Patents

Literature

166results about How to "Reliable positioning and clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

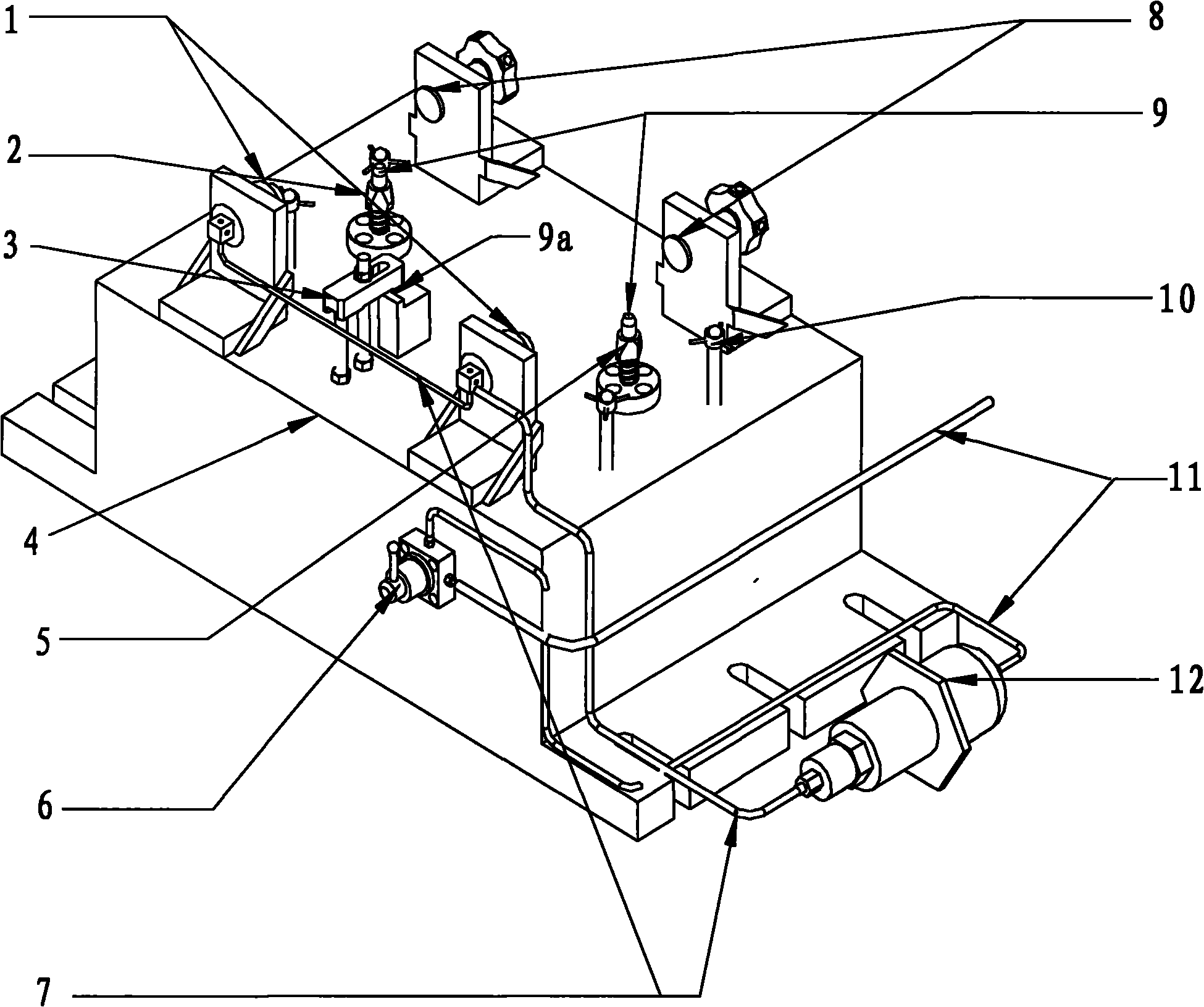

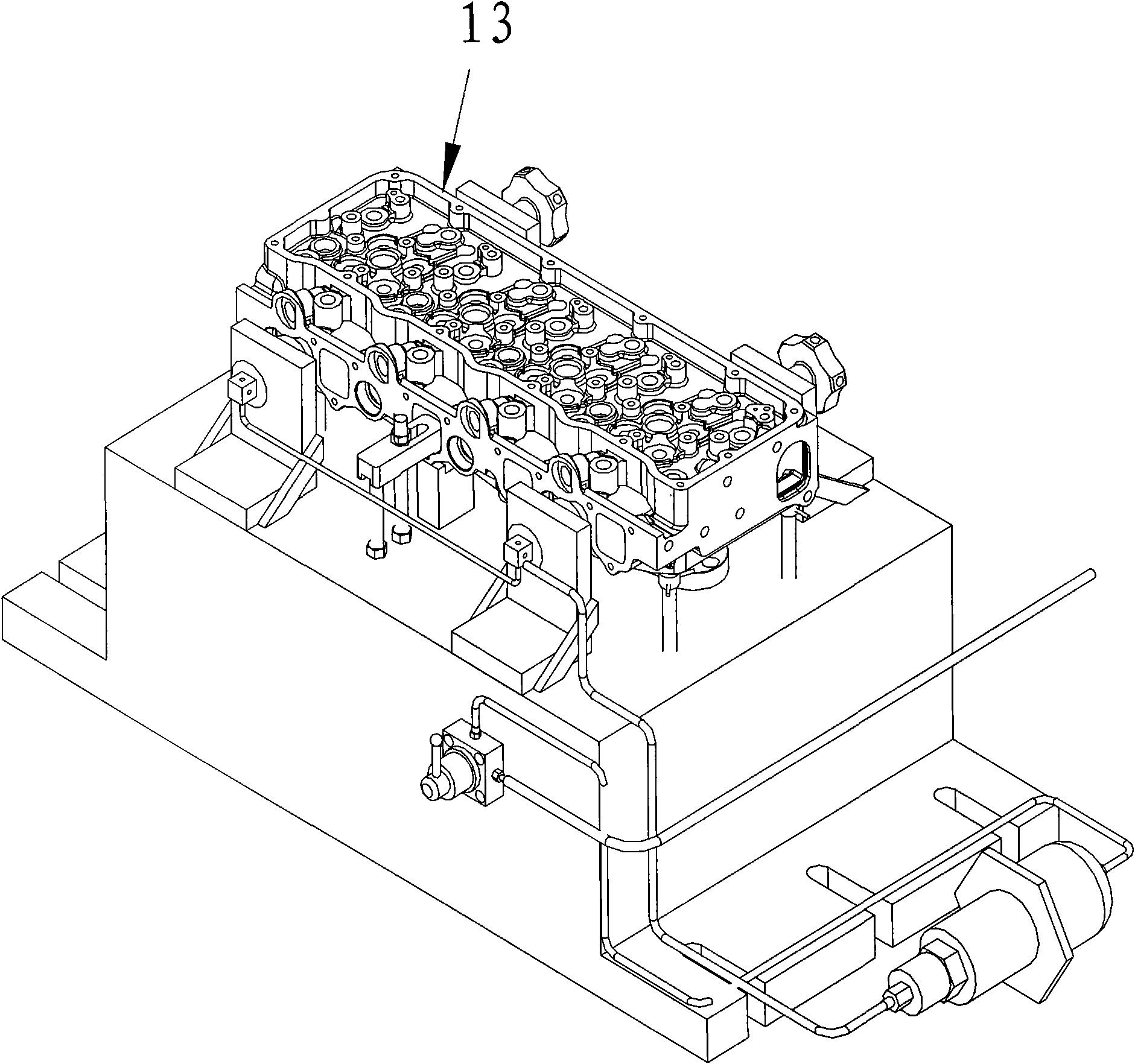

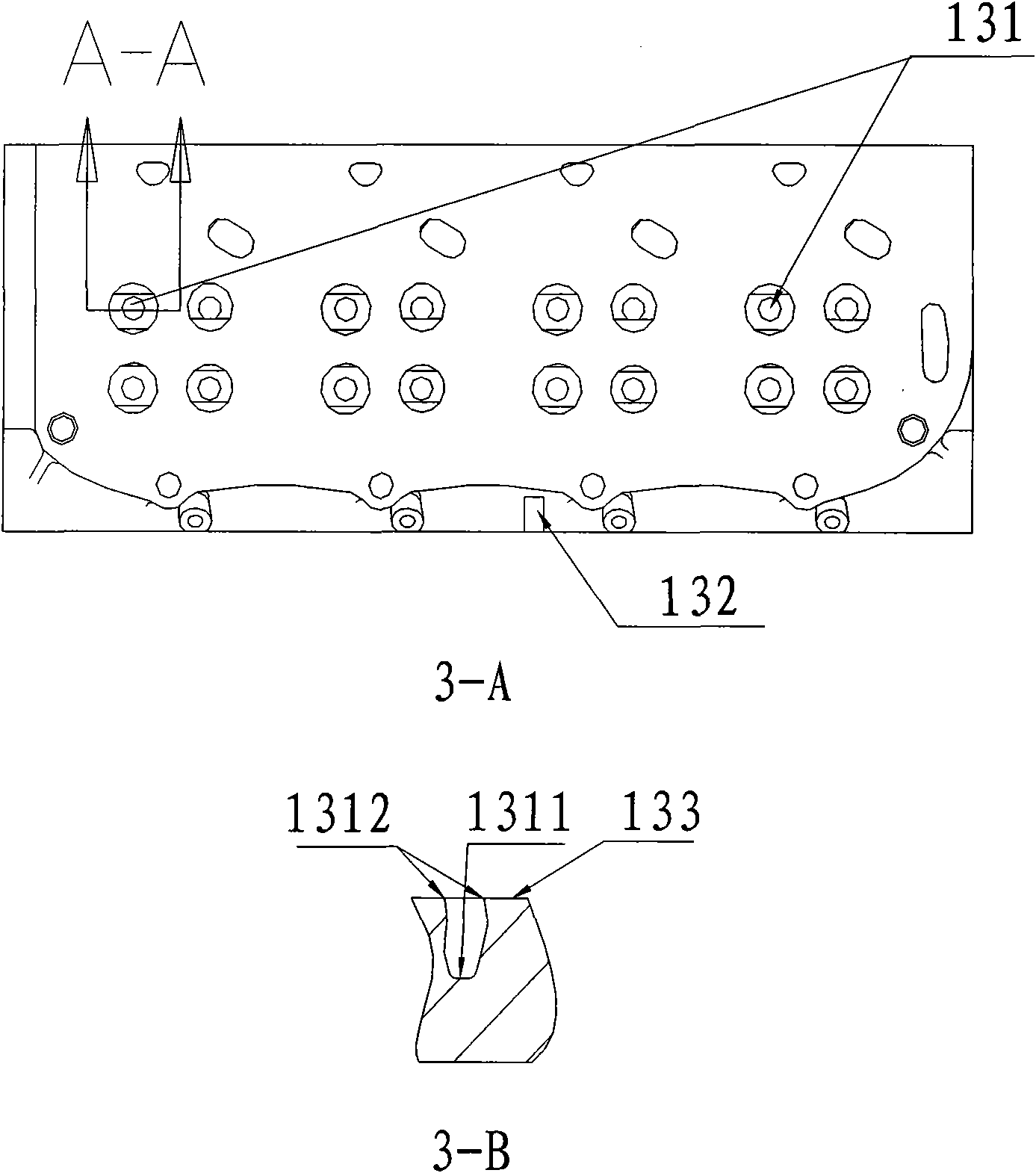

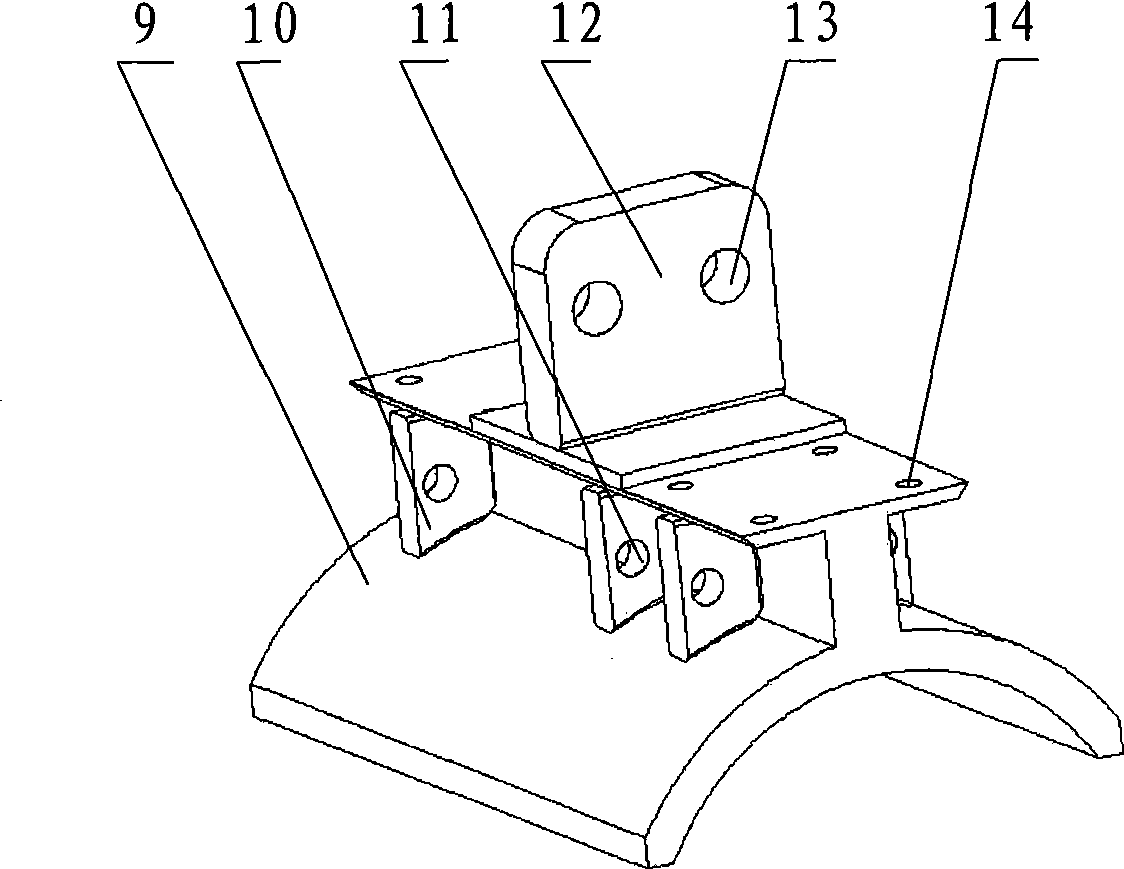

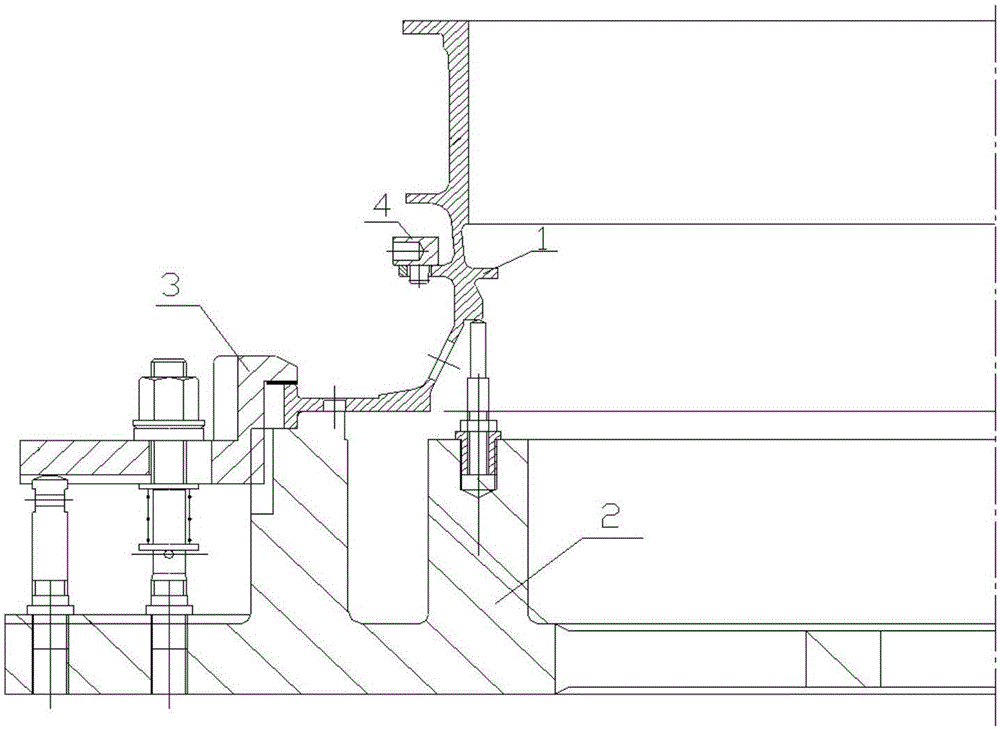

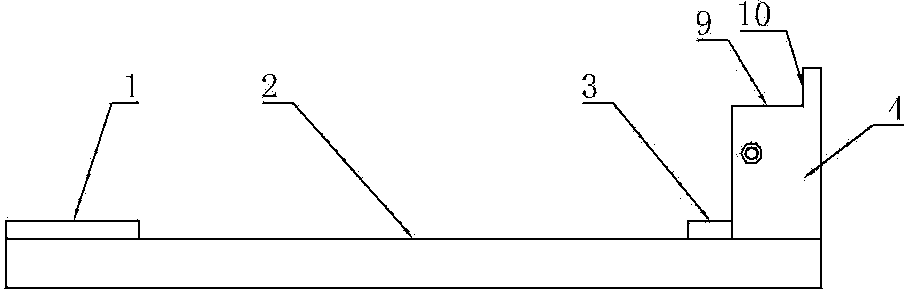

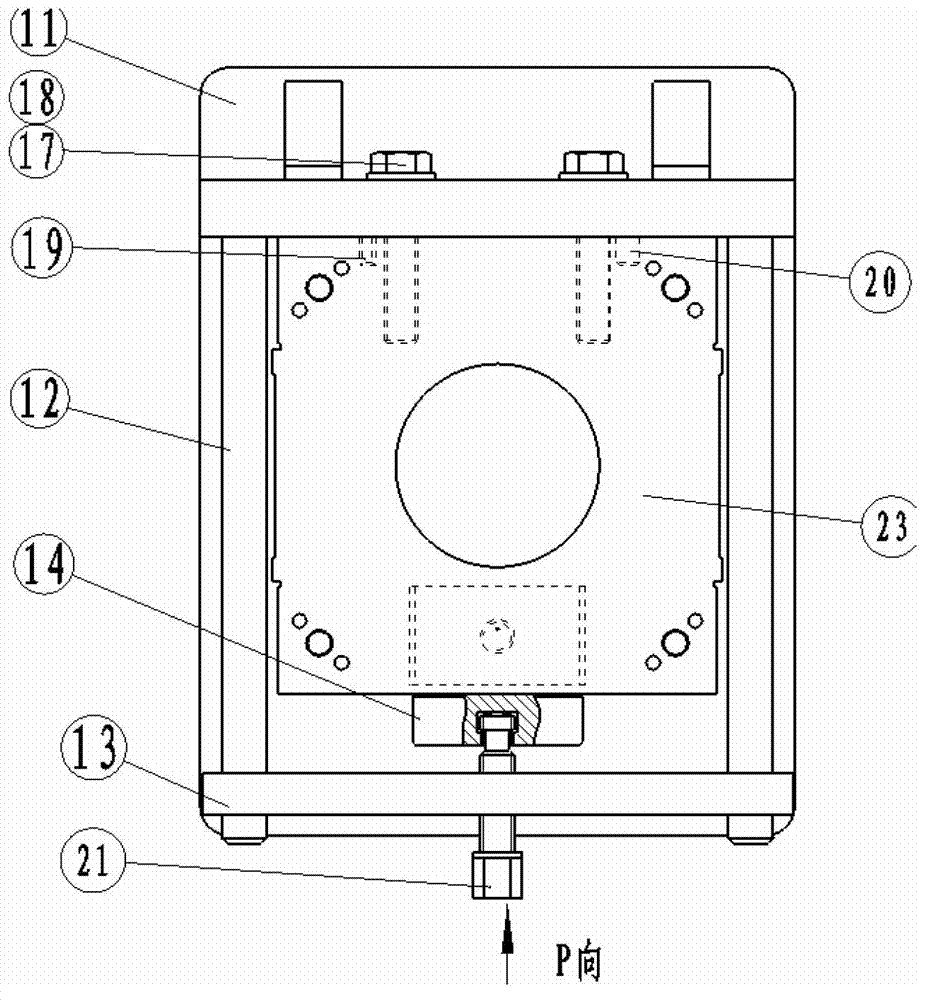

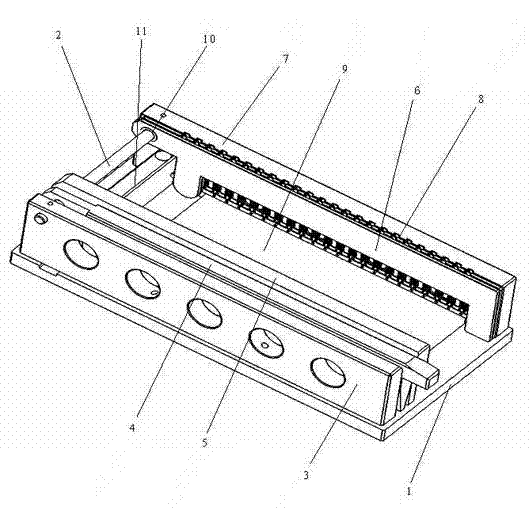

Cylinder cover positioning and clamping device in the process of finish-milling top surface of cylinder cover

ActiveCN101879680ASimple structureGood positioning consistencyMilling equipment detailsPositioning apparatusInlet channelConical surface

The invention discloses a cylinder cover positioning and clamping device in the process of finish-milling the top surface of a cylinder cover, which comprises a clamp seat provided with a three-point positioning support mechanism for positioning the bottom surface of the cylinder cover, and a side clamping mechanism positioned on the clamp seat and on the two sides of the cylinder cover. The three-point positioning support mechanism comprises two front and back cylinder cover air inlet channel boss support points and a support platform positioned in the middle; the two cylinder cover air inlet channel boss support points are respectively sleeved with a centering conical-surface pin; a spring is arranged under the centering conical-surface pin; the centering conical-surface pin is matched with an air inlet passage of the bottom surface of the cylinder cover, so that the two front and back cylinder cover air inlet channel boss support points are always contacted with the central part of the air inlet passage boss; the middle support platform is matched with the bottom platform of the cylinder cover; and the side clamping mechanism comprises a manual clamping jaw positioned on one side of the clamp seat, an oil cylinder positioned on the other side of the clamp seat and a press block which is matched with the middle support platform. The device has the advantages of simple structure, good positioning consistency and reliable clamping.

