Patents

Literature

49 results about "Spindle positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

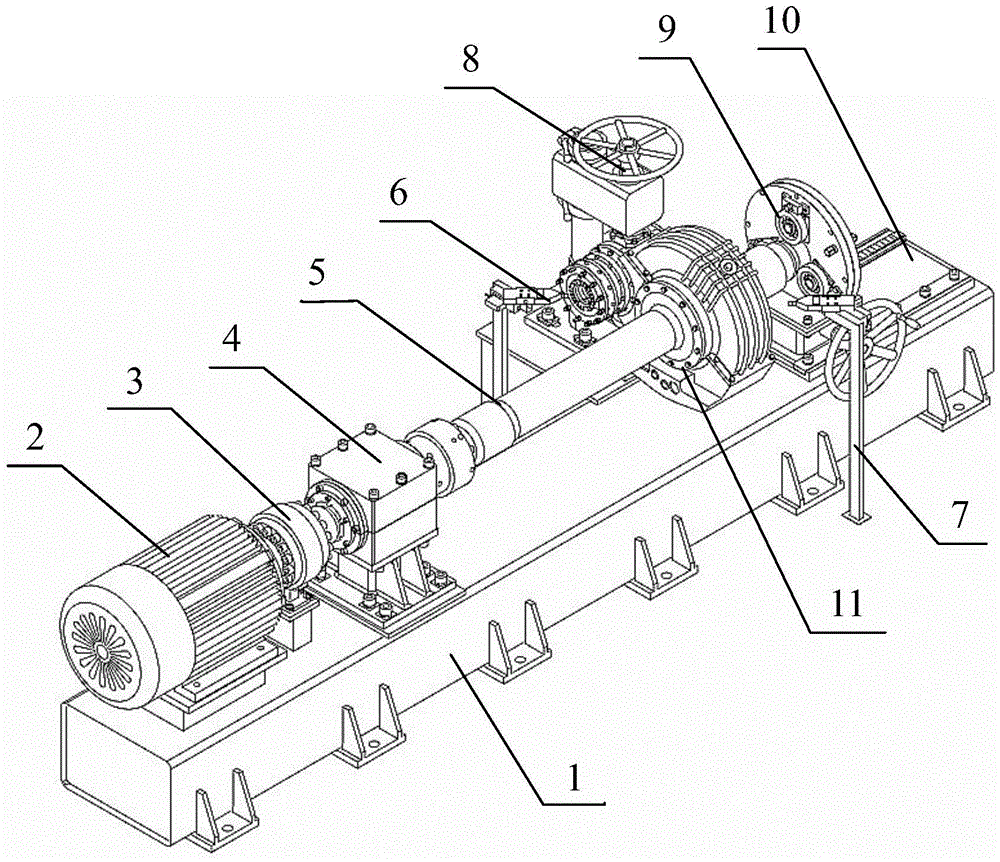

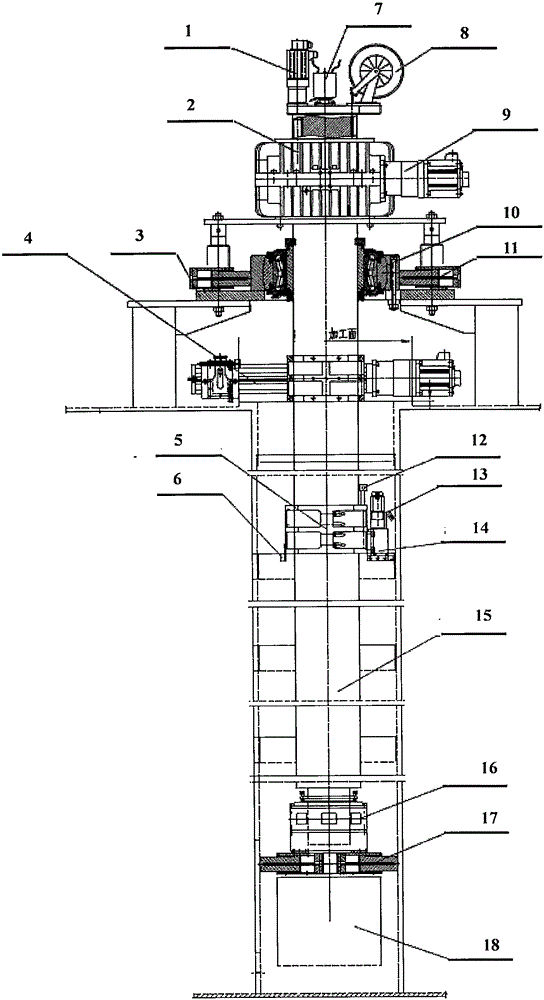

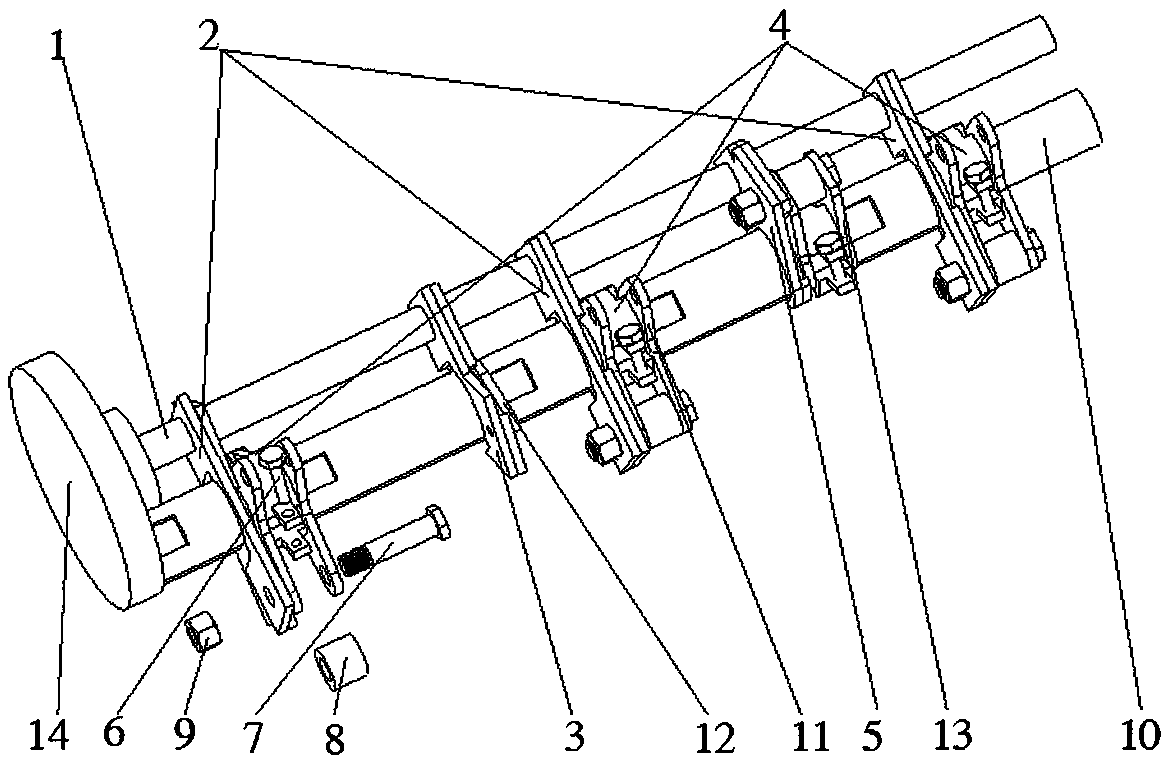

High-speed spindle on-line automatic balancing experiment system

ActiveCN102095555AMeet the needs of high-speed dynamic balanceHigh balance precisionStatic/dynamic balance measurementElectricityAudio power amplifier

The invention discloses a high-speed spindle on-line automatic balancing experiment system. A spindle is arranged on a spindle positioning seat; a magnetic grid encoder is arranged on a bearing on the inner side of the spindle; displacement sensors are arranged the outer sides of two ends of the spindle; on-line dynamic balance devices are arranged at two ends of the spindle; balance water ponds in the on-line dynamic balance devices are arranged on a spindle rotor; a water gun is fixed on an experiment shock absorption platform; a spindle unbalance simulation devices is fixed on end faces of two sides of the spindle rotor through threads; the displacement sensors are connected with a high-speed synchronous data acquisition instrument through a charge amplifier; a photoelectric sensor is connected with the high-speed synchronous data acquisition instrument; and the magnetic grid encoder is connected with a high-speed synchronous counting card through a 1Vpp signal conditioning module. An industrial control computer is connected with an on-line automatic balancing device controller through a universal serial bus. Through the high-speed spindle on-line automatic balancing experiment system, high-speed spindle on-line automatic balancing experiment can be realized, and the system has the characteristics of high speed, accuracy and integrated level and the like.

