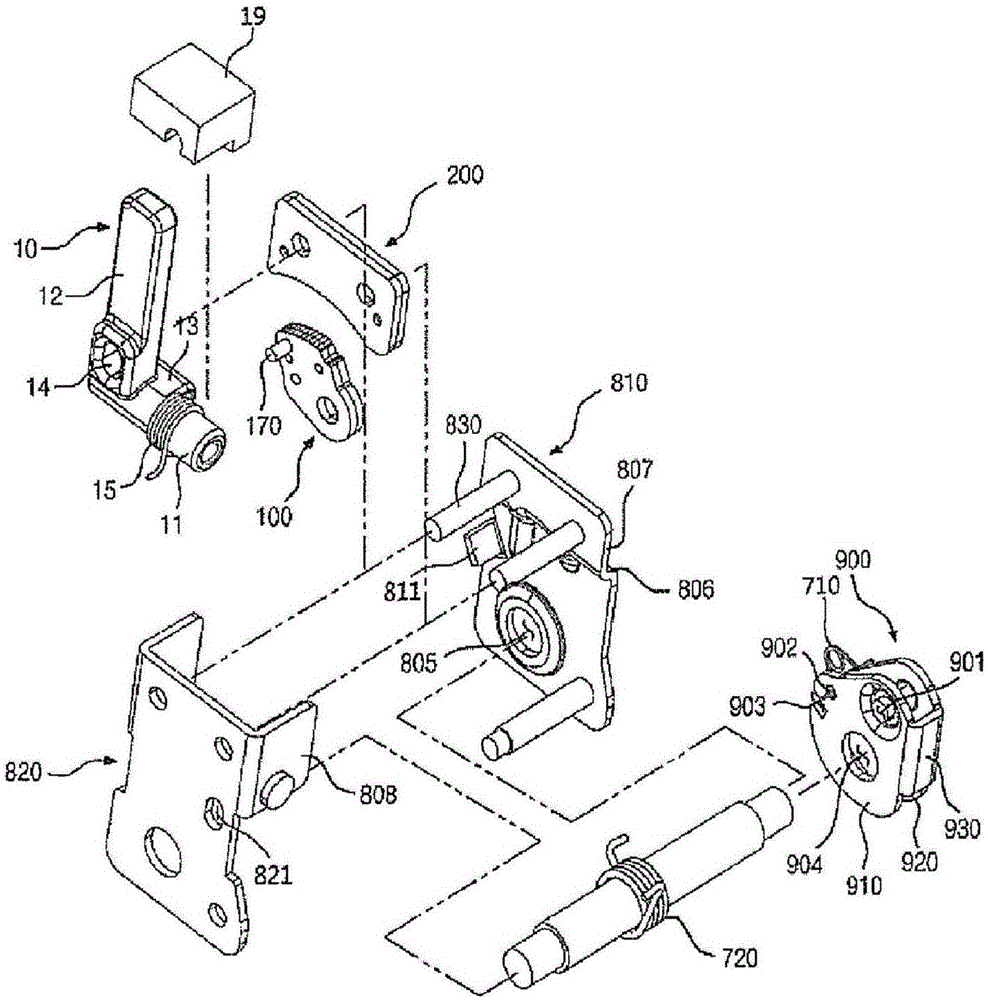

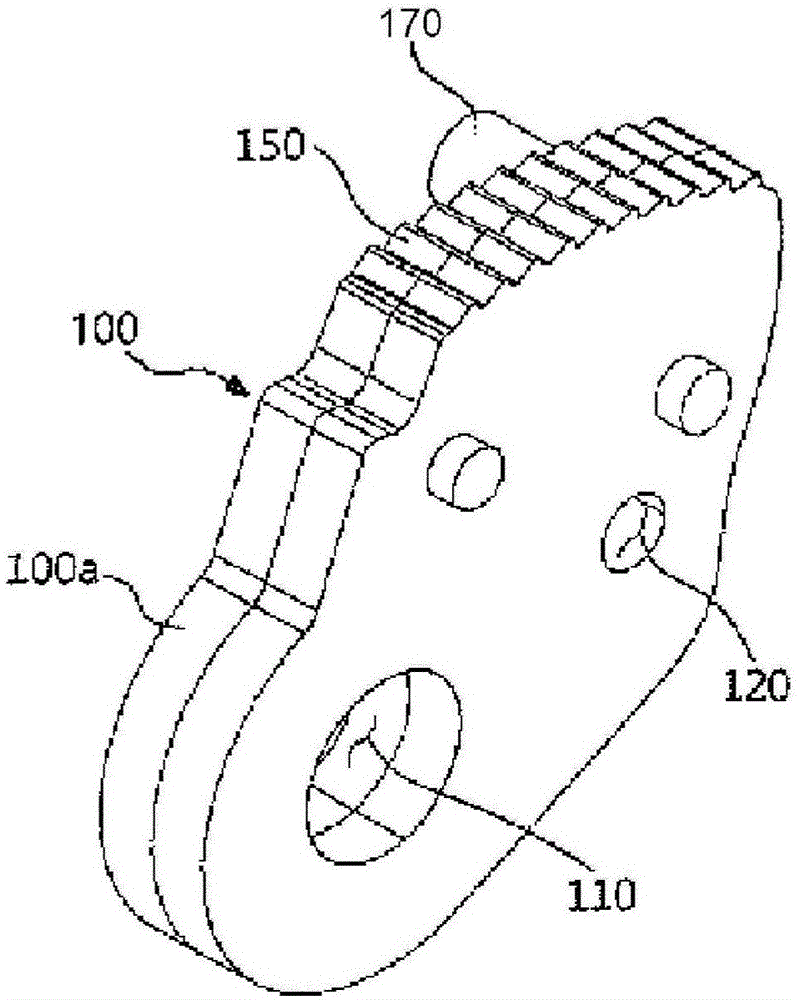

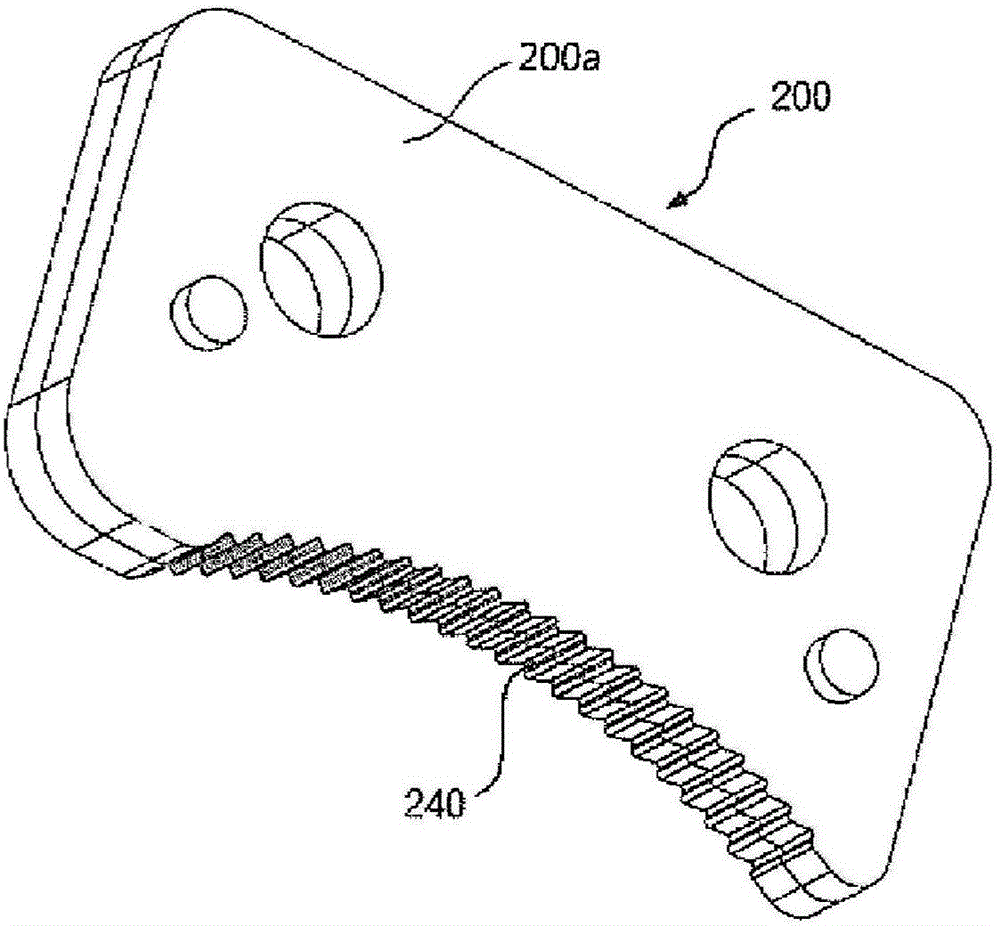

ActiveCN106029442AEfficient use ofReduce manufacturing costVehicle seatsStoolsMechanical engineering

The present invention relates to a headrest moving device, wherein a lever member, which is connected to the seat or the headrest in a pivoted state, presses the pole, thereby releasing the engagement between the pole and the ratchet. A consumer can release the locking at any position by operating a lever member externally protruded from the headrest after the consumer has moved the headrest. So, the way of releasing the locking can be easily recognized by the consumer, therefore the consumer can effectively and easily utilize the headrest moving device.

Owner:WOOBO TECH CO LTD

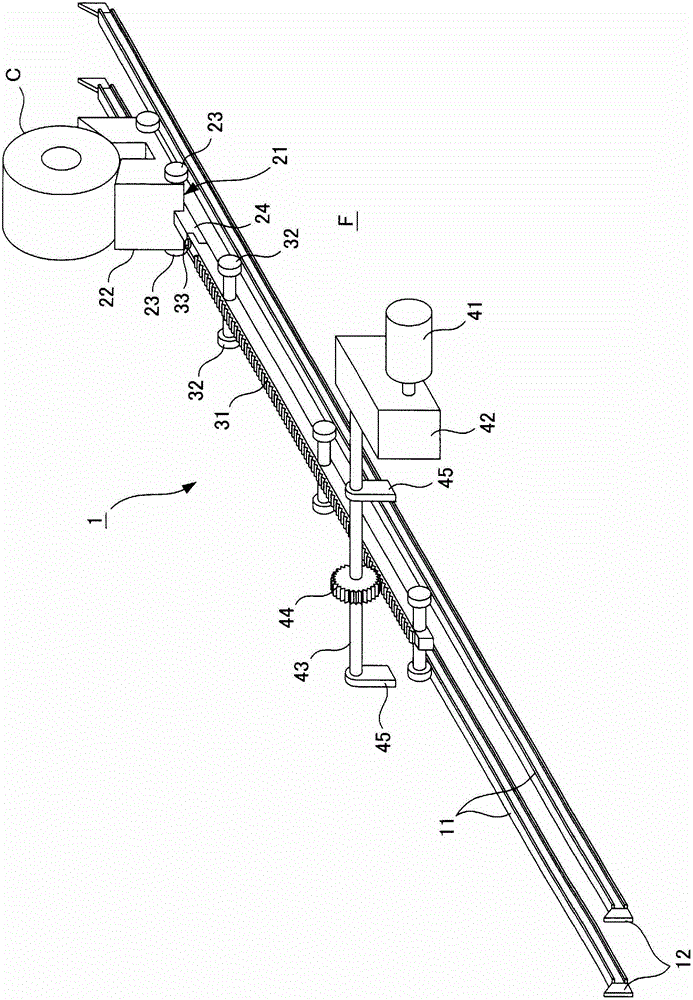

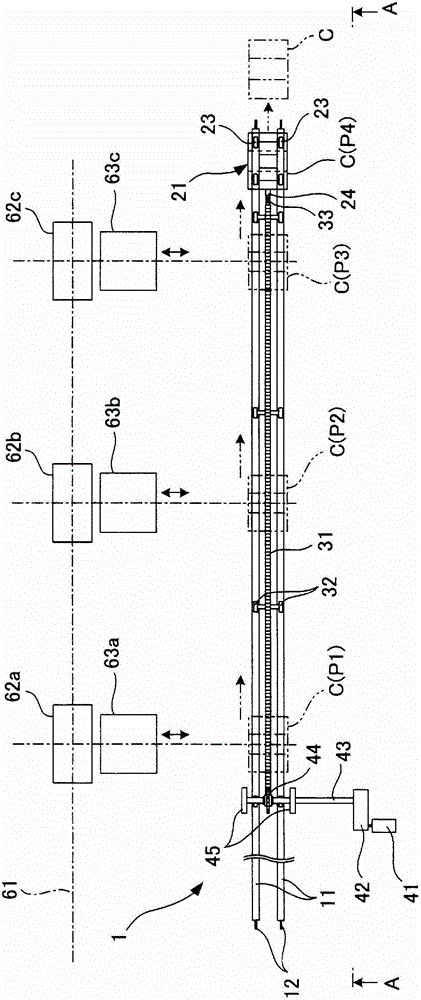

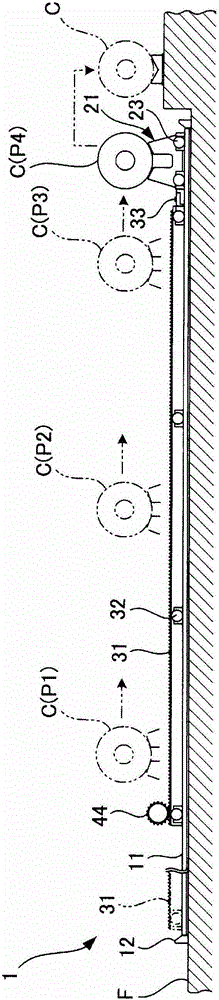

Binding machine

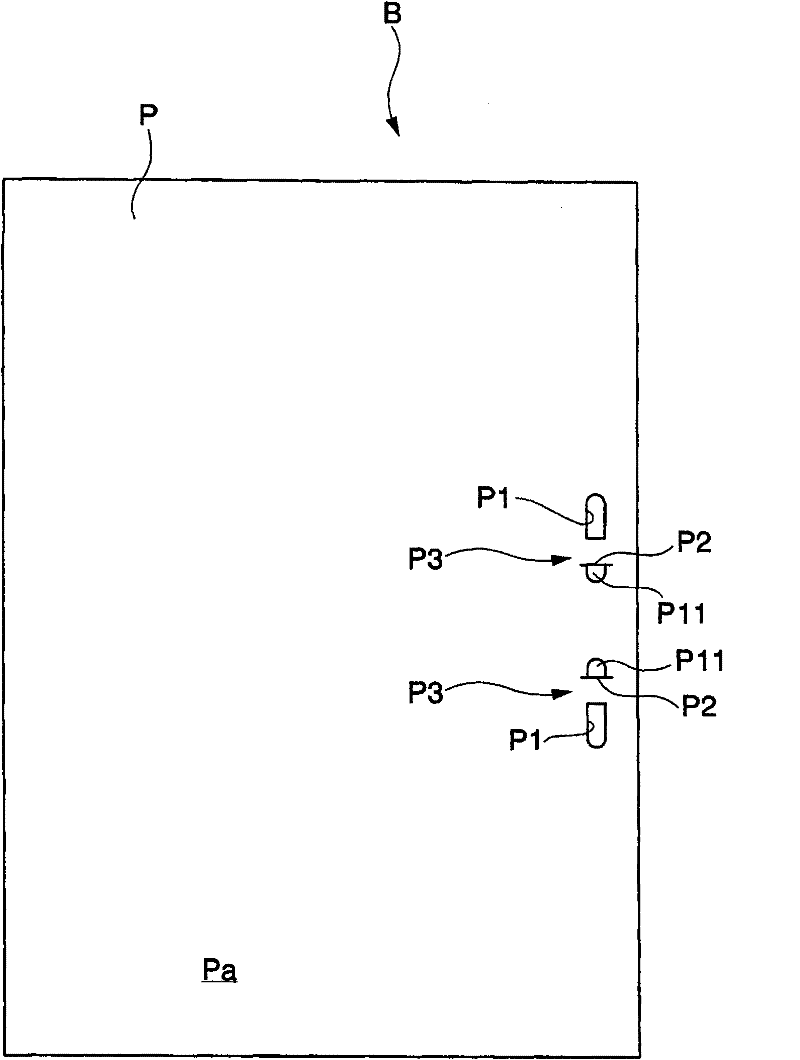

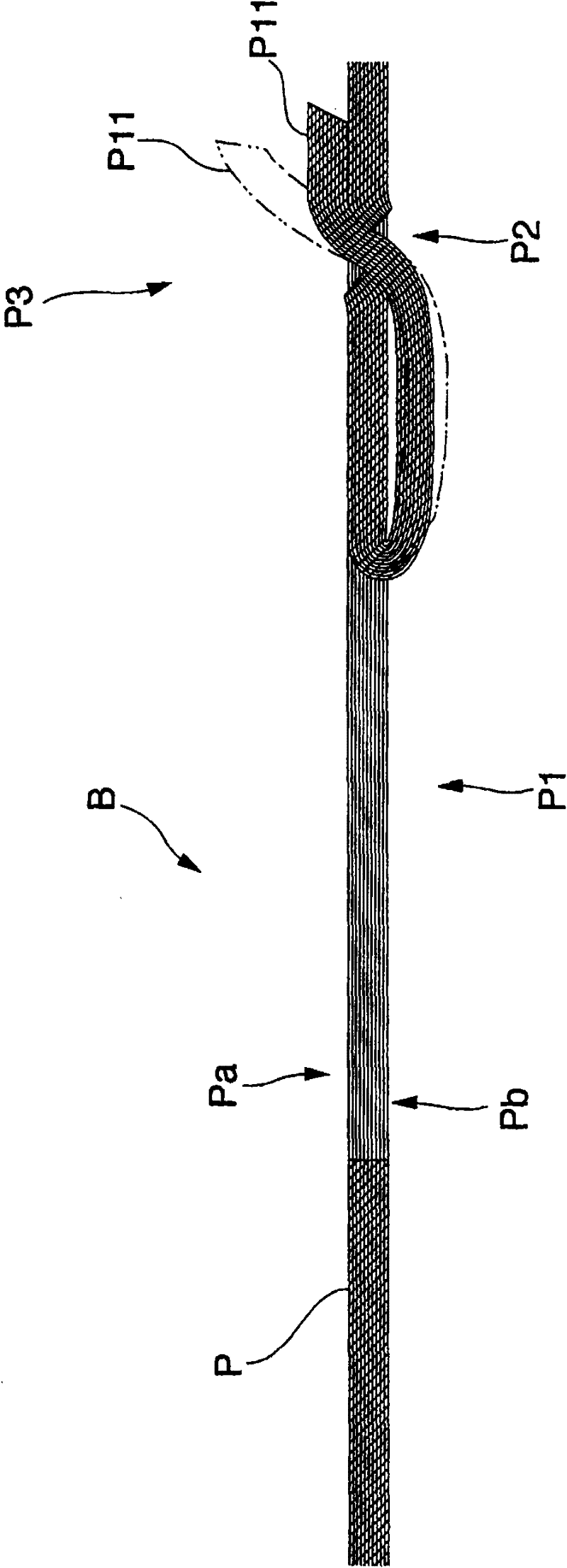

ActiveCN101797852ADefects that reduce engagementStay engagedSheet bindingArticle deliveryPaper sheetEngineering

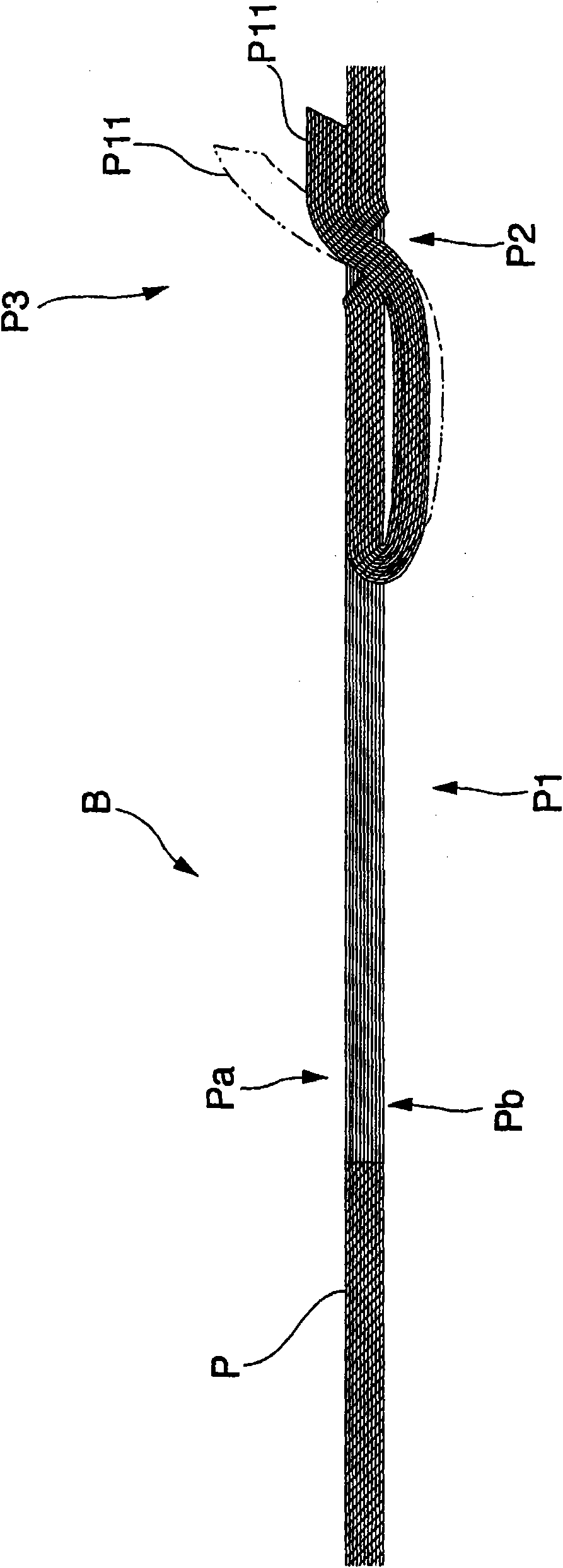

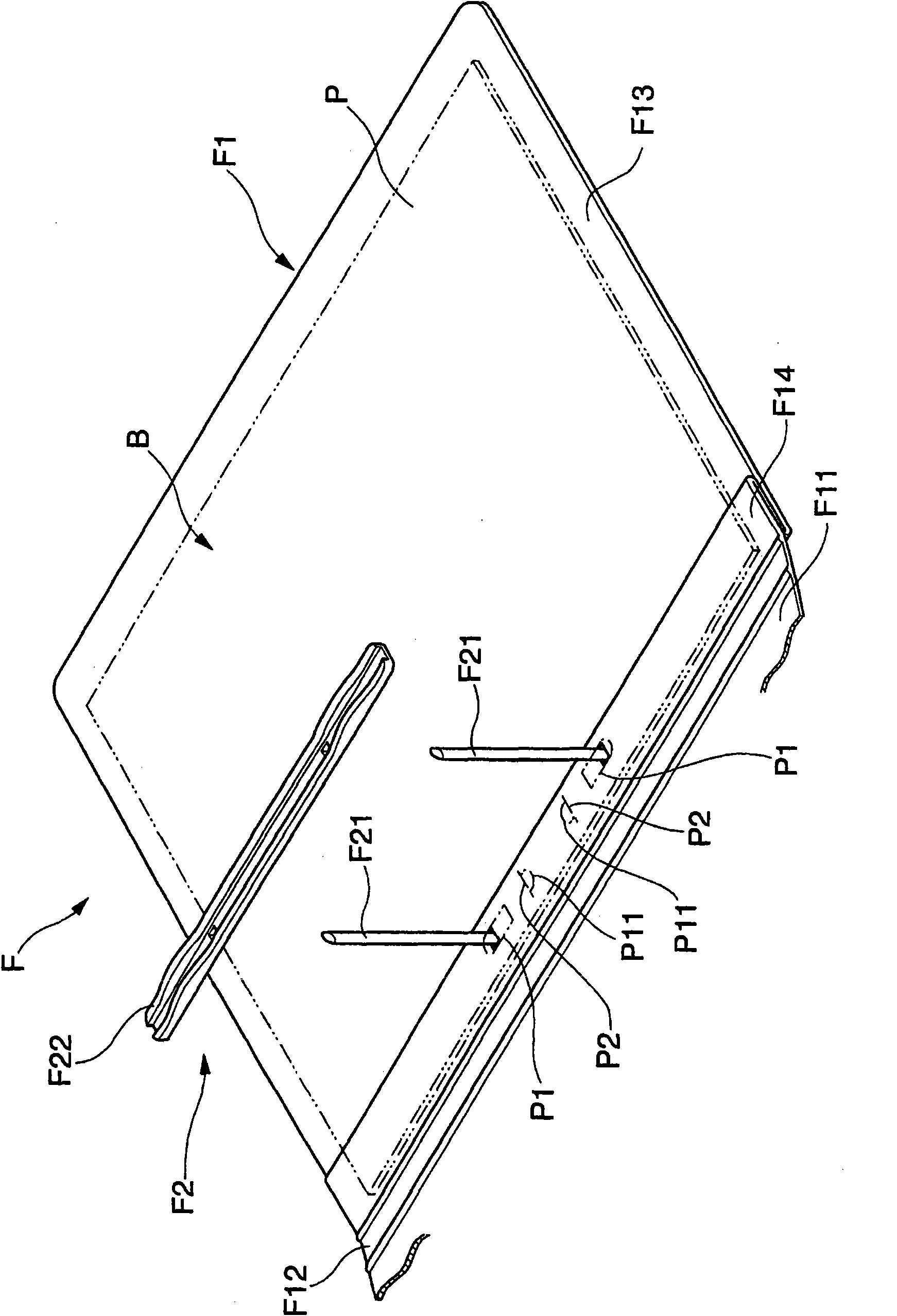

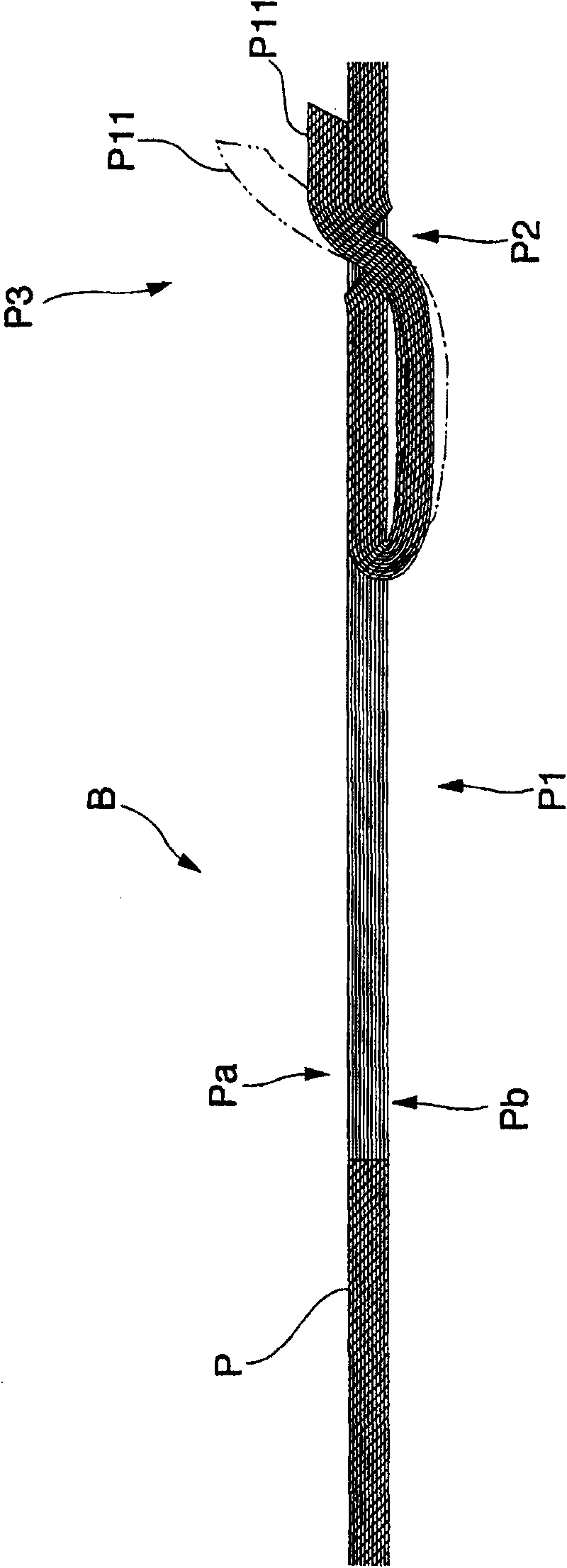

The invention provides a binding machine, which can prevent a joint part hooking a binding machine main body when the thickness size of the joint part is bigger when binding a plurality of sheets. The binding machine (1) of the invention utilizes a carrier (2), a pitching-in blade (91) and a punching blade (92) to cut superposed paper sheets (P) into cut sheets (P11). The superposed paper sheets (P) are jointed and bound. The binding machine is characterized in that the machine is provided with a sticking mechanism for sticking the back (Pd) of the paper sheets (P) with the carrier (2) when jointing the superposed paper sheets (P) and a sticking releasing mechanism for releasing the sticking state of the jointed part (P3) and the carrier (2) after being jointed.

