Hard-soldering deformation control method for turbine blade and special fixture for hard-soldering

A technology of steam turbine blades and special fixtures is applied in the welding deformation control of the final stage blades of large steam turbines, and the deformation control field of Stellite alloy sheets for corrosion-proof brazing. Defects and other problems, to achieve the effect of controlling blade brazing deformation, simple and reliable operation, and simple clamping

Active Publication Date: 2014-04-30

WUXI TURBINE BLADE

View PDF7 Cites 11 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the anti-corrosion brazing of the steam inlet edge of the last stage blade of the steam turbine will be deformed due to the influence of welding heat effect, so it directly affects the dimensional accuracy of the blade and the dimensional correction of the blade, and if the welding correction is performed, it will cause brazing defects and residual stress and other unstable factors

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

[0024] Below in conjunction with accompanying drawing, specifically describe the method for steam turbine blade brazing deformation control of the present invention:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

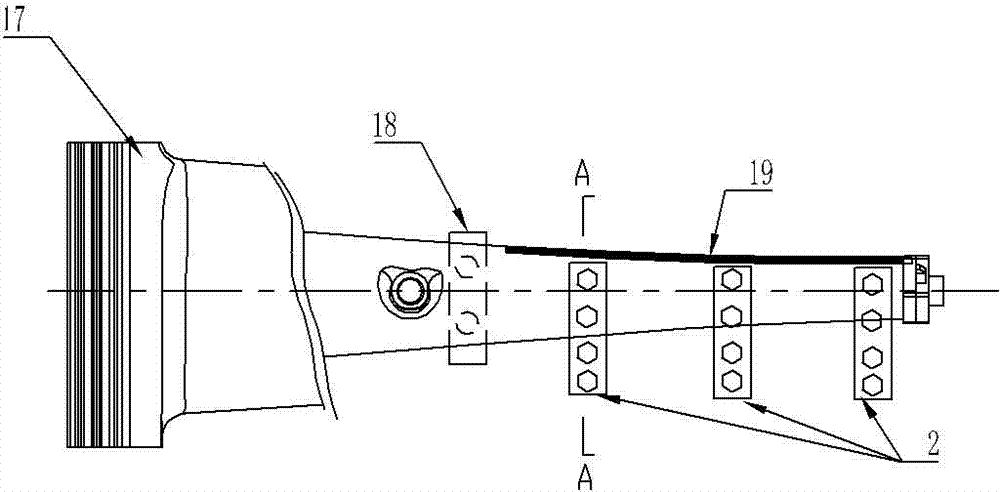

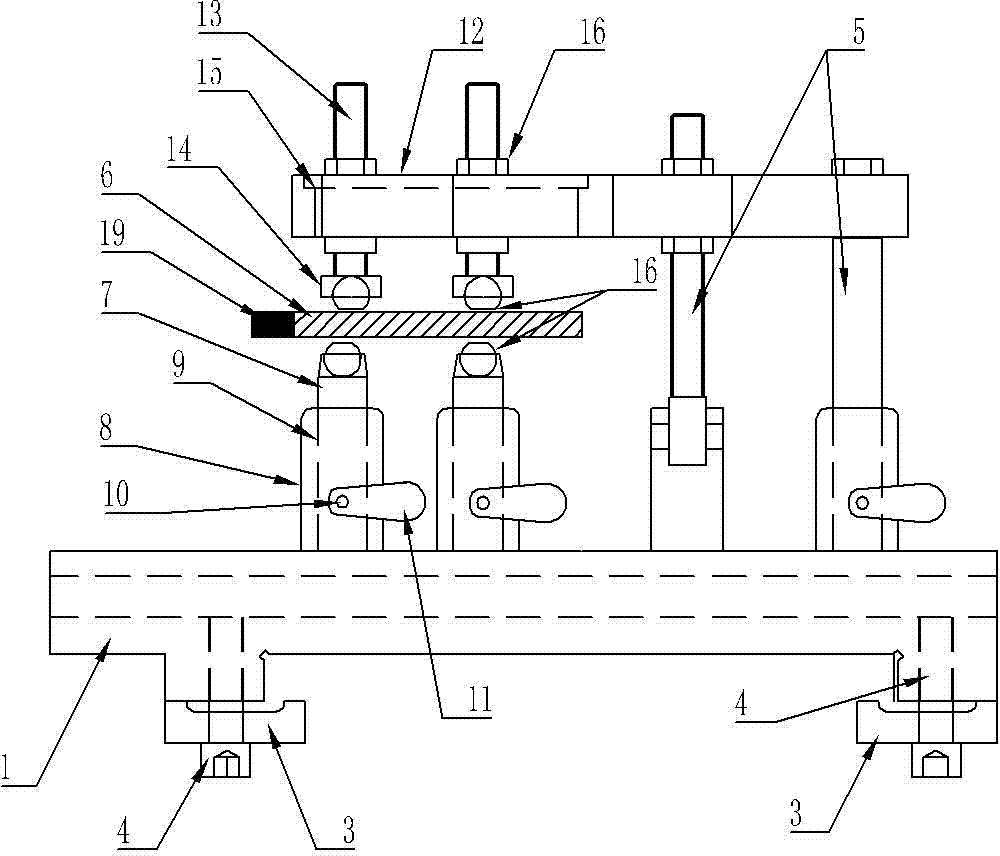

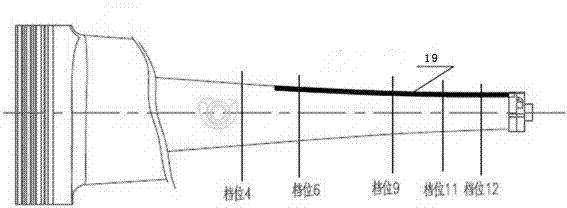

The invention provides a hard-soldering deformation control method for a turbine blade. The hard-soldering deformation control method for the turbine blade can effectively reduce the hard-soldering deformation of stellite alloy sheets at the steam inlet sides of last-stage large blades of a turbine. The hard-soldering deformation control method for the turbine blade is characterized by comprising the following steps: detecting the hard-soldering deformation and deformation tendency of a test blade by comparing the blade hard-soldering area of the blade before and after the hard-soldering with a blade theoretical model, obtaining a main hard-soldering