Fastening structure for a large solar module, and solar module

A fixed structure, solar technology, applied in the fixed base/support of solar collectors, solar thermal energy, elongated structural members for load-bearing, etc., can solve the problem of no solar module support structure, high failure rate, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

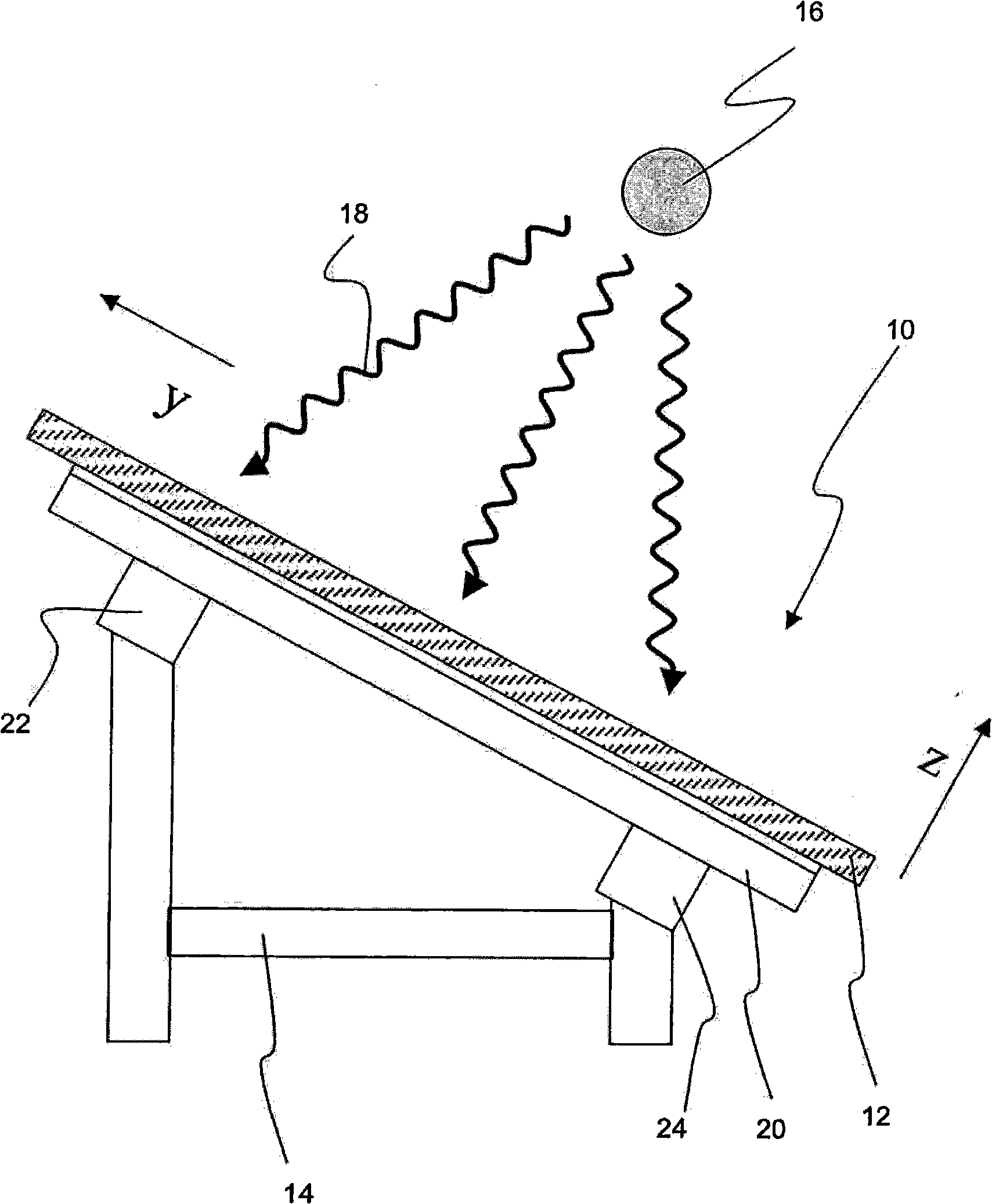

[0096] figure 1 An arrangement 10 is illustrated for a solar module typically used, for example, in a photovoltaic solar power plant. It can be seen that the solar module 12 is disposed on the base 14 . The solar module 14 is irradiated with UV rays 18 by the sun 16 . The solar module 12 converts UV radiation photoelectrically into electrical current as is known per se. The invention basically relates to a fastening structure for a solar module 12 .