Owner:KOKUYO CO LTD

Binding machine

ActiveCN101746177AAvoid the problem of excessive thickness thickeningStays firmly engagedSheet bindingArticle deliveryPunchingPulp and paper industry

The invention provides a binding machine, which can effectively maintain the joint state of a jointed joint part when a plurality of sheet pieces are bound. The binding machine (1), by using cutting pieces (P11) obtained by cutting the overlapped paper (P) by means of a objective table (2), a cutting blade (910 and a punching blade (92), mutually joint the paper (P) for binding. The binding machine is characterized in that the binding machine has a compressing mechanism, which can make the jointed joint portion (P3) of the paper (P) compressed and deformed in the thickness direction. In this way, because the jointed joint portion is compressed, the joint portion (P3) can be effectively prevented from hanging other articles or fingers due to the swelling of the cutting pieces (P11), the joint state of the joint portion (P3) can be steadily maintained, and the thickness of the joint portion (P3) can be reduced.

Owner:KOKUYO CO LTD

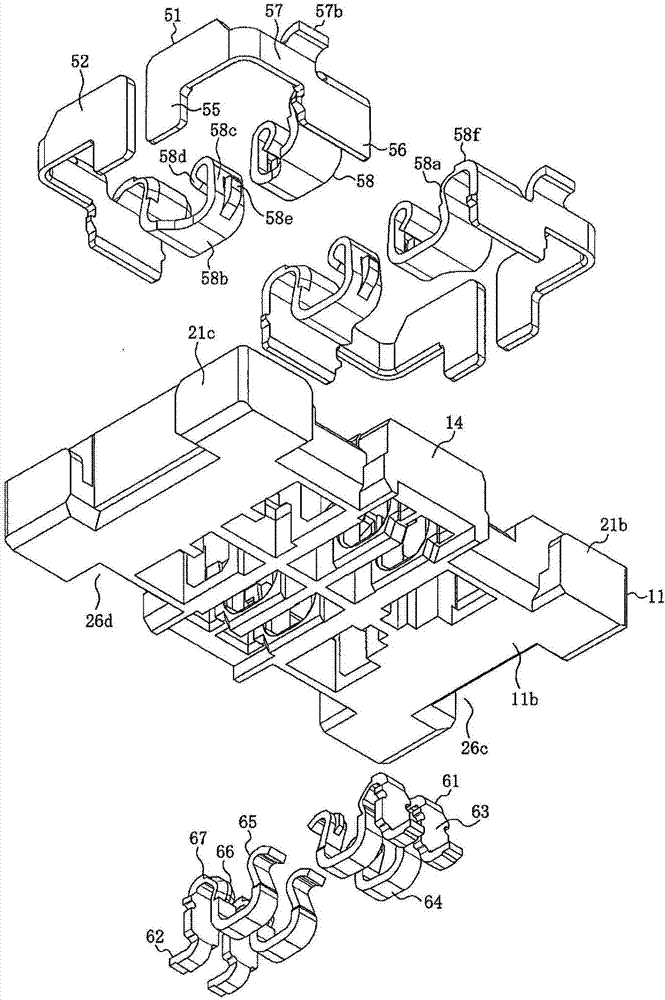

Intensified component, connector with the component, connection mechanism of electric component and substrate

InactiveCN1538573AReduce crackingStay engagedCouplings bases/casesInternal fittingsSurface mountingEngineering

PURPOSE: A reinforcing tap, a connector including the reinforcing tap, and a connecting structure of an electrical component and a board are provided to maintain the connection of the connector and the board even when a large external stress is applied to the connection structure or the connection structure is placed in a high-temperature environment. CONSTITUTION: A reinforcing tap(4) is attached to a housing(3) of a surface mounting connector(1). The housing has a shorter side and a longer side. The reinforcing tap has a portion attached to the longer side of the housing and a portion bonded to a circuit board. The bonded portion has a bonding plane perpendicular to the shorter and longer sides. The bonding plane has the first face parallel with the shorter side of the housing and the second face parallel with the longer side of the housing. The second face is connected to the first face through a curved face to face the housing.

Owner:JST MFG CO LTD

Jig structure for semiconductor package and semiconductor package comprising same

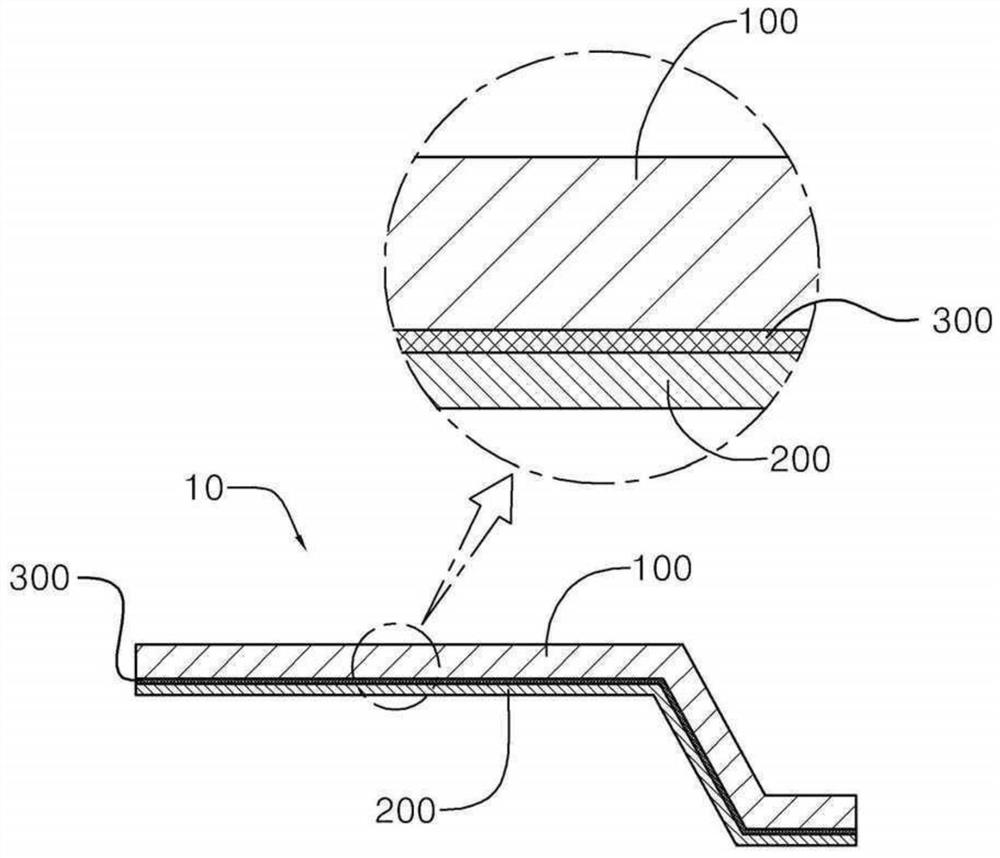

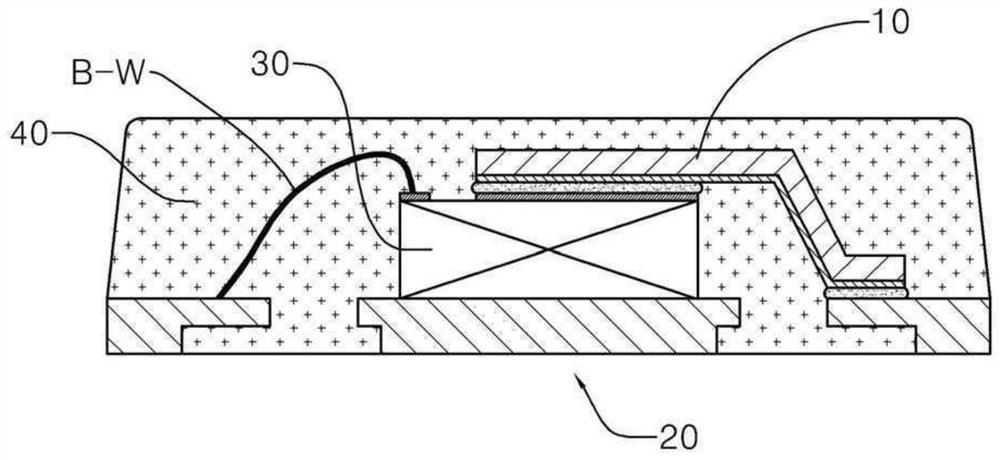

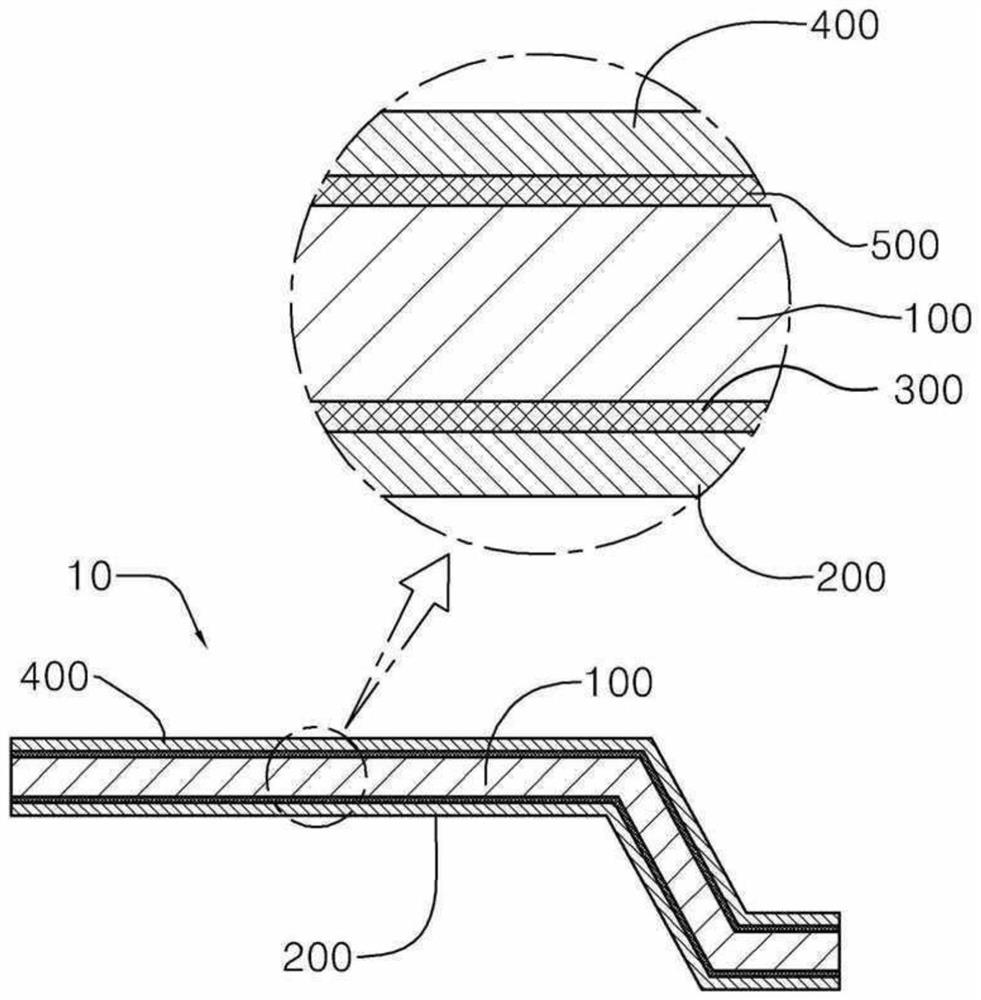

PendingCN111834322ALow priceReduce weightSemiconductor/solid-state device detailsSolid-state devicesSemiconductor packageElectrical connection

The present invention relates to a jig structure for a semiconductor package, and more specifically, to a jig structure suitable for a semiconductor package made of metal layers of different materials, instead of a single metal, thereby reducing the price of a semiconductor package manufactured by applying lightweight metal material at a low cost that would not be applicable in the past, and achieving a lightweight. That is, the jig structure for electrically connecting the structure of the package in the semiconductor package of the present invention is characterized in that the jig structureincludes: a main metal layer that maintains the shape of the jig structure; and a first functional layer that is laminated on one side of the main metal layer and suitable for a different type of metal from the main metal layer; and a first bonding layer that is formed between the first functional layer and the main metal layer, and is suitable for metal capable of bonding the first functional layer to the main metal layer.