Owner:GUANGXI YUCHAI MASCH CO LTD

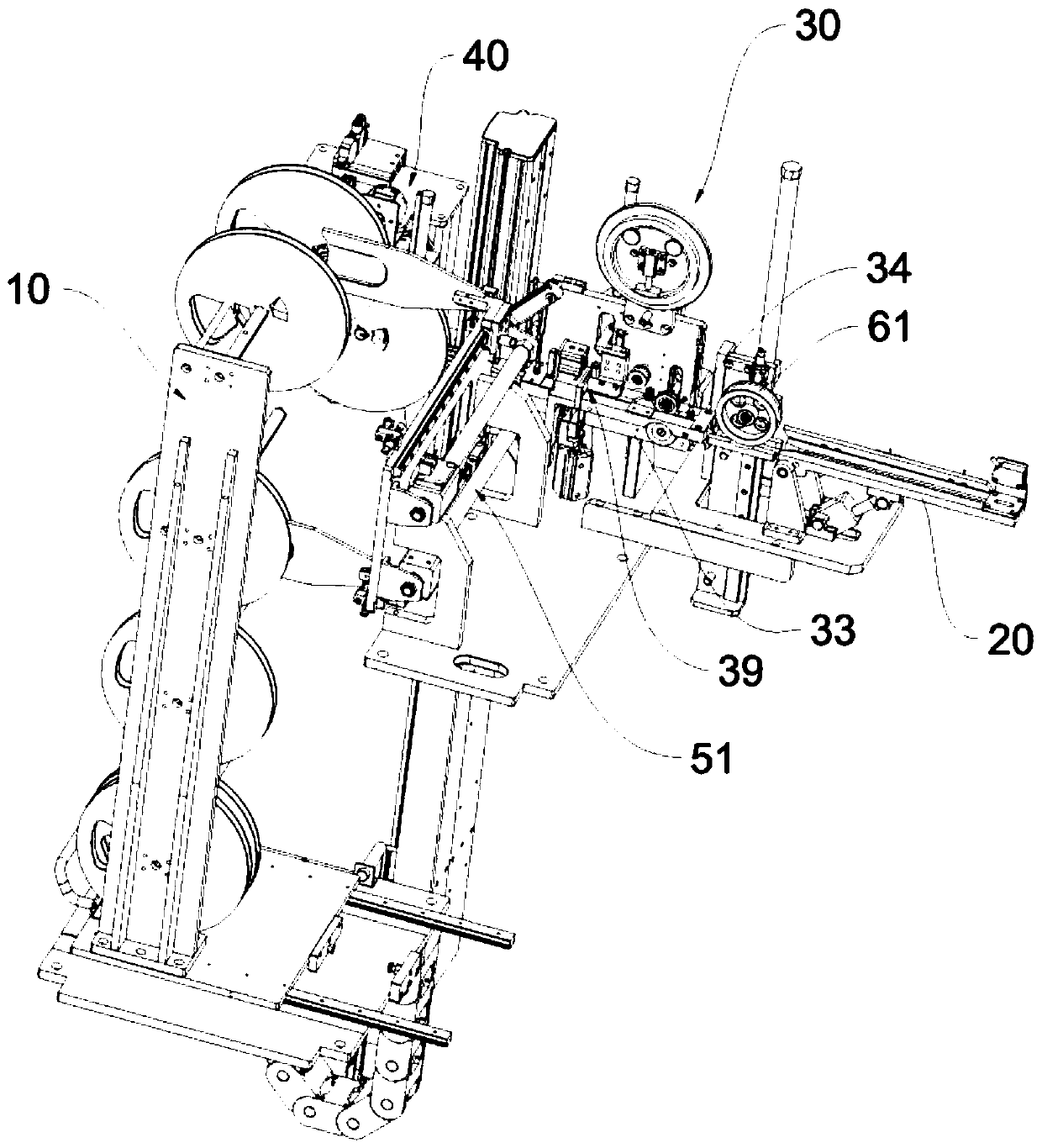

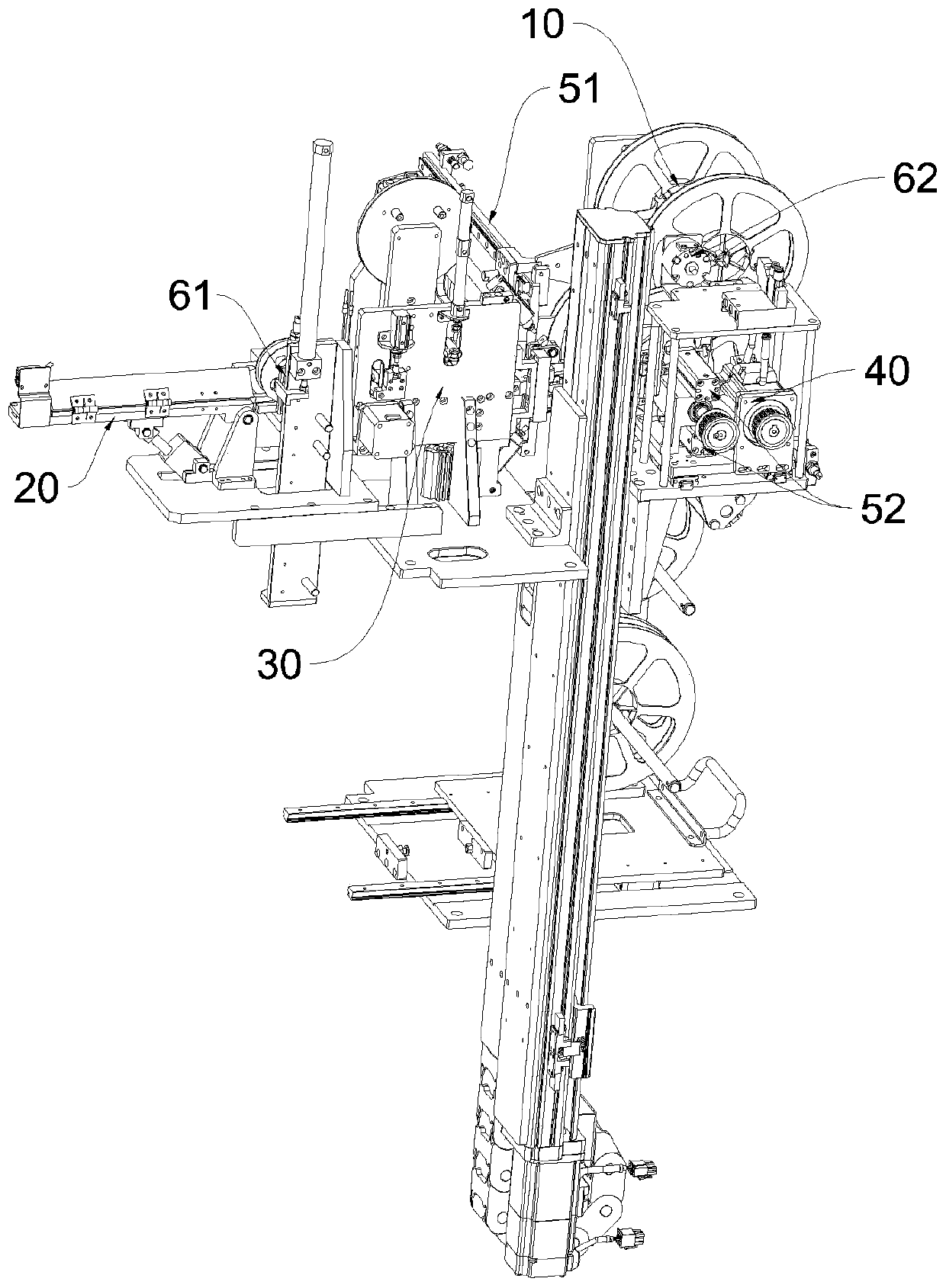

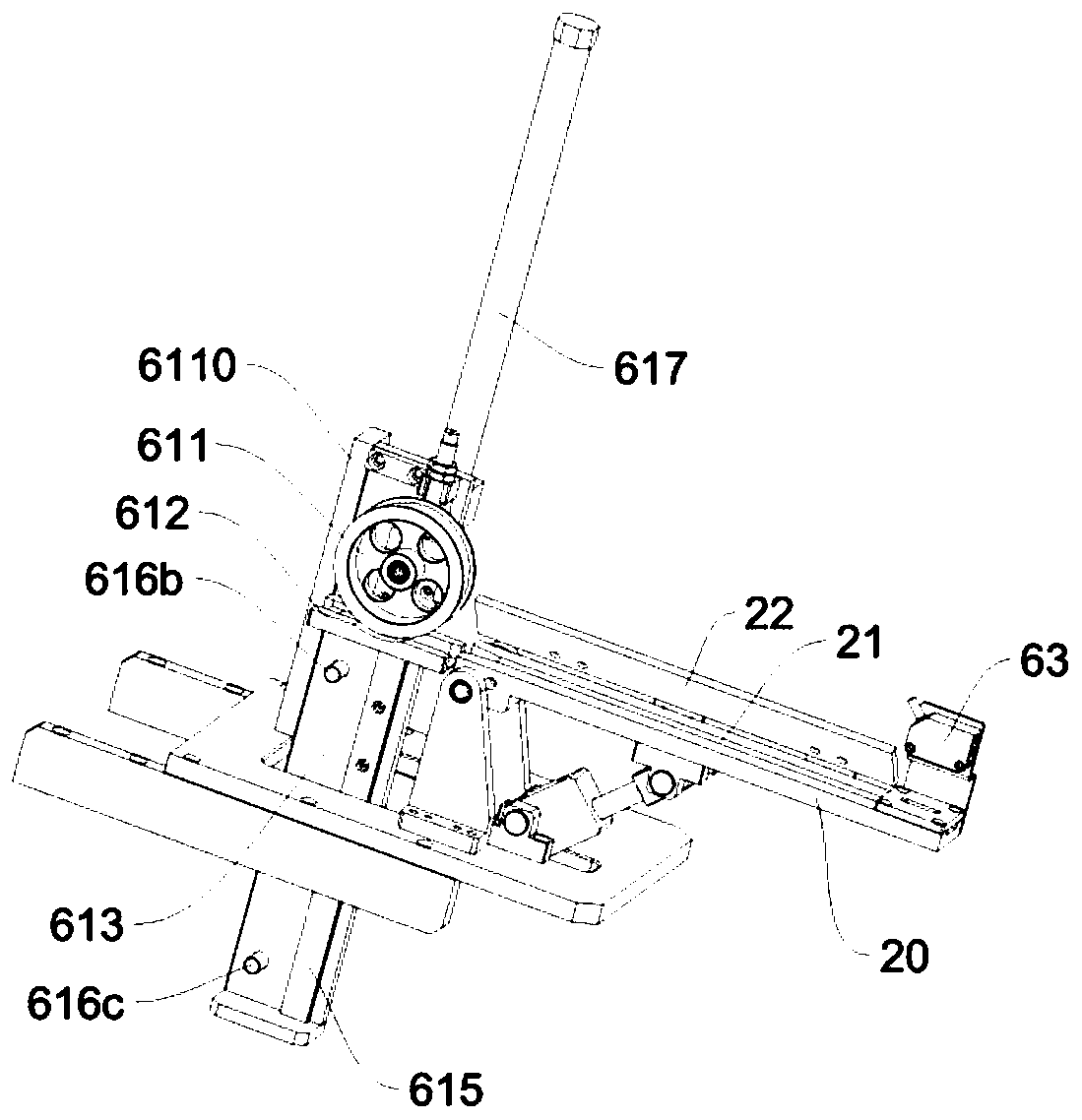

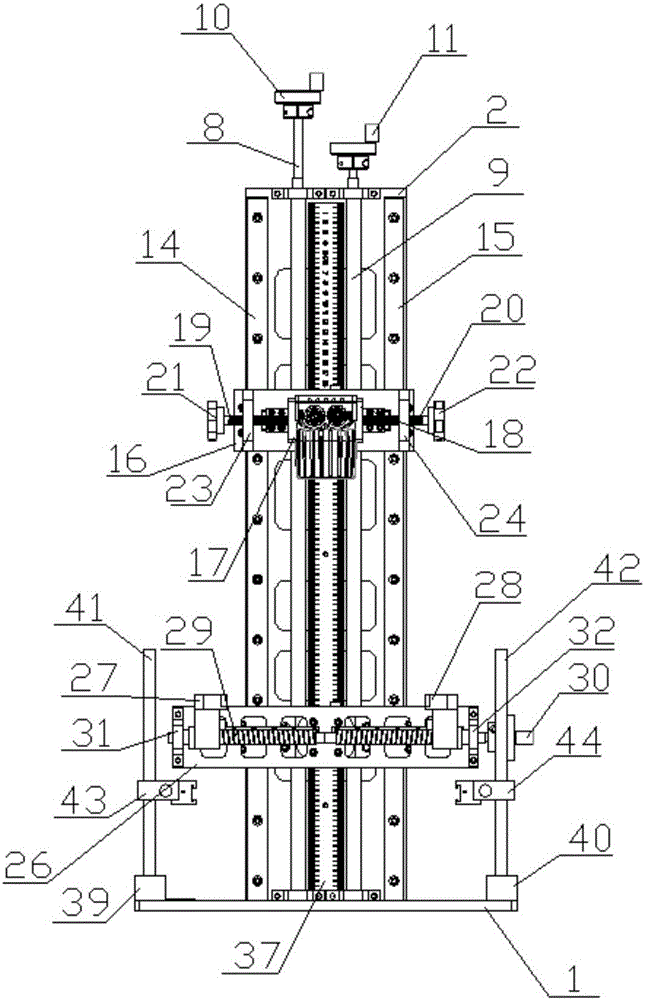

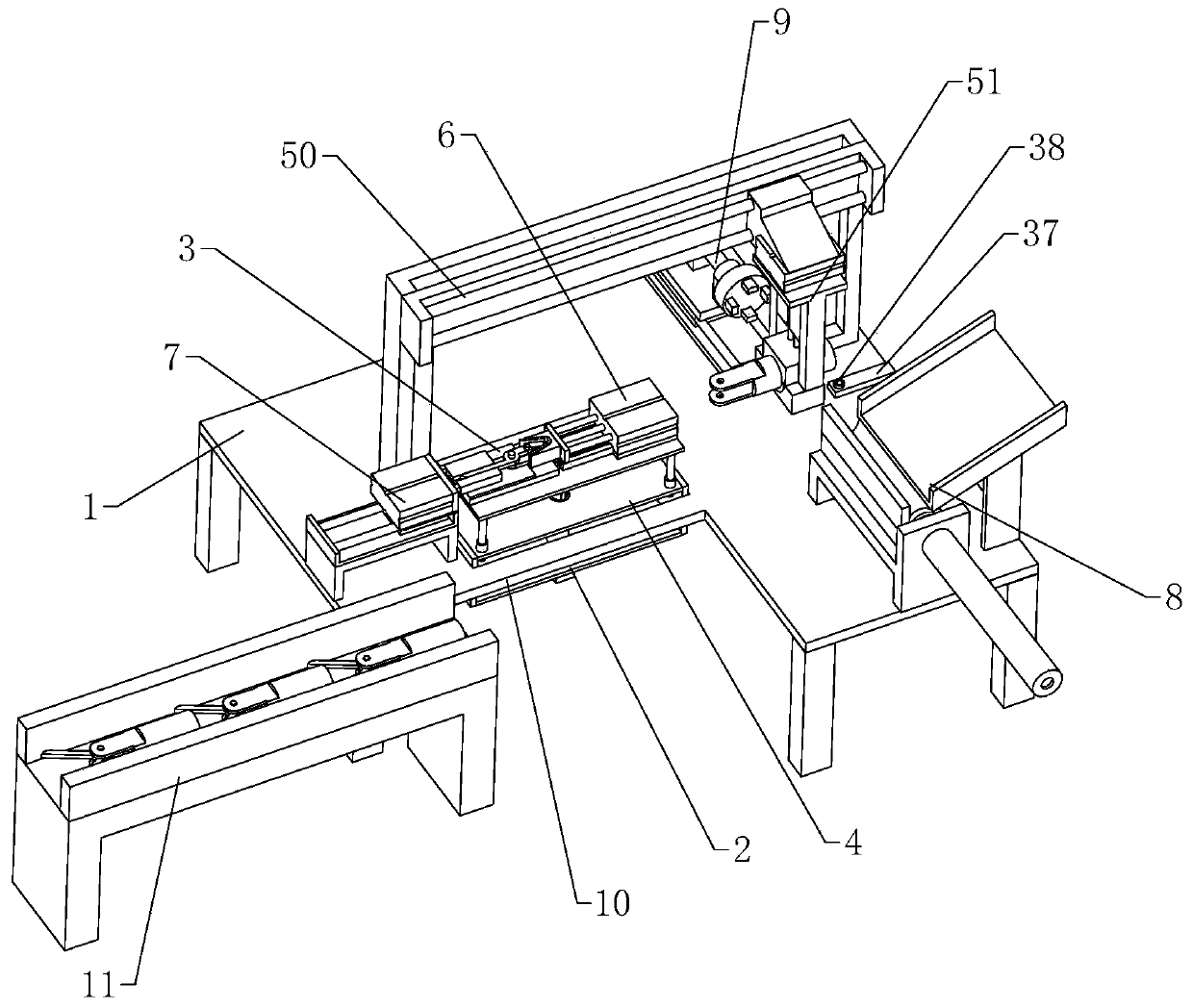

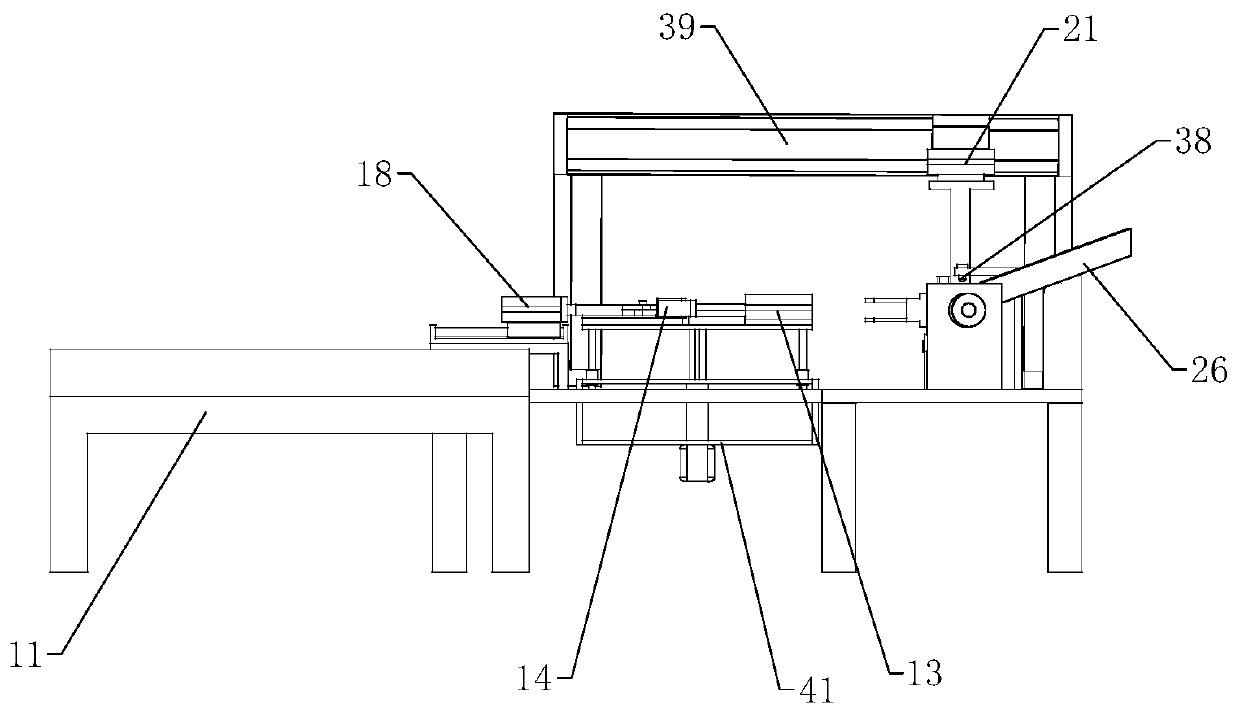

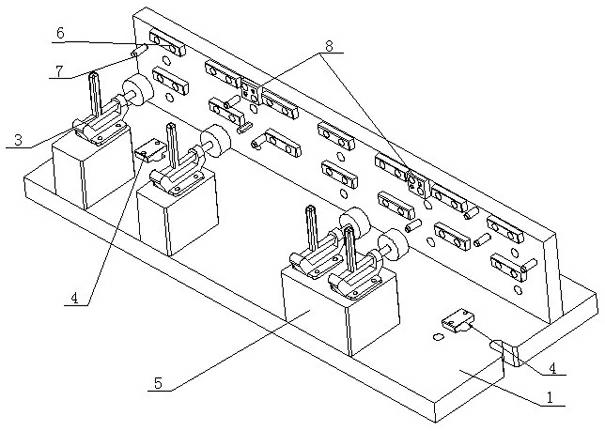

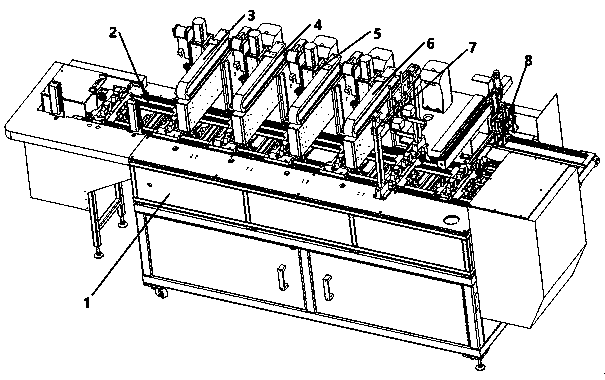

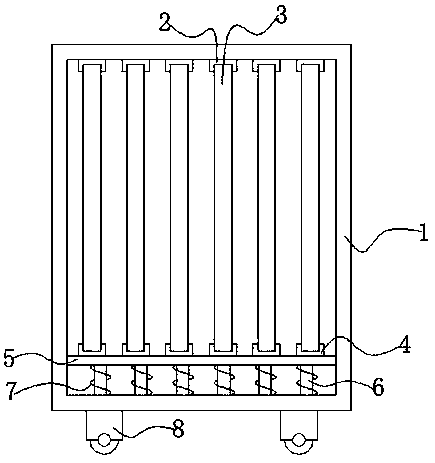

Automatic carrier band winding and collecting system

PendingCN110116925AContinuous and tight windingPlay a role in tension controlWebs handlingEngineeringElectronic component

The invention provides an automatic carrier band winding and collecting system. The automatic carrier band winding and collecting system can solve the problems that according to an existing automaticcarrier band winding and collecting system, due to instable carrier band tension, the carrier band winding work efficiency is low, and the labor intensity of workers is large, and meanwhile the problems that in the carrier band winding and collecting process, due to carrier band tension changes, a carrier hand and an electronic element are damaged can be solved. The automatic carrier band windingand collecting system comprises a disc storage device, a receiving track, a feeding device, a winding device, a disc feeding and discharging device and a tension control device, wherein the receivingtrack and the winding device are arranged on the feeding end side and the discharging end side of the feeding device correspondingly, and the disc storage device is arranged on the front side of the winding device. The tension control device controls continuous carrier bands to be wound to material discs through the winding device with the constant tension, wherein the carrier bands are received by the receiving track from the carrier band discharging end of equipment of the previous procedure.