Owner:XI AN JIAOTONG UNIV

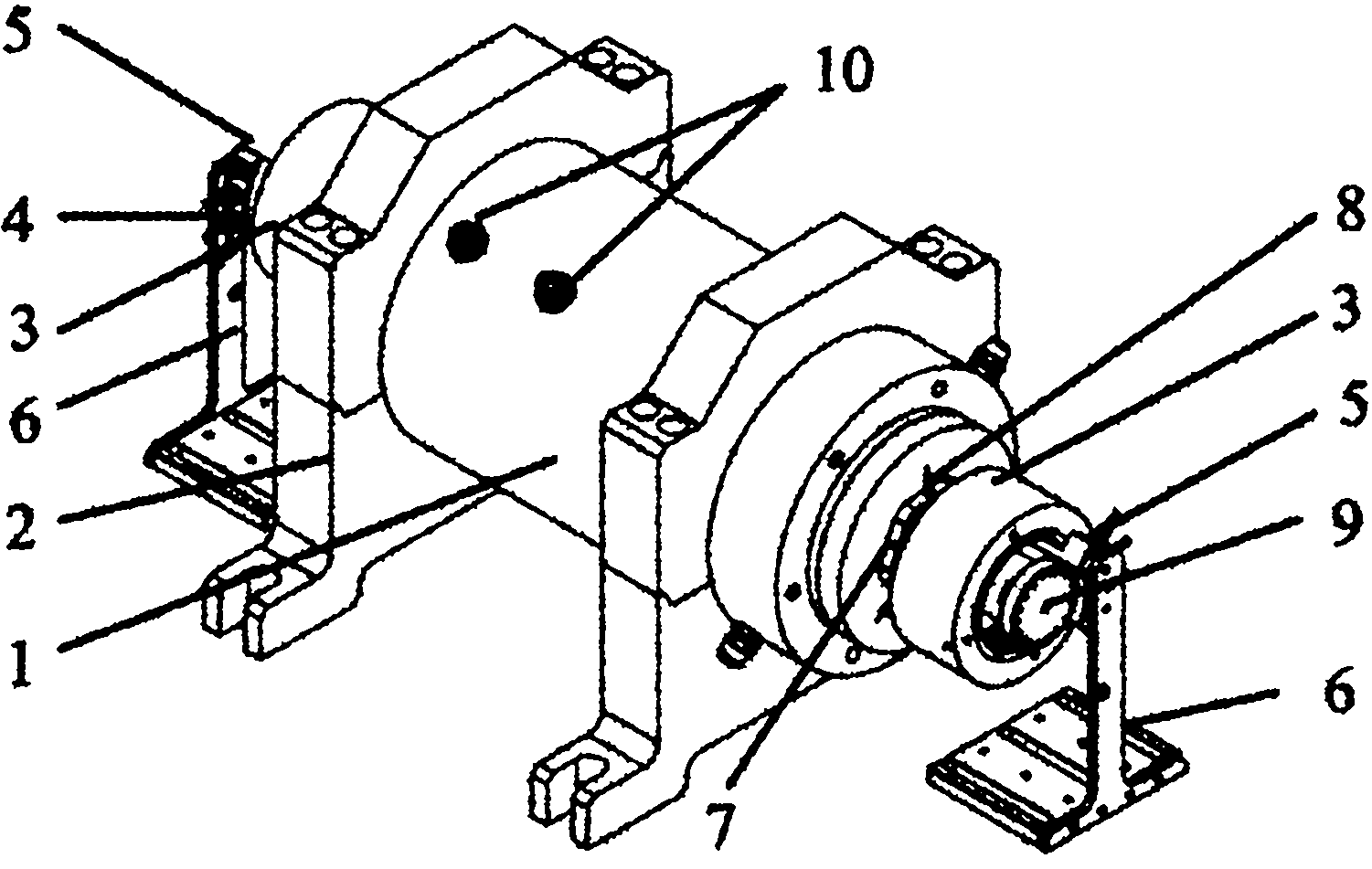

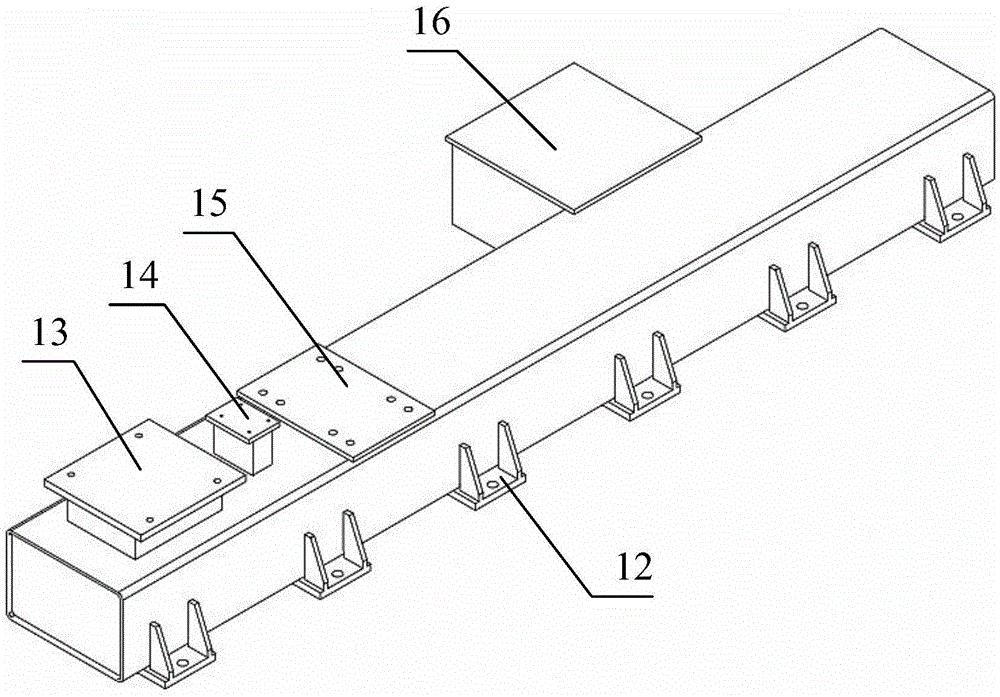

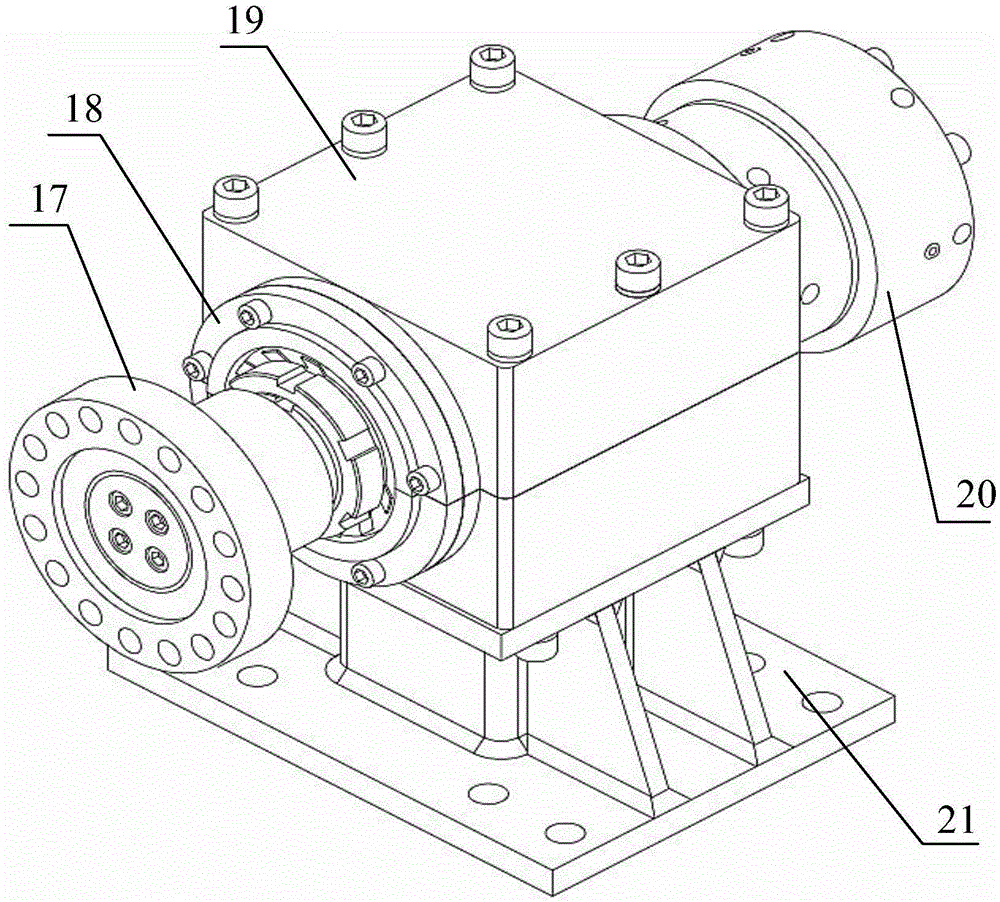

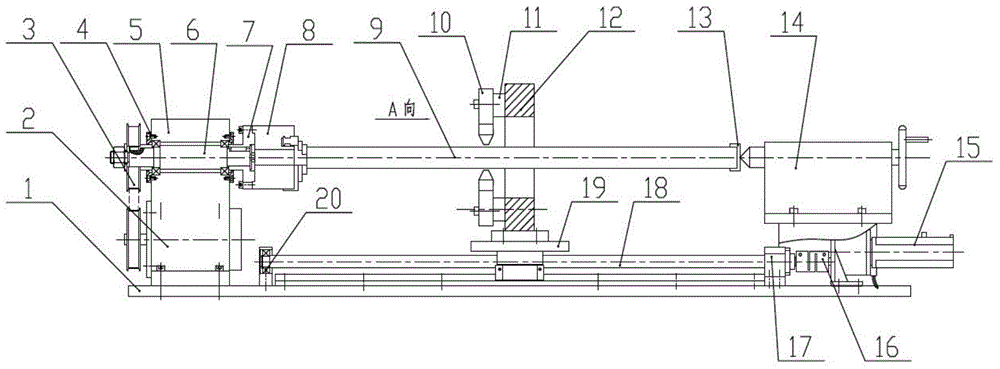

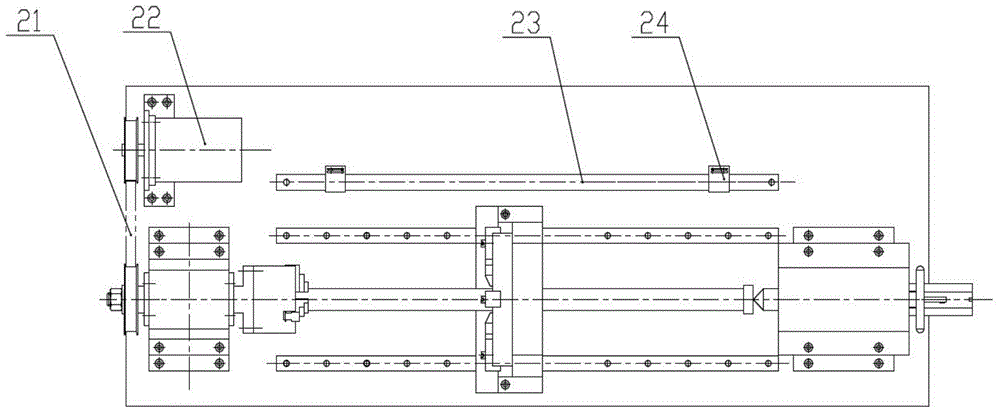

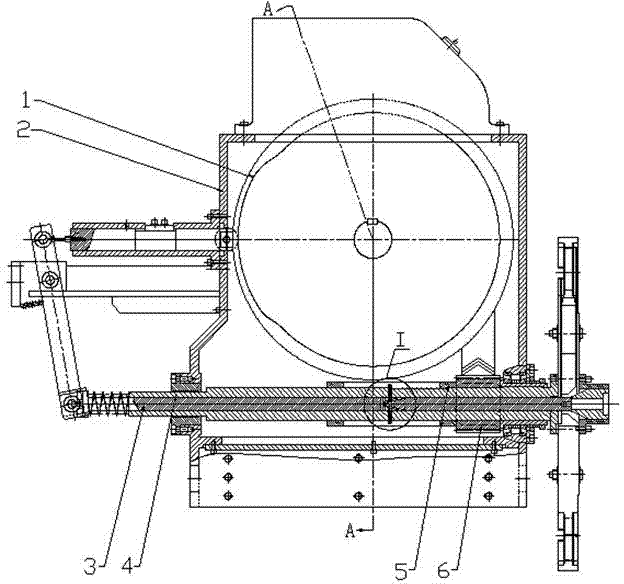

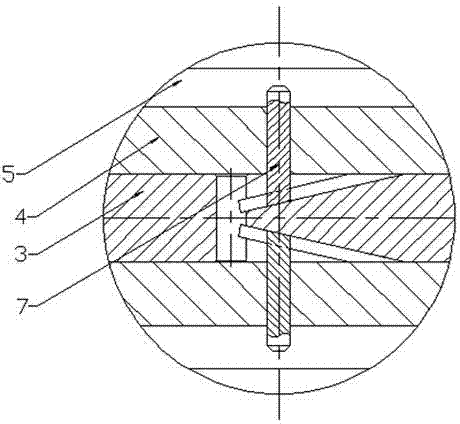

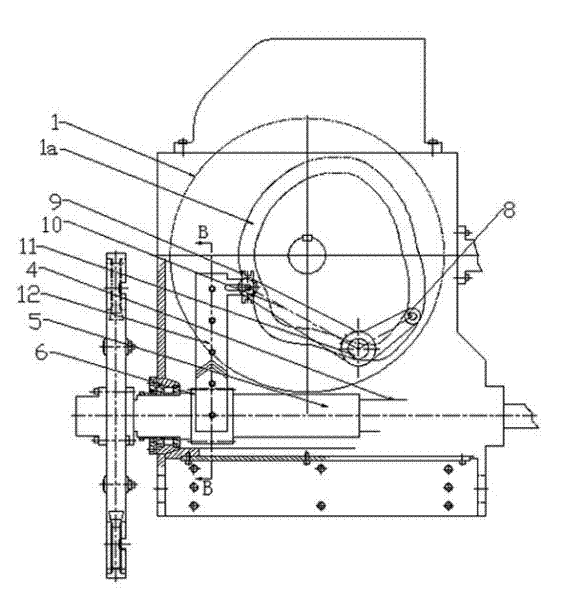

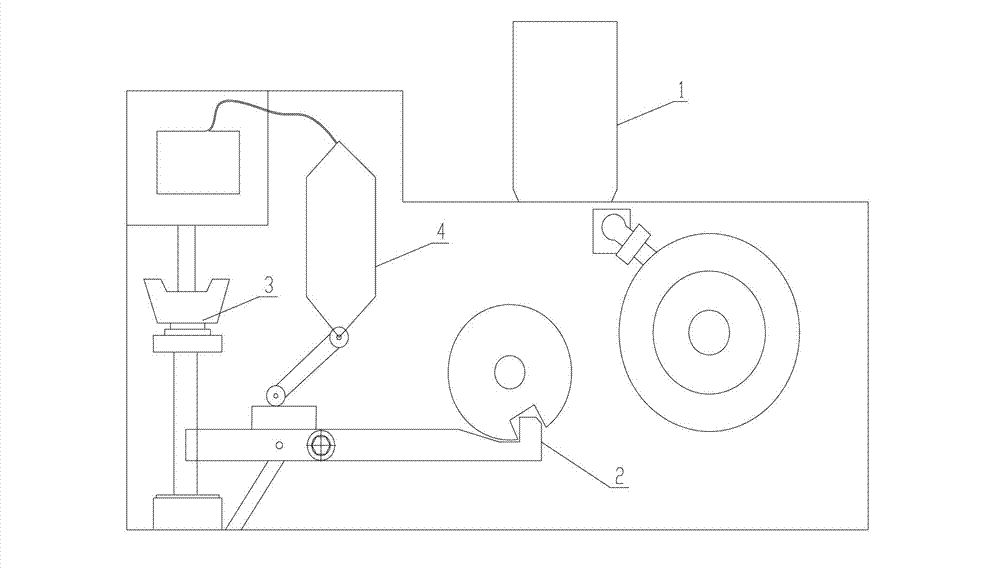

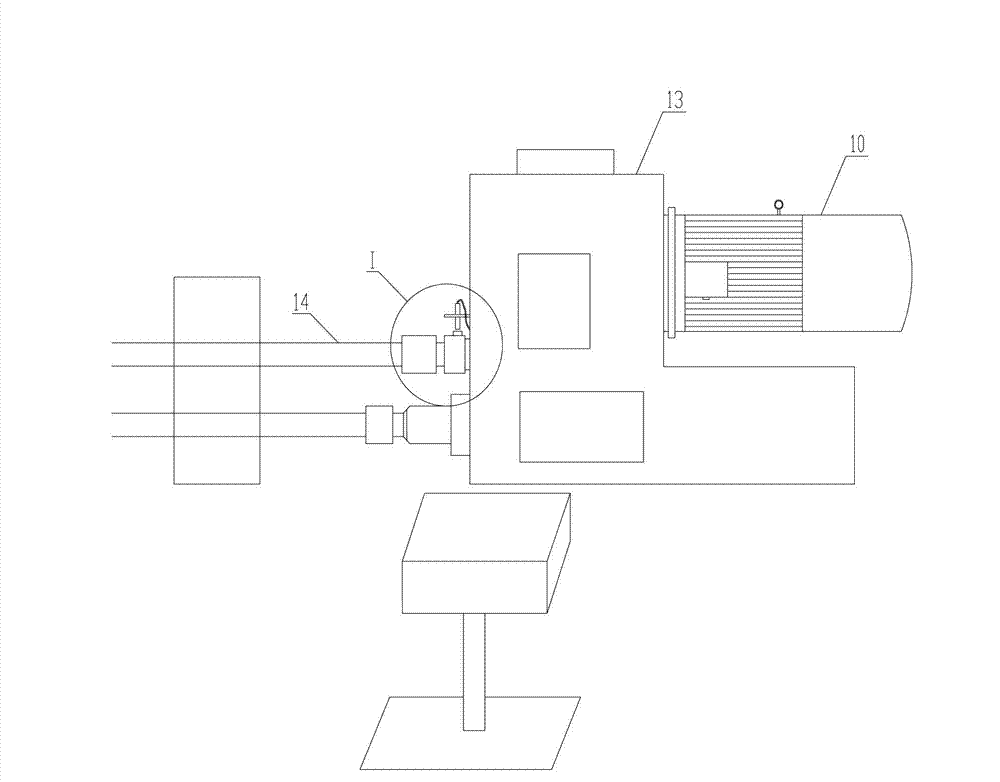

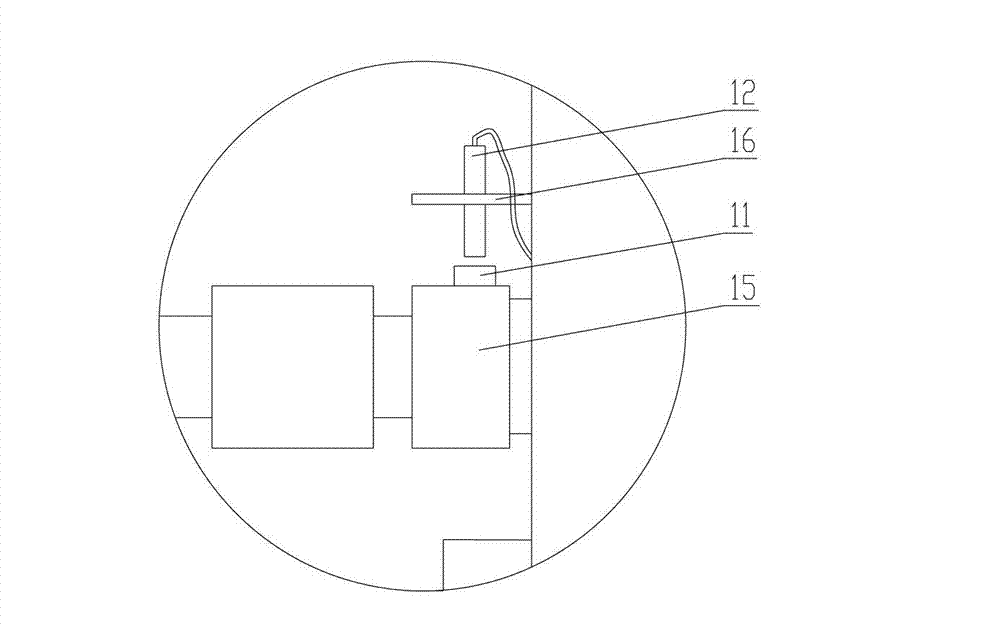

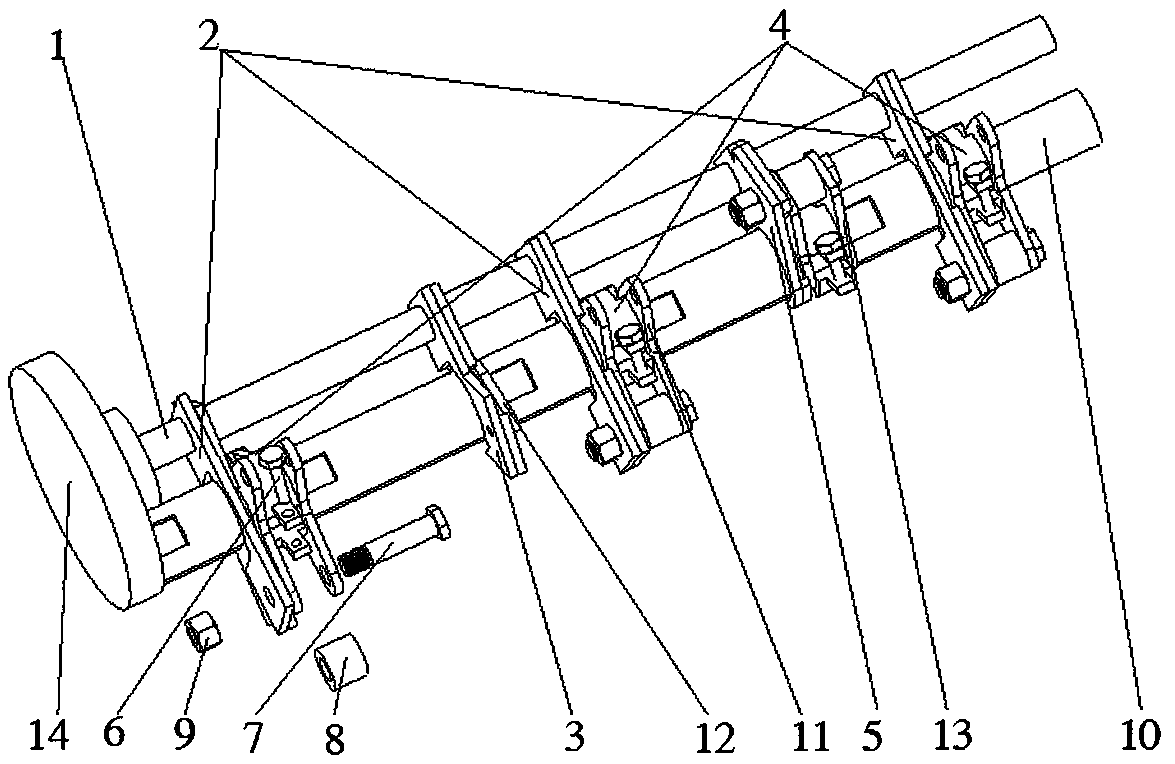

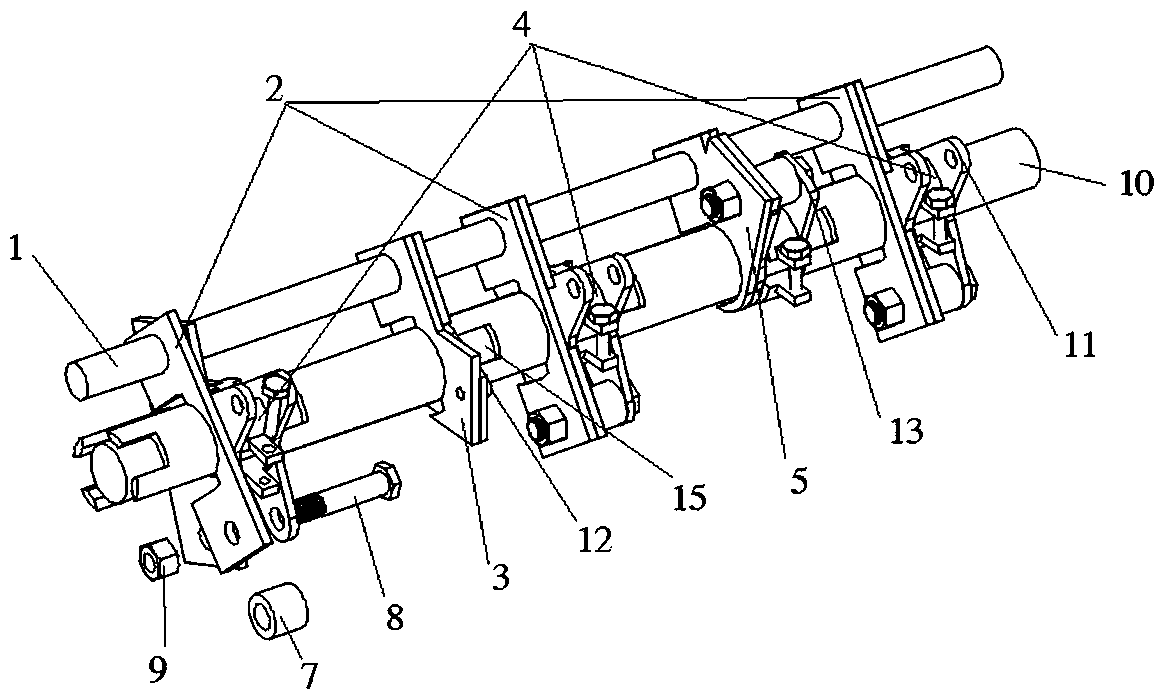

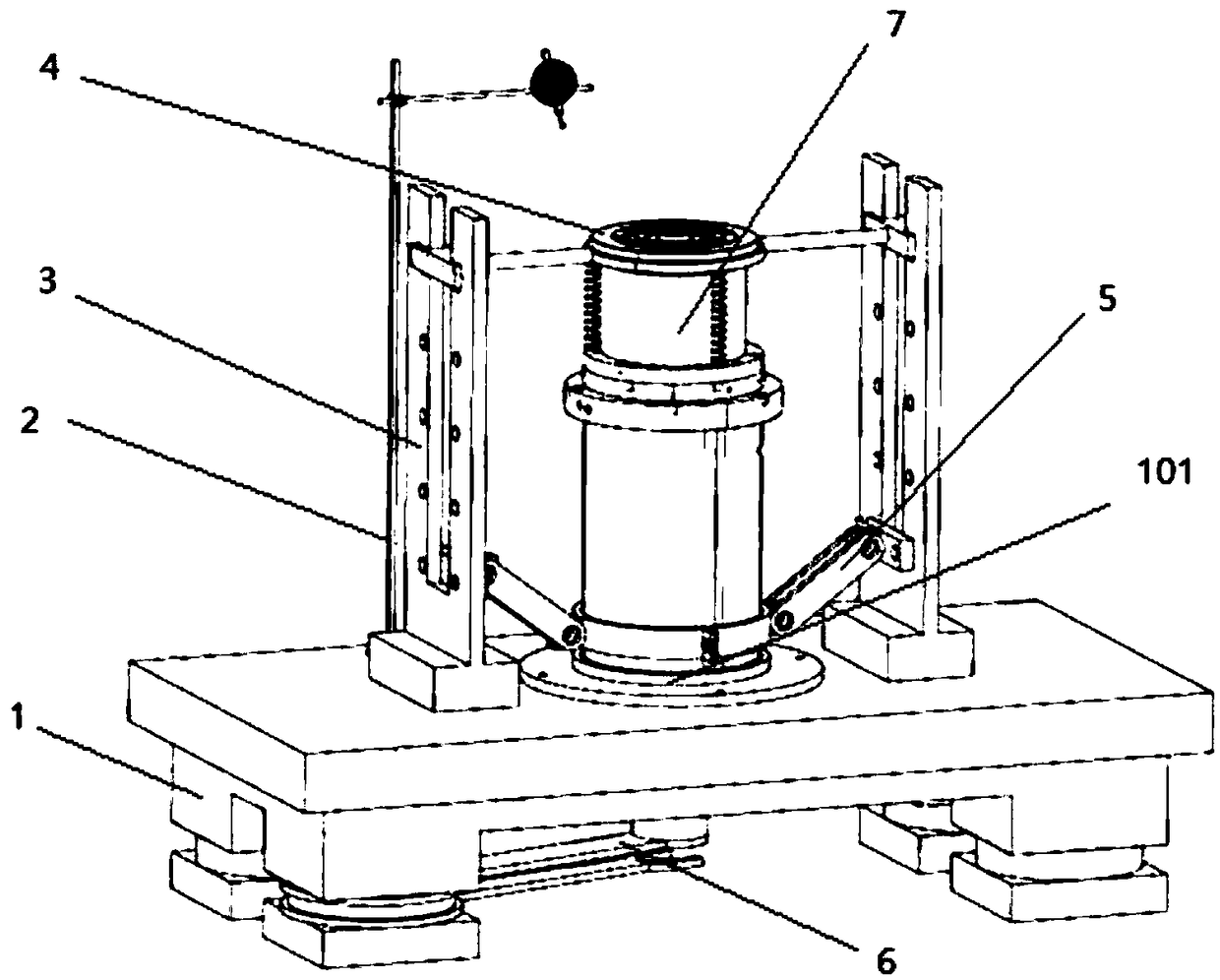

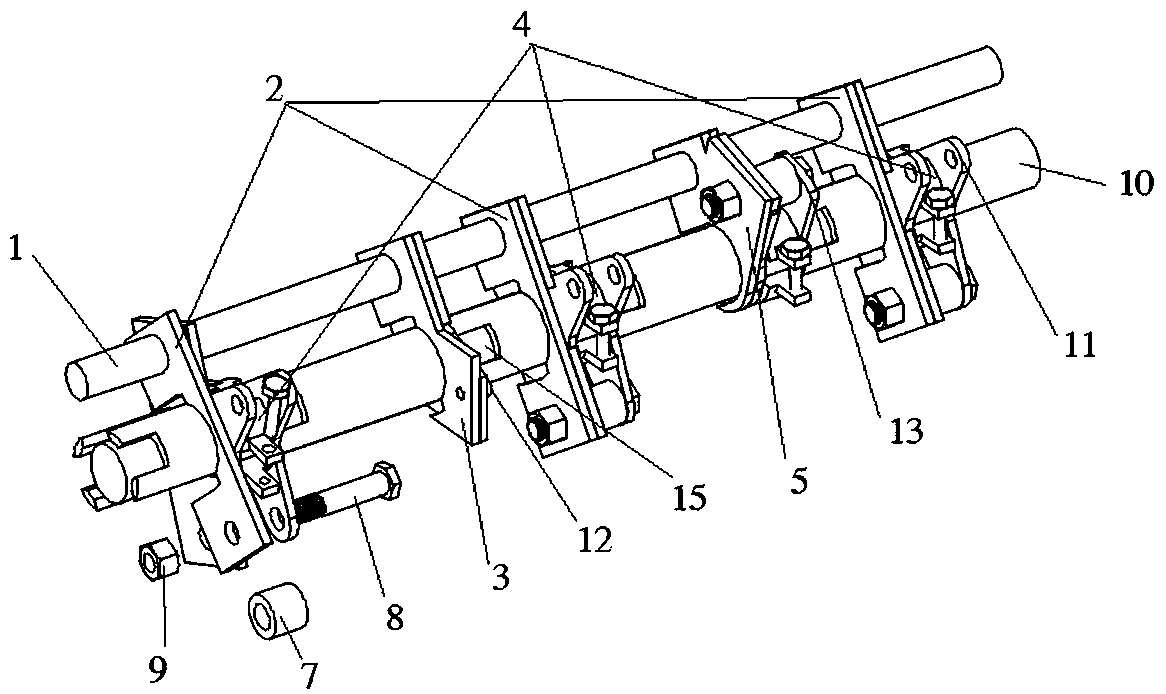

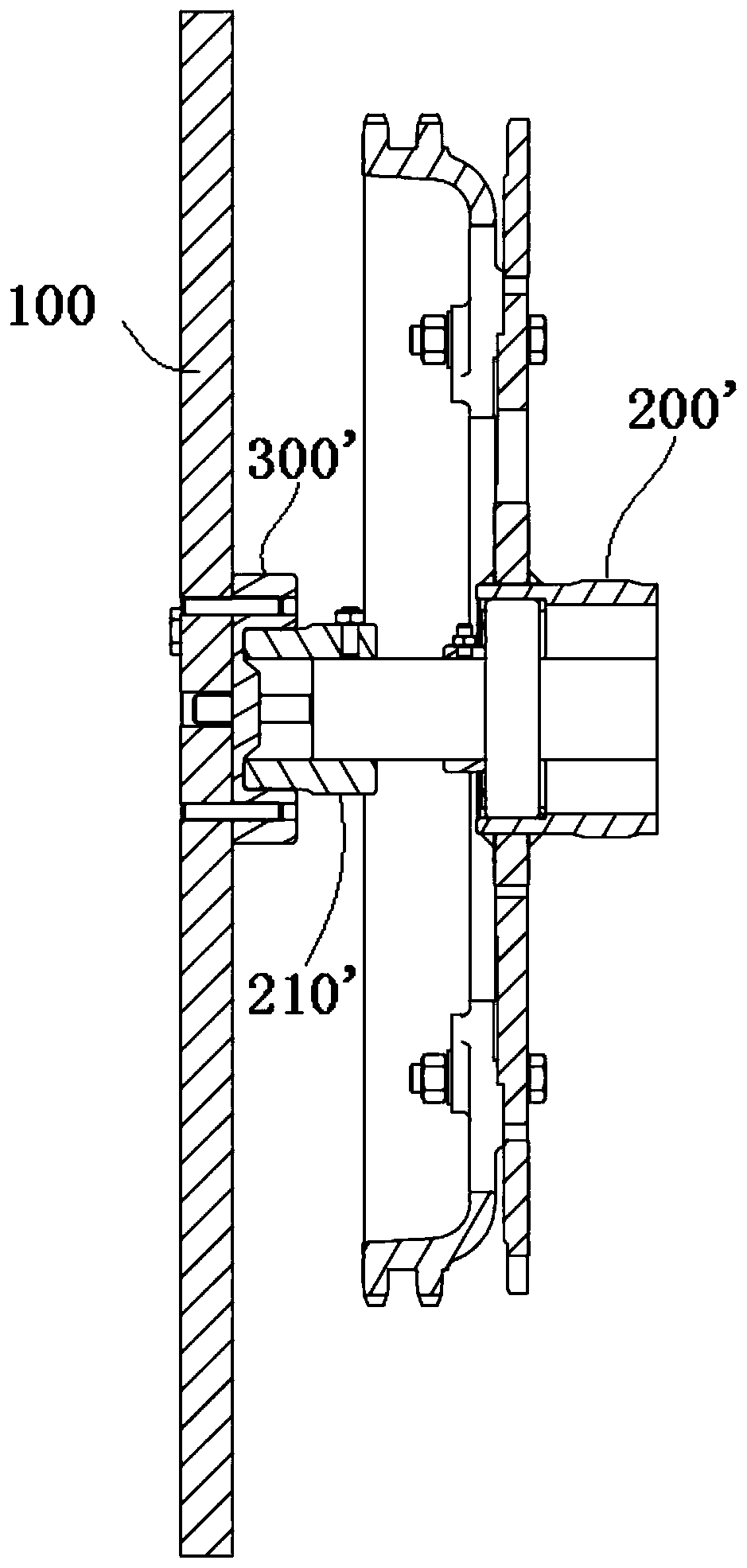

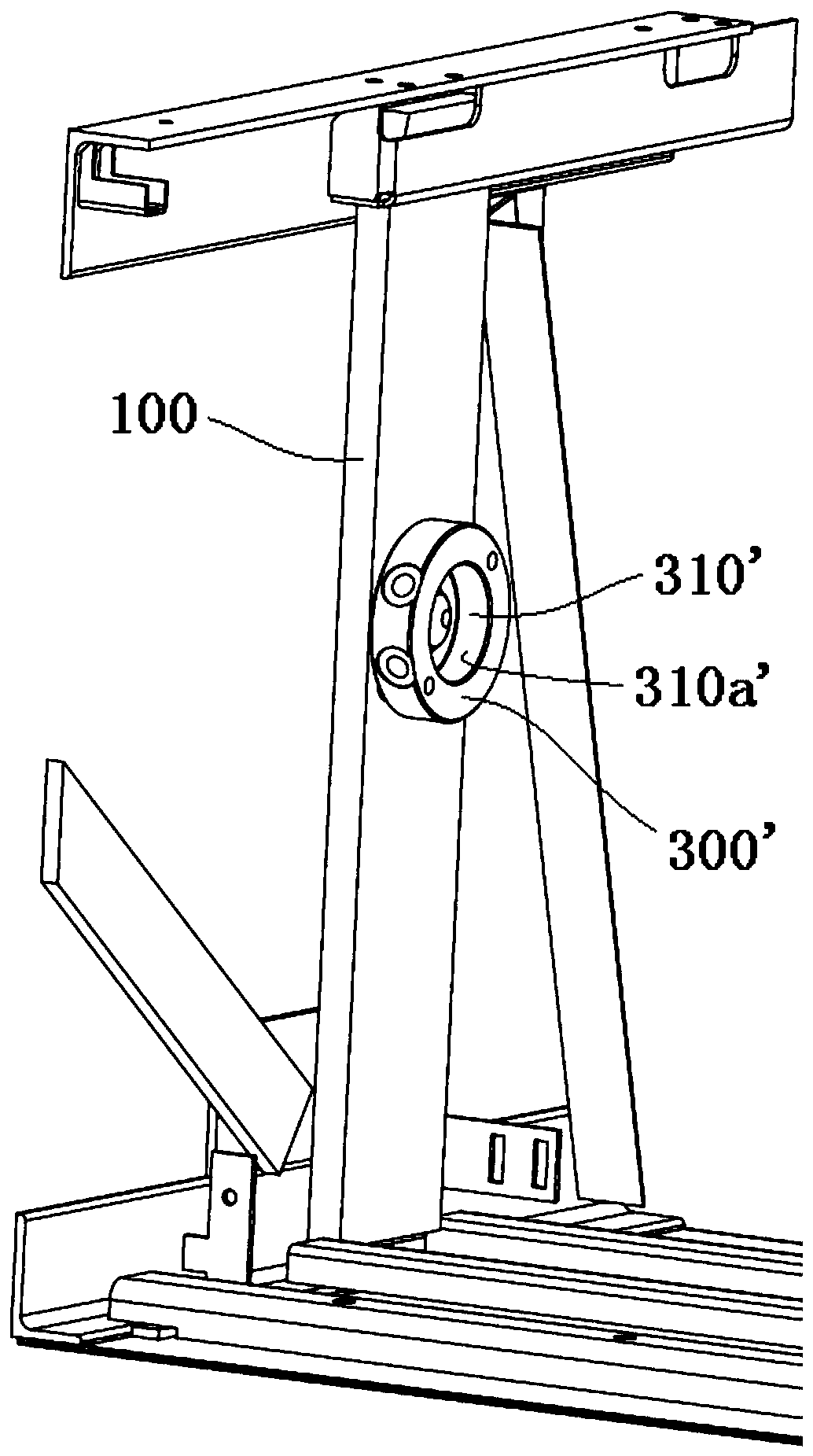

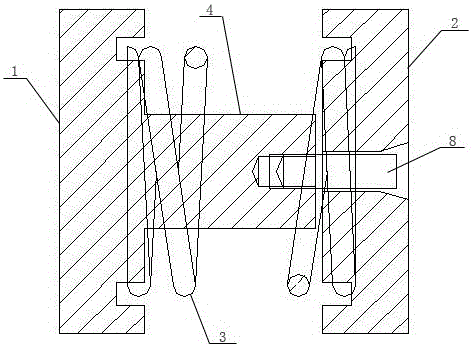

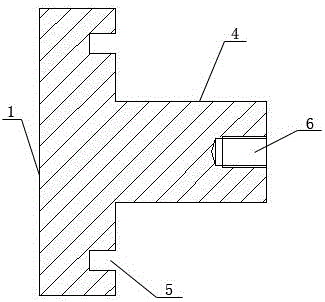

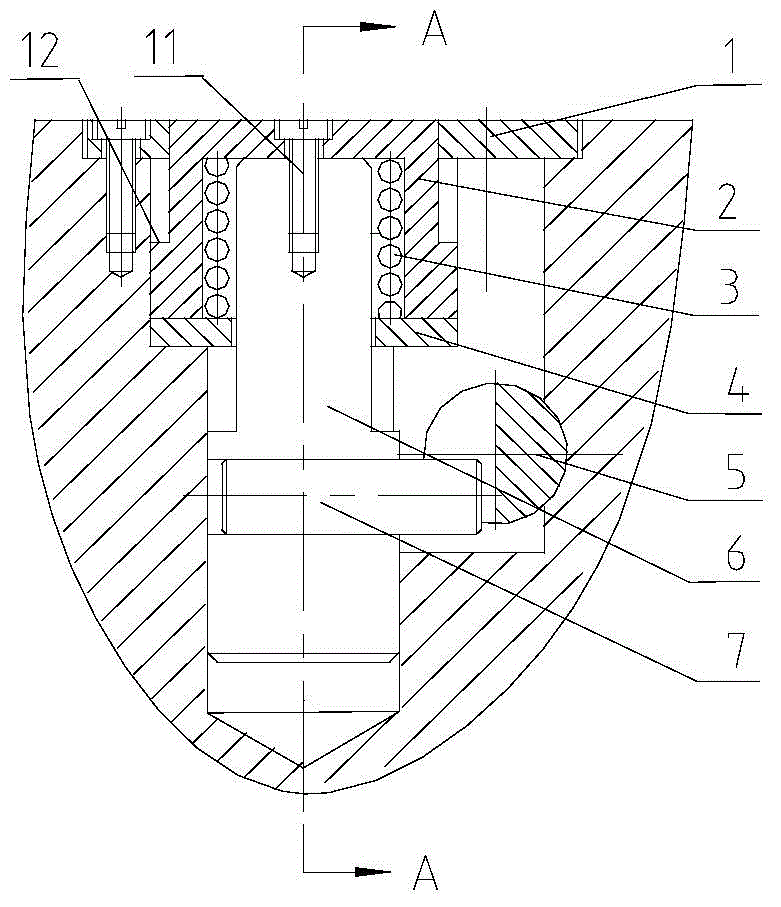

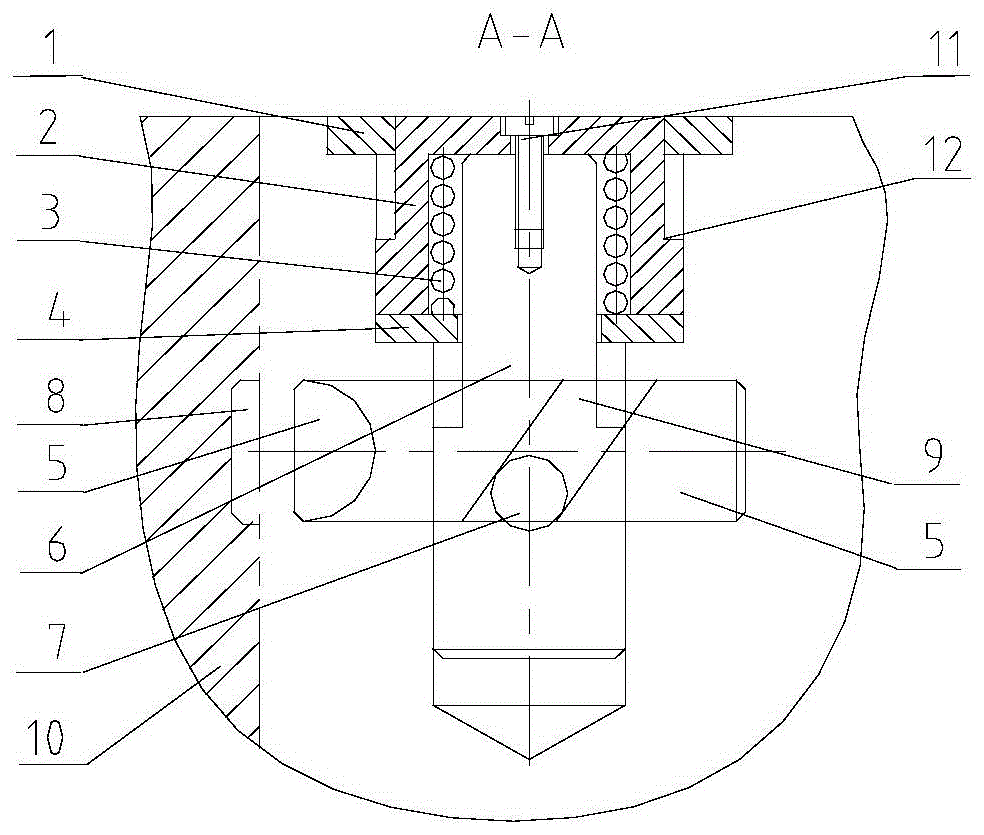

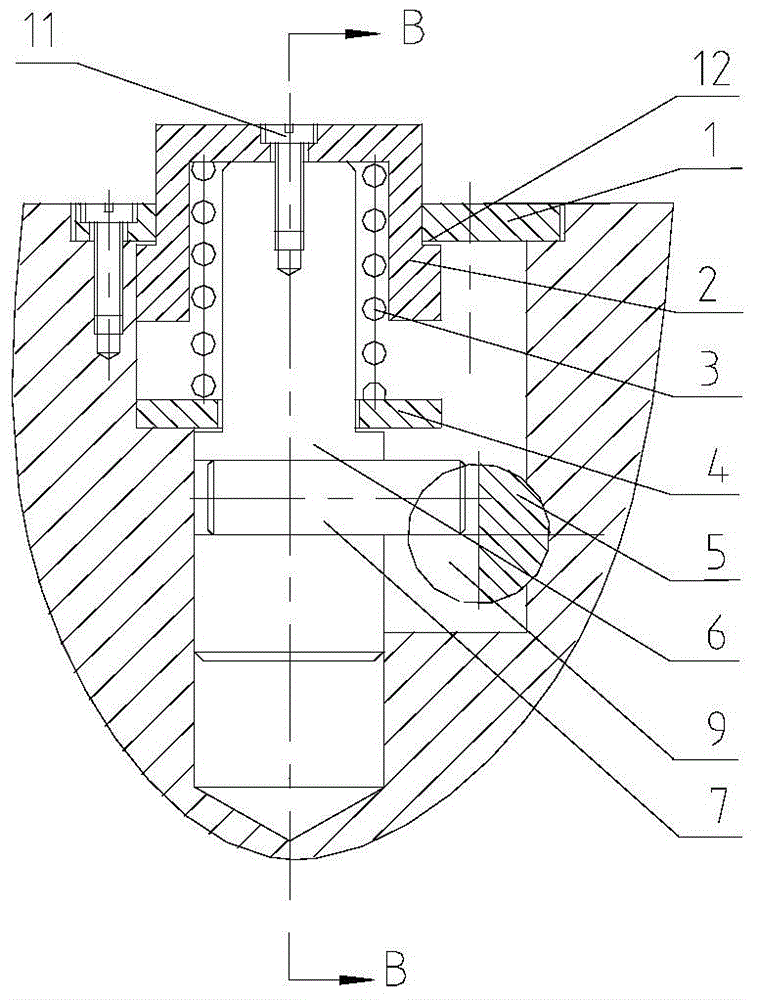

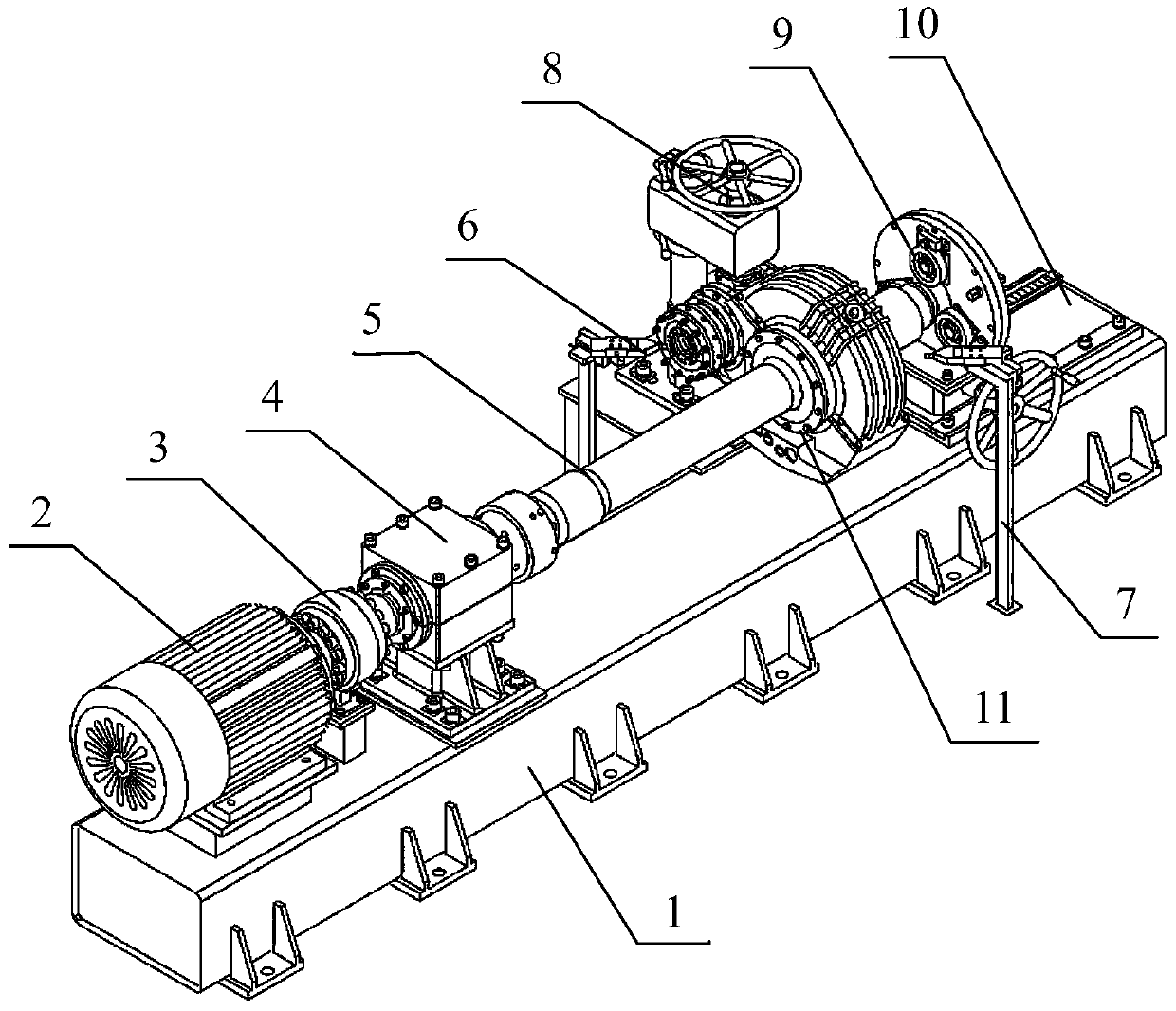

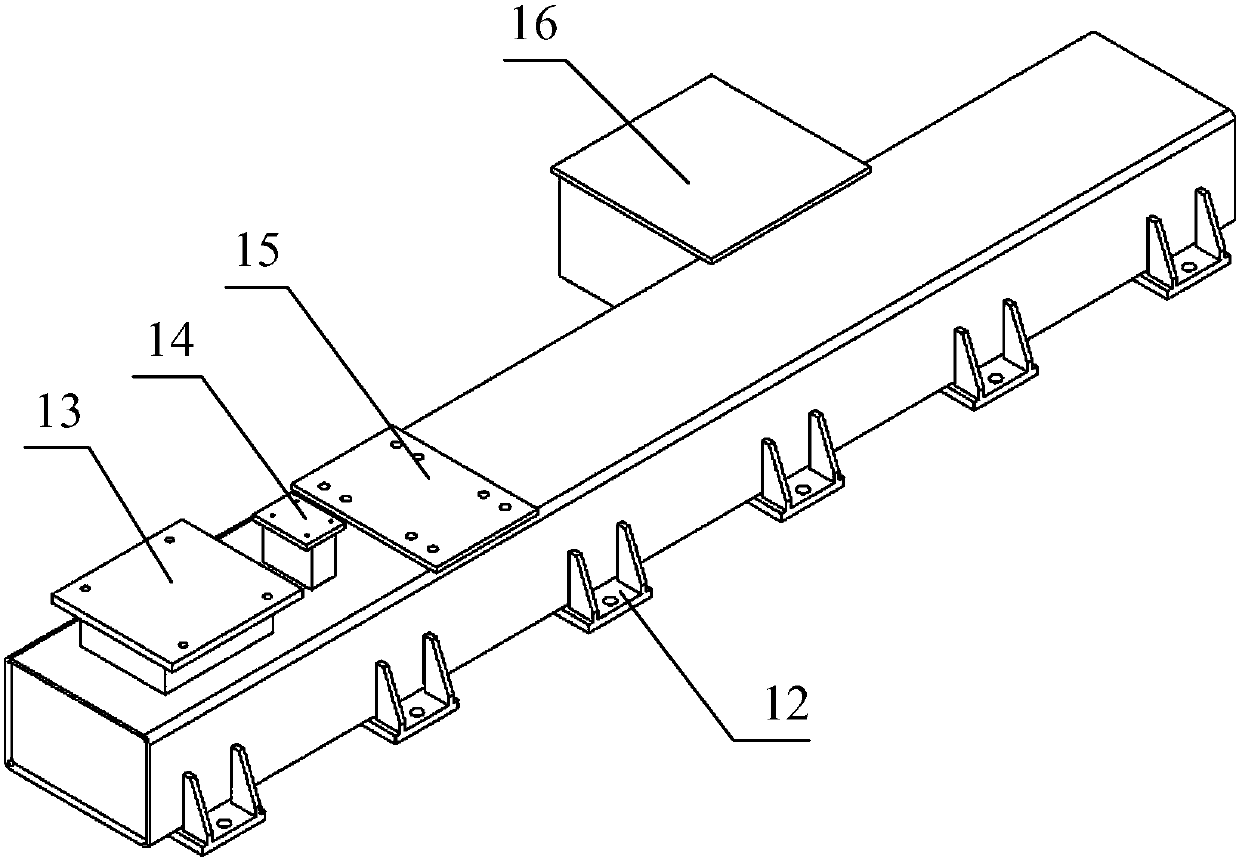

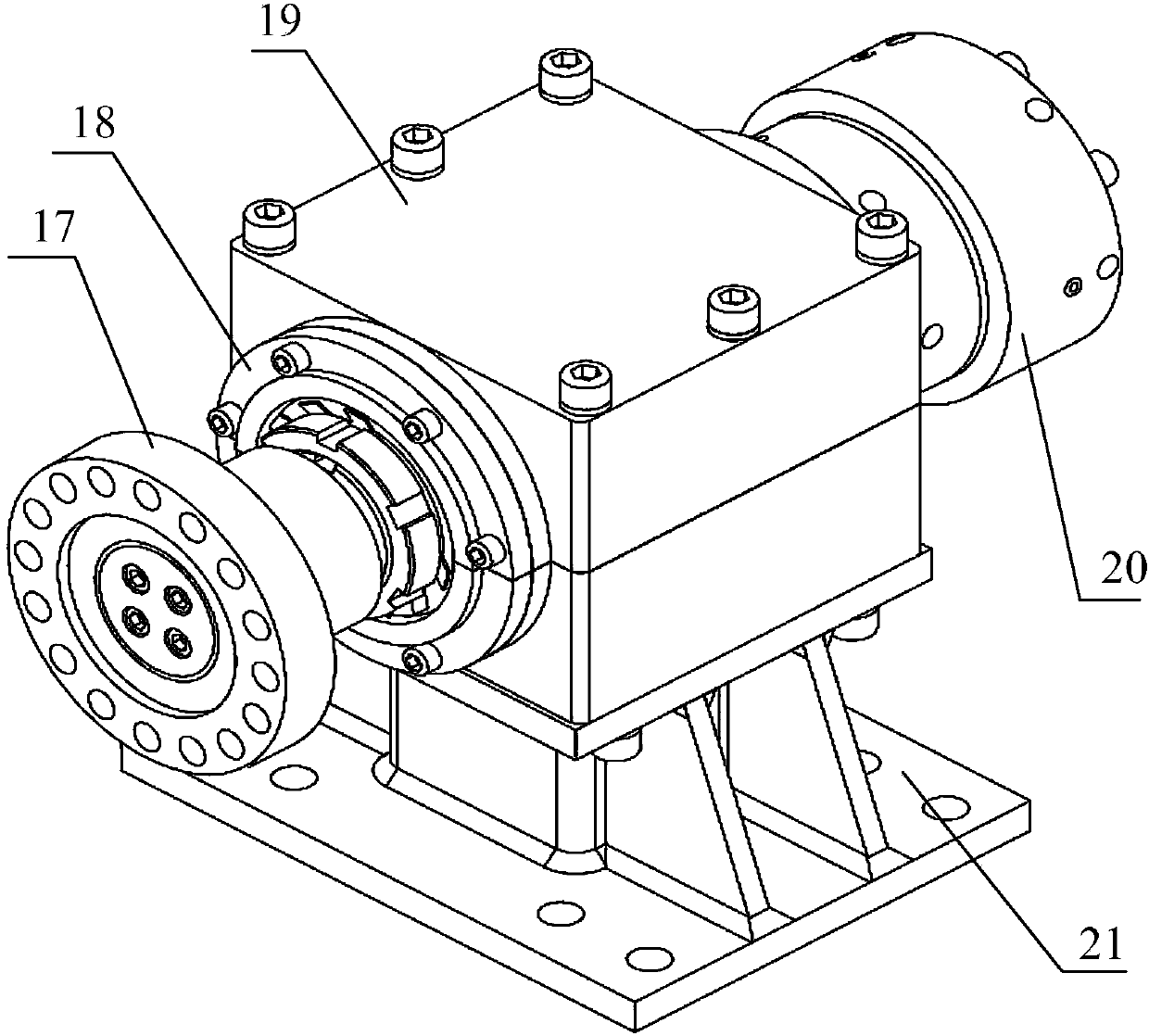

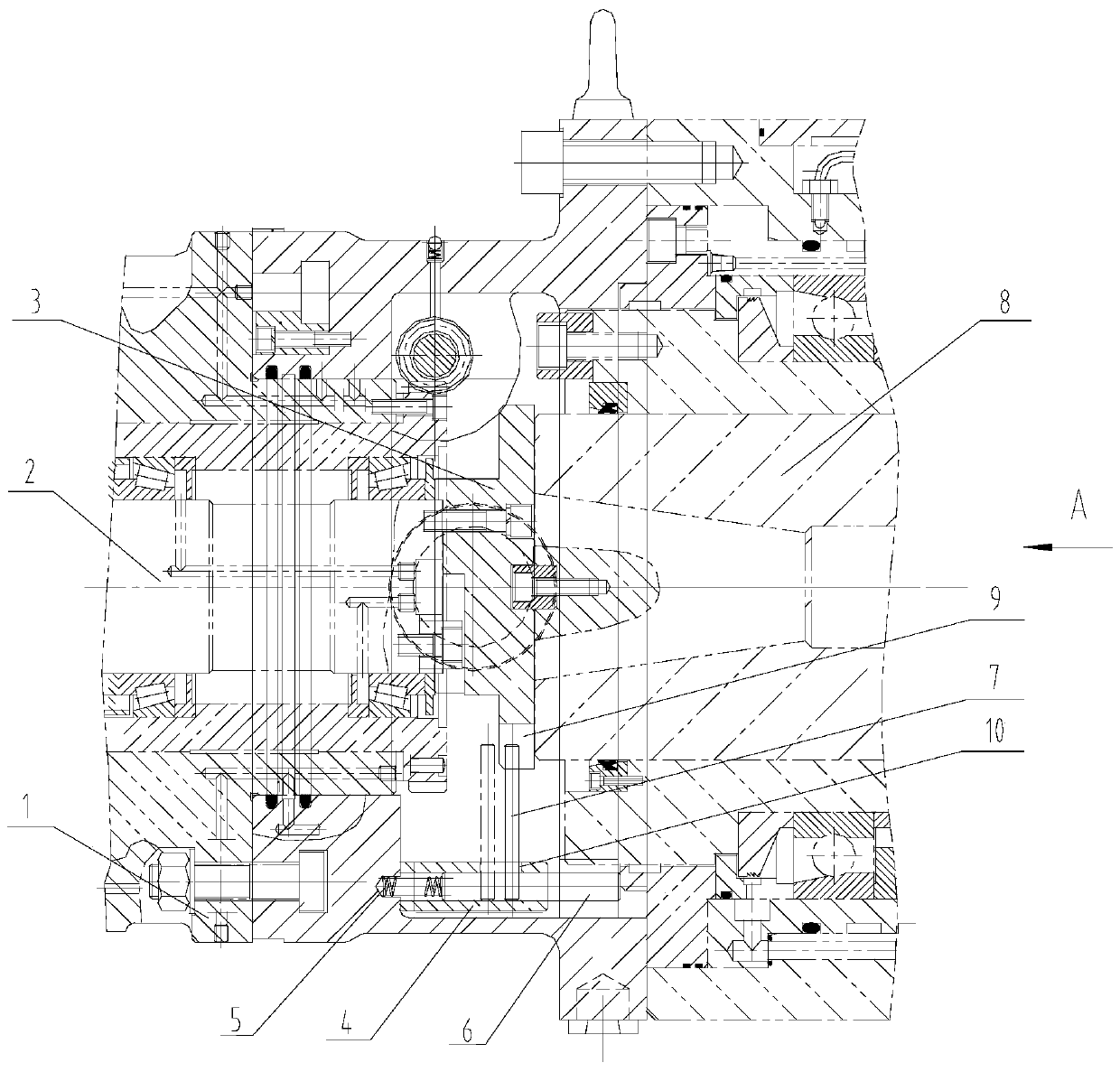

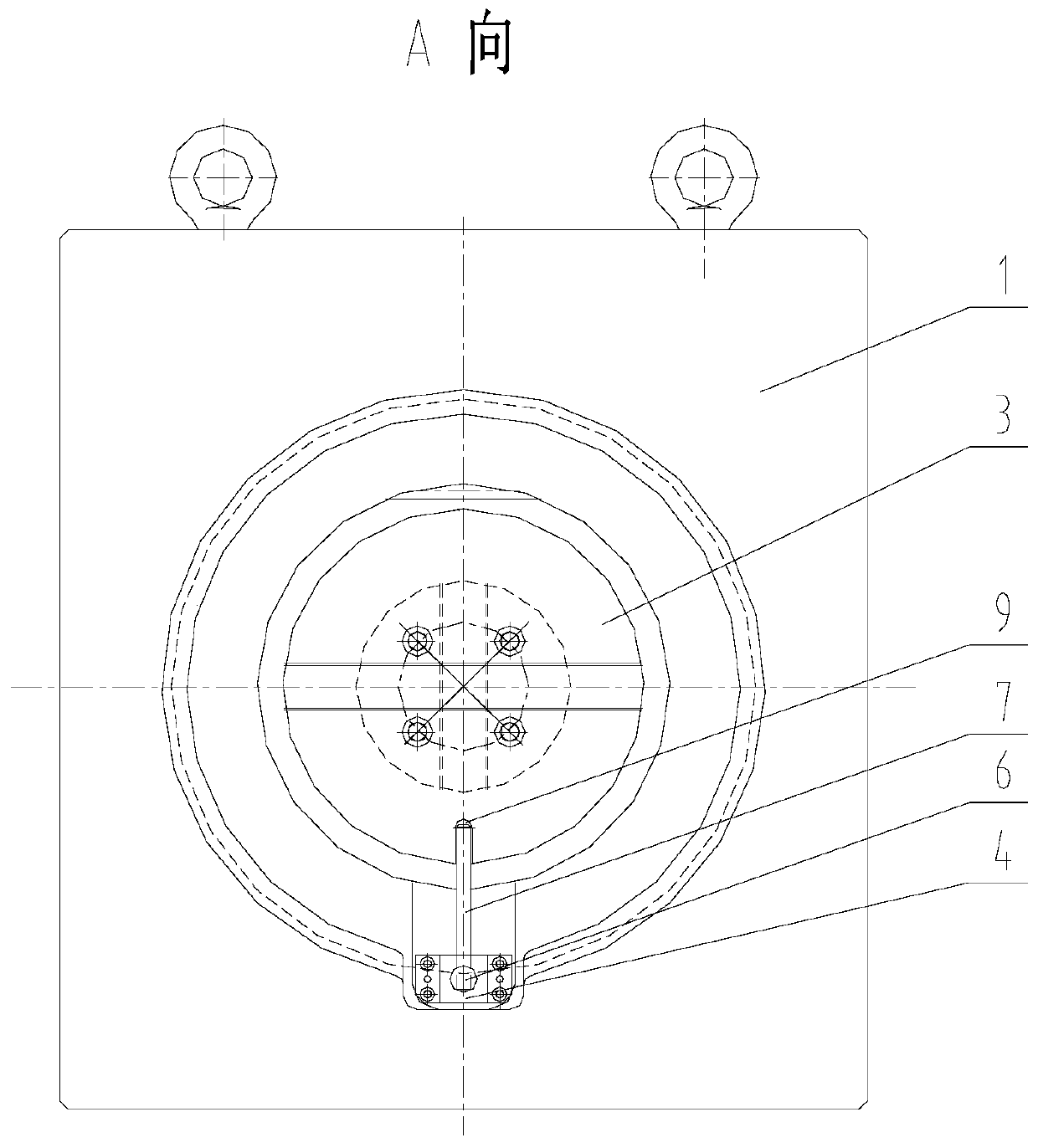

Gearbox no-load running-in test bed with self-centering positioning and clamping device

ActiveCN105527096AGuaranteed concentricitySafe and secure clampingMachine gearing/transmission testingMobile endEngineering

The invention relates to a gearbox no-load running-in test bed with a self-centering positioning and clamping device. The gearbox no-load running-in test bed is mainly composed of a driving device, a fixed end elastic clamping spindle positioning and clamping device, a movable end self-centering positioning and clamping device, a gearbox input end compression upright post device, a noise testing device and a test bed base, wherein the driving device is connected and mounted to the left end of the test bed base (1) via bolts, the fixed end elastic clamping spindle positioning and clamping device (4) is mounted on the left side of the test bed base (1), the movable end self-centering positioning and clamping device (9) is mounted at the right end of the test bed base (1), and the gearbox input end compression upright post device (8) is mounted on the test bed base (1) via a T-shaped bolt. The gearbox no-load running-in test bed solves a series of technical problems that the existing gearbox no-load running-in test bed is complex in dismantling and mounting, damages axle spindles and cannot meet high revolution speed and the like.

Owner:JILIN UNIV

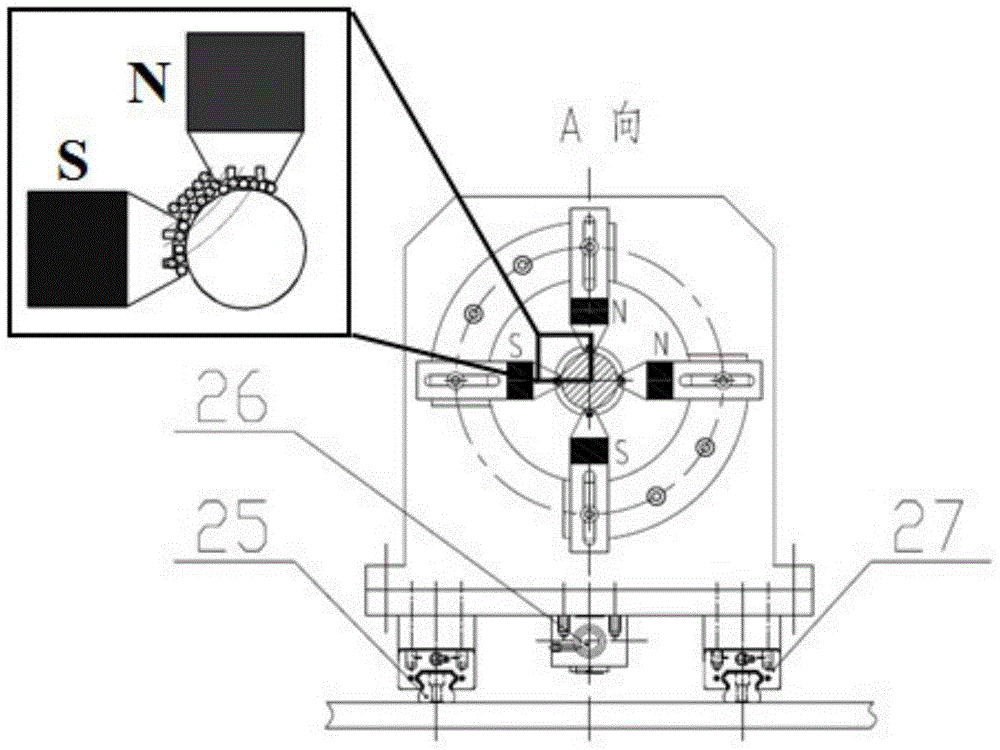

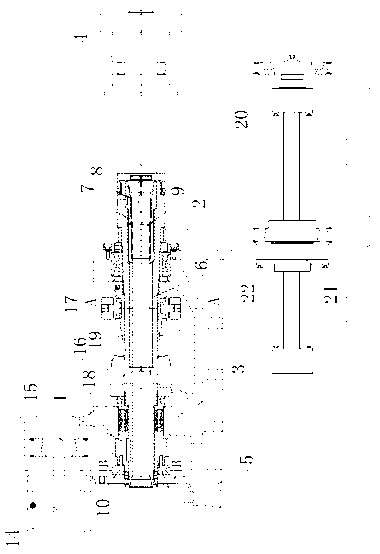

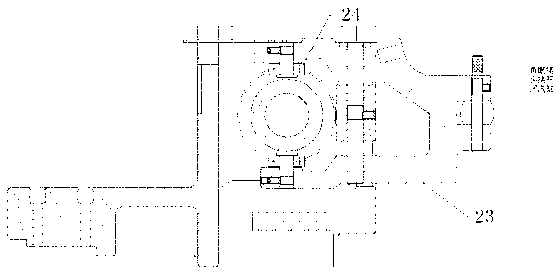

Device for grinding lead screw precisely

InactiveCN104589161AWon't scratchWon't breakRevolution surface grinding machinesThread cutting apparatusSurface roughnessMagnetic poles