Owner:JMJ KOREA CO LTD

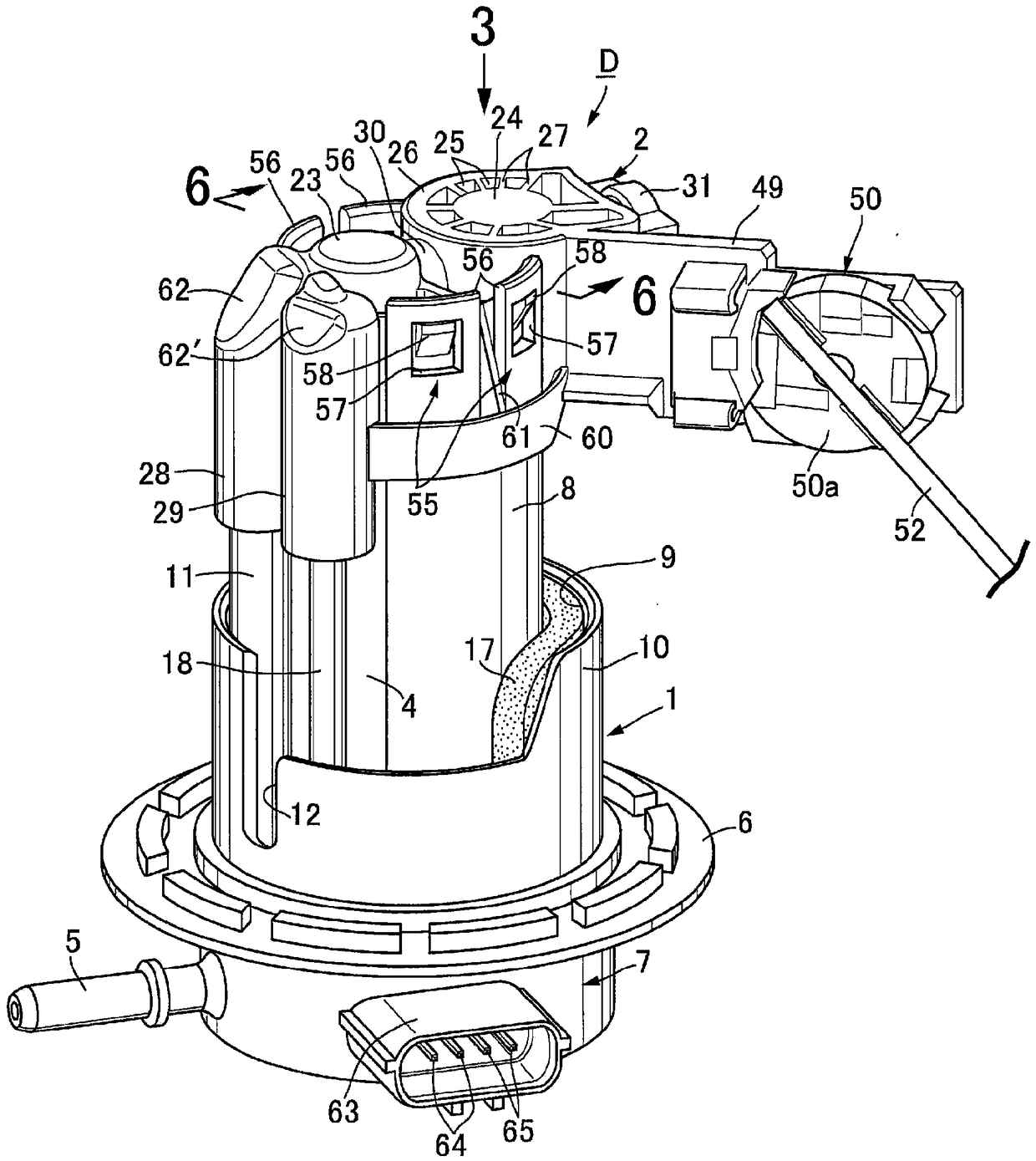

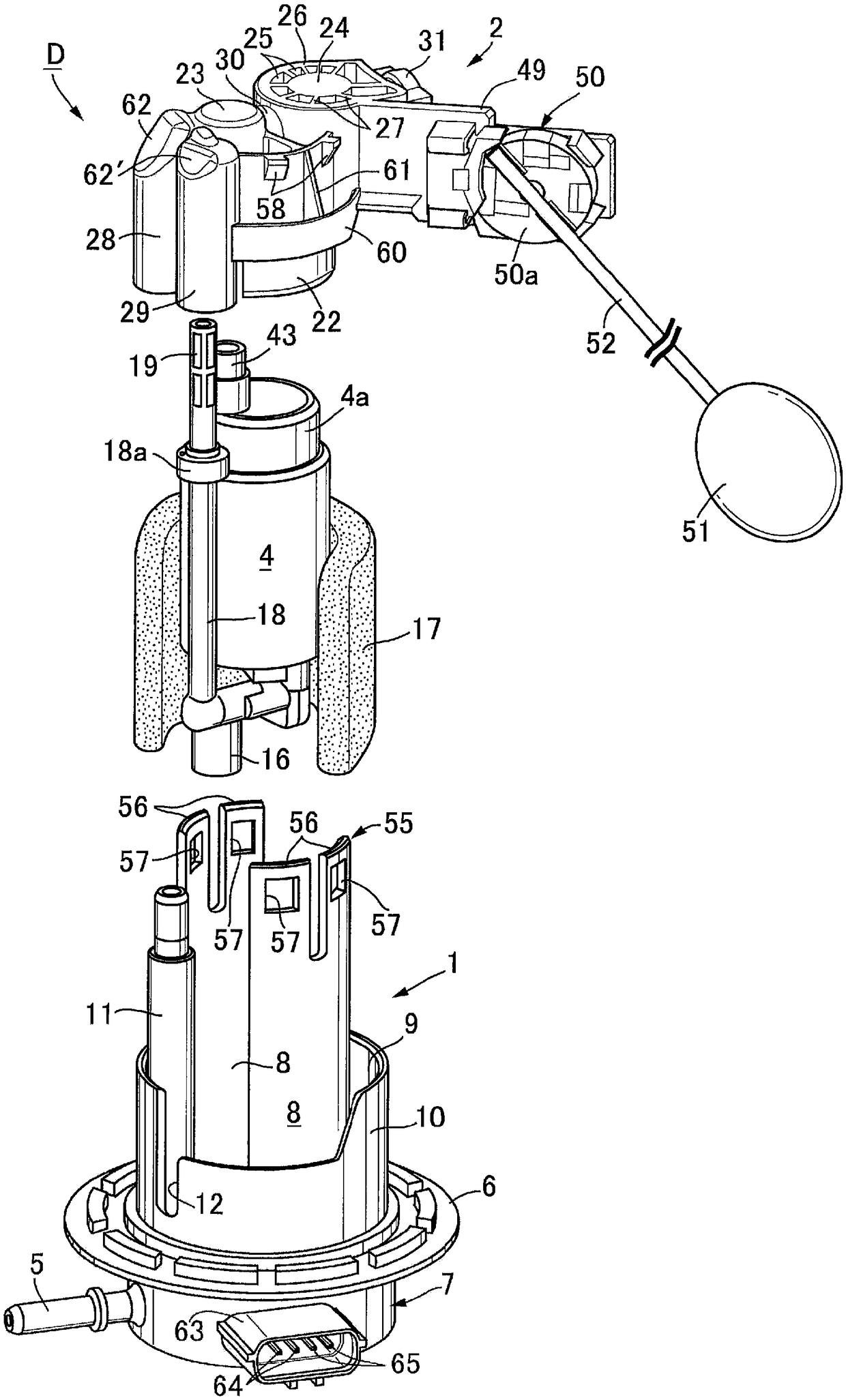

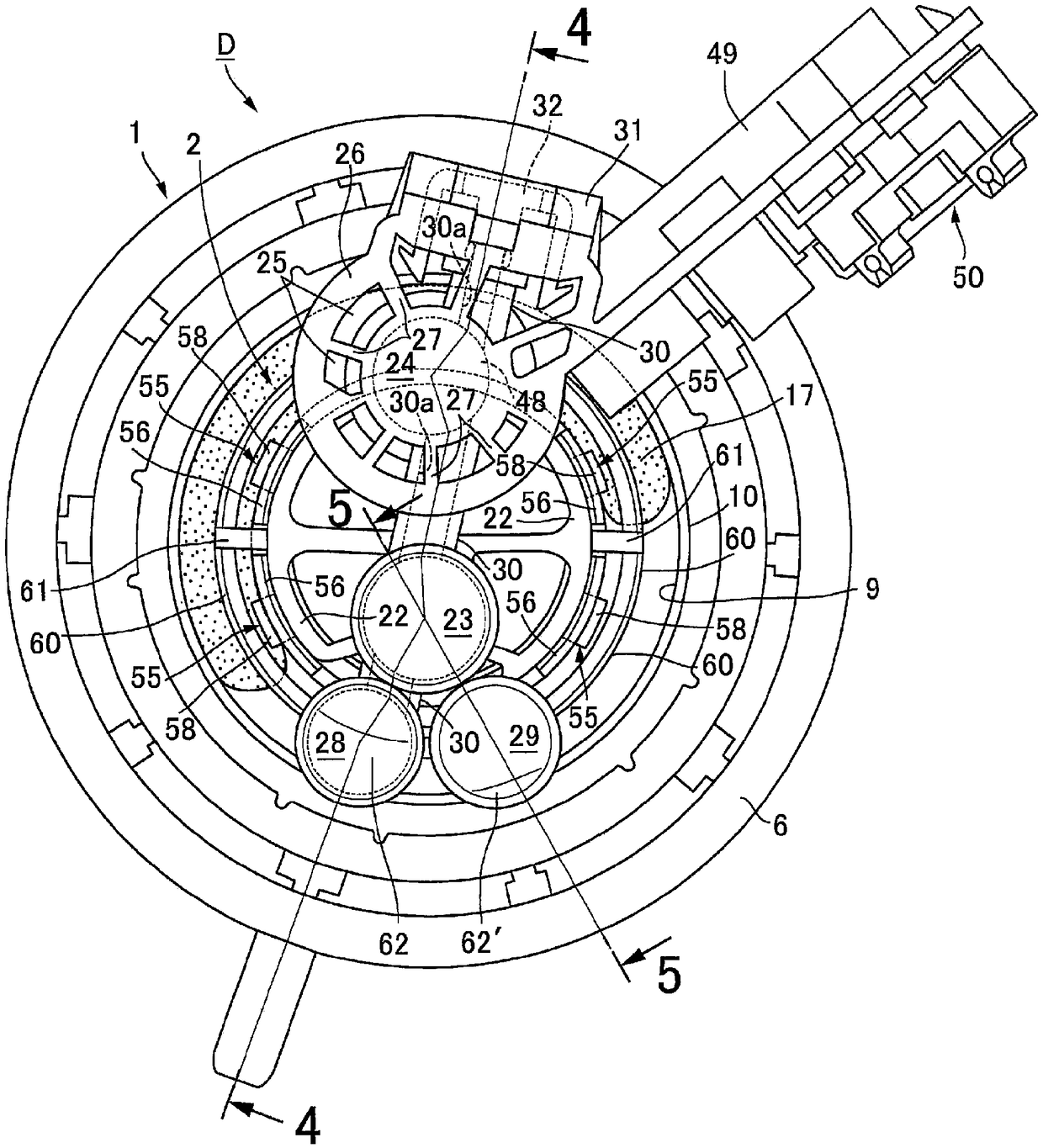

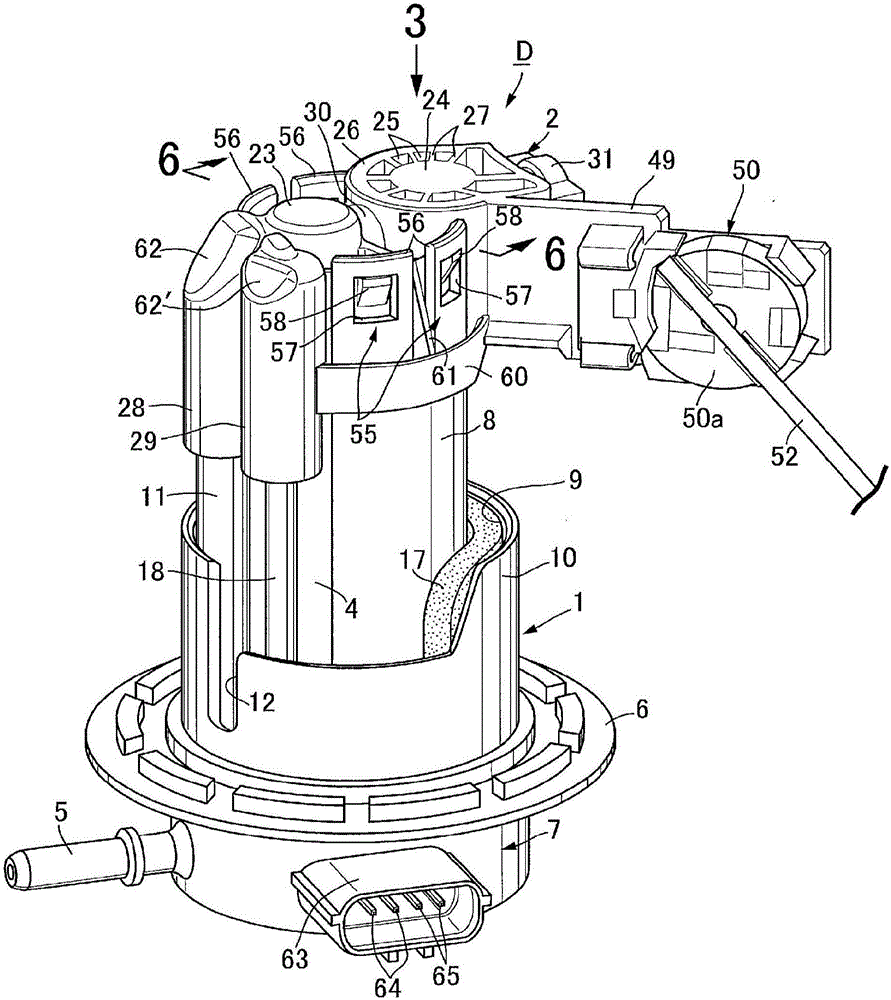

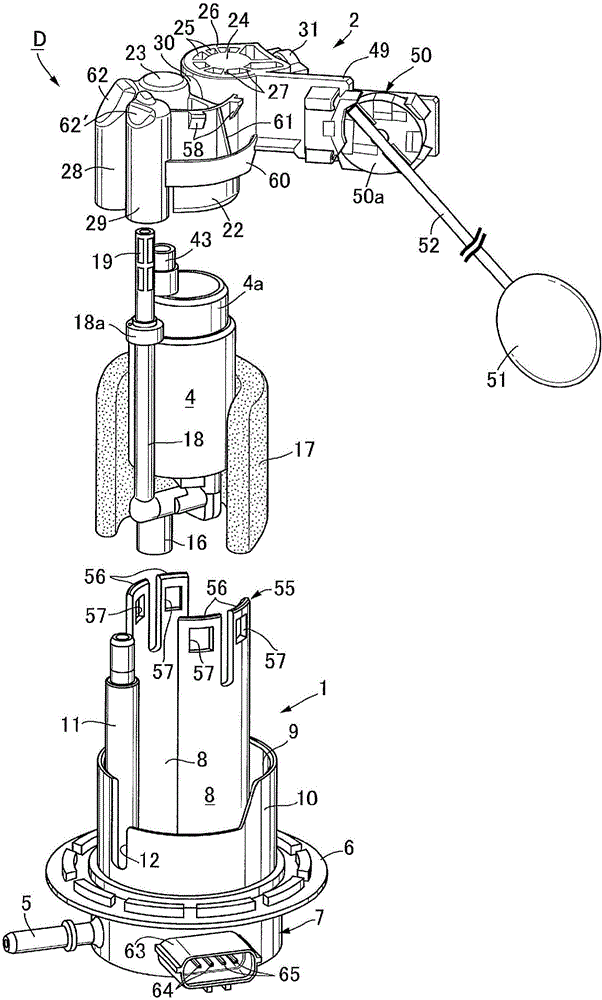

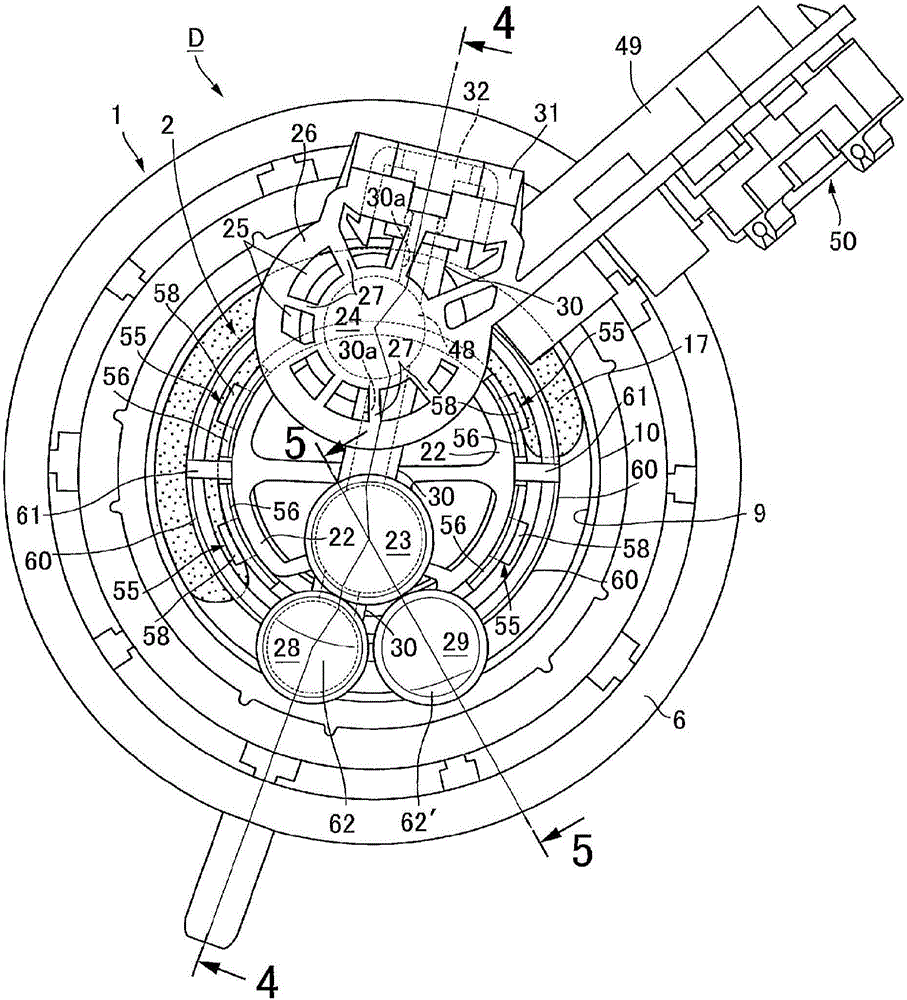

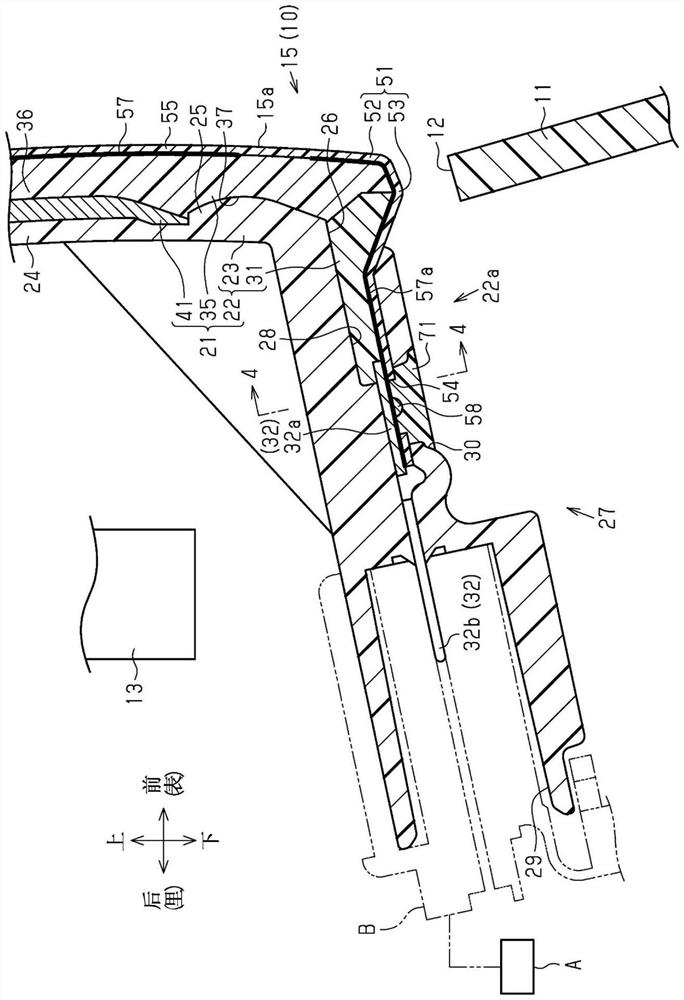

fuel supply device

ActiveCN106103965BEasy to separateImprove maintainabilityMachines/enginesLiquid fuel feedersEngineeringFuel supply

A fuel supply device, comprising: a fuel pump (4) is held by a pump holding wall (8) of a first casing (1) and a fitting wall (22) of a second casing (2); The buckle fixing mechanism (55) connects these pump holding walls (8) and the fitting walls (22), and uses the elastic piece (56), the locking hole (57) and the locking claw (58) to form a buckle Fixing mechanism (55), the elastic piece (56) makes the fitting wall (22) fit with the inner circumference of the pump holding wall (8), extends from the end of the pump holding wall (8) and fits with the fitting wall (22) contact with the outer surface of the fitting wall (22), the locking hole (57) is provided at the end of the elastic piece (56), the locking claw (58) protrudes from the outer surface of the fitting wall (22), and the elastic piece ( 56) is engaged with the locking hole (57), and a restricting wall (60) that restricts the deflection of the elastic piece (56) outward in the radial direction is provided in the second housing (2). Accordingly, it is possible to provide a fuel supply device that can easily release the engaged state of the snap fixing mechanism without being obstructed by the attachment flange.

Owner:HITACHI ASTEMO LTD

Connector assembly

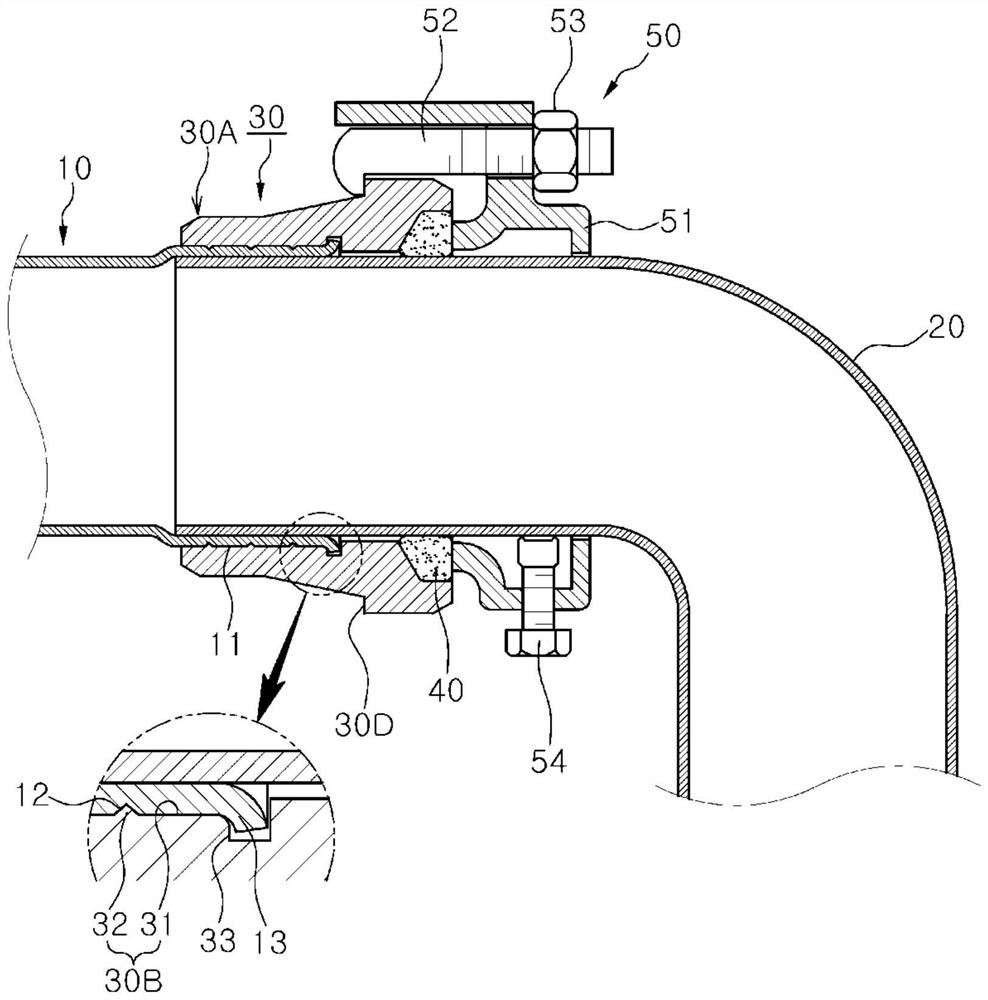

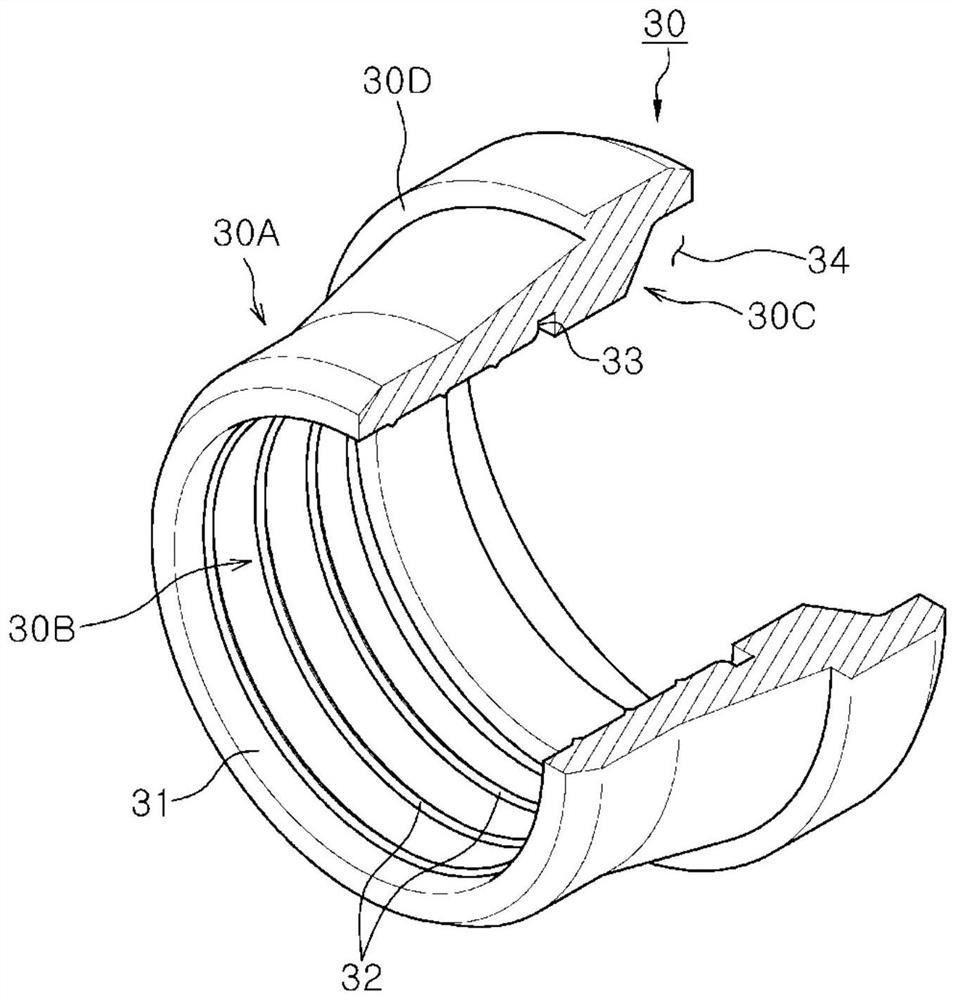

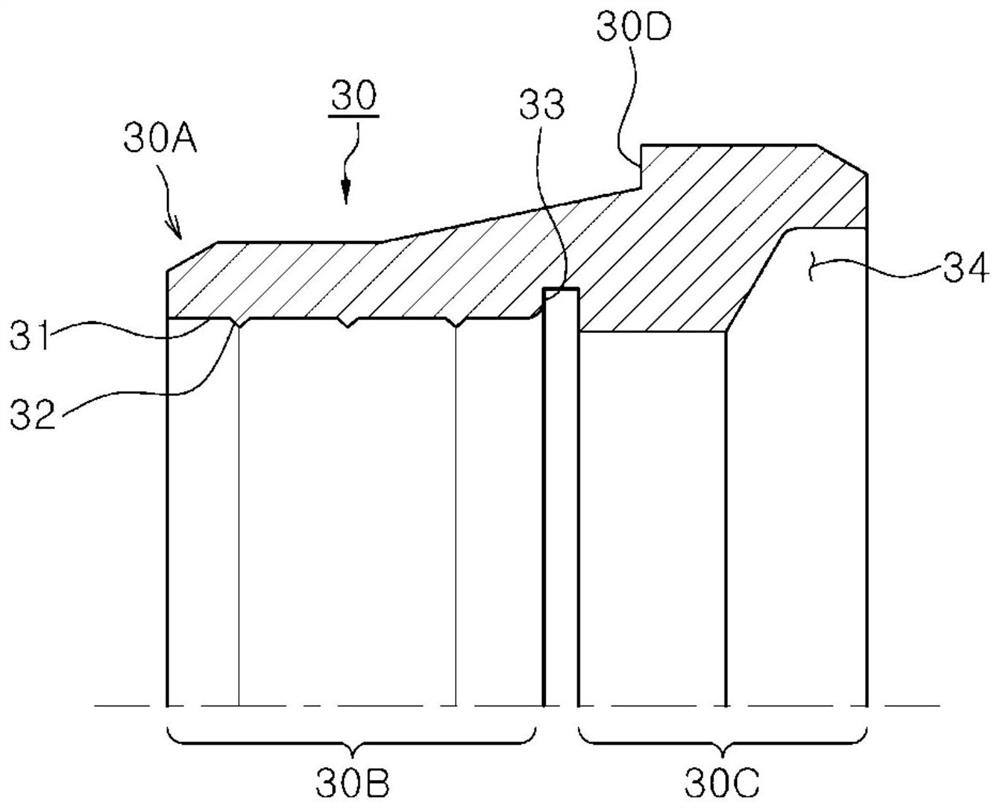

ActiveCN104781994ASmooth interlockingReliable interlockingVehicle connectorsCouplings bases/casesBand shapeElectric wire

A connector assembly is provided with: a housing (1) which holds an electrical wire-side terminal (2) and which is fitted in a mounting hole formed in the case of a counter-connection device; and a seal member (3) which is mounted in a groove (16) formed in the outer peripheral section (11) of the housing and which maintains the inside of the case in a liquid-tight condition. The seal member (3) has on the bent portions thereof protrusion-shaped sections (33) which are formed so as to protrude in the widthwise direction from an annularly continuing band-shaped peripheral edge. The groove (16) has recess-shaped sections (18) which are formed by recessing a groove wall (16b) such that the recess-shaped sections (18) correspond to the protrusion-shaped section (33). The protrusion-shaped sections (33) and the recess-shaped sections (18) engage with each other.

Owner:YAZAKI CORP

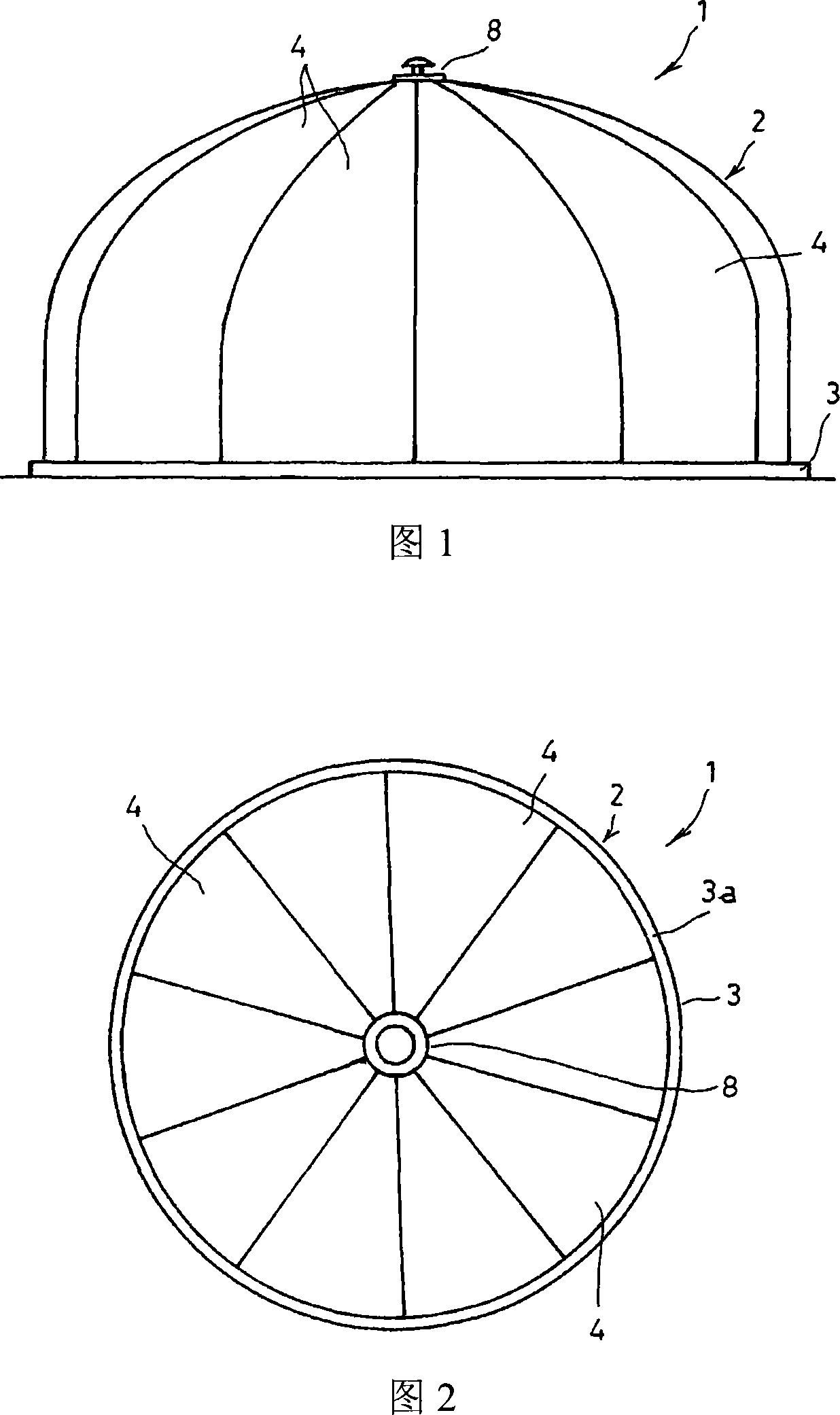

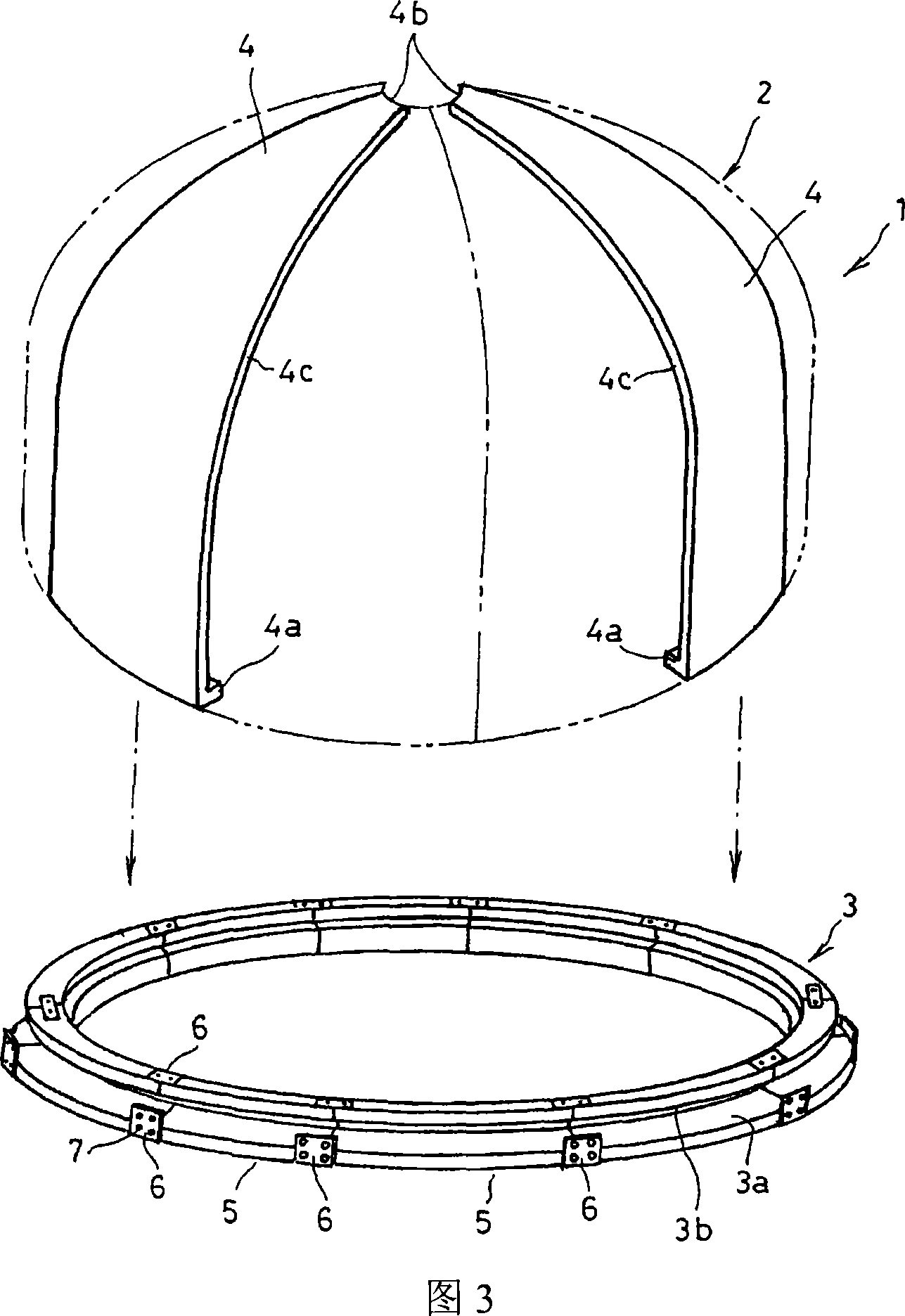

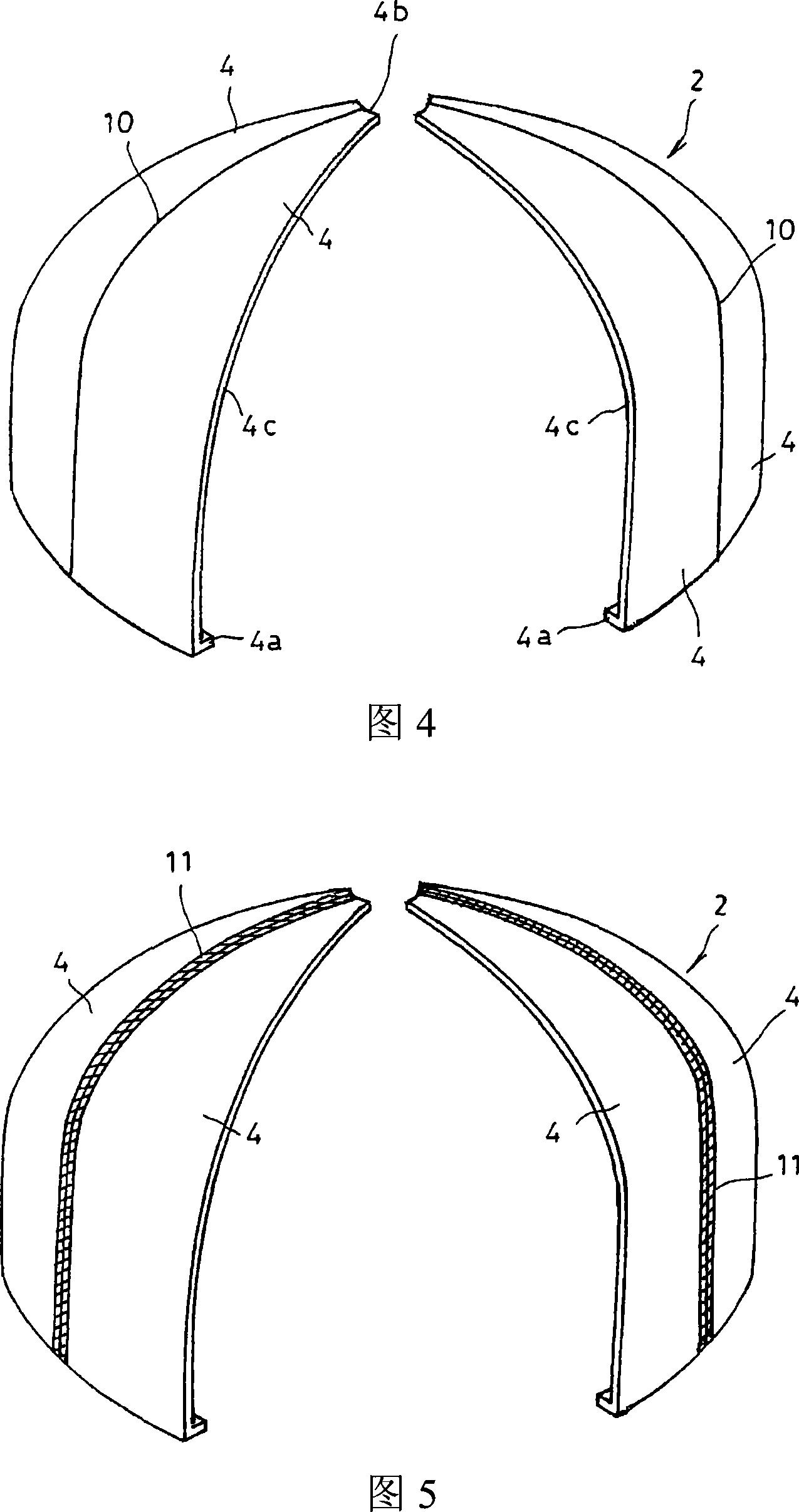

Combined house and construction method thereof

ActiveCN101137801AStay engagedAvoid crackingCovering/liningsSpace heating and ventilation safety systemsFiberUltraviolet