Owner:无锡固立德电子器材有限公司

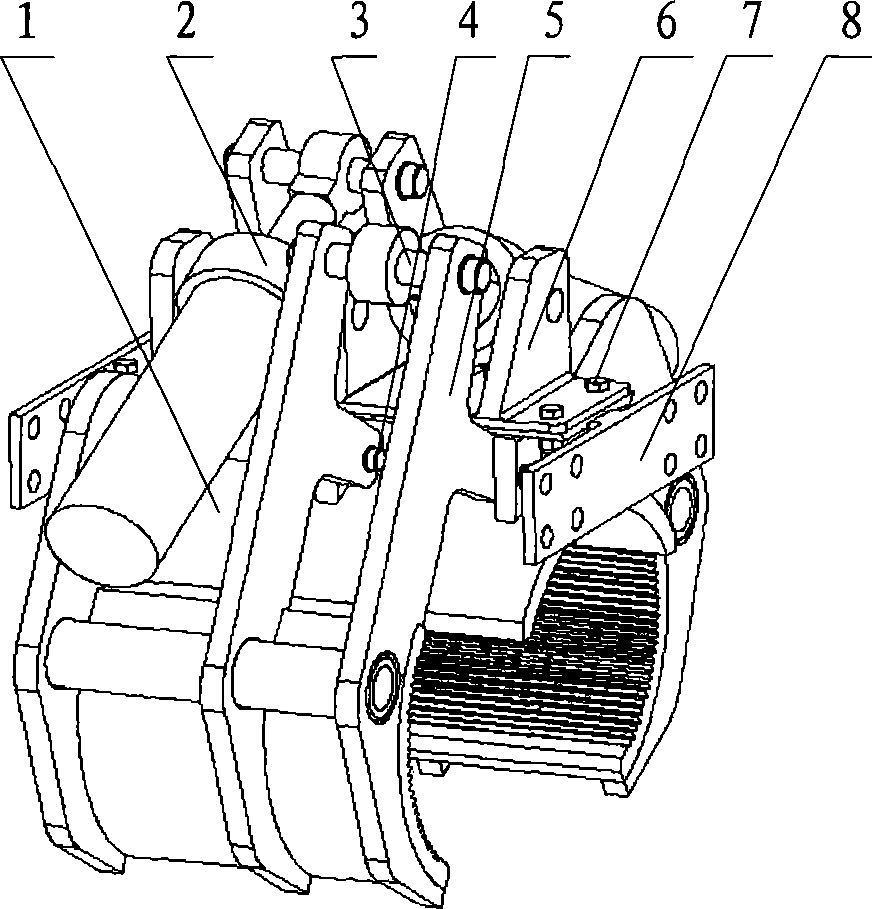

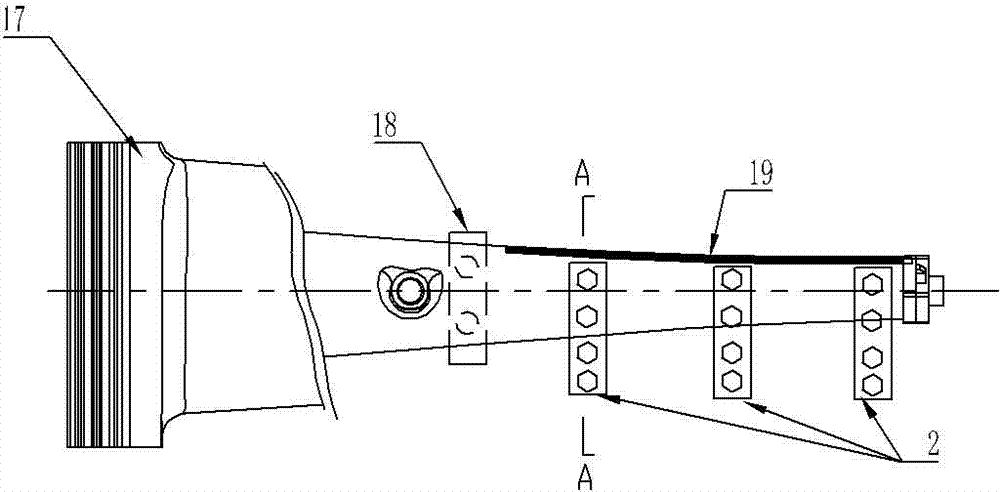

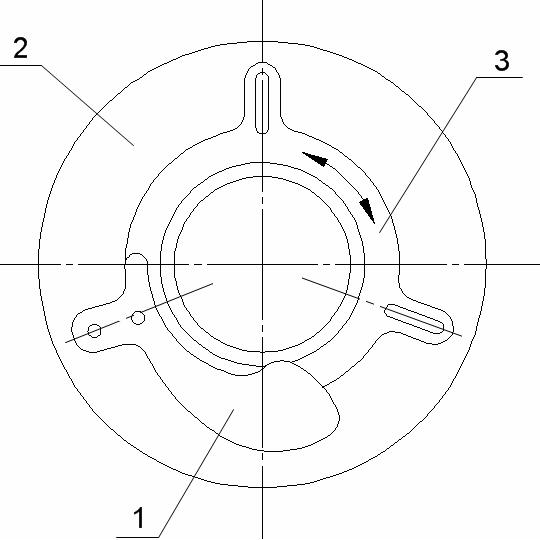

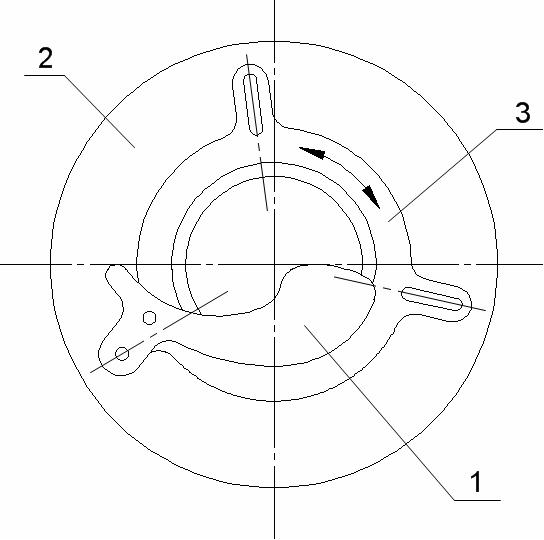

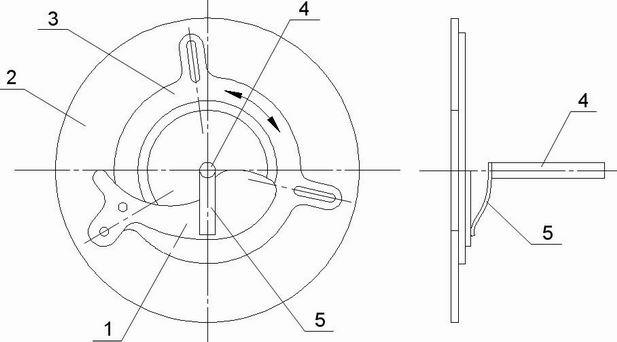

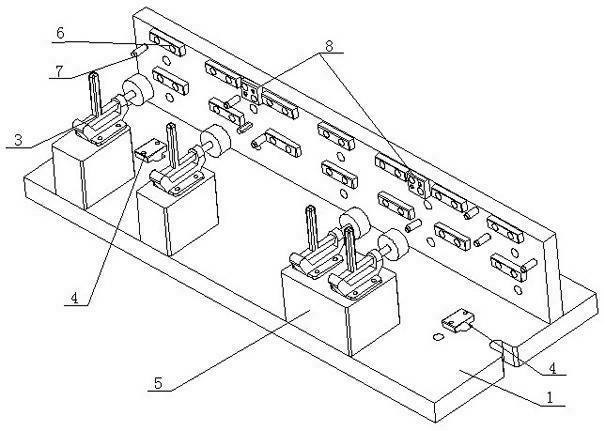

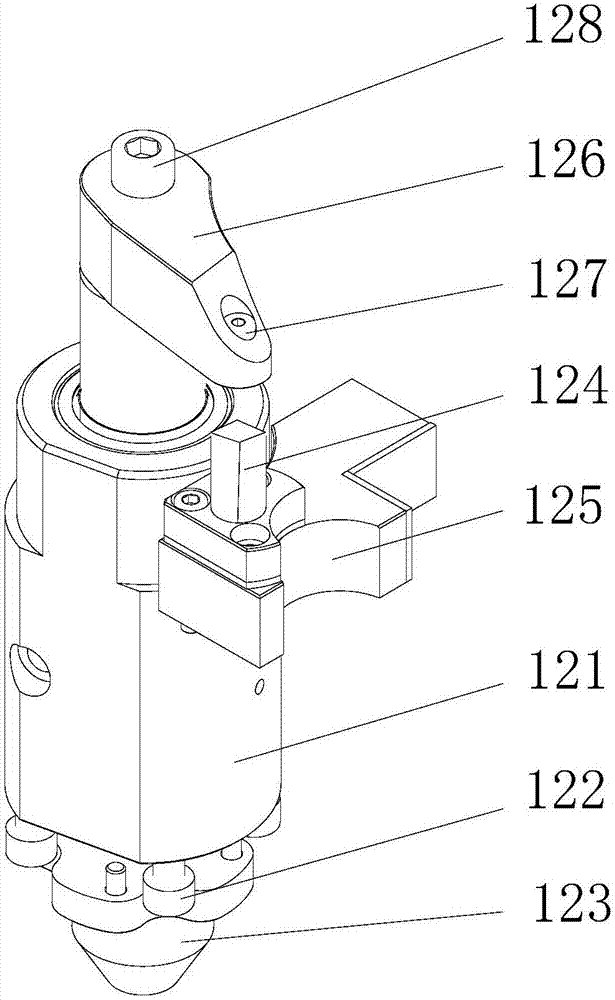

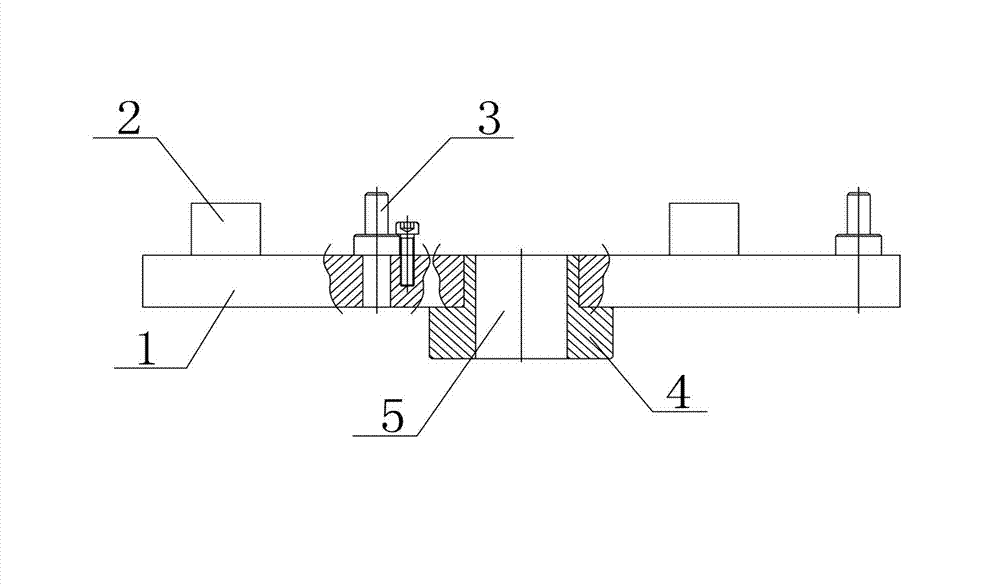

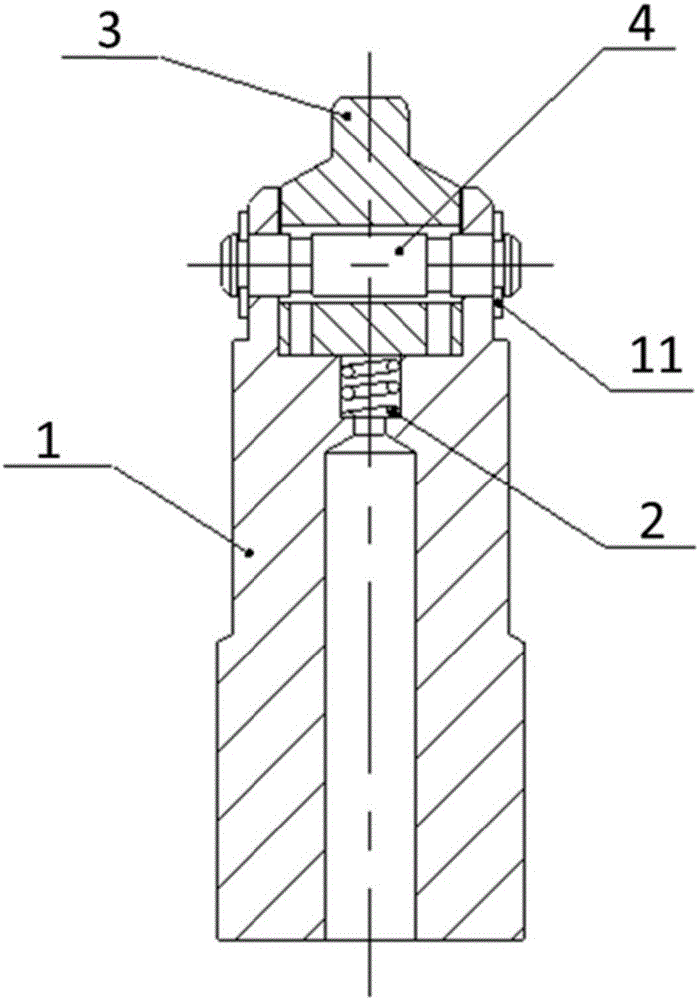

Positioning and clamping device special for submarine pipeline flange automatic joint tool

ActiveCN101418875AReduce volumeReduce weightPipe laying and repairEngineeringOperational requirements

The invention provides a special positioning and clamping device for an automatic submerged pipe flange connecting machine. The device comprises a master jaw 1, a hinged hydraulic cylinder 2, a jaw 5, a hydraulic cylinder mounting lug 6 and a jaw mounting lug 8, wherein the hydraulic mounting lug 6 is fixed on the master jaw 1; the hinged hydraulic cylinder 2 is connected with the master jaw 1 through the hydraulic mounting lug 6 and is connected with the jaw 5 through a pin shaft 3; the jaw 5 is connected with the master jaw 1 through a rotating shaft 4; and the jaw mount lug 8 has two pieces which are welded at two sides of the master jaw respectively. The invention provides a positioning and clamping device for a deepwater automatic flange connecting machine which can adapt to deep-sea environment and meet the operational requirements of the deepwater automatic flange connecting machine on positioning and clamping.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Part angle alignment method and clamp thereof

ActiveCN106271801ASuitable for processingEasy to operatePositioning apparatusMetal-working holdersProcess alignmentEngineering

The invention discloses a part angle alignment method and a clamp thereof. The method comprises the steps that a process alignment block is firstly manufactured according to the structure of a part, a process alignment hole and mounting holes are machined in the process alignment block, and the process alignment hole or an angular straightening face is machined at the zero-degree position of the clamp; then the clamp is mounted on a machine tool, the process alignment hole or the angular straightening face on the clamp is aligned, the zero-degree angular position is set, and the clamp is pressed; the part is mounted on the clamp and pressed; then the process alignment block is mounted on the part through the process alignment hole and the mounting holes in the process alignment block; finally, a dial indicator is used for metering to straighten the angular straightening face on the clamp and align the alignment hole in the clamp to determine the zero-degree position, the process hole in the part or the process alignment hole in the process alignment block is aligned, the zero-degree angular position of the part is determined, and the zero-degree position of the machine tool is determined. The method is simple in operation process, reasonable in step and accurate in alignment, and by directly aligning an angular alignment locating hole in a locating block, the method is convenient to use and suitable for machining of batched parts.