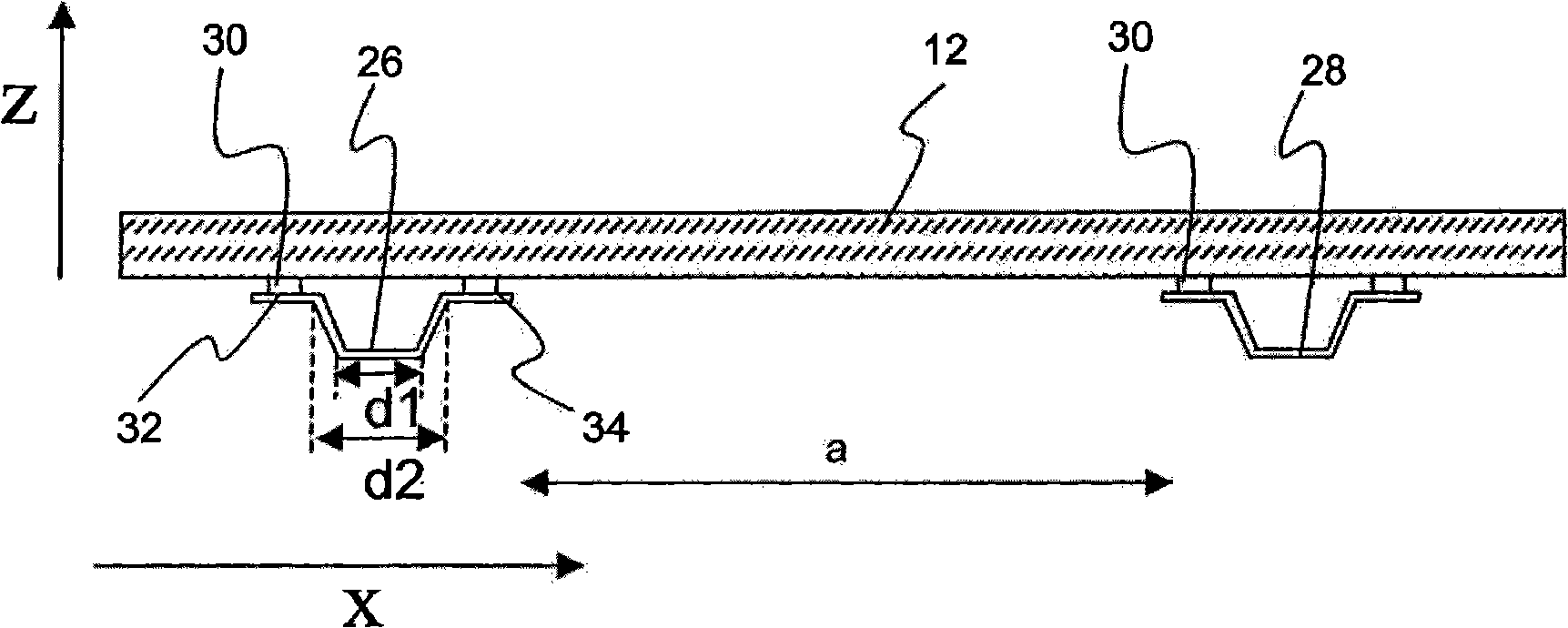

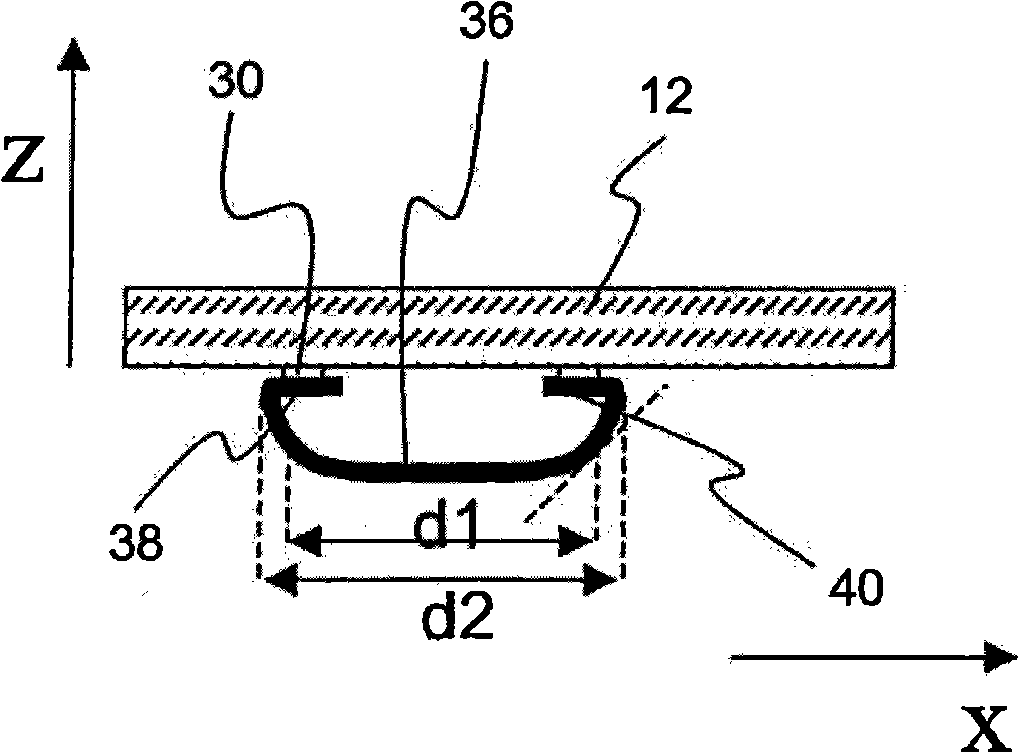

[0097] The solar module 12 is constructed without a frame and is relatively large, for example having dimensions of 2.6m x 2.2m. Such large solar modules must be supported on their rear sides. To this end, the longitudinal profile members 20 are fixed to the rear side of the solar module 12 at regular distances relative to each other and extend substantially parallel to each other in the Y direction. In an X direction orthogonal to the plane of the figure, transverse brackets 22 , 24 extend and are provided for fitting the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com