The invention provides a combined house and a construction method thereof which can prevent cracks in wall materials, strengthen the connection strength between plates, and improve livability. The construction method of the modular house involved in the present invention includes: using an adhesive mixed with mortar powder to join a plurality of plates made of foamed styrene formed by dividing the shape of the house to form a house body; The mesh-like patch made of inorganic fibers, so that the patch covers at least the joint part of the panels; the exterior and interior sides of the house body are coated with inorganic fibers and mortar powder dispersed in the resin coating with a certain thickness. The process of coating the external wall material with water repellency and UV protection on the outdoor wall material, and coating the clay-like paint from natural materials on the indoor wall material.

Owner:YUGENKAISHA JAPAN TSUSYO

Transfer bar

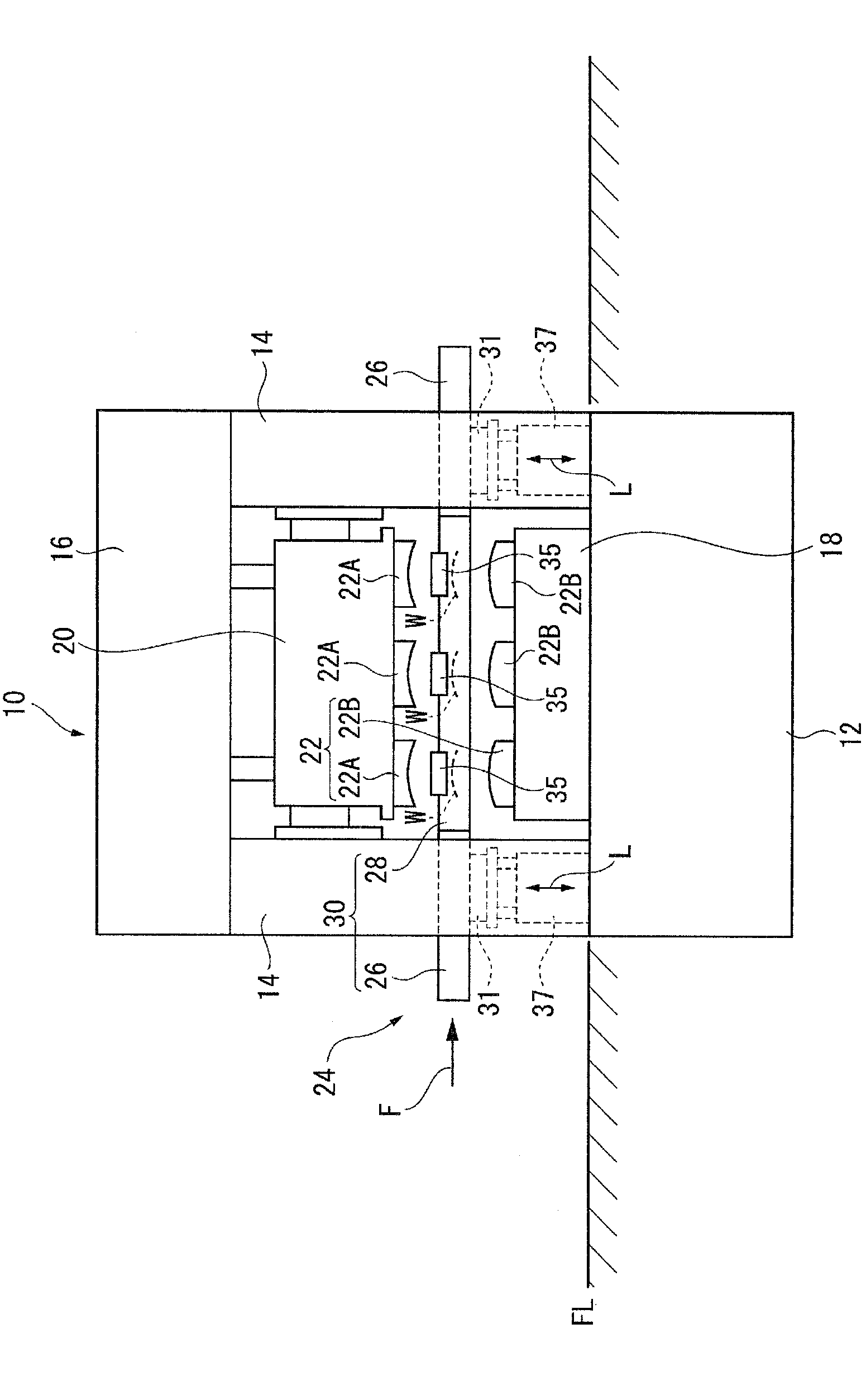

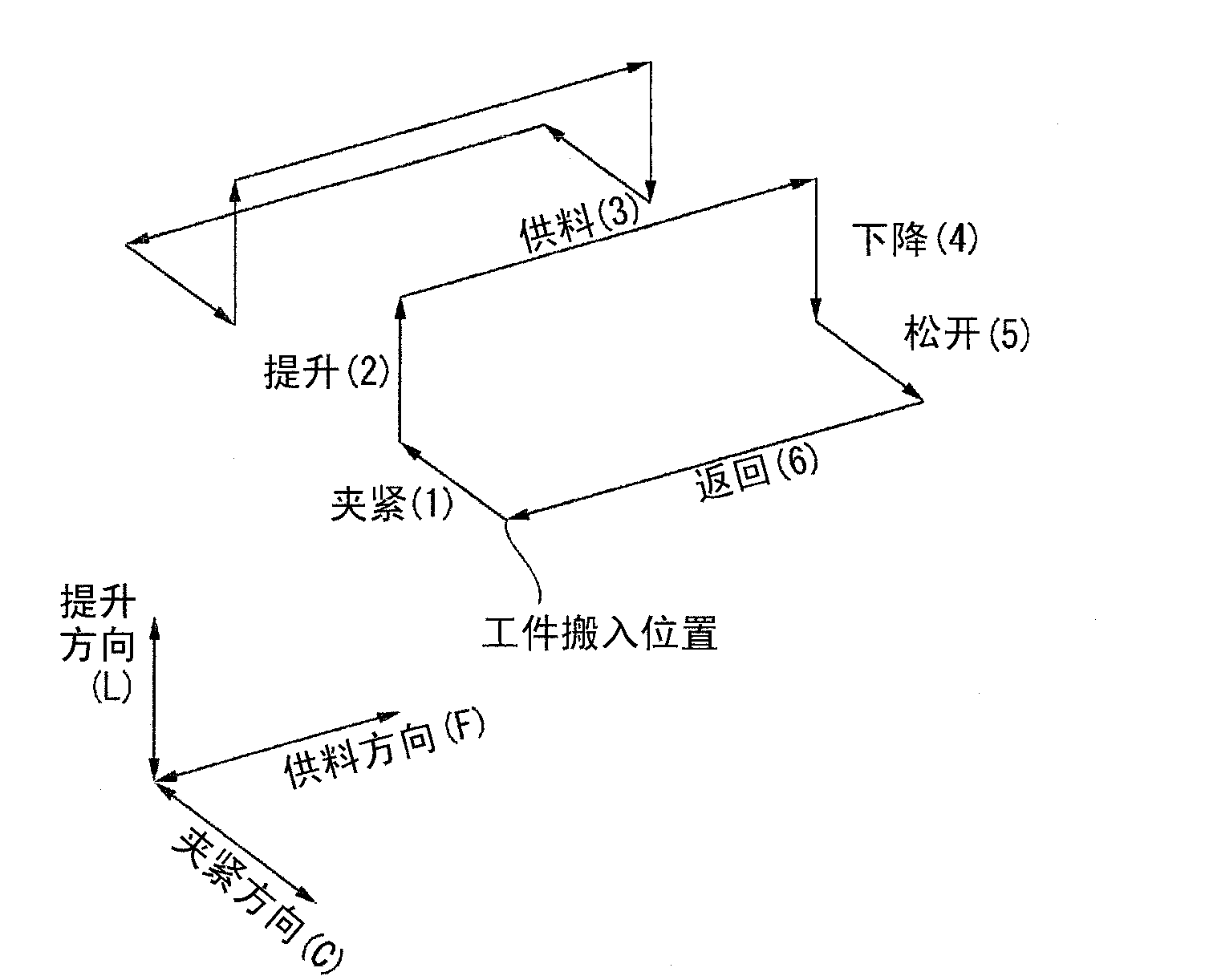

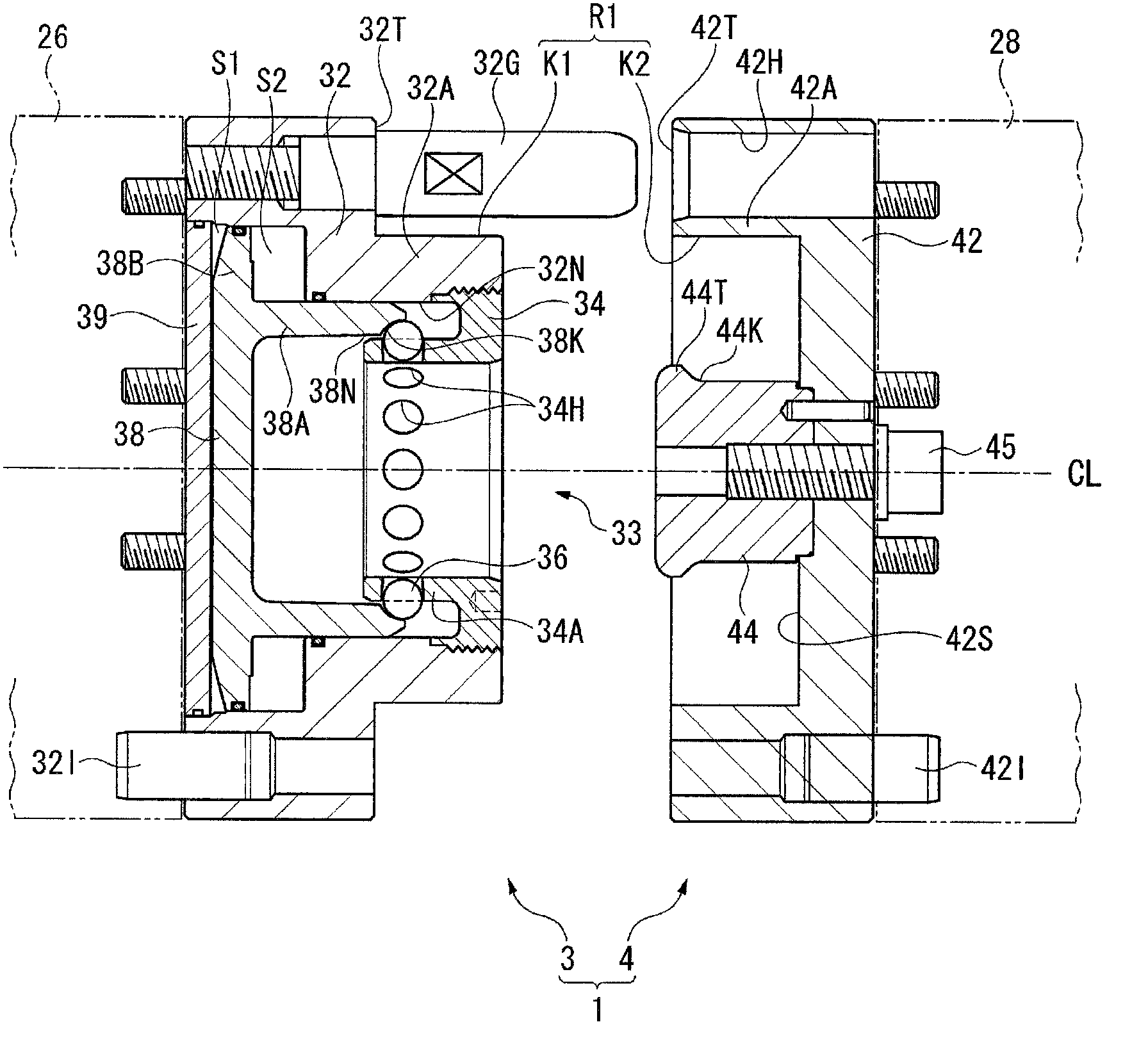

ActiveCN102725081AImprove rigidityResistance to bending momentMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

Owner:KOMATSU LTD +2

Fuel supply device

ActiveCN106103965AEasy to separateImprove maintainabilityMachines/enginesLiquid fuel feedersEngineeringFuel supply

Provided is a fuel supply device in which a fuel pump (4) is held by the pump holding wall (8) of a first housing (1) and the fitted wall (22) of a second housing (2) and the pump holding wall (8), and the fitted wall (22) are connected via a snap-fit mechanism (55). The snap-fit mechanism (55) is configured from: an elastic piece (56) that fits the fitted wall (22) to the inner periphery of the pump holding wall (8) and that extends from the tip of the pump holding wall (8) and comes into contact with the outer surface of the fitted wall (22); a locking hole (57) that is provided to the tip section of the elastic piece (56); and a locking claw (58) that is provided so as to protrude from the outer surface of the fitted wall (22) and that engages with the locking hole (57) as a result of the elastic force of the elastic piece (56). A regulating wall (60) that regulates bending of the elastic piece (56) in the radially outward direction is provided to the second housing (2). As a result, it is possible to provide a fuel supply device in which the engaged state of a snap-fit mechanism can be easily released without interference from an attachment flange.