Owner:AECC AVIATION POWER CO LTD

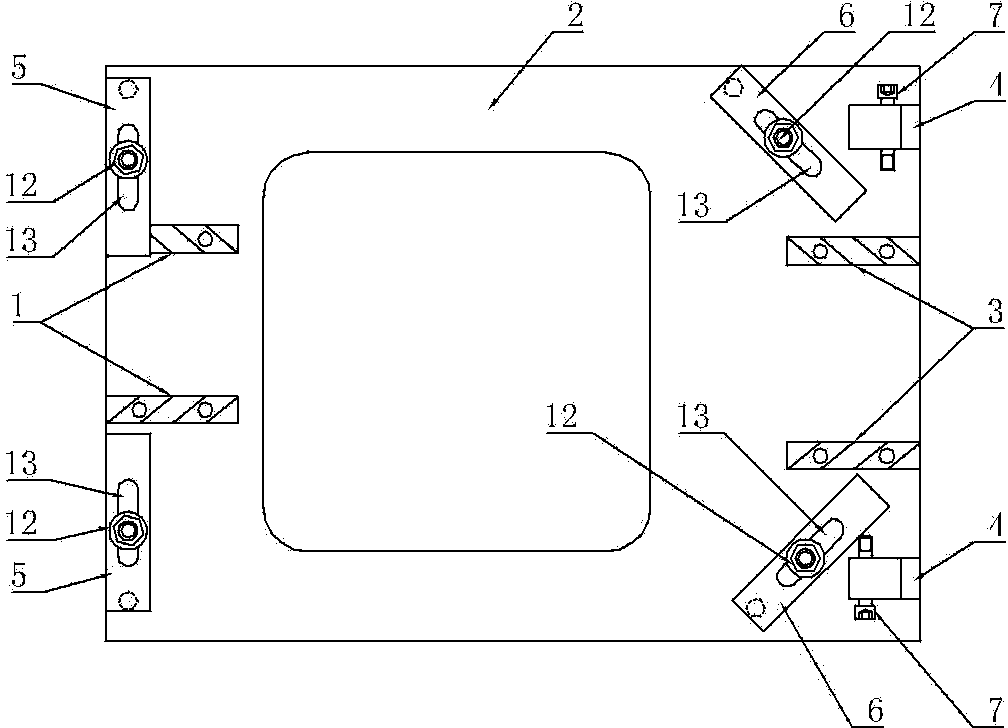

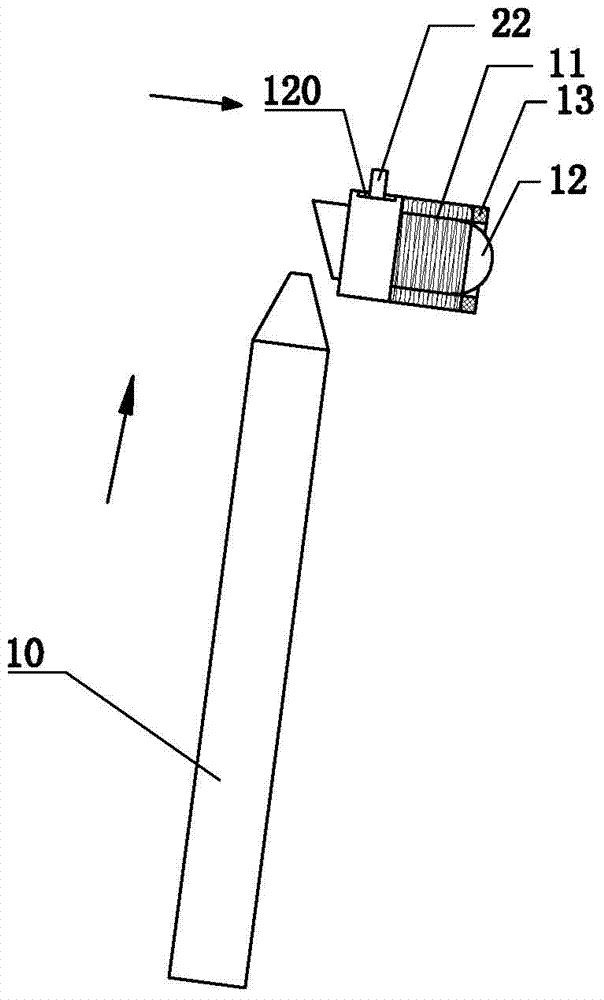

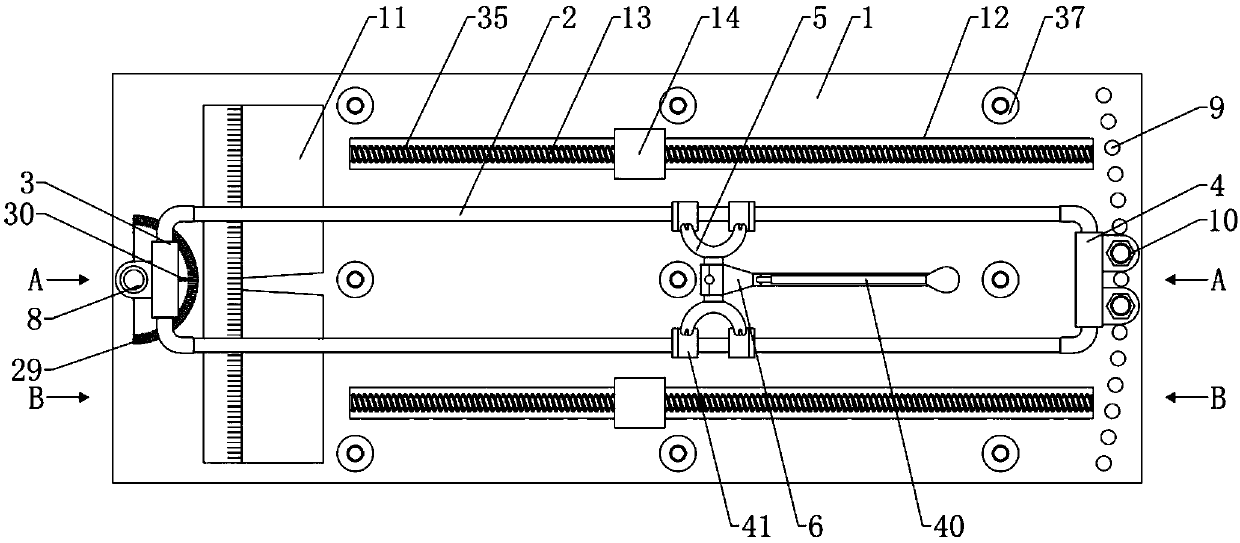

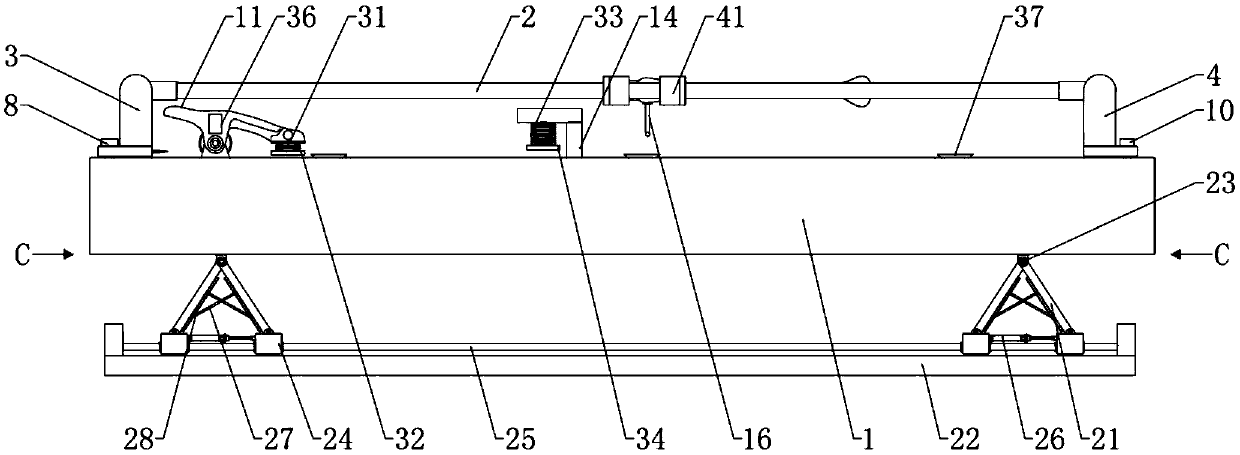

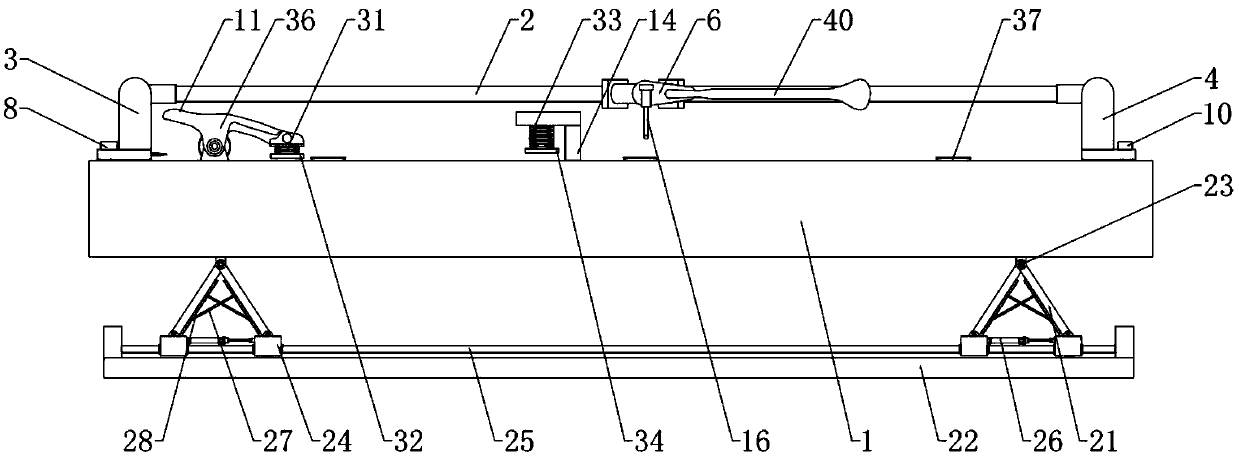

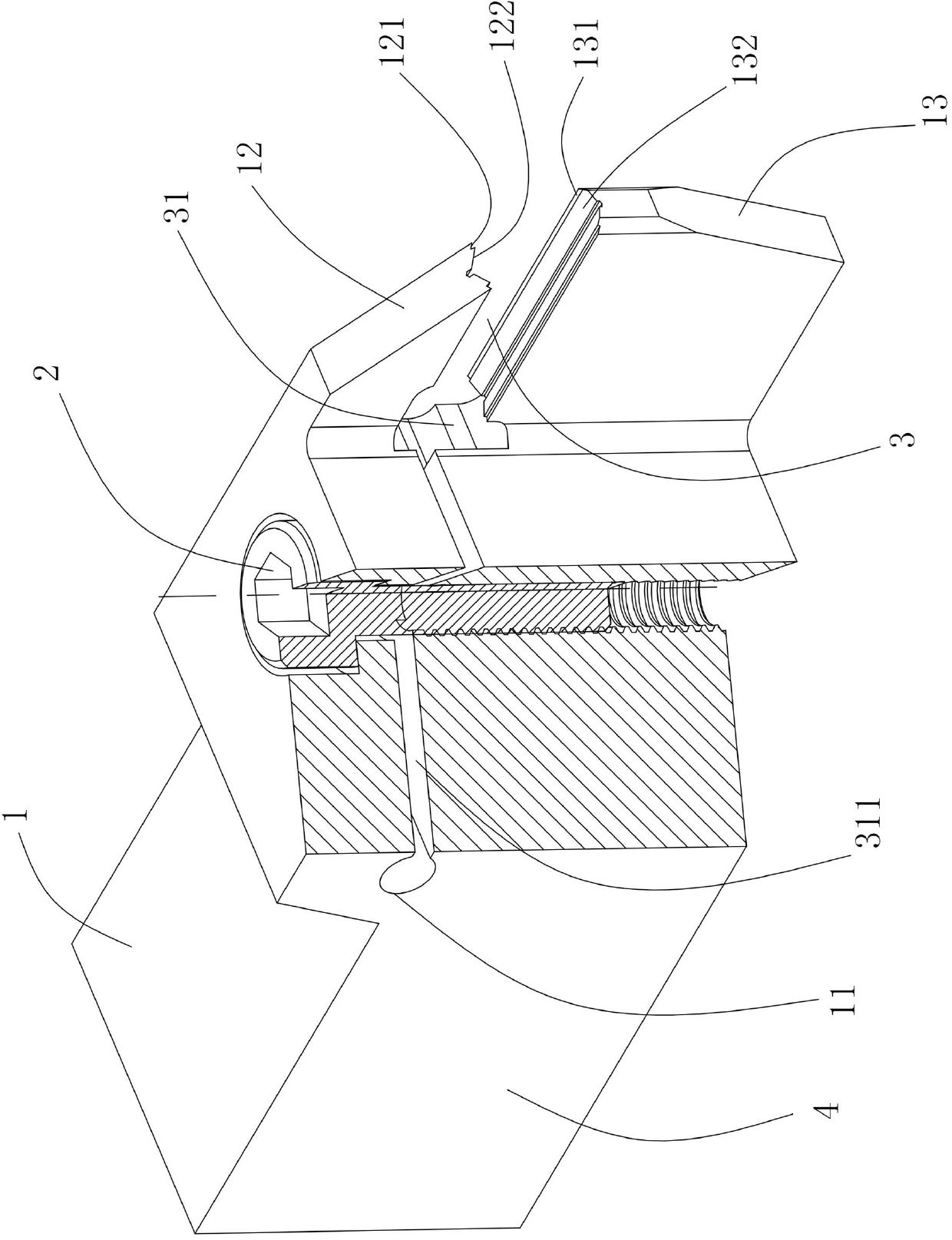

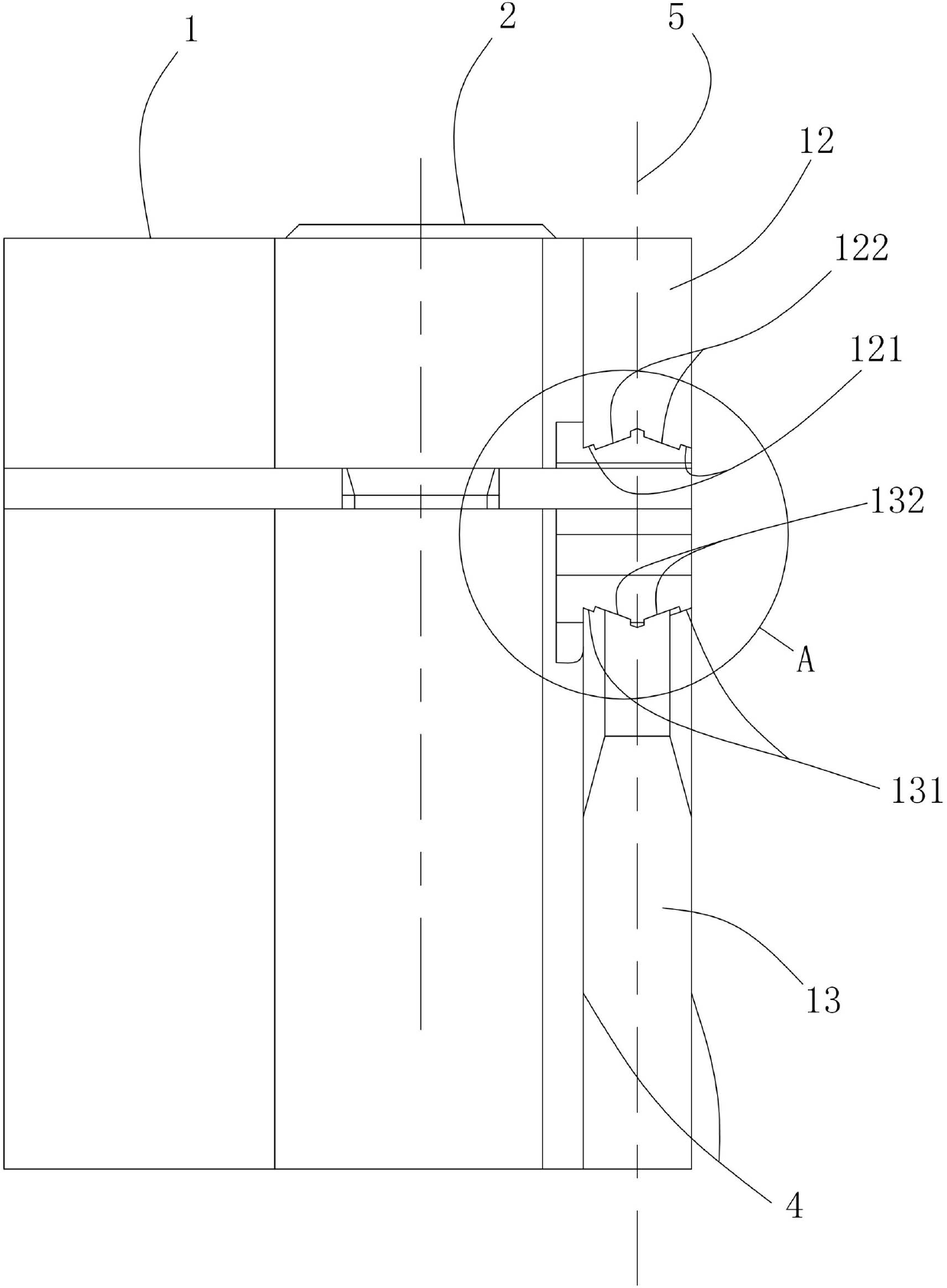

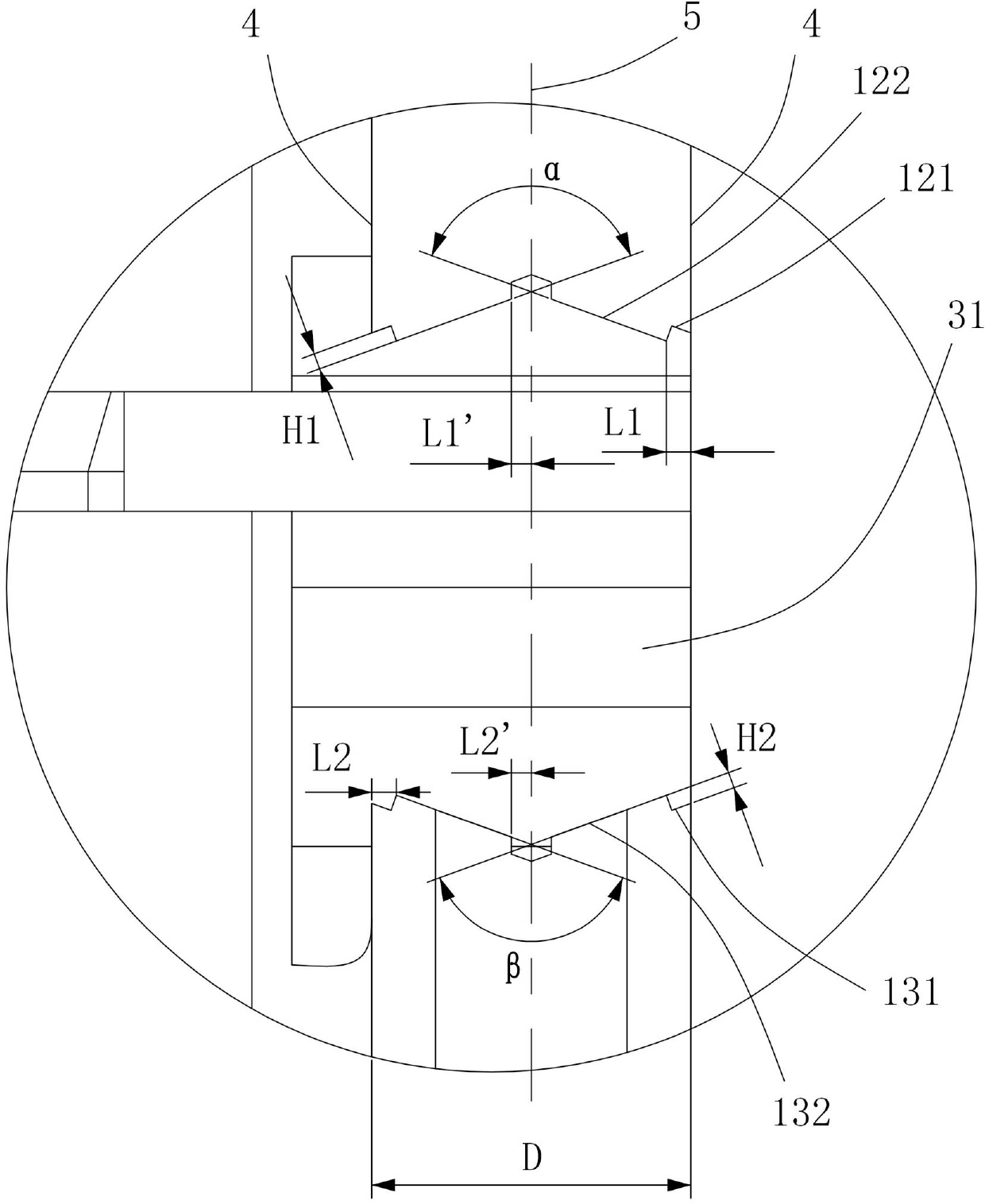

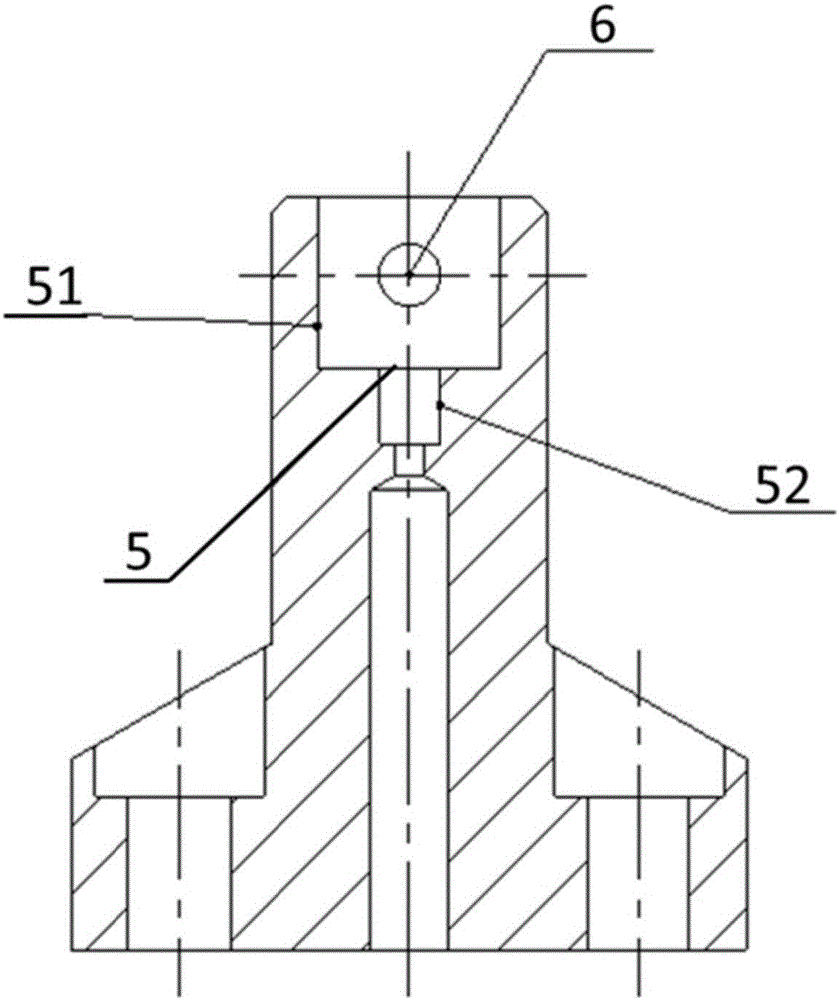

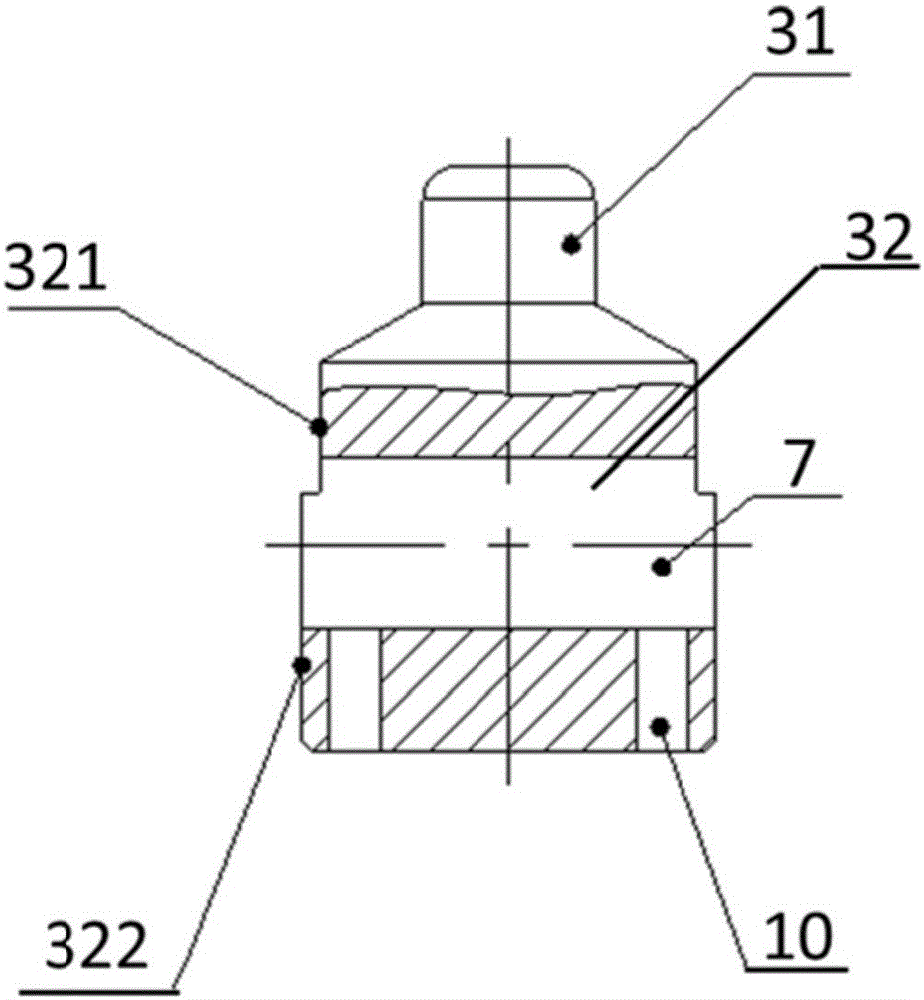

Universal clamp device for vane overall length machining

ActiveCN103659378AReliable positioning and clampingIncrease usagePositioning apparatusMetal-working holdersForgeMachining

The invention provides a universal clamp device for vane overall length machining. The problem that a production cycle is long, and production efficiency is low caused by a square box locating mode in vane overall length machining is solved. The universal clamp device comprises a base and is characterized in that two vane tip branch plates and two vane root branch plates are arranged at the horizontal two ends of the base respectively, vane tip pressing plates and vane root pressing plates are arranged on the longitudinal outer side ends of the two vane tip branch plates and the two vane root branch plates on the base respectively, vane root clamping bases are arranged on the longitudinal outer side ends of the two vane root branch plates on the base respectively, reverse-L-shaped grooves are formed in the top faces of the vane root clamping bases, line alignment blocks for vane forge piece longitudinal locating are placed in the reverse-L-shaped grooves of the two vane root clamping bases and tightly abut against the inner groove walls of the reverse-L-shaped grooves, longitudinal thread through holes are formed in the two vane root clamping bases, and locking screws are arranged in the thread through holes.

Owner:WUXI TURBINE BLADE

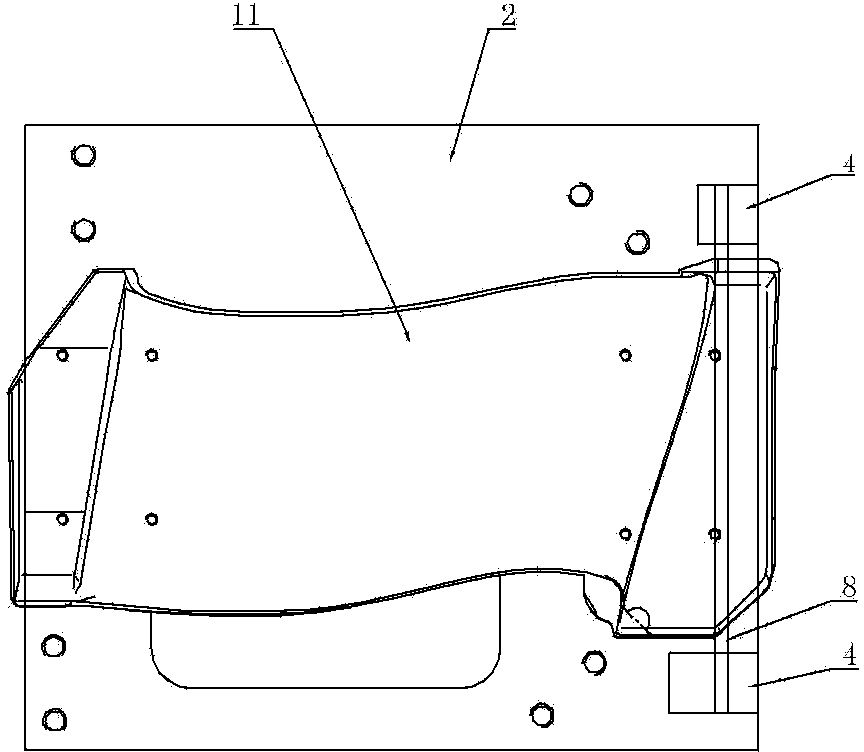

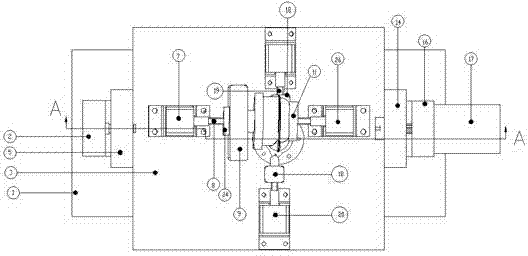

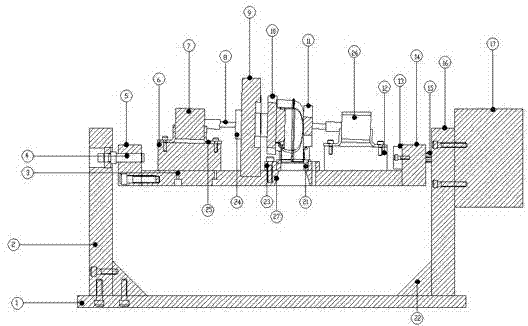

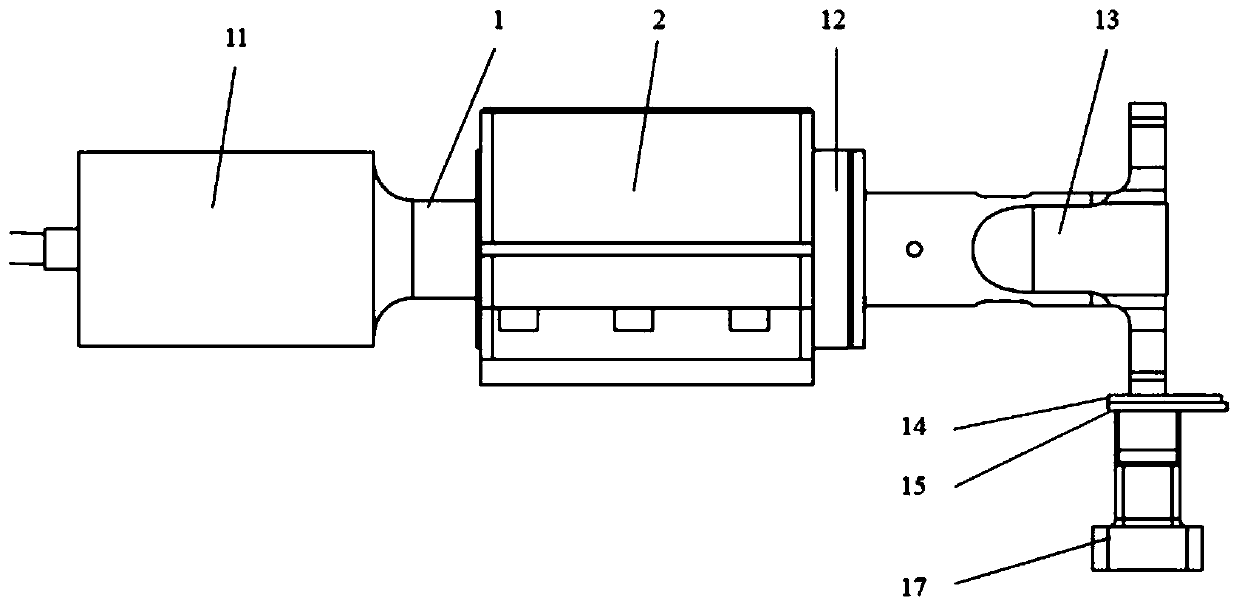

Special tooling for turning high-precision thin-wall cylinder liner bores

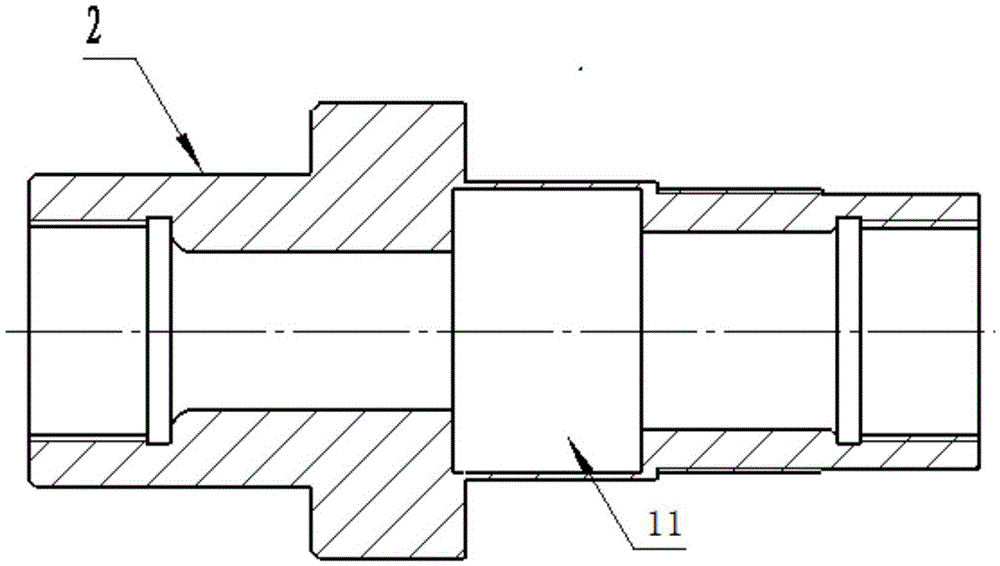

InactiveCN104493600AReliable positioning and clampingUniform clamping forcePositioning apparatusMetal-working holdersCircular coneEngineering

The invention discloses a special tooling for turning high-precision thin-wall cylinder liner bores, which comprises an internal taper sleeve, an elastic clamp and an axial positioning disk, the left end of the internal taper sleeve is connected with a spindle flange, the right end of the internal taper sleeve is connected with the axial positioning disk, the right side of the internal taper sleeve is provided with a taper hole, the taper hole is connected with a cylindrical hole of the left side, the sidewall of one side of the cylindrical hole is provided with a guide hole, a vent hole is formed in the left side of the guide hole, the elastic clamp comprises an internal cylindrical hole and an external conical surface, the external conical surface is connected with an external cylindrical surface, a pull rod holder is arranged on the external cylindrical surface, the pull rod holder is provided with a pull rod-fixing hole, a washer is arranged at the right side of the pull rod-fixing hole, the outer diameter of the washer is greater than the inner diameter of the pull rod-fixing hole, the excircle of the end of an oil cylinder pull rod is matched with the pull rod-fixing hole, the end of the oil cylinder pull rod is provided with a threaded hole, and the oil cylinder pull rod is connected with the washer. The structural precision of the special tooling is high, a thin-wall cylinder liner can be positioned and clamped reliably, clamping stress is uniform, the deformation of the thin-wall cylinder liner caused by clamping force is reduced, and the precision requirement of workpieces is met.

Owner:JINAN FIRST MACHINE TOOL GROUP

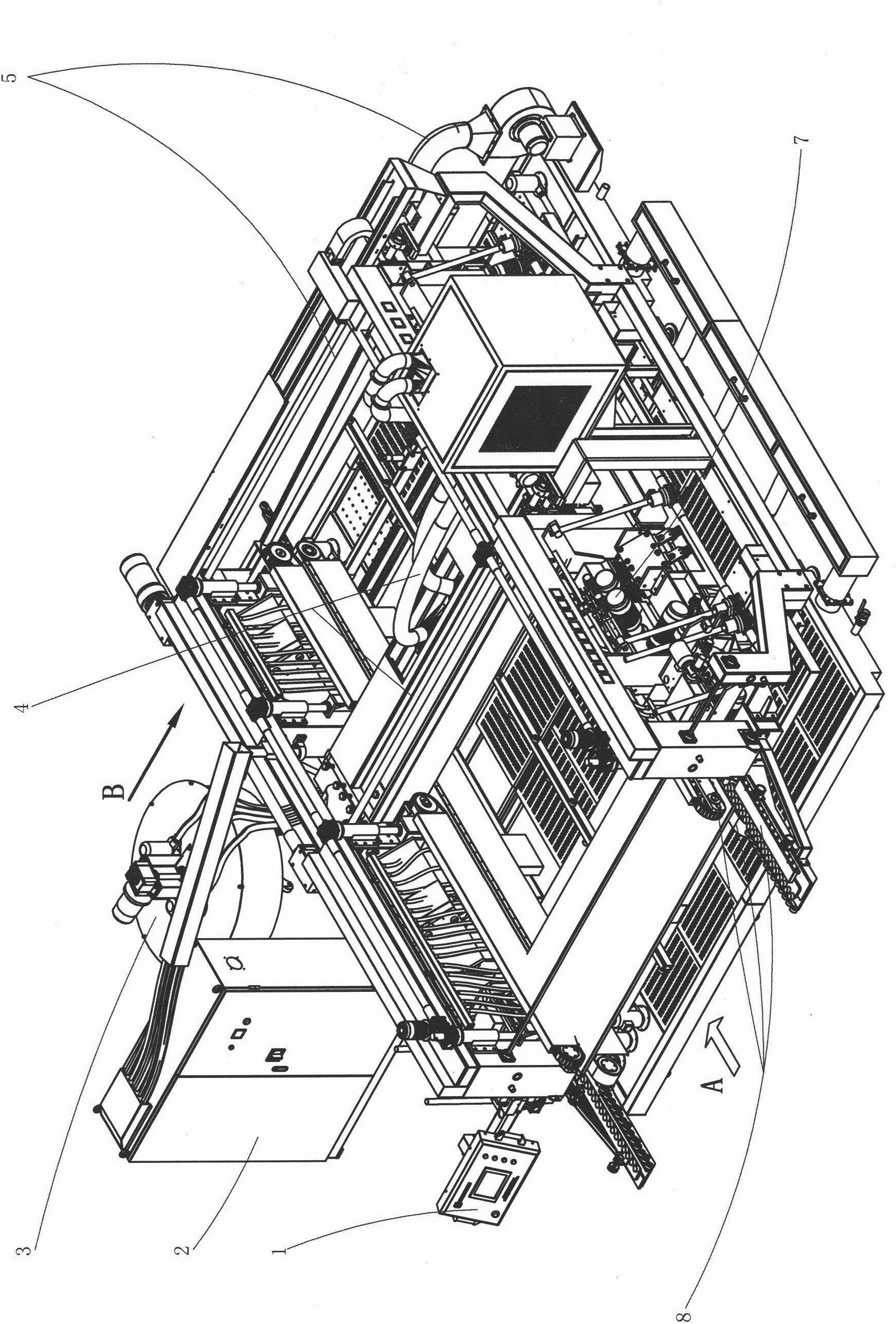

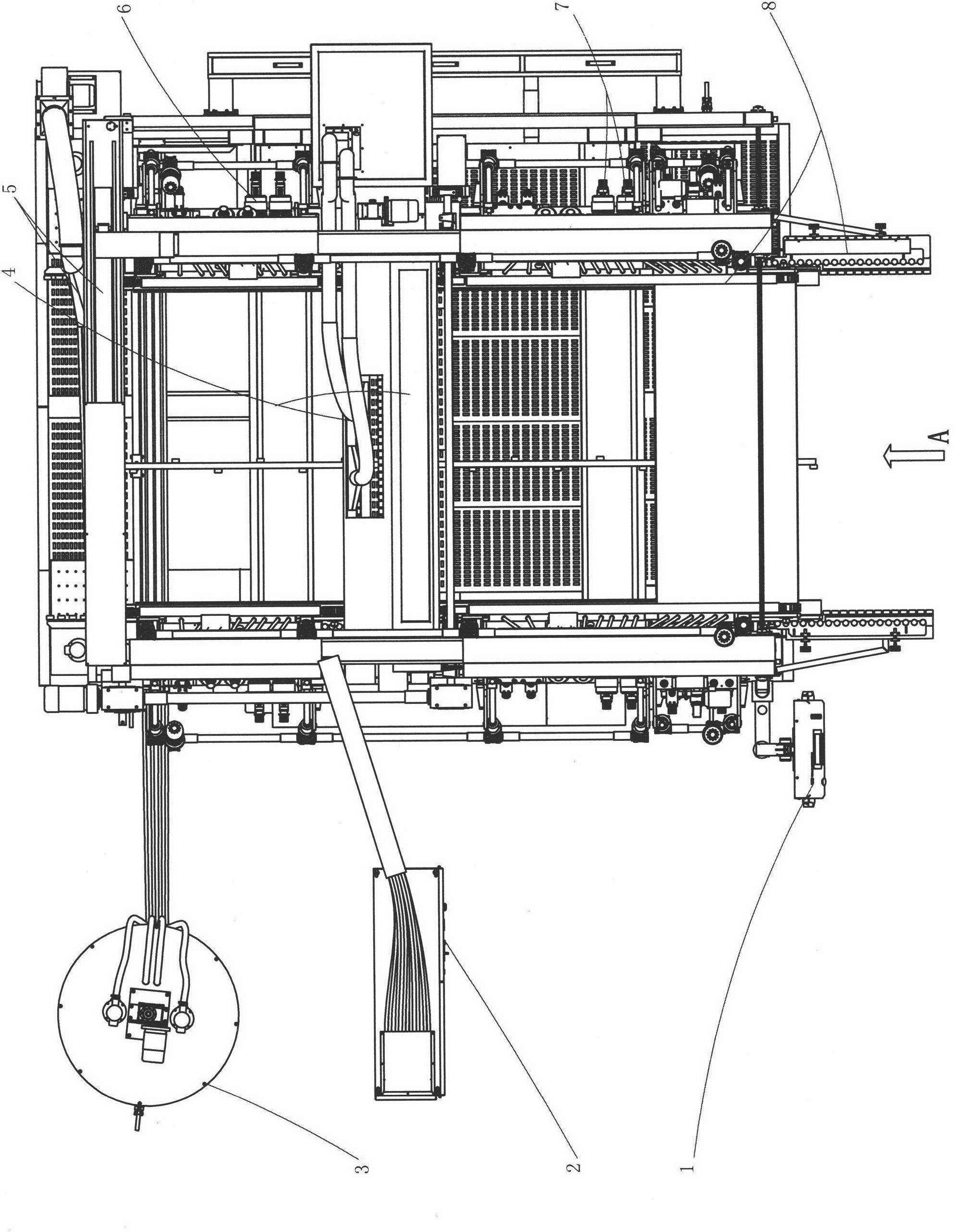

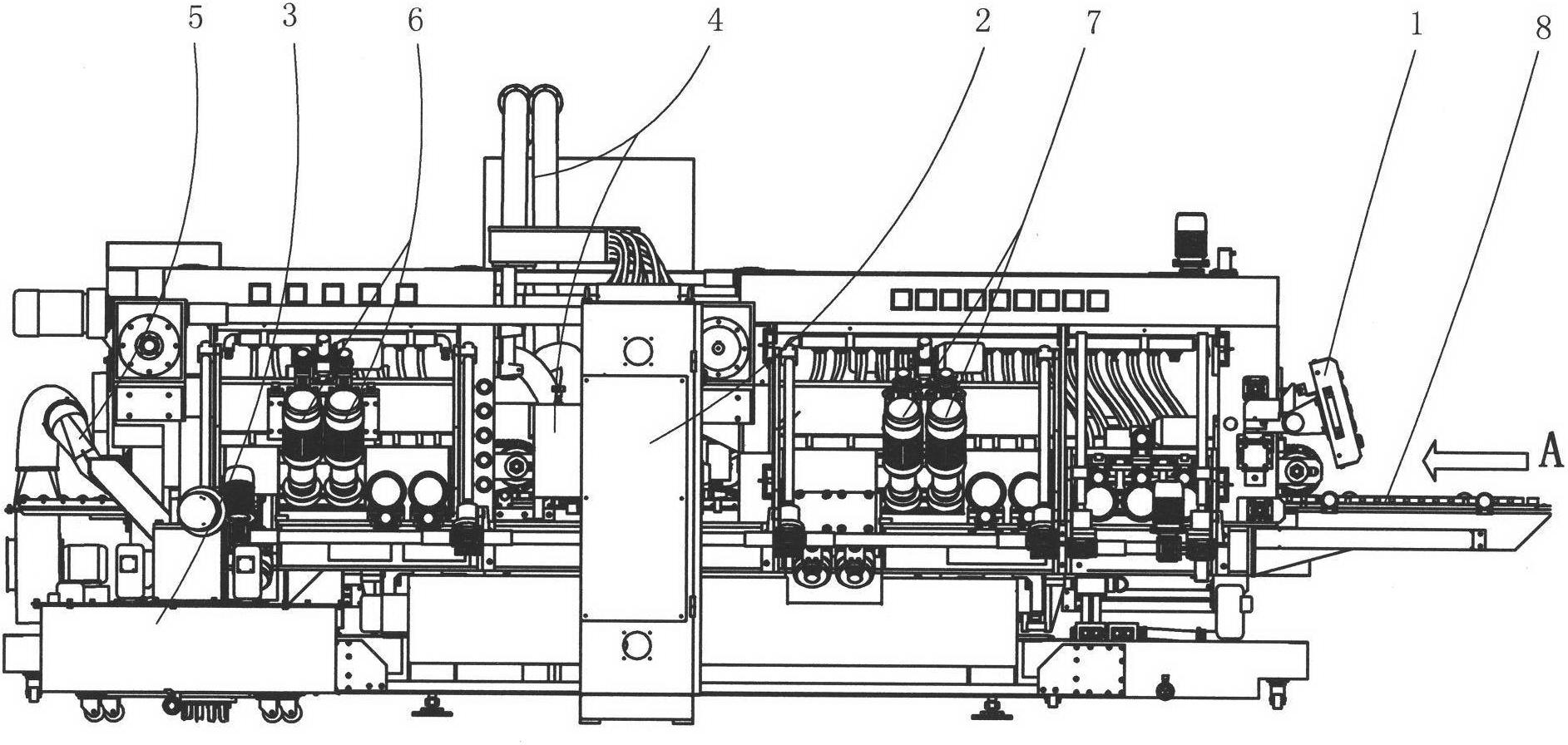

Glass deep processing method and equipment

InactiveCN102672572ATo achieve anastomosisImprove quality and efficiencyEdge grinding machinesGrinding work supportsEngineeringBrightness perception

The invention provides a novel glass deep processing method and equipment. The procedures such as coarse grinding, fine grinding, and polishing of cerium-oxide felt wheels are finished by glass double-edge processing equipment. The processing method comprises the steps of glass positioning and feeding-in, double-edge coarse-fine grinding, cleaning, drying, double-edge polishing, spraying, cleaning, drying, feeding and the like. The invention has the advantages that the difficulty that the polishing of the cerium-oxide felt wheels can not be used on the same double-edge grinding machine in the prior art is successfully solved, the polishing technology of the cerium-oxide felt wheels is applied on the same double-edge grinding machine, the reliability is achieved for the clamping and the positioning, the coincidence of the fine-grinding angle and the polishing angle is realized, the glass processing quality and the glass processing efficiency are improved, and the development of the double-edge grinding machine towards high accuracy and high brightness is realized.