deformation area and hard-soldering deformation direction of the test blade, and when performing hard-soldering of the stellite alloy sheets to the product blade having the same specification with the test blade, using a special fixture for hard-soldering to apply an over-deformation stress with direction opposite to the hard-soldering deformation direction to the main deformation area of the product blade corresponding to the test blade. The special fixture for hard-soldering comprises a machine tool guide rail connecting seat and multiple groups of chuck mechanisms, wherein the multiple groups of chuck mechanisms are mounted on the machine tool guide rail connecting seat, and the multiple groups of chuck mechanisms are uniformly arranged along the length direction of the hard-soldering area of the stellite alloy sheet of the blade.

Description

technical field [0001] The invention relates to the field of welding deformation control of the last-stage blade of a large-scale steam turbine, in particular to the field of control of the corrosion-proof brazing deformation of the Stellite alloy sheet of the last-stage blade of a steam turbine, specifically a method for controlling the brazing deformation of a large steam turbine blade and brazing Special fixture device. Background technique [0002] The steam inlet side of the last stage blade of a large steam turbine is corroded due to the erosion of wet steam and condensed water droplets during operation, and brazing Stellite alloy sheets on the steam inlet side of the blade is currently the most effective anti-corrosion measure. Used by the steam turbine design factory. However, the anti-corrosion brazing of the steam inlet edge of the last stage blade of the steam turbine will be deformed due to the influence of welding heat effect, so it directly affects the dimensi...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23K3/08B23K1/00

CPCB23K1/0018B23K3/087

Inventor 王烜烽曹小丽毛志刚汤先辉魏立峰

Owner WUXI TURBINE BLADE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com