A kind of electronic encapsulation material and preparation method thereof of rapid curing at room temperature

An electronic packaging material, fast curing technology, used in non-polymer adhesive additives, adhesive types, polyether adhesives, etc., to achieve high adhesion, increased service life, and easy sizing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

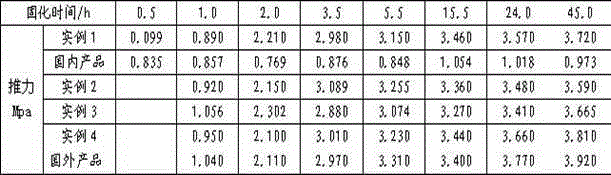

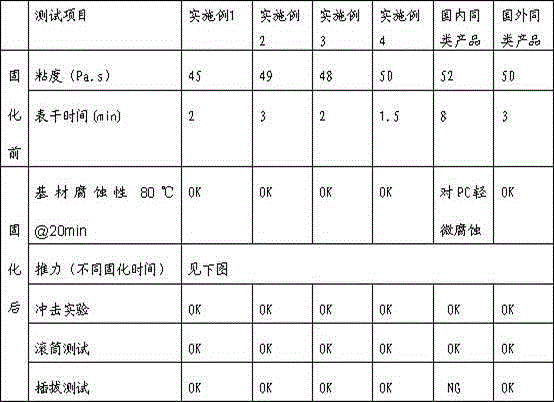

Examples

Embodiment 1

[0022] 30 parts of silane-terminated polyether S303H, 30 parts of silane-terminated polyurethane 1050MM, 5 parts of diisononyl phthalate, 4 parts of Sylophobic702, 1 part of bis(2,2,6,6-tetramethyl-4 -piperidinyl) sebacate, 1 part of 2-(2'-hydroxy-3'5'-di-tert-butyl)-5-chloro-benzotriazole was added to the stirring tank in turn, stirred and dispersed for 60 minutes and Vacuum, the vacuum degree is not less than -0.098MPa, then add 1 part of vinyltrimethoxysilane into the stirred tank and mix for 10 minutes under nitrogen protection, 1 part of N-β-aminoethyl-γ-aminopropyltrimethoxy Add silane into the stirred tank and mix for 10 minutes under nitrogen protection. Finally, add 0.5 parts of U-220H into the stirred tank and mix for 10 minutes under vacuum. The vacuum degree is not less than -0.098MPa, N 2 Just seal the package.

Embodiment 2

[0024] 50 parts of silane-terminated polyether SAT400, 50 parts of silane-terminated polyurethane 1050MM, 20 parts of diisodecyl phthalate, 8 parts of Sylophobic702, 2 parts of bis(2,2,6,6-tetramethyl-4 -piperidinyl) sebacate, 2 parts of 2-(2'-hydroxy-3'5'-di-tert-butyl)-5-chloro-benzotriazole were added to the stirring tank in turn, stirred and dispersed for 60 minutes and Vacuum, the vacuum degree is not less than -0.098MPa, then add 3 parts of vinyltrimethoxysilane into the stirred tank and mix for 10 minutes under nitrogen protection, 4 parts of N-β-aminoethyl-γ-aminopropyltrimethoxy Add silane into the stirred tank and mix for 10 minutes under nitrogen protection. Finally, add 2 parts of stannous octoate into the stirred tank and mix for 10 minutes under vacuum. The vacuum degree is not less than -0.098MPa, N 2 Just seal the package.

Embodiment 3

[0026] 40 parts of silane-terminated polyether MAX602, 40 parts of silane-terminated polyurethane 1050MM, 12 parts of SAX-015, 6 parts of Sylophobic702, 1.5 parts of bis(2,2,6,6-tetramethyl-4-piperidinyl) Sebacate, 1.5 parts of 2-(2'-hydroxy-3'5'-di-tert-butyl)-5-chloro-benzotriazole were sequentially added into the stirring tank, stirred and dispersed for 60 minutes and vacuumed, the vacuum degree Not less than -0.098MPa, then add 2 parts of methyltrimethoxysilane into the stirring tank and mix for 10 minutes under nitrogen protection, 1.5 parts of N-β-aminoethyl-γ-aminopropyltrimethoxysilane and 1 part of γ - Add glycidyloxypropyltrimethoxysilane into the stirring tank and mix for 10 minutes under nitrogen protection. Finally, add 1.2 parts of U-220H into the stirring tank and mix for 10 minutes under vacuum. The vacuum degree is not less than -0.098MPa, N 2 Just seal the package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com