Owner:广东亿海机械制造有限公司

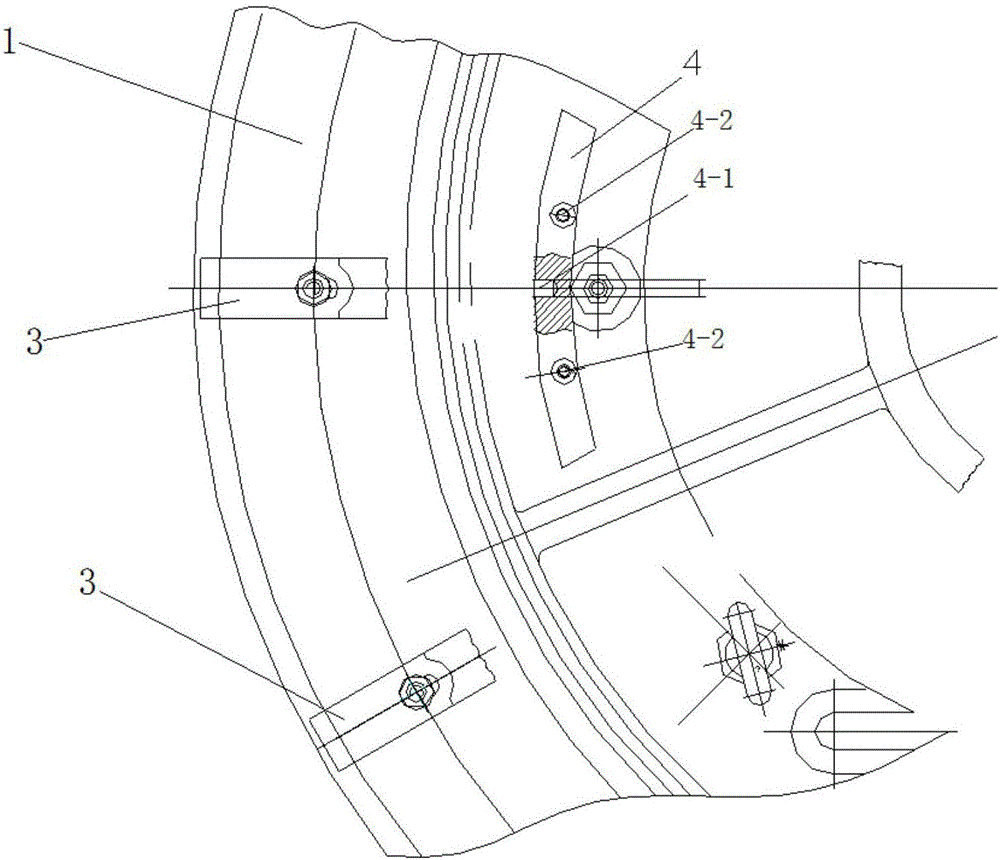

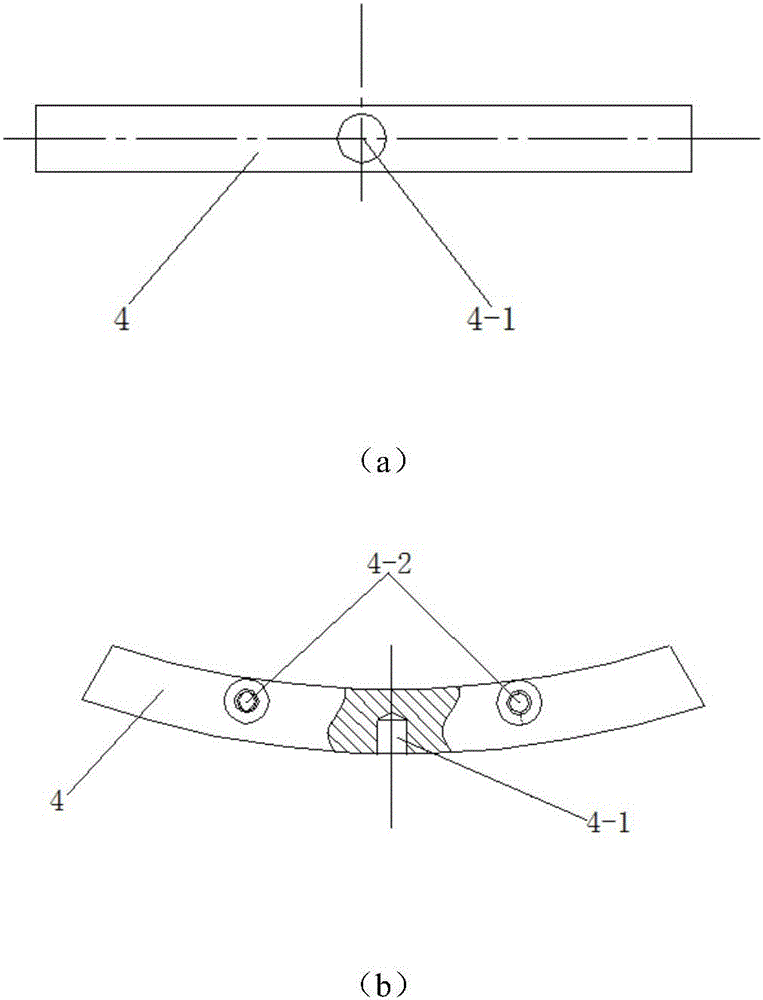

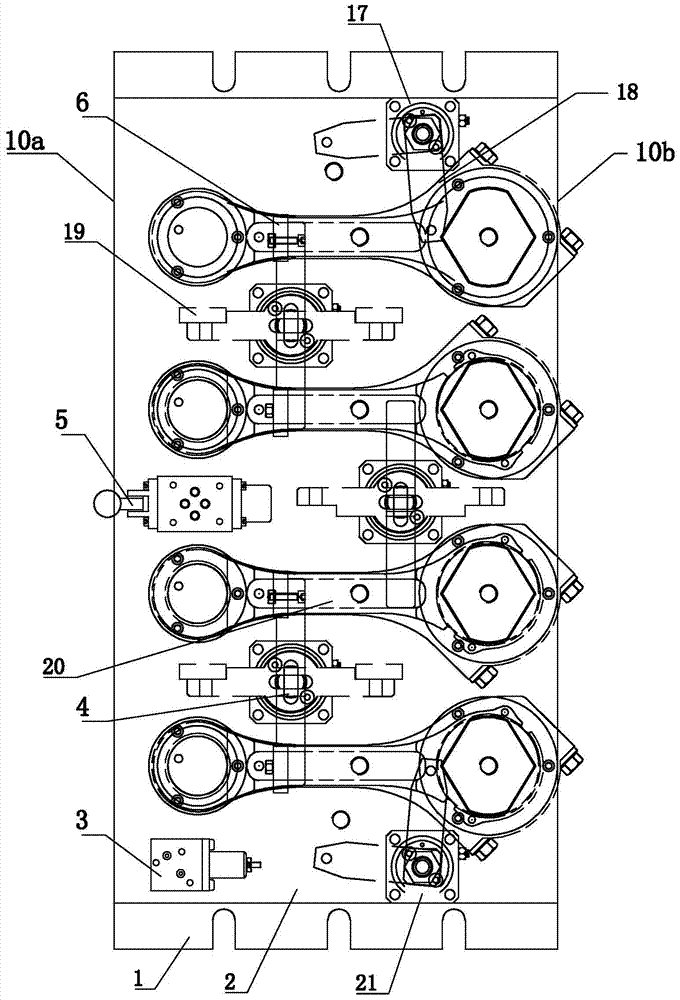

Hard-soldering deformation control method for turbine blade and special fixture for hard-soldering

ActiveCN103752983ABrazing Distortion ControlEasy clampingSoldering auxillary devicesStellite alloyTurbine blade

The invention provides a hard-soldering deformation control method for a turbine blade. The hard-soldering deformation control method for the turbine blade can effectively reduce the hard-soldering deformation of stellite alloy sheets at the steam inlet sides of last-stage large blades of a turbine. The hard-soldering deformation control method for the turbine blade is characterized by comprising the following steps: detecting the hard-soldering deformation and deformation tendency of a test blade by comparing the blade hard-soldering area of the blade before and after the hard-soldering with a blade theoretical model, obtaining a main hard-soldering deformation area and hard-soldering deformation direction of the test blade, and when performing hard-soldering of the stellite alloy sheets to the product blade having the same specification with the test blade, using a special fixture for hard-soldering to apply an over-deformation stress with direction opposite to the hard-soldering deformation direction to the main deformation area of the product blade corresponding to the test blade. The special fixture for hard-soldering comprises a machine tool guide rail connecting seat and multiple groups of chuck mechanisms, wherein the multiple groups of chuck mechanisms are mounted on the machine tool guide rail connecting seat, and the multiple groups of chuck mechanisms are uniformly arranged along the length direction of the hard-soldering area of the stellite alloy sheet of the blade.

Owner:WUXI TURBINE BLADE

Drilling device for automobile engine hood

PendingCN109570559AHigh precisionReliable positioning and clampingWork clamping meansLarge fixed membersInstalled basePiston rod

The invention discloses a drilling device for an automobile engine hood. The drilling device comprises a bottom plate, a vertical plate and a top plate; a lifting air cylinder is installed at the topend of the bottom plate, a piston rod of the lifting air cylinder is connected with the lifting plate, the bottom end of the lifting plate is provided with a first motor, the rotating shaft of the first motor penetrates through the lifting plate to be connected with the rotating plate, balls are installed at the bottom end of the rotating plate, the balls are located in an annular groove formed inthe top end of the lifting plate, and a boss and positioning air cylinders are arranged at the top end of the rotating plate; and a sliding hole is formed in the middle of the top plate, a screw rodmotor is arranged at the top end of the top plate, a screw rod of the screw rod motor is provided with a sliding block, a second motor is arranged on the sliding block, a through hole is formed in thetop end of the sliding block, a rotating shaft of the second motor penetrates through the through hole and the sliding hole to be connected with a drill bit installing base, and a drill bit is installed on the drill bit installing base. The drilling device solves the problems that an existing drilling device is not fastened and a plurality of holes are not drilled conveniently; and the drilling device has the advantages of being capable of clamping and fastening, facilitating drilling of a plurality of holes and the like.

Owner:芜湖名阳机械制造有限公司

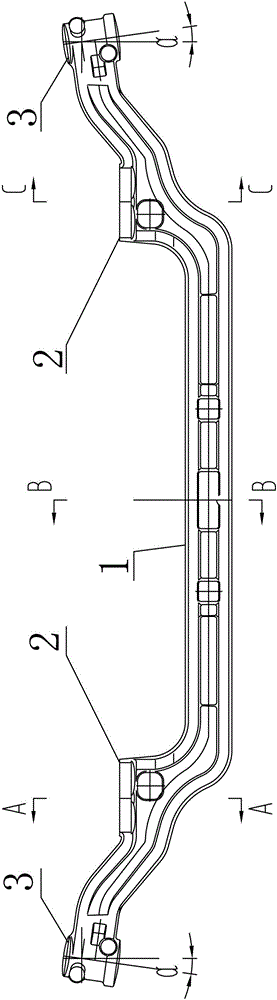

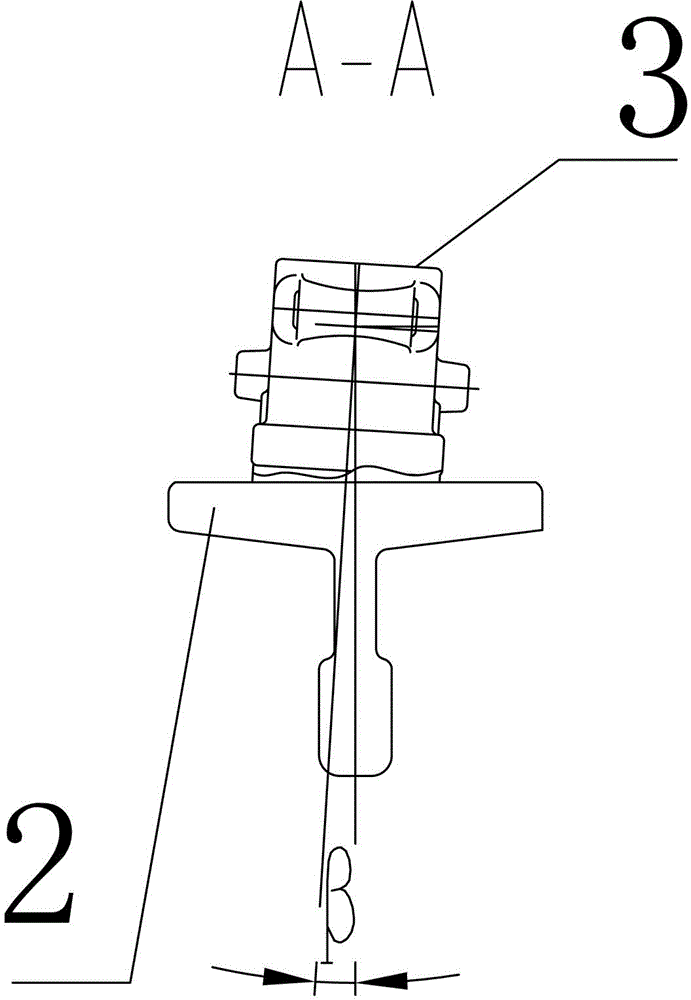

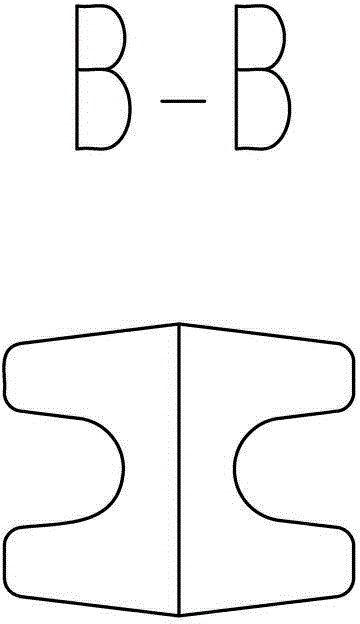

Special front shaft machining clamp capable of automatically aligning caster angle and inward camber

InactiveCN104924123ASuperiorReduce distortionAutomatic control devicesFeeding apparatusFistCaster angle

The invention provides a special front shaft machining clamp capable of automatically aligning a caster angle and an inward camber. The caster angle and the inward camber of a workblank are automatically aligned within a certain amount of deformation of the workblank of a front shaft, a front shaft leaf spring face is directly milled after alignment is performed, and a coordinated system using the aligned front shaft leaf spring face as the positioning basis is built and used as the basis during subsequent machining. According to the scheme, the clamp comprises a front shaft H-shaped beam portion auxiliary supporting structure, an H-shaped beam portion auxiliary clamping structure, a clamping H-shaped beam portion, a wedge iron self-locking clamping unit, a manual thread clamping unit, a floating supporting device and an inward camber correcting unit, wherein the front shaft H-shaped beam portion auxiliary supporting structure can abut against the front shaft H-shaped beam portion so as to play a supporting role, the H-shaped beam portion auxiliary clamping structure can compress the portion above the front shaft H-shaped beam portion, the clamping H-shaped beam portion is matched with the H-shaped beam portion auxiliary supporting structure, the wedge iron self-locking clamping unit is arranged at the rear portion of the front shaft leaf spring face, the manual thread clamping unit is arranged at the front portion of the front shaft leaf spring face and used in cooperation with the wedge iron self-locking clamping unit to clamp the front shaft leaf spring face portion, the floating supporting device is arranged at the lower portion of the front shaft leaf spring face, and the inward camber correcting unit is arranged at the position of a front shaft left fist face and used for correcting the front shaft inward camber.

Owner:ANYANG INST OF TECH

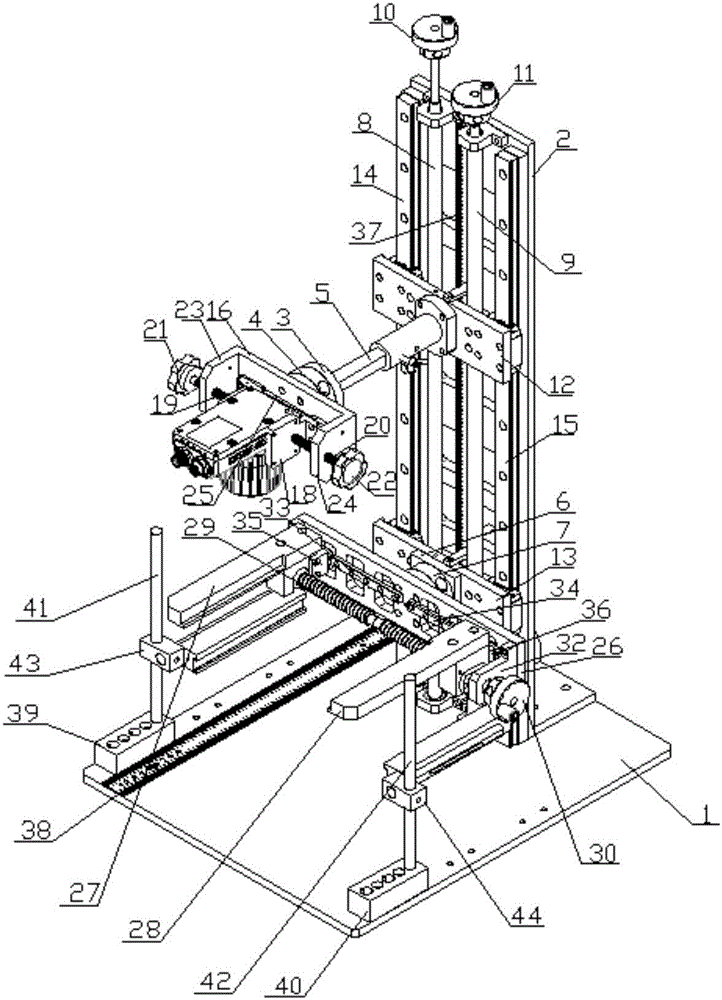

Laboratory test machine

PendingCN106353330AImprove efficiencyHigh precisionOptically investigating flaws/contaminationEngineeringLaboratory test

The invention discloses a laboratory test machine which comprises a horizontal test platform, a bracket arranged on the horizontal test platform and a camera fixing component and a light source fixing component with vertical degree of freedom arranged on the bracket, wherein the camera fixing component is arranged above the light source fixing component and comprises a first rotation mechanism and a first clamping mechanism; the first rotation mechanism comprises a first fixing part and a first rotation part rotatably connected with the first fixing part; the first fixing part is connected with the bracket through a horizontal telescopic sleeve; the first clamping mechanism is fixed on the first rotation part; the light source fixing component comprises a second rotation mechanism and a second clamping mechanism; the second rotation mechanism comprises a second fixing part mounted on the bracket and a second rotation part rotatably connected with the second fixing part; and the second clamping mechanism is fixed on the second rotation part. The laboratory test machine disclosed by the invention is suitable for the mounting fixation and regulation of various cameras and light sources, meets the imaging and lighting requirements of the products different in size and is easy and convenient for assembly / disassembly.

Owner:SUZHOU DINNAR TECH FOR AUTOMATION CO LTD

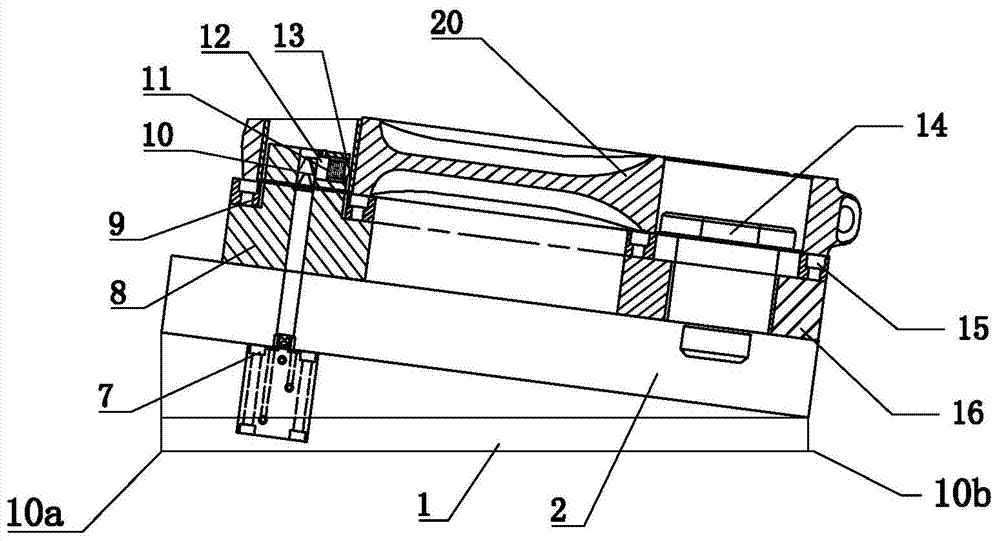

Hydraulic clamping and positioning device for slope processing of connecting rod

ActiveCN104325327AStable jobRapid positioningPositioning apparatusMetal-working holdersBaseboardEngineering

The invention discloses a hydraulic clamping and positioning device for slope processing of connecting rod. The hydraulic clamping and positioning device for slope processing of connecting rod comprises a baseboard provided with a clamp board, wherein a small end hole positioning device is arranged on the clamp board, the small end hole positioning device comprises a first cushion block provided with a first through hole, a horizontal through hole is formed in a boss of the first through hole, an ejecting column is arranged inside the horizontal through hole, a piston rod of a thin-wall oil cylinder extends from the first through hole and abuts against a cone head rod, the cone head slope of the cone head rod can push the slope of the ejecting column to position a small end hole, a large end hole positioning device comprises a second cushion block provided with a second through hole in the middle, a positioning pin of the second through hole positions a large end hole, and two single head pressing boards and a plurality of double head pressing boards are used for clamping a connecting rod. A hydraulic oil cylinder can fast position and clamp the small end hole, the large end hole is positioned by the positioning pin, the hydraulic oil cylinder also can fast control the pressing of the single head pressing boards and the double head pressing boards on the connecting rod of each working position, so that the connecting rod slope processing can be smoothly conducted, and the processing efficiency is improved.

Owner:山东盛祥智能制造有限公司

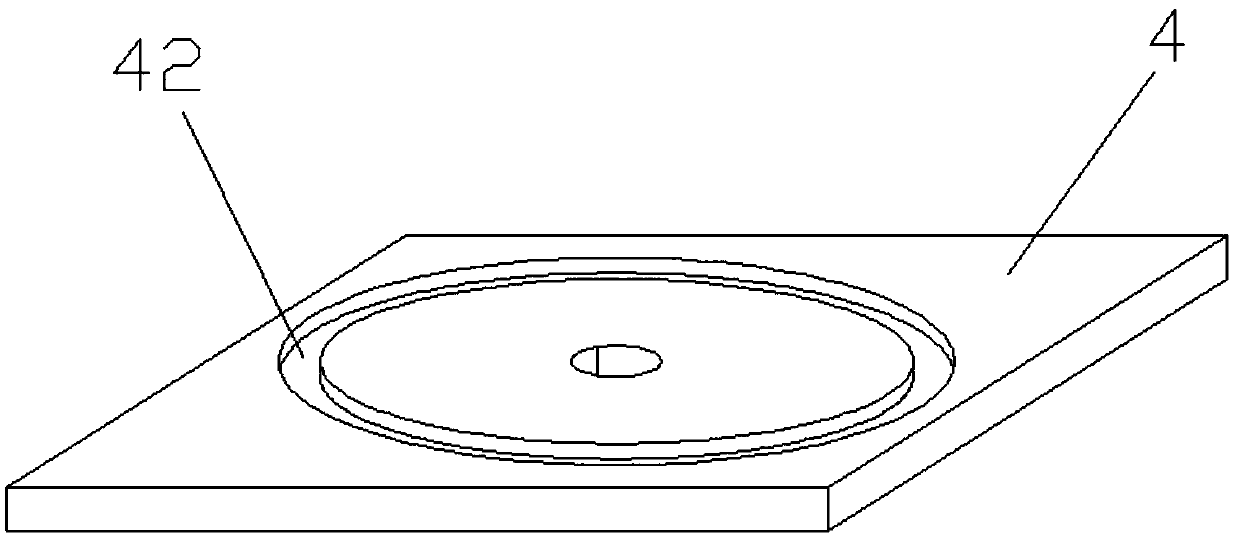

Flange spot welding clamp for automobile exhaust recirculation cooling system diffuser

ActiveCN102554542APrecise positioningGuaranteed positioning accuracyWelding/cutting auxillary devicesAuxillary welding devicesDrive shaftPulp and paper industry

The invention provides a flange spot welding clamp for an automobile exhaust recirculation cooling system diffuser. The clamp can ensure the positioning precision of a flange and a diffuser shell during spot welding. The clamp comprises a bottom plate. The clamp is characterized by also comprising a support frame, a rotary cylinder and workpiece positioning and clamping devices; the support frame comprises a support plate, and a support block is arranged at each of two transverse ends of the support frame; the rotary cylinder is fixed on the support block at the transverse right end of the support frame; two transverse ends of the bottom plate are arranged on the support blocks through connecting blocks, and the connecting block at the right end is connected and fixed with an output transmission shaft of the rotary cylinder; and a flange positioning boss is fixed on the bottom plate, the flange positioning boss is provided with an inner hole matched with the shape of the flange, the bottom plate is provided with a conical through hole at the position opposite to the flange positioning boss, and one workpiece positioning and clamping device is arranged on each of the transverse side and the longitudinal side of the flange positioning boss on the bottom plate.

Owner:WUXI DAWN DIE & STAMPING

Multi-function cutting machine

ActiveCN109624102AImprove stabilityImprove accuracyWorking accessoriesMetal working apparatusEngineeringMultiple function

The invention relates to a multi-function cutting machine. The multi-function cutting machine includes a cutting work table, a cutter assembly used for cutting a plate to be cut, wherein the cutter assembly is slindingly mounted on a guiding rod in a matched mode, the tail end of a cutter fixing column is hinged to a cutter with extensible function, a first connecting block is rotatably connectedwith the upper end surface of the cutting work table through a pin shaft, a second connecting block is locked in the screw holes of the cutting work table through locking bolts, one side of the upperend surface of the cutting work table is fixedly connected with a clamped clamping body used for clamping the edge of one side of the plate to be cut, at least two rectangular grooves are formed in the upper end surface of the cutting work table, clamping parts for clamping the edge of the other side of the plate to be cut are arranged on a sliding rod in a sliding mode, and an adjusting part foradjusting the height and the inclination angle of the cutting work table is arranged at the lower end of the cutting work table. According to the multi-function cutting machine, stability of positioning, accuracy of cutting and the application range of using are improved, the operation is convenient for workers, and the multi-function cutting machine is applicable to cutting plates with a certainthickness range and a certain size range.