Owner:HITACHI ASTEMO LTD

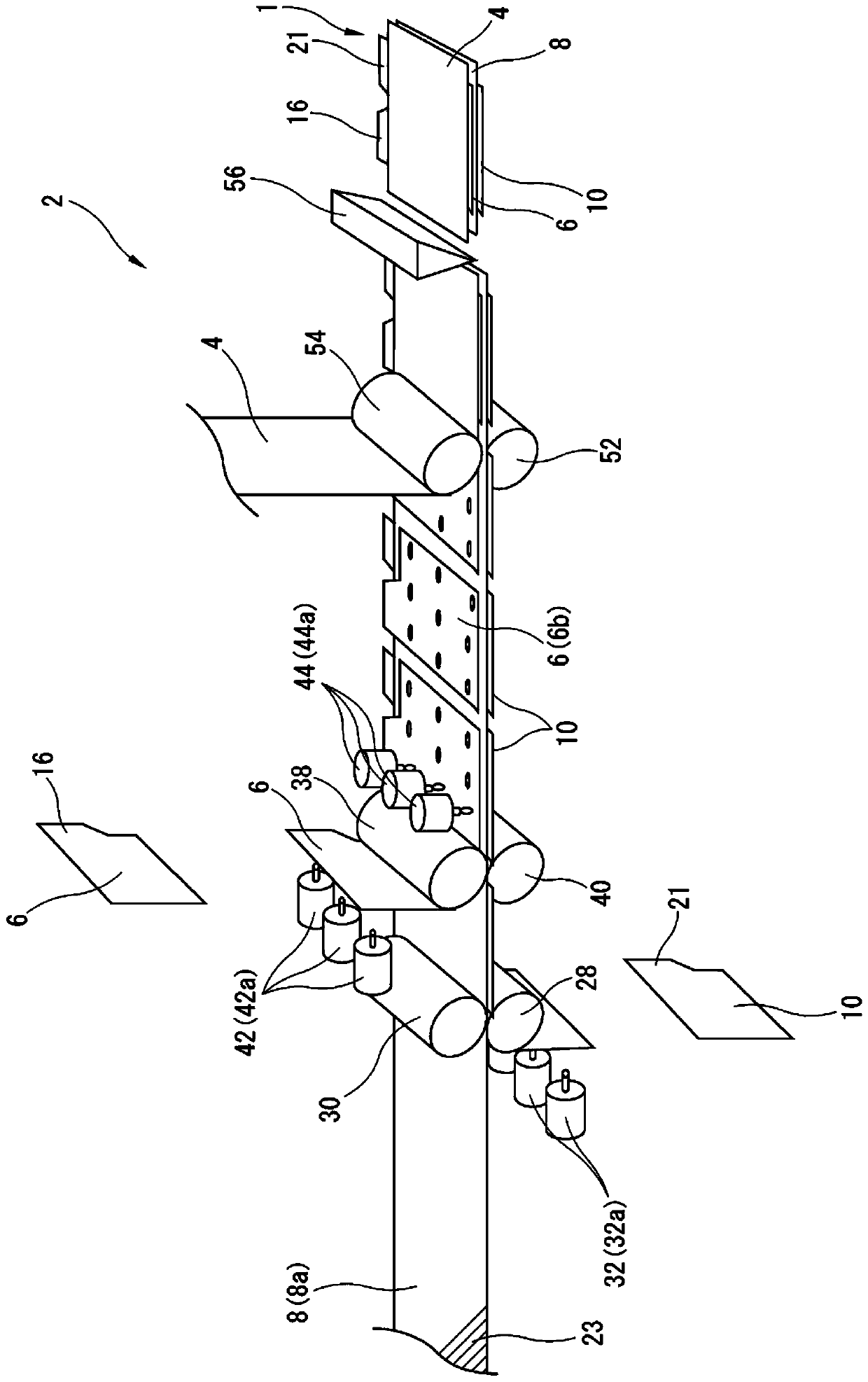

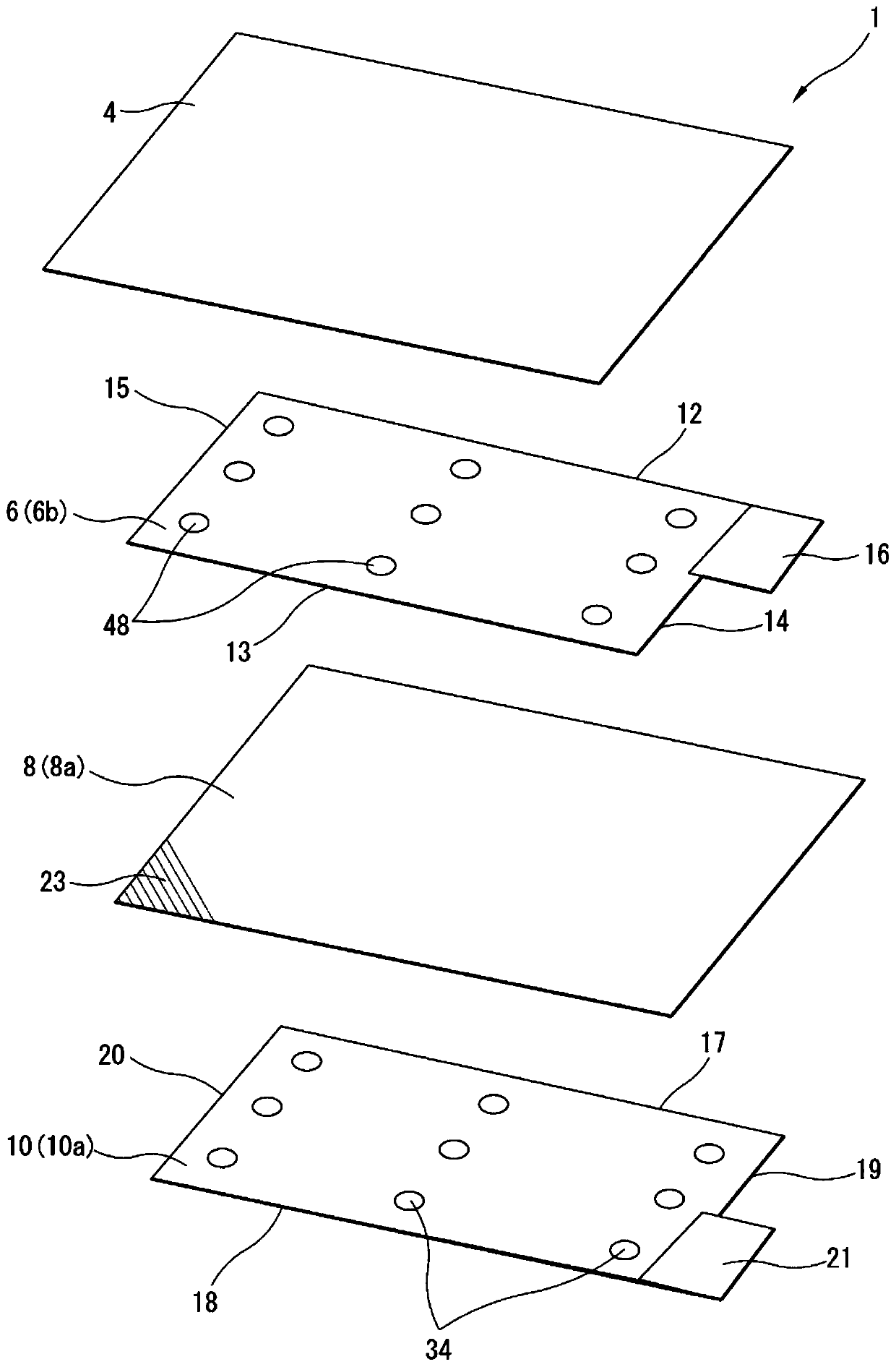

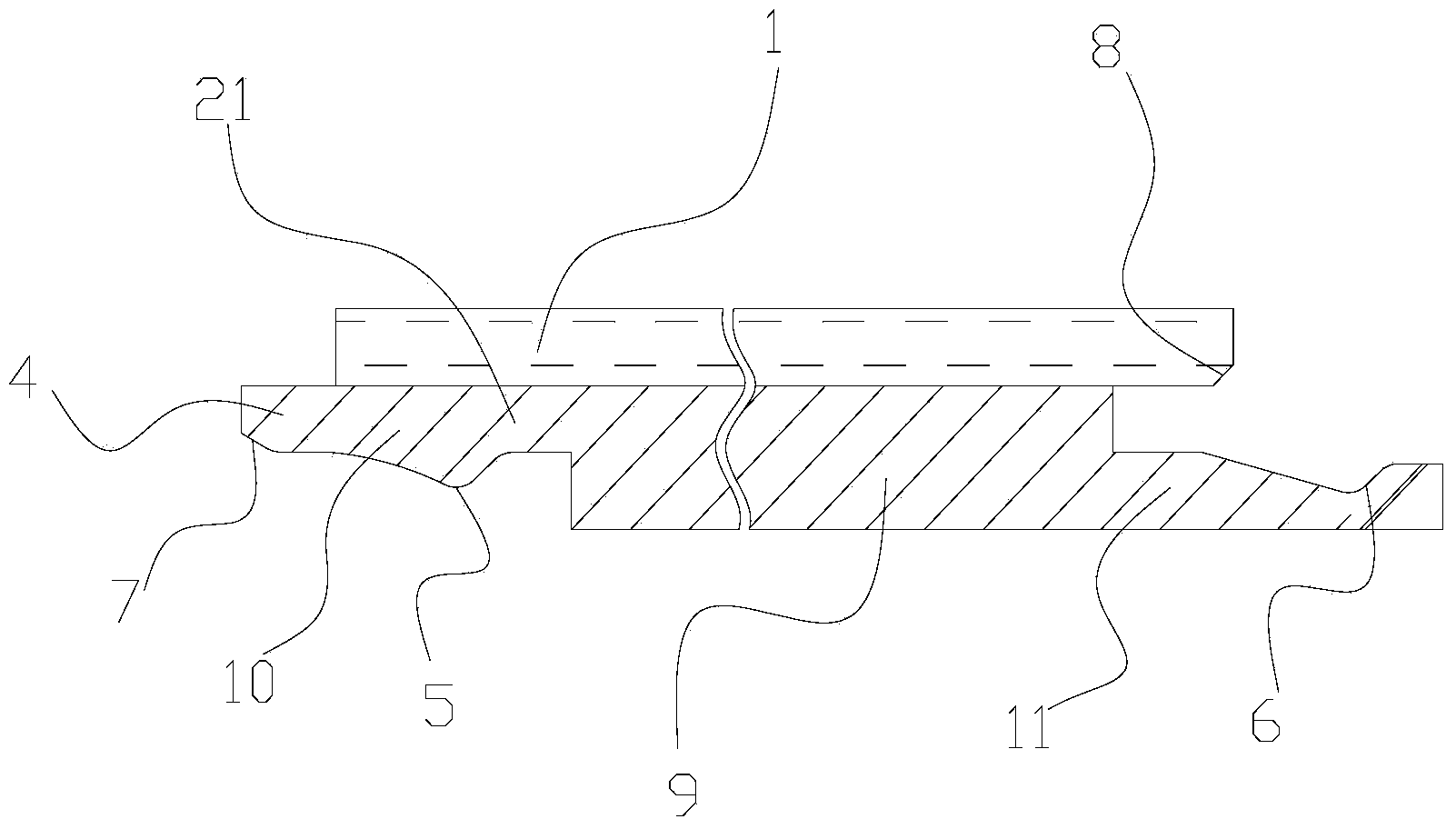

Method for producing mono-cell

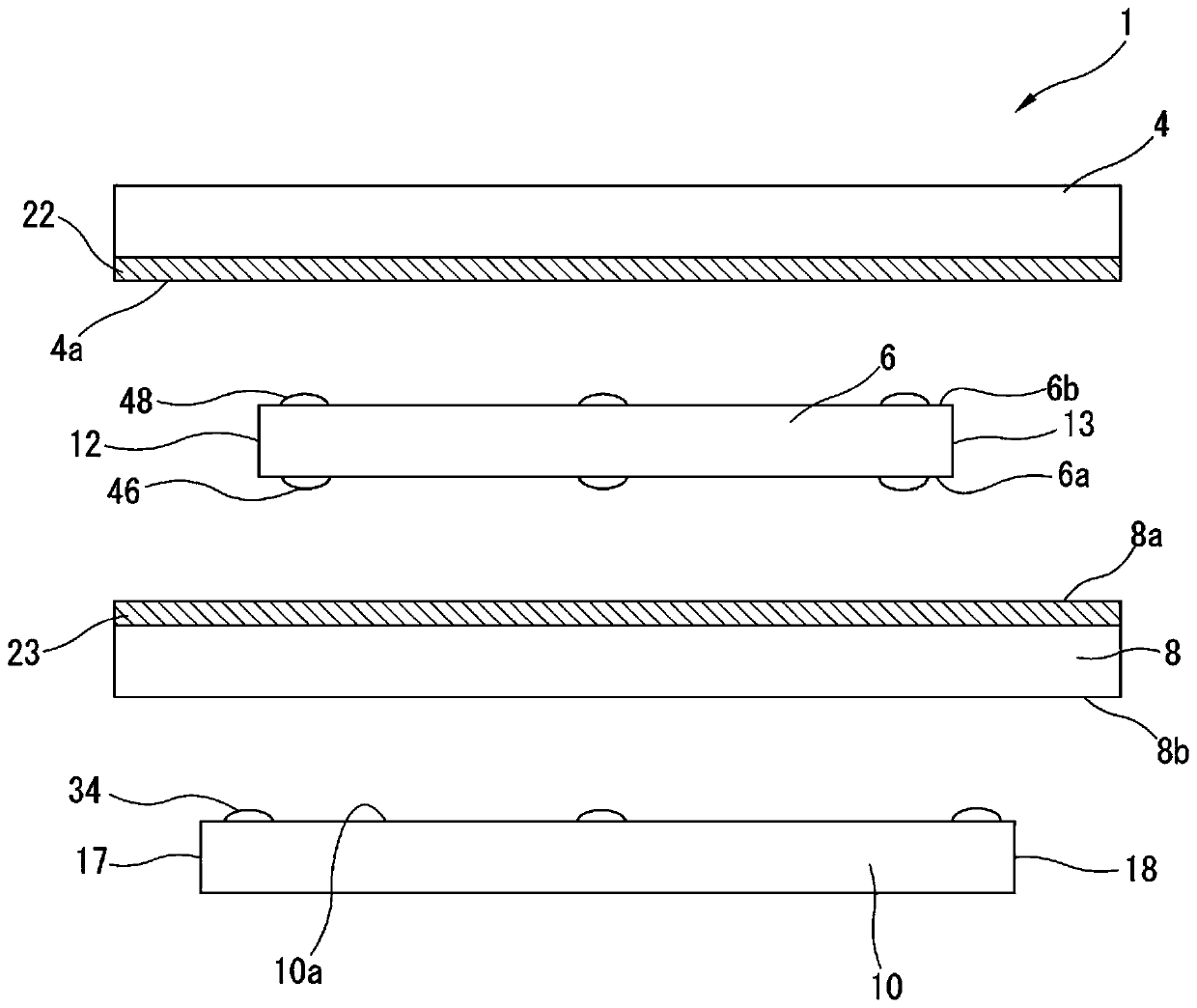

InactiveCN110352520AInhibition of peelingPrevent peelingAssembling battery machinesLarge-sized flat cells/batteriesChemistryAdhesive

In this method for producing a mono-cell (1), the mono-cell (1) comprises a separator (4), a positive electrode (6), a separator (8), and a negative electrode (10) which are joined with one another. Each separator (4, 8) has a ceramic layer (22, 23) on a surface opposing the positive electrode (6). On each of the lower surface (6a) and the upper surface (6b) of the positive electrode (6), an adhesive (46, 48) is applied at a plurality of points lined up on a straight line along the width direction (W) orthogonal to the mono-cell transportation direction (D). When an application length is defined as the product of the number of application points of the adhesive (46, 48) lined up in the width direction (W) and the application diameter of each adhesive, the number of application points and the application diameter are set such that a value found by dividing, by said application length, a force applied to each ceramic layer (22, 23) on the basis of acceleration and the weight of the separator (4) etc. during suction and transportation becomes smaller than the necessary peeling strength per unit length of the ceramic layer (22, 23).

Owner:ENVISION AESC JAPAN LTD

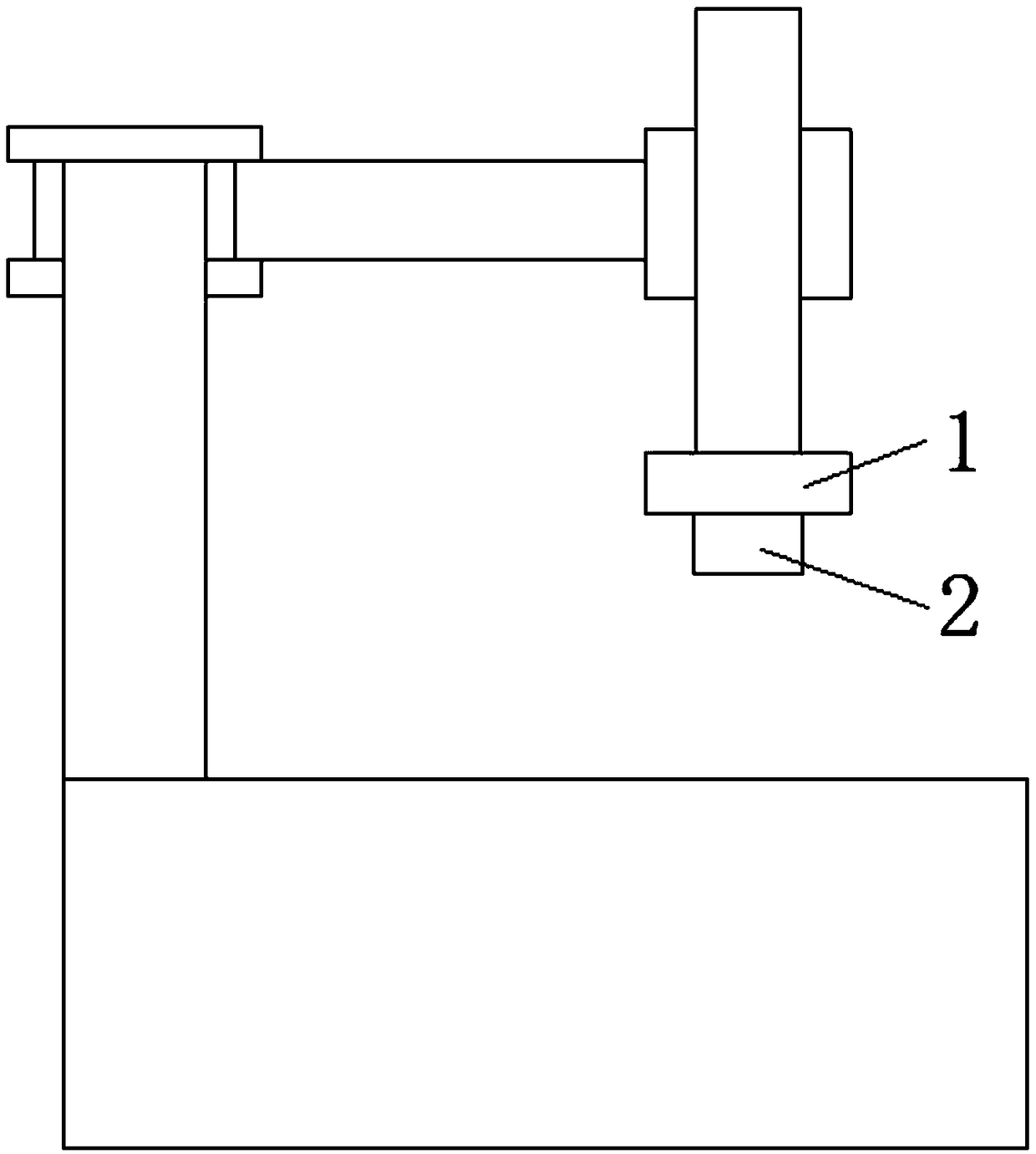

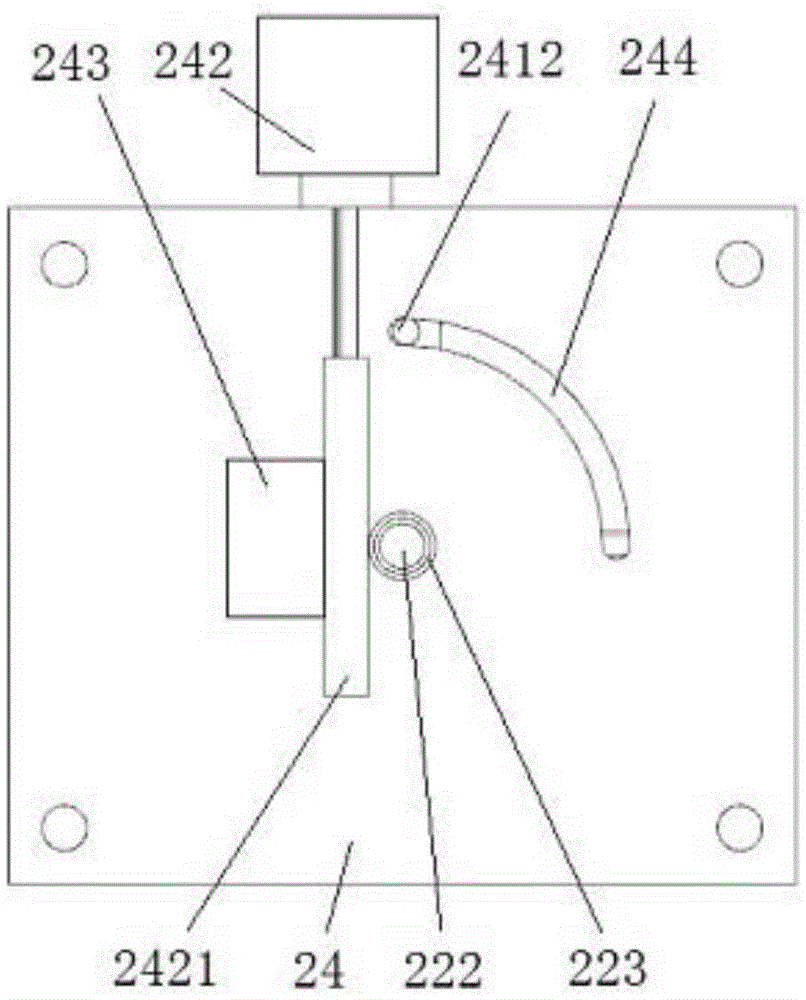

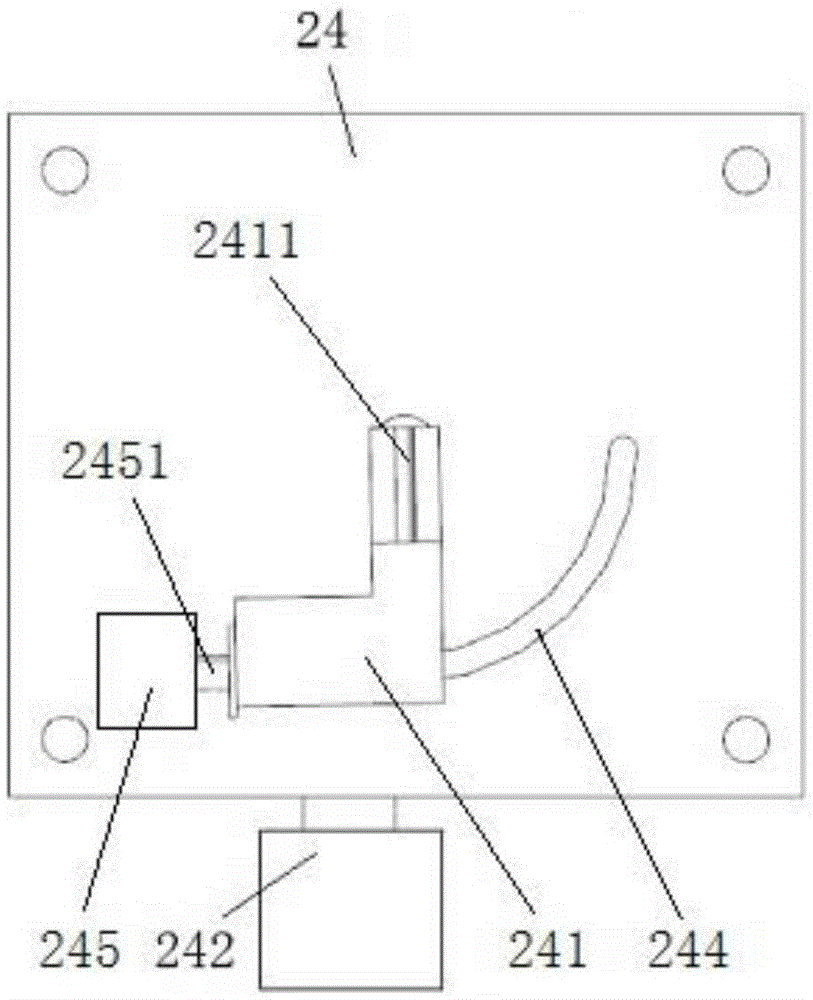

Mechanical polishing device

InactiveCN109227330AImprove stabilityAvoid automatic movementPolishing machinesGrinding work supportsEngineeringThreaded rod

The invention discloses a mechanical polishing device. The mechanical polishing device comprises an electricity box, a vertical supporting rod, a transverse supporting rod, a mechanical clamp and a clamping head; a fixed plate is fixedly connected to the bottom of the mechanical clamp, a cavity is formed in the fixed plate, a threaded rod is rotationally connected in the cavity through a bearing,two threads oppositely arranged are formed in the rod wall of the threaded rod, and are symmetrically arranged with respect to the center of a rotating groove, two sliding blocks are in threaded connection to the threaded rod, and are symmetrically arranged with respect to the threaded rod, a strip-type hole communicated with the rotating groove is formed in the bottom of the fixed plate, the twosliding blocks run through the strip-type hole and extend outwards, the ends, extending to the outside, of the two sliding blocks are fixedly connected with the clamping head, a rotating hole corresponding to the threaded rod in position is also formed in the side wall of the fixed plate, and the threaded rod extends into the rotating hole. By means of the mechanical polishing device, a polishingpiece can be firmly clamped, and the stability of the polishing piece in the processing process is improved.

Owner:TIANJIN LONGCHI MACHINERY MFG CO LTD

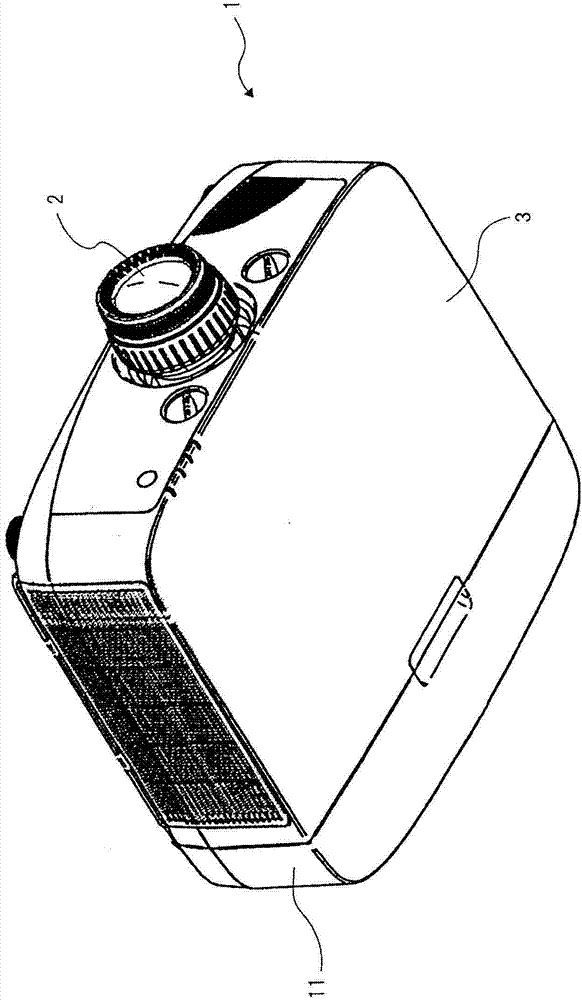

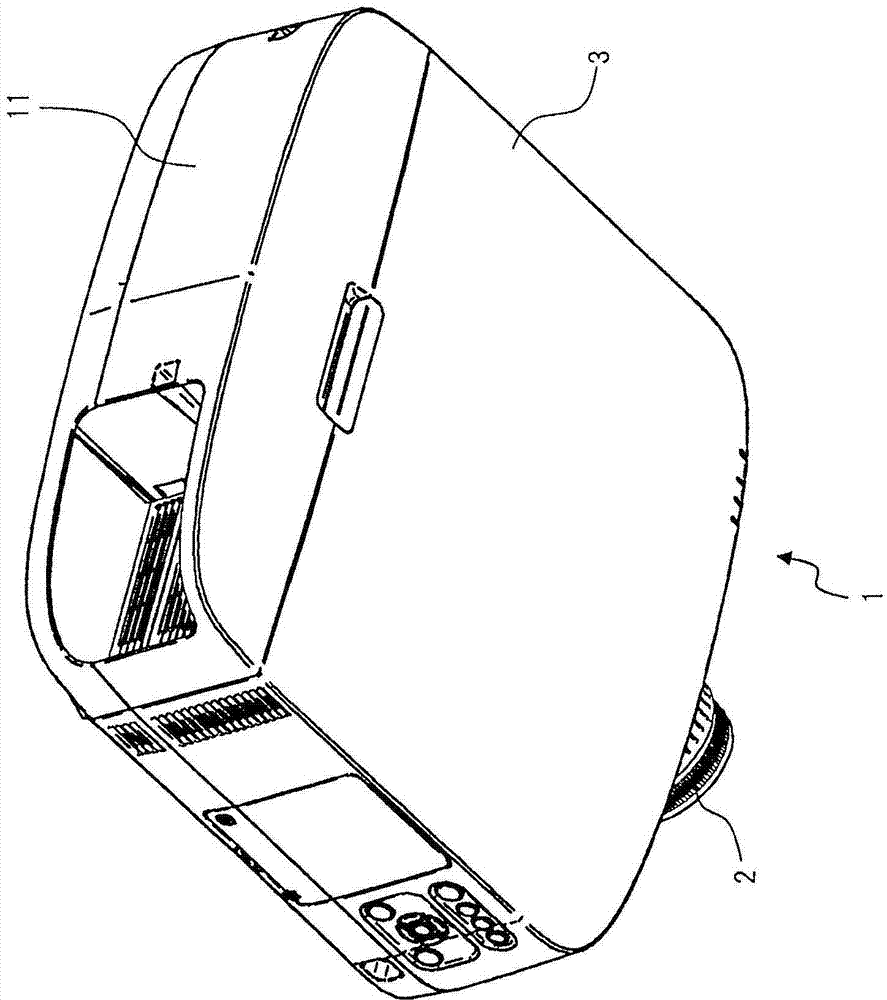

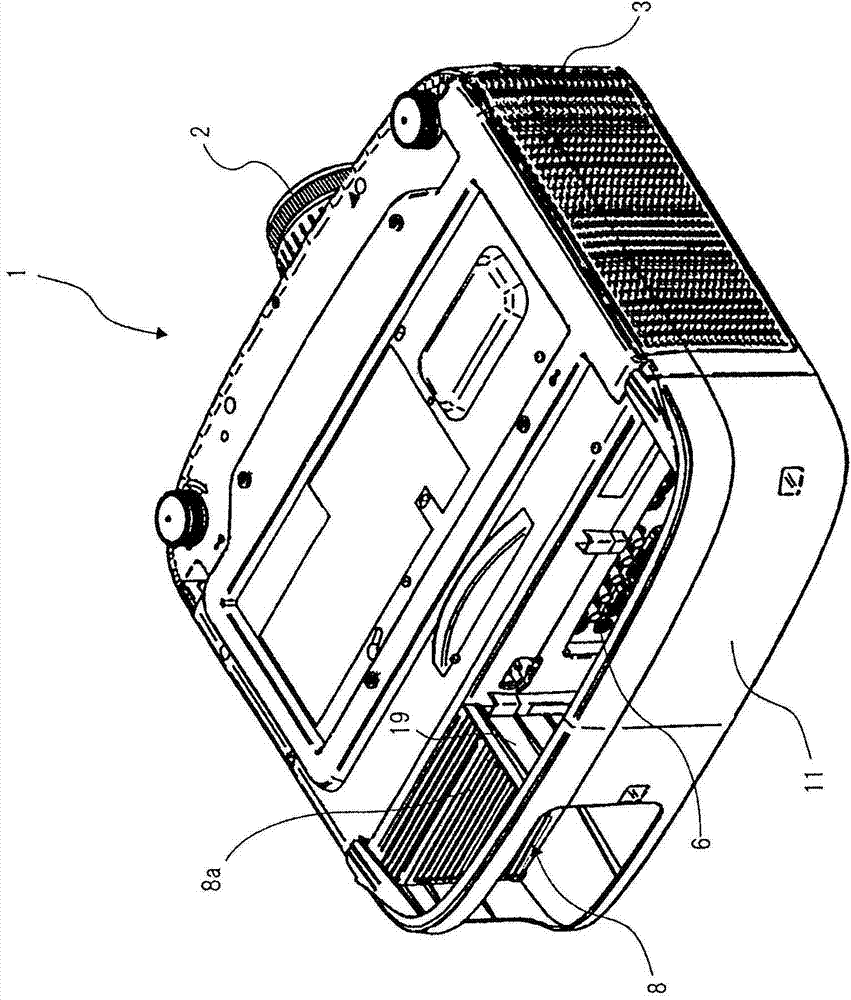

Electronic apparatus

Owner:NEC DISPLAY SOLUTIONS LTD

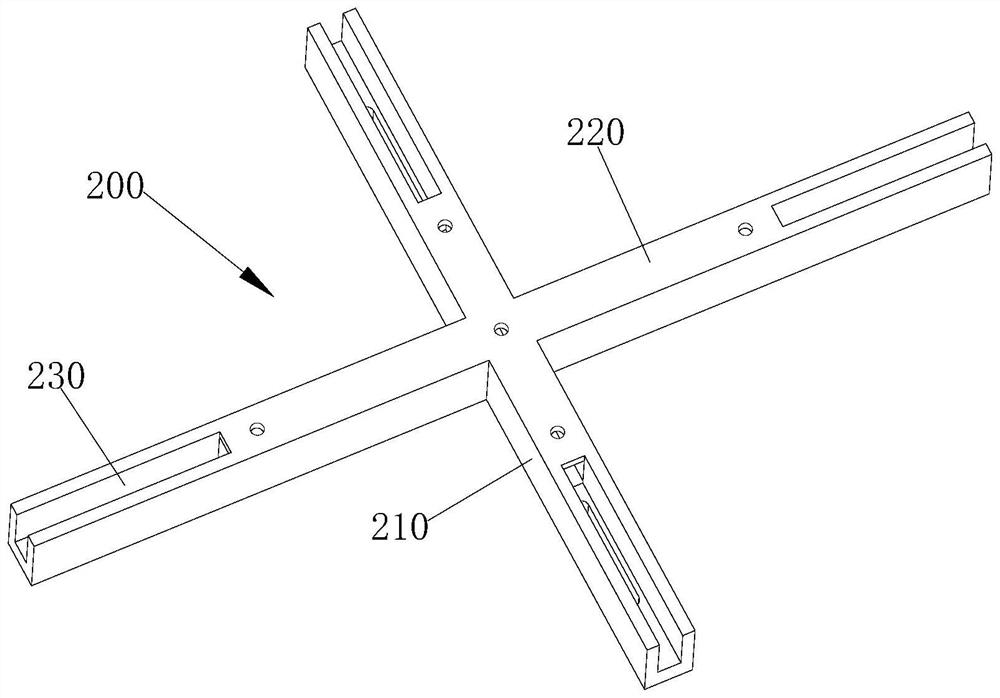

Transverse and longitudinal adjusting auxiliary device for butt joint installation of station equipment

InactiveCN114603525AImprove installation efficiencyEasy to adjustWork benchesMetal-working hand toolsButt jointDrive shaft

Owner:梁云招

Connector

ActiveCN104682047BEnsure electrical connectionStay engagedCoupling contact membersElectrical connectionStructural engineering

The present invention provides a connector that can reliably keep a reinforcing metal fitting engaged with a reinforcing metal fitting of another connector, maintain electrical connection between the reinforcing metal fittings, and maintain docking with another connector. A connector body includes a butt guide portion, which is formed at both longitudinal ends to butt the connector body of another connector; a reinforced metal accessory includes: a body portion extending transversely along the connector body; a side plate portion , connected to the body part and extending along the longitudinal direction of the connector body; and a contact arm part connected to the side plate part; reinforced metal fittings are installed on the left and right sides of the docking guide part; the contact arm part includes a first and a first facing each other the second contact part; and when the connector body butts with the connector body of another connector, the reinforced metal fitting installed on the other connector body is inserted between the first and second contact parts, and the first contact and the second contact part Keep another reinforcing metal fitting on both sides and establish contact with it.