The invention discloses a device for grinding a lead screw precisely, which can improve the precision grinding quality and efficiency of the lead screw. The device comprises a base plate, a cushion block, a synchronous pulley, a spindle end cover, a spindle positioning seat, a spindle, a flange plate, a three-jaw self-centering chuck, a grinding magnetic pole group, a curved iron, a magnetic pole supporting seat, a workpiece support, a tailstock, an auxiliary servo motor, a shaft coupler, a first lead screw positioning bearing block, the lead screw, a supporting plate, a second lead screw positioning bearing block, a synchronous belt, a main servo deceleration motor, a sensor positioning seat, a limit sensor, two slideways, a lead screw nut and a sliding block. According to the device disclosed by the invention, the specifications of the magnetic poles in the grinding magnetic pole group can be replaced upon the type of the lead screw, the operation is simple and the cost is low. The device is flexibly contacted with the workpiece by a magnetic abrasive brush, so the surface of the workpiece cannot be scratched and damaged during precision grinding; after the surface of the lead screw is ground and polished, the surface roughness can be reduced and the smoothness can be increased; besides that, with the residual compressive stress on the surface, the fatigue strength and the service life of the surface can be improved.

Owner:UNIV OF SCI & TECH LIAONING

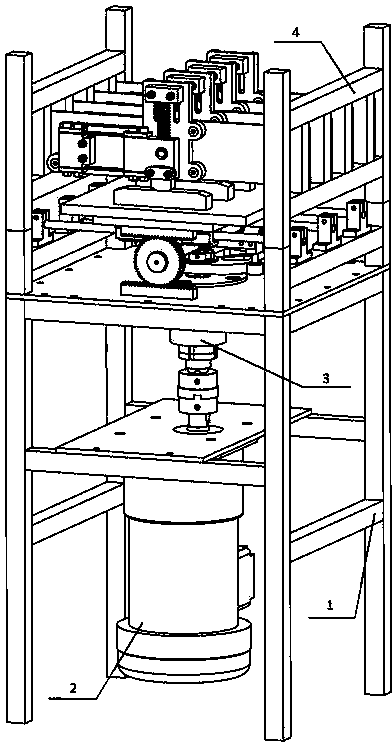

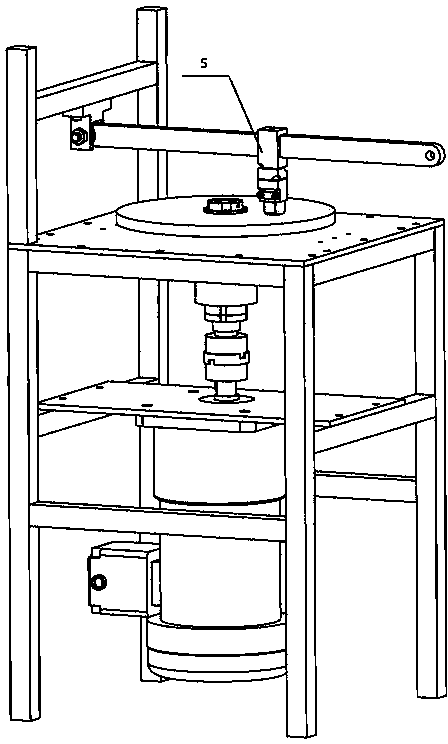

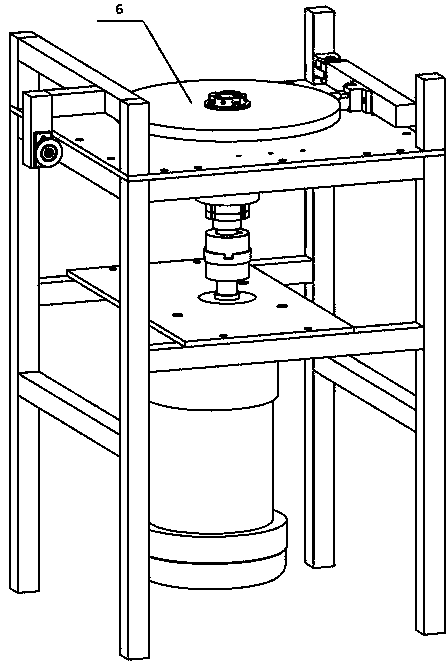

Multifunctional wear test device for material wear analysis

ActiveCN103913392AReduce volumeLow costInvestigating abrasion/wear resistanceFrequency changerElectric machine

The invention discloses a multifunctional wear test device for material wear analysis. The multifunctional wear test device comprises a frame, speed-regulated power systems and spindle positioning mechanisms, wherein each speed-regulated power system comprises a motor and a frequency converter; totally Q groups of speed-regulated power systems are arranged and are fixed on the frame; Q is a natural number and is more than or equal to 1; totally Q groups of spindle positioning mechanisms are arranged and correspond to the speed-regulated power systems one by one; each spindle positioning mechanism comprises a positioning mechanism and a spindle; the lower end of the spindle is connected with the motor through a coupler. The multifunctional wear test device also comprises R groups of reciprocating wear modules, S groups of pin disc type wear modules and T groups of ring block type wear modules, wherein R, S and T are integers, R is more than or equal to 0, S is more than or equal to 0, T is more than or equal to 0, and R+S+T is equal to Q. Disassembly can be manually performed by using each module, the volume of the machine is greatly reduced, joints among the modules are conveniently connected, only the needed modules are needed to be processed during processing and use, and the cost is greatly reduced.

Owner:ZHEJIANG UNIV

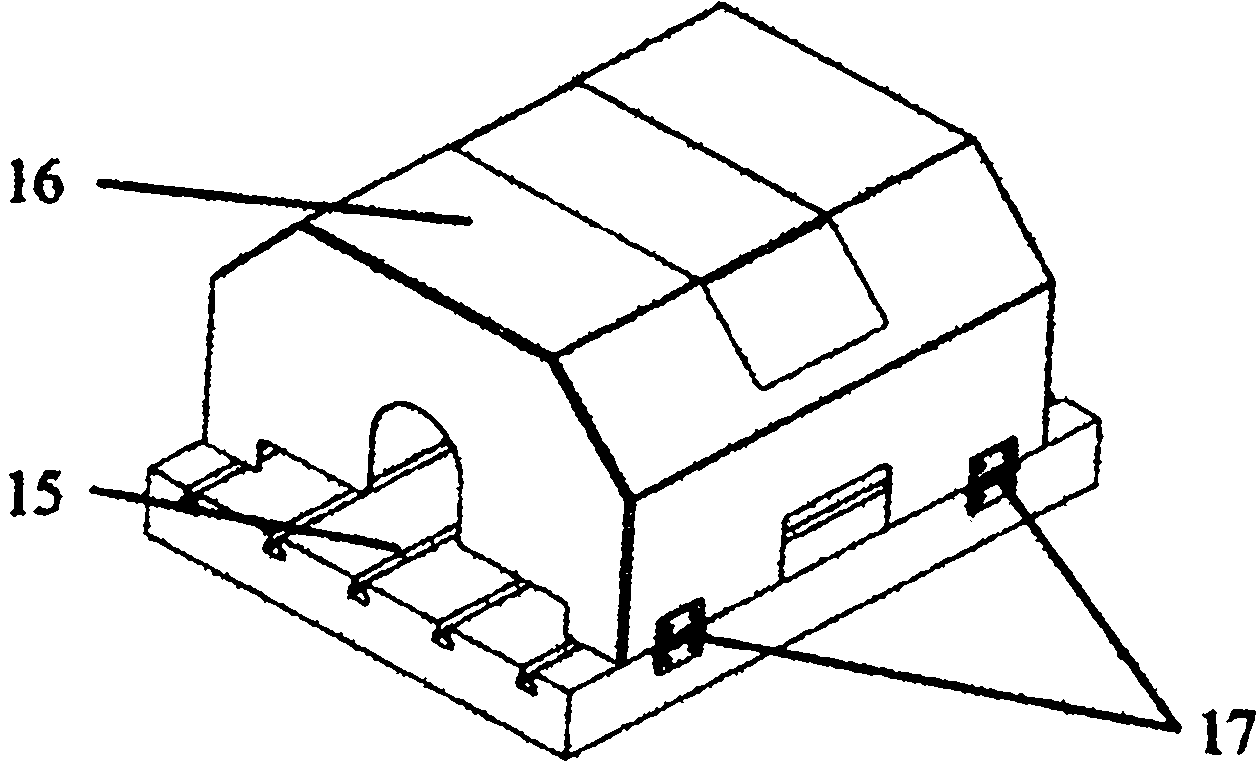

Automatic control device for doffer

ActiveCN102634891AIncrease the level of automationIncrease productivityTextiles and paperNumerical controlYarnAutomatic control

