Connector assembly

A connector assembly, electrical connection technology, applied in the direction of vehicle connectors, connections, parts of connecting devices, etc., can solve problems such as deterioration of sealing performance, inconsistency in performing tight contact of sealing parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

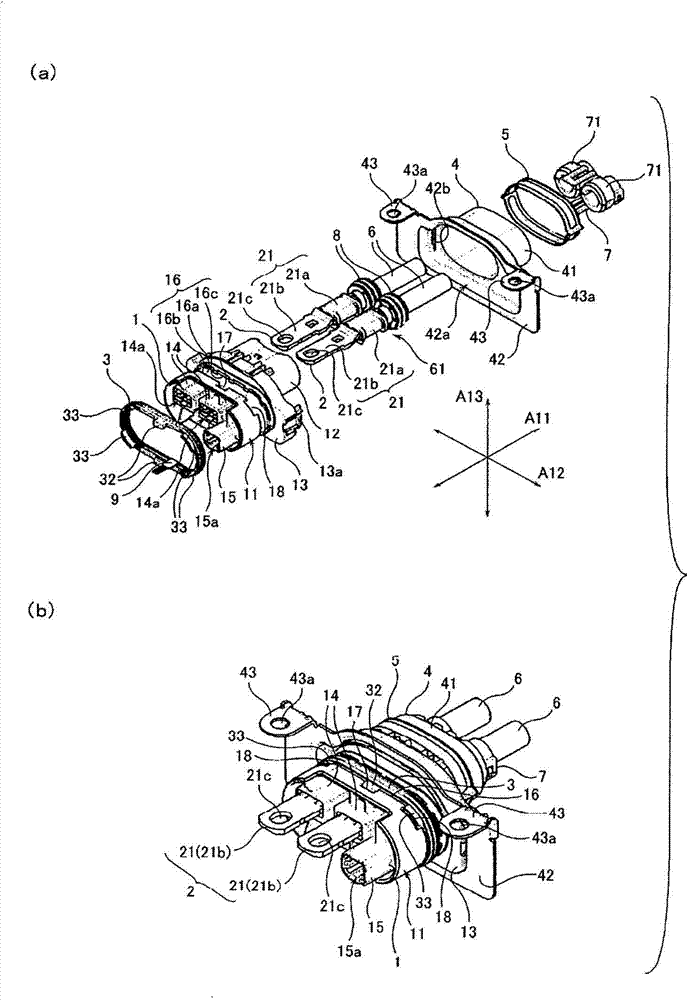

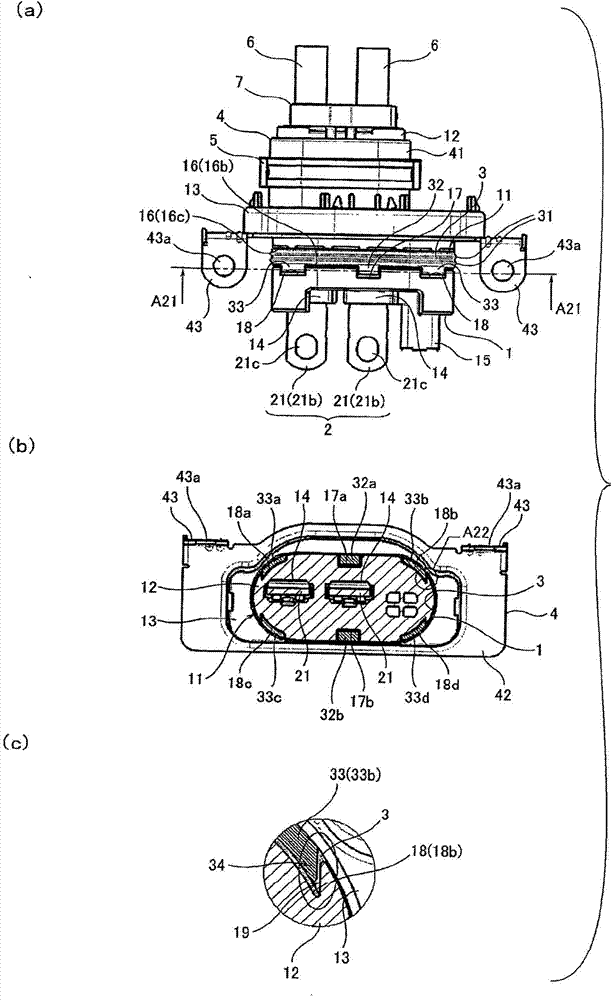

[0032] A connector assembly according to the present invention will be described below with reference to the accompanying drawings. The connector assembly according to the present invention is an interconnection member for electrically connecting (specifically, electrically connecting and separation). For example, a case can be assumed as a suitable example in which an inverter of a motor mounted on a vehicle such as an electric car driven using a motor, a hybrid car driven using both an engine and a motor is connected to a The electrical junction box (junction box) of the power supply unit that supplies power to the motor.

[0033] figure 1 (a) and 1(b) are diagrams showing the overall structure of a connector assembly according to an embodiment of the present invention, wherein, figure 1 (a) is a perspective view of a connector assembly disassembled into constituent parts, figure 1 (b) is shown assembled figure 1 A perspective view of the overall structure in the state ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com