Owner:MOLEX INC

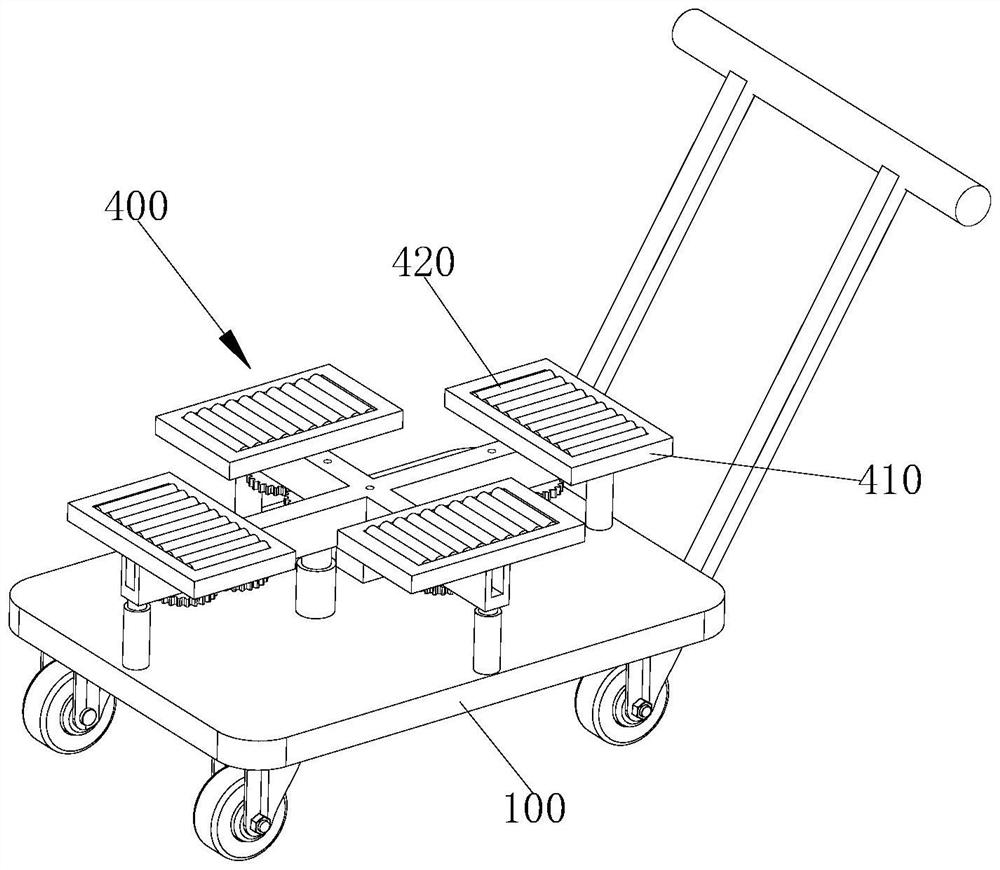

Rack mobile coil handling device

InactiveCN102712418BHigh-speed and stable handlingStay engagedRack railwaysWagons/vansEngineeringPinion

Owner:PRIMETALS TECHNOLOGIES JAPAN LTD

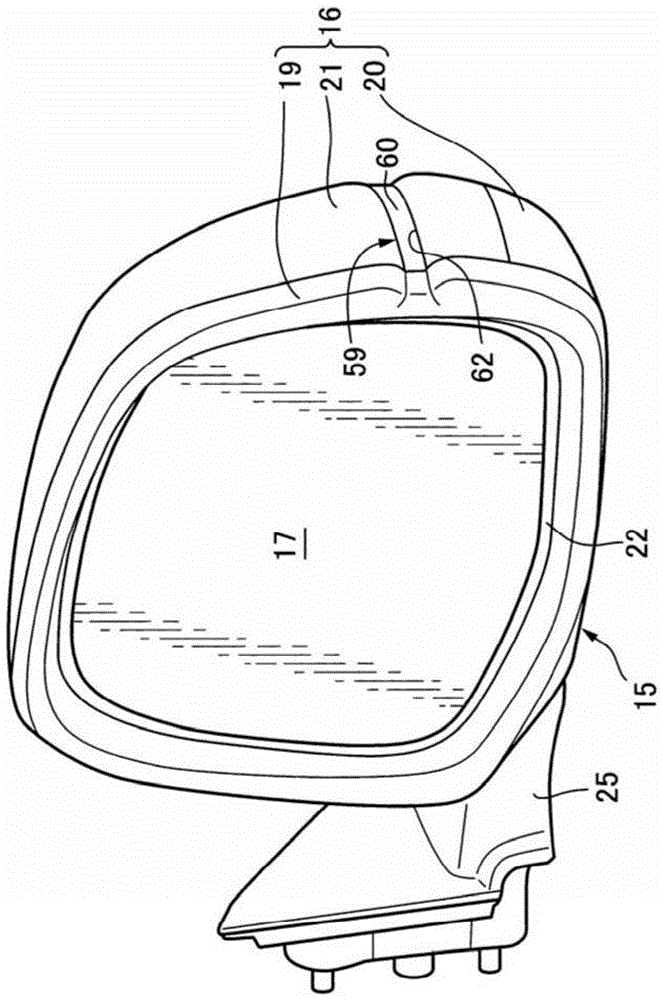

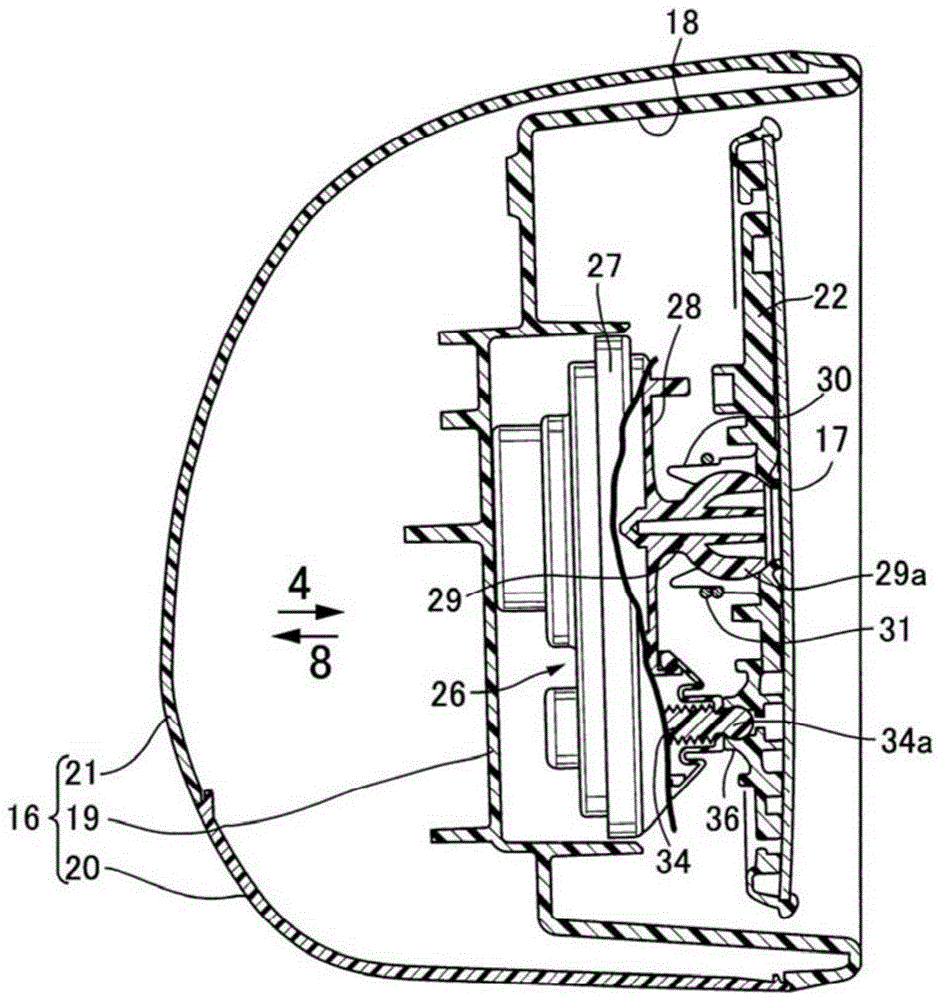

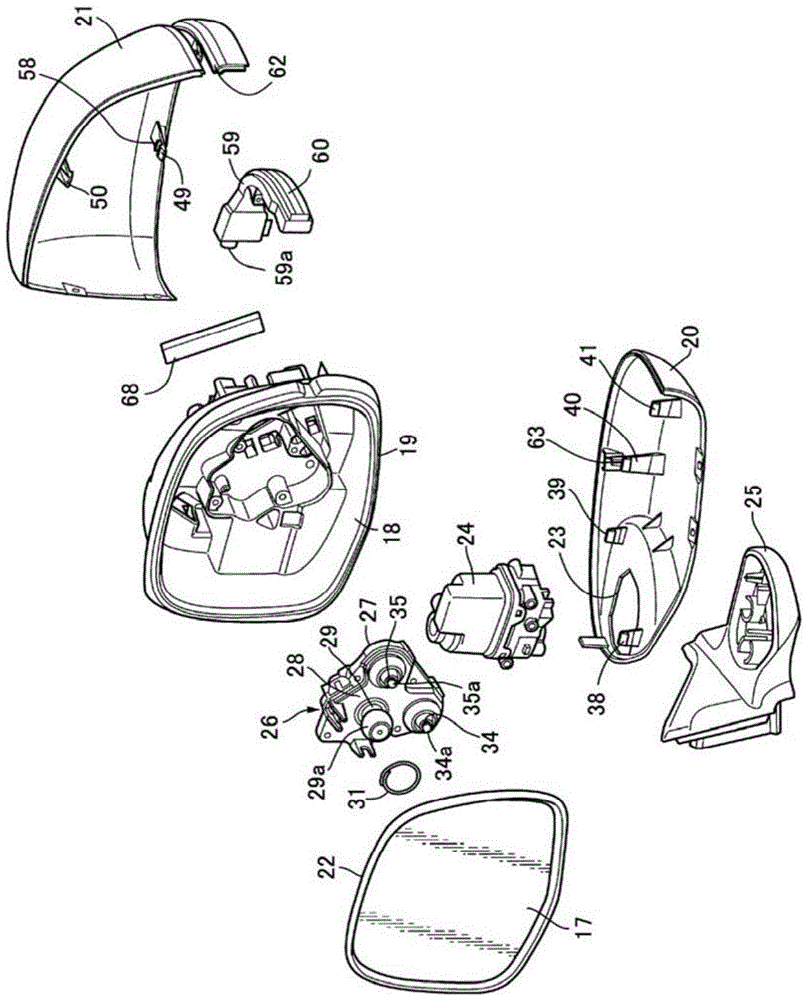

Vehicle door mirrors

ActiveCN104590128BInhibition of disengagementSuppress shape complexityMountingsAntenna detailsRear-view mirrorCar door

Owner:美蓓亚智连科创零件有限公司

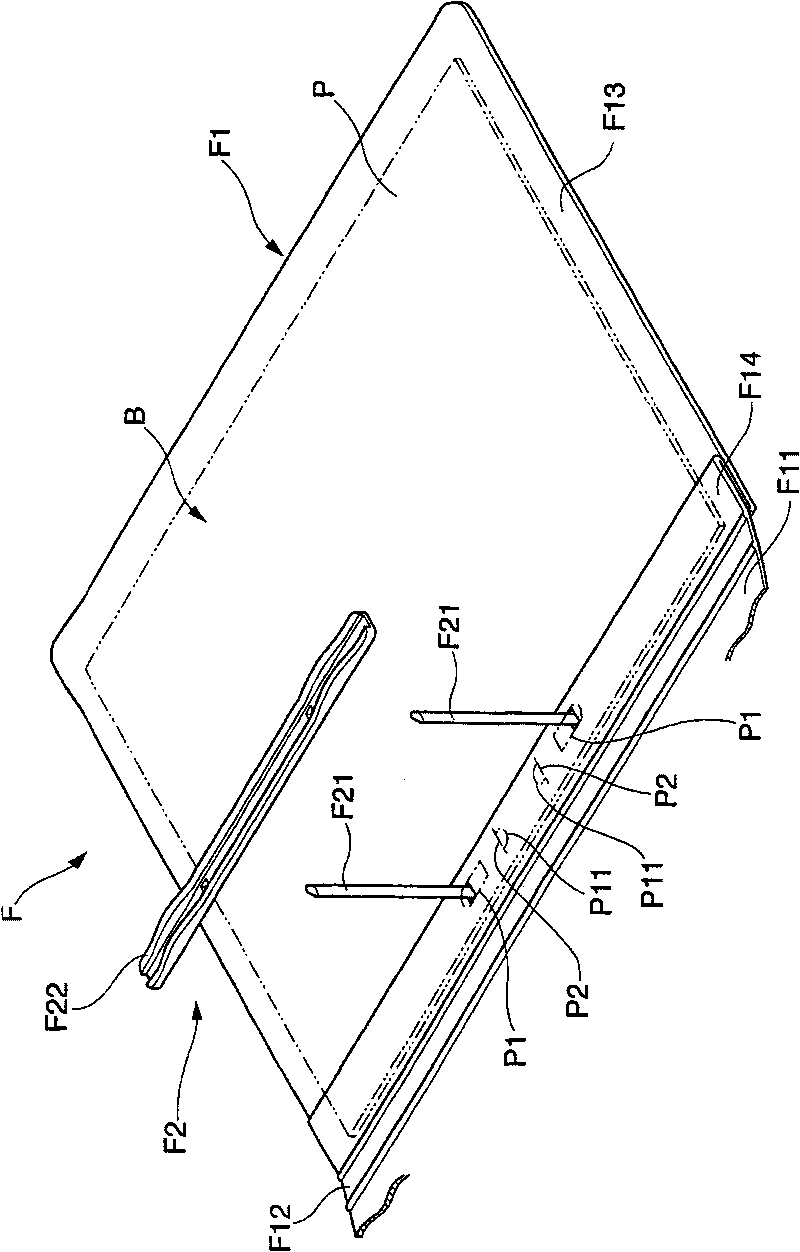

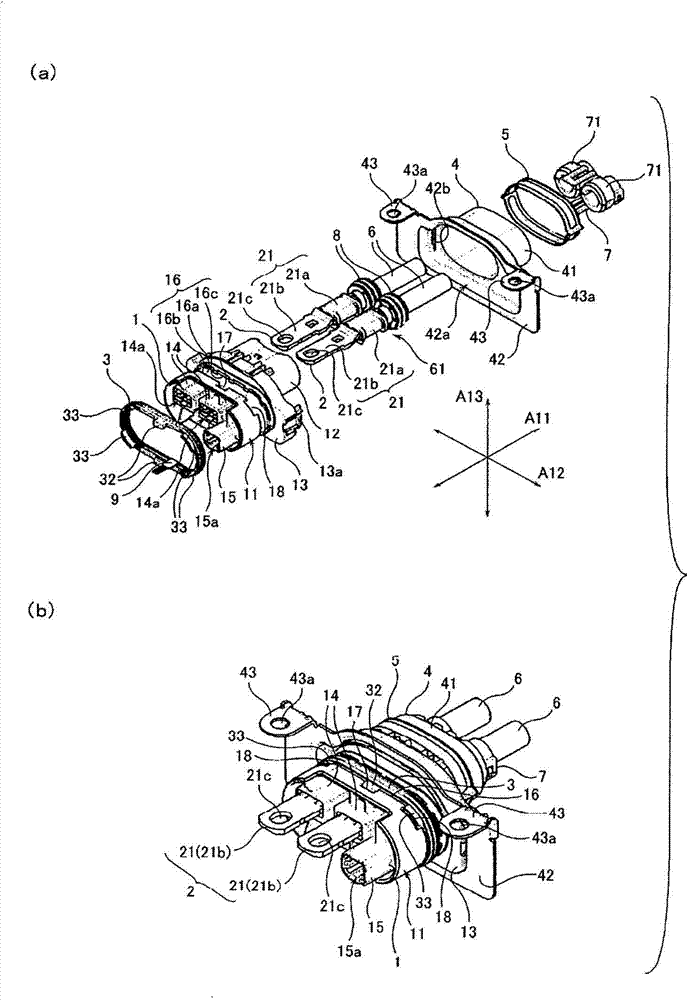

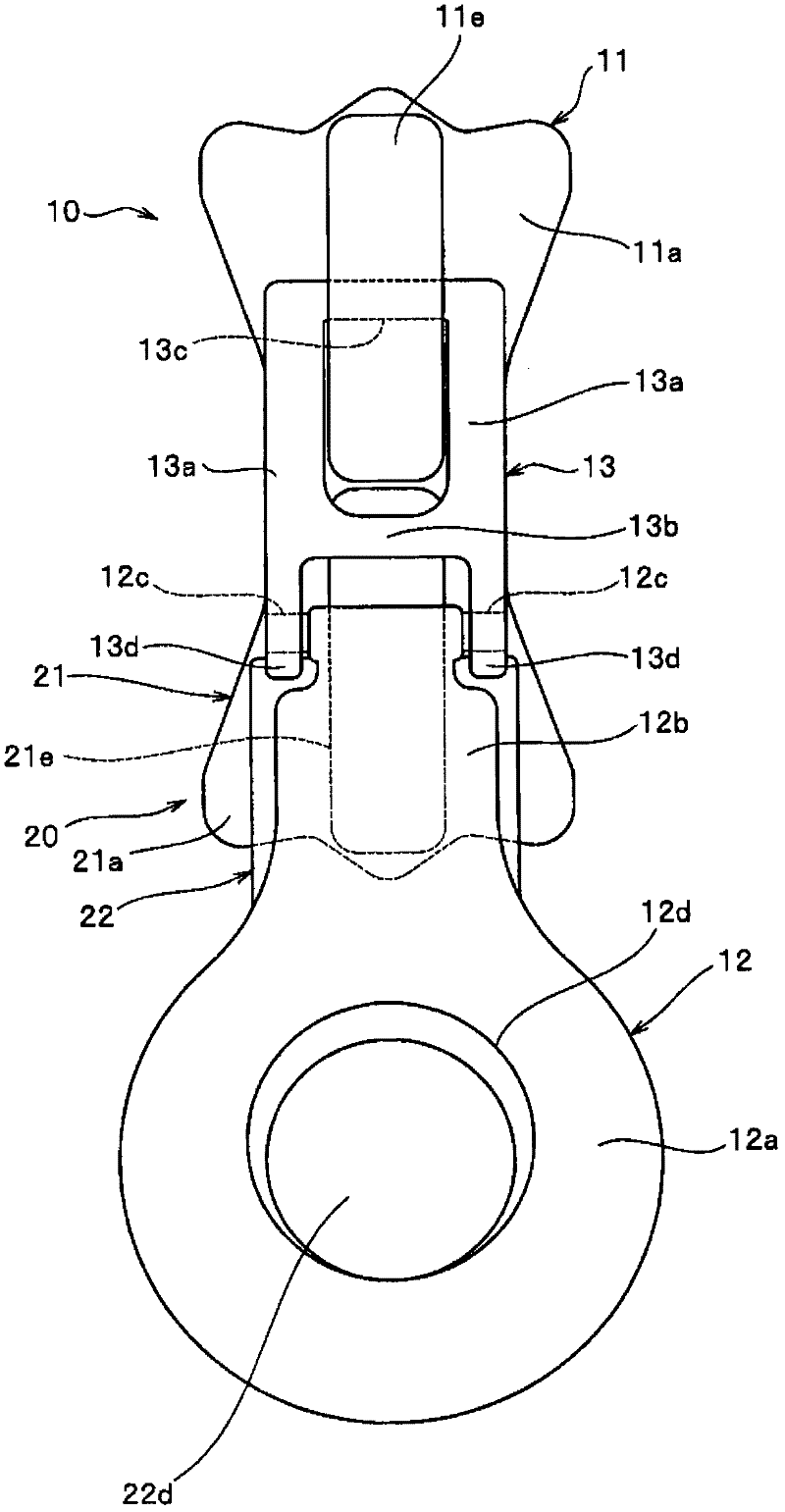

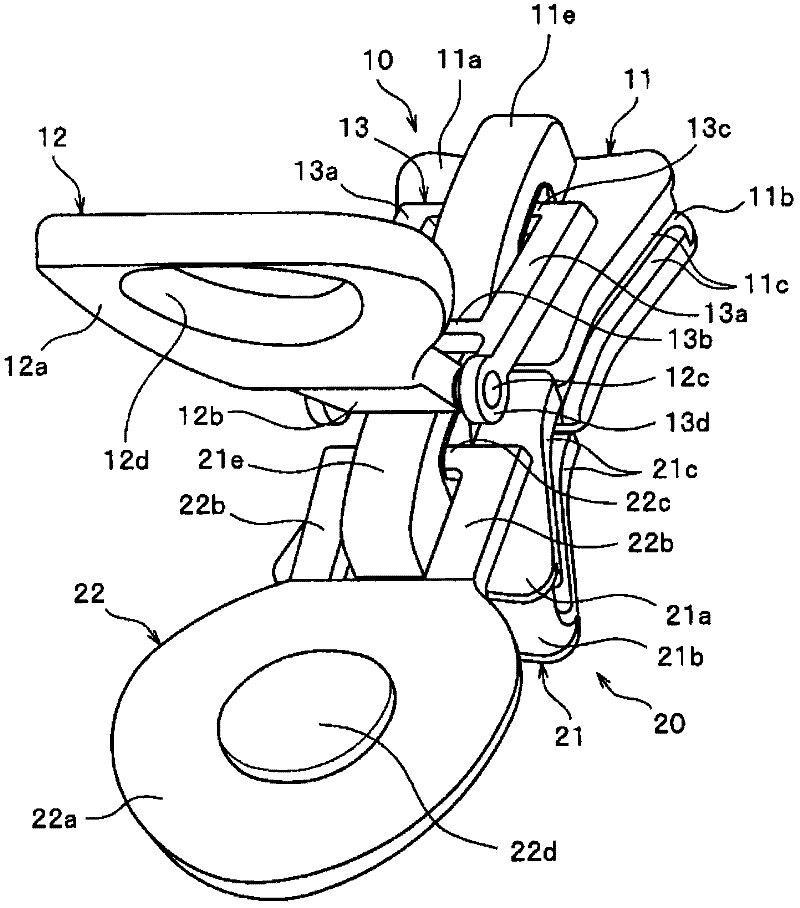

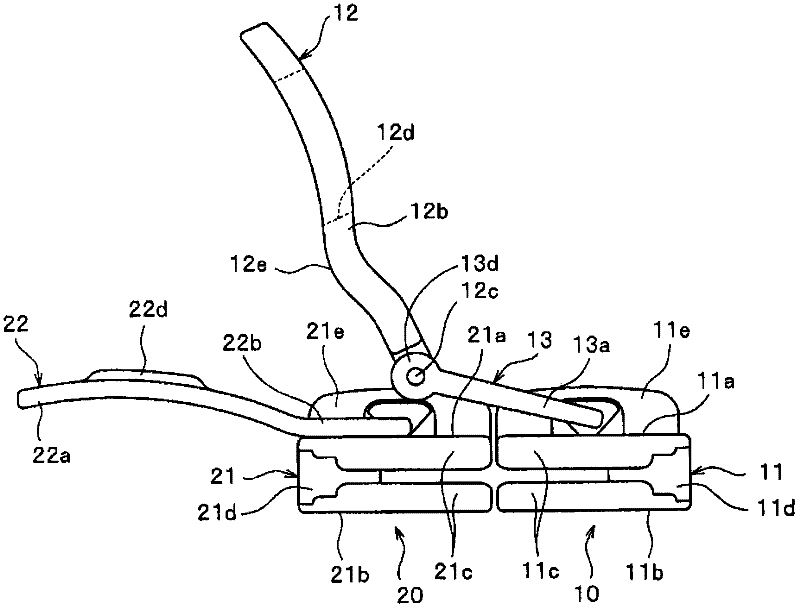

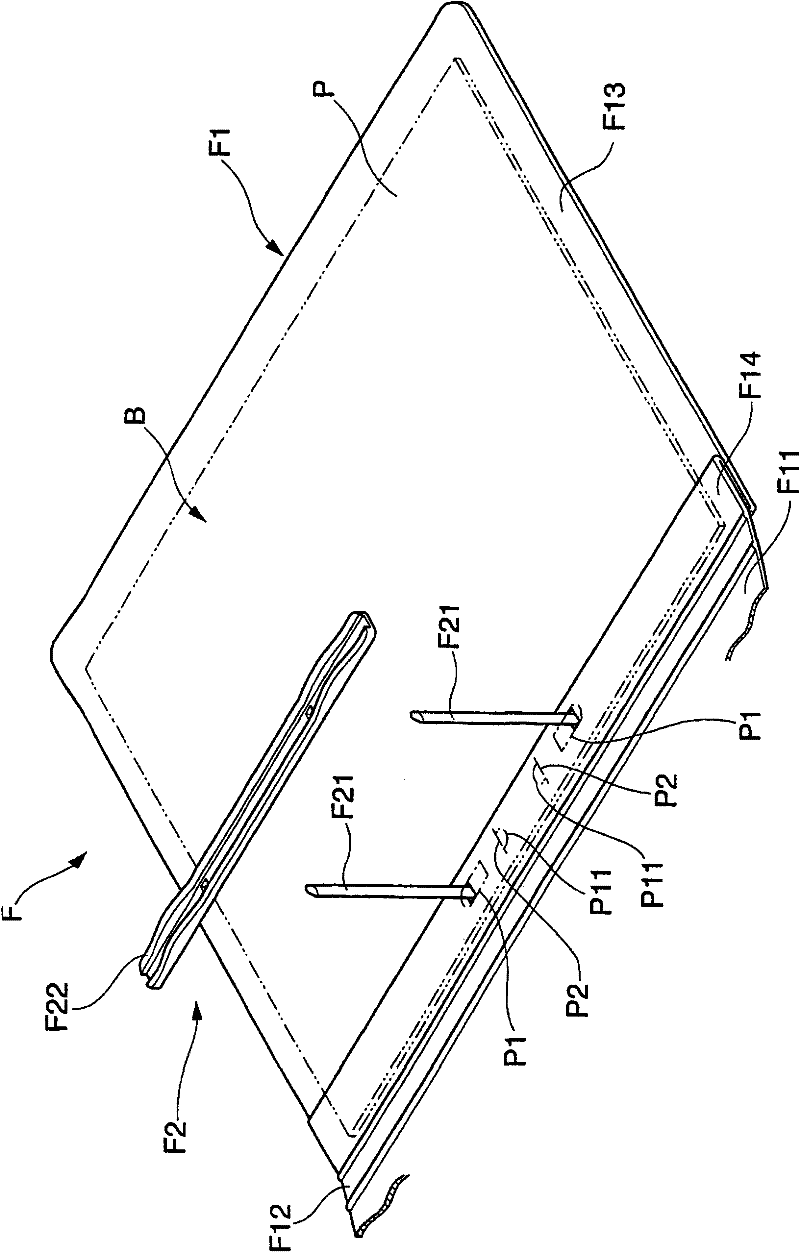

Slide fastener

The invention provides a slide fastener that has a left and right pair of fastener stringers having element rows arranged thereon, an insert pin and a box pin each formed integrally with one end of a corresponding one of the element rows, and a first slider (10) having a first pull tab (12) and a second slider (20) having a second pull tab (22), the first and second sliders (10, 20) being passed over the element rows with respective rear openings of the first and second sliders opposed to each other. The first and second pull tabs (12, 22) have engaging structures for engaging the first and second pull tabs with each other. When the first and second pull tabs (12, 22) are engaged with each other, the first and second sliders (10, 20) are retained in a state in which the rear openings are opposed to each other. The first pull tab (12) is pivotably connected to a first slider body (11) via a first link section. Engaging the pull tabs of the first and second sliders (10, 20) with each other reliably positions the first and second sliders (10, 20) relative to each other to allow smooth insertion of the pin into the sliders. Thus, the construction improves the easiness of operation of the slide fastener.

