Nuclear power steam turbine bearing off-line turnover device

A technology of turning over device and steam turbine, applied in the direction of workbench, manufacturing tools, etc., can solve problems such as affecting the maintenance of other equipment, damage to bearing mating surfaces, complicated working procedures, etc., to eliminate risks and safety hazards, eliminate equipment sealing surface damage, Avoid the effects of frequent use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The off-line flipping device for a nuclear power steam turbine bearing provided by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

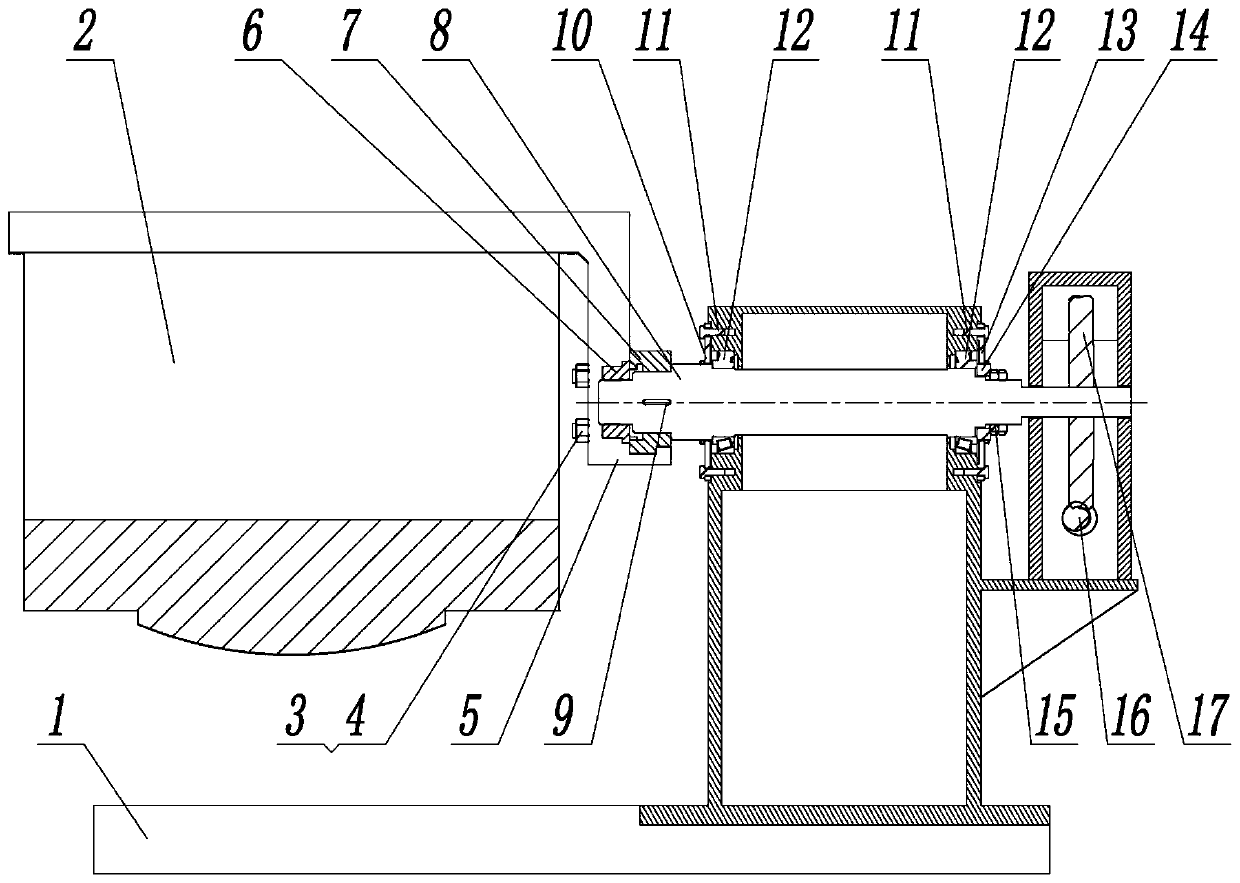

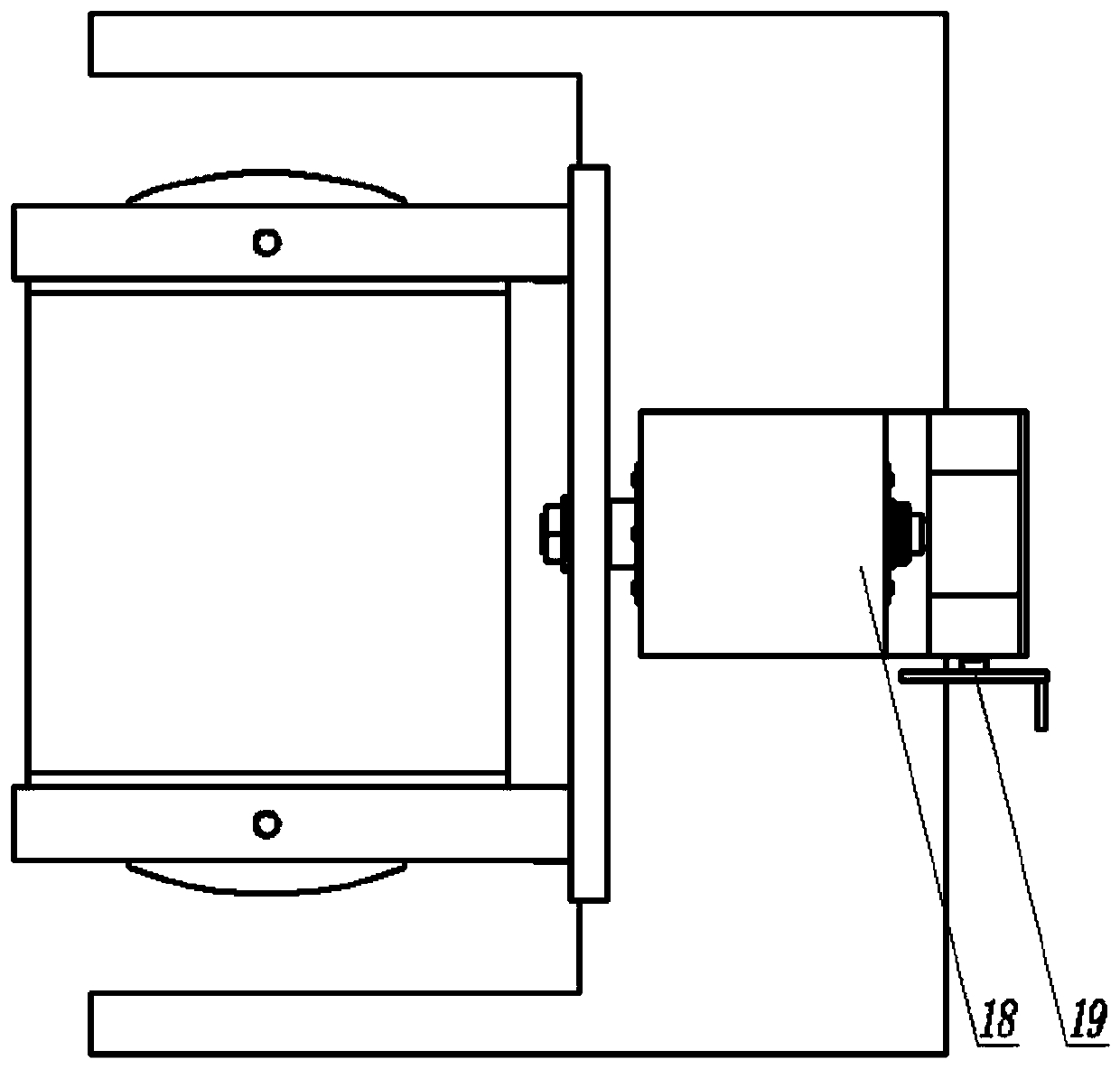

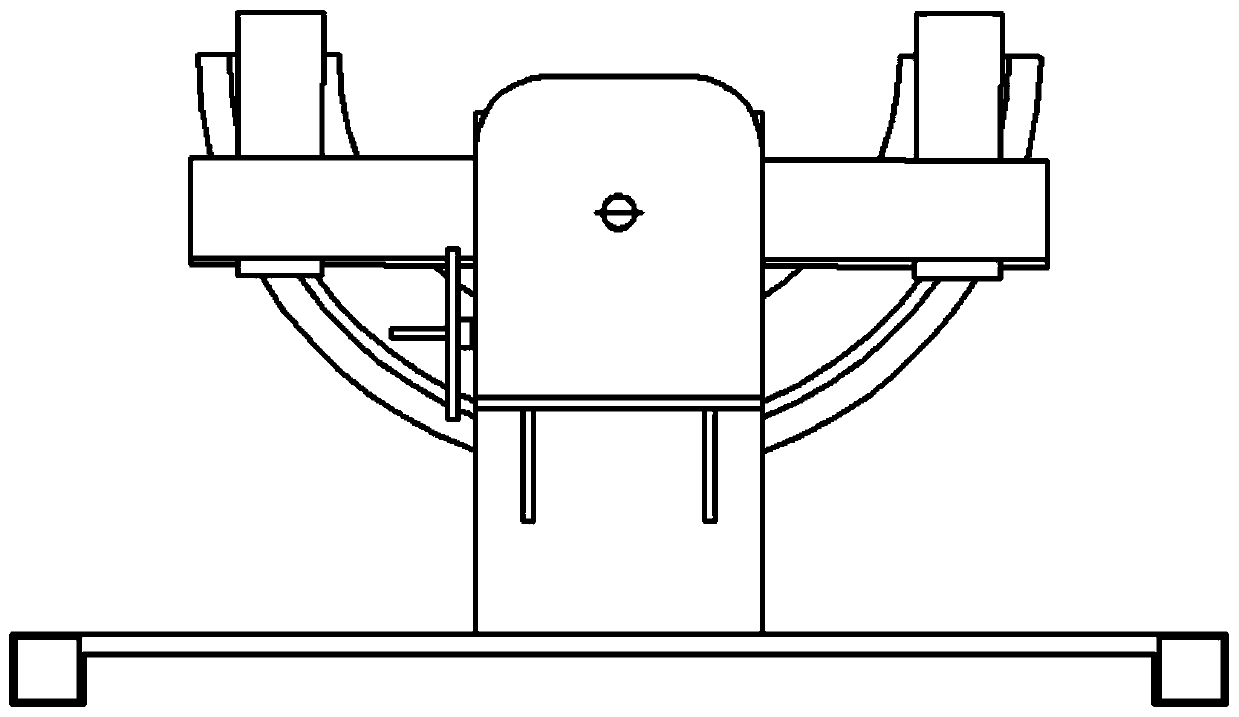

[0026] Such as Figure 1-4 As shown, a kind of nuclear power steam turbine bearing off-line turning device provided by the present invention includes a bracket 1, a support arm fixing nut 3, a support arm fixing bolt 4, a sliding support arm 5, a front lock nut 6, a support arm slide rail 7, and a transmission Main shaft 8, key 9, front bearing gland 10, gland bolt 11, supporting bearing 12, rear bearing gland 13, spindle positioning ring 14, lock shaft nut 15, worm 16, turbine 17, bearing chamber 18, hand wheel 19 ;

[0027] Bracket 1 is used to support the shafting and transmission parts. Its upper end is welded with a bearing chamber 18. The bearing chamber 18 has a through hole through which the transmission spindle 8 passes. The front and rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com