Owner:CHINA OTSUKA PHARM CO LTD

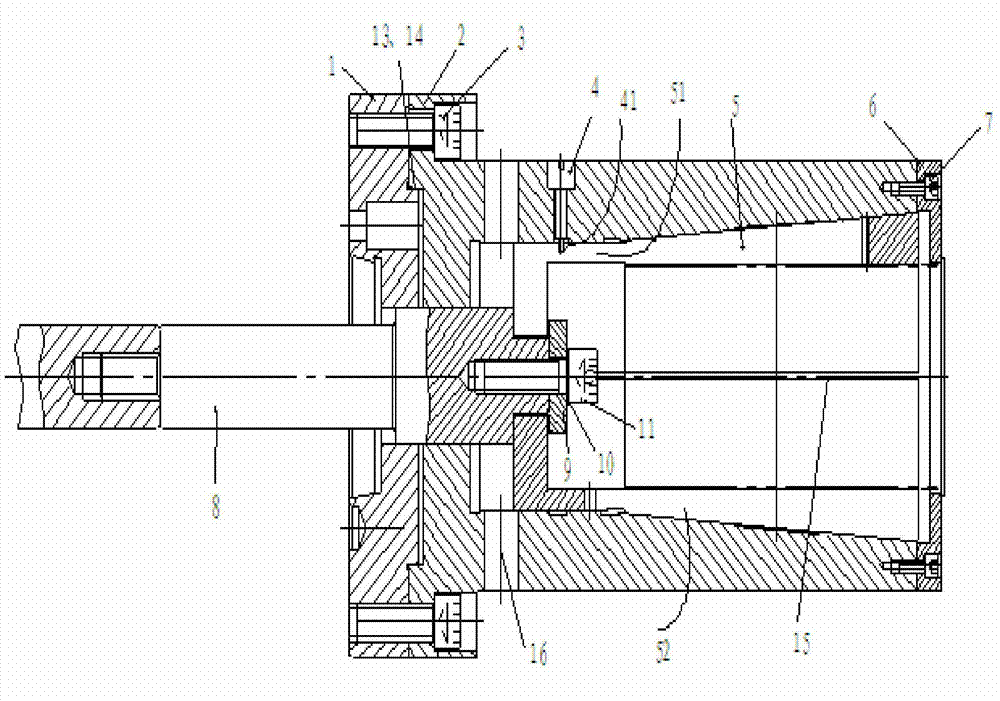

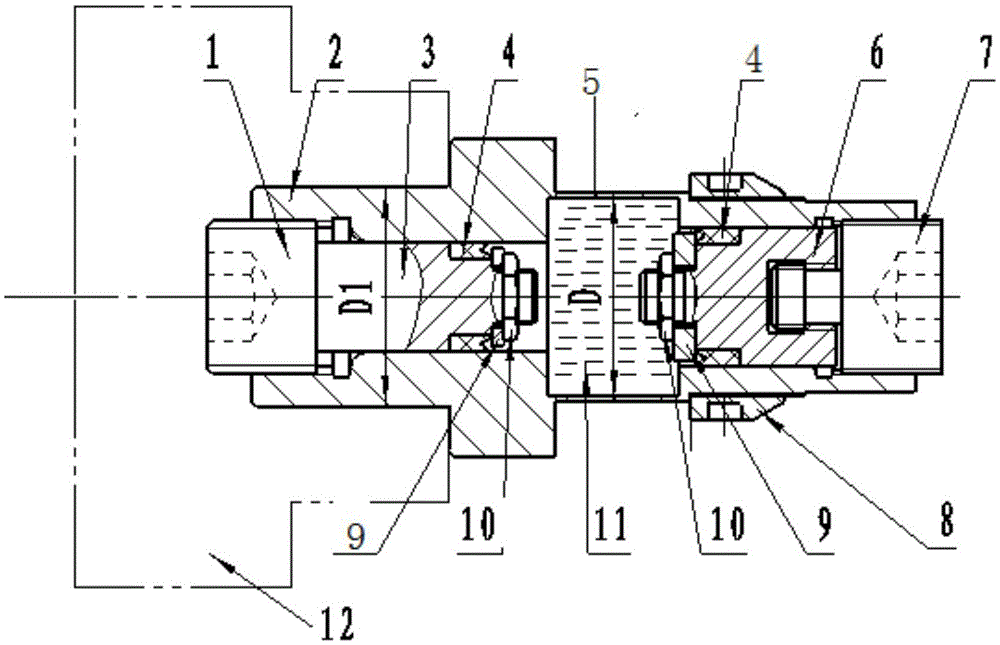

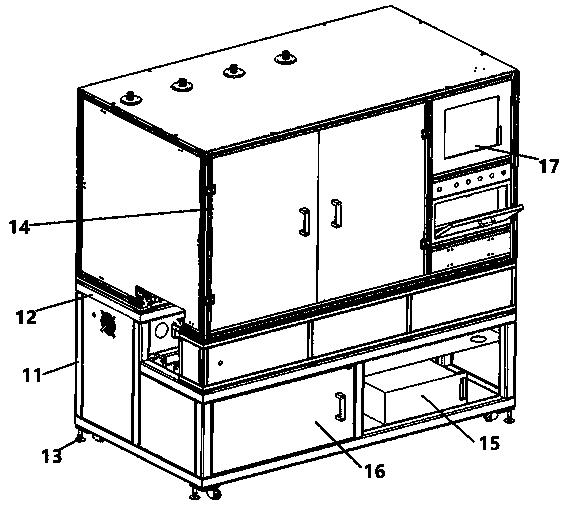

Hydraulic tensioning clamping mandrel for thin-wall shaft sleeve

InactiveCN105458317AReliable positioning and clampingSimple structureExpansion mandrelsEngineeringMachine tool

The invention discloses a hydraulic tensioning clamping mandrel for a thin-wall shaft sleeve. The hydraulic tensioning clamping mandrel is provided with a mandrel body located to the end face of a machine tool chuck or a spring sleeve. A step shaft table for locating the end face of a part to be machined is manufactured on the mandrel body, and step holes for assembling of plungers and a hydraulic oil cavity communicated with the step holes are formed in the two ends. The left pressure adjusting plunger (3) is sealed at the left end of the hydraulic oil cavity from the leftward step hole of the mandrel body (2), the right pressure adjusting plunger (6) is sealed at the right end of the hydraulic oil cavity from the rightward step hole of the mandrel body, and a closed container is formed. The to-be-machined part assembled on a rightward barrel of the mandrel body is clamped between the end face of the step shaft table of the mandrel body and a compressing nut (10) through the compressing nut (10). Sealing screws (7) are screwed down to drive the plungers to move and compress hydraulic oil in the hydraulic oil cavity, and the to-be-machined part clamped on the external circle tensioning mandrel body on the thin wall of the hydraulic oil cavity is expanded through pressure generated by the hydraulic oil cavity under the action of oil pressure. The hydraulic tensioning clamping mandrel is easy to manufacture and high in clamping precision, and a clamping area is stable and reliable in clamping.

Owner:SICHUAN LINGFENG AVIATION HYDRAULIC MACHINERY

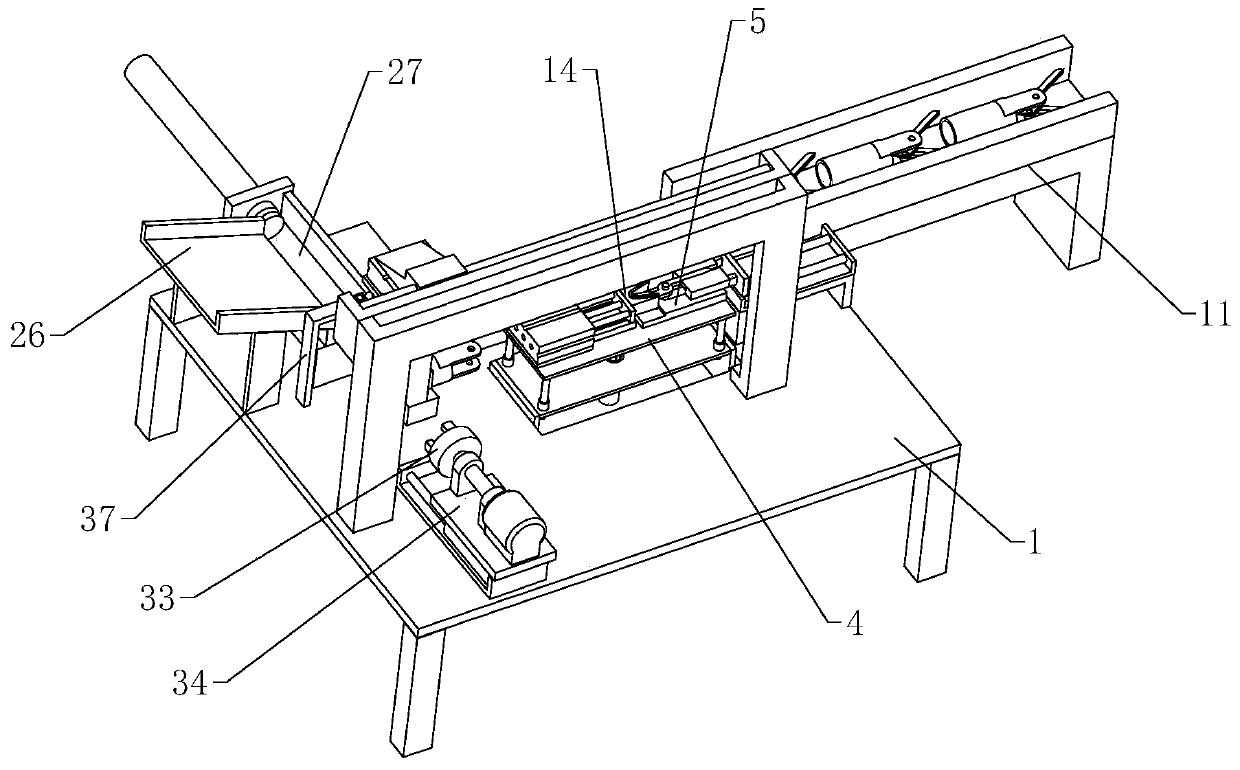

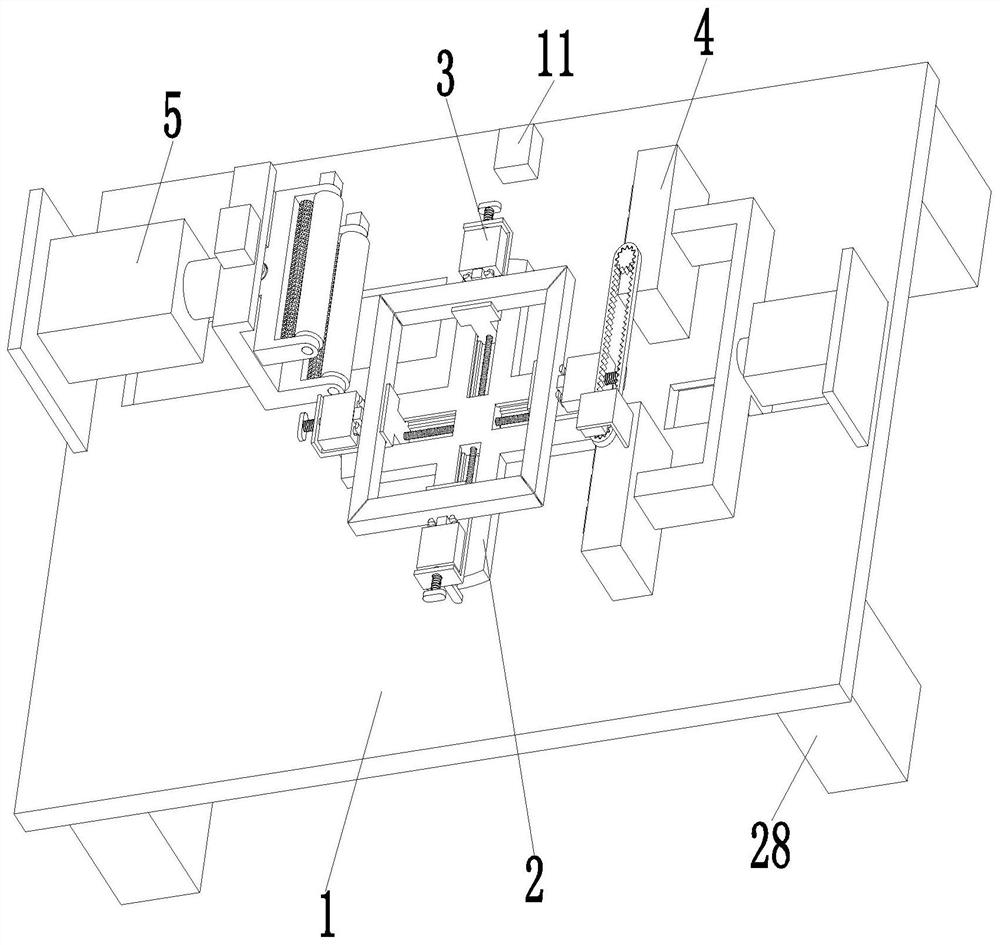

Assembling device for sampling tongs for gastroenterology department

InactiveCN110842543APlay the role of guide limitReliable positioning and clampingSurgeryAssembly machinesGastroenterology departmentMechanical engineering

The invention relates to the technical field of processing of medical sampling tongs, in particular to an assembling device for sampling tongs for a gastroenterology department. The assembling devicecomprises a processing table, and further comprises a tong head positioning mechanism, a clamping positioning mechanism, a sleeve tool moving mechanism and a sleeve feeding and correcting mechanism, wherein the tong head positioning mechanism comprises a lifting assembly and an accommodating positioning assembly; the lifting assembly is positioned at the bottom of the processing table, and comprises a lifting plate; the clamping positioning mechanism comprises an accommodating jig capable of accommodating tong heads and an adjusting component, and further comprises a clamping component; the sleeve feeding and correcting mechanism comprises a sleeve feeding component and a sleeve correcting component; the sleeve tool moving mechanism comprises a horizontal moving component and a horizontaloverturning positioning component; an operation incision is formed in one side, close to the lifting plate, of the processing table; and a discharging conveyor is arranged on one side of the operationincision. All that is needed is to place the tong heads on the accommodating jig manually in sequence, the automatic assembly can be realized, and the working efficiency is improved.

Owner:CHENGDU GUANYU TECH

Garlic root cutter with cutting area controllable

InactiveCN102615658APrecise positioningReliable feedingMetal working apparatusRootstockElastic plastic

A garlic root cutter with cutting area controllable relates to the field of deep-processing mechanical equipment for vegetable rootstock cutting. A fixing plate, a cutting area opening control plate, three bucket-shaped plates distributed in the peripheral direction at intervals of 60 degrees, an elastic blade, a lifting hopper, a feeding barrel, an elastic plastic guide wheel and the like form a critical portion. Pin shafts on the inner sides of the bucket-shaped plates are fixed on the fixing plate, and pin shafts on the outer sides of the bucket-shaped plates are arranged on a groove of the control plate. The blade is fixed on a knife shaft, matched with the opening control plate and the like in use and controlled by a motor. The range the a rotary knife can cut can be controlled according to sizes of garlic roots so that garlic skins or garlic cloves can be prevented from being damaged, and reliable garlic head positioning and feeding can be achieved. An elastic ejecting device below a feeding mechanism can lead garlic heads to be reliably positioned and clamped and accurately cut, continuous feeding, root cutting, bagging and other technological processes of the garlic heads can be achieved through an automatic line, and production efficiency is high.

Owner:SHANDONG UNIV OF TECH

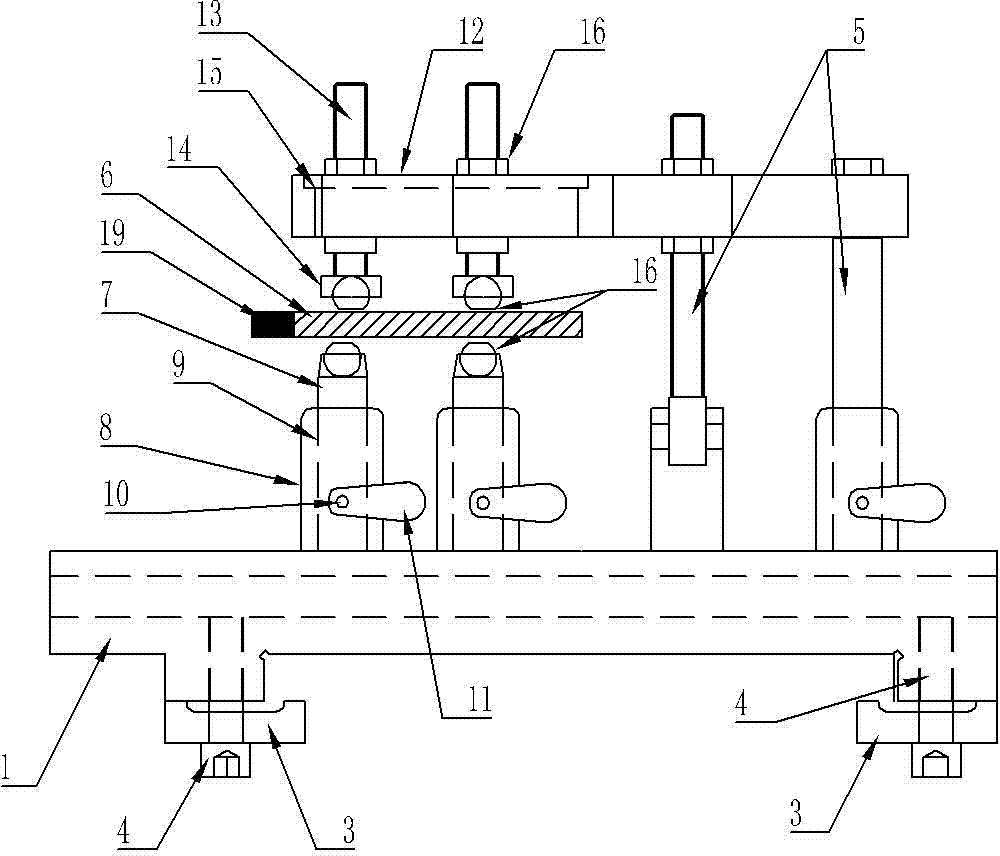

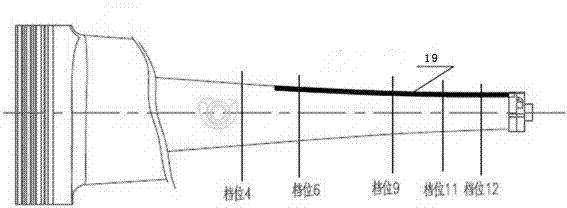

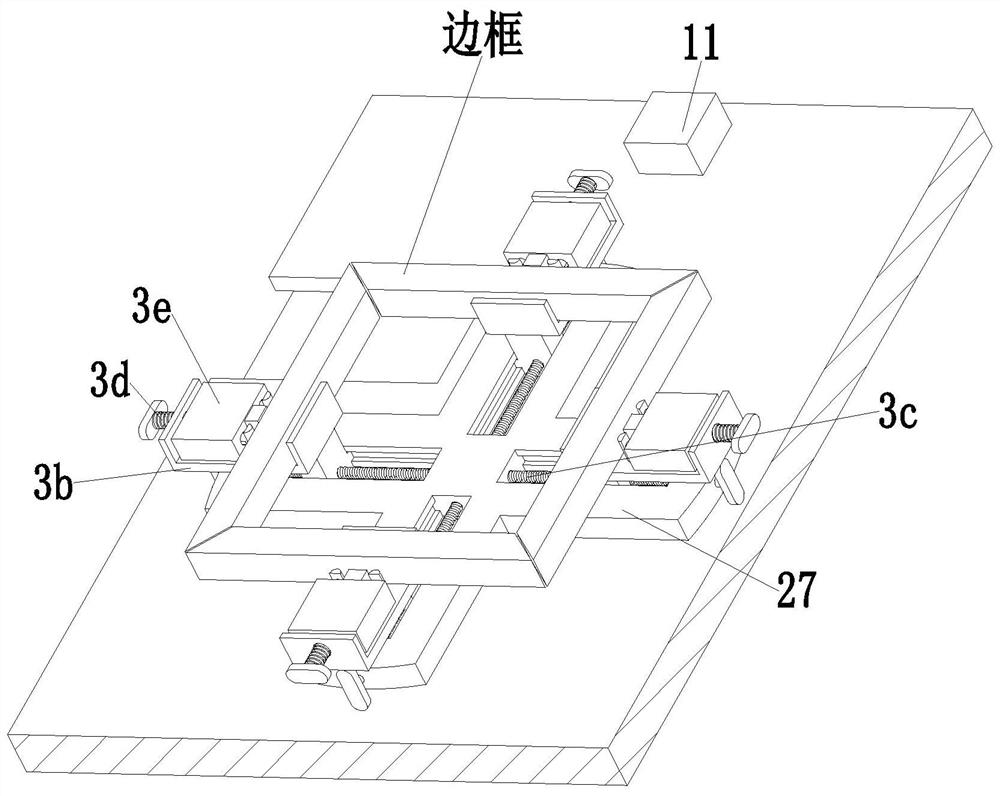

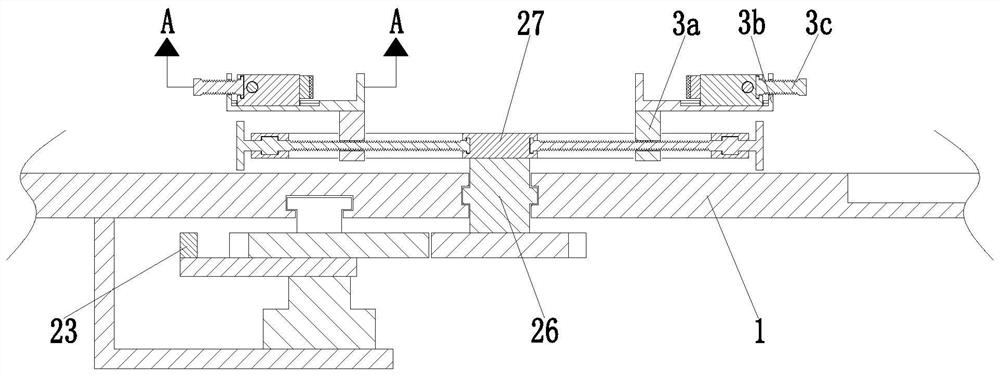

Intake manifold milling plane clamp device

InactiveCN102554658AAccurate clamping and positioningReliable positioning and clampingPositioning apparatusMetal-working holdersUltimate tensile strengthMachine tool

The invention discloses an intake manifold milling plane clamp device, which can solve the problems of low workpiece positioning accuracy, instable machining quality and high labor intensity of workers brought by only clamping the workpiece by using a pressing plate in the conventional intake manifold milling plane machining. The intake manifold milling plane clamp device comprises a bottom plate, a workpiece positioning plate, a high-power clamp hand and a machine tool positioning block, wherein the workpiece positioning plate is vertically arranged on the bottom plate; the high-power clamp hand is fixed to the bottom plate through a cushion block and is just opposite to a positioning surface of the workpiece positioning plate; and the machine tool positioning block penetrates through the bottom plate and is fixed to the bottom plate through a bolt.