Owner:YKK CORP

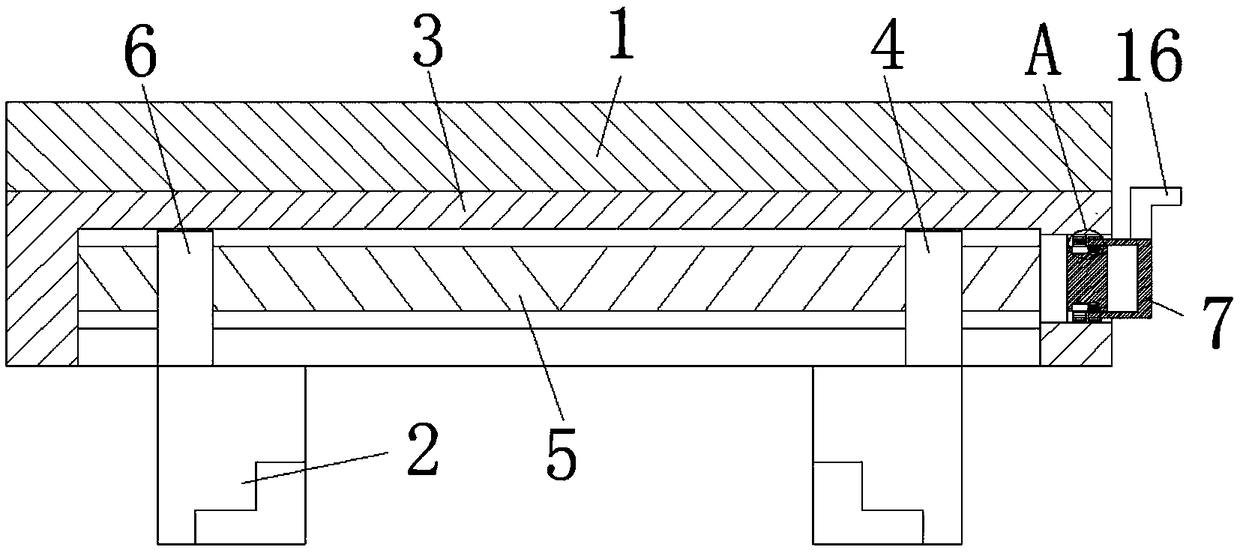

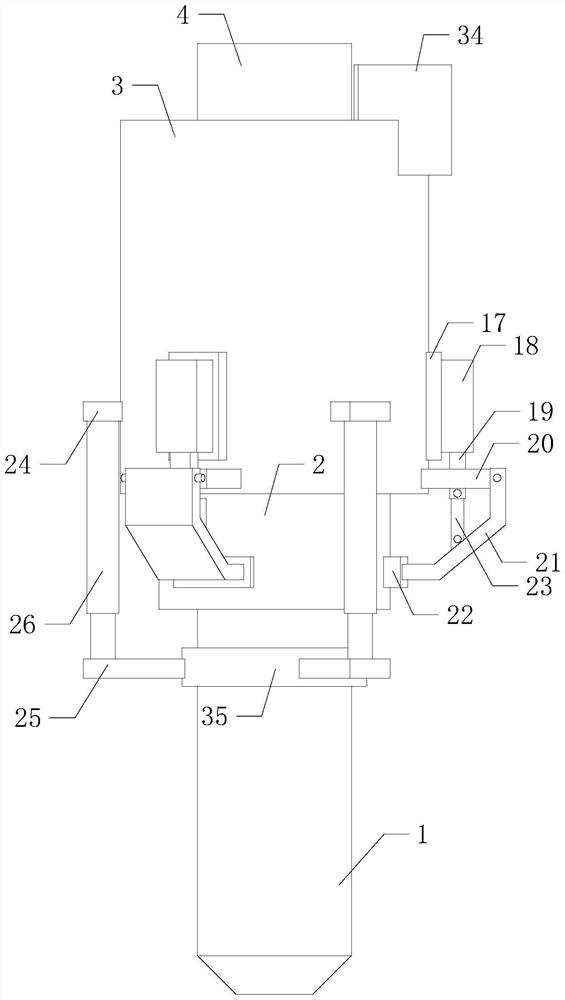

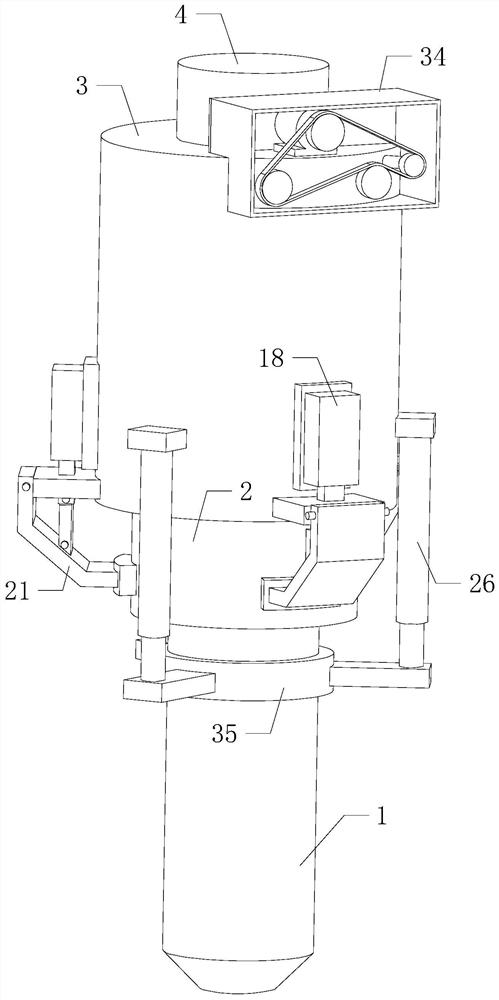

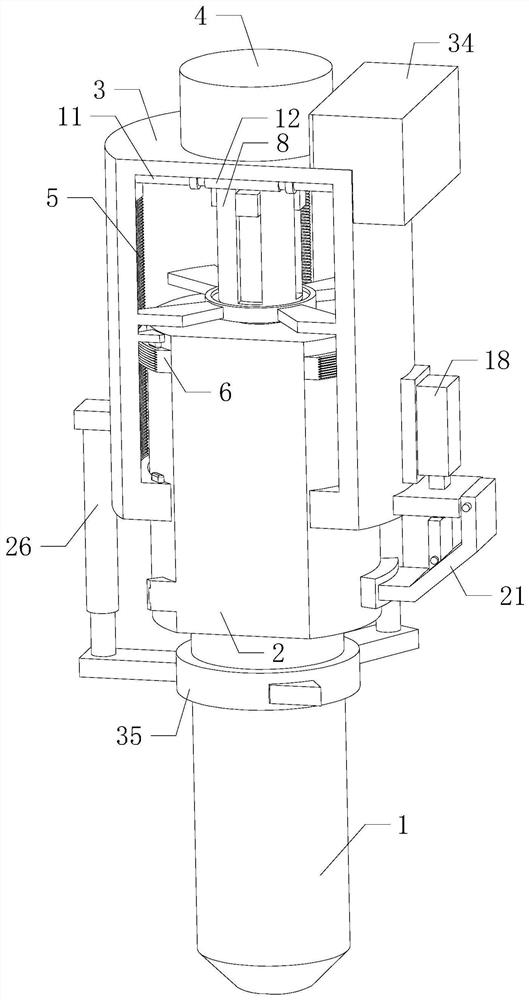

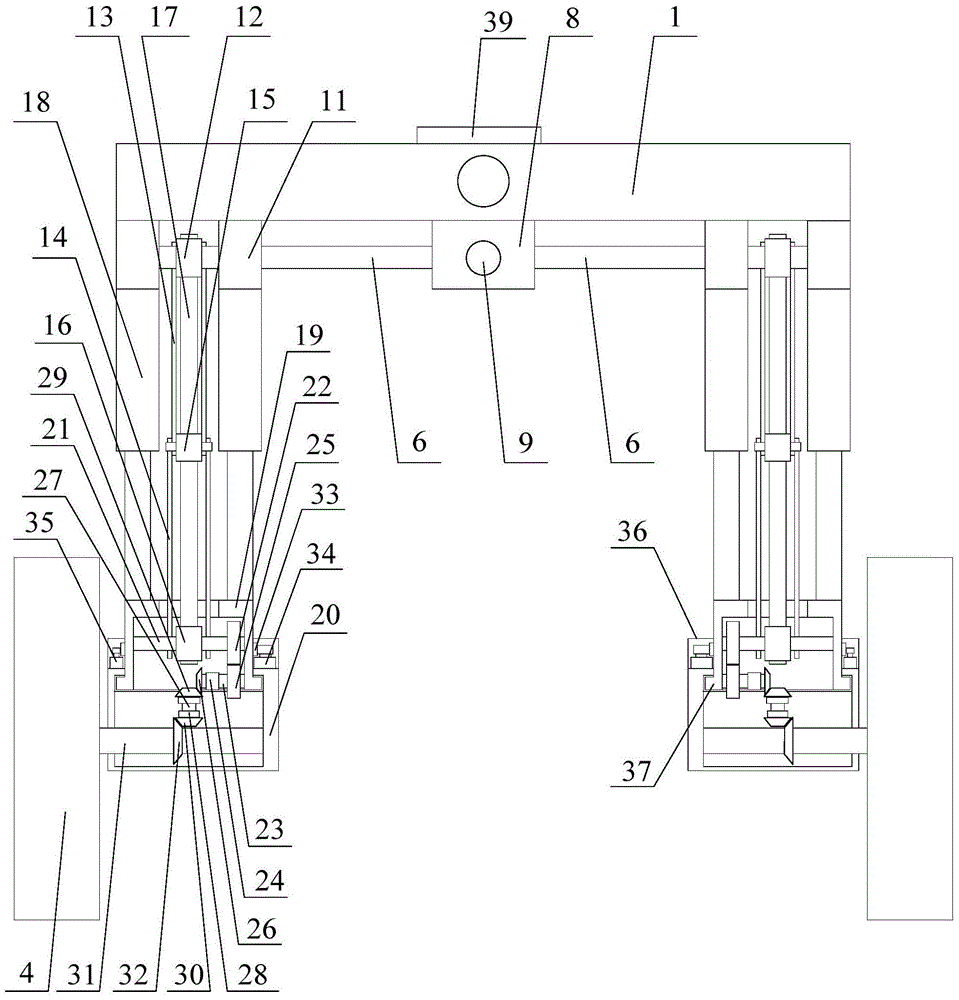

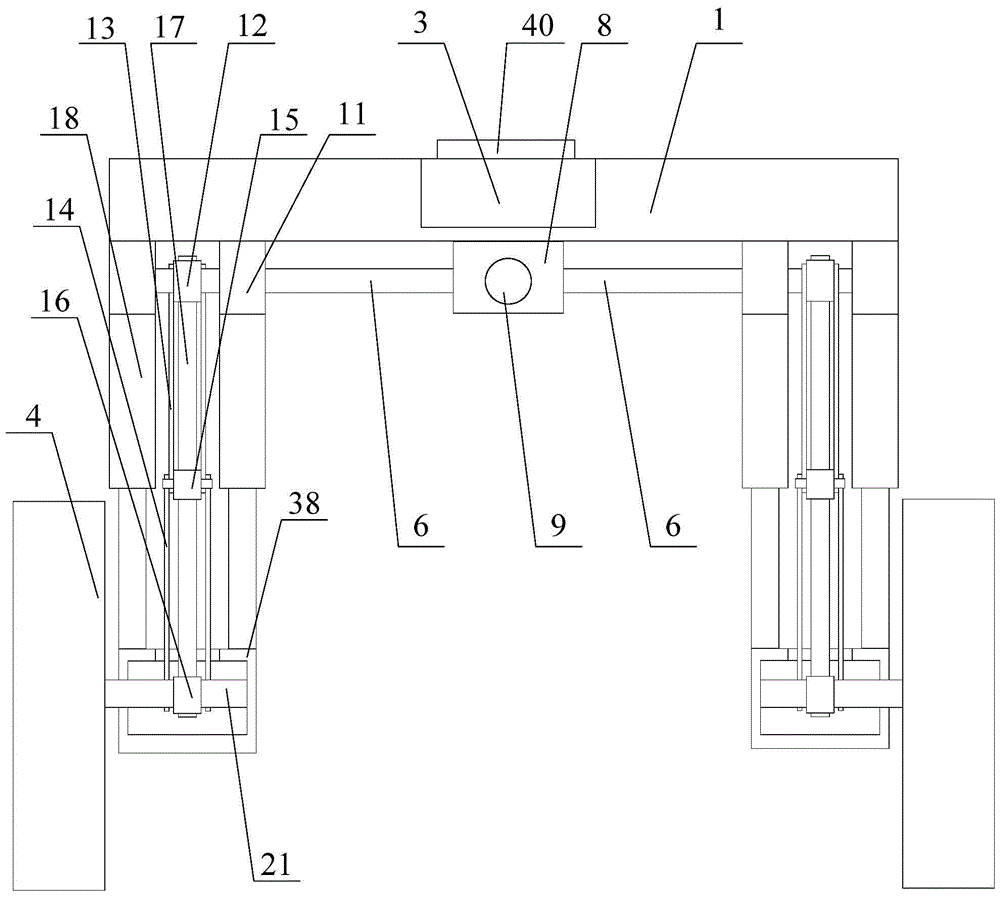

Core roller multi-station device for ring rolling machine

The invention relates to the technical field of ring rolling equipment, and particularly relates to a core roller multi-station device for a ring rolling machine. The height position of a core rollercan be conveniently adjusted by adjusting the station of the core roller, so that when a workpiece with a small height is machined, the workpiece is in contact with the upper side of the core roller,the situation that the distance between the contact position of the workpiece and the core roller and the top fulcrum of the core roller is large, and consequently the workpiece causes overstock deformation is avoided, the idle length of the upper side of the core roller is reduced, the core roller is conveniently protected, the service life of the equipment is prolonged, and the practicability and reliability are improved. The core roller multi-station device comprises the core roller, an adjusting shaft, an adjusting bin and a connecting shaft, wherein the bottom of the adjusting shaft is mounted at the top of the core roller; a cavity is formed in the adjusting bin; a through opening is formed in the bottom of the cavity in a communicating mode; the top of the adjusting shaft is inserted into the cavity through the through opening; and the outer wall of the adjusting shaft is in contact with the inner wall of the through opening and can slide relative to the inner wall of the through opening.

Owner:ZHUCHENG SHENGYANG MACHINERY

Binding machine

ActiveCN101746177BAvoid the problem of excessive thickness thickeningStays firmly engagedSheet bindingArticle deliveryPunchingPulp and paper industry

The invention provides a binding machine, which can effectively maintain the joint state of a jointed joint part when a plurality of sheet pieces are bound. The binding machine (1), by using cutting pieces (P11) obtained by cutting the overlapped paper (P) by means of a objective table (2), a cutting blade (910 and a punching blade (92), mutually joint the paper (P) for binding. The binding machine is characterized in that the binding machine has a compressing mechanism, which can make the jointed joint portion (P3) of the paper (P) compressed and deformed in the thickness direction. In this way, because the jointed joint portion is compressed, the joint portion (P3) can be effectively prevented from hanging other articles or fingers due to the swelling of the cutting pieces (P11), the joint state of the joint portion (P3) can be steadily maintained, and the thickness of the joint portion (P3) can be reduced.

Owner:KOKUYO CO LTD

Socket pipe, pipe with socket pipe, and pipe connection structure using socket pipe

The socket pipe provided by the invention comprises a pipe connecting part, the pipe connecting part is provided with an extruding inner surface and at least one protruding tip part, and the extrusioninner surface is provided with an inner periphery attached to the outer periphery of the inserted first pipe, and the at least one protruding tip protrudes from the extrusion inner surface and is embedded in the outer peripheral surface of the first pipe.; the pipe connecting part is arranged opposite to the pipe connecting part, so that the second pipe is inserted, the opening pipe is connectedto the first pipe through a good strength and a sealing property. Furthermore, the present invention provides a pipe with a socket and a pipe connection structure using the same as the socket pipe isincluded.

Owner:株式会社涂料韩国

Mould pressing floor board and manufacturing method and mould thereof

The invention provides a mould pressing floor board and a manufacturing method and a mould thereof. The mould pressing floor board comprises a surface compound layer and a base material layer which are overlapped up and down, wherein an upper extension part and a lower extension part are respectively formed on two surfaces of the base material layer through the mould; next, the surface compound layer and the base material layer are mould-pressed after being overlapped; joint tongues are respectively formed on the upper extension part by using position and structure relationships after the overlapping of the surface compound layer and the base material layer; mortises matched with the joint tongues are formed between the upper side of the lower extension part and the lower side of the surface compound layer, so that the splicing between every two adjacent mould pressing floor boards is realized. By applying the mould pressing floor board and the manufacturing method and the mould thereof, the problems caused by floor board grooving can be avoided; in mould pressing, the raw material of the mould pressing floor board is high in utilization rate, so that the manufacturing cost of the floor board is reduced; moreover, the mould pressing floor board is high in shape precision and stable in dimension; the splicing between the mould pressing floor boards is tighter and more attractive; the problem that the installation of the mould pressing floor board is influenced due to mortise blockage is also solved.

Owner:湖南恒益美环保建材有限公司

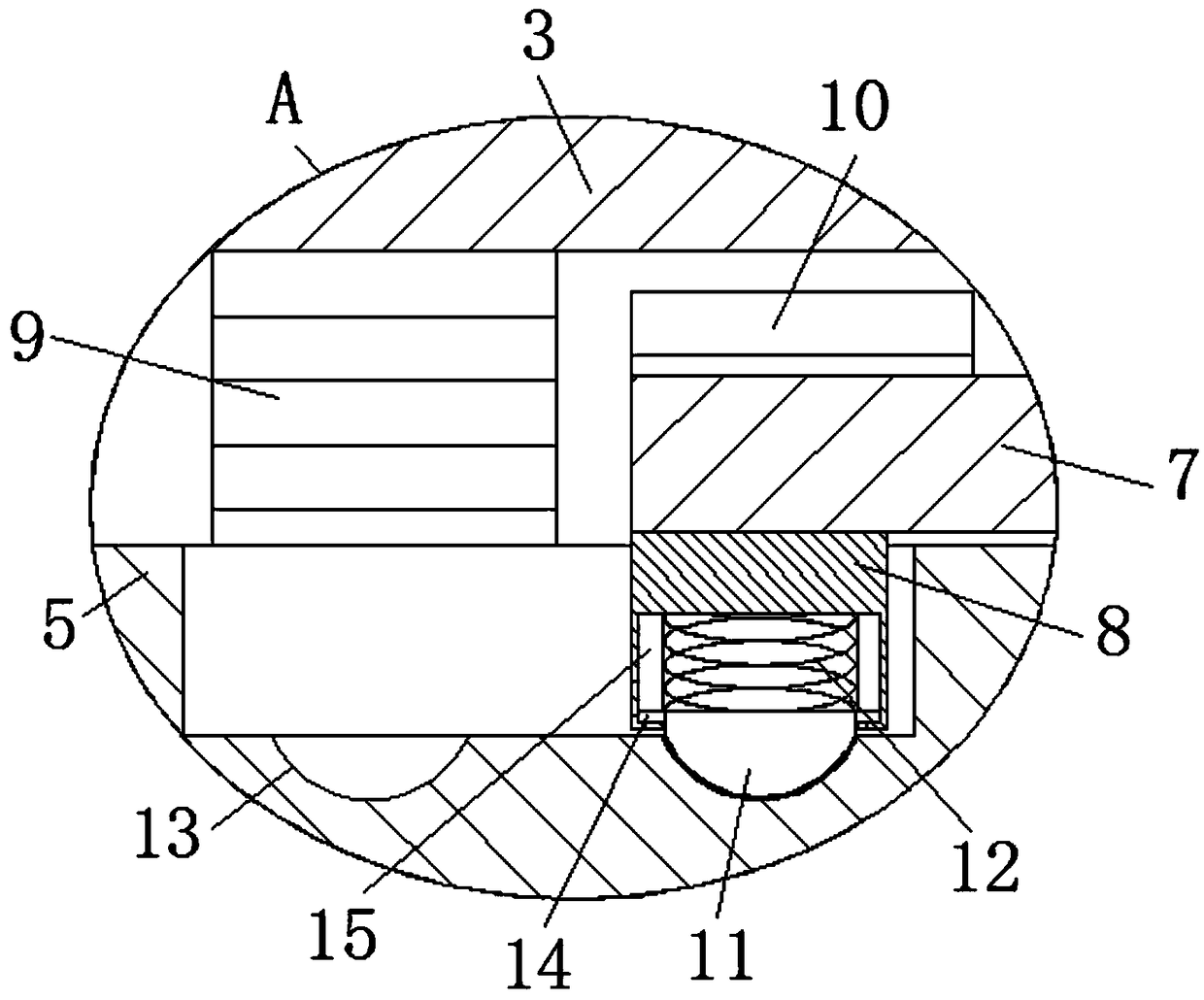

Wire clamp

ActiveCN111295810BThe stuck state is stableKeep awayAdjusting/maintaining mechanical tensionApparatus for overhead lines/cablesScrew threadElectric wire