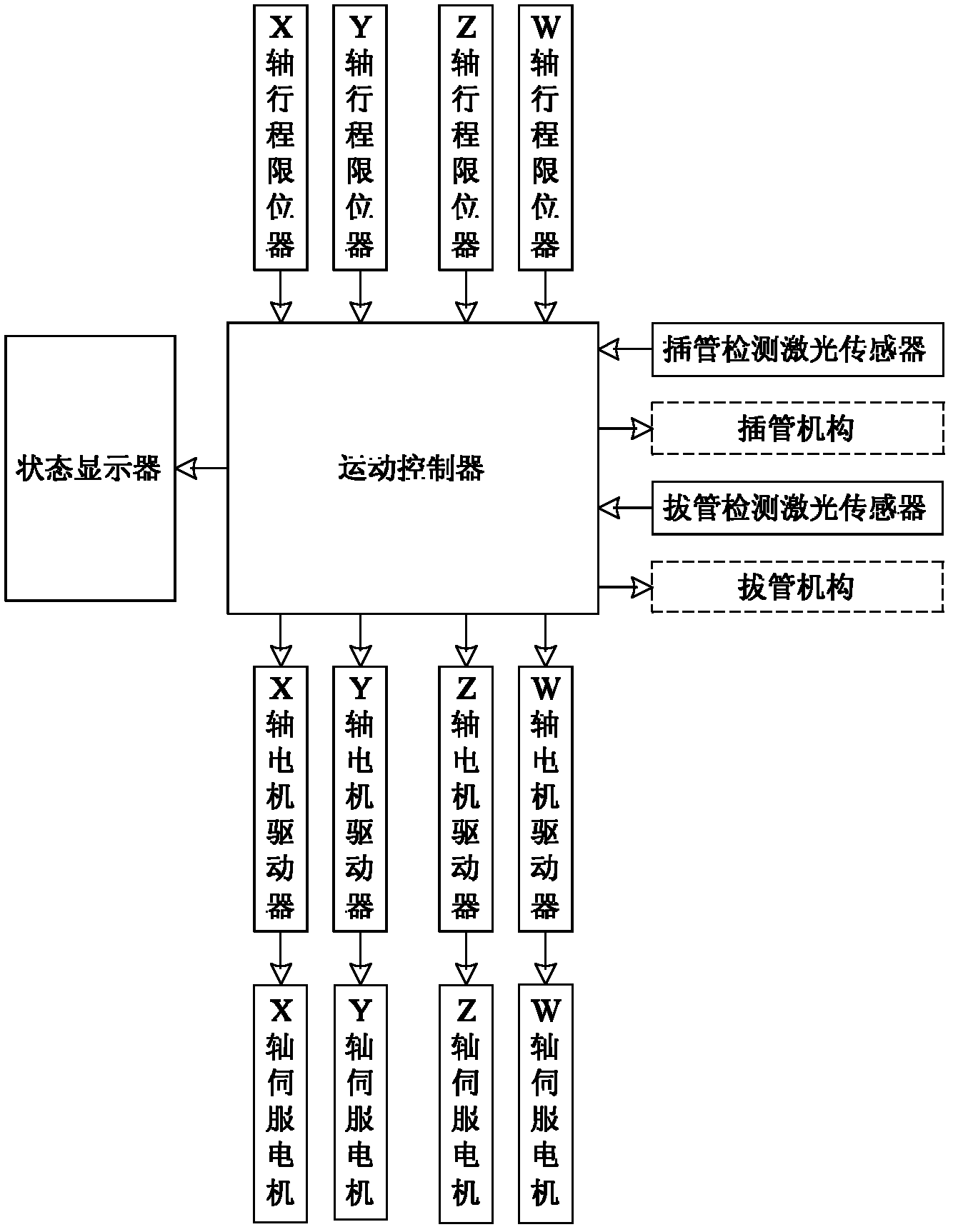

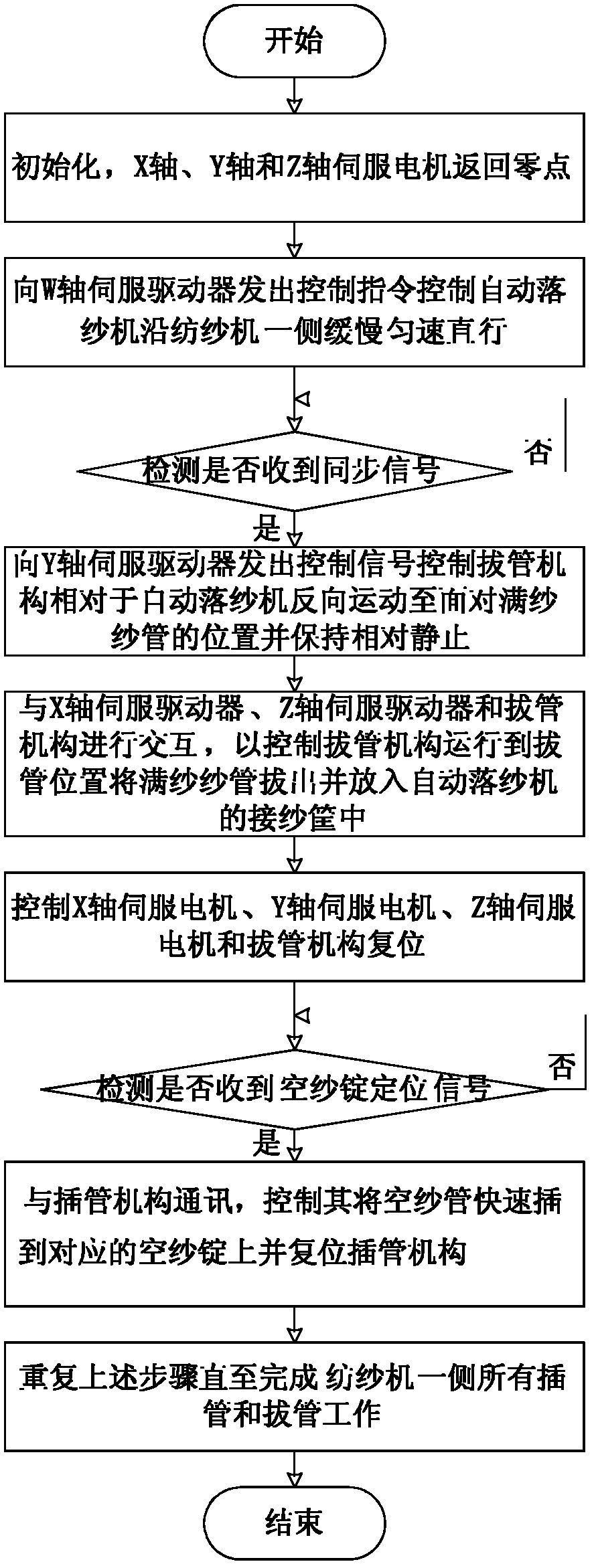

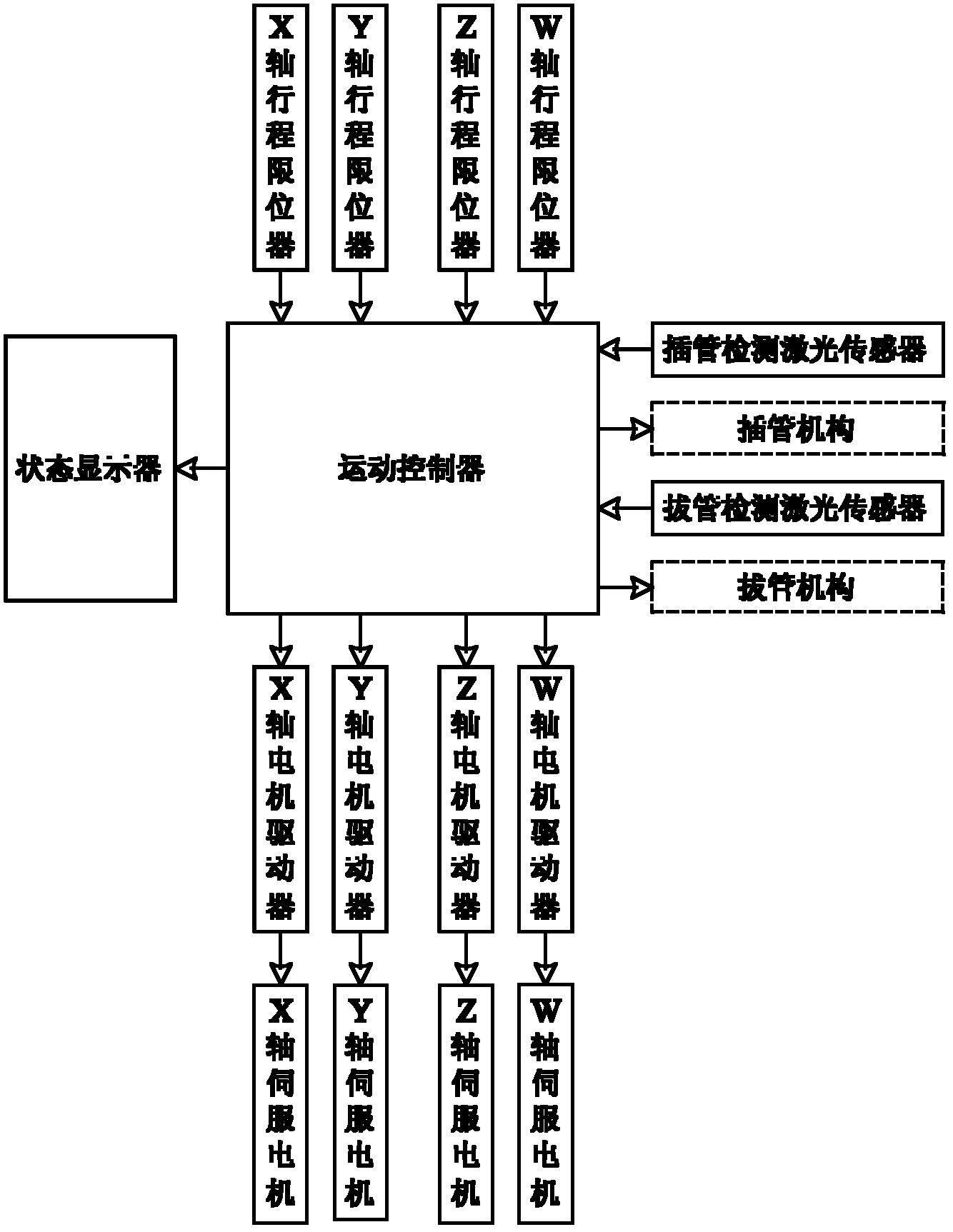

The invention discloses an automatic control device for a doffer. A W-axis servo motor is used for the forward movement of the automatic doffer, and an X-axis servo motor, a Y-axis servo motor, and a Z-axis servo motor are used for the three-dimensional motion of a tube-pulling mechanism relative to the doffer; when a motion controller receives a synchronous signal sent by a tube-pulling detection laser sensor, the tube-pulling mechanism is controlled via the Y-axis servo motor to move relative to the travelling direction of the automatic doffer to a position facing a yarn tube with full yarns, and to keep relatively static, and then the yarn tube with the full yarns is pulled out and placed in a yarn-receiving basket of the automatic doffer by controlling the X-axis servo motor, the Z-axis servo motor and the tube-pulling mechanism; and when an empty spindle positioning signal sent by a tube-inserting detection laser sensor is received, a tube-inserting mechanism is communicated and controlled to insert an empty yarn tube on a corresponding empty spindle, so as to realize automatic tube-pulling and tube-inserting control on the doffer, thus improving the automation level and the production efficiency of the doffer.

Owner:TONGLING SOBONE INTELLIGENT EQUIP

Thread guide bar improved arrangement for circular knitting machines

InactiveCN1690283AEasy to assemble and reliableAssembly made easyWeft knittingEngineeringMechanical engineering

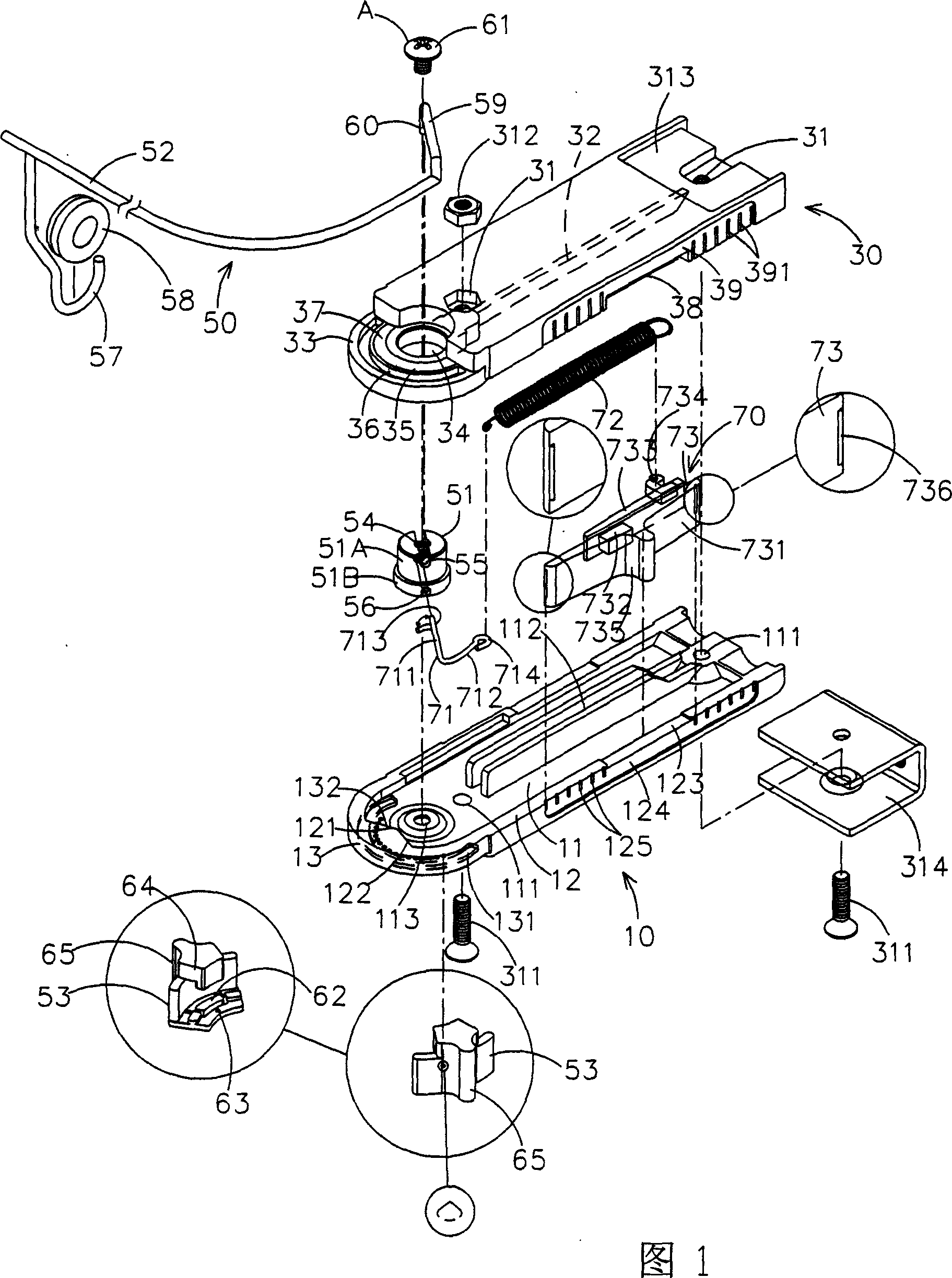

The invention provides an improved structure of thread guide bar block of knitting machine, including a base, a cover, swing mechanism and tension mechanism. The base has a spindle positioning part; the cover with a through axle hole is connected to the base and cover it; the swing mechanism includes at least a spindle and a thread guide bar, while the spindle, with a screw hole and a locating slot transversely connecting this screw hole, is mounted between the spindle positioning part of base and the axle hole of cover; said thread guide bar is embedded in the locating slot of this spindle and locked with the screw hole by a bolt to depend and be located on the thread guide bar; said tension mechanism includes a connecter, extension spring, and tension adjusting knob, wherein, one end of the connecter links said spindle, and another one links said extension spring; said tension adjusting knob embedded into the side of base and cover connects extension spring; by this structure, quick and easy installment of this thread guide bar is reached, and the economic benefit is improved.

Owner:陈仁惠 +1

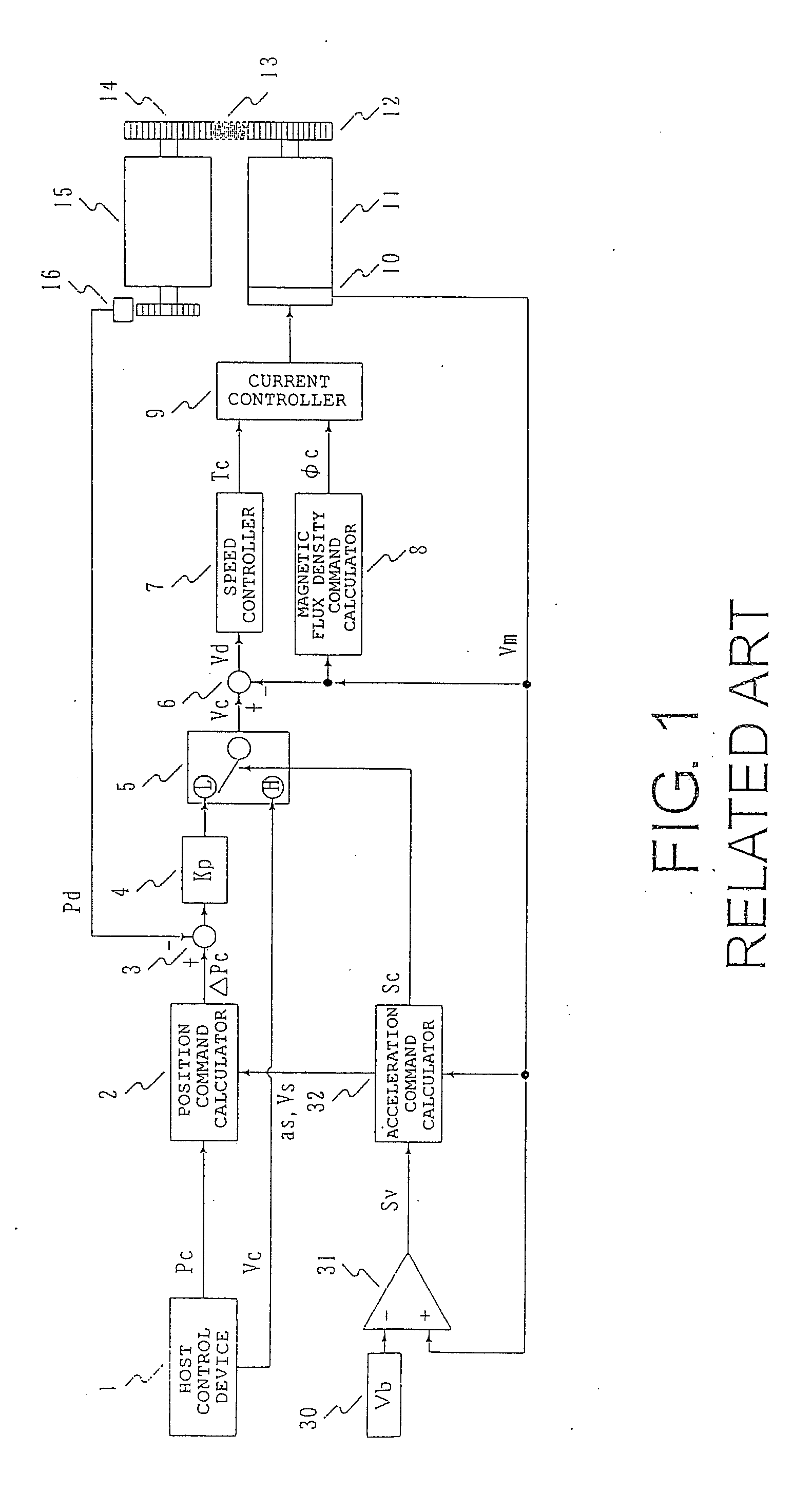

Spindle positioning device

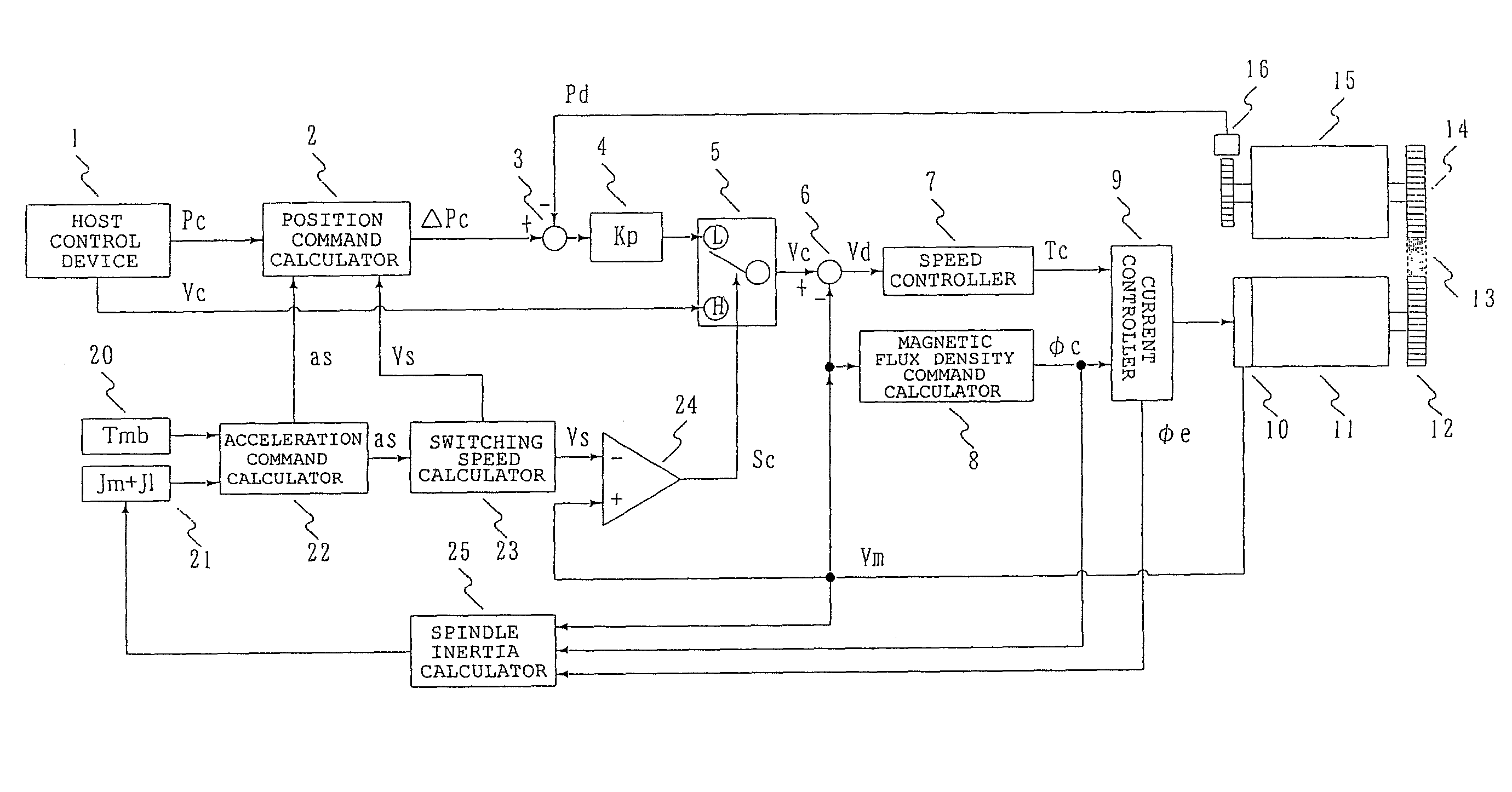

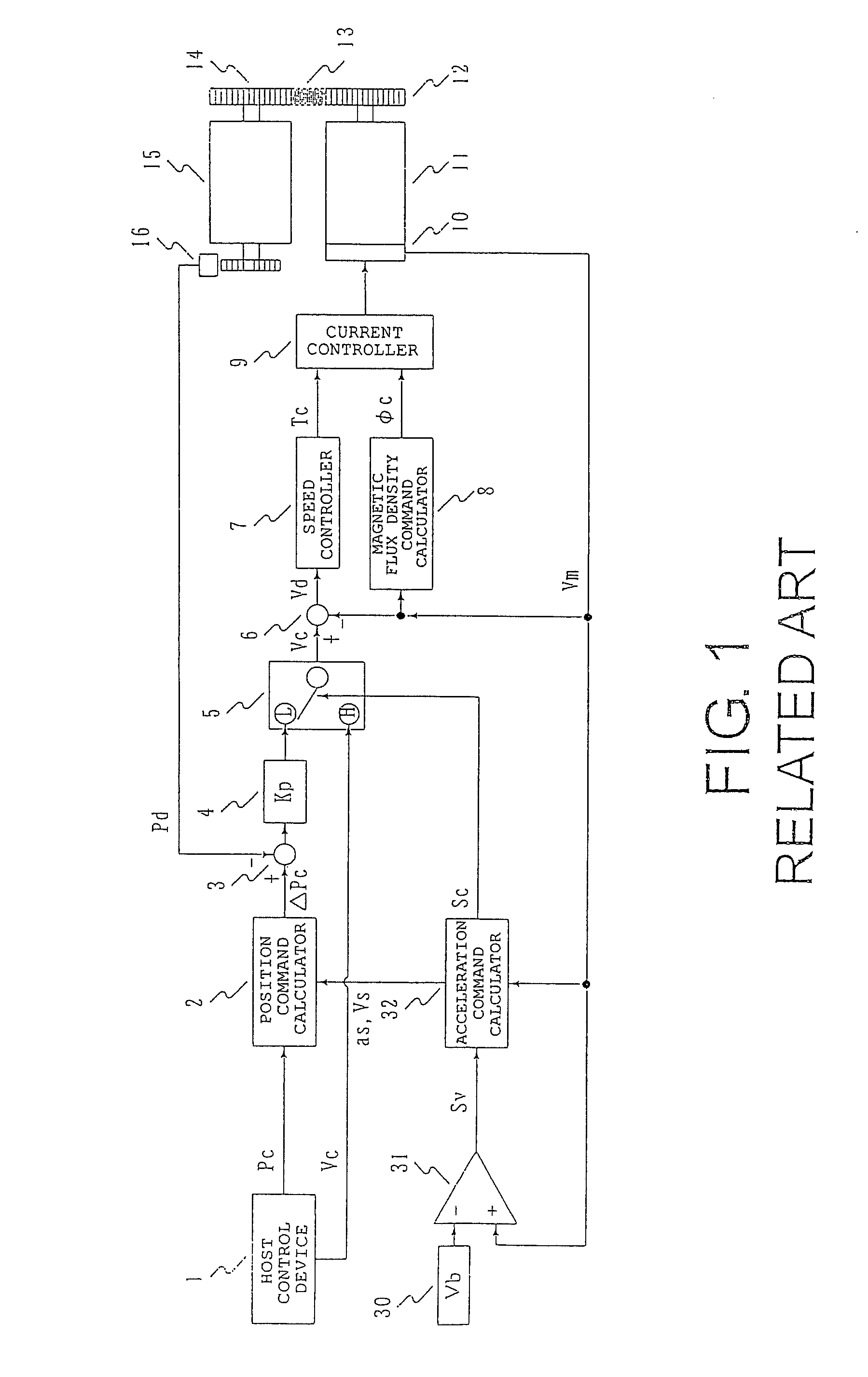

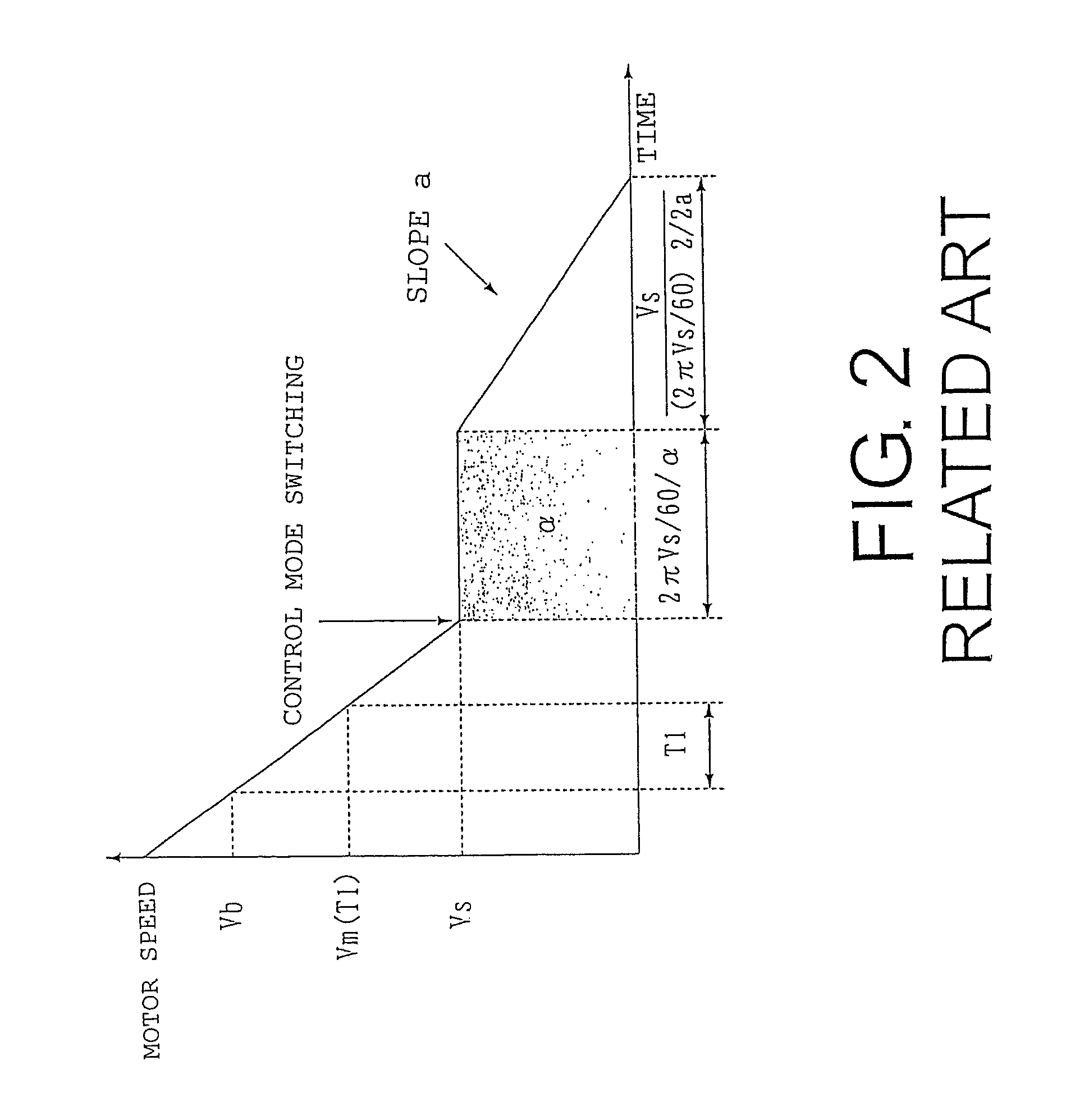

ActiveUS20130234643A1Rapid positioningAutomatic control devicesElement comparisonMotor speedPosition control

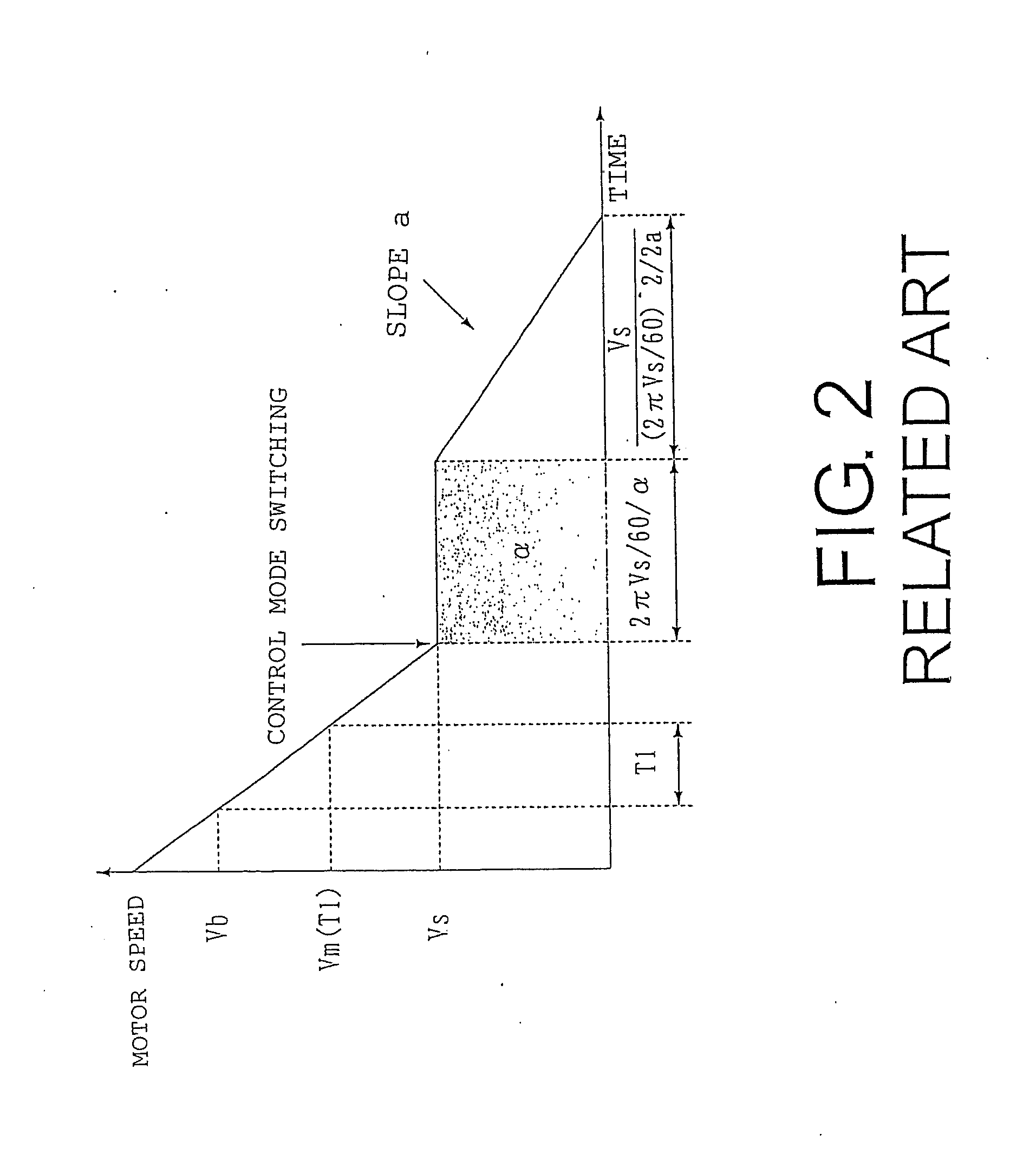

An acceleration command calculator 22 calculates an acceleration command “as” based on an output torque Tmb of the spindle motor applied when the rotational speed is less than or equal to a base rotational speed and an inertia Jm+Jl of the overall spindle. A switching speed calculator 23 calculates a control mode switching speed Vs based on the acceleration command “as”. A control mode switching switch 5 switches from a speed control mode to a position control mode when the motor speed Vm becomes less than or equal to the control mode switching speed Vs, to stop the spindle at a desired rotational position. The control mode switching speed Vs may be a value calculated using the following equation:Vs=60×(amax×0.5)1 / 2,where a maximum acceleration that can be achieved at this time is represented by a max.