Owner:WUXI DAWN DIE & STAMPING

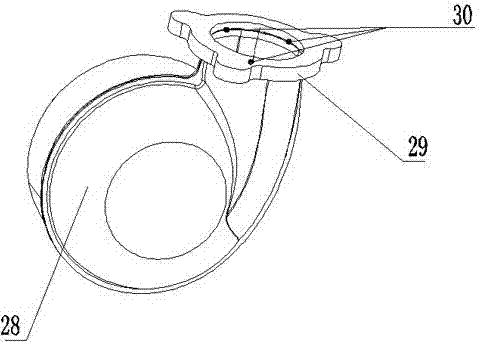

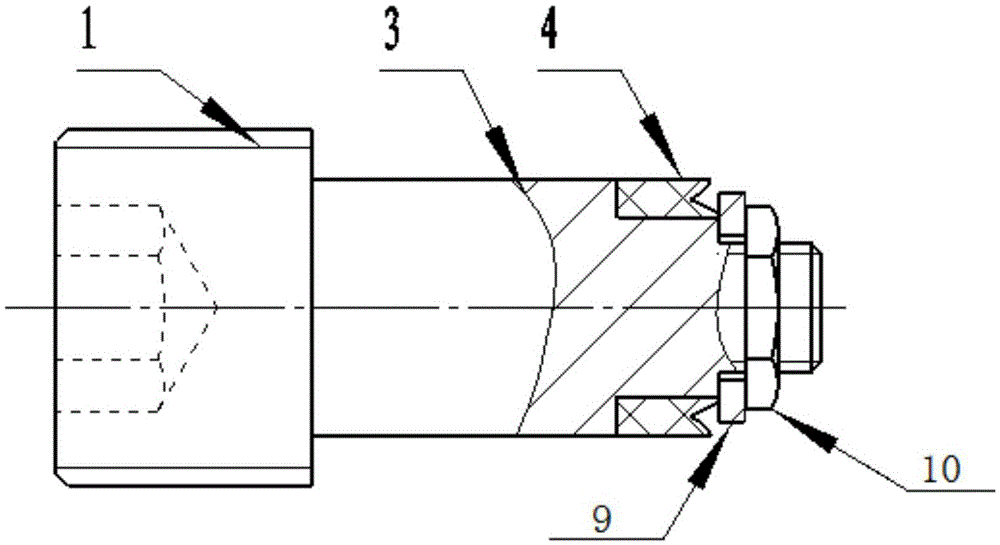

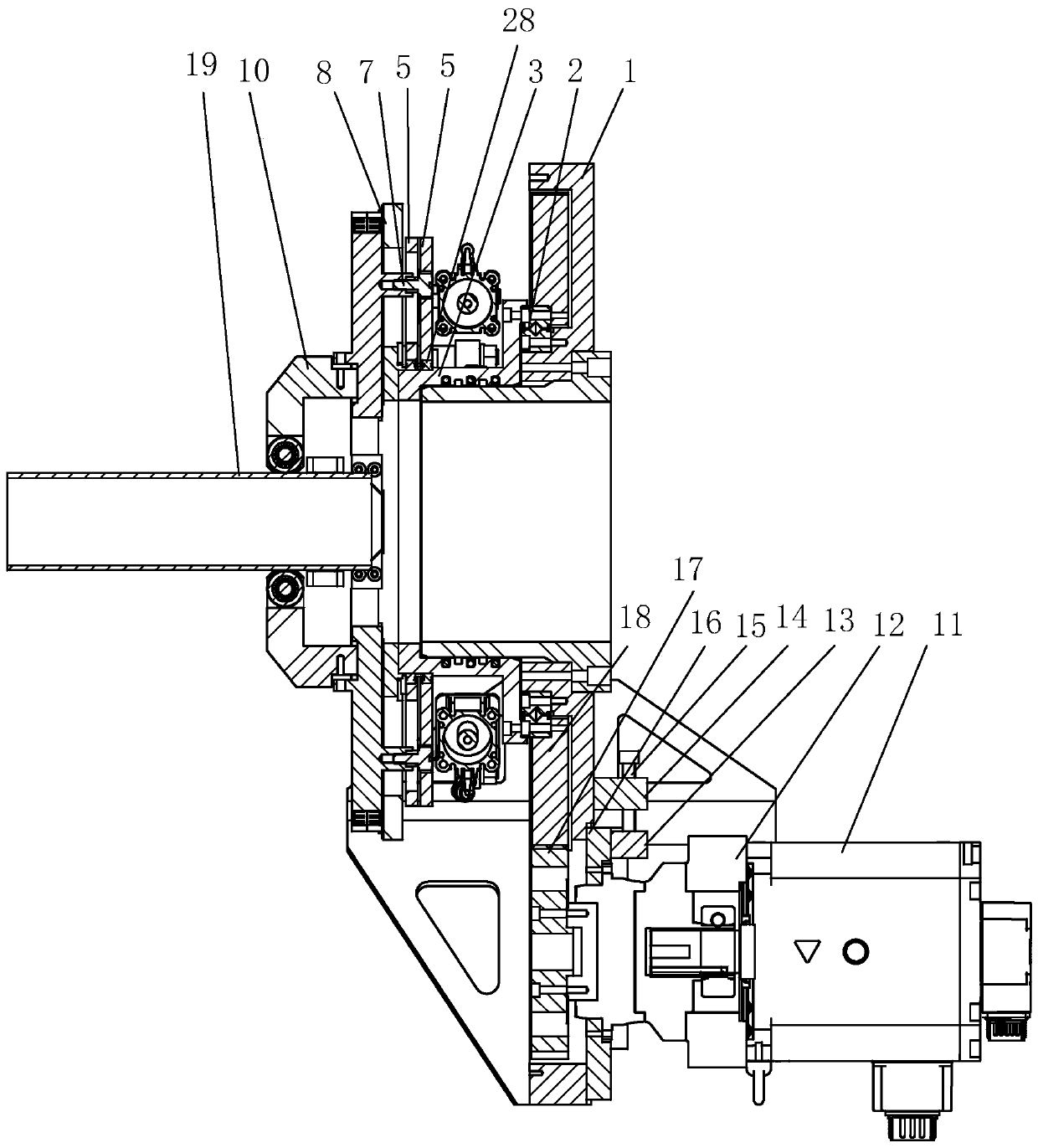

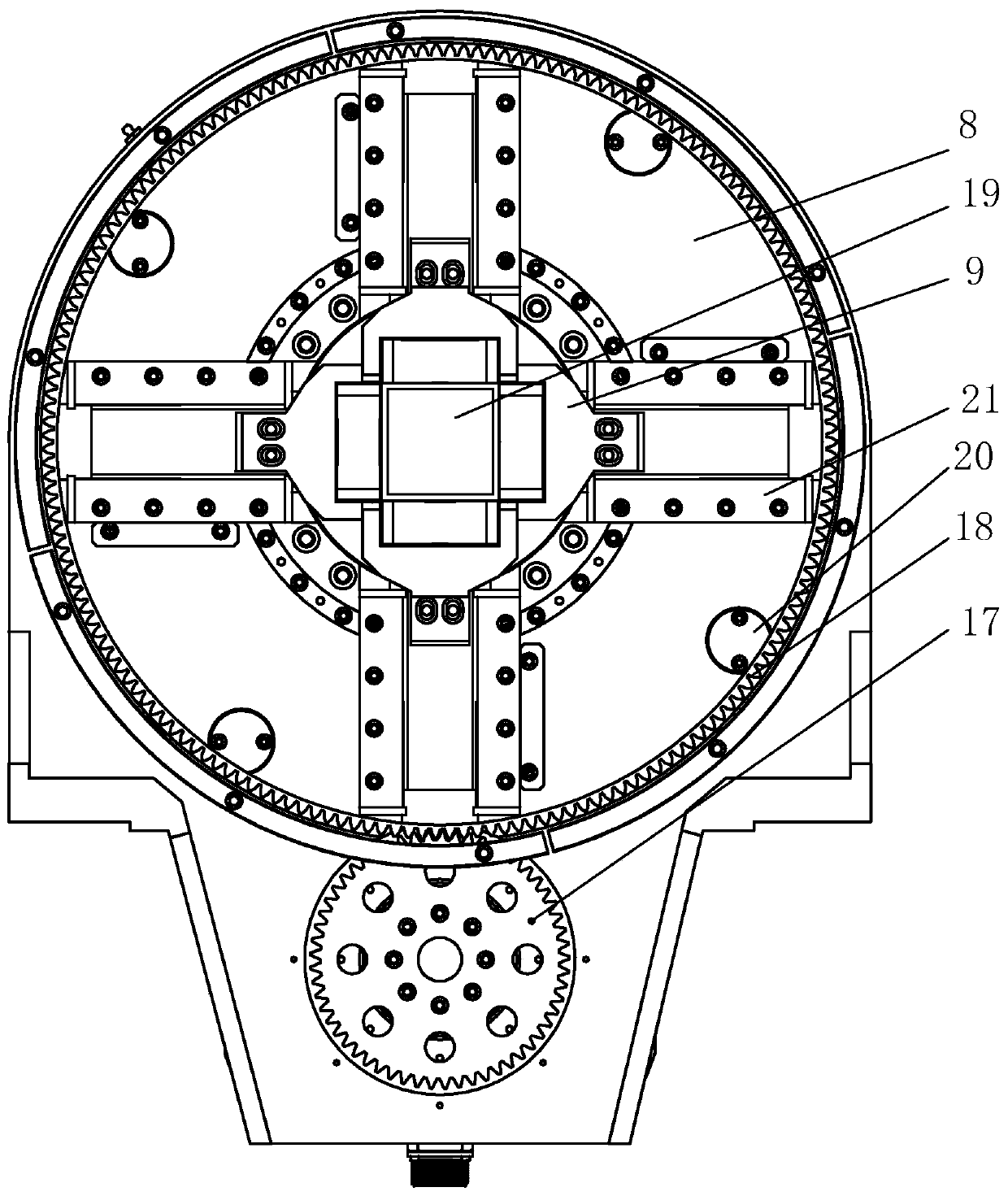

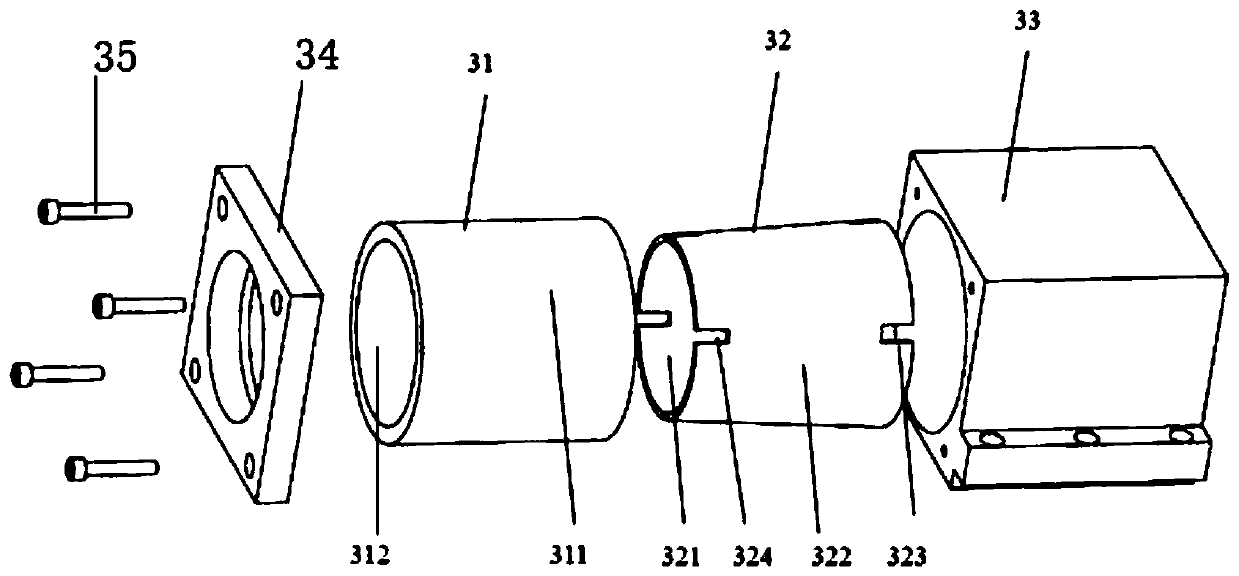

Automatic pipe centering clamping and rotating device for laser cutting

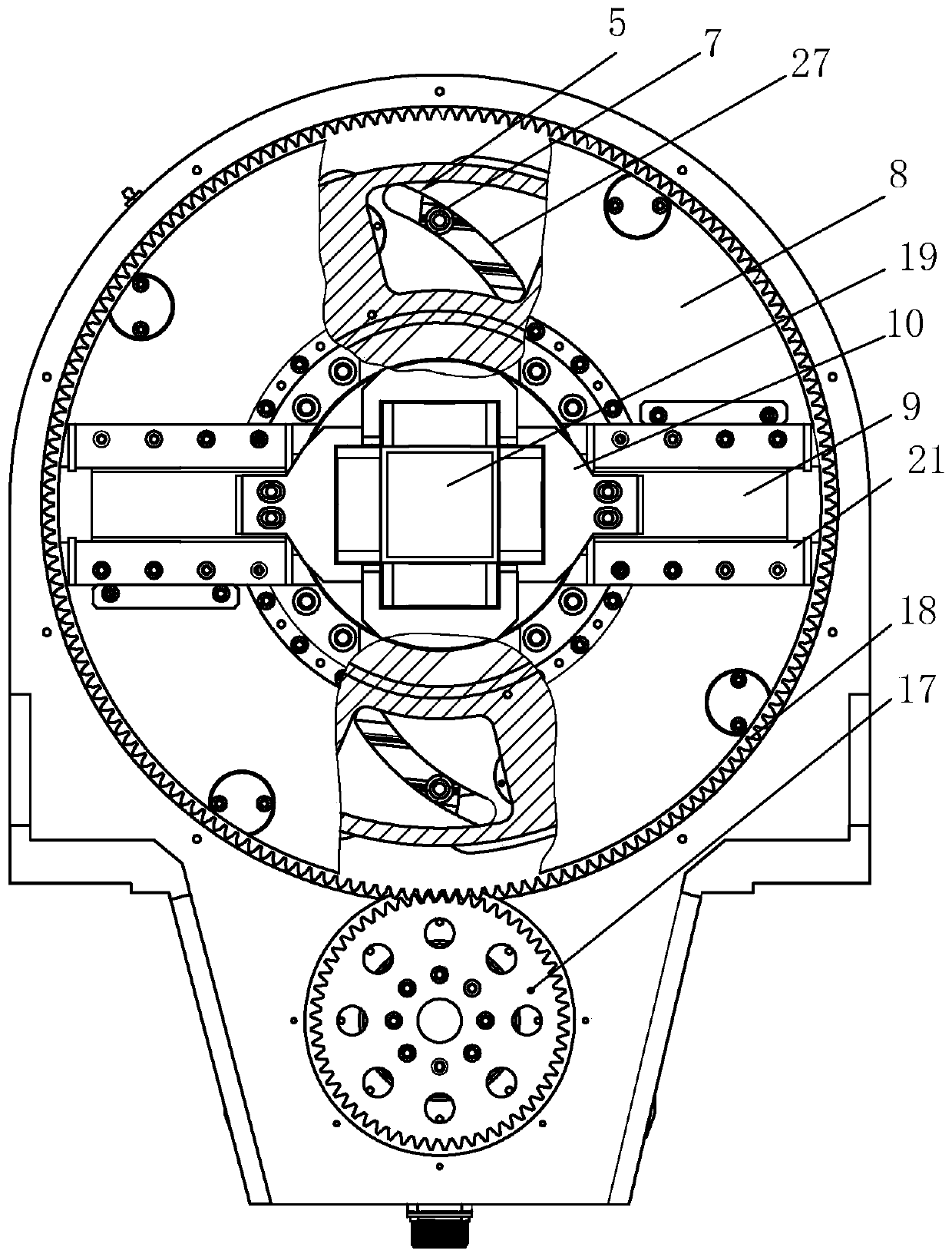

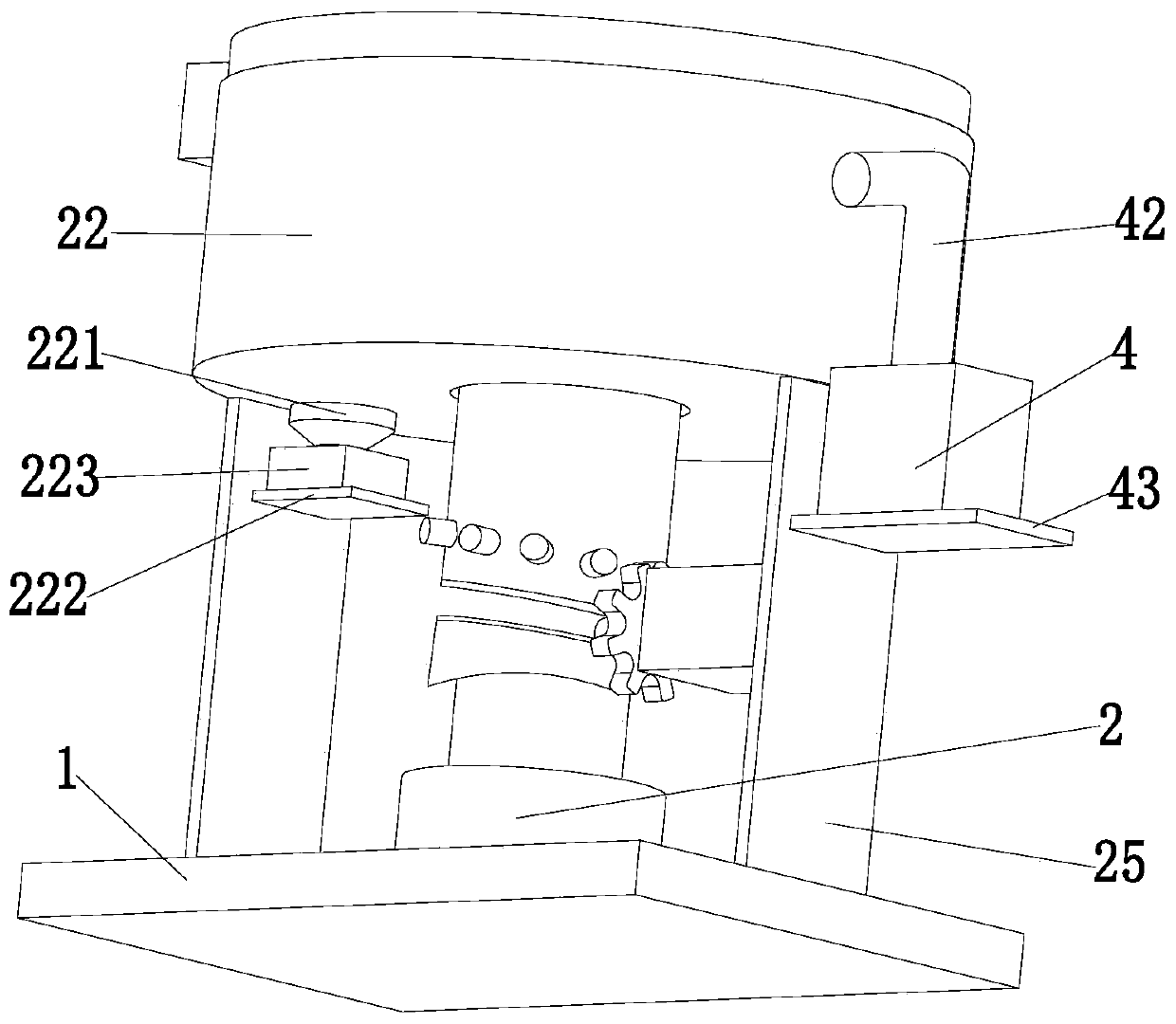

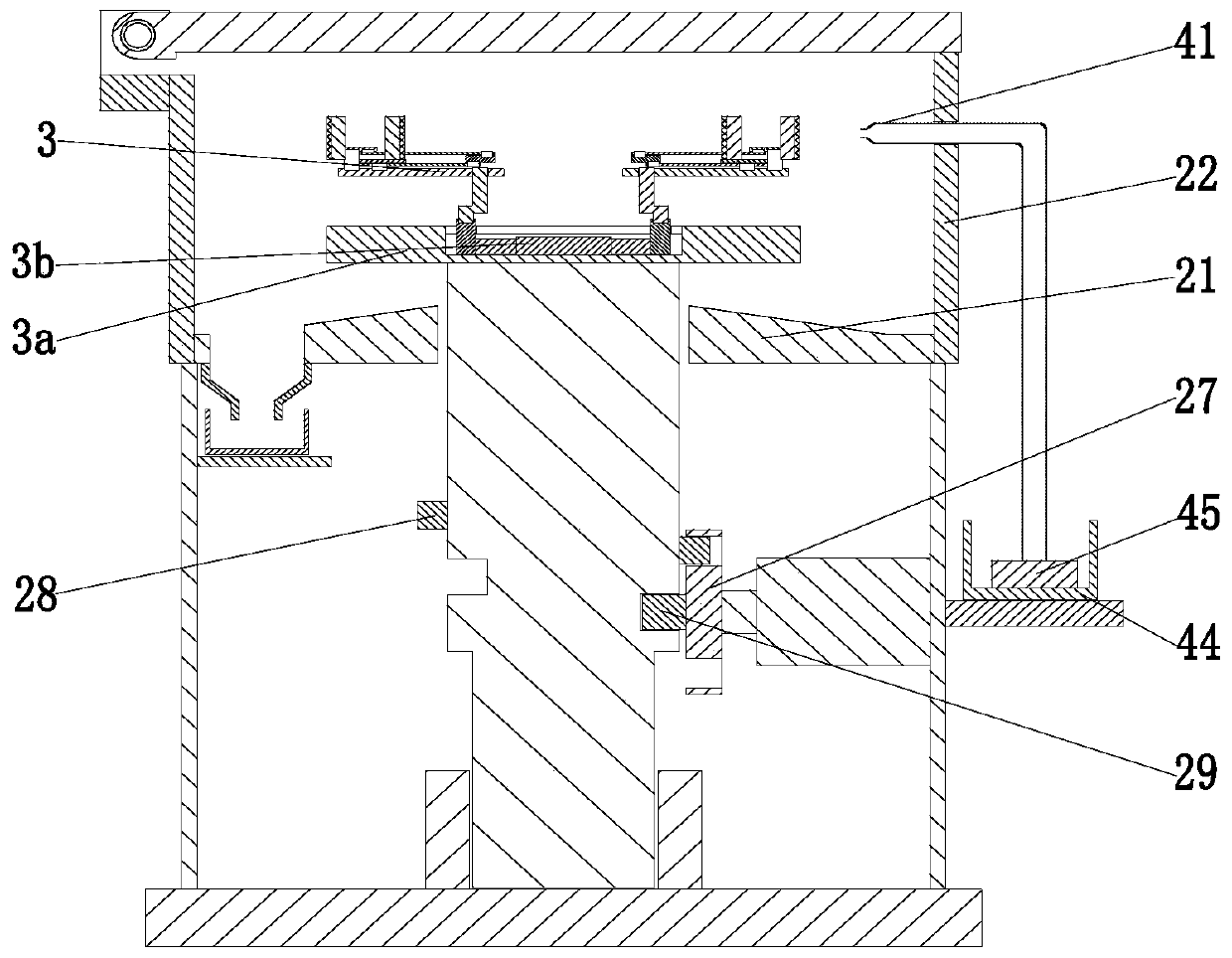

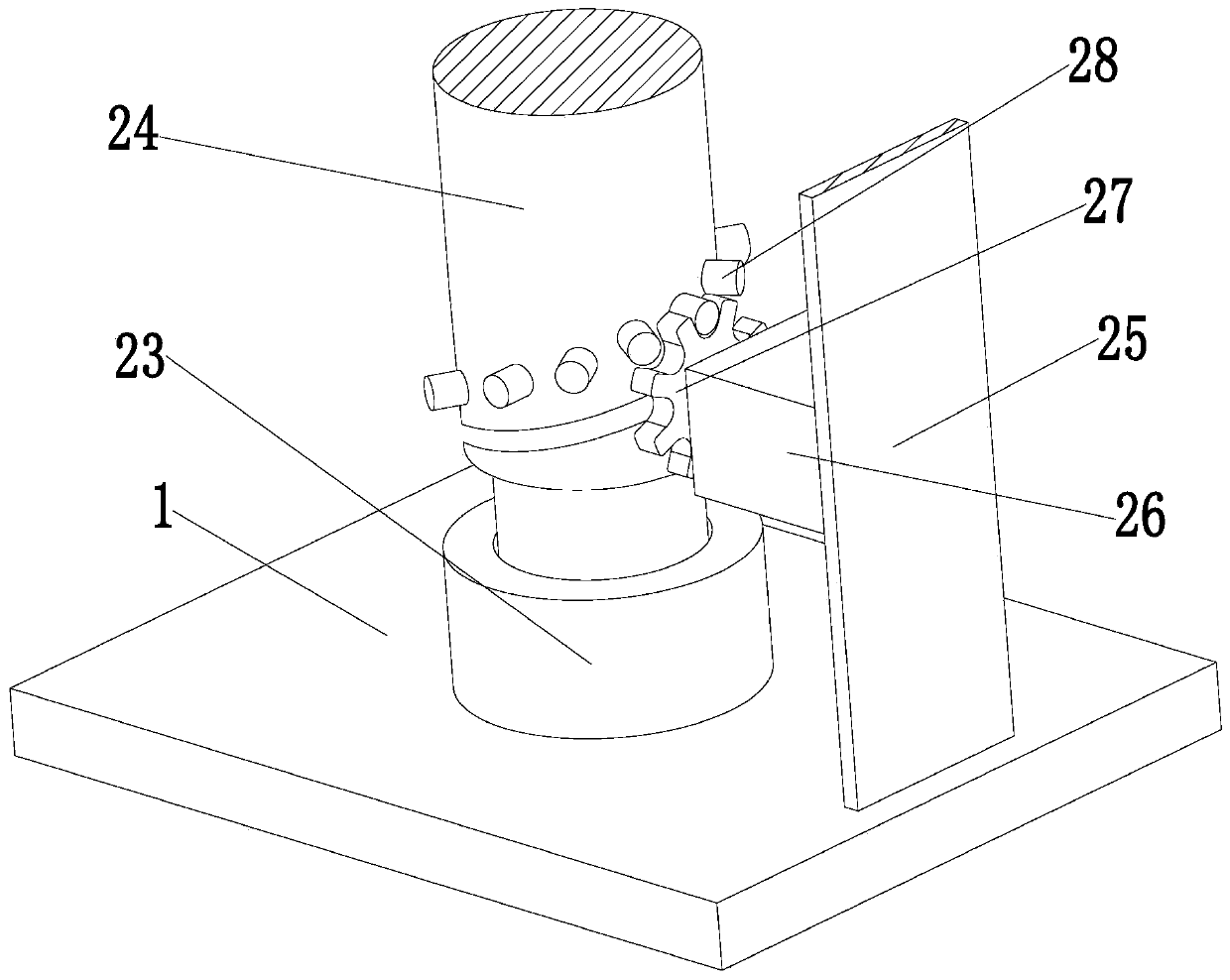

ActiveCN110125557AGuaranteed normal rotationRealize high-precision positioningLaser beam welding apparatusEngineeringLaser cutting

The invention relates to an automatic pipe centering clamping and rotating device for laser cutting. The automatic pipe centering clamping and rotating device comprises a base body, the base body is provided with a main shaft connecting bearing, the base body is connected with a main shaft body sleeving an outer ring of the main shaft connecting bearing in a sleeved mode through the main shaft connecting bearing, the base body is provided with a rotating mechanism for driving the outer ring of the main shaft connecting bearing to rotate, the main shaft body is rotationally connected with a synchronous movement mechanism, the main shaft body is connected with a guide rail base, the guide rail base is provided with an air cylinder driving assembly for driving the synchronous movement mechanism to operate, and the synchronous movement mechanism is connected with a plurality of clamping units used for clamping pipes. According to the automatic pipe centering clamping and rotating device for laser cutting, the pipes of different specifications and sizes can be automatically clamped at a time in a full stroke, the pipes can also be driven to synchronously rotate, so that the pipe circumferential cutting advantage is realized, moreover, the synchronous movement of the clamping units is ensured by arranging the synchronous movement mechanism, so that the centers of the pipes are concentric with the rotating center of the main shaft of the automatic pipe centering clamping and rotating device, clamping and positioning are reliable, so that the precision of cutting is guaranteed.

Owner:PENTA CHUTIAN LASER (WENZHOU) CO LTD

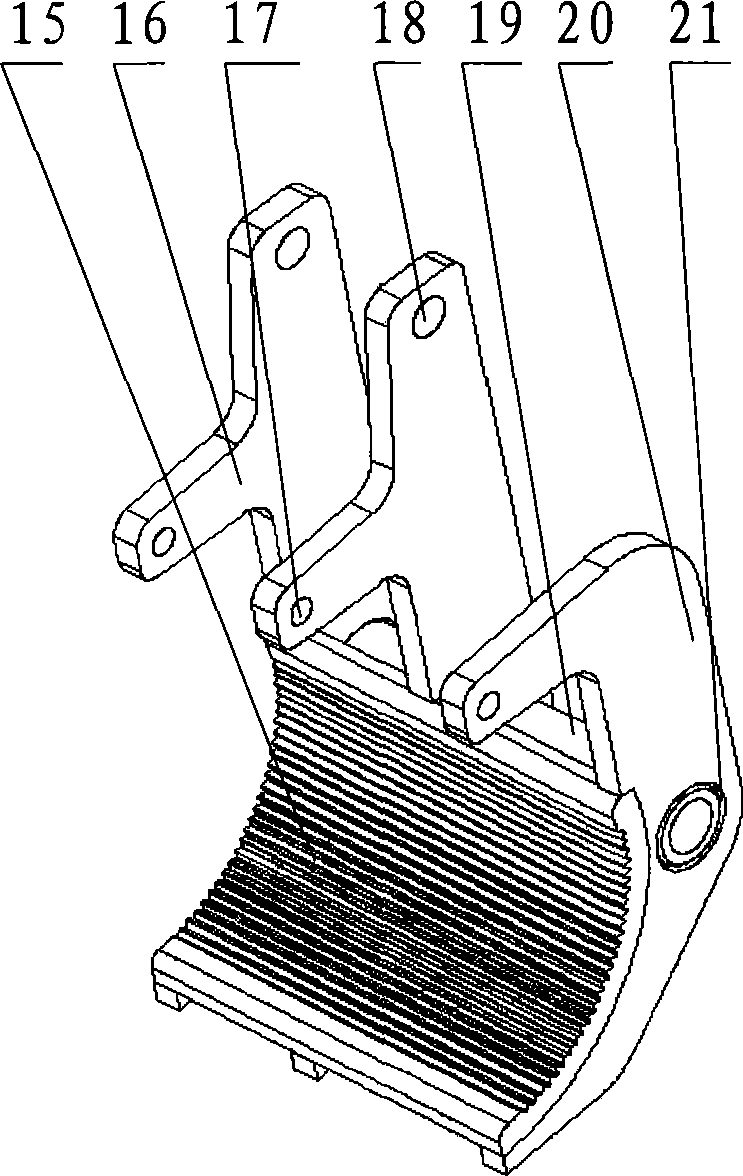

Boiler accessory surface spraying device and surface spraying process

ActiveCN111299003AReduce utilizationImprove work efficiencyLiquid spraying apparatusSpray boothsClosed chamberEngineering

The invention relates to a boiler accessory surface spraying device and surface spraying process. The boiler accessory surface spraying device comprises a bottom plate, a rotating device, a clamping device and a paint spraying device, wherein the rotating device is installed on the bottom plate, the clamping device is installed at the upper end of the rotating device, and the paint spraying deviceis installed on the rotating device. The boiler accessory surface spraying device and surface spraying process can solve the following problems in the paint spraying of an existing boiler accessory fire grate segment that 1, when the traditional fire grate segment is subjected to paint spraying, an operator has to wear a protective suit and use a paint spraying gun to conduct paint spraying operation on the fire grate segment in a closed chamber, the paint contact time is too long, and the body of the operator is prone to harm; and 2, spraying on the surface of the fire grate segment is not uniform through adopting a traditional paint spraying machine, and paint cannot be collected and recycled, so that the utilization rate of the paint is reduced. According to the boiler accessory surface spraying device and surface spraying process, the working efficiency of paint spraying is improved, and the beneficial effects of wide application range, uniform spraying, high working efficiency and the like are achieved.

Owner:济南黄台煤气炉有限公司

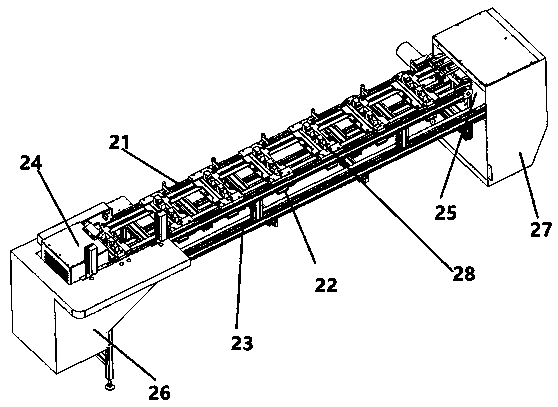

Full-automatic soldering machine

InactiveCN109570677AImprove processing efficiencyImprove product quality stabilityWelding/cutting auxillary devicesAuxillary welding devicesSolderingMechanical engineering

The invention discloses a full-automatic soldering machine comprising a base, a jig transport reflow device, a first soldering device, a second soldering device, a third soldering device, a fourth soldering device, a detecting device and a discharging device. The jig transport reflow device is fixed on the base, and the first soldering device, the second soldering device, the third soldering device, the fourth soldering device, the detecting device and the discharging device are sequentially fixed on the base from left to right. The full-automatic soldering machine has the beneficial effects that the full-automatic soldering manner is adopted to replace the manual processing manner, and the processing efficiency and the stability of the product quality are improved; the full-automatic soldering machine is provided with mechanisms for automatically conveying, jacking and positioning jigs, products are clamped and positioned on the jigs, the clamping and positioning structure of the products is simple, clamping and positioning are stable, and the qualification rate of the products is better improved; and meanwhile, two product placing blocks are fixed on the jigs and can be replacedalong with the products, and the equipment flexibility is improved.

