A gearbox no-load running-in test bench with self-centering positioning and clamping device

A technology for positioning and clamping and clamping device, applied in the field of rail vehicle gearbox test platform, can solve the problems of complex disassembly and installation, damage to axle journals, unable to meet high rotation speed, etc., to achieve installation and disassembly, increase the contact area , the effect of low manufacturing and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention is described in detail below in conjunction with accompanying drawing:

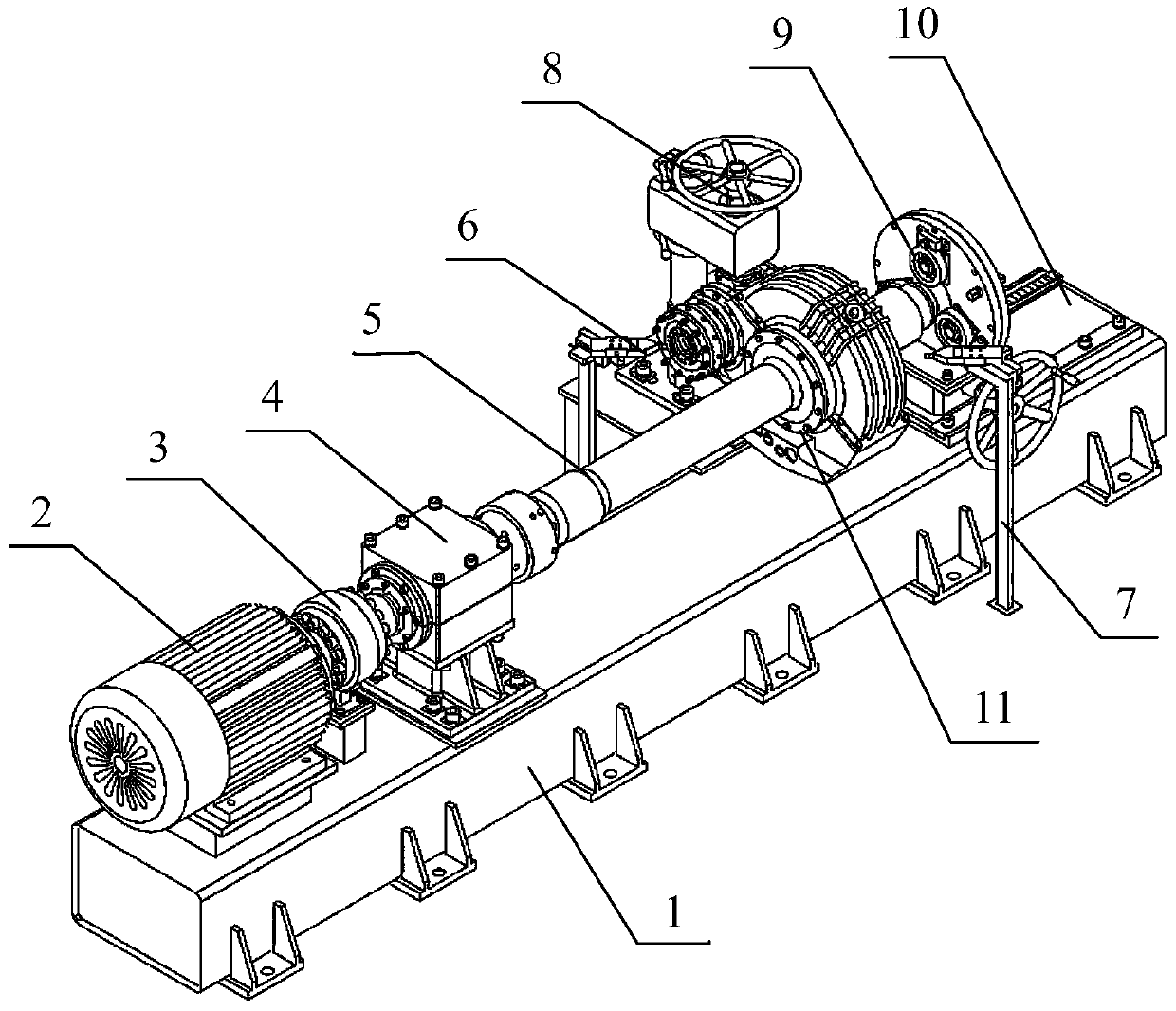

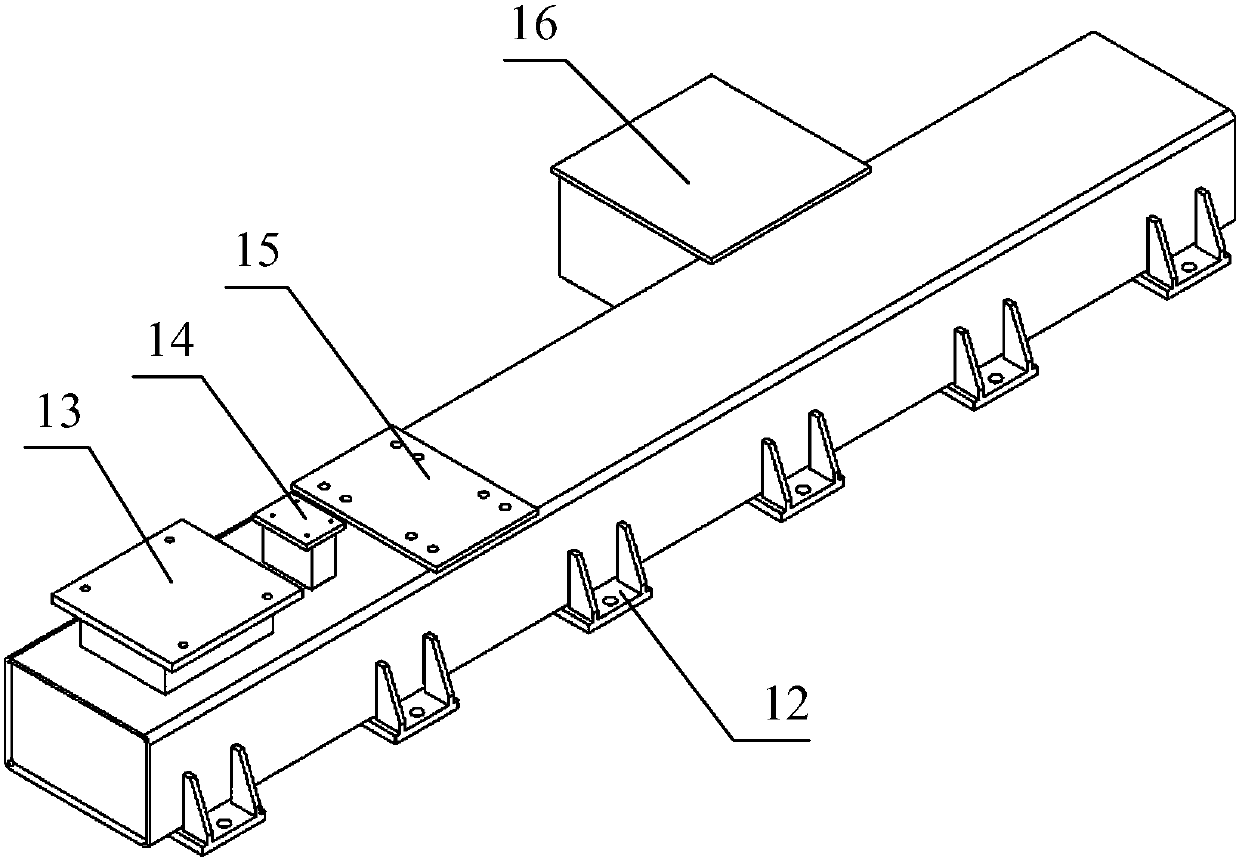

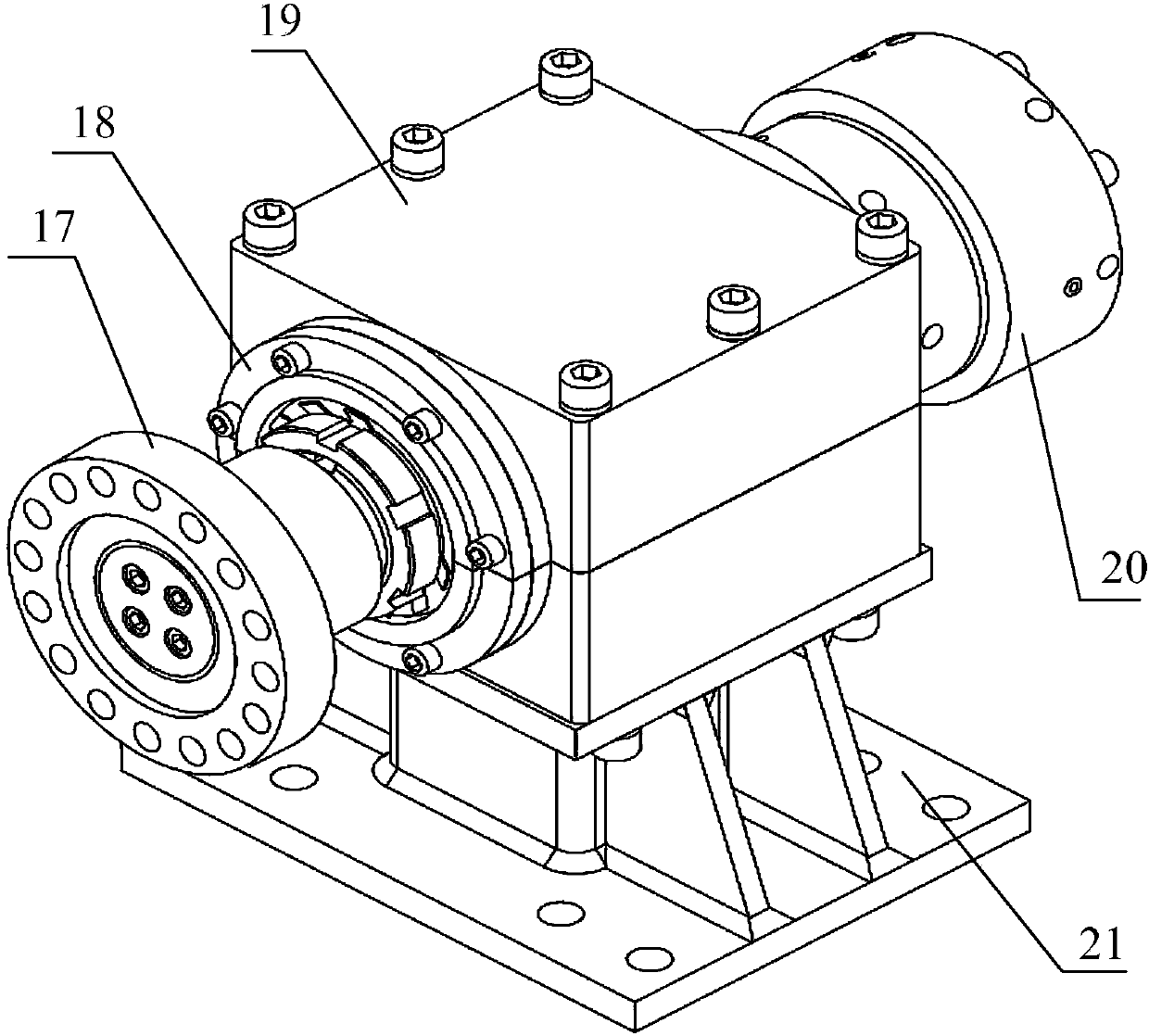

[0040] The object of the present invention is to provide a train gearbox no-load running-in test bench with self-centering positioning and clamping device, which is used to detect the running-in condition of the gearbox under no-load state, so that the gearbox can meet the requirements of existing high-speed trains. its technical requirements. A certain power is applied to the input end of the gearbox, and no load is applied to the end of the axle, so that the gearbox runs under no-load conditions. A torque speed sensor is installed between the driving motor and the gearbox, which can adjust different speeds and torques to apply power to the gearbox; the positioning and clamping device at one end of the wheel shaft is fixed, and is clamped with elastic clamp type double bearings The main shaft is positioned and clamped and transmits the power torque, and the other end is mobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com