Owner:OKUMA CORP

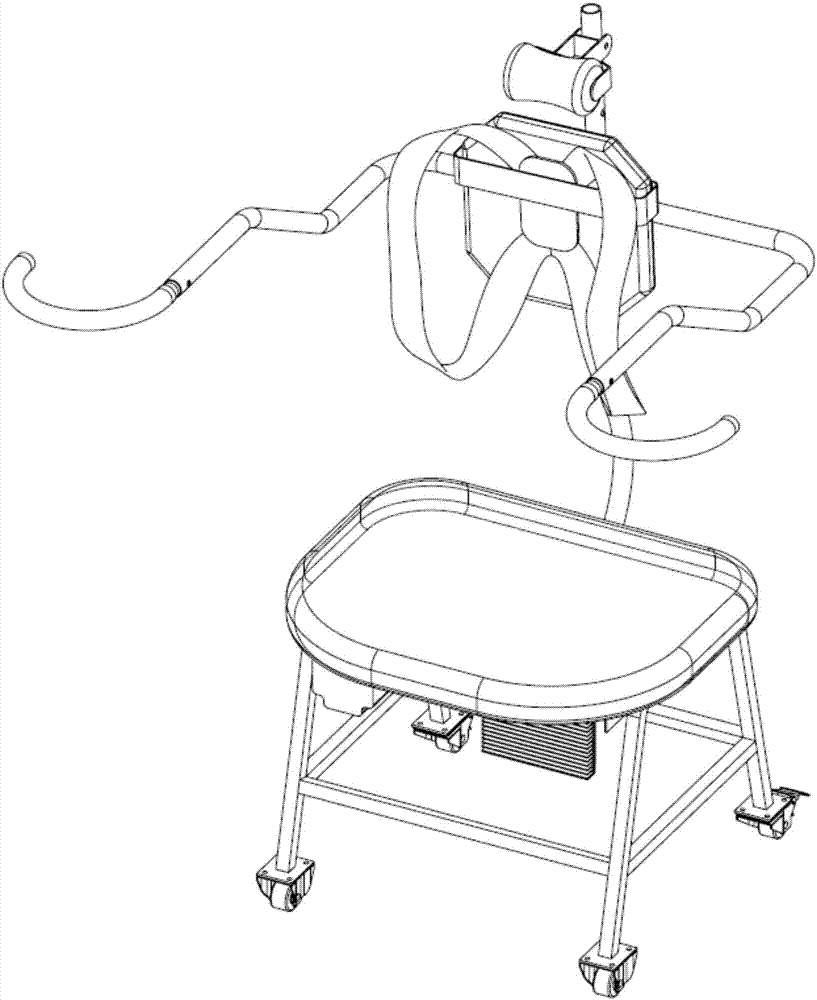

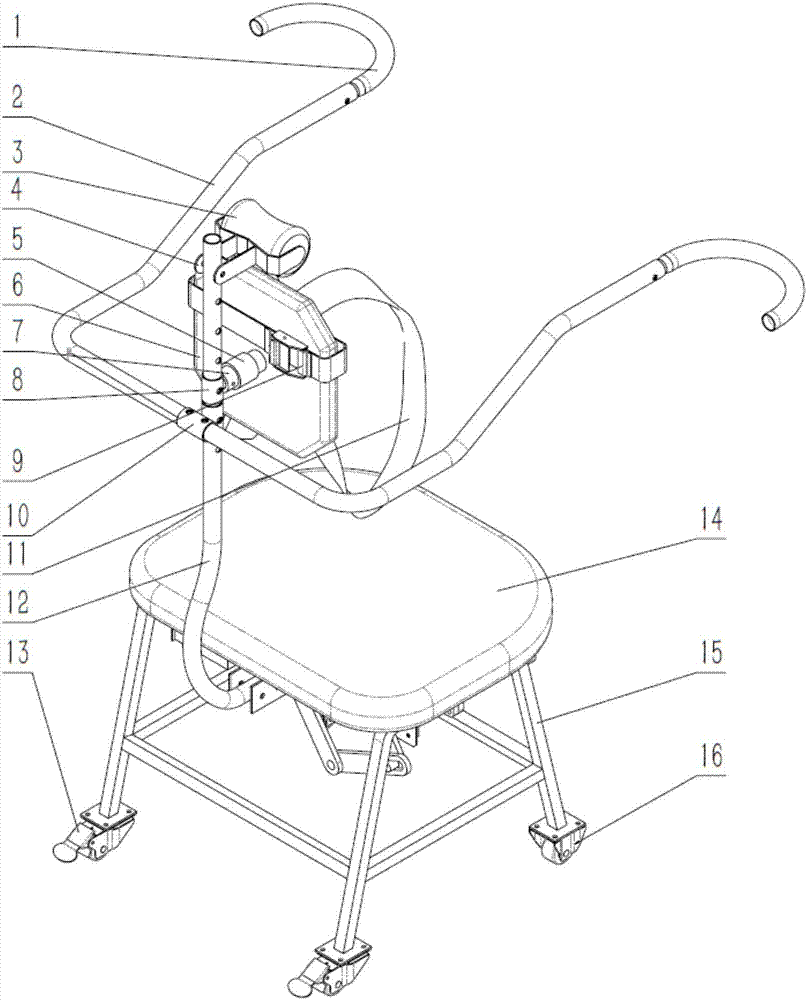

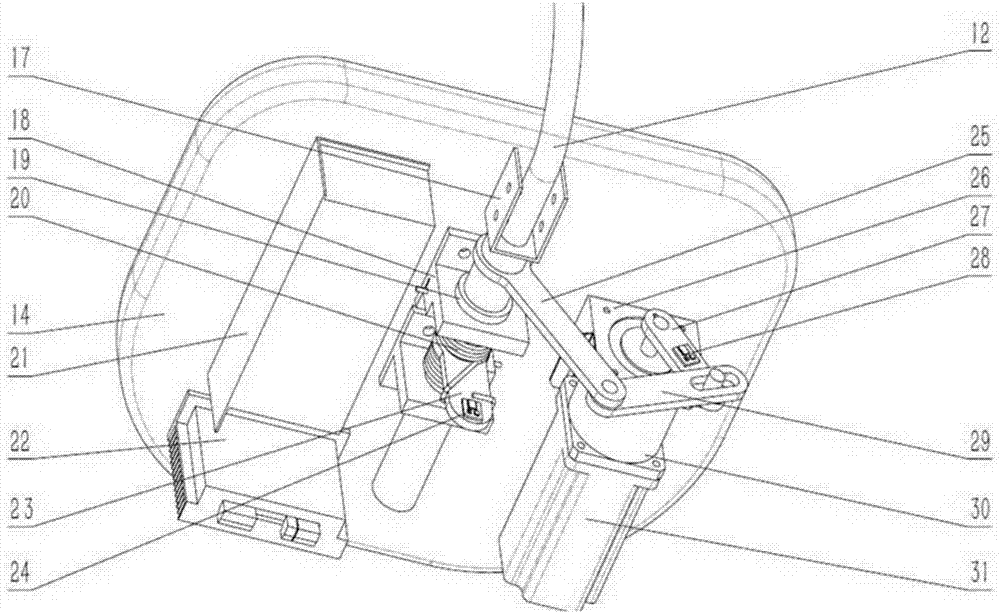

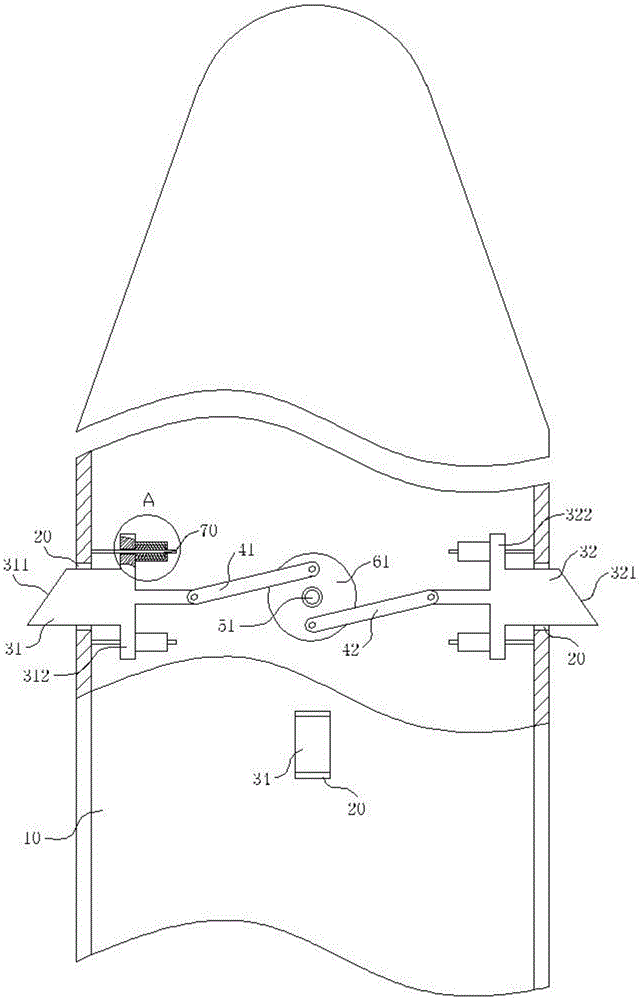

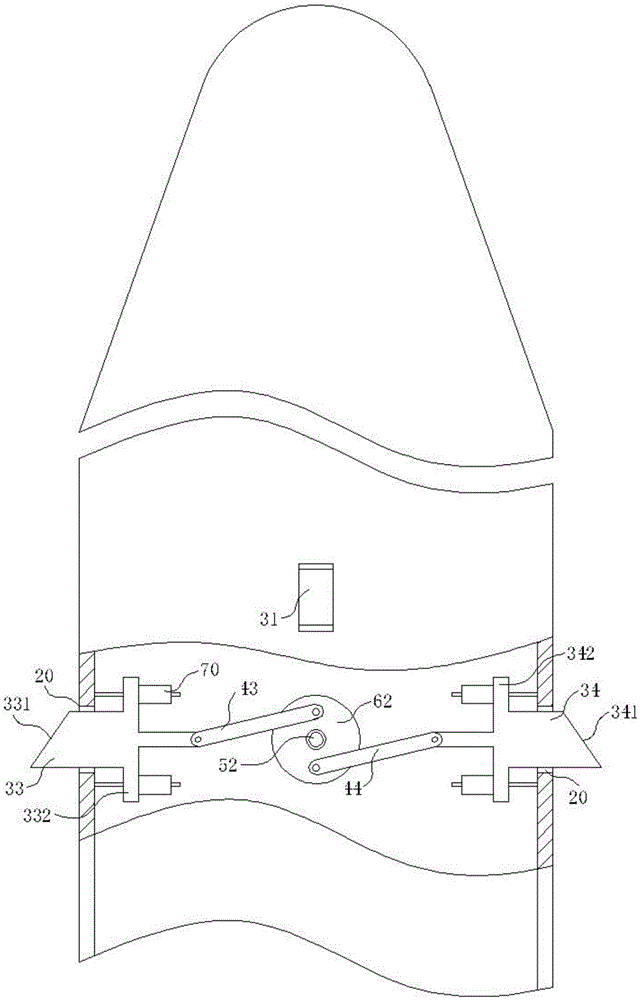

Sitting balance rehabilitation training robot and control method thereof

ActiveCN107019617AFully consider securityReasonable layoutChiropractic devicesEye exercisersAngular degreesEngineering

The invention discloses a sitting balance rehabilitation training robot and a control method thereof. The robot comprises a seat structure, a sliding chute four-connection-rod drive structure, a spindle drive structure, a spindle inclination angle sensor and a crank angle sensor, wherein the seat structure comprises supporting armrest frames, a back cushion, a backrest, a supporting cushion and the like; the sliding chute four-connection-rod drive structure comprises a rocker, a reduction gear support, a crank, sliding chute connection rods, a stepping reduction gear, a stepping motor and the like; the spindle drive structure mainly comprises a drive spindle, a spindle support, a check ring, a torsional spring, a spindle positioning block and the like. The inclination angle of a patient is recorded and measured by the spindle inclination angle sensor, the rotation speed and direction of the motor are controlled through real-time feedback, the patient is pushed by the backrest, armrests and other auxiliary systems to be straightened; the motor is controlled to rotate inversely and reset through real-time feedback by means of the angle sensor, the rocker and the sliding chute connection rods are separated, and the crank of the motor resets to the zero point position.

Owner:TSINGHUA UNIV +1

Position changing transmission mechanism of automatic tool changing device

InactiveCN102601658ASolve the contradiction that the forward and reverse rotation angles are not equalSimple structurePositioning apparatusMetal-working holdersLocking mechanismGear wheel

The invention provides a position changing transmission mechanism of an automatic tool changing device, which comprises a tool position changing portion and a transmission clutch portion. The technical scheme includes that the tool position changing portion is meshed with a transmission gear hollowly sleeved on a tool arm spindle via a rack mechanism, the rack mechanism is in movement linkage with a composite cam, the transmission clutch portion structurally includes that one side of a spindle sleeve hollowly sleeved on the tool arm spindle is fixedly connected with the transmission gear, a T-shaped groove is machined in the middle of a push rod of a tool locking mechanism, a certain angle is formed between the bottom of the T-shaped groove and the axis of the push rod, a T-shaped pin is mounted in the T-shaped groove and inserted into a tool arm spindle positioning hole, and a corresponding axial groove is arranged on the spindle sleeve. The gear and rack mechanism is combined with the composite cam, movement forms are converted, whether the tool arm spindle rotates or not is controlled by the transmission clutch portion, accordingly, tool position change is controlled, a tool position change mode adopting an arc-surface indexing cam as a main transmission body is completely replaced, and the position changing transmission mechanism has the advantages of simple structure, convenience in manufacture and low cost.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

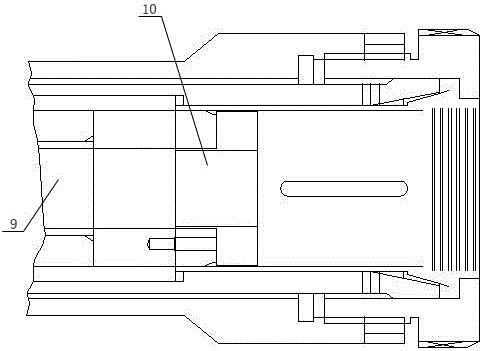

Horizontal boring machine and spindle positioning mechanism thereof

InactiveCN102922000AAccurate locationExact stopAutomatic control devicesMeasurement/indication equipmentsMechanical engineeringSpindle positioning

The invention discloses a spindle positioning mechanism of a horizontal boring machine. The mechanism comprises a controller, a spindle motor for driving a boring rod to rotate, a position induction part and a sensor, wherein the position induction part is arranged on the boring rod; the sensor is used for detecting the position induction part; the signal output end of the sensor is connected with the controller; and when the boring rod stops positively rotating and negatively rotates to a stop allowable position, the sensor detects the position induction part and outputs a signal to the controller, and the controller controls the spindle motor to stop. By the mechanism, the positioning accuracy and reliability of a spindle of the horizontal boring machine can be obviously improved. The invention also discloses the horizontal boring machine with the spindle positioning mechanism.

Owner:WEICHAI POWER CO LTD

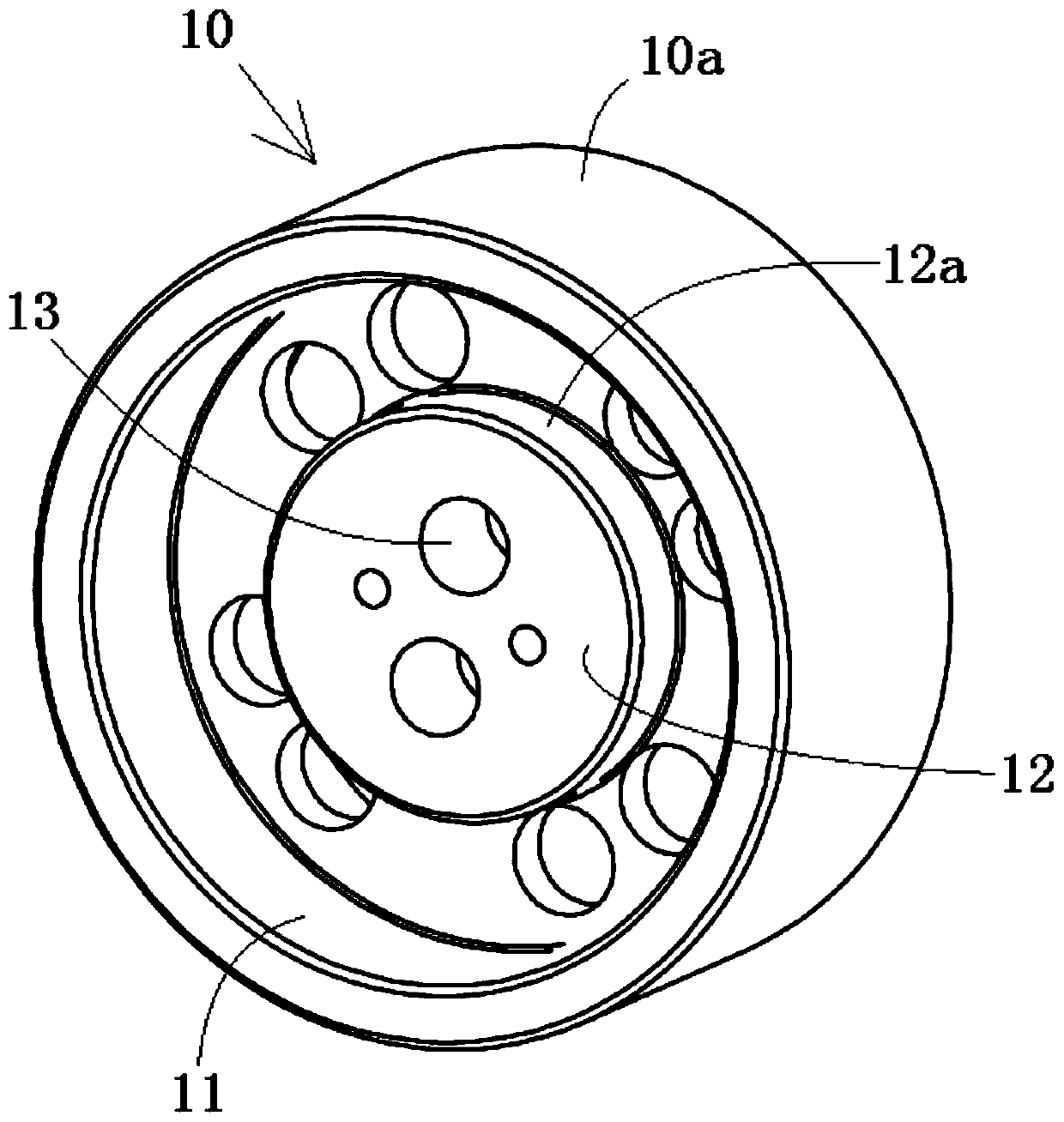

Lathe spindle unit

InactiveCN103008693AHigh positioning accuracyReduce yieldDriving apparatusEngineeringSpindle positioning

The invention relates to a lathe spindle unit, which comprises a spindle, a front bearing and a rear bearing which are arranged on the spindle, a guide sleeve and a spline part, wherein the spindle is arranged on a bearing seat, a top rod is arranged in the spindle, a collet sleeve is fixed at the front end of the top rod, a collet is arranged in the collet sleeve, an elastic part is arranged between the collet and the collet sleeve, the rear end of the spindle is provided with a spindle positioning device, and the spindle positioning device comprises a positioning wheel, a positioning pin and a positioning cylinder. According to the lathe spindle unit disclosed by the invention, the positioning precision of the spindle is improved, the output rate of inferior-quality products is reduced, the production efficiency is improved, the temperature rise is low, and the influence on the precision of a processed product is small.

Owner:付艳丽

Deep hole/blind hole processing technology with automatic spindle positioning effect

ActiveCN105057712AAdjust and correct axis deviationAutomatic control devicesMeasurement/indication equipmentsSpherical bearingEngineering

The invention relates to a deep hole / blind hole processing technology with an automatic spindle positioning effect. After a machine tool is preliminarily hung and fixed to a part in which a deep hole / blind hole is processed, a spindle of the machine tool can realize automatic position detection, adjustment and correction of axis deviation, and automatic fastening and positioning. A displacement sensor is adopted to scan and detect the surface of the deep hole / blind hole, acquire data, analyze and calculate the ideal axis position of the deep hole / blind hole, and judge the deviation between the axis position and the ideal position of the spindle of the machine tool; a mechanism capable of feeding radially and axially and performing rotational motion is designed; a spherical bearing support, a bottom bearing support and four-axis linkage adjusting control mechanisms are designed to realize the automatic adjusting and positioning of the position of the spindle. The deep hole / blind hole processing technology is applicable to mounting, using, debugging, maintaining, processing, repairing, detecting and the like of large-sized machine tool equipment and parts in the fields of hydropower stations, nuclear power stations, naval vessels, ships mining and the like, and is also applicable to automatic positioning of spindles during general hole part processing and various operation processes.

Owner:FOSHAN XINCHENG HONGDING MACHINERY TECH CO LTD

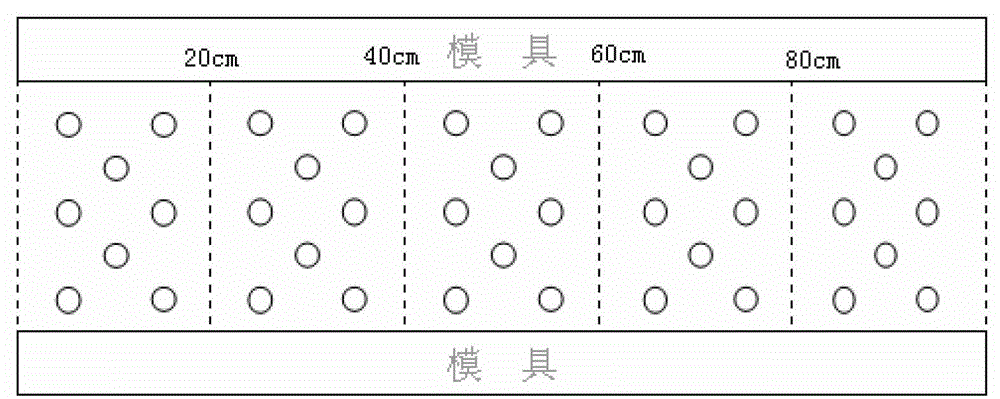

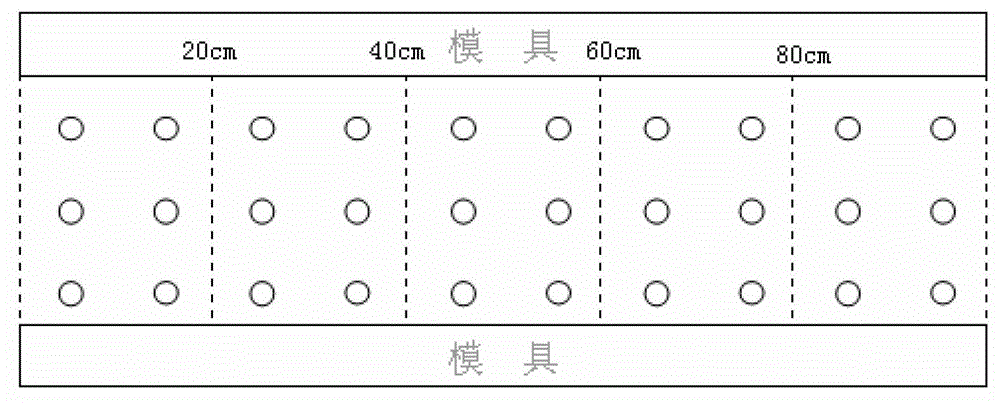

Seeding matrix and unibract fritillary bulb planting method

InactiveCN102870538AControl planting densityControl depthPlantingHorticultureEngineeringPlant density

The invention provides a seeding matrix which comprises a main plate in the middle and spindled positioning posts at two ends of the main plate. The main plate is rectangular, more than 1m in length and more than 0.2m in width. The length of the spindled positioning posts is larger than the width of the main plate. The invention further provides a unibract fritillary bulb planting method. By the use of the seeding matrix and the panting method, planting density and depth of unibract fritillary bulb can be controlled simply and effectively, full stand time of bulbs is shortened effectively, and yield of the unibract fritillary bulb is increased evidently.

Owner:SICHUAN NEAUTUS FRITILLARIA CIRRHOSA ECOLOGY MEDICINAL MATERIAL +1

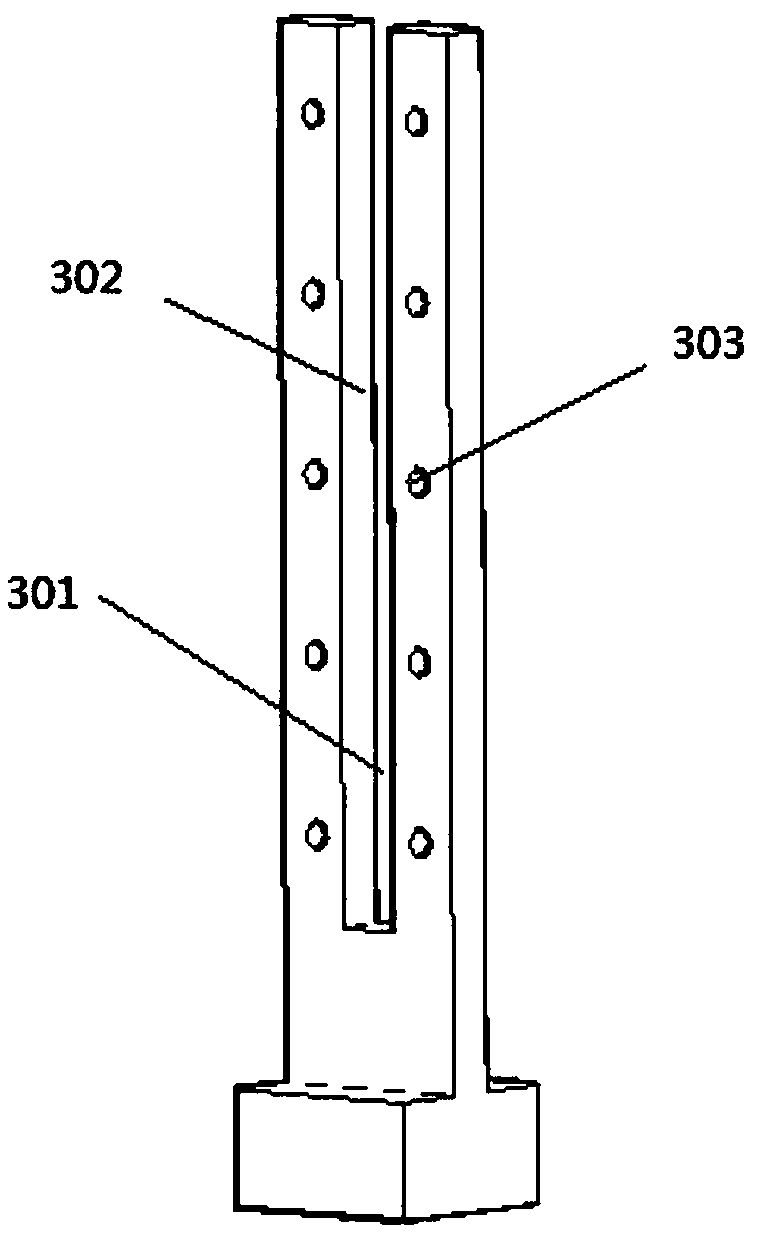

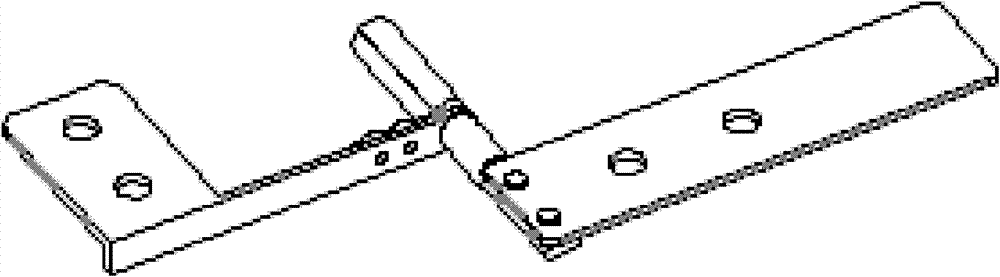

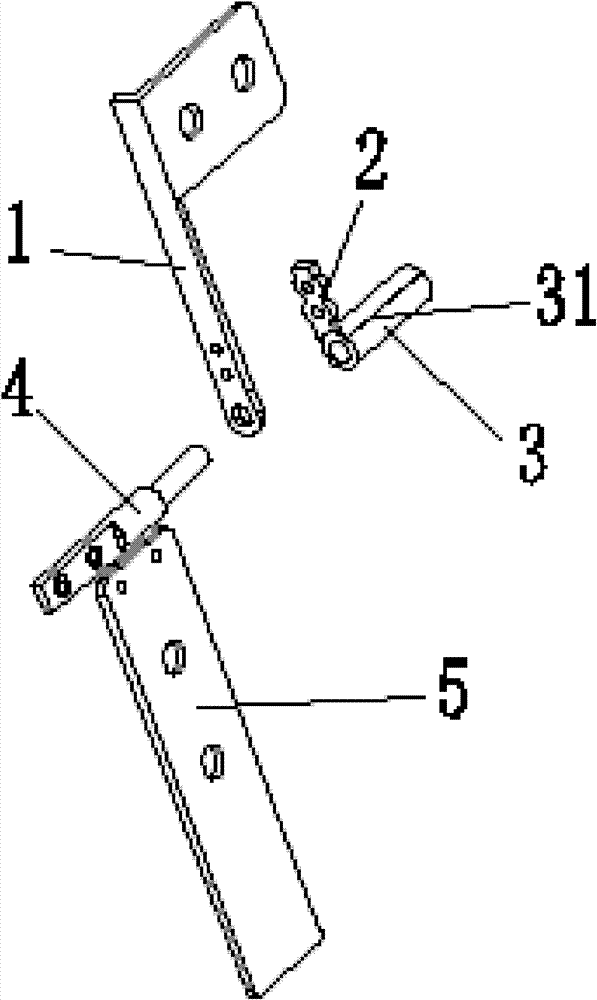

Welding device of breaker spindle connecting levers

PendingCN107790911AImprove work efficiencyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringArm position

The invention relates to a welding device of breaker spindle connecting levers. The welding device comprises a support seat and a support stand column perpendicularly mounted on the support seat, wherein a spindle support face is arranged on the support seat and is matched with the end face at one end of a spindle in a sliding support manner; at least two connecting lever positioning pieces used for being in location fit with the spindle and positioning corresponding connecting levers on the spindle are rotatably assembled on the support stand column; and each of the connecting lever positioning pieces comprises an angle positioning part used for being in location fit with corresponding connecting levers to enable the connecting levers to keep relative angles. The support stand column perpendicular to the support seat is mounted on the support seat; and the connecting lever positioning pieces are rotatably assembled on the support stand column, so that the angle positioning parts on the connecting lever positioning pieces carry out angle positioning on all connecting levers, the situation during welding, the spindle and the connecting levers are rotated to enable a worker not to move to and fro and to weld the circumferential contact surface of the spindle and the connecting levers, and the working efficiency is improved.

Owner:HENAN SENYUAN ELECTRIC CO LTD

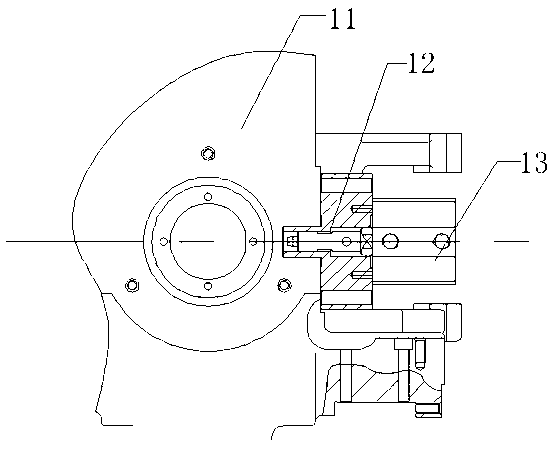

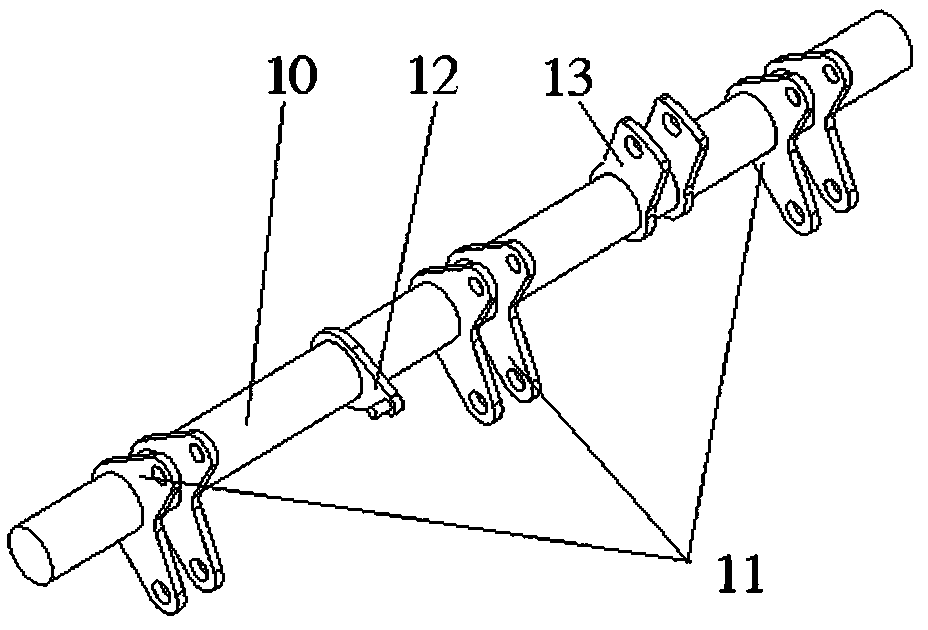

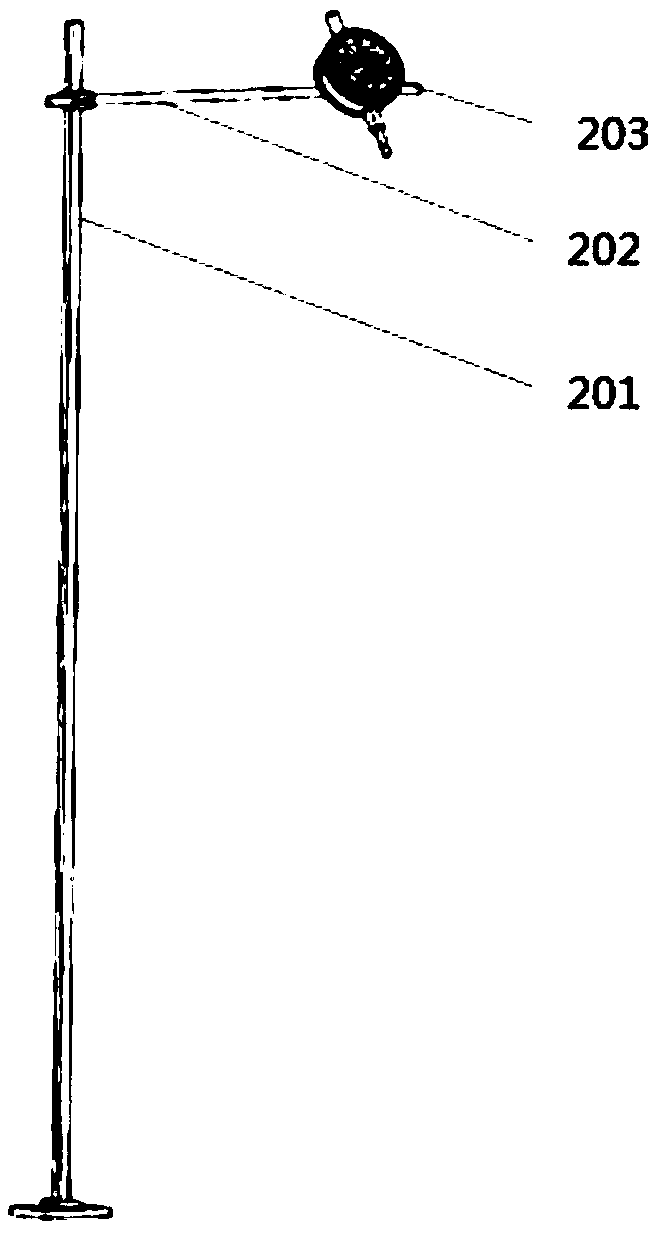

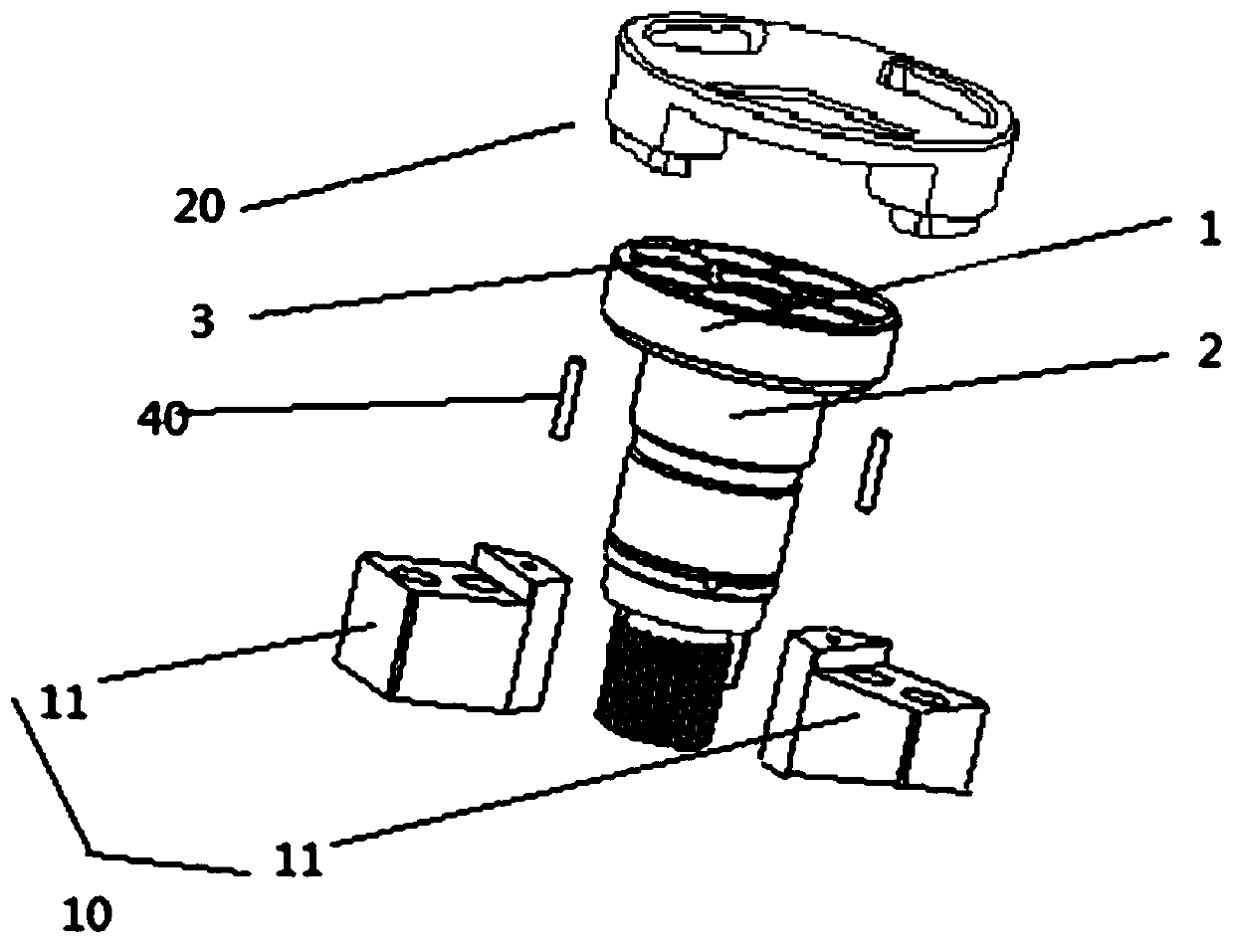

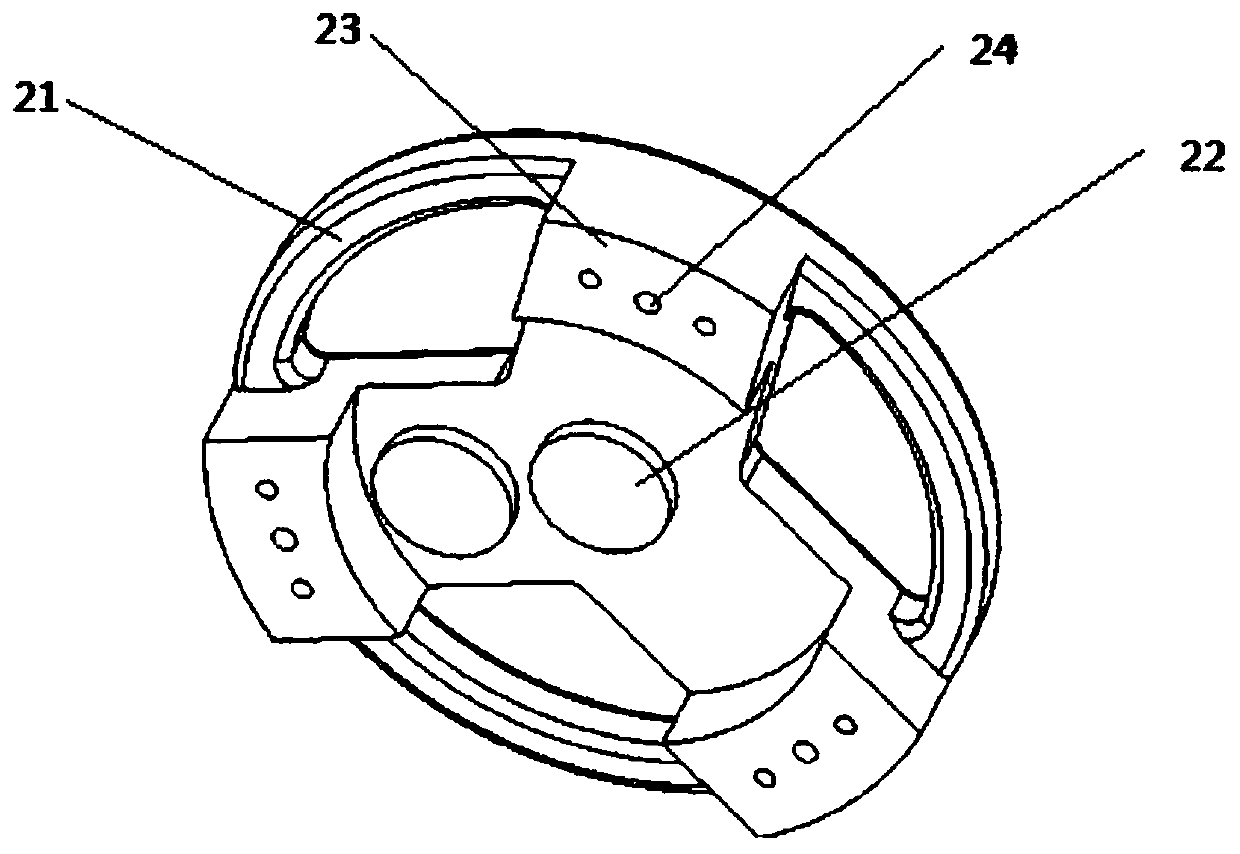

Spindle device for ensuring installing concentricity of cotton picker head

The invention discloses a spindle device for ensuring installing concentricity of a cotton picker head and belongs to the technical field of manufacture of cotton harvesting machines. The spindle device for ensuring the installing concentricity of the cotton picker head is composed of a spindle and a spindle positioning mechanism, wherein a spindle bevel gear in the spindle device is meshed with a bevel gear in a spindle seat pipe. The spindle is mainly composed of a spindle rod, the spindle bevel gear arranged at the rear end of the spindle rod and a spindle head arranged at the front end of the spindle rod. The spindle positioning mechanism is mainly composed of a spindle sleeve, a first spindle bearing and a second spindle bearing, wherein the first spindle bearing and the second spindle bearing are fixedly arranged in the inner cavity of the spindle sleeve, the lower end face of the first spindle bearing is provided with a first oblique chamfer, and the upper end face of the second spindle bearing is provided with a second oblique chamfer. The spindle device can ensure the concentricity of a picking device in the assembling process and is simple and ingenious in structural design.

Owner:星光正工(江苏)采棉机有限公司

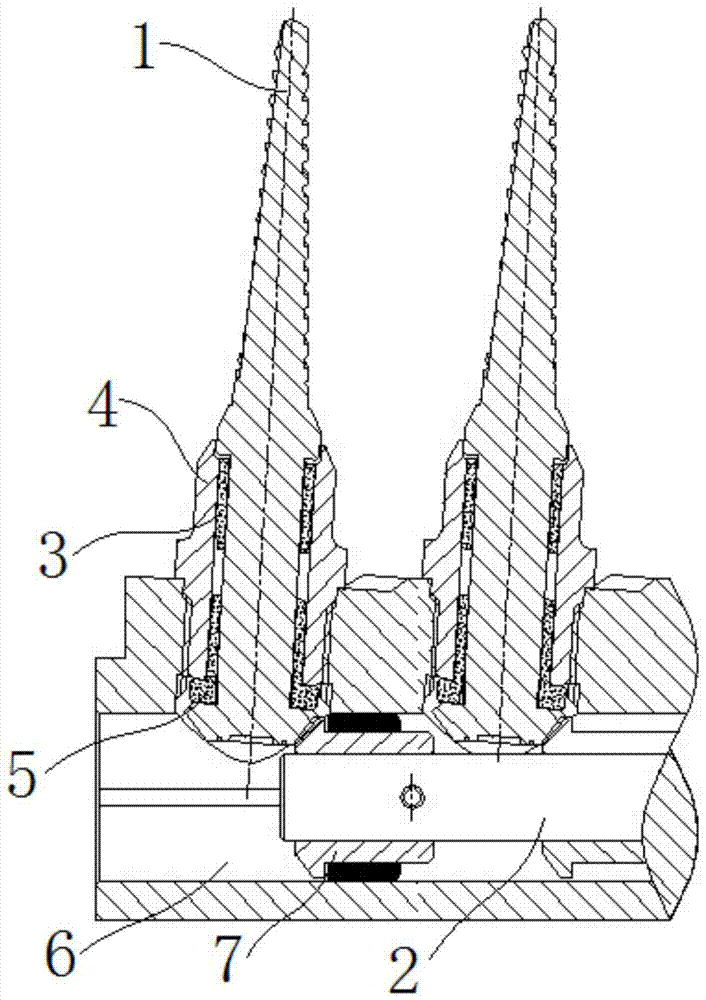

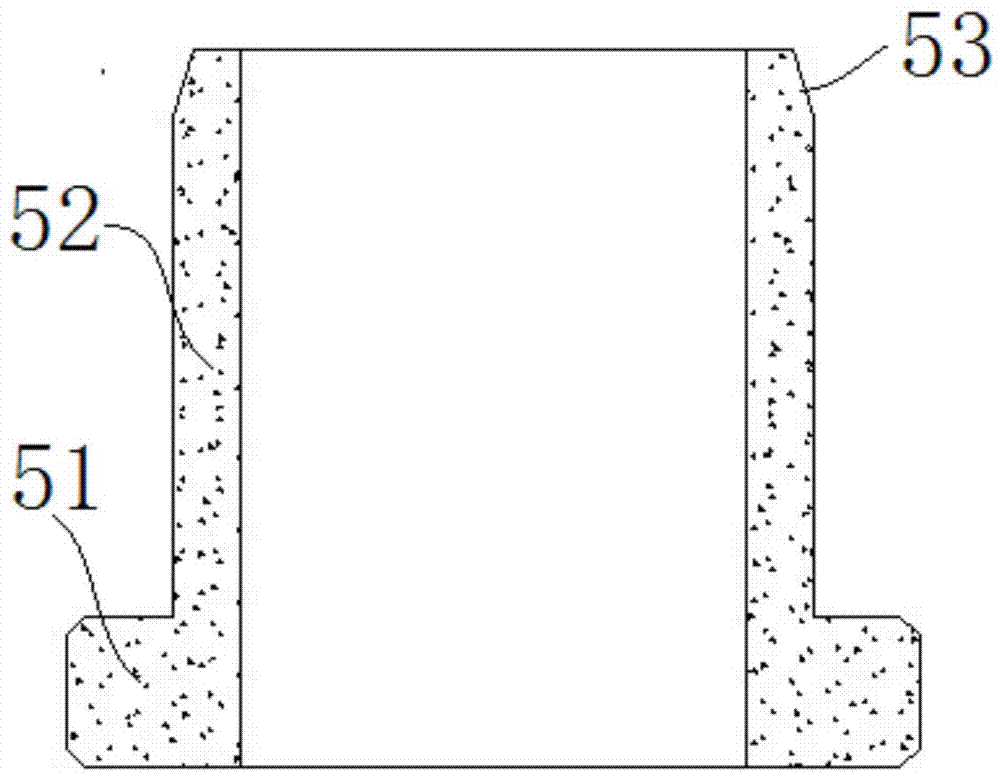

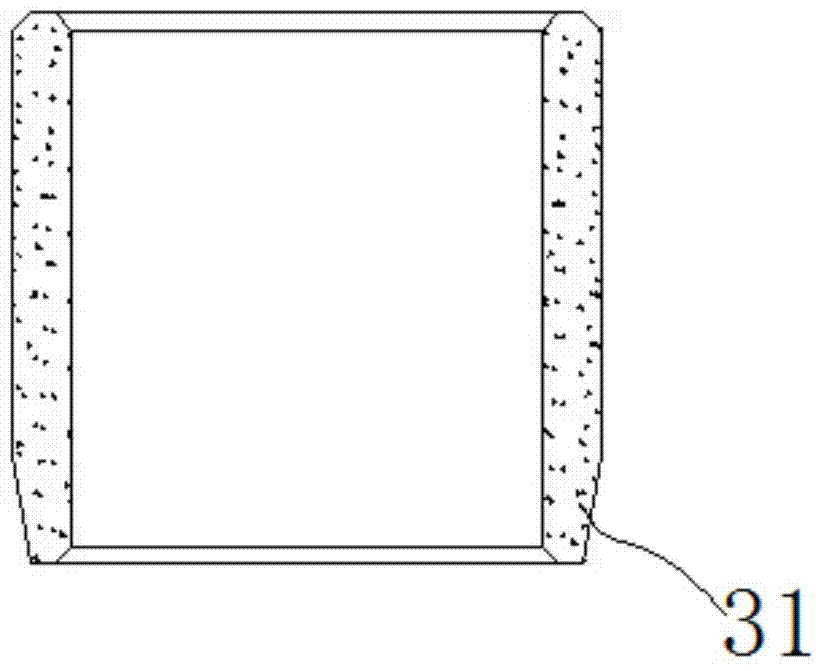

Electric spindle assembling tool for pre-loading elastic loads

PendingCN108942168ASolve the problem of difficult tighteningAchieve positioningMetal working apparatusElectricityMeasurement device

The invention discloses an electric spindle assembling tool for pre-loading elastic loads. The electric spindle assembling tool comprises a base and a spindle positioning device, an auxiliary clampingdevice, a pre-loading device, a fixing device and a measuring device, wherein the base is used for bearing an electric spindle to be assembled; the spindle positioning device is arranged below the base in a movable connection mode, and is used for positioning the electric spindle; the two ends of the auxiliary clamping device are installed on the fixing device, and is used for preventing the electric spindle from tilting in the assembling process; the two ends of the pre-loading device are installed on the fixing device, and is used for applying an elastic load; the measuring device is arranged on the base, and is used for detecting the axial and radial jumping of the electric spindle. According to the electric spindle assembling tool for pre-loading elastic loads, the problem that the bearing is difficult to tighten after the bearing is cooled in a thermal assembling mode is solved, the positioning of the electric spindle is realized, so that the assembling precision and the assembling efficiency are improved, and the standardized operation can be realized.

Owner:SHANGHAI JIAO TONG UNIV

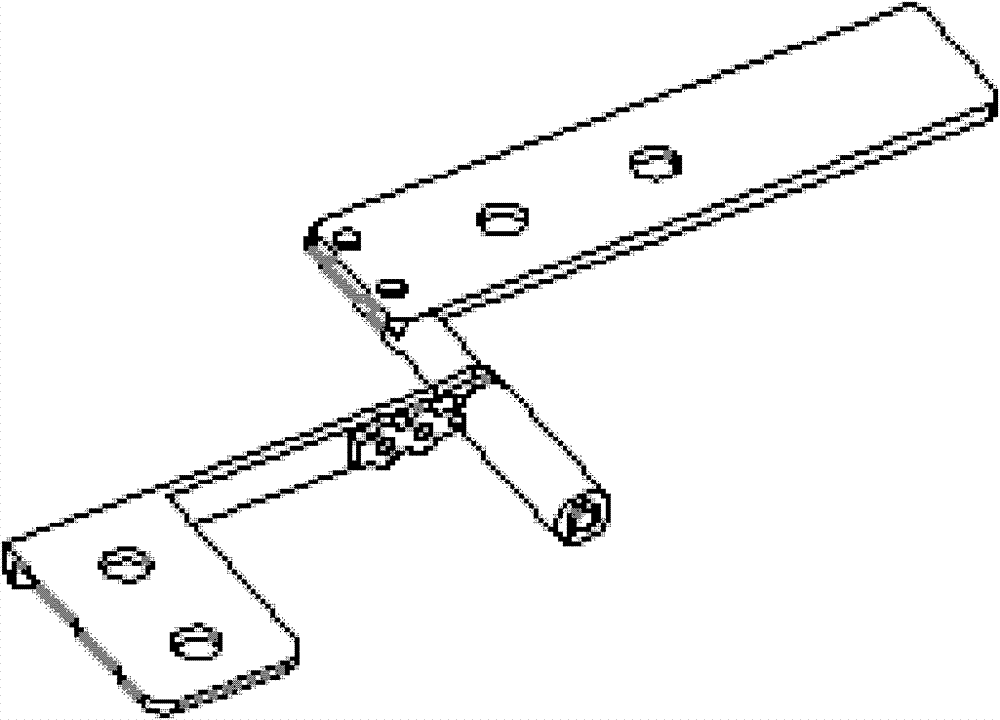

Welding tool of breaker spindle connecting levers

PendingCN107790944AGuaranteed Position RequirementsGuaranteed Angle RequirementsWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringMechanical engineering

The invention relates to a welding tool of breaker spindle connecting levers. The welding tool comprises a support seat, wherein at least two connecting lever positioning pieces are arranged on the support seat and are used for being in location fit with a spindle and positioning corresponding connecting levers on the spindle; each of the connecting lever positioning pieces comprises an axial positioning part and an angle positioning part; the axial positioning part is used for being matched with the space between corresponding connecting levers on the spindle; and the angle positioning part is used for being in location fit with corresponding connecting levers to enable the connecting levers to keep relative angles. The at least two connecting lever positioning pieces used for positioningcorresponding connecting levers on the spindle are arranged on the support seat; and the axial positioning part used for being matched with the space between corresponding connecting levers on the spindle and the angle positioning part used for being in location fit with corresponding connecting levers to enable the connecting levers to keep relative angles are arranged on each of the connectinglever positioning pieces, so that the demanded position and angle requirements when the connecting levers are welded on the spindle are ensured and the welding error is reduced.

Owner:HENAN SENYUAN ELECTRIC CO LTD

Method used for replacing escalator driving spindle

The invention discloses a method used for replacing an escalator driving spindle. The method comprises following steps that an original driving spindle and an original spindle sleeve ring are dismounted from a truss, and an original spindle adapter part is retained on the truss; one side of a first tool is assembled on the original spindle adapter part; a second tool is assembled on the first tool; the second tool is fixed to the truss; the first tool and the original spindle adapter part are dismounted from the truss; the other side of the first tool is assembled on a new spindle adapter part; the first tool and the new spindle adapter part are jointly assembled in the second tool; the new spindle adapter part is fixed to the truss; the first tool and the second tool are dismounted from the truss; the new driving spindle and the new spindle sleeve ring are assembled on the new spindle adapter part; and according to the method, the first tool and the second tool can precisely transmitoriginal spindle positioning benchmark to a new spindle, the new driving spindle after replacement can be precisely assembled on the position, relative to the truss, of the original driving spindle.

Owner:SCHINDLER CHINA ELEVATOR CO LTD

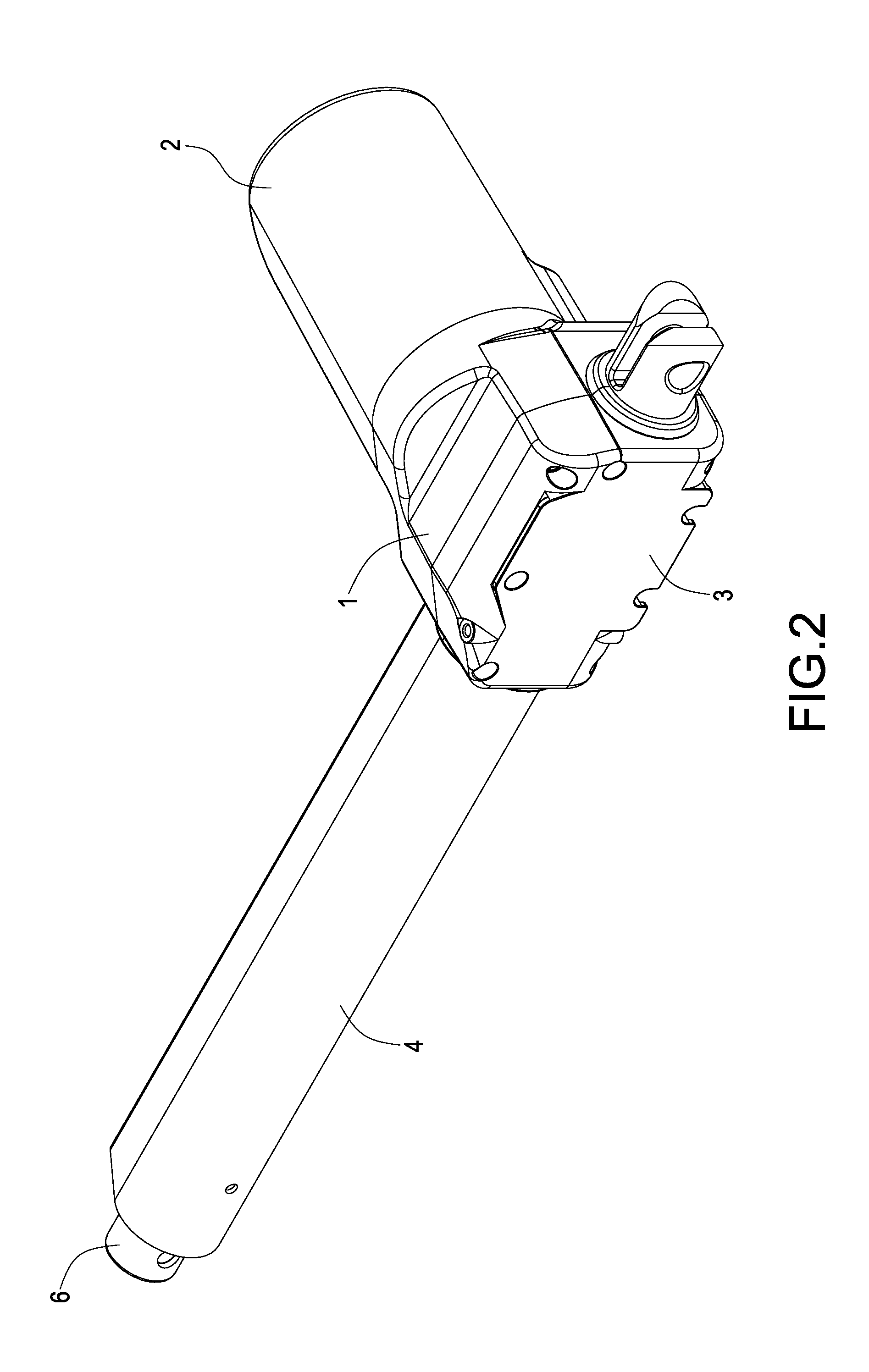

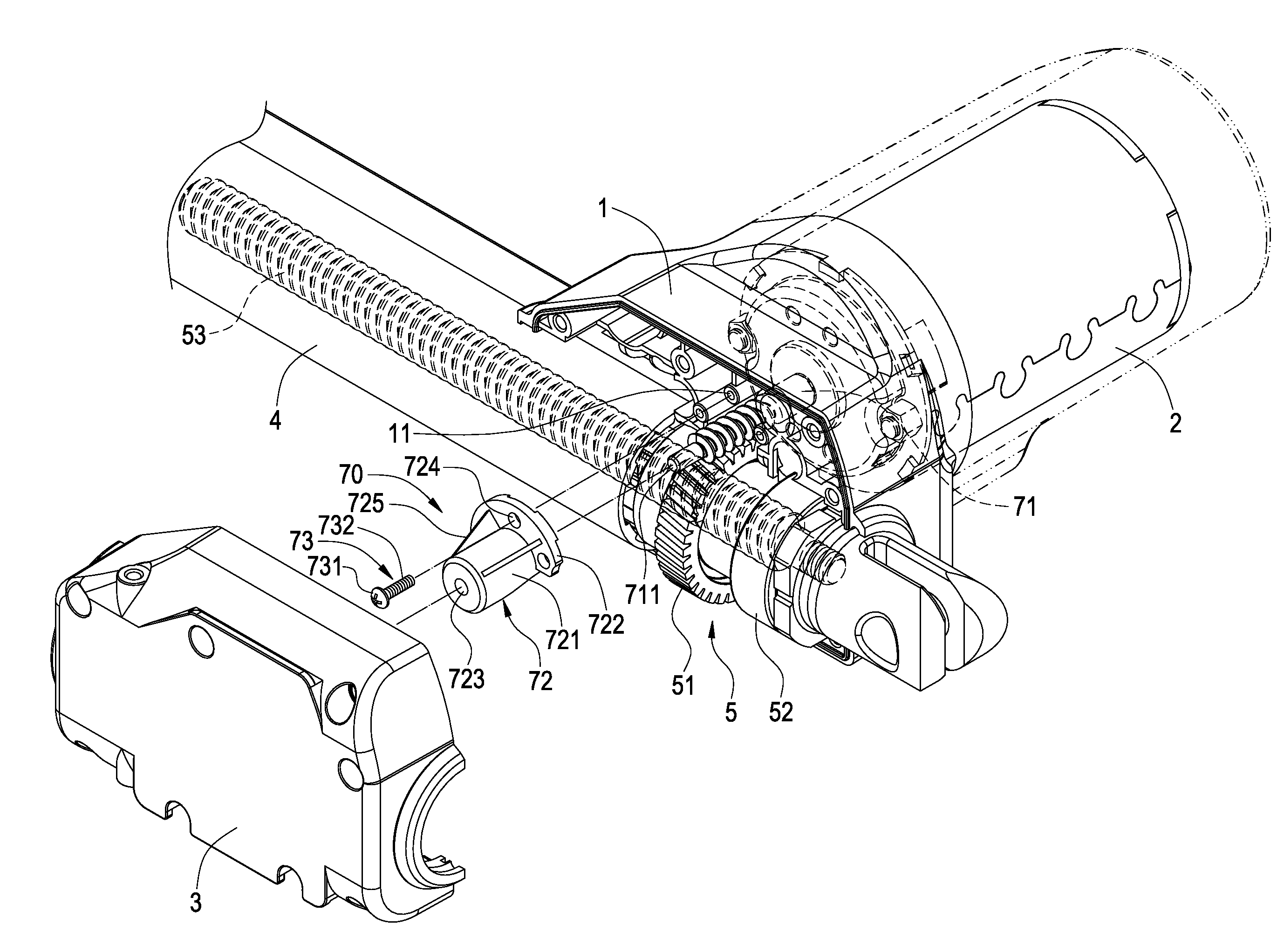

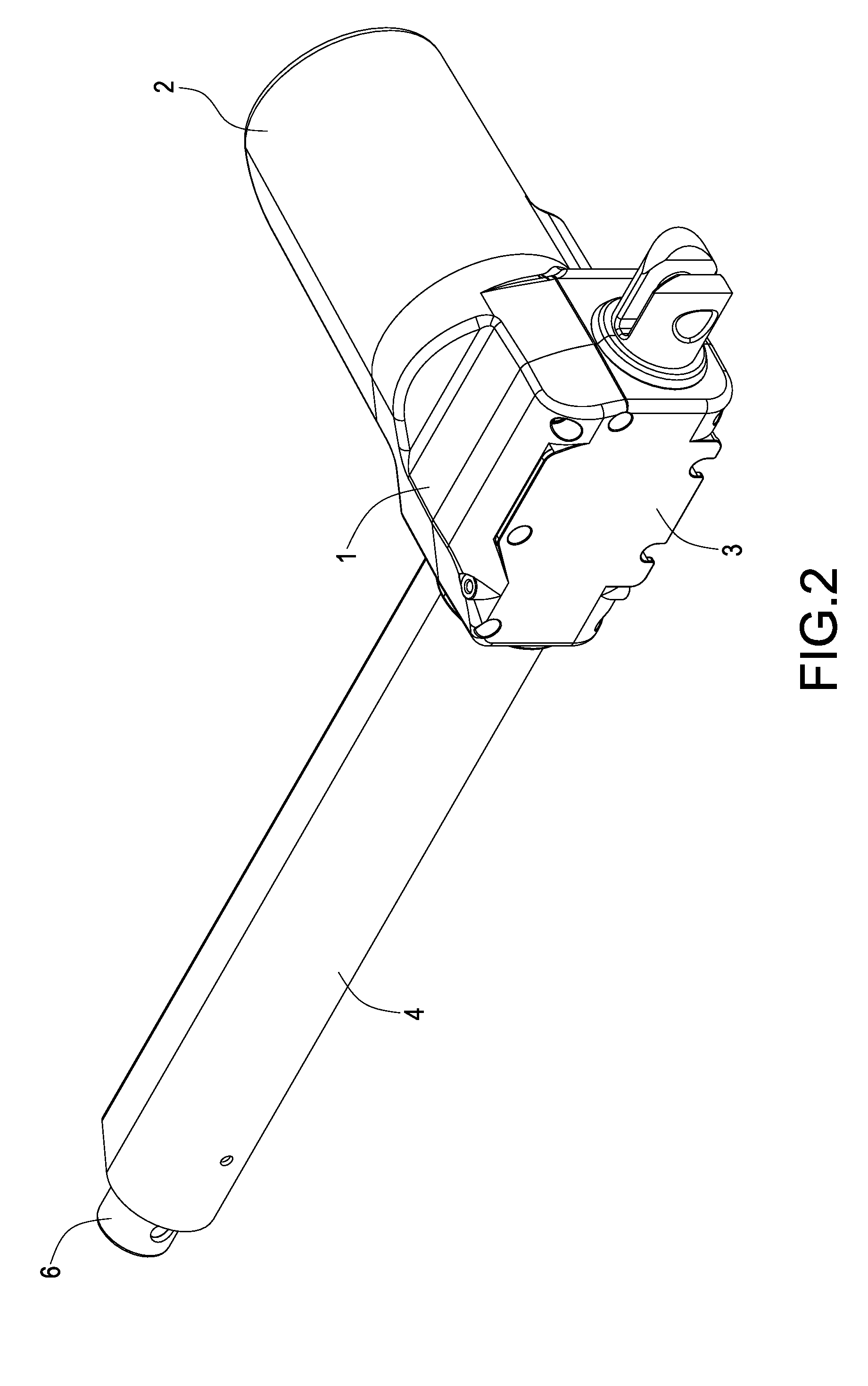

Spindle positioning means of linear actuator

ActiveUS7902704B2Avoid breakingOvercome mistakesMechanical energy handlingPropulsion systemsEngineeringLinear actuator

Owner:TIMOTION TECH CO LTD

Improvement on computer spindle positioning mechanism

InactiveCN102789282ARealize the rotation and positioning of the rotating shaftReduce frictionDigital processing power distributionEngineeringMechanical engineering

The invention discloses improvement on a computer spindle positioning mechanism. The computer spindle positioning mechanism is installed between a computer main board and a liquid crystal screen board, and comprises a mandrel, a movable bracket and a fixed bracket, wherein the movable bracket is connected with the liquid crystal screen board; the fixed bracket is connected with the computer main board; one end of the mandrel is fixed with the fixed bracket; the other end of the mandrel stretches into and is tightly assembled inside a edge round after penetrating through the movable bracket; the edge round is made of rigid materials, and the end part of the edge round is fixed on the movable bracket and the side part of the edge round is provided with an opening groove in the axial direction; the edge round is fixed on the movable bracket through an auxiliary bracket; one end of the auxiliary bracket is welded and fixed at the side part of the edge round along the vertical direction, and is formed into a welding reinforcing part; the other end of the auxiliary bracket is fixed on the movable bracket by screws; and the opening groove is arranged on a side part of the welding reinforcing part on the edge round. With the adoption of the improvement, the effect that a laptop is lightly opened but heavily closed is achieved through a torsion force, and the laptop is also convenient to assemble.

Owner:安捷资讯科技(苏州)有限公司

Positioning device used for numerical control tube bending machine

ActiveCN106180317AResolve reboundHigh precisionMetal-working feeding devicesPositioning devicesNumerical controlEngineering

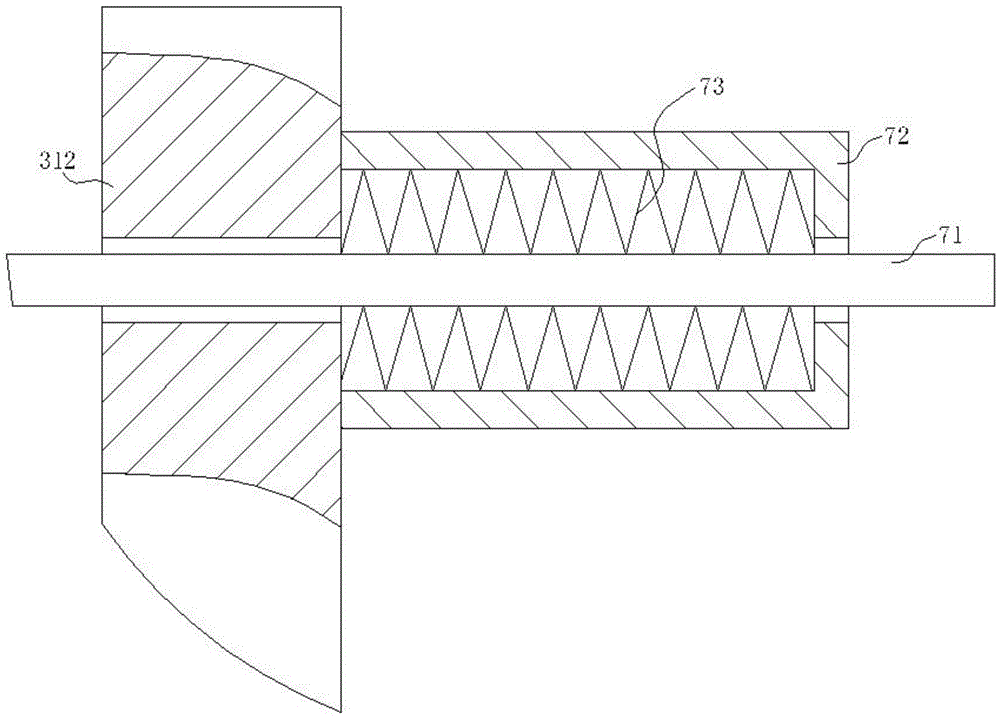

The invention discloses a positioning device used for a numerical control tube bending machine. The numerical control tube bending machine comprises a machine tool spindle. The positioning device comprises a left flange plate, a right flange plate and a spring arranged between the left flange plate and the right flange plate. Either of the left flange plate and the right flange plate can overcome the elastic force of the spring to move axially relative to the other flange plate which is fixedly connected with the end face of the machine tool spindle of the numerical control tube bending machine. The space for relative movement of the left flange plate and the right flange plate is controlled within the range of 3-5 mm. The overall axial length of the positioning device is consistent with the length of the portion, removed from the numerical control tube bending machine, of the machine tool spindle. According to the positioning device used for the numerical control tube bending machine, an elastic buffer space is provided for rebounding of a tube in the tube feeding process of the numerical control tube bending machine by replacing a positioning mechanism on an original numerical control tube bending machine, and the rebounding problem of the tube in the tube feeding process is effectively solved accordingly; and the stability of an original equipment spindle positioning device is greatly promoted, the tube machining dimension precision is greatly improved, and the rejection rate is decreased to the maximum.

Owner:CRRC MEISHAN

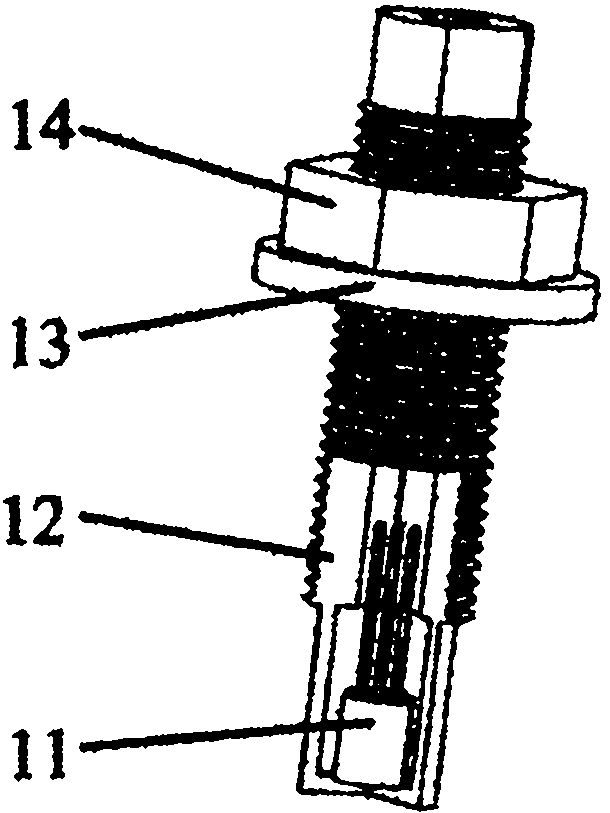

Cutter head spindle spring positioning device

InactiveCN105773265AOvercome the problem that misalignment cannot be joined, and even the key will be damagedSimple structurePositioning apparatusMetal-working holdersFastenerSpindle positioning

The invention relates to a cutter head spindle positioning device. The cutter head spindle positioning device is arranged in a cutter head accessory and comprises a pressing sleeve, a pressing cover, a base plate, an ejection rod, a bolt, a pin and a spring. The ejection rod and the pressing sleeve are fixed through a fastener. The base plate is arranged on the lower portion of the pressing sleeve. A limiting mechanism matched with the pressing cover is arranged on the pressing sleeve. The pressing cover is arranged on the end face of the cutter head accessory. The spring is arranged between the ejection rod and the pressing sleeve. One end of the pin is arranged on the ejection rod, and the other end of the pin is inserted into a bolt taper slot. When the accessory is in a working state, a ram applies pressure to the end face of the pressing sleeve when the accessory is taken, the pin located in the bolt taper slot drives the bolt to move to be away from a center shaft, and rotation of the center shaft is not influenced. When the accessory is in a non-working state, the pressing sleeve and the ejection rod are jacked, and the pin drives the bolt to extend to insert into the center shaft of the accessory, so that the center shaft is immovable, a key on the center shaft does not deviate, and the end face key of the center shaft can be accurately matched with a key slot of the accessory. The positioning device provided by the invention has the advantages of being simple and compact in structure, convenient to use and reliable.

Owner:WUHAN HEAVY MACHINE TOOL GRP

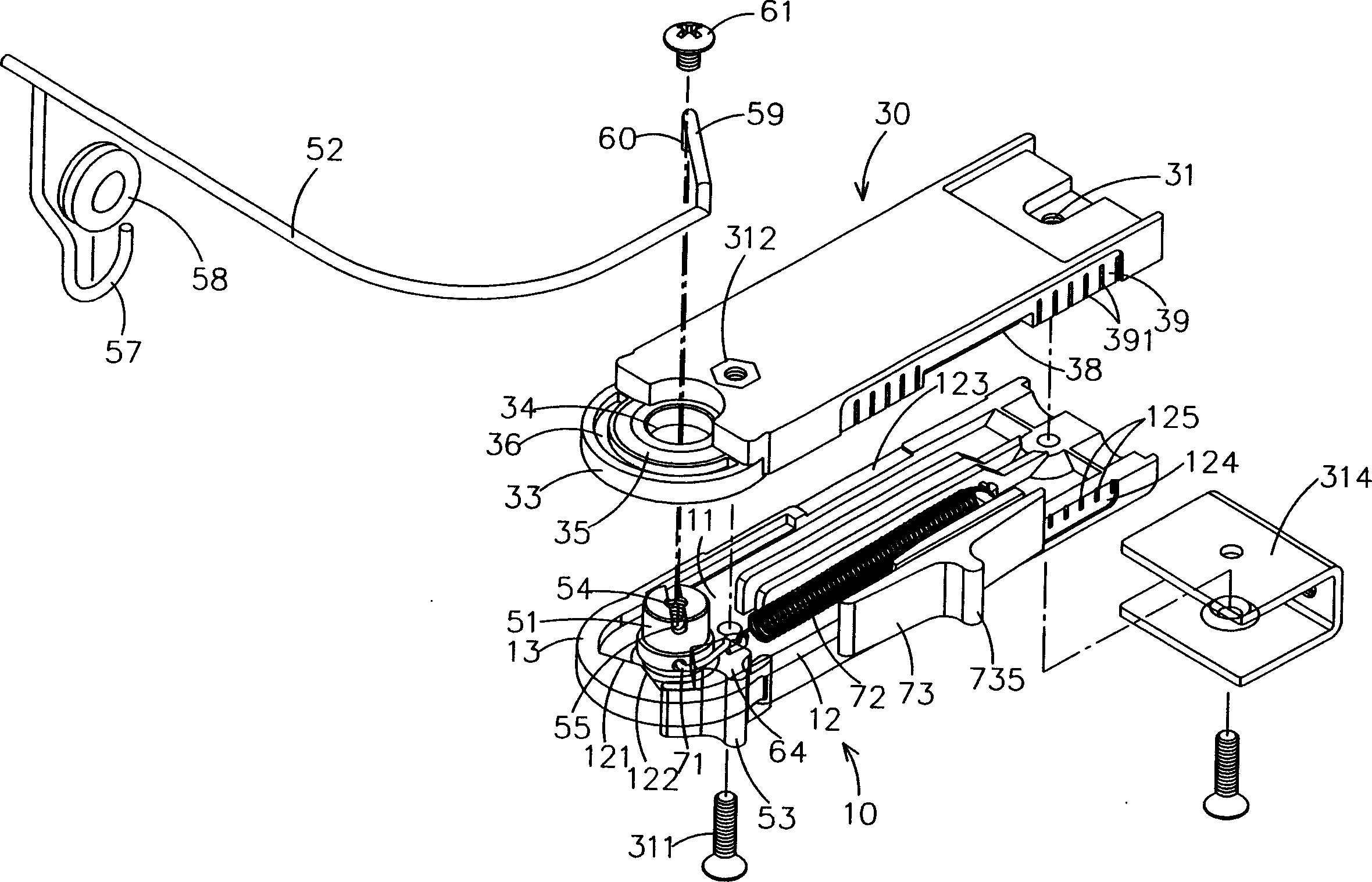

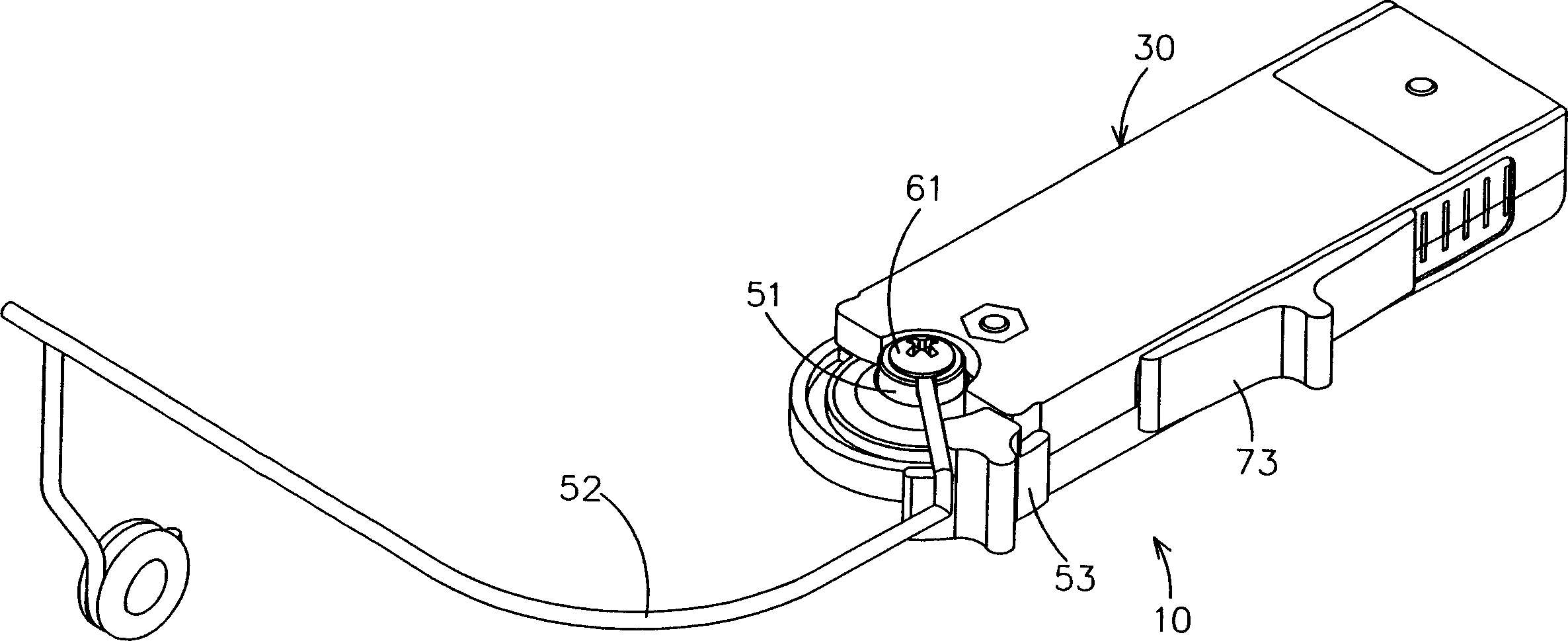

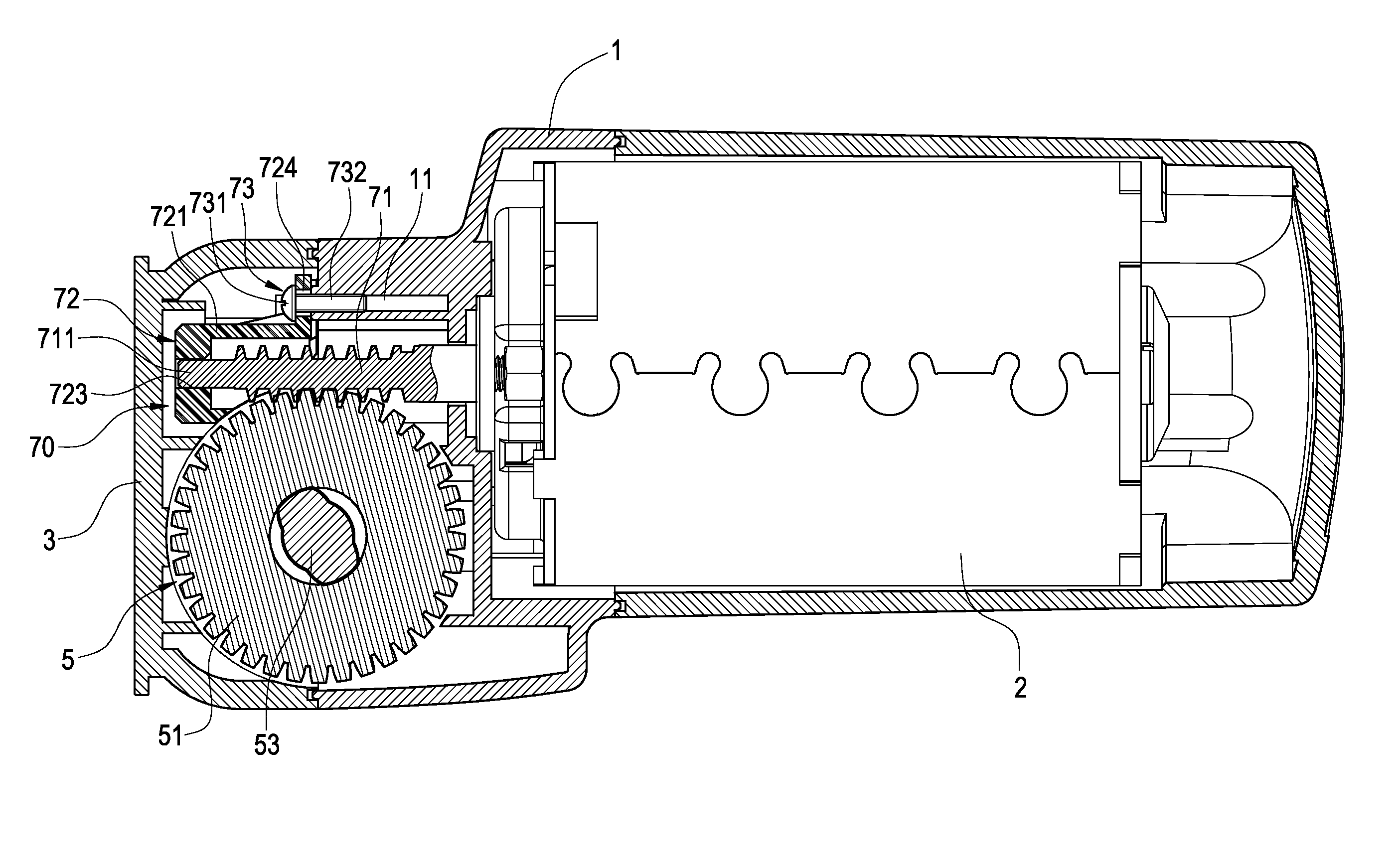

Spindle positioning means of linear actuator

ActiveUS20100225187A1Reduce manufacturing costReduce material costsMechanical energy handlingPropulsion systemsLinear actuatorSpindle positioning

A linear actuator includes a base having a positioning post and a motor fixed on one side of the base. A spindle positioning means includes a spindle, a seat and a fixing element. The spindle protrudes from the motor and penetrates the base. One side of the spindle away from the motor is formed with a free end. The seat includes a cylinder and an extension plate protruding outwards from the periphery of the cylinder. The extension plate is provided with a trough. The cylinder is connected to the free end of the spindle. The trough of the extension plate is located to correspond to the positioning post. The fixing element passes through the trough to fix the seat on the positioning post. Via this arrangement, the breakage of the spindle caused by a lateral force can be prevented efficiently.

Owner:TIMOTION TECH CO LTD

A gearbox no-load running-in test bench with self-centering positioning and clamping device

ActiveCN105527096BGuaranteed concentricitySafe and secure clampingMachine gearing/transmission testingEngineeringTest bench

Owner:JILIN UNIV

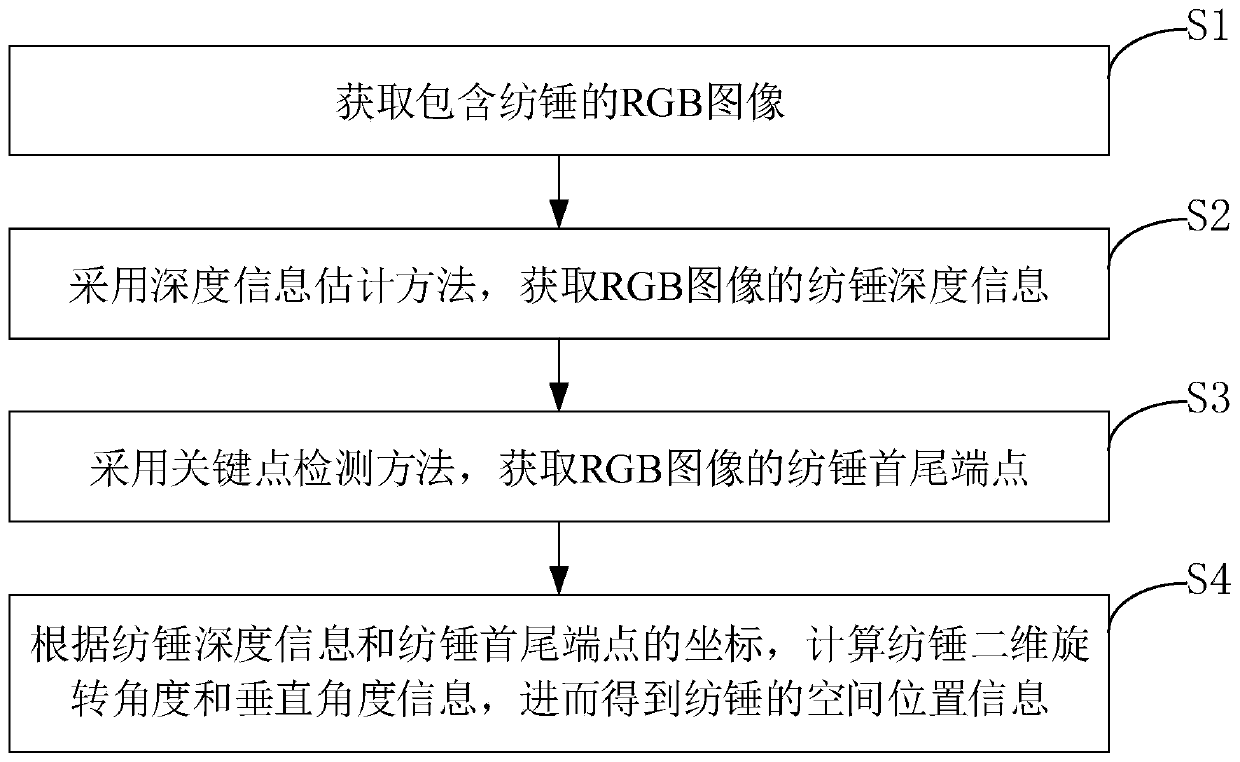

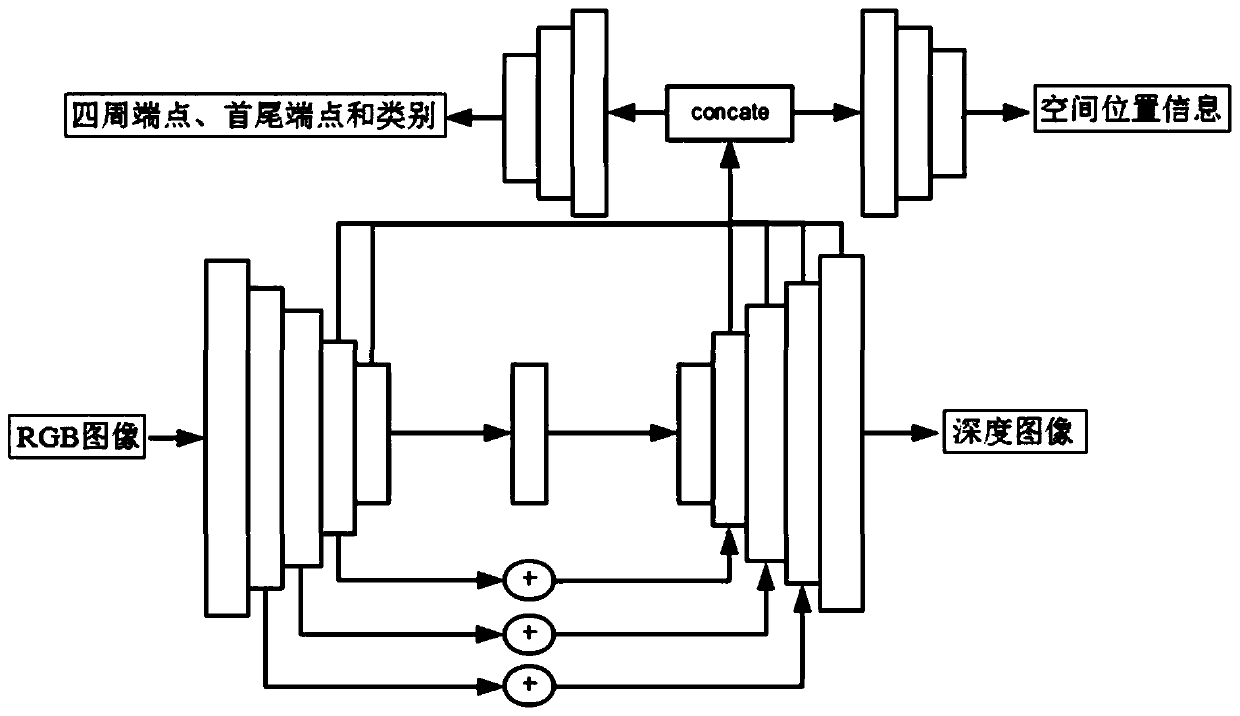

Spindle positioning method based on depth target detection

PendingCN110956656AGet rid of dependenceEfficient and precise positioning methodImage enhancementImage analysisMedicineRgb image

The invention discloses a spindle positioning method based on depth target detection. The spindle positioning method comprises the steps: obtaining an RGB image containing a spindle; acquiring spindledepth information of the RGB image by adopting a depth information estimation method; adopting a key point detection method to obtain spindle head and tail end points of the RGB image; and accordingto the spindle depth information and the coordinates of the head and tail end points of the spindle, calculating two-dimensional rotation angle and vertical angle information of the spindle, and thenobtaining spatial position information of the spindle. The spindle positioning method based on depth target detection detects the depth information of the spindle in the RGB image to get rid of dependence on a depth camera, performs key point and category detection on the spindle in the image to assist calculation of spindle spatial position information, meanwhile, adopts multi-result output, adjusts and trains a network structure according to results, can find problems conveniently and timely, and finally can obtain the efficient and accurate positioning method for the spindle based on the neural network.

Owner:BEIJING UNIV OF TECH

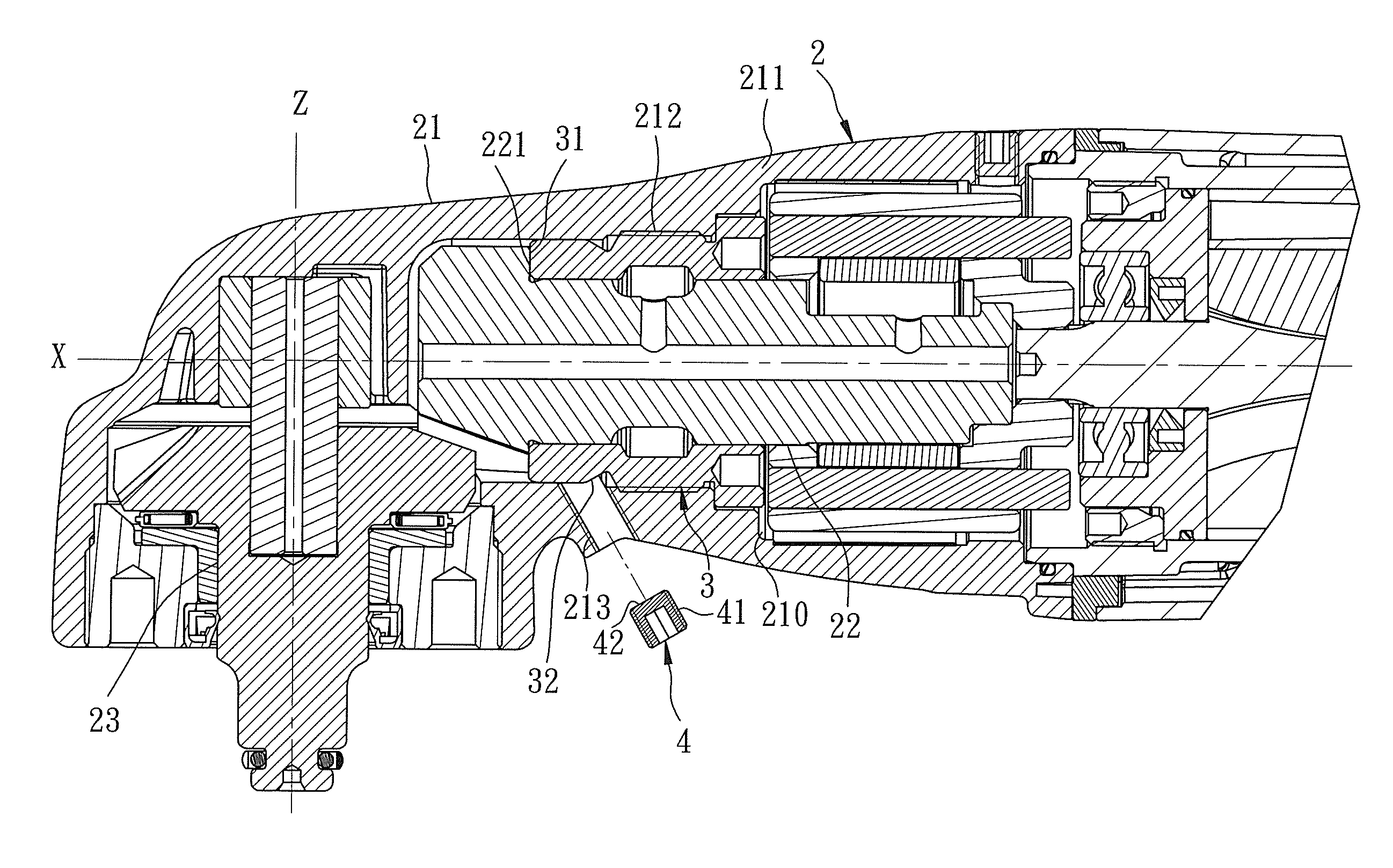

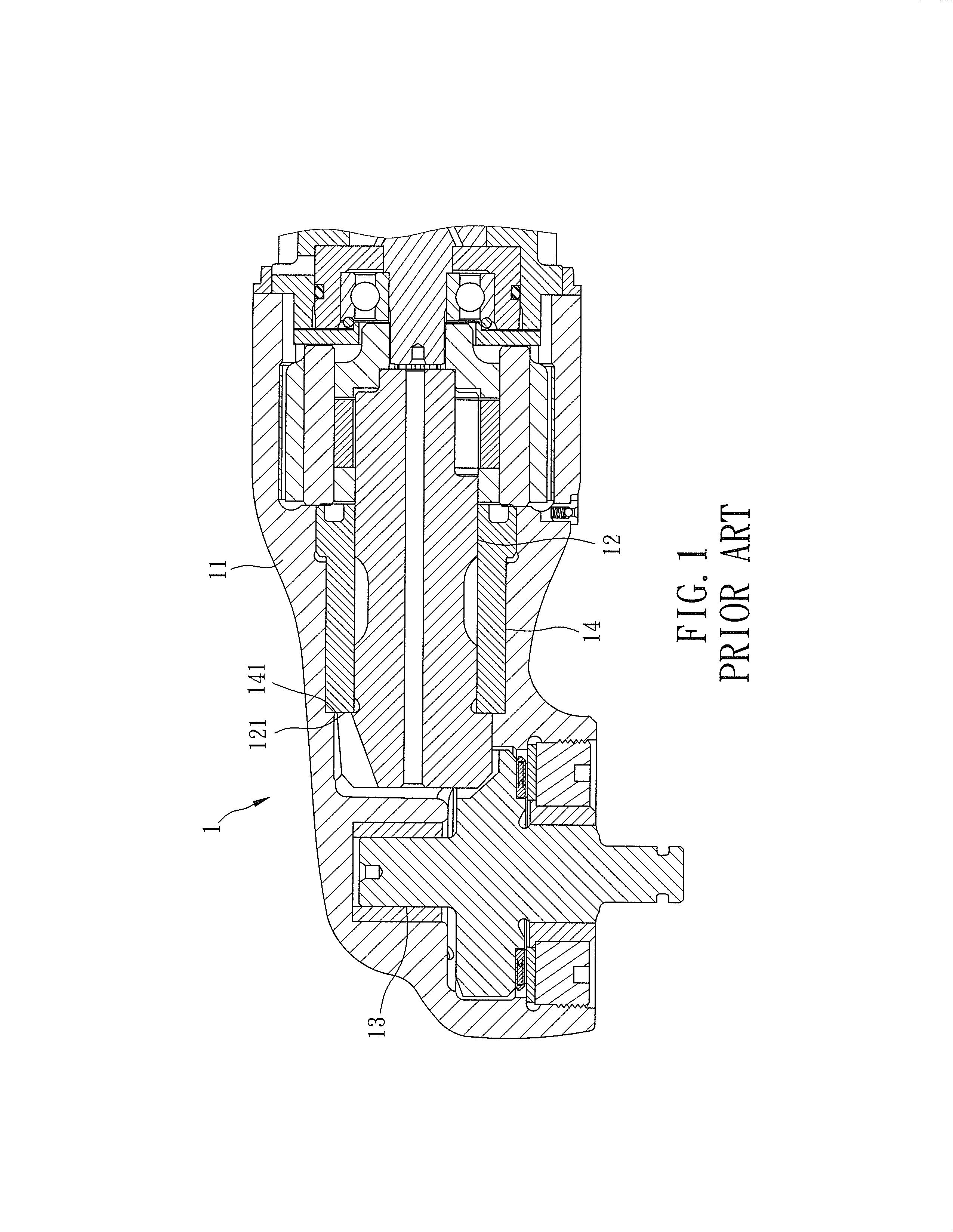

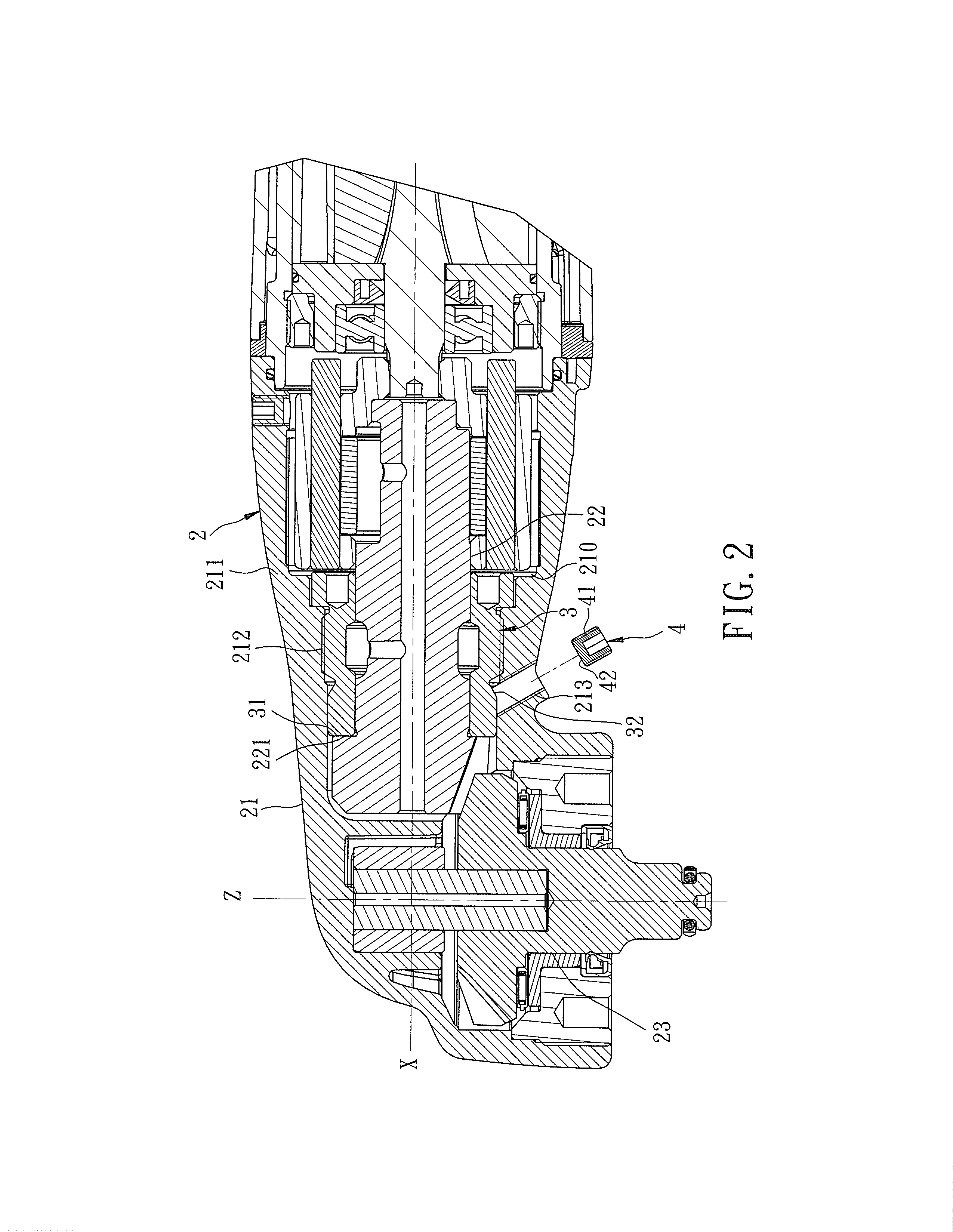

Pneumatic impact tool with a spindle positioning device

ActiveUS20130180746A1Prevent movementConstructionsReciprocating drilling machinesClassical mechanicsControl theory

A pneumatic impact tool includes a spindle extending along an X-axis, an output shaft extending along a Z-axis, and a spindle positioning device that includes a bushing and a stop pin. The bushing is threaded in a housing, and has a stop surface and a frustoconical outer surface. The stop surface obstructs the spindle from moving away from the output shaft. The frustoconical outer surface has opposite first and second ends. The first end is nearer to the X-axis and farther away from the Z-axis than the second end. The stop pin is disposed removably in the housing, and has an engaging surface abutting against the frustoconical outer surface, so as to prevent the bushing from moving in the housing in a direction away from the output shaft.

Owner:BASSO IND CORP

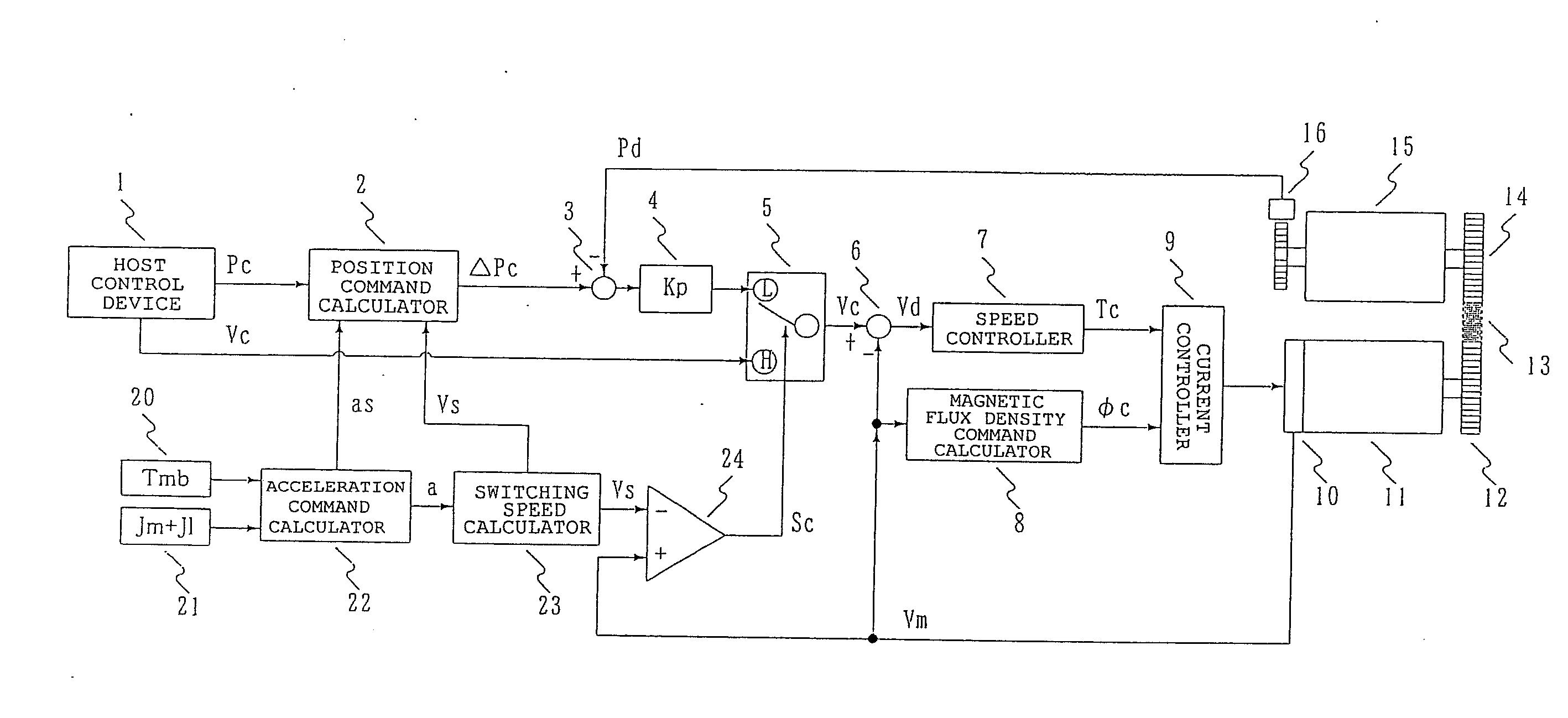

Spindle positioning device

ActiveUS9190946B2Rapid positioningAutomatic control devicesComputer controlMotor speedPosition control

An acceleration command calculator calculates an acceleration command “as” based on an output torque Tmb of the spindle motor applied when the rotational speed is less than or equal to a base rotational speed and an inertia Jm+Jl of the overall spindle. A switching speed calculator calculates a control mode switching speed Vs based on the acceleration command “as”. A control mode switching switch switches from a speed control mode to a position control mode when the motor speed Vm becomes less than or equal to the control mode switching speed Vs, to stop the spindle at a desired rotational position. The control mode switching speed Vs may be a value calculated using the following equation: Vs=60×(amax×0.5)1 / 2, where a maximum acceleration that can be achieved at this time is represented by a max.

Owner:OKUMA CORP

Hydraulic pump spindle positioning assembly and hydraulic pump spindle machining device

The invention relates to the technical field of machining tools, in particular to a hydraulic pump spindle positioning assembly and a hydraulic pump spindle machining device. The hydraulic pump spindle positioning assembly comprises a first positioning piece and a second positioning piece which are detachably connected with each other, the first positioning piece is fixed on a chuck, the first positioning piece is used for supporting one side, far away from a to-be-machined hole, of the spindle, and a gap exists between the first positioning piece and the side wall on one side; and the secondpositioning piece comprises a base body and at least two positioning parts arranged on the base body, and the positioning parts are used for forming pin hole positioning with the to-be-machined hole in the spindle. According to the hydraulic pump spindle positioning assembly, tool setting can be performed before a first ball socket is machined, the tool setting does not need to be repeated, and the machining efficiency is improved.

Owner:杭州力龙液压有限公司

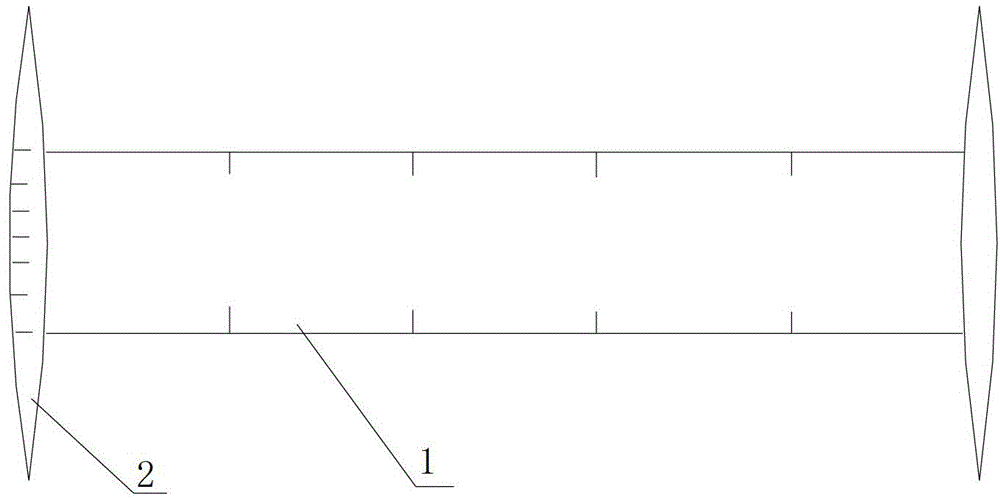

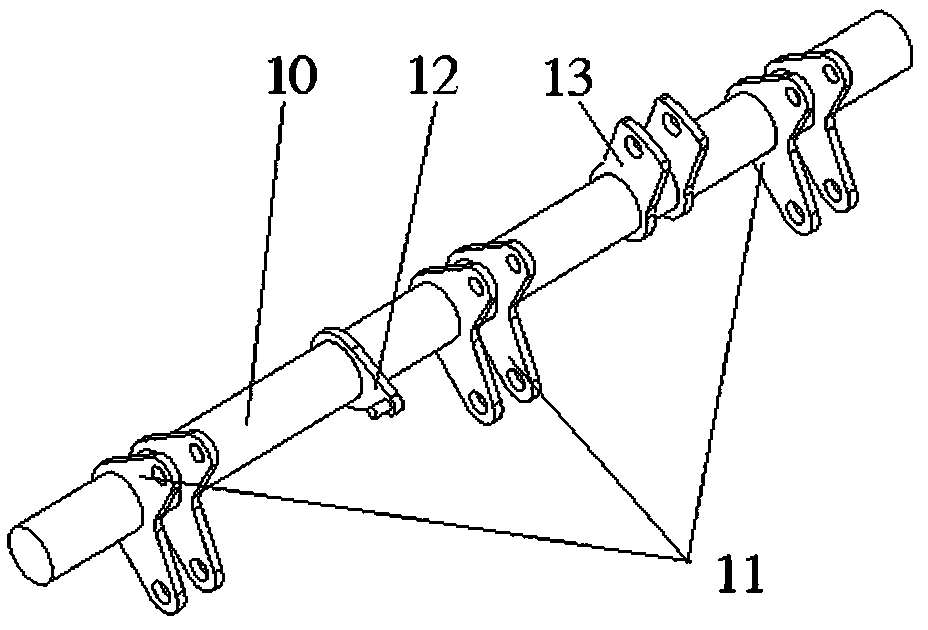

Spindle bar capable of positioning textile bobbins

The invention discloses a spindle blade capable of positioning a textile bobbin. The spindle blade comprises a hollow blade body (10), four openings (20) formed in the blade body (10), telescopic blocks capable of telescoping in the openings (20), levers and a center wheel, wherein one end of each lever is movably connected to one end, positioned inside the blade body, of the corresponding telescopic block; the other end of each lever is movably connected onto the center wheel. The center wheel is mounted on a transverse rod, the center wheel can rotate around the transverse rod, the transverse rod is fixed on the blade body (10), and the transverse rod passes through the axial lead of the blade body (10). When the bobbin sleeves on the spindle blade from the top down, the lower end of the bobbin can contact the telescopic blocks, the telescopic blocks retract towards the inside of the blade body, the telescopic blocks drive the levers, the levers drive the center wheel to rotate, the center wheel drives another lever and telescopic block connected onto the center wheel, and the distances that the two telescopic blocks retract towards the inside of the blade body are equivalent. Therefore, the effect of centralized positioning for the bobbin is reached, and thus the degree of twist of yarns is improved.

Owner:汪建建

Attachment milling head spindle positioning structure

ActiveCN105798368BGuaranteed dockingImprove work efficiencyMilling equipment detailsTransverse axisEngineering

The invention relates to a main shaft positioning structure of an accessory milling head, comprising a transition housing, a main shaft of an accessory milling head, a positioning dial, a positioning key block, a pressure spring, a small transverse shaft and a positioning pin. The accessory milling head spindle is installed in the transition housing, the positioning dial is connected with the accessory milling head spindle, which can drive the accessory milling head spindle to rotate, one end of the positioning pin is inserted into the keyway opened on the positioning dial, and the other end is fixed on the small horizontal shaft On; the small horizontal shaft and the pressure spring are placed in the positioning key block. The invention has a simple structure, can ensure the normal docking of the main shaft of the machine tool and the main shaft of the accessory without manual observation and adjustment, improves the working efficiency when the milling head of the accessory is mounted, and provides a basis for automatic replacement of the accessory.

Owner:WUHAN HEAVY MACHINE TOOL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com