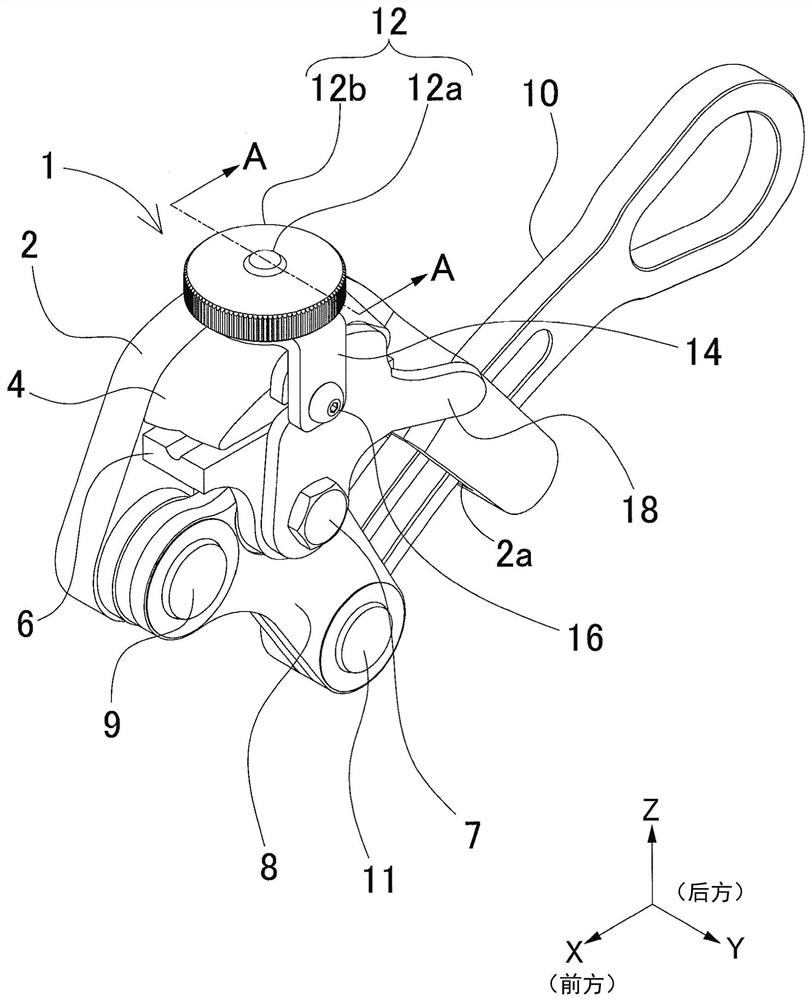

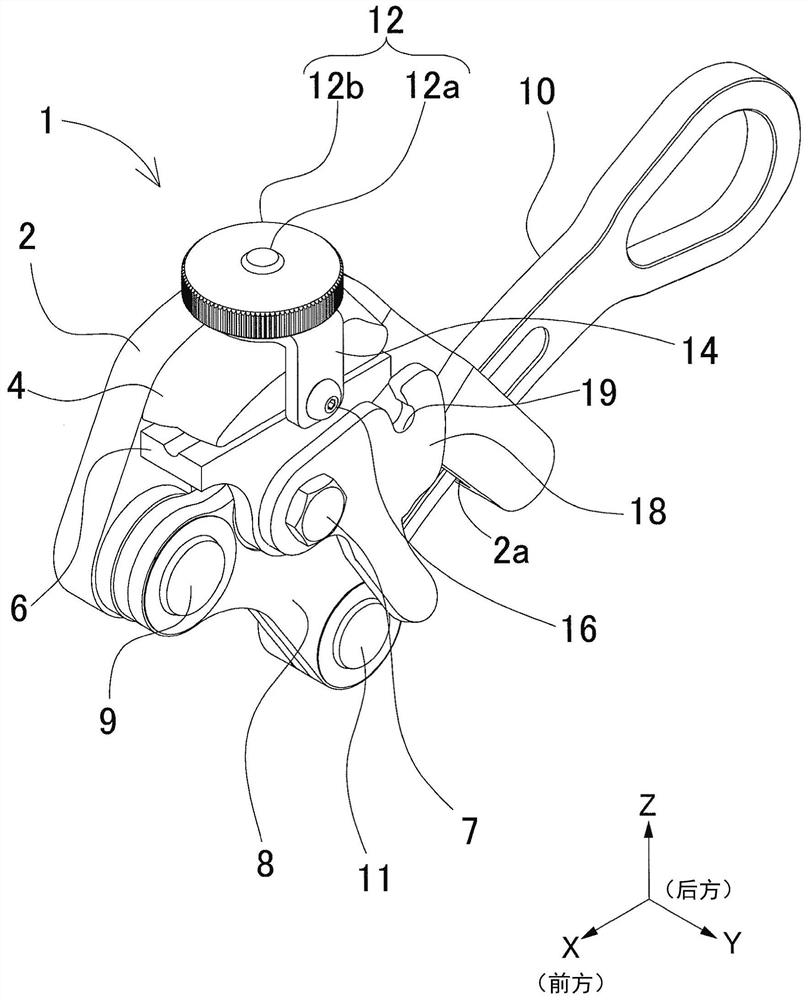

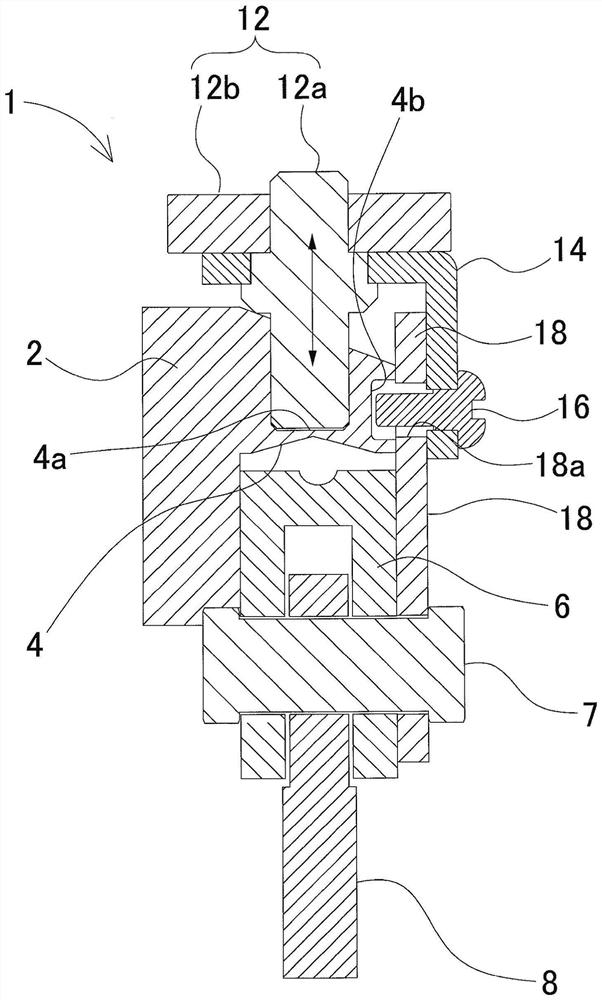

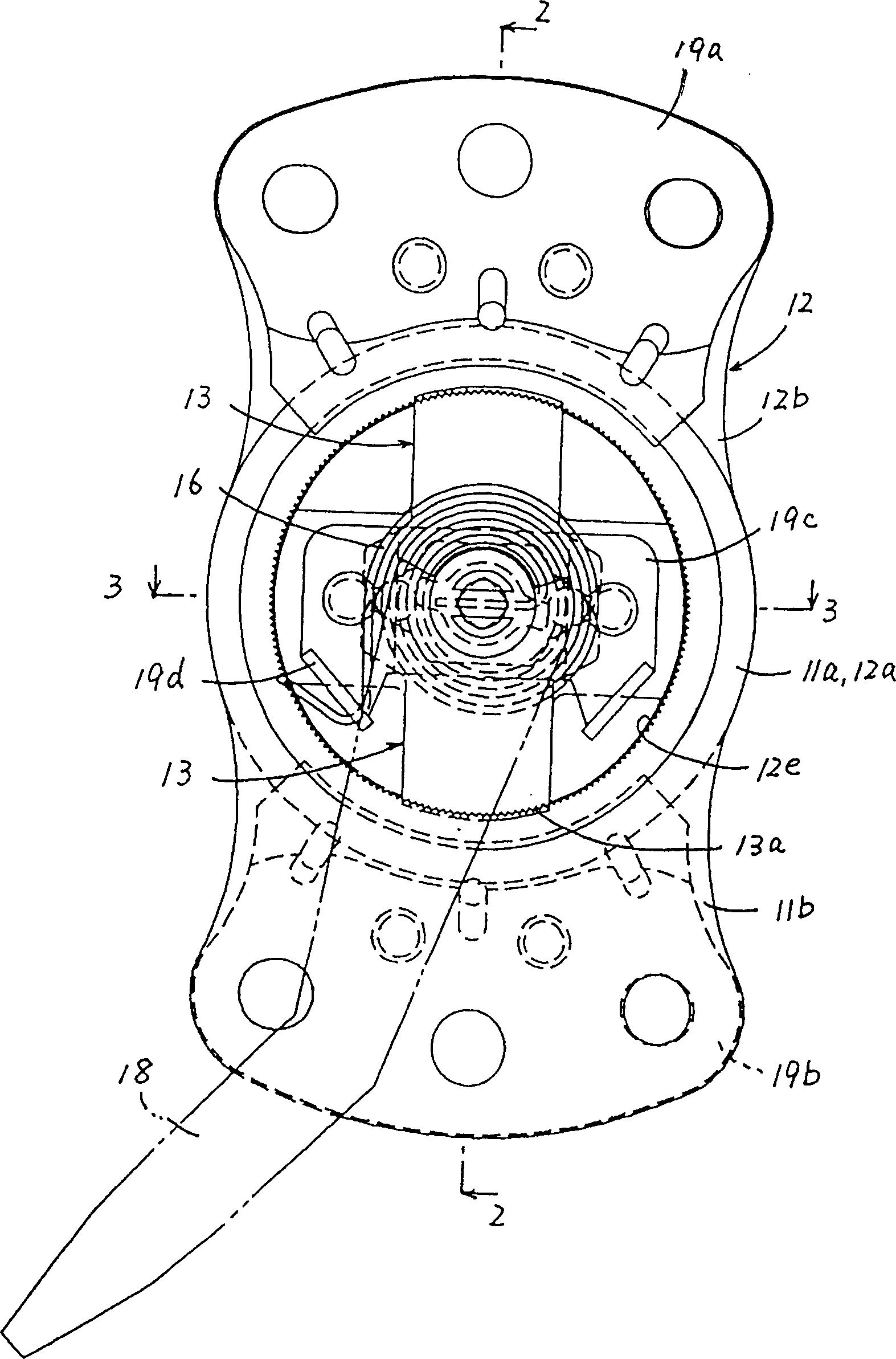

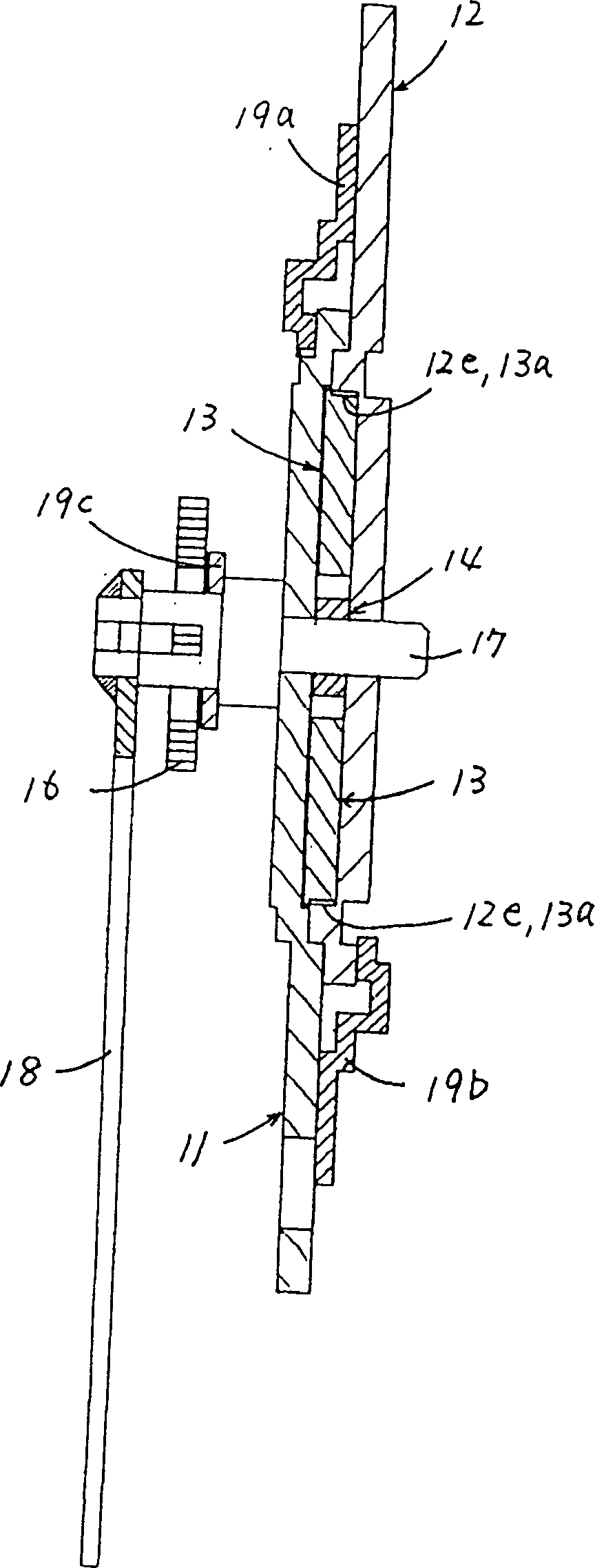

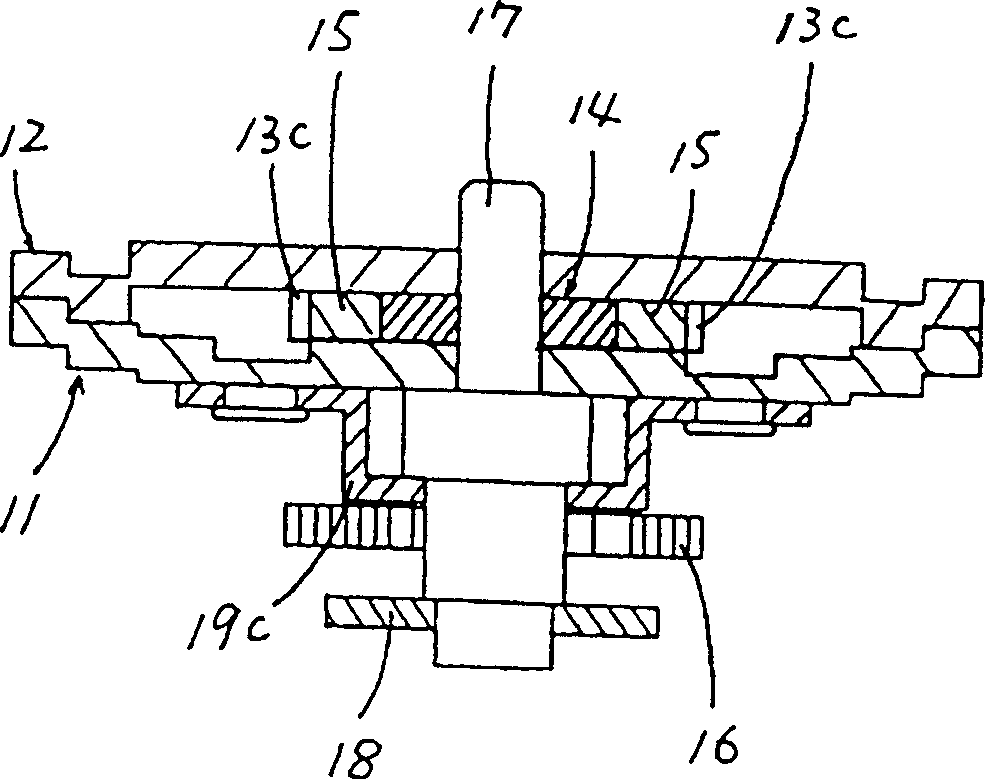

Provided is a wire gripper capable of performing locking and unlocking operations without lowering work efficiency regardless of the diameter of a linear body to be gripped. Above the main body (2) of the wire gripper (1), a fixed wire gripping portion (4) filled in one side surface of the electric wire is integrally arranged. The actuating part (8) is pivotally supported on the main body (2) in a freely rotatable manner. In addition, the movable clamping part (6) is rotatably supported on the actuating part (8) at a position opposite to the fixed clamping part (4). . The following displacement mechanism is arranged on the fixed clamping part (4), and the threaded part (12) constituted by the threaded shaft (12a) and the handle (12b) operates the displacement supporting part (14) to make it shift. An engagement pin (16) is integrally provided on the displacement support portion (14) so as to be movable in a displacement direction. A hook portion (18) capable of engaging with an engaging pin (16) is rotatably supported on the movable line gripping portion (6). By twisting the handle (12b) in the state where the hook (18) is engaged with the engaging pin (16), the movable wire retaining part (6) is pulled toward the fixed wire retaining part (4) to obtain a locked state .

Owner:NAGAKI SEIKI CO LTD

Backrest device

InactiveCN1117539CStrong lock stateGuaranteed meshingMovable seatsReclining chairsEngineeringUltimate tensile strength

An arc shape bore part on the back part of a slide pole is borne by an arc shape bearing part of a bearing plate to keep an engaging condition between the slide pole and a ratchet to regulate the rotation of the slide pole under load action to prevent lowering of engaging strength caused by the rotation of the slide pole to increase the engaging strength. It prevents lowering of the interlocking strength between a slide pole and a ratchet under a load action in a reclining device in which a slide pole assembled with a first connecting arm is slid to engage with a ratchet equipped on a second connecting arm to lock both arms.

Owner:ARACO CORP

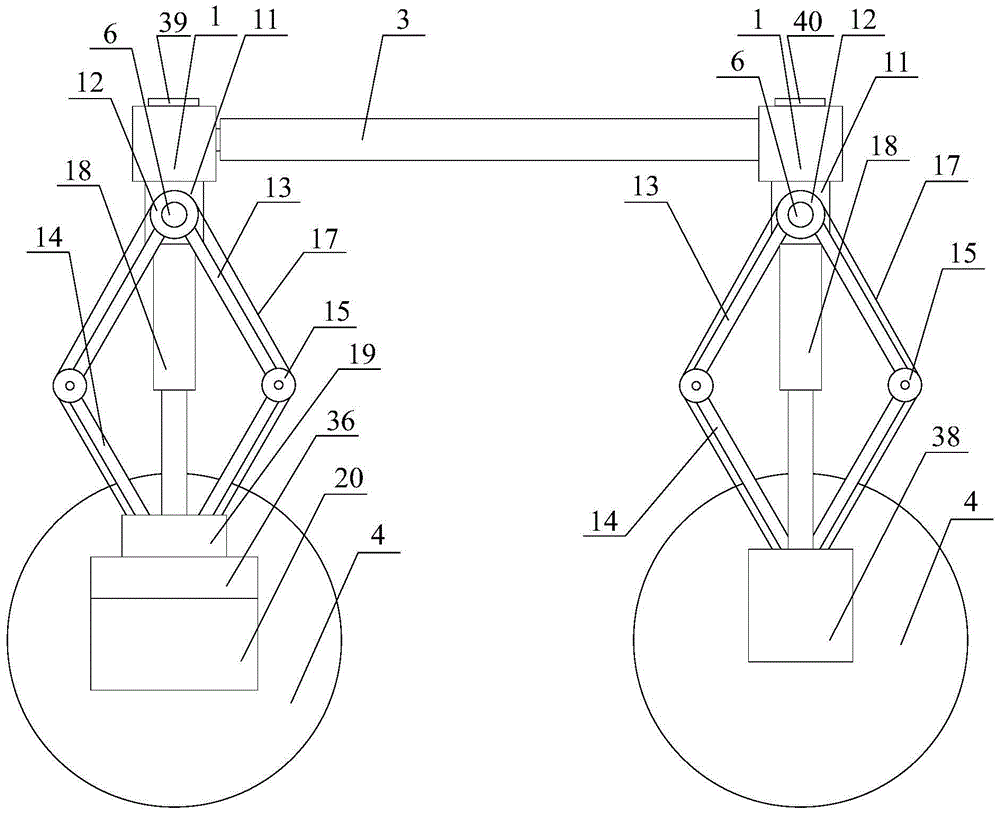

A self-balancing forest vehicle chassis

InactiveCN104742679BImprove support strengthImprove reliabilitySteering partsResilient suspensionsHorizontal transmissionTransmitted power

The invention provides an automotive chassis for a self-balance forest. The automotive chassis comprises a front transverse beam, a back transverse beam, a connecting beam, two horizontal transmission mechanisms, four lifting transmission mechanisms, two front driving mechanisms, two back driving mechanisms, a front inclination sensor, a back inclination sensor and a controller. The horizontal transmission mechanisms are used for transmitting power in the horizontal direction, the lifting transmission mechanisms are used for lifting adjustment and transmission, the front driving mechanisms are used for front wheel driving and steering, the back driving mechanisms are used for back wheel driving, the front inclination sensor and the back inclination sensor are used for detecting the automotive balance in real time, and the controller is used for controlling work of the lifting transmission mechanisms and the front driving mechanisms in real time. By means of the automotive chassis, the balance performance of an automotive body can be adjusted in real time; the automotive chassis is particularly suitable for the uneven ground in the forest, and has the better application prospect.

Owner:BEIJING FORESTRY UNIVERSITY

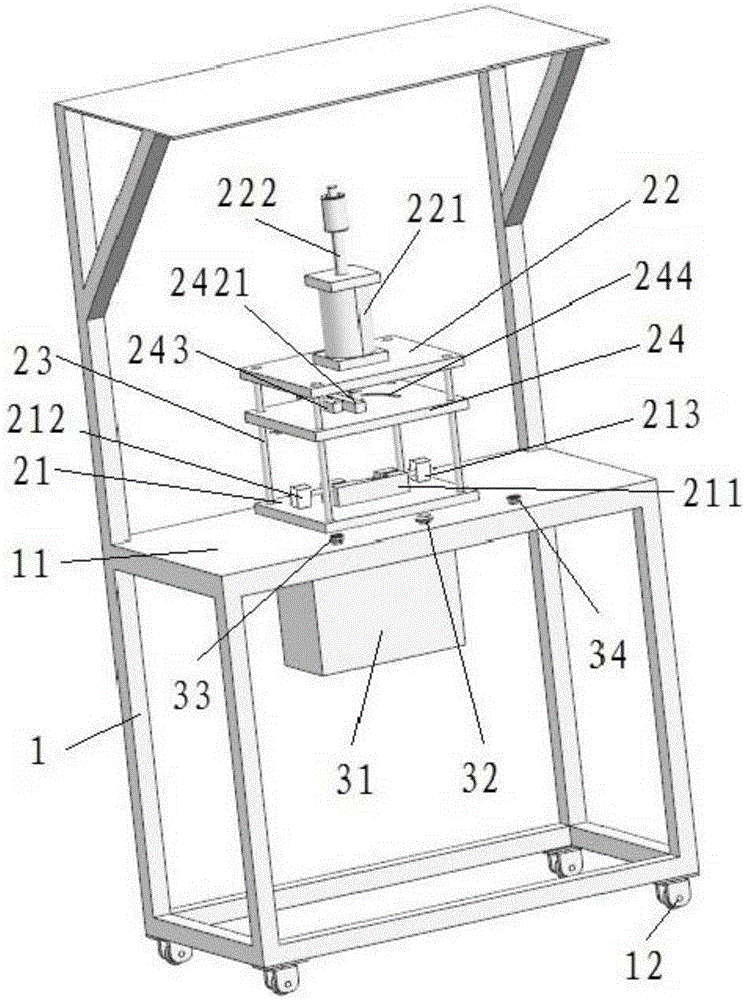

Shaft assembly pressing and rotating return device

ActiveCN104227377BSmooth rotationImprove versatilityMetal working apparatusMetal-working hand toolsGear wheelEngineering

The invention discloses a laminating, rotating and returning device of a shaft lever assembly for assembling a shaft lever and a shaft base of an automobile sun shield. The device comprises a rotary mechanism which is used for driving a lower carrier to rotate and return; the rotary mechanism comprises gears fixed on an upper carrier, racks driving the gears to rotate, and a second air cylinder fixed on a sliding plate and used for driving the racks to advance and retreat. Compared with the prior art, through adding the rotary mechanism, the internal stress of the shaft lever and the shaft base can be immediately eliminated after laminating, so that the resistance of the shaft lever assembly in using rotation angle range is uniform.

Owner:苏州巴士麦普科技有限公司

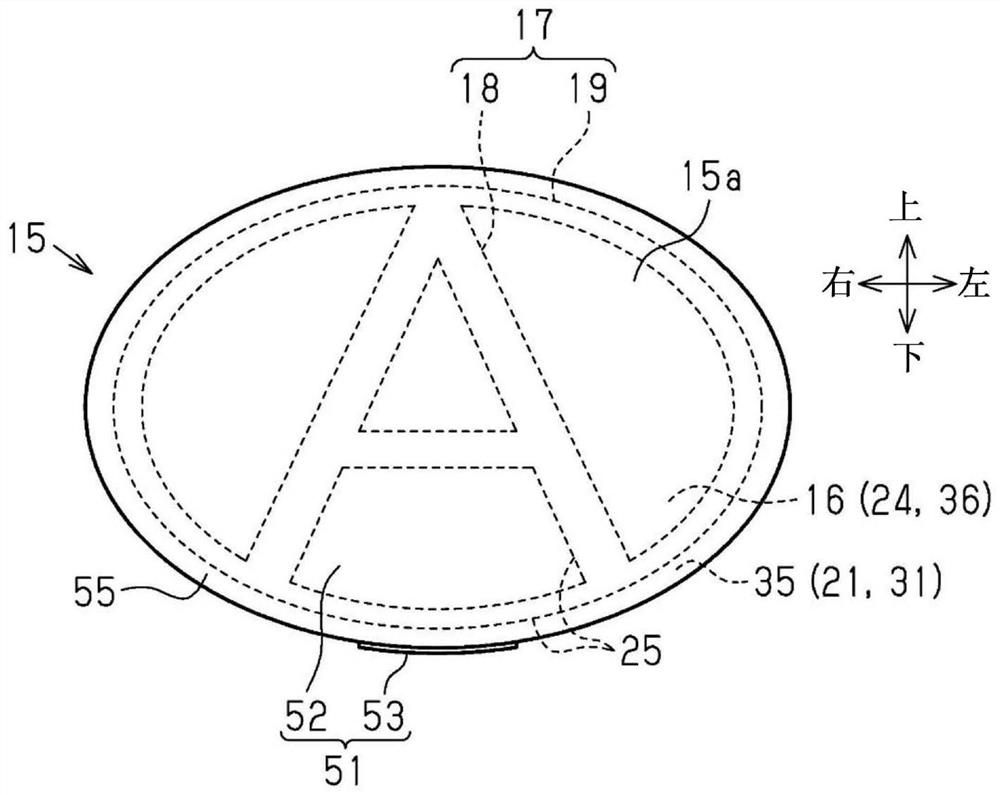

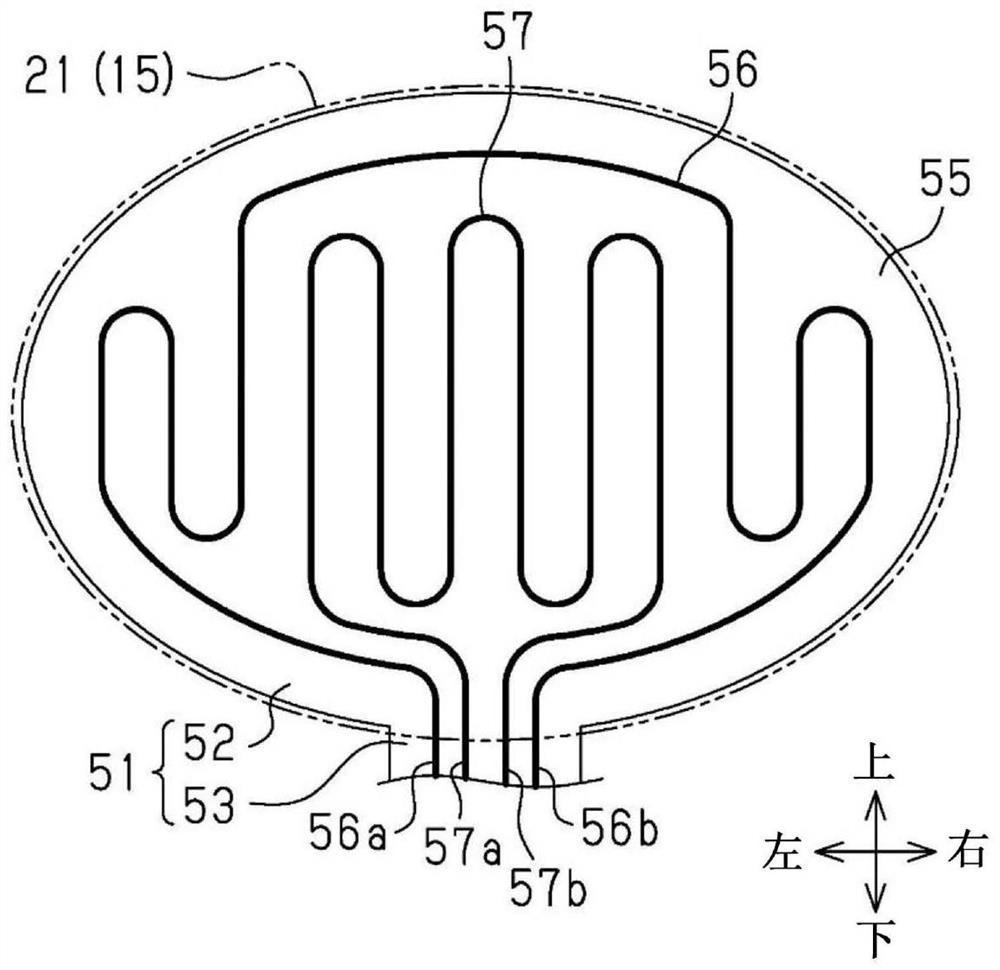

Vehicle exterior decoration

PendingCN114763105AMaintain good engagementStay engagedTransparent/reflecting heating arrangementsVehicle componentsWater stopEngineering

The invention relates to an exterior decoration for a vehicle, which can well maintain the connection state of a heater wire relative to a connector pin even if the surrounding temperature changes repeatedly. A vehicle logo (15) as an exterior decoration for a vehicle is provided with a decoration main body (21), a heating sheet (51), and a connector pin (32). The decorative main body part is provided with a base material (22) and a transparent resin layer (35), and the heating sheet is provided with a heating main body part (52) and an extending part (53). A portion of the protruding portion of the heater wire (57) is joined to the connector pin (32) inside the outer peripheral portion (22a) of the base material by a joining portion (58). In the outer peripheral portion, a window portion (30) for joining the heater wire (57) and the connector pin through a joining portion (58) is formed in a state in which the joining portion is exposed to the outside of the outer peripheral portion. The window portion is provided with a water stop portion (71) that restricts the entry of water into the joining portion. The water stop portion is formed by filling the window portion with a potting material.

Owner:TOYODA GOSEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com