Owner:深圳市祁科作物科技有限公司

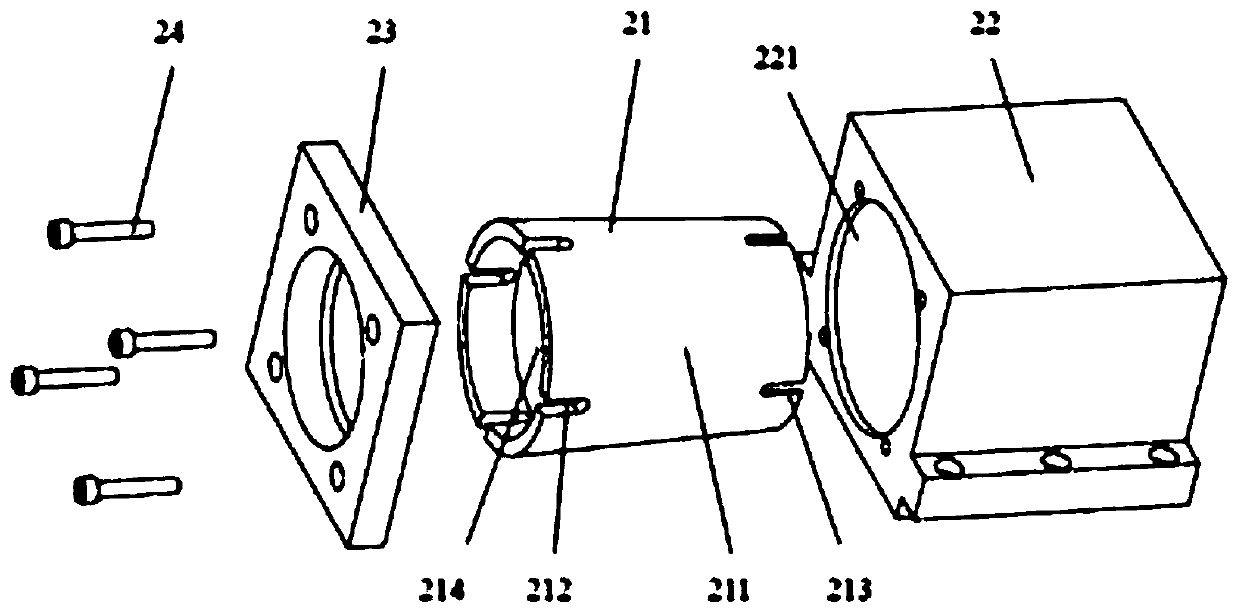

Clamp for ultrasonic welding machine

InactiveCN109909598AQuick positioning clampingFirm positioning and clampingWelding/cutting auxillary devicesAuxillary welding devicesUltrasonic weldingEngineering

The invention discloses a clamp for an ultrasonic welding machine. The clamp is reasonable and simple in structure, low in production cost, convenient to install and complete in function, and can realize rapid positioning and clamping of a welding triplicate assembly, and effectively improve the welding quality and the working efficiency. The clamp comprises a machine base, a bush and an end cover, wherein the machine base is fixed to a workbench of the welding machine, the bush is arranged at an inner ring of the machine base and provided with a groove, and the end cover is provided with a fixing screw hole and exerts clamping force. The bush is embedded into the machine base, the ultrasonic welding triplicate assembly is placed inwards, and ultrasonic triplicate leveling is completed. When the end cover is fixed to the machine base, the bush deforms in the machine base, so that the triplicate assembly can be stably clamped, the leveling state of the triplicate assembly is kept, and the purposes of fast positioning and clamping of the triplicate assembly are realized.

Owner:SBT ULTRASONIC TECH CO LTD

Damping transportation box of wood boards

InactiveCN109367981AAvoid damageSimple structureContainers to prevent mechanical damageInternal fittingsEngineeringWood plank

The invention discloses a damping transportation box of wood boards. The damping transportation box of the wood board is characterized in that a plurality of upper positioning clamping blocks are fixedly arranged on the inner wall of a top plate of a box body, the top ends of the fixed wood boards are fixedly clamped in clamping grooves of the upper positioning clamping blocks, the bottom ends ofthe wood boards are fastened and inserted in clamping grooves of lower positioning clamping blocks, the lower positioning clamping blocks are fixedly arranged on the upper surface of a supporting plate, the two side plate ends of the supporting plate are propped against the inner walls of the two sides of the box body, a plurality of rubber supporting columns are fixedly connected to the lower surface of the supporting plate, and a plurality of rubber supporting columns are fixedly arranged on the inner bottom surface of the box body. By the adoption of the technical scheme, the damping transportation box is simple in structure and convenient to assemble and mount, the wood boards are positioned and clamped firmly through the upper positioning clamping blocks and the lower positioning clamping blocks, so that transportation shaking of the wood boards are avoided; and moreover, the plurality of rubber supporting columns are arranged in the box body to play a role in buffering and supporting, so that the situations that the wood boards are damaged due to the jolt and the jump in the transportation process are avoided.

Owner:安徽建联木业有限公司

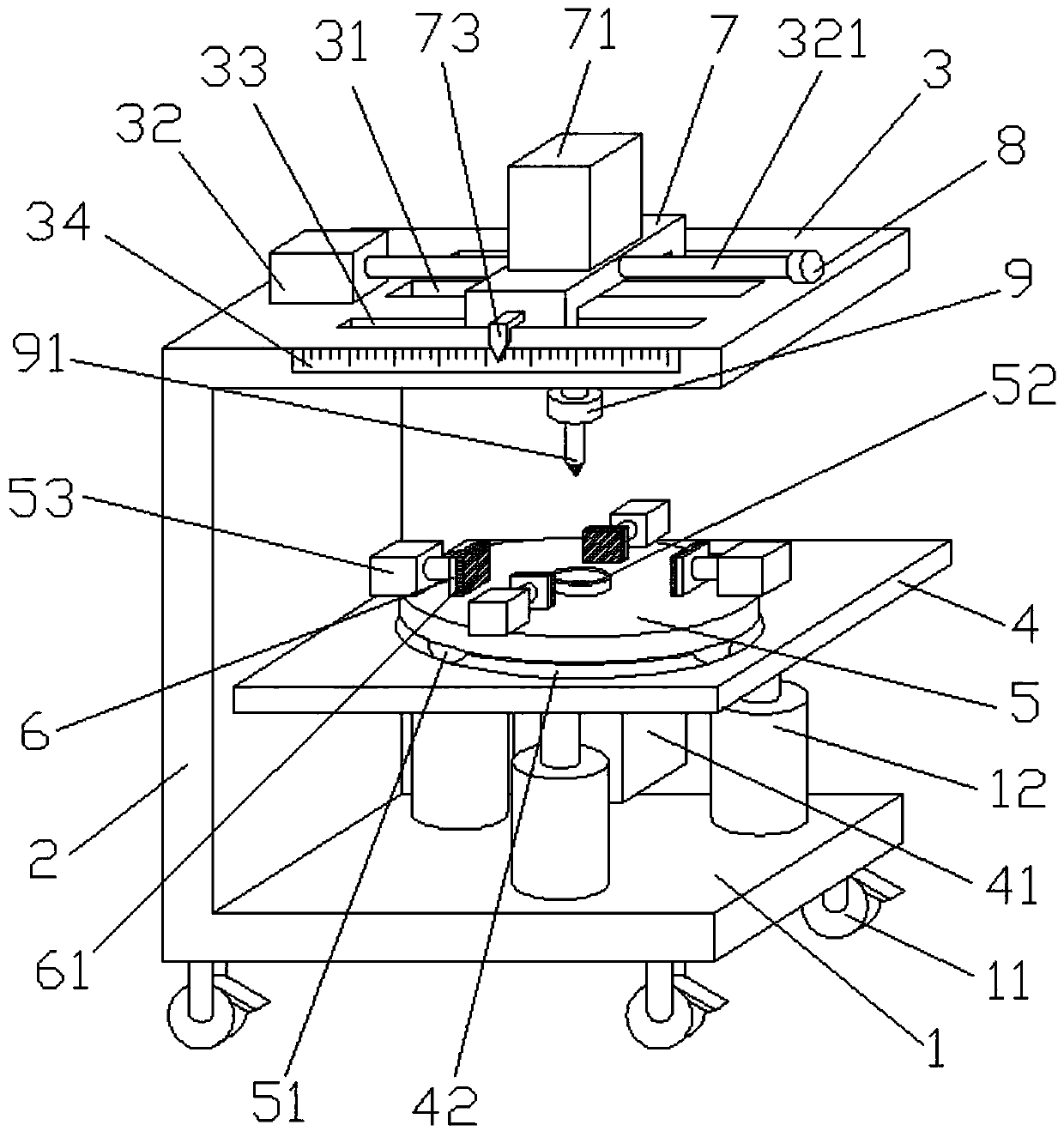

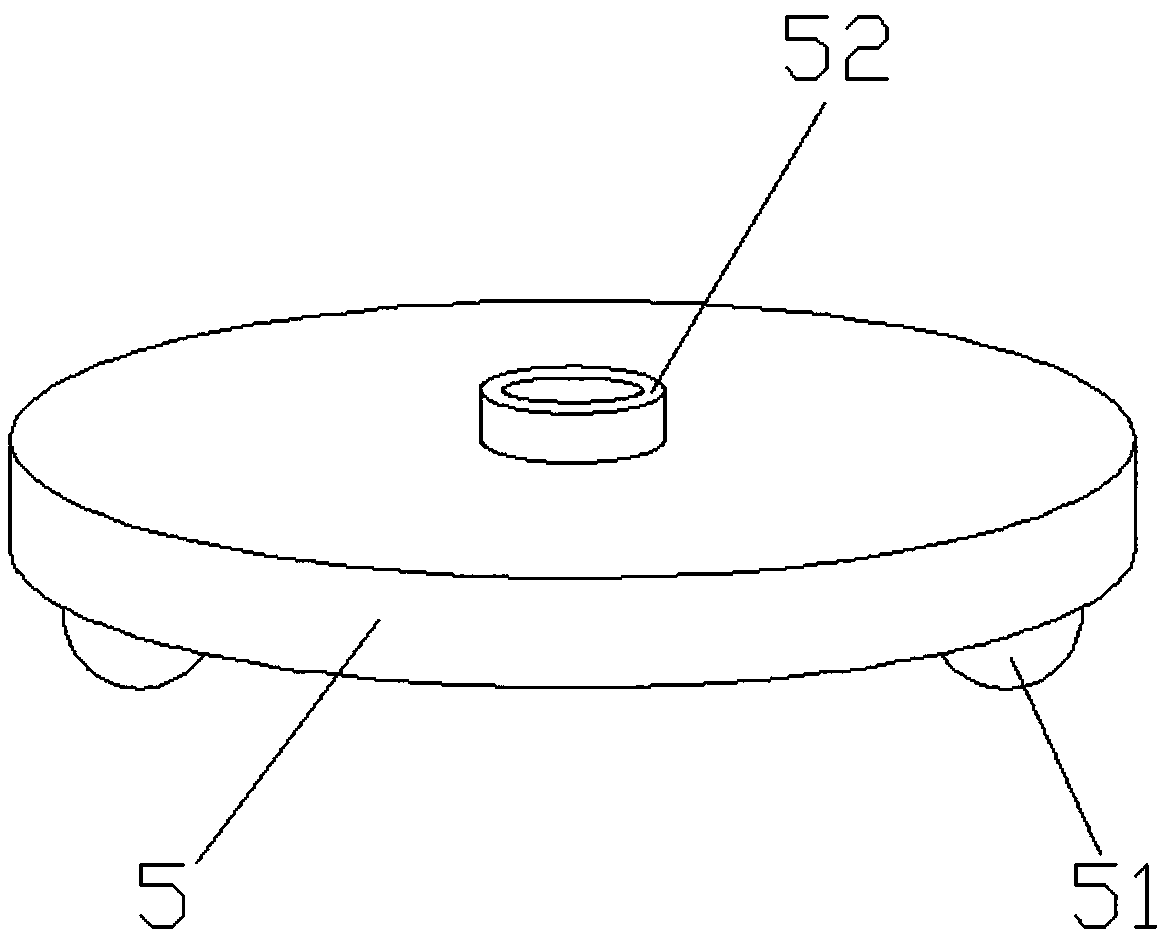

Intelligent processing machine and processing method for backlight module production

InactiveCN113182977AReduce production efficiencyEasy to polishPolishing machinesGrinding drivesEngineeringMachine

The invention relates to an intelligent processing machine and processing method for backlight module production. The intelligent processing machine for backlight module production comprises a bottom plate, a rotating device, an adjusting device, a grinding device and a polishing device, wherein the rotating device is installed at the lower end of the bottom plate, the adjusting device is installed on the rotating device, the grinding device is installed at the right end of the bottom plate, and the polishing device is installed at the rear side of the right end of the bottom plate. By means of the intelligent processing machine and processing method for backlight module production, the problems which exist during welding splicing and grinding of front frames of existing backlight modules can be solved, and the problems are as followings: (1) the front frames of the traditional backlight modules need to be subjected to splicing positioning treatment before being welded, splicing positioning is mostly conducted through hand holding, and then welding treatment is conducted, so that splicing is unstable, and the welding quality of the front frames is affected; and (2) when the front frames of the existing backlight modules are welded and then ground, grinding treatment is mostly conducted manually, the manual grinding and polishing efficiency is low, and the grinding quality is not high, so that the production efficiency of the front frames is reduced.

Owner:武汉敏之捷光电科技有限公司

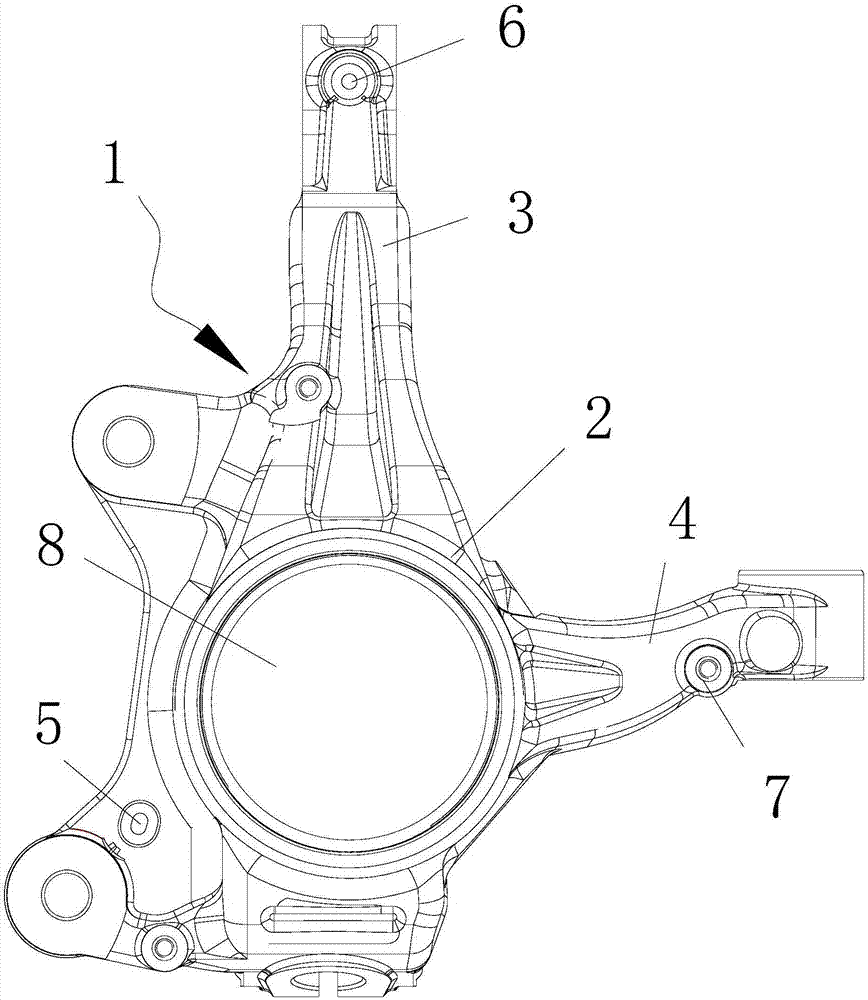

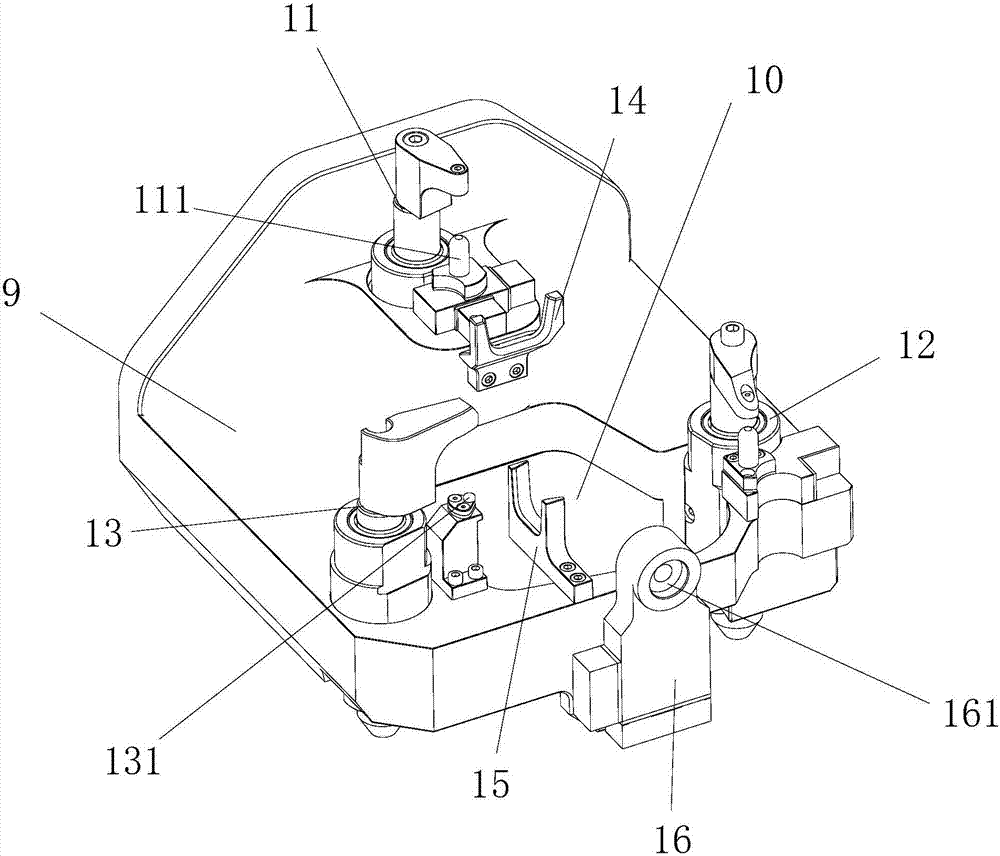

Automobile steering knuckle as well as steering knuckle positioning and fastening device

ActiveCN107235076AFirm positioning and clampingLimited rotational freedomSteering linkagesPositioning apparatusMarine engineering

The invention provides an automobile steering knuckle as well as a steering knuckle positioning and fastening device. The automobile steering knuckle comprises a steering knuckle body in which a steering shaft hole is formed, wherein a first positioning part, a second positioning part and a third positioning part which are arranged in a triangular shape are formed on the steering knuckle body; the first positioning part and the second positioning part are clamping and fixing parts which are formed on the steering knuckle body and can be connected with an external mechanism in a clamping manner; one of the clamping and fixing parts is in a strip shape; and the third positioning part can be abutted and connected with the external mechanism. The invention also provides a steering knuckle positioning and fastening device for positioning and fastening the automobile steering knuckle. According to the automobile steering knuckle disclosed by the invention, complete positioning of the steering knuckle can be achieved by the arrangement of the first positioning part, the second positioning part and the third positioning part to guarantee stable positioning and fastening of the steering knuckle; and besides, the structure of a steering knuckle positioning and fastening fixture can be simplified, so that the problems that the design is difficult and collision accidents are easy to occur caused by complicated structure of the fixture can be solved, and the automobile steering knuckle is good in practicability.

Owner:GREAT WALL MOTOR CO LTD

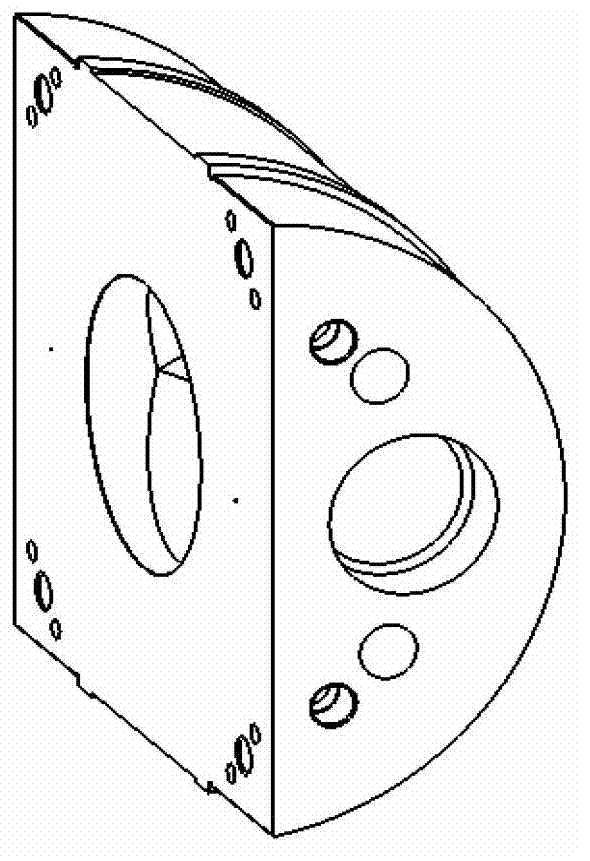

Surface grinding fixture and method for processing semi-circular pump swash plate

The invention relates to a surface grinding fixture and a method for processing a semi-circular pump swash plate. The surface grinding fixture comprises a fixture body, a compression mechanism for compressing a part to be subjected to surface grinding, and a locating pin and a screw which are arranged on the fixture body; the part to be subjected to surface grinding is located through the locating pin and the fixture body and is fixedly connected with the fixture body through the screw; the part to be subjected to surface grinding comprises a surface to be ground; and the compressing mechanism is pressed on the side surface of the part to be subjected to surface grinding and is fixedly connected with the fixture body. The invention provides the surface grinding fixture and the method for processing the semi-circular pump swash plate, which can simplify the adjustment process, are stable and reliable to clamp and locate and reduce the roughness of part surfaces.

Owner:XIAN AERO ENGINE CONTROLS

Tool holder for grooving cutting blade

ActiveCN102601403AAvoid deformationReduced positioning contact areaTurning toolsTool holdersEngineeringSupport surface

The invention discloses a tool holder for grooving a cutting blade. The tool holder comprises a tool holder body and a fastener, a clamping portion of the tool holder body consists of an upper clamping portion and a lower supporting portion, an upper positioning surface of the upper clamping portion and a lower positioning surface of the lower supporting portion enclose a blade clamping groove, a rear supporting surface and an elastic extending section are arranged at the rear end of the blade clamping groove, the elastic extending section extends backwards to the neck of the tool holder body, the fastener penetrates through the upper portion and the lower portion of the elastic extending section, M discontinuous upper positioning tables are arranged on the upper positioning surface, and N discontinuous lower positioning tables are arranged on the lower positioning surface, wherein 2<=M<=6, and 2<=N<=6. The tool holder for grooving the cutting blade has the advantages that positioning positions and angles can be automatically adjusted, plastic deformation of the tool body can be effectively suppressed, and the tool holder is stable in structure and long in service life.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Fixture for vertical LED (light emitting diode) lead frame

InactiveCN102347406AReduce manufacturing costQuick placementSemiconductor/solid-state device manufacturingWork holdersEngineeringLead frame

The invention relates to a fixture for a vertical LED (light emitting diode) lead frame. The fixture comprises a bottom plate, a positioning block, a backing plate, a guiding axle, a compressing strip, a press plate, clamping pieces, a corrugated gasket, a left side plate and a right side plate, wherein the positioning block is fixed at one end of the bottom plate, the backing plate is fixed on one side of the positioning block, the left and right side plates are fixed at the upper parts of two sides of the bottom plate, and the guiding axle is fixed between the upper end parts of the left and right side plates; one ends of the compressing strip, the press plate and the clamping piece are sleeved on the guiding axle through pin holes on the one ends; the corrugated gasket is arranged between the adjacent two clamping pieces; and the vertical LED lead frame is arranged between the clamping pieces. The fixture provided by the invention has simplicity of operation and reliability of clamping and positioning, and the fixture can be adapted to vertical LED lead frames of different heights by only replacing the backing plate, thereby greatly reducing the quantity of types of fixture required by enterprises, lowering the production cost of enterprises and raising the labor productivity.

Owner:THE 45TH RES INST OF CETC

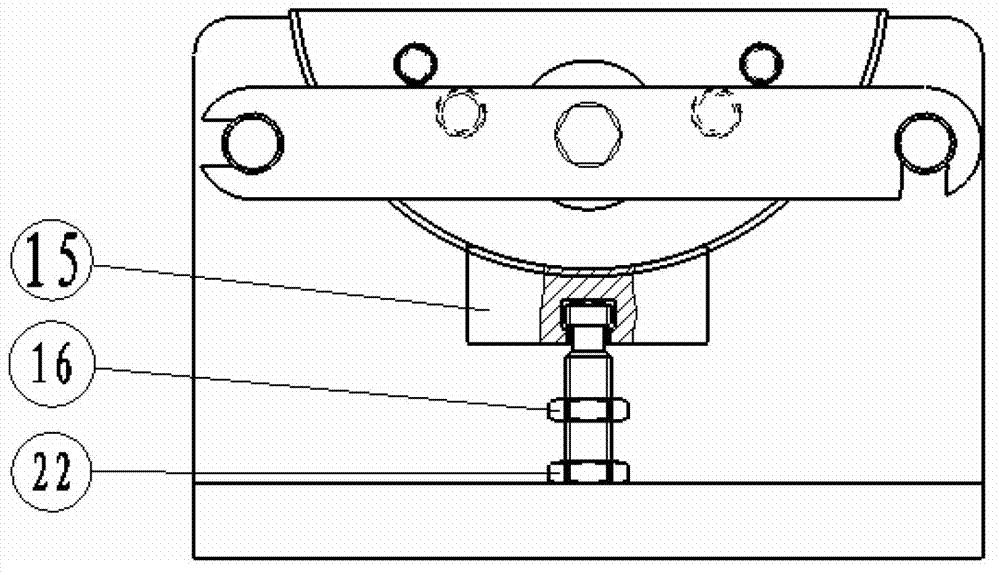

Diesel-engine box-body clamp

InactiveCN102785096AFirmly connectedSimple structurePositioning apparatusMetal-working holdersBiochemical engineeringDiesel engine

Owner:CHONGQING BAIJI SIXING DIE CASTING

Blank locating detection device

ActiveCN106141812AImprove structural strengthExtended service lifeMeasurement/indication equipmentsEngineeringAir tightness

The invention provides a blank locating detection device which comprises a base, a spring, a locating block and a bolt; a first hole perforating axially and a second hole perforating radially are formed in the base; the first hole comprises a mounting hole part located at the upper part and a first air hole part located at the lower part; the spring is fixed in the first air hole part; the locating block is slidingly matched with the mounting hole part; a gap is formed between the locating block and the mounting hole part; the locating block is provided with a third hole perforating radially; the bolt is inserted into the second hole and is fixed to the base; a cavity is formed between the bolt and the third hole; and a gap is formed between the locating block and the bottom of the mounting hole part under the action of the spring. During working, the locating block moves downwards to be fitted with the bottom of the mounting hole part under the action of a clamping force, by this time, detection gas can not be discharged outwards because an external leakage passage of the detection gas is closed, so that the purpose of airtightness detection of the locating surface of a blank is achieved. The blank locating detection device is high in structural strength, high in reliability and long in service life, a clamping locating process is stable, and the impact on a workpiece